Coal mixture with desulfurization effect and preparation method and application of coal mixture

A technology for mixture and raw coal, applied in the field of clean coal, can solve the problems of low utilization rate of desulfurizers, large equipment and operation investment, etc., and achieve the effects of improving self-desulfurization efficiency, improving utilization rate, and simple preparation and utilization methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 25kg of block lime with a CaO content of 87.4% and an average particle size of 20mm into 150kg of water to prepare a lime slurry, keep it standing for 15 minutes, and measure the Ca(OH) in the slurry 2 The average particle diameter of the particles was 7 μm. Add 50 kg of raw coal with an average particle size of 0.5 mm into the lime slurry and stir evenly to obtain a mixture of coal and lime slurry. The mixture is dehydrated to a material with a water content of about 30% by vacuum filtration, and sent to an infrared heating and drying device for further drying to prepare a coal mixture with a water content of 5% and a desulfurization effect. By determination, the Ca(OH) in the mixture 2 The content is 30%, the raw coal content is 60%, and the impurity content is 5%.

[0034] Use the nitrogen adsorption instrument to measure the specific surface area and the pore distribution results of the limestone commonly used in the industry and the coal mixture with desulfur...

Embodiment 2

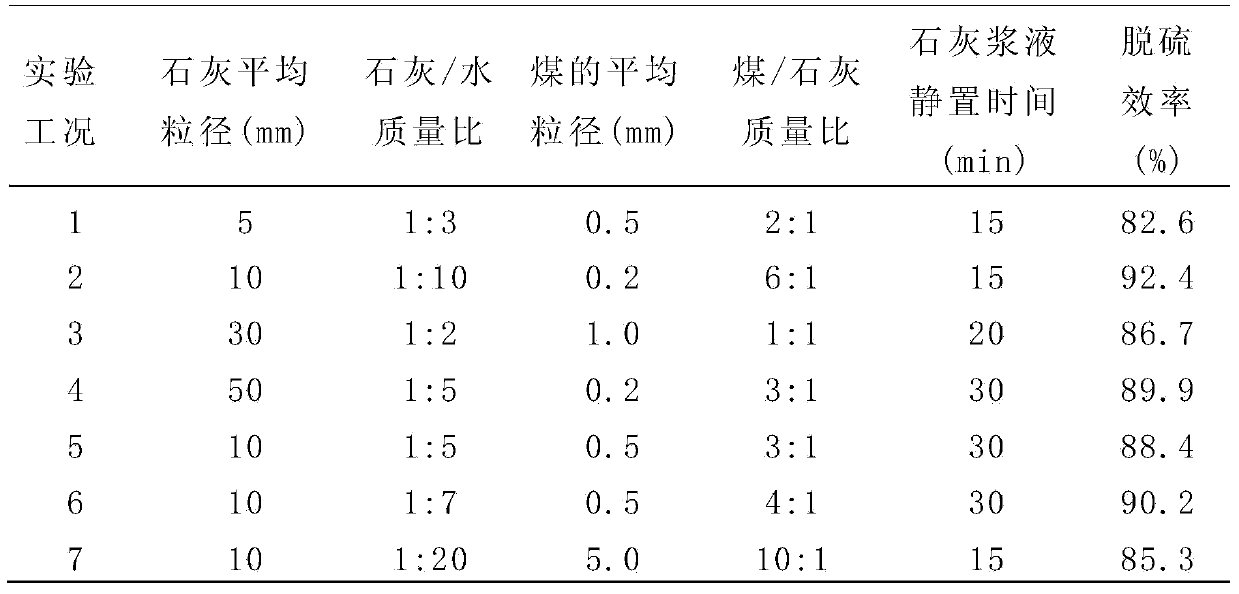

[0039] The coal mixture with desulfurization effect under several typical conditions is prepared according to the method of the invention. Table 2 lists the desulfurization efficiency of the coal mixture with desulfurization effect obtained under some typical preparation conditions. The experimental process of measuring the desulfurization efficiency is carried out on a circulating fluidized bed test bench with a bed temperature of 900°C, a coal sulfur content of 0.8%, a calcium-sulfur molar ratio of 1.5, and a thermal power of 160kw. As the basis and basis for comparing the desulfurization efficiency of the prepared coal mixture with desulfurization effect, the desulfurization efficiency of industrial limestone was measured to be 65% through the above experimental process.

[0040] Table 2 Desulfurization efficiency of coal mixtures with desulfurization effect obtained under typical preparation conditions

[0041]

[0042] According to the results in Table 2, it can be se...

Embodiment 3

[0044]Lime slurry was prepared by mixing block lime with a CaO content of 90% and an average particle size of 30 mm and water at a mass ratio of 1:5, and allowed to stand for 20 minutes. Add coal with an average particle size of 0.5 mm into the lime slurry, the mass ratio of coal to lump lime is 2:1, and mix evenly by stirring to obtain a mixture of coal and lime slurry. By using the method of mixing with raw coal to achieve the purpose of reducing the moisture content of the mixture of coal and lime slurry, a coal mixture with desulfurization effect is prepared, and the moisture content in the mixture is 10%, Ca(OH) 2 The coal content is 2.5%, and the raw coal content is 87.3%. The coal mixture is fed into the furnace together with the remaining coal through the coal feeding belt of the circulating fluidized bed boiler. The main operating parameters of the circulating fluidized bed boiler are: power 150MW, coal sulfur content 0.7%, calcium sulfur molar ratio 1.5. The average...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com