Patents

Literature

52results about How to "Reduce carbon content in fly ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

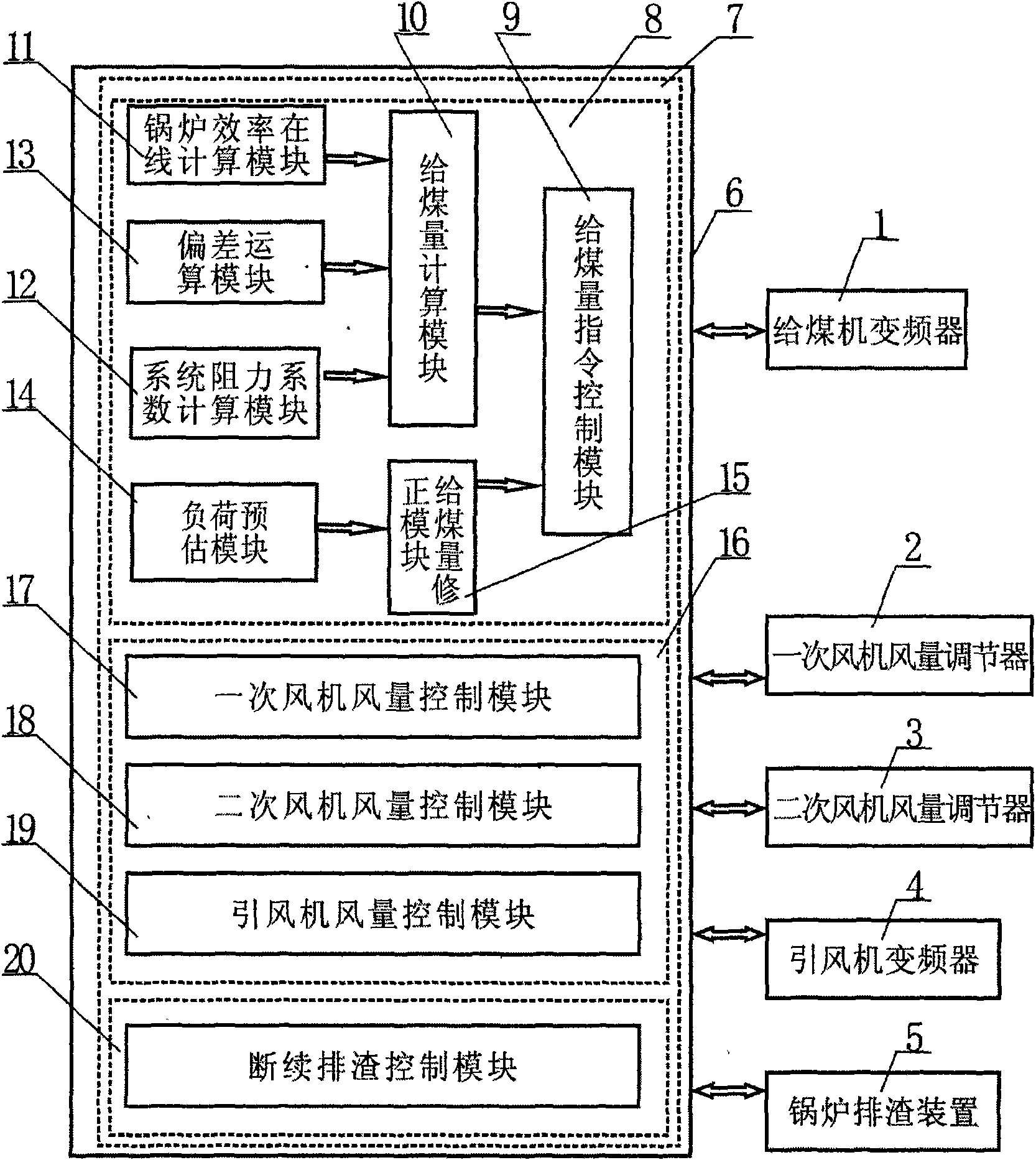

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

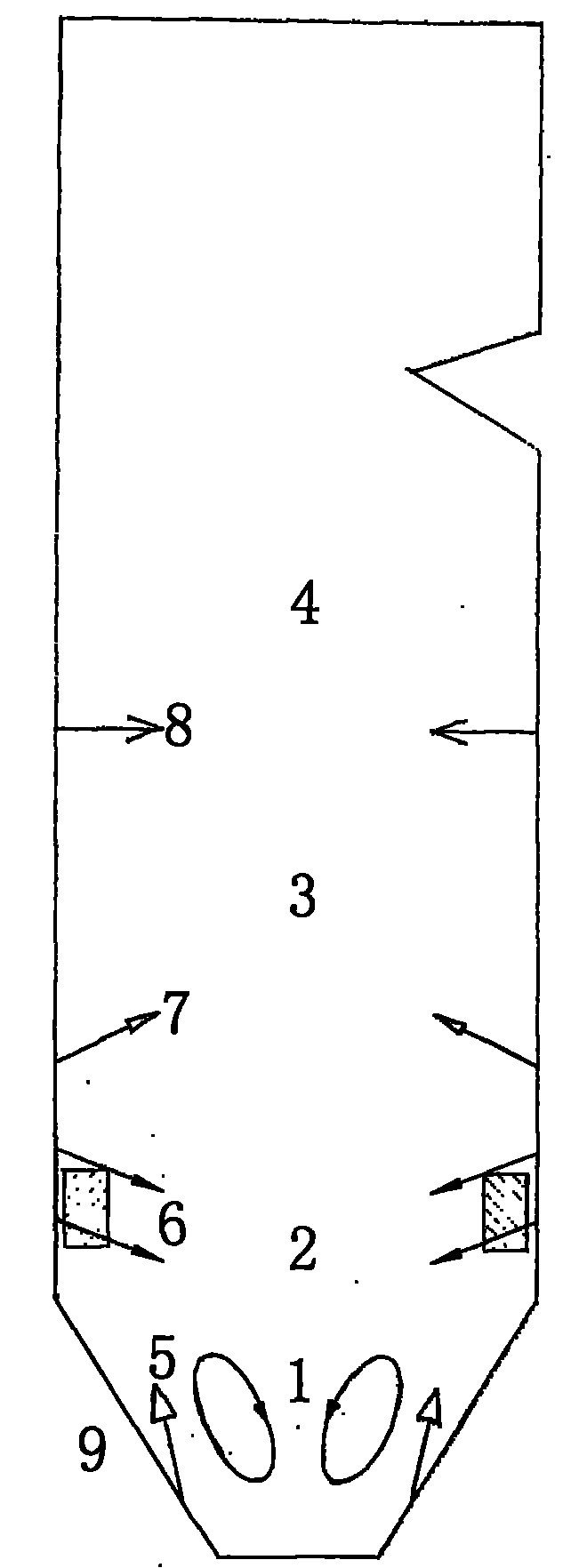

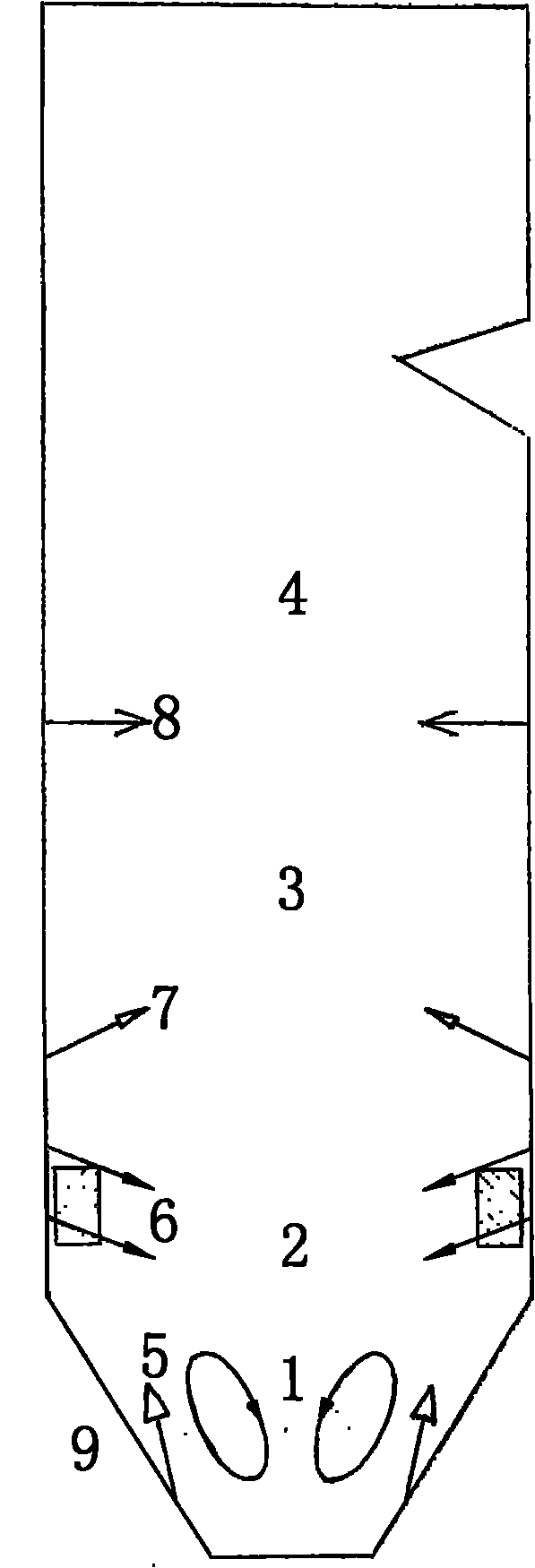

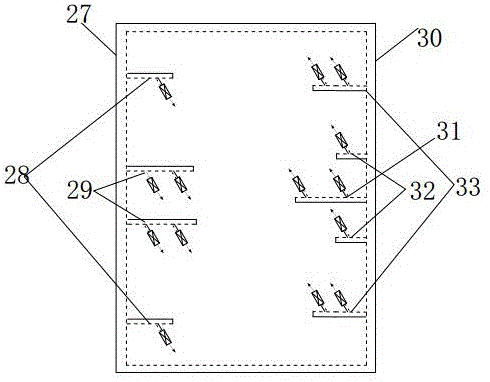

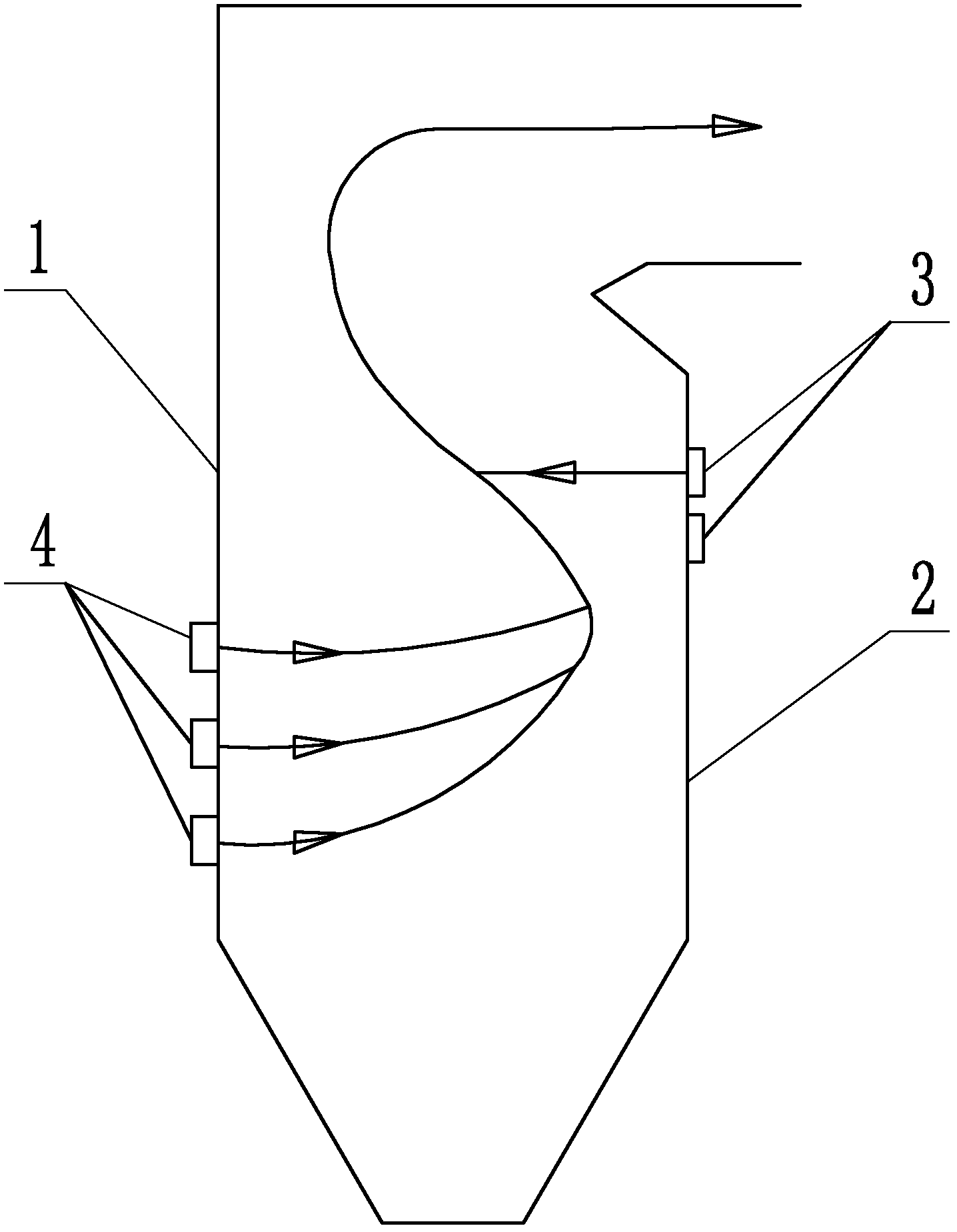

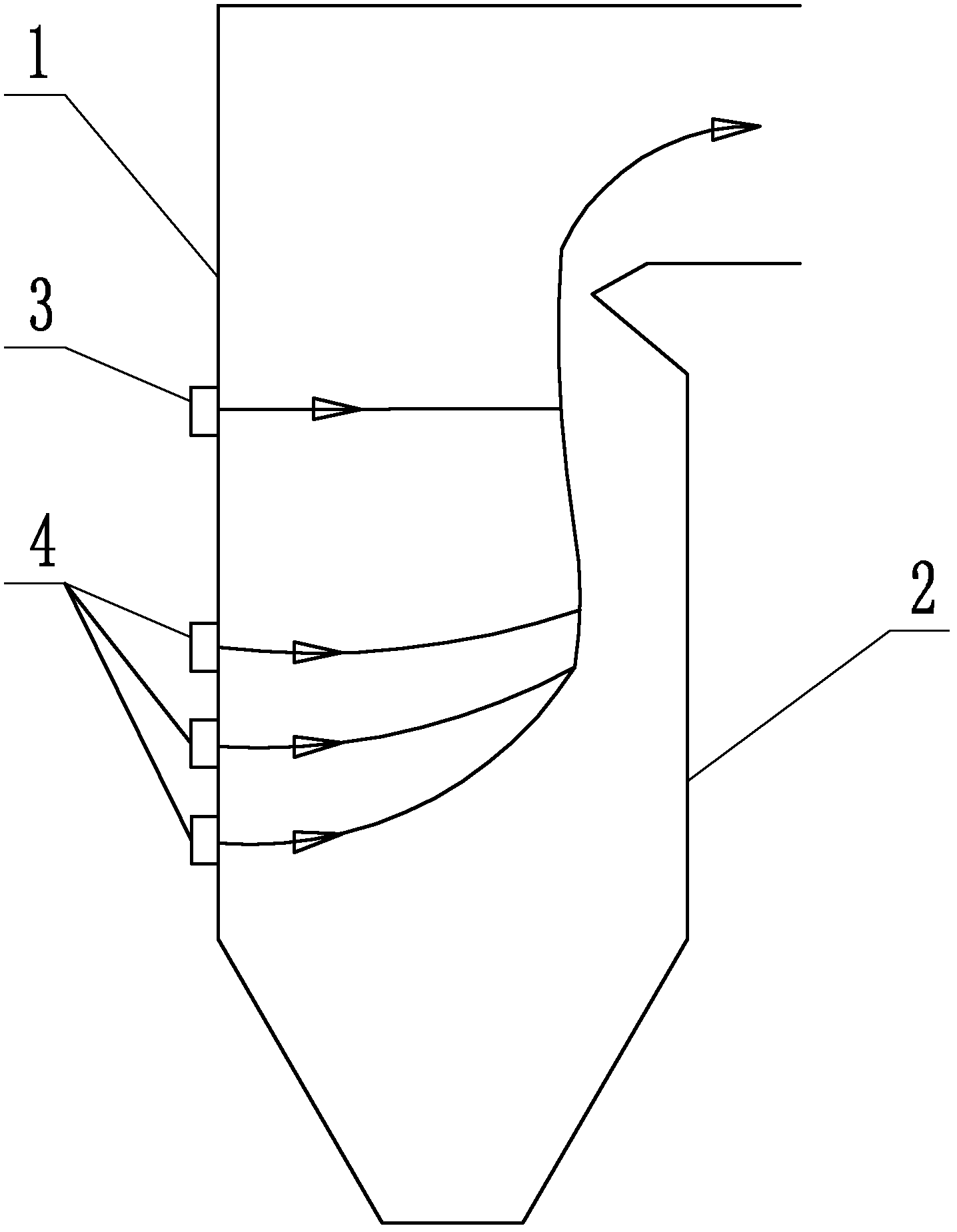

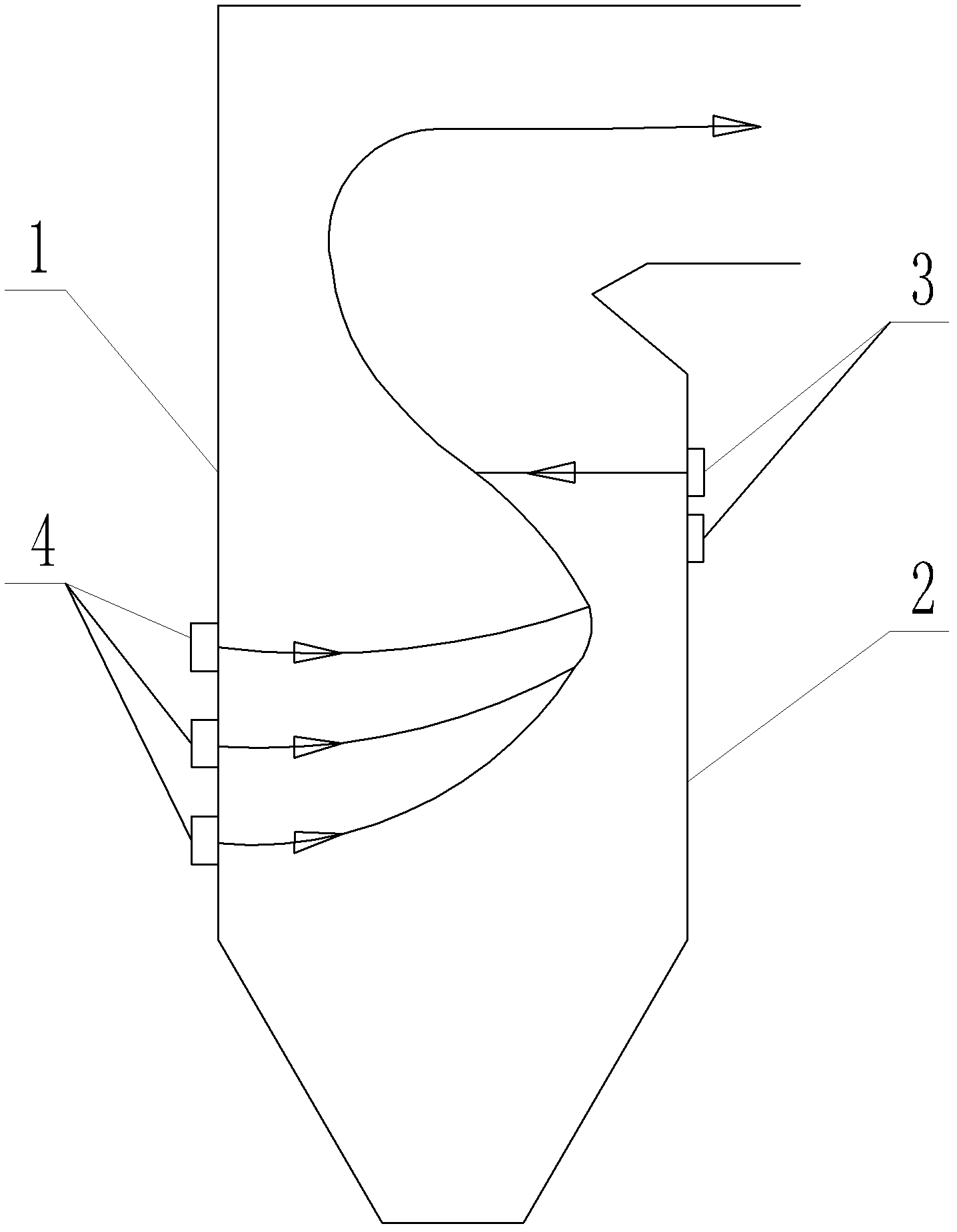

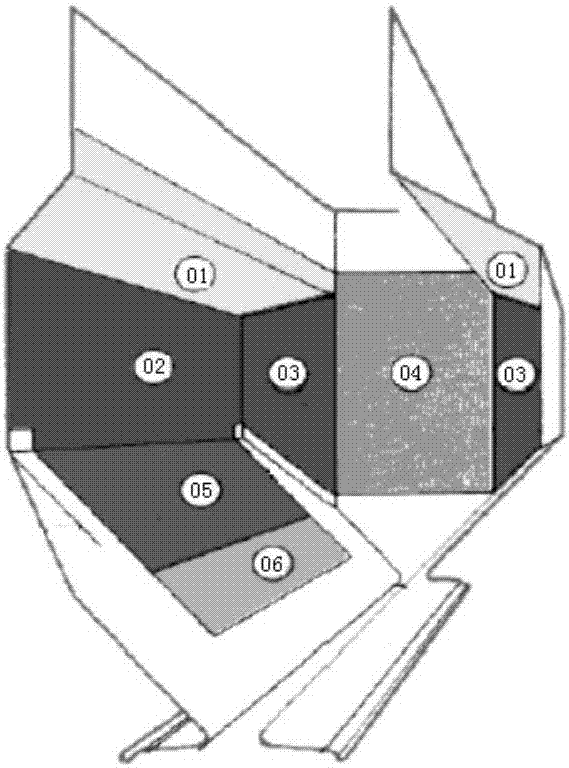

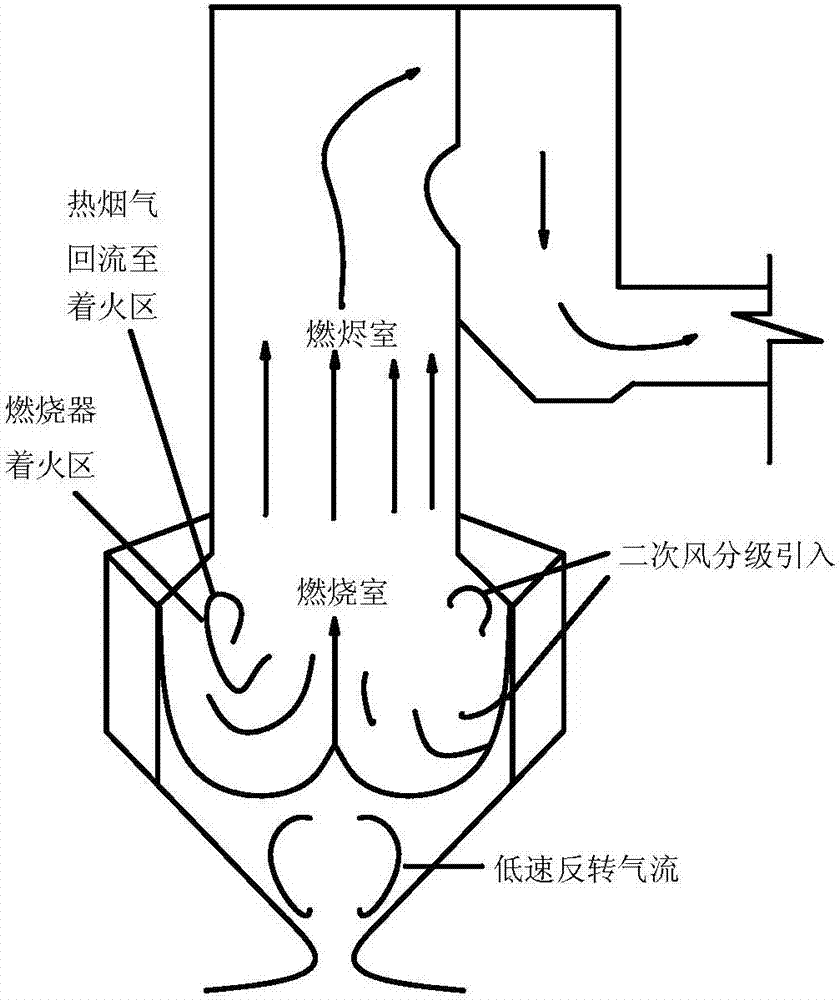

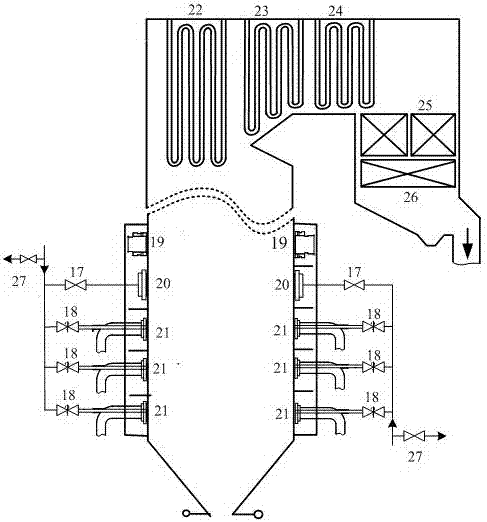

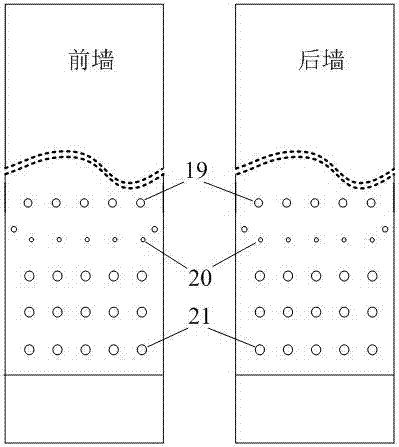

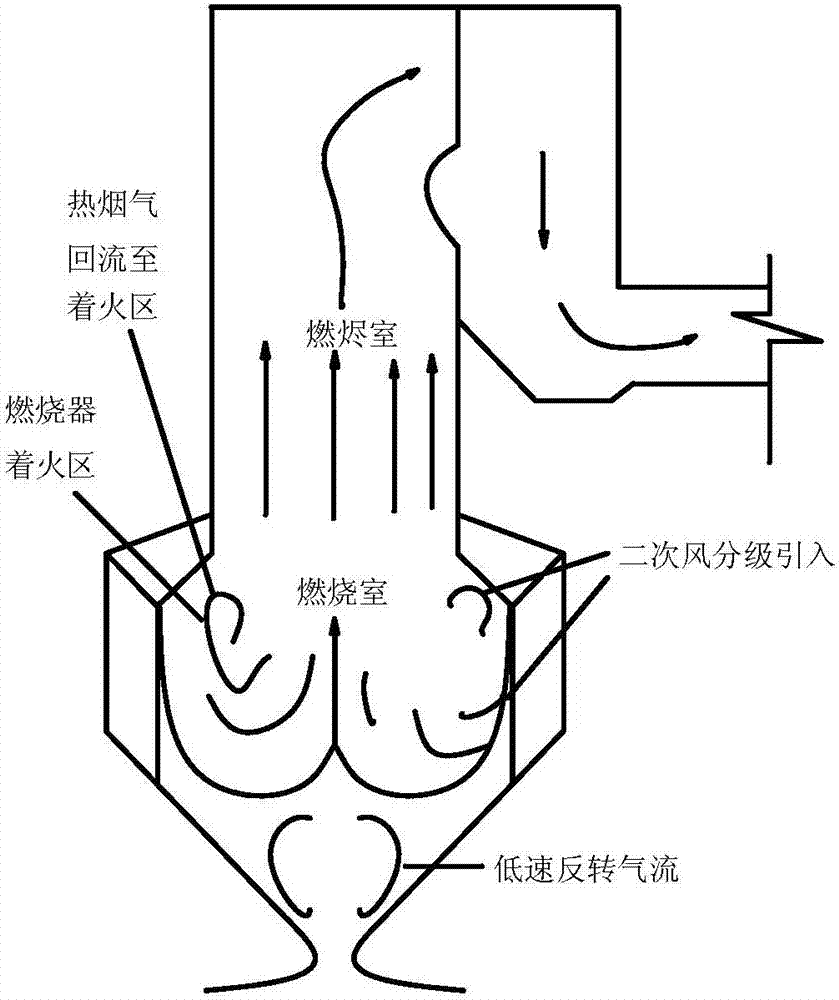

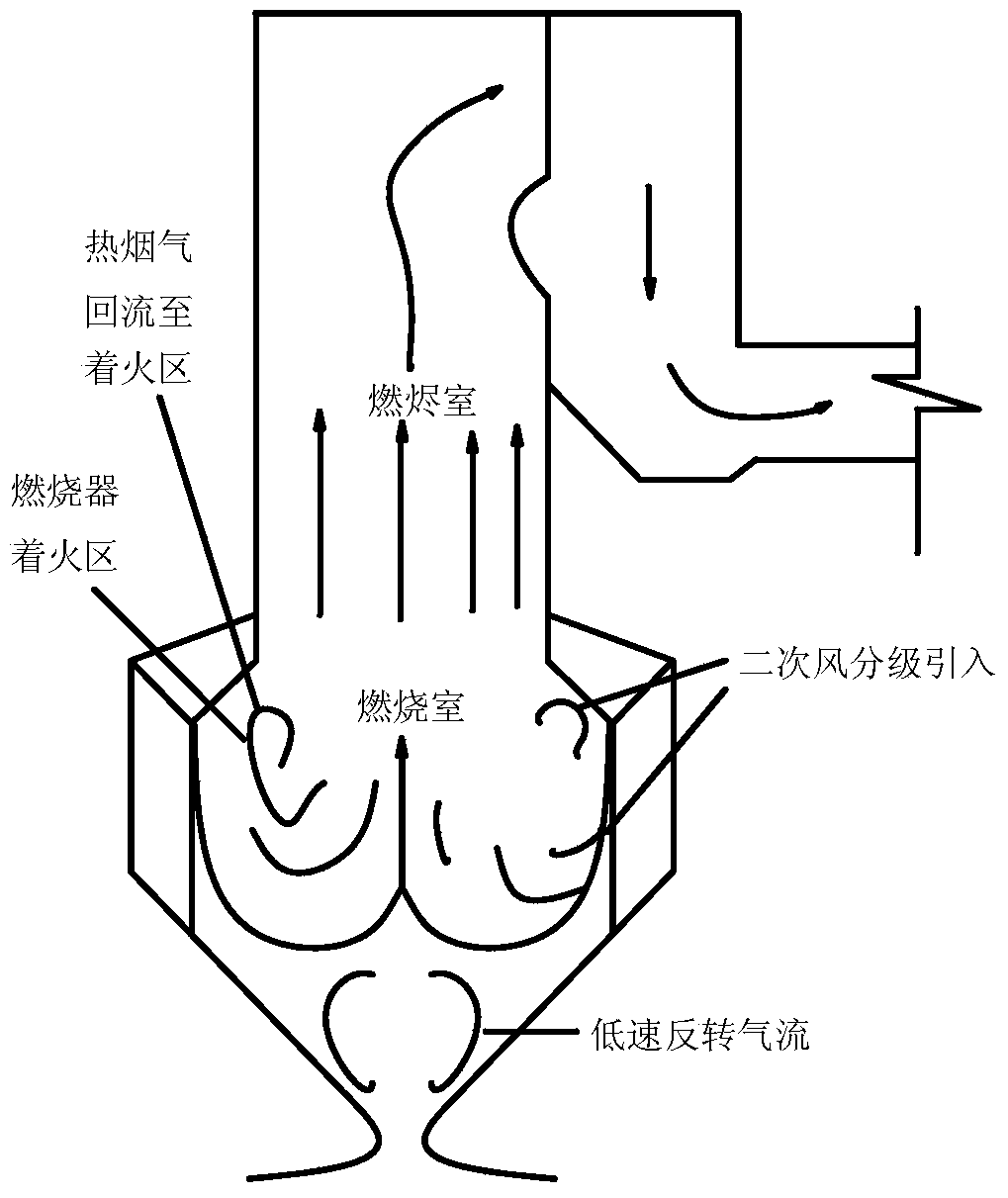

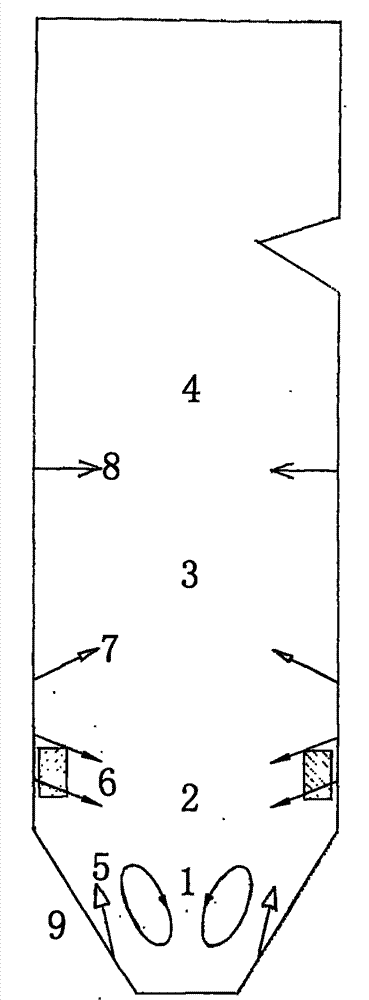

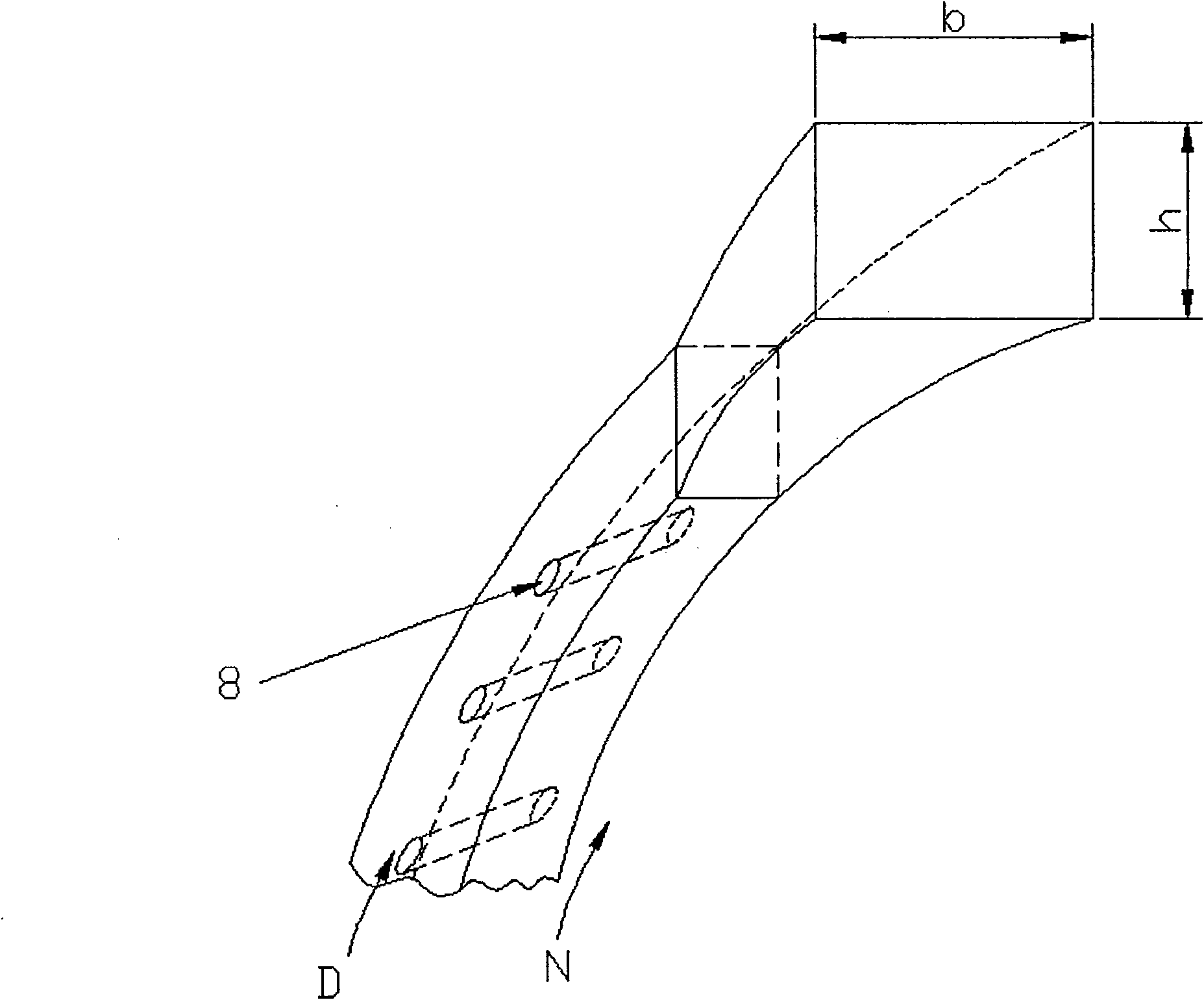

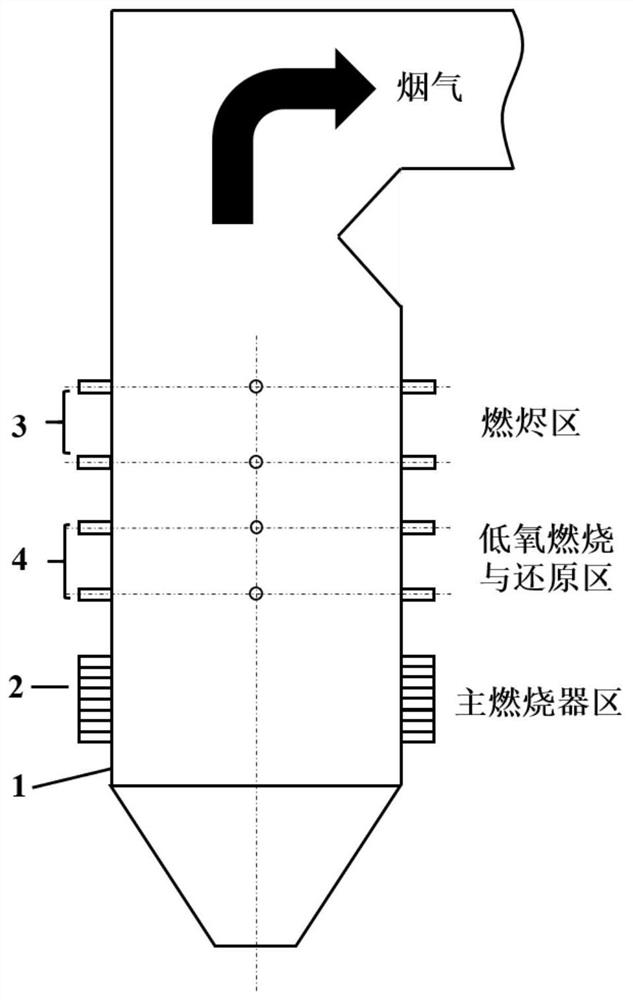

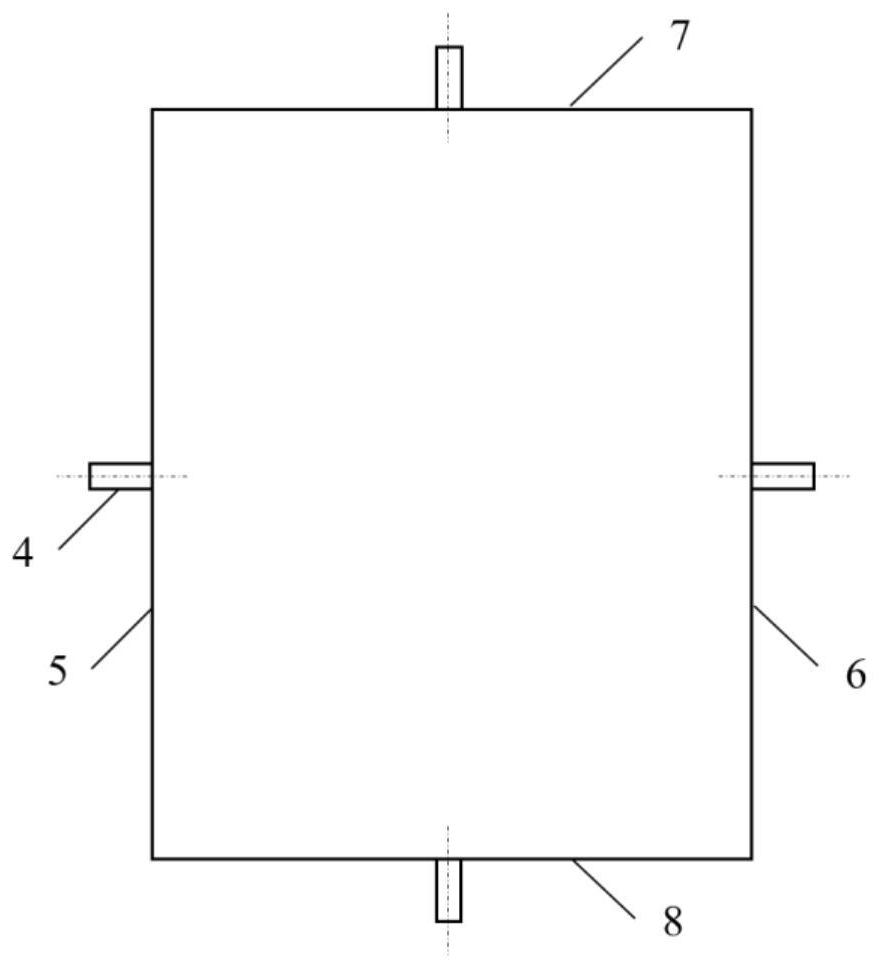

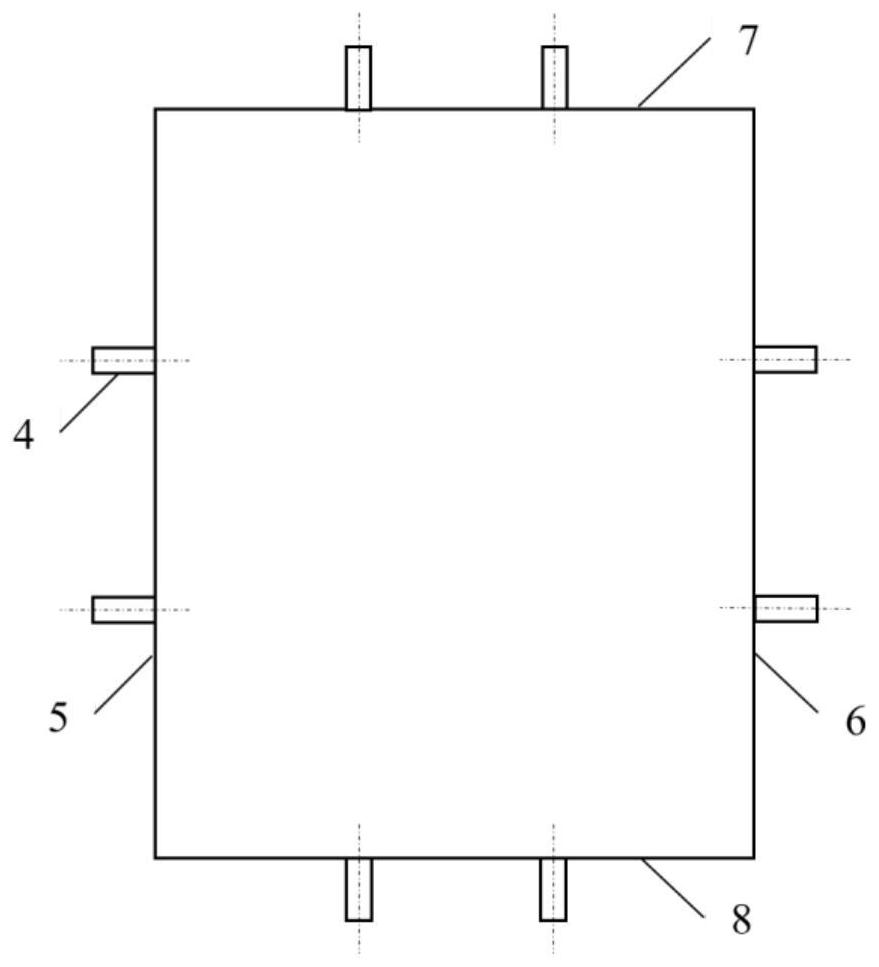

Low NOx coal dust combustion method and device based on underfire air and overfire air

InactiveCN102003701AEmission reductionReduce carbon content in fly ashCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBottom ashEngineering

The invention relates to a combustion improvement technology of an industrial fire coal boiler, aiming to provide a low NOx coal dust combustion method and device based on underfire air and overfire air. The method comprises: injecting parts of two-strand air required for combustion into a hearth from a boiler bottom ash hopper; strongly mixing with aslant downward injected fuel jet flow; fully utilizing the space of the bottom ash hopper to prolong smoke dwell time; burning fuel in a low-temperature oxidation zone; preventing volatile components from converting to nitric oxide; upwards and aslant injecting upper-layer fuel to form a reducing zone, so as to reduce generated nitric oxide into N2; and lowering nitric oxide emission amount. The invention also provides a boiler device for realizing the method. Under the condition that the original combustion condition is not influenced essentially, the invention effectively lowers the emission of nitric oxide and is easy to reform the existing boiler.

Owner:ZHEJIANG UNIV

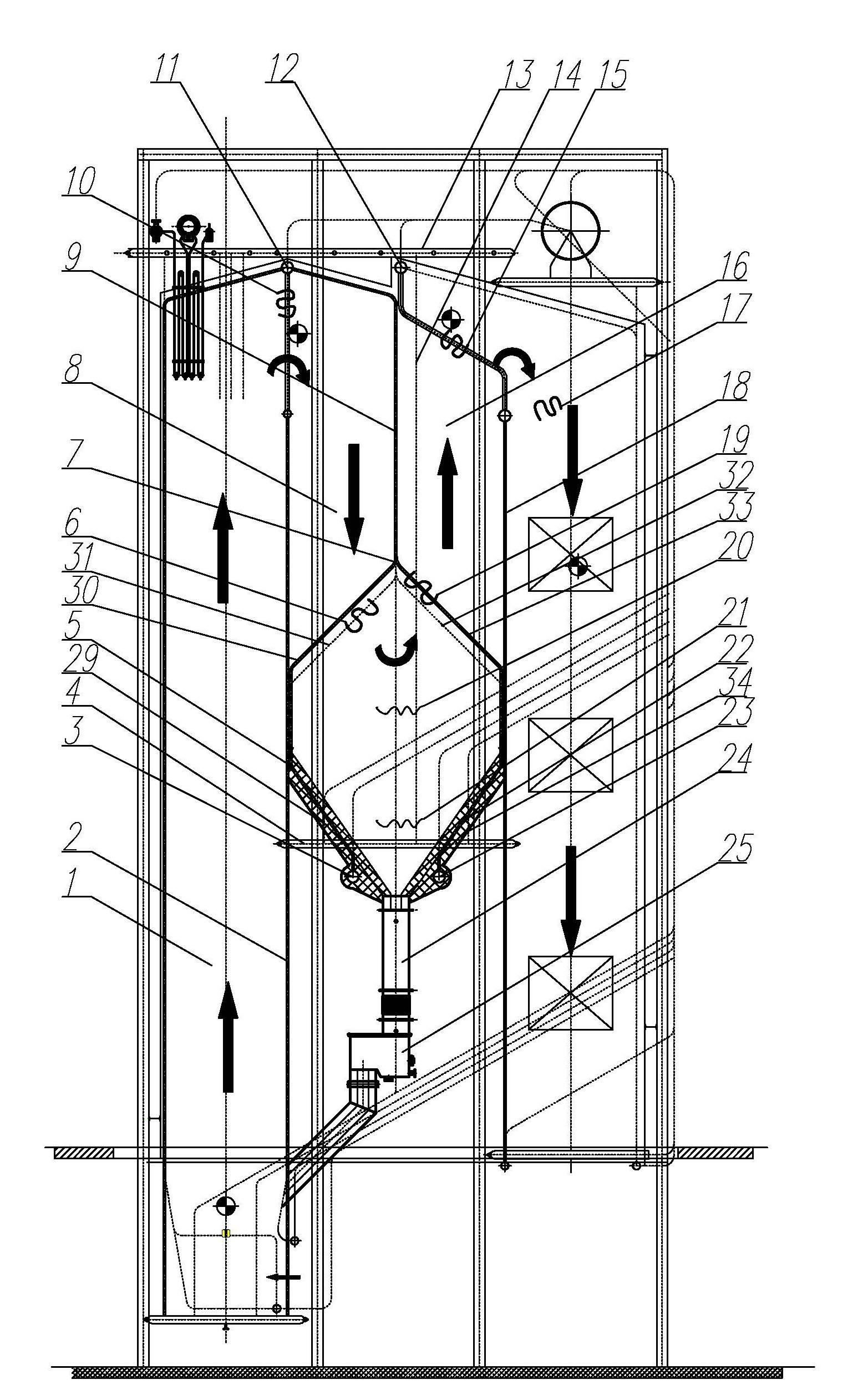

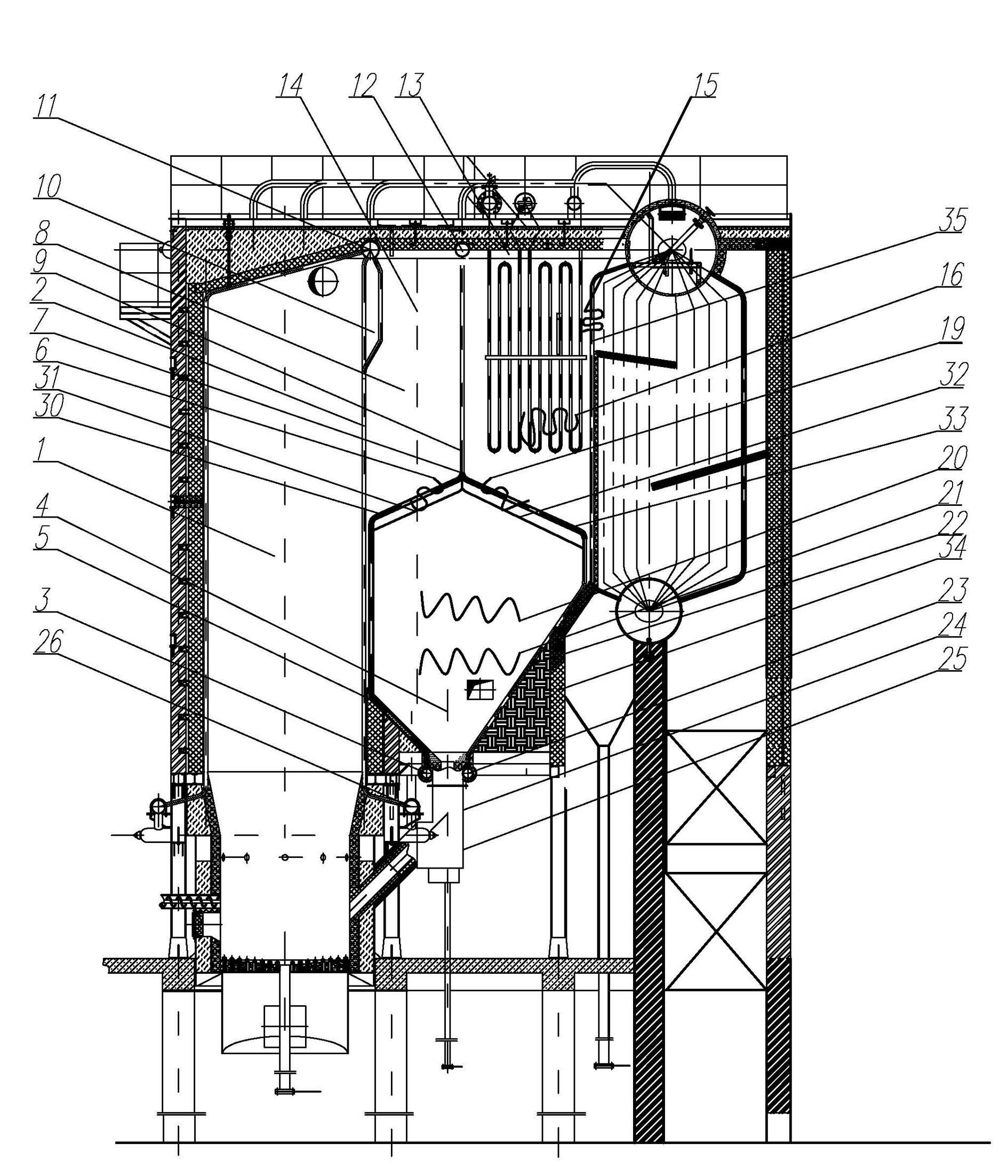

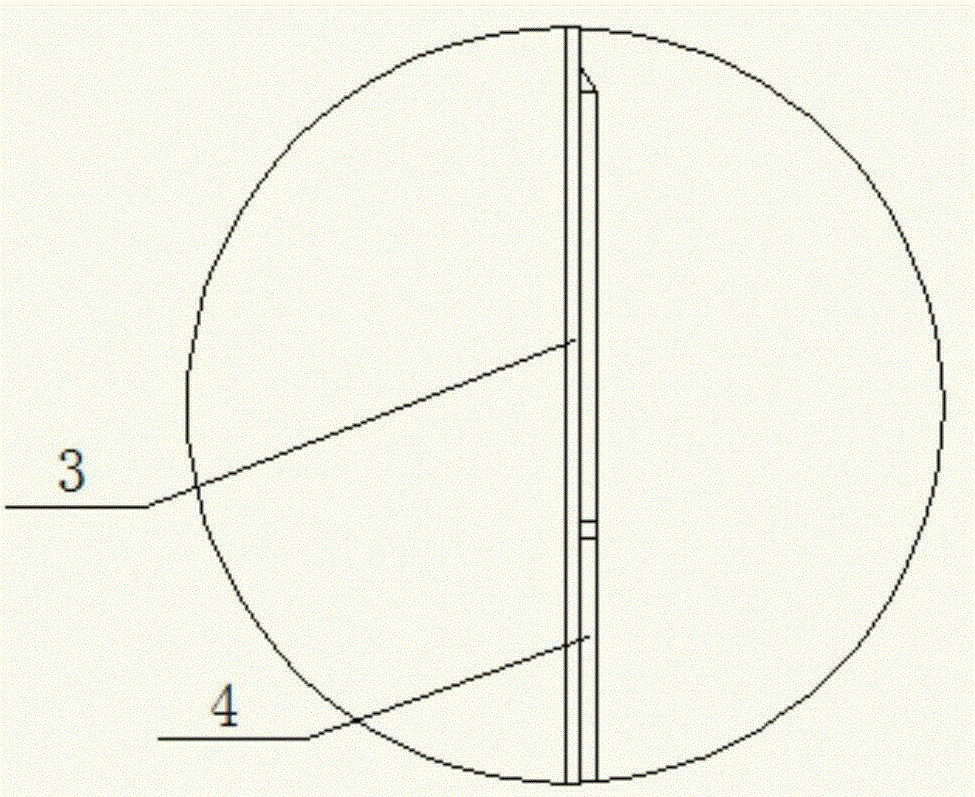

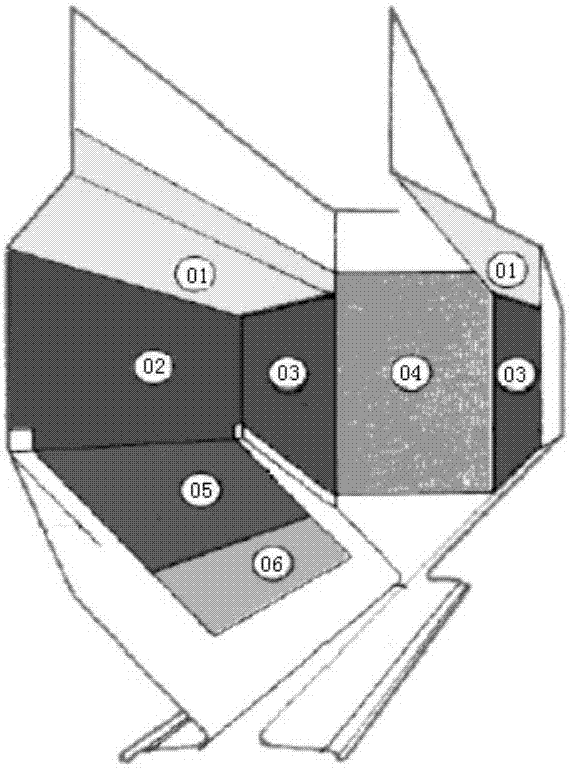

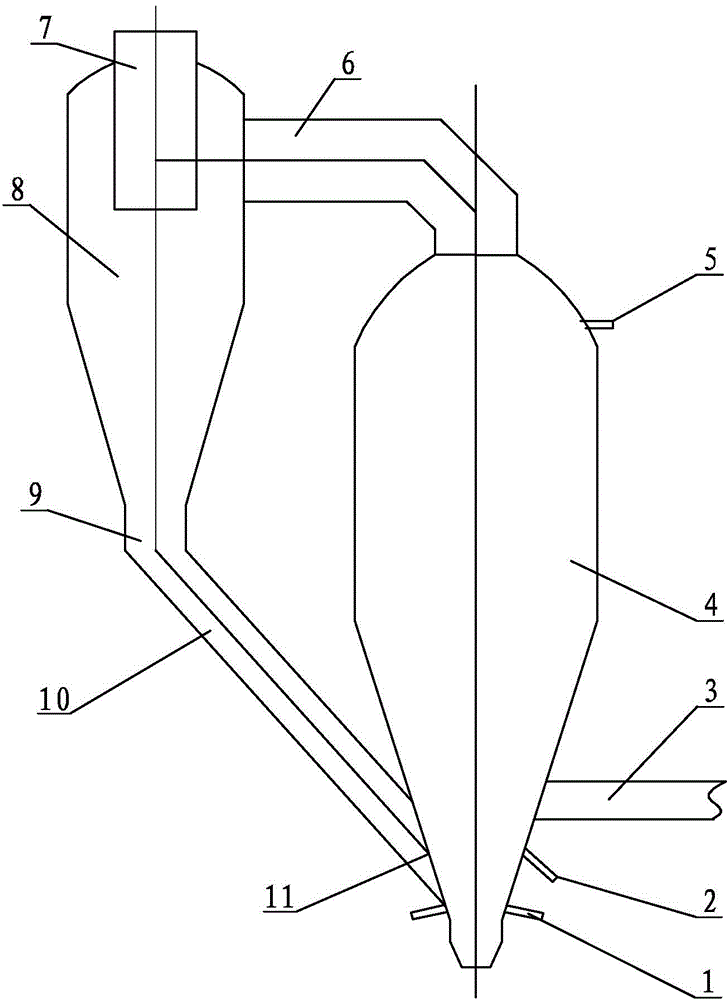

Gas-solid separator of recirculating fluidized bed boiler and boiler comprising same

ActiveCN102588959AReduce power consumptionSave long runFluidized bed combustionDispersed particle separationCycloneEngineering

A gas-solid separator of a recirculating fluidized bed boiler comprises a downward flue and an upward flue which are separated from front to back by a membrane-type guided flue gas downward and upward turning screen; the downward flue and the upward flue are communicated with each other through a swerving passageway and a feed bin which is hermetically installed below the downward flue and the upward flue; a flue gas inlet is arranged at the front upper part of the gas-solid separator and a flue gas outlet is arranged at the back upper part of the gas-solid separator; four walls of the gas-solid separator are all water cooled walls which are integrated with the boiler; the gas-solid separator further comprises a flow equalizing and separating tube bundle and an abrasion-proof communication pipe which are located on the swerving passageway; the upper end of the flow equalizing and separating tube bundle on the swerving passageway is communicated with a lower cross collecting tank of the membrane-type guided flue gas downward and upward turning screen, and the lower end of the flow equalizing and separating tube bundle on the swerving passageway is communicated with a cross collecting tank of the feed bin; and the upper end of the abrasion-proof communication pipe on the swerving passageway is communicated with the lower cross collecting tank of the membrane-type screen, and the lower end of the abrasion-proof communication pipe on the swerving passageway is communicated with a cross collecting tank of the communication pipe. In the case of circulation at low ratio, inertia gravity is used for single stage separation, and in the case of circulation at high ratio, when the speed of the smoke in the upward flue is high, low-temperature cyclone separation can be combined with inertia gravity separation for double-stage separation.

Owner:王森

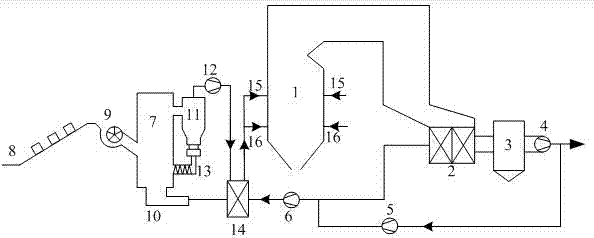

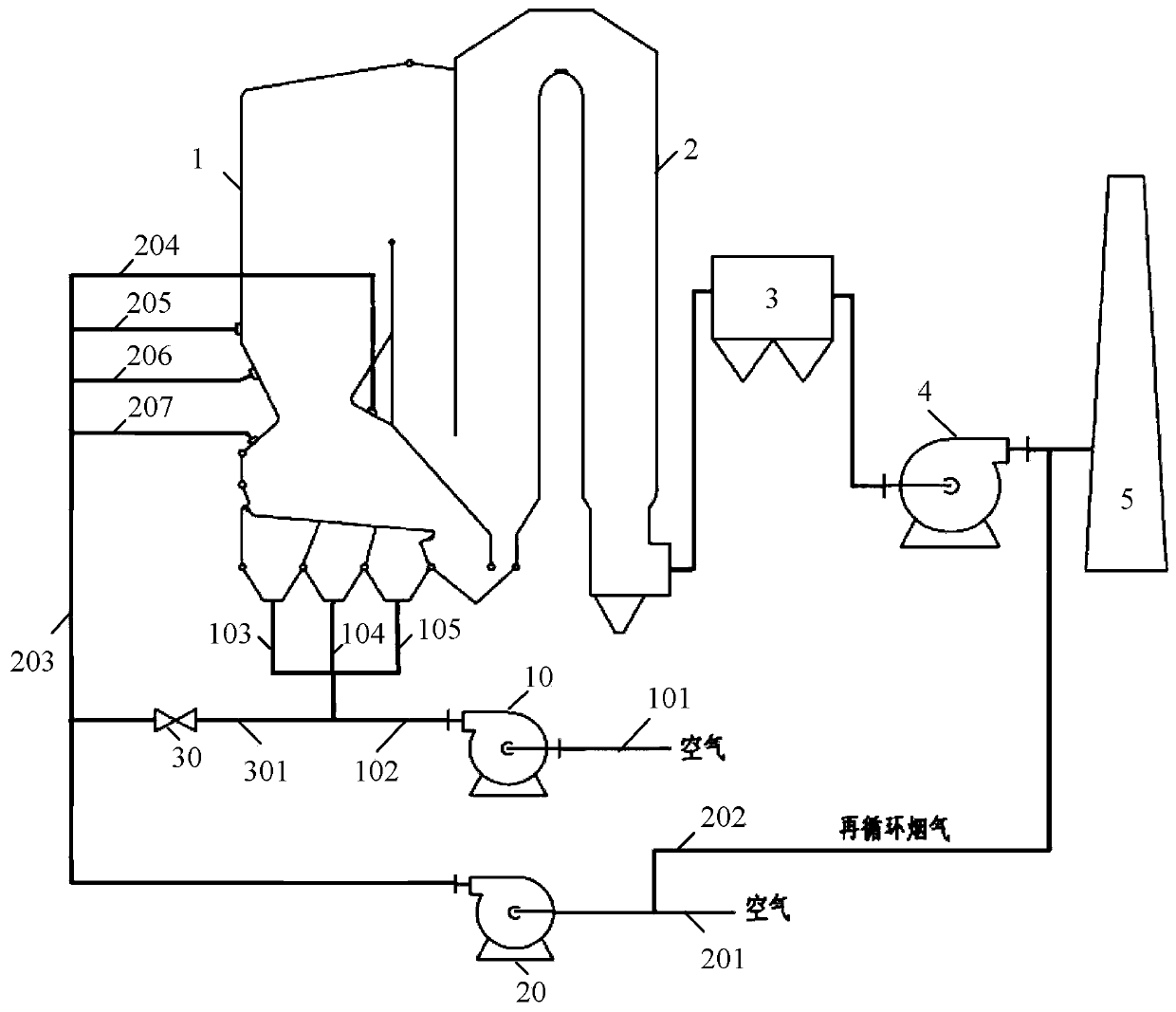

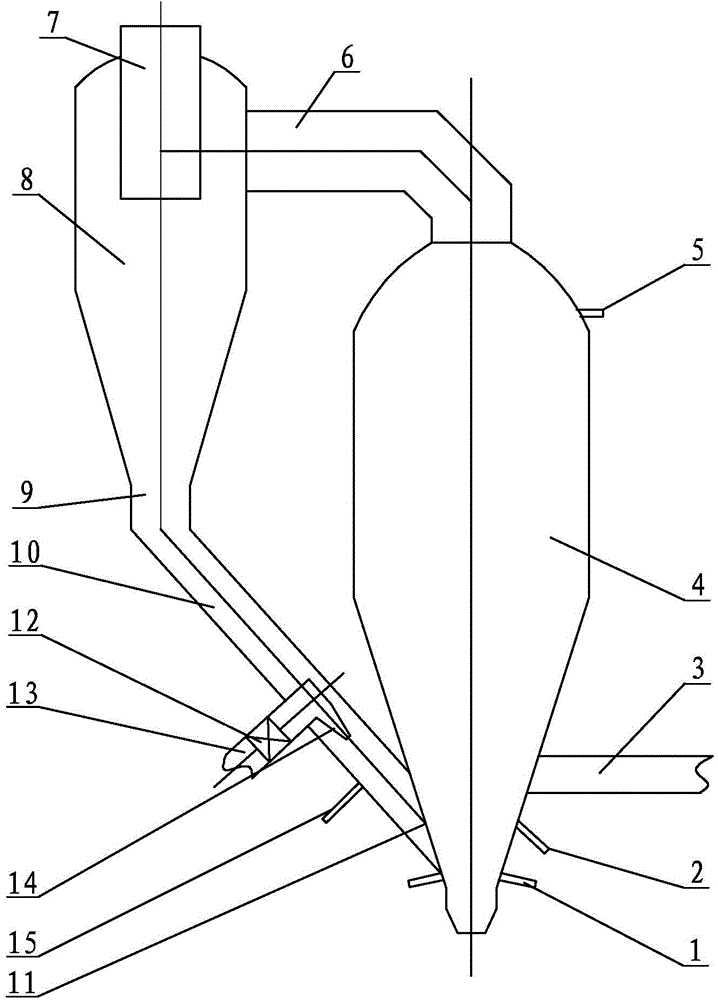

Low-nitrogen combustion technique based on circulating fluidized bed boiler

ActiveCN106051749ASolve the reduction of NOx emissionsSolve the high carbon content of fly ashFluidized bed combustionFluegas recirculationBurning outCirculating fluidized bed boiler

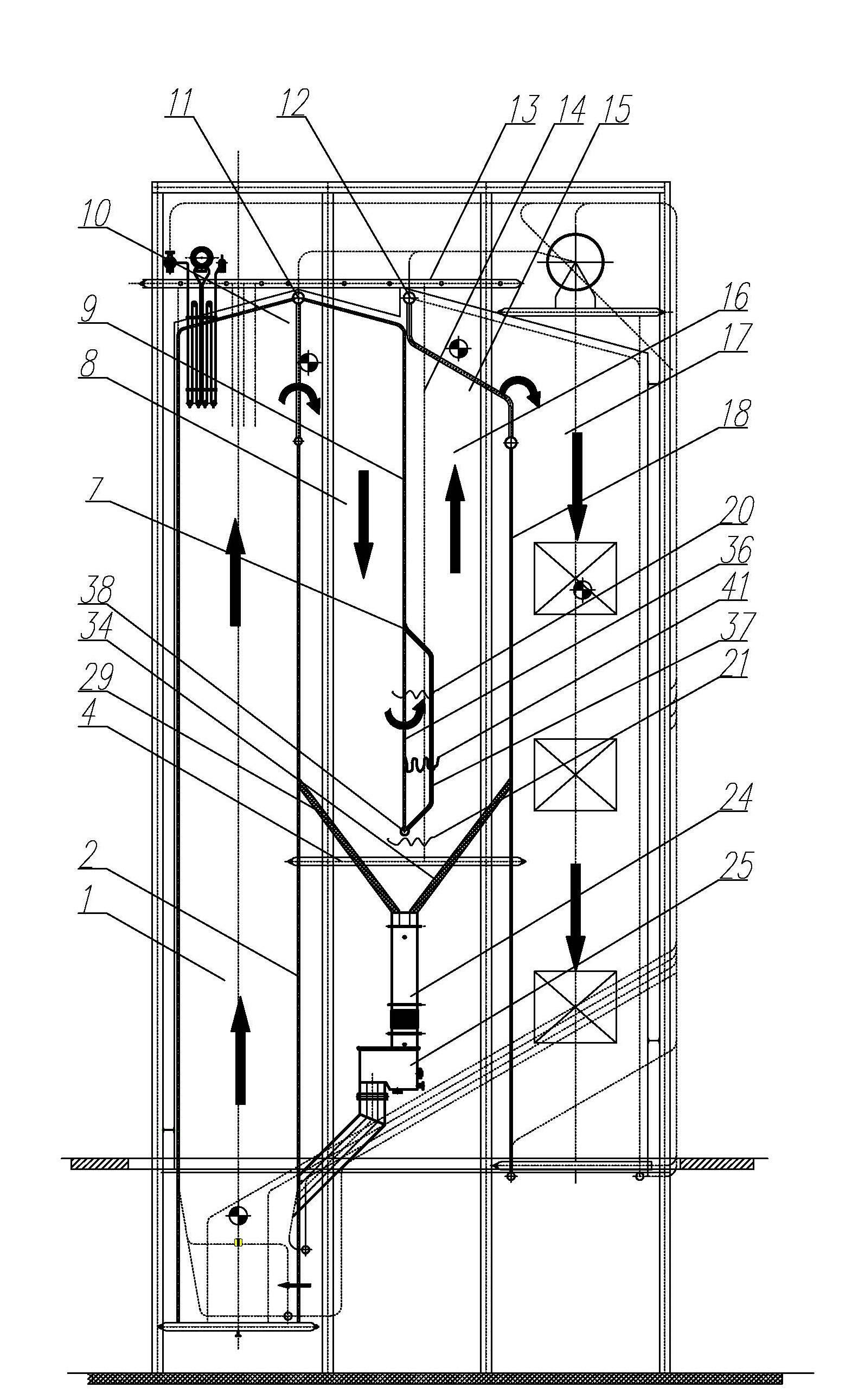

The invention discloses a low-nitrogen combustion technique based on circulating fluidized bed boiler. The circulating fluidized bed boiler comprises a boiler body, a cyclone separator, a deduster, an induced draft fan, a primary air supply system and a secondary air supply system which are connected in sequence. A smoke recirculation pipe is drawn out behind the induced draft fan. The primary air supply system and the secondary air supply system are connected to the smoke recirculation pipe in parallel. A burn-out chamber is arranged at an outlet of the cyclone separator. The low-nitrogen combustion technique based on the circulating fluidized bed boiler comprises the following steps that pulverized coal enters the boiler body under the action of primary air, specifically, the amount of smoke recirculation air in the primary air accounts for 8-10% the total air amount of the primary amount, and the amount of the primary air accounts for 40-45% of the total air amount; secondary air is introduced into the boiler body through the secondary air supply system, specifically, the amount of smoke recirculation air in the secondary air accounts for 12-14% the total air amount of the secondary air; fine flying ash enters the burn-out chamber; and over fire air is introduced into the burn-out chamber. According to the low-nitrogen combustion technique based on the circulating fluidized bed boiler, the burn-out chamber is arranged at the outlet of the separator, and part of smoke is mixed into the primary air and the secondary air, so that generation of NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

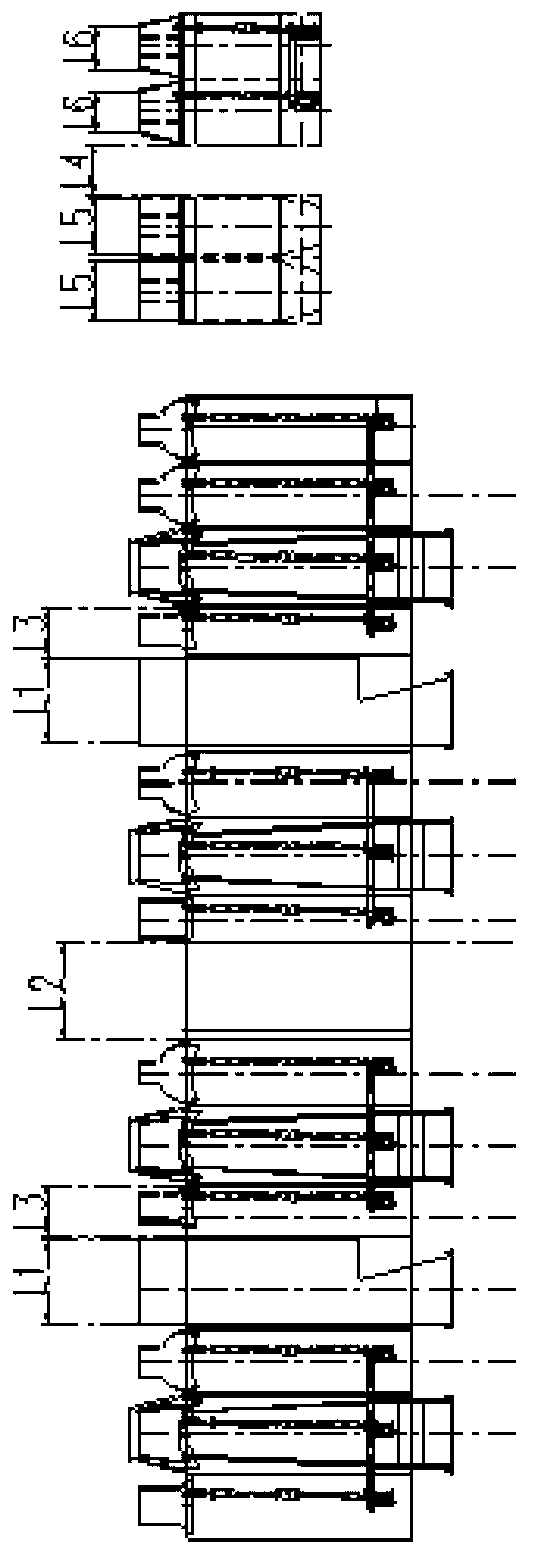

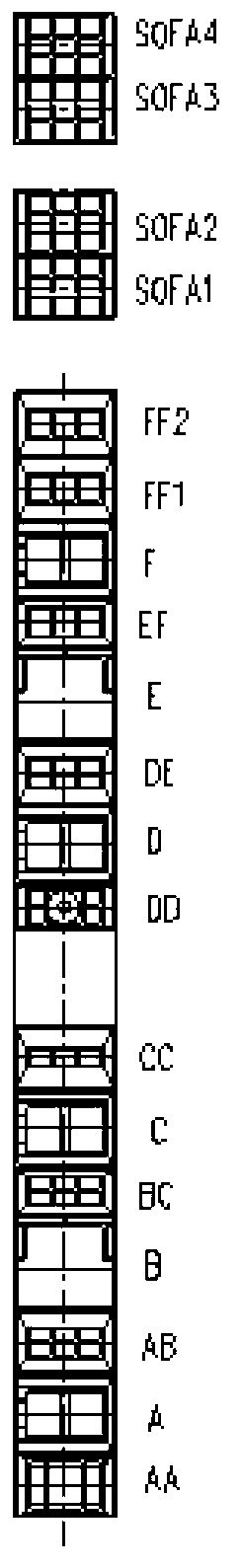

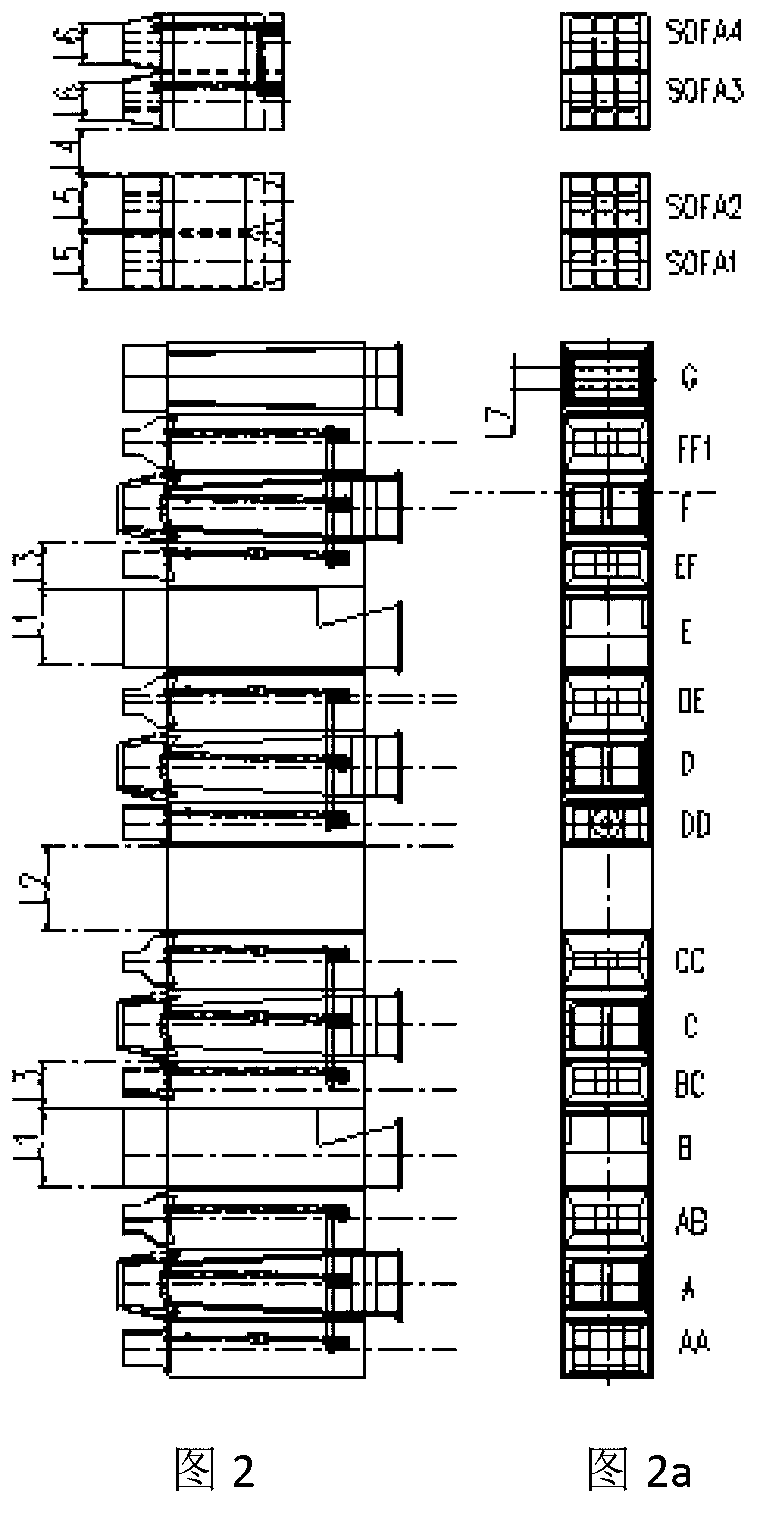

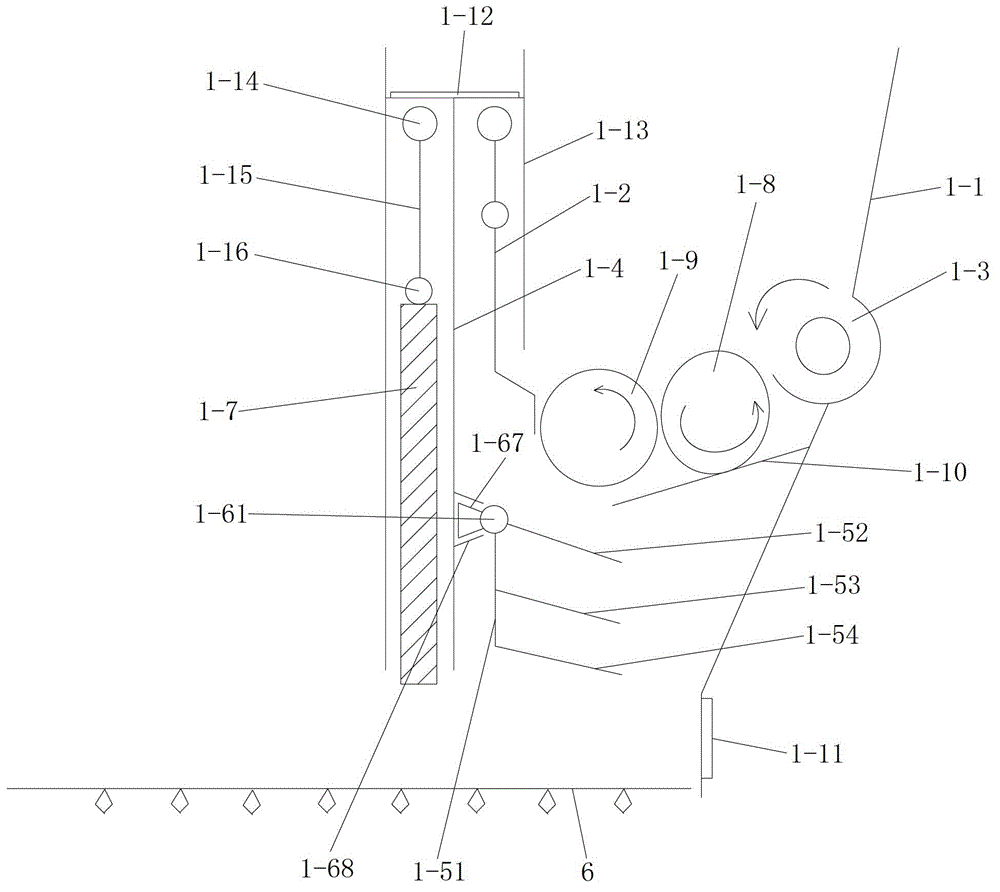

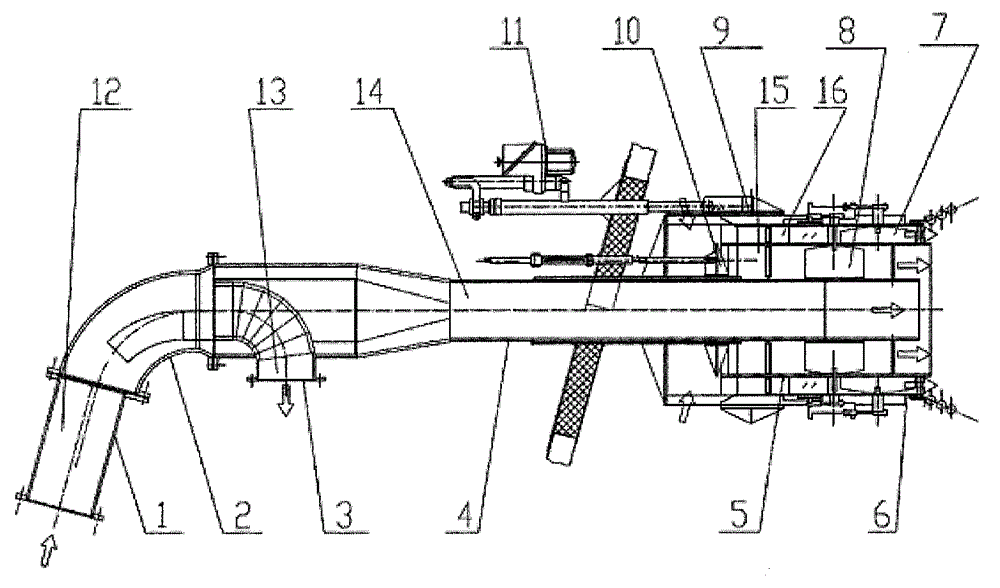

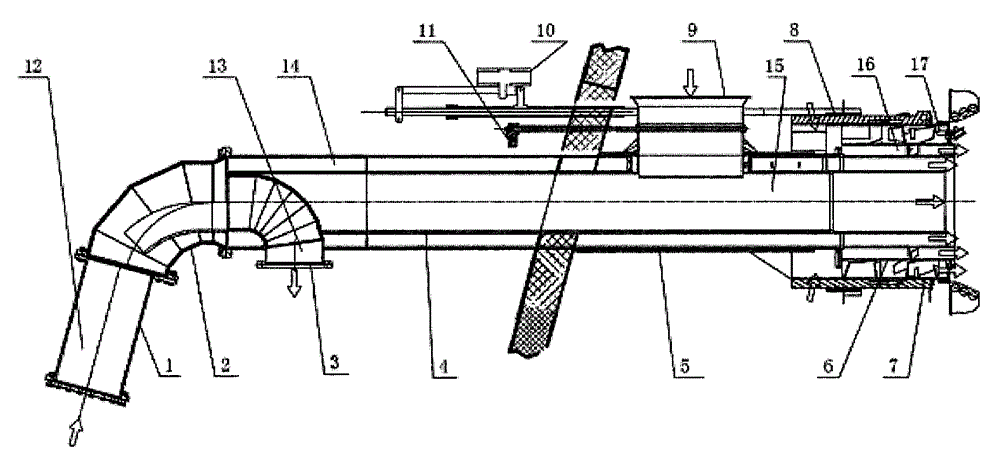

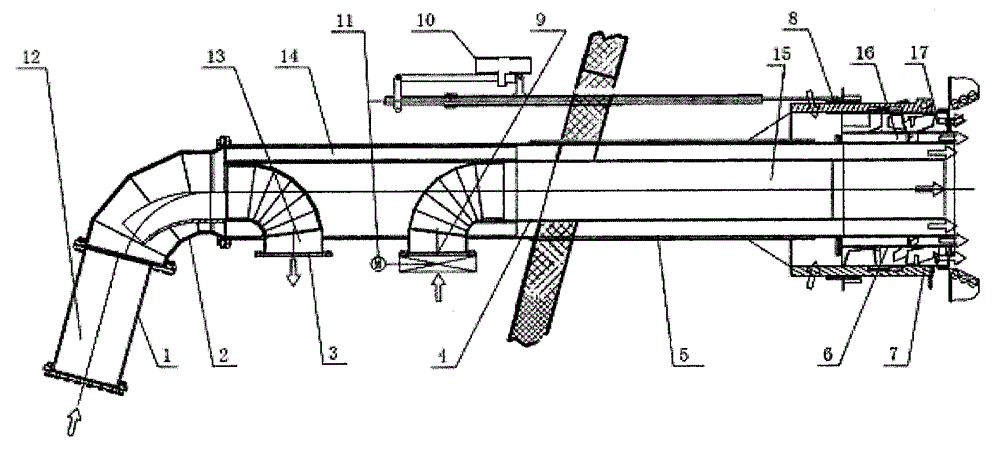

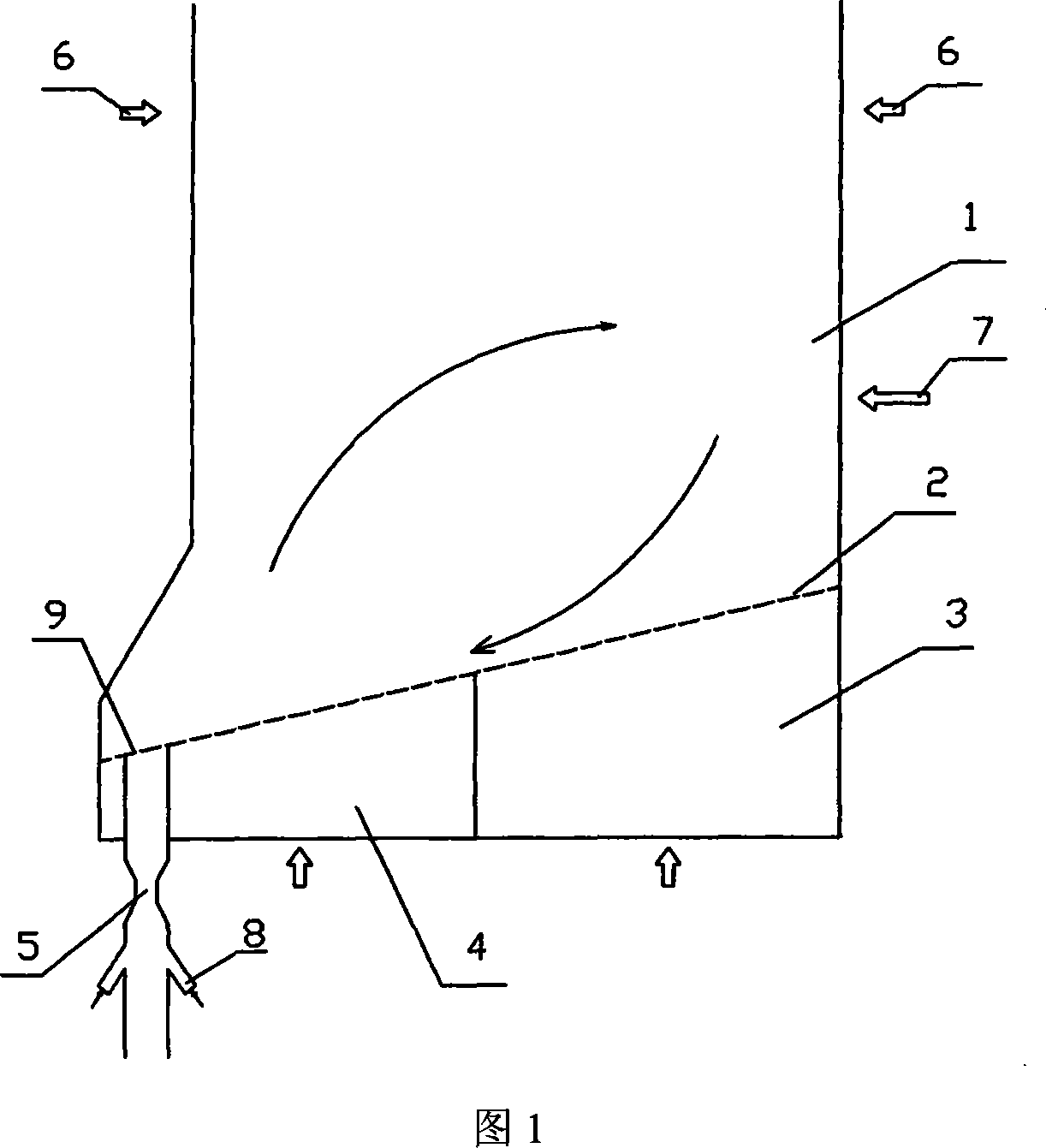

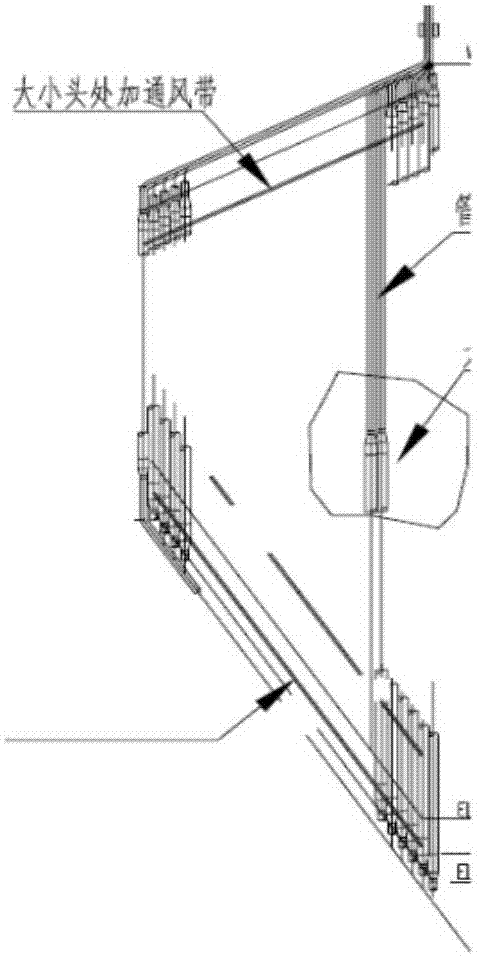

Low-nitric-oxide direct-current pulverized coal combustor adaptive to meager coal boiler

ActiveCN103267279AReduce generationReduce carbon contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

The invention relates to a low-nitric-oxide direct-current pulverized coal combustor adaptive to a meager coal boiler, which can achieve stable and economical combustion, and also reduces nitric oxide emission to the lowest level, so that the low-nitrogen combustion modifying technique of the meager coal boiler is improved. The low-nitric-oxide direct-current pulverized coal combustor adaptive to the meager coal boiler comprises main combustor groups which are arranged on four corners of a hearth of the meager coal boiler in a four-angle tangential circle combustion mode, are matched with a water-cooling wall high-temperature-prevention corrosion system of the hearth, and are identical in structure; each main combustor group comprises pulverized coal combustors arranged at intervals and secondary air spray ports; the upper parts of the main combustor groups are provided with corresponding separation burnout air groups; a layer of precombustion chamber back flow combustor is arranged in each n-layer of pulverized coal combustors; the jet flow rotation direction of the main combustor groups is the anticlockwise direction; the rotation direction of secondary air ports close to the upper parts of the precombustion chamber back flow combustors is the clockwise direction, and the imaginary tangential circle diameter is greater than the imaginary tangential circle diameter of the main combustors; separation burnout air groups include upper groups and lower groups; and the jet flow of the lower groups is in an imaginary tangential circle mode, and the jet flow of the upper groups is in an opposed combustion mode.

Owner:STATE GRID CORP OF CHINA +1

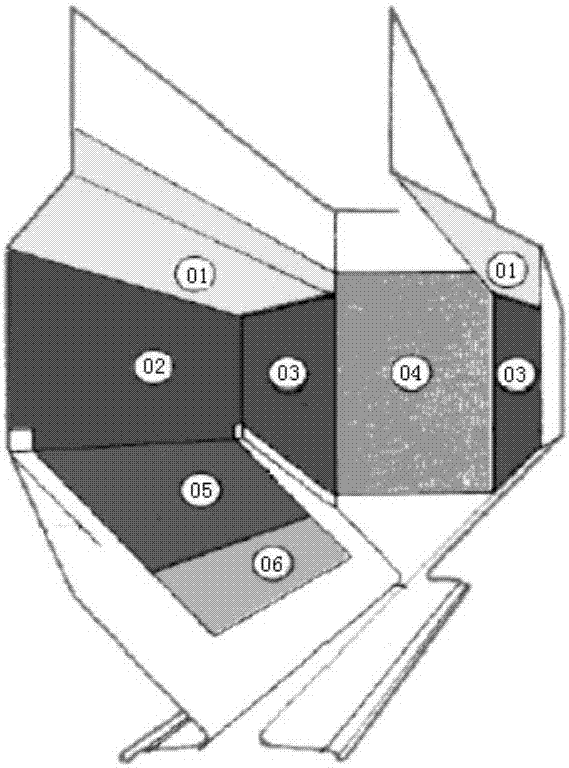

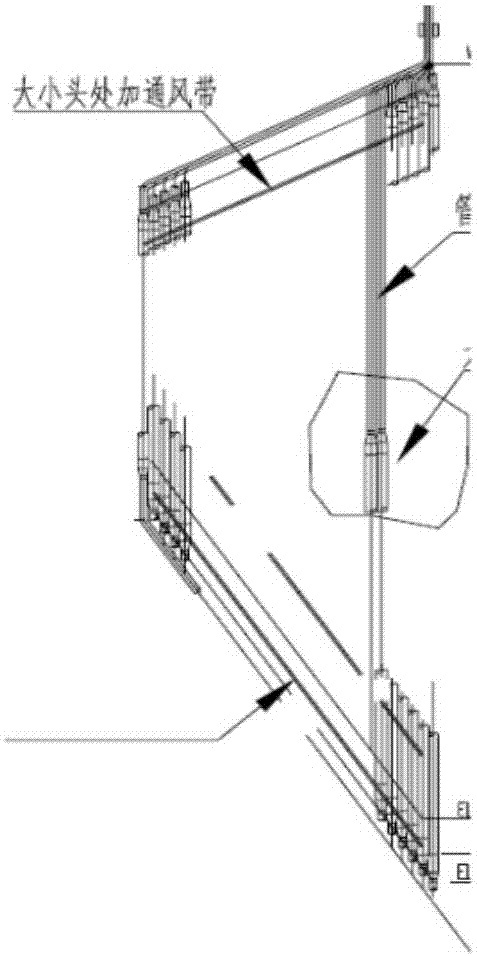

Cyclone burner and air burnout arrangement structure for boiler

InactiveCN102620285AReduce carbon content in fly ashImprove operational efficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustion

A cyclone burner and an air burnout arrangement structure for a boiler relate to cyclone burners and air burnout arrangement structures, and solve the problems of low boiler combustion efficiency and intensification of rear wall slagging and high temperature corrosion of an existing air burnout arrangement structure with the cyclone burner arranged on a front wall. An air burnout spout is arranged on the rear wall of the boiler and positioned laterally above the cyclone burner. The cyclone burner and the air burnout arrangement structure for the boiler are used for reducing unburned carbon in flue dust of the boiler and improve operating efficiency of the boiler.

Owner:HARBIN INST OF TECH

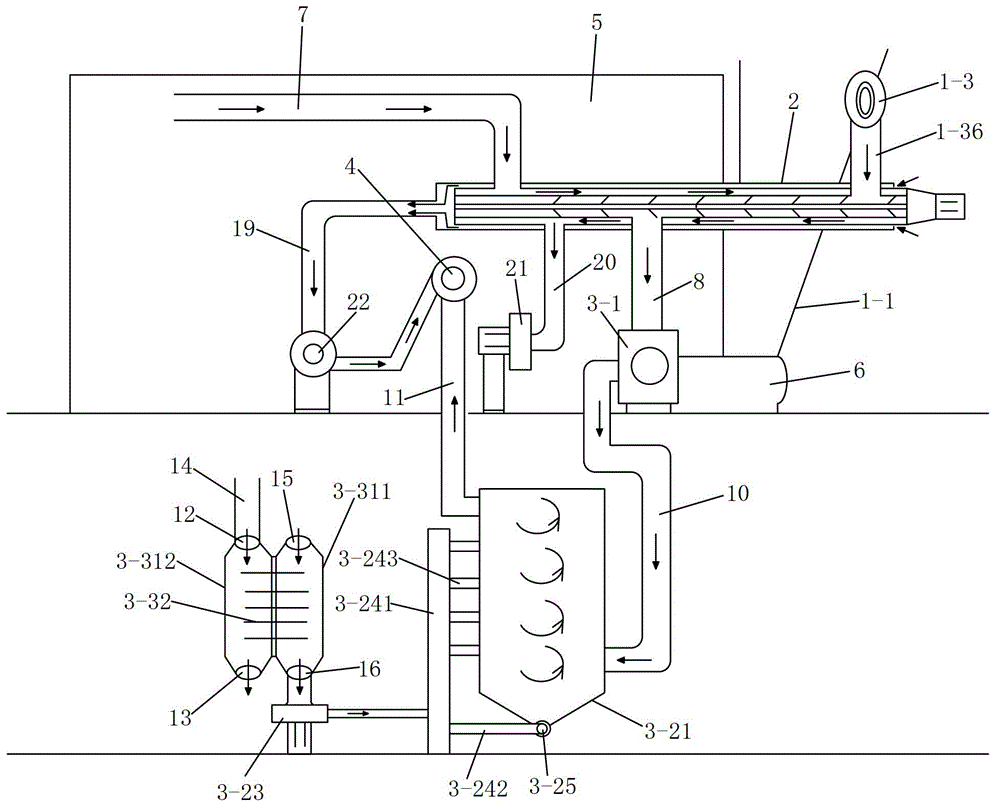

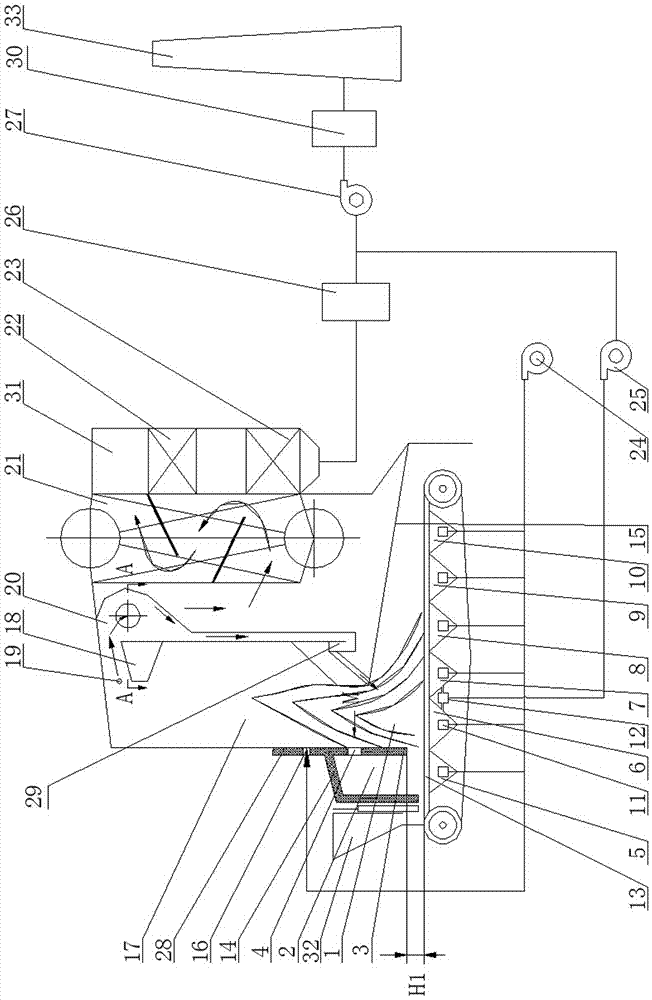

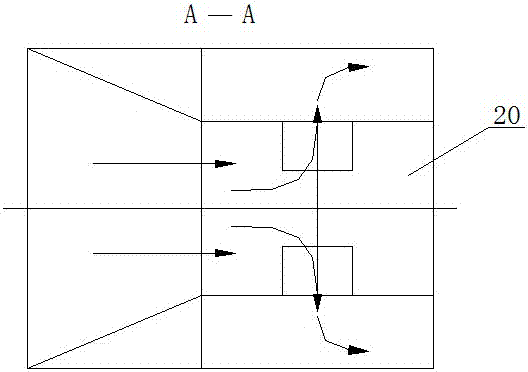

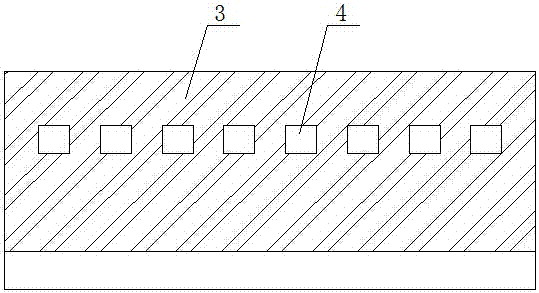

Online low-nitrogen oxygen-rich combined combustion energy-saving system

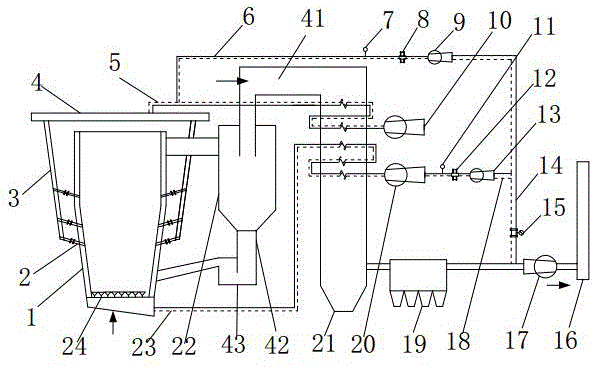

InactiveCN102721041ASimple structureReasonable designIndirect carbon-dioxide mitigationLump/pulverulent fuel feeder/distributionPre treatmentCoal

The invention discloses an online low-nitrogen oxygen-rich combined combustion energy-saving system. The system comprises a pretreatment comprehensive coal hopper which is mounted on a chain-type coal firing boiler, feeds the raw coal in layers and in rows into a chain-type coal firing boiler grate and sorting powdery coal on line; a drying / preheating heat exchanger for drying and delivering the powdery coal which is sorted by the pretreatment comprehensive coal hopper and preheating the air; a coal powder fine-sorting device connected with the drying / preheating heat exchanger and used for finely sorting the powdery coal which is dried by the drying / preheating heat exchanger; and a low-nitrogen oxygen-rich coal powder combustor used for feeding the high-quality coal powder which is finelysorted by the coal powder fine-sorting device into the chain-type coal firing boiler grate. The online low-nitrogen oxygen-rich combined combustion energy-saving system has the advantages of simple structure, reasonable design and good use effect; can treat inferior coal on line to obtain the energy-saving modification technique with the optimum use effect while minimizing the minimum cost, can increase the utilization efficiency of inferior coal, reduce the waste of energy and reduce the use cost.

Owner:SHAANXI PANLONG IND

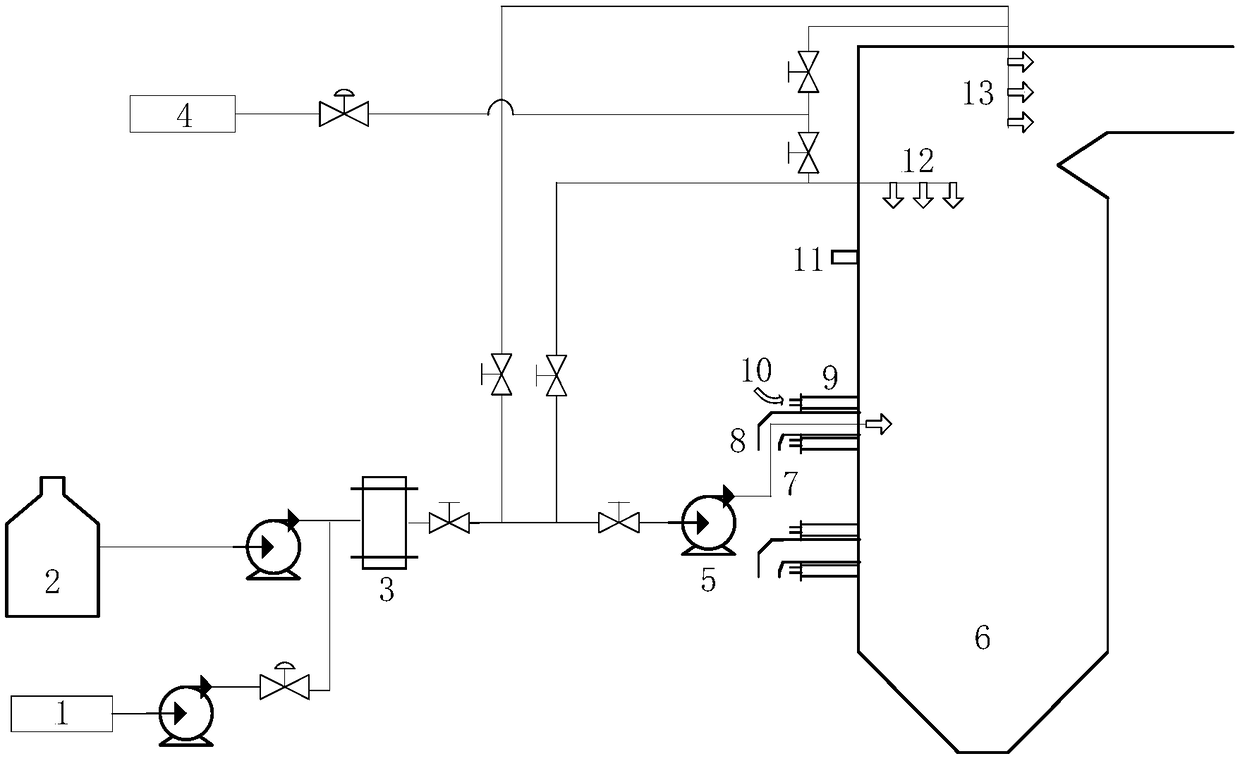

Denitration system and method for cooperative high-temperature ammonia spraying of low-nitrogen combustor of utility boiler

ActiveCN108905590AReduce oxygen contentPromote denitrification reactionDispersed particle separationCombustorRetention time

The invention provides a denitration system and method for cooperative high-temperature ammonia spraying of a low-nitrogen combustor of a utility boiler. The system comprises a urea solution supply system, a combustor group arranged on a utility boiler, an OFA spraying opening for introducing SOFA air, wall type spray guns and long spray guns; a secondary air pipe of the uppermost-layer combustorof the combustor groups is connected with a recirculating flue gas pipeline and an ammonia spray gun is arranged in a primary air pipeline; air is introduced into secondary air pipelines of other combustors; and the ammonia spray guns, the wall type spray guns and the long spray guns are respectively used to provide a urea solution through a connected urea solution supply system. The reducing agent coverage range is improved. The retention time of ammonia gas in a reducing atmosphere is remarkably prolonged, and the denitration efficiency can be improved. Escaped ammonia is oxidized in an SOFAair region, and the ammonia escaping level can be reduced. Water in the urea solution reacts with coke to generate OH active radicals, so that the reduction performance of flue gas in a combustor region can be improved, reactions of the ammonia gas with nitrogen oxides are promoted, and denitration efficiency is improved.

Owner:CHINA HUANENG GRP CO LTD +1

Coal pulverizer equipment

The invention discloses coal pulverizer equipment. The coal pulverizer equipment comprises a base, wherein a body support is arranged on the base, a sealed barrel with smooth and flat inner walls is connected onto the body support, all inner walls of the barrel are in smooth transition, a plurality of barrel liner plates are arranged on the inner walls of the barrel, and a mounting gap between the adjacent barrel liner plates is sealed by an inorganic material; a coal feeding pipe is arranged in the center of the top of the barrel, and a grinding roller assembly is arranged below the coal feeding pipe; a sealing air pipe is connected onto the grinding roller assembly, an air inlet is formed in the bottom of the barrel, and a pulverized coal discharge pipe is arranged at the top of the barrel and is connected with a vertically mounted separator. A local mechanism in a coal pulverizing system is changed, so that the retaining time of pulverized coal in the coal pulverizer is shortened, the safety performance of the coal pulverizing system is improved, then the temperature of hot primary air at an outlet of the coal pulverizer is increased, the hot air entering proportion is increased, the cold air entering proportion is decreased, and the purposes of reduction of carbon content of slag and improvement of boiler efficiency are achieved while the temperature of the outlet of the coal pulverizer is increased and the carbon content of fly ash of a boiler is reduced.

Owner:XUZHOU QUANZHONG ELECTRIC POWER TECH CO LTD

W-shaped flame boiler grading combustion method

InactiveCN107355802AIncrease burnoutReduce generationSolid fuel pretreatmentStaged combustionFlue gasSlag

The invention relates to a W-shaped flame boiler grading combustion method. Free-burning coal reacts with oxygen to form first grade combustion; the free-burning coal is formed by bituminous coal or a mixture between the bituminous coal and meager coal; and high-temperature flue gas atmosphere formed in the first stage ignites anthracite wrapped up with the high-temperature flue gas and second grade combustion is formed. A method for determining an optimal mixture ratio of a mixture ratio of the bituminous coal and the anthracite and a mixture ratio of the bituminous coal, the meager coal and the anthracite comprises steps of pre-deciding a boiler combustion strategy according to coal quality elements and an industrial analysis result, and comparing and analyzing boiler work conditions when different combustion strategies are employed to achieve an optimal boiler grading combustion coal type ratio, and an coal mill coal powder injection way. A combustion coal and the anthracite mixture ratio is determined during the boiler grading combustion process, so second combustion burn-off rate can be effectively improved; and secondary flying ash and large slag carbon content can be reduced.

Owner:中国大唐集团科学技术研究总院有限公司

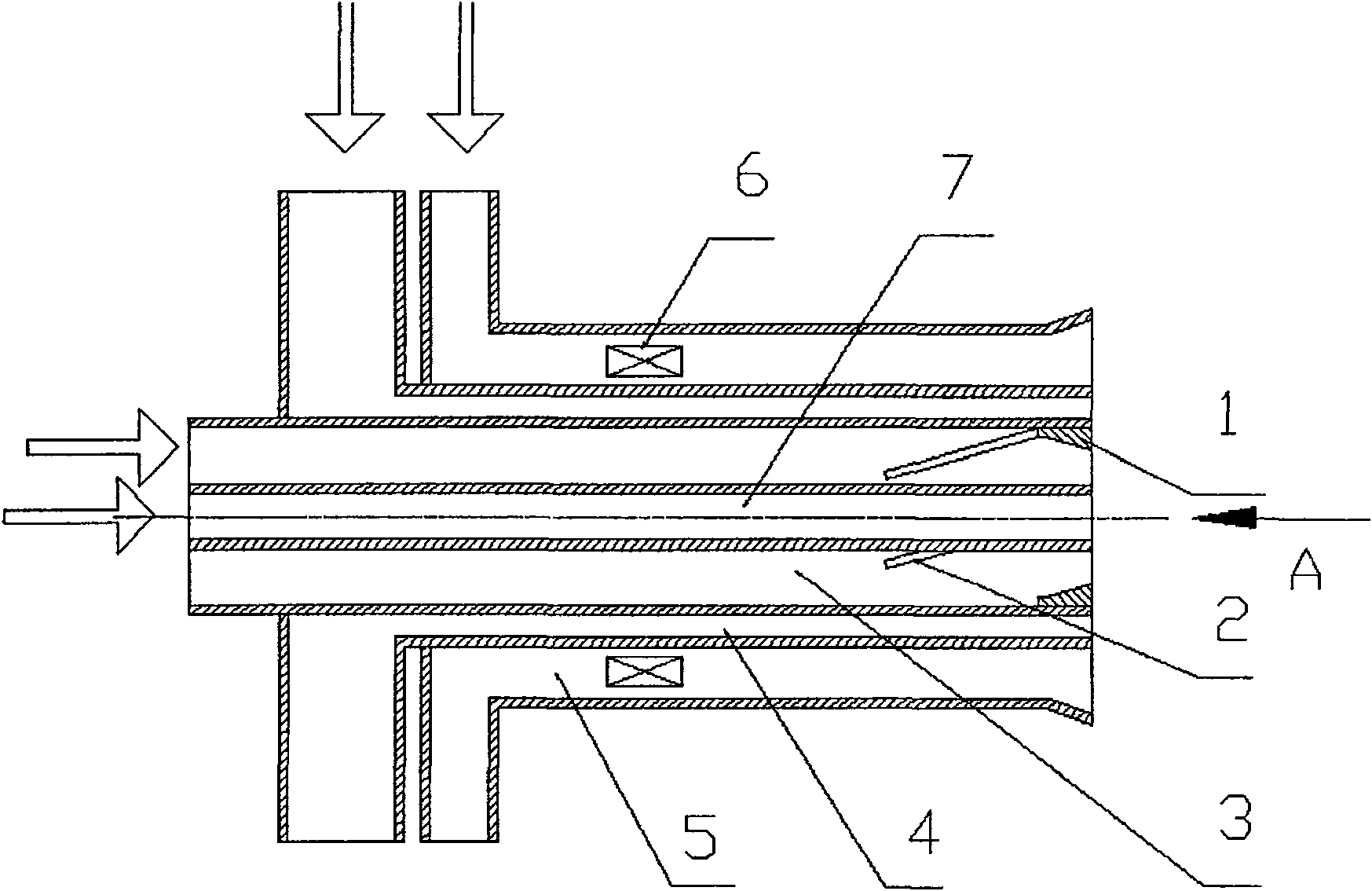

Center air ring concentrated type turbulent burner

InactiveCN104154532AIncrease profitAir distribution optimizationPulverulent fuel combustion burnersCoal pipelineFly ash

A center air ring concentrated type turbulent burner comprises a primary air pulverized coal pipeline, an internal secondary air duct, an external secondary air duct, an exhaust gas pipe, a deflective guide pipe, an elbow and a pulverized coal nozzle. A center air pipeline is arranged in the primary air pulverized coal pipeline, the primary air pulverized coal pipeline and the center air pipeline form an annular channel, pulverized coal is heated by high-temperature center air and internal secondary air in the annular channel and can be heated more uniformly, and therefore more volatiles can be easily separated out, and timely ignition and steady burning of the pulverized coal can be easily achieved. The pulverized coal nozzle is of a circular ring shape, the pulverized coal is surrounded by the center air, the internal secondary air and the external secondary air after being ejected out from the circular-ring-shaped nozzle, two layers of flames are formed after the pulverized coal is ignited, burning of the pulverized coal is more violent and more efficient, and the fly ash carbon content and the cinder carbon content can be effectively decreased.

Owner:TRANSTEK IND HK LTD KOWLOON

Coal-fired boiler combustion operation method and combustion operation system

PendingCN107120639APrevent dust and slaggingAvoid corrosionCombustion using gaseous and pulverulent fuelGaseous fuel feeder/distributionLower gradeProcess engineering

The invention discloses a coal-fired boiler combustion operation method and a combustion operation system. According to the combustion operation method, biomass gasified gas is injected into a hearth to assist fire coal burning. Not only can the problems of the dust deposition, scorification and corrosion be avoided, but the emission concentration of SO2 and NOx can be reduced remarkably, the carbon content of flue dust is reduced, and the high grade use of low grade biomass energy is realized.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

High temperature fluidized bed combustion device

InactiveCN101144619ADischarge in timePromote internal circulationFluidized bed combustionApparatus for fluidised bed combustionLow speedEngineering

The invention relates to a high temperature fluid bed combustion device in the energy resource field. The device comprises a furnace, an inclined uneven air distribution plate, a low speed primary air chamber, a high speed primary air chamber, an air classification deslagging pipe, a secondary air inlet opening, a material inlet opening, classifying air pipes and a deslagging opening. The connection relations are that the inclined uneven air distribution plate is arranged at the bottom of the furnace, the low speed primary air chamber and the high speed primary air chamber are arranged under the inclined uneven air distribution plate, the low speed primary air chamber is positioned under the lower end position of the inclined uneven air distribution plate, the high speed primary air chamber is positioned under the higher end position of the inclined uneven air distribution plate, the secondary air inlet opening is arranged on the upper part of the furnace, the material inlet opening is arranged on the furnace wall close to the low speed primary air chamber, the deslagging opening is positioned at the crossing position of the lower end of the inclined uneven air distribution plate and the furnace wall, one end of the air classification deslagging pipe is connected with the deslagging opening, the classifying air pipes are arranged on the two sides of the air classification deslagging pipe, and the classifying air pipes are communicated with the air classification deslagging pipe. The device of the invention is simple, the investment expense is low, the reliability is high, the overall combustion reaction speed is enhanced, and the fly ash carbon content is reduced.

Owner:SHANGHAI JIAO TONG UNIV

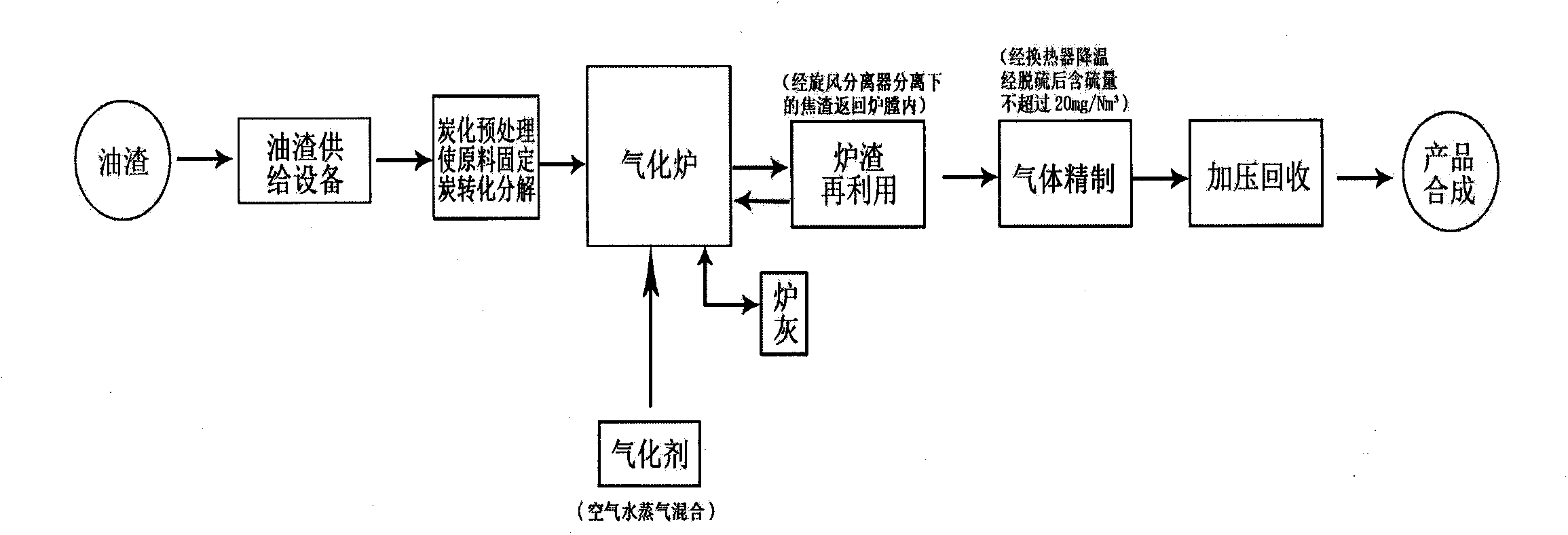

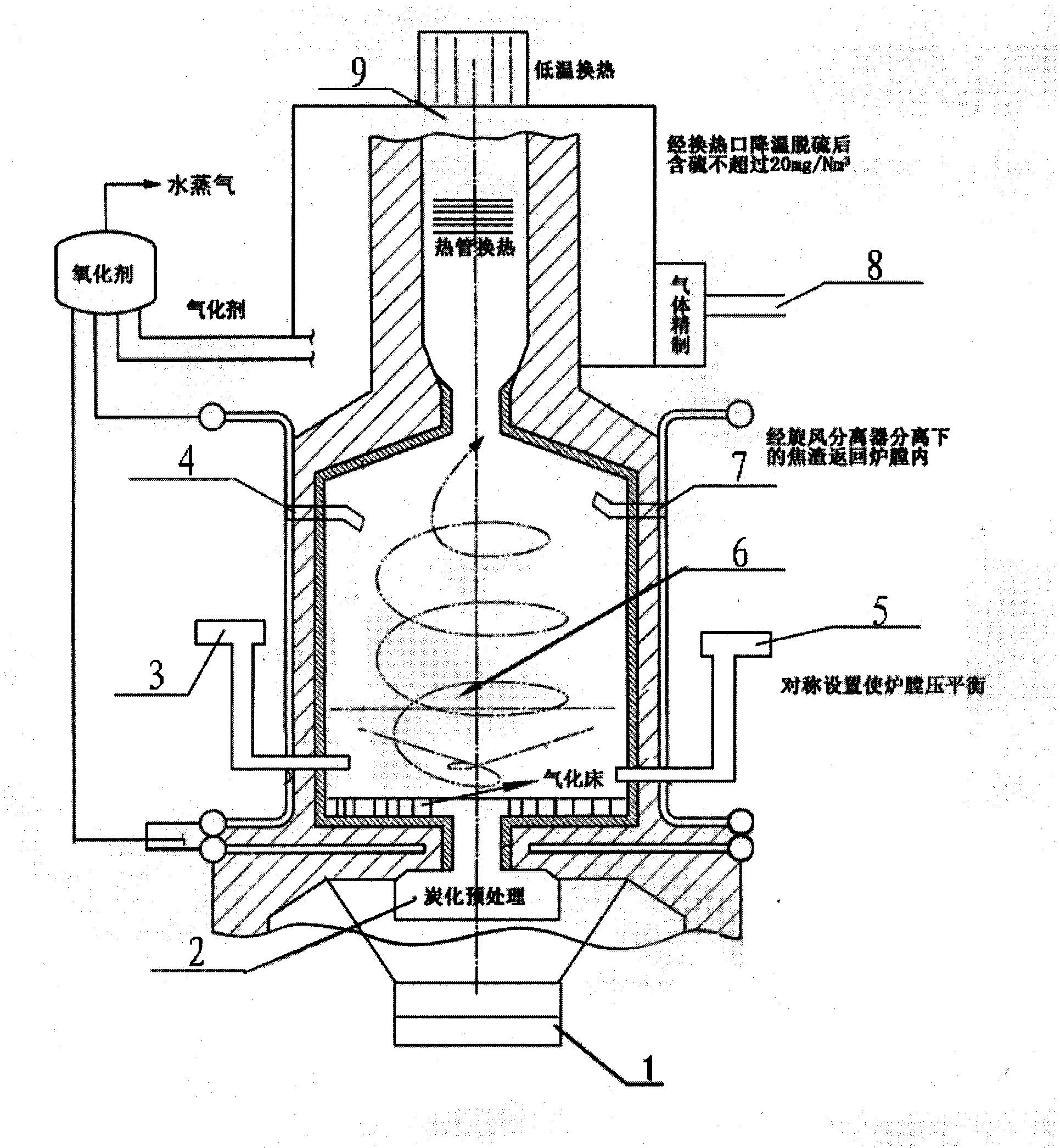

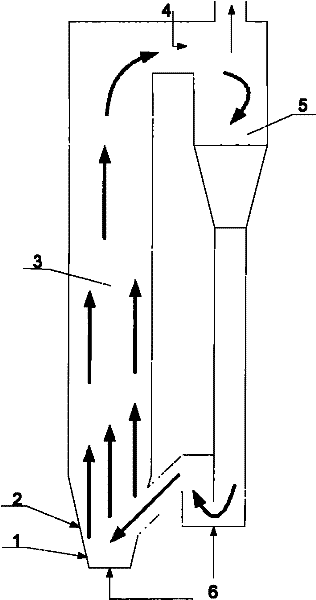

Secondary gasification treatment method for oil residue caused in gas production

The invention discloses a secondary gasification treatment method for oil residue caused in gas production. The secondary gasification treatment method for oil residue caused in gas production comprises the following steps: delivering an oil residue raw material with the particle diameter of 10mm below to an oxygen carbonizing furnace for carbonizing treatment, further gasifying the oil residue raw material, then transmitting the mixture gas into a cone section at the bottom of a gasification furnace so as to react with a gasifying agent, wherein the temperature of the gasifying agent is 750 DEG C, the pressure and temperature of the top of a gas furnace are respectively 15Kpa and 98 DEG C; flowing the gas out to enter a primary cyclone separator, returning the separated residue ash back to the hearth of the gasification furnace through a return pipe, and entering the gas into a dry type dust collection system after being subjected to dust collection treatment by a secondary cyclone separator, then cooling the gas again by a heat pipe exchanger, and recovering the desulfurized gas in a pressurization system. According to the secondary gasification treatment method, the gasification efficiency is high, the fluidization quality is improved, the flying ash quantity, flying as carbon content, ash slag carbon content in the gas can be greatly reduced, and the effective utilization rate and gasification efficiency of the oil residues can be improved.

Owner:杜维兴

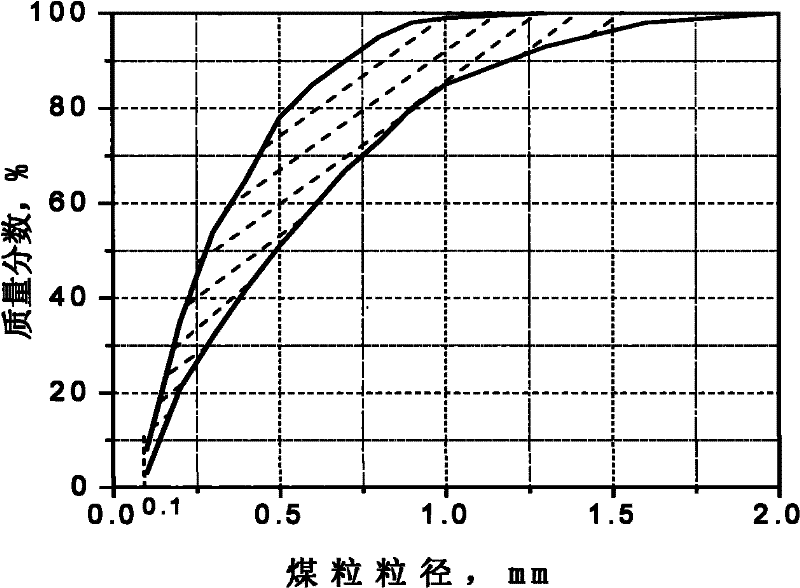

Combustion process method for granular coal circulating fluidized bed boiler

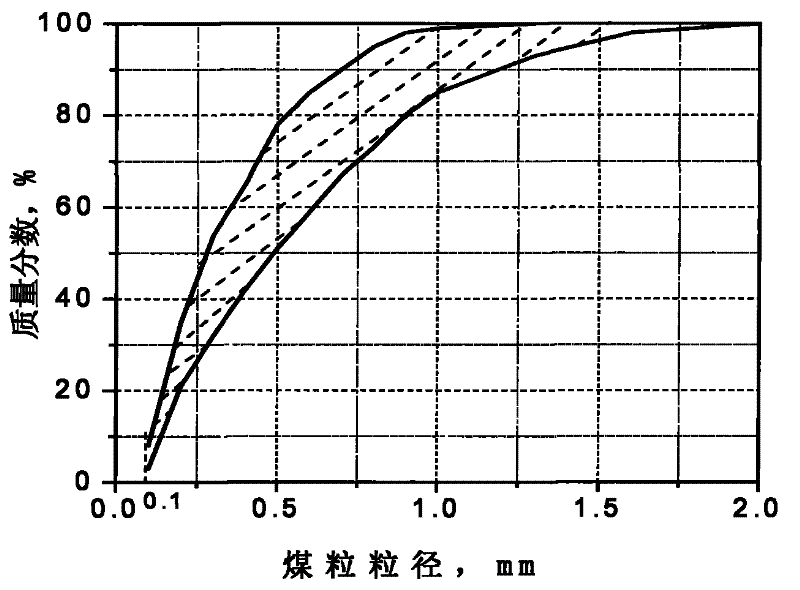

ActiveCN101761922BBurn fullyReduce the possibility of "deactivation"Fluidized bed combustionApparatus for fluidised bed combustionAir velocityEmission standard

The present invention discloses a combustion method for a pea coal circulating fluidized bed boiler and relates to the coal combustion technique. According to the method, pea coal particles with a diameter less than 2mm are taken as a fuel, limestone particles with a diameter less than 0.6mm are taken as a desulfurizing agent, and the fuel and the desulfurizing agent are added into a hearth. The combustion temperature in the boiler is controlled to be 850 to 950 DEG C; the fluidizing air speed is controlled to be 2 to 3.5m / s; the bed pressure drop is controlled to be 1 to 3kPa, and the primary air pressure head is controlled to be 5 to 7kPa; and when the NOx content of smoke is higher than an emission standard, ammonia water serving as a denitrifying agent is sprayed at an inlet of a cyclone separator. The pea coal with the small grain diameter serves as the fuel, so the invalid large particles content of the fuel is reduced, and the bed pressure drop and a primary air pressure head can be effectively reduced; because the height of a dense-phase area is reduced, the wear degree of a hearth heated surface can be reduced; and meanwhile, the fuel grain diameter is reduced, so that the stay time of the particles in the hearth is properly reduced, the 'inactivation' possibility of the fuel is efficiently decreased and the combustion efficiency is increased.

Owner:TSINGHUA UNIV

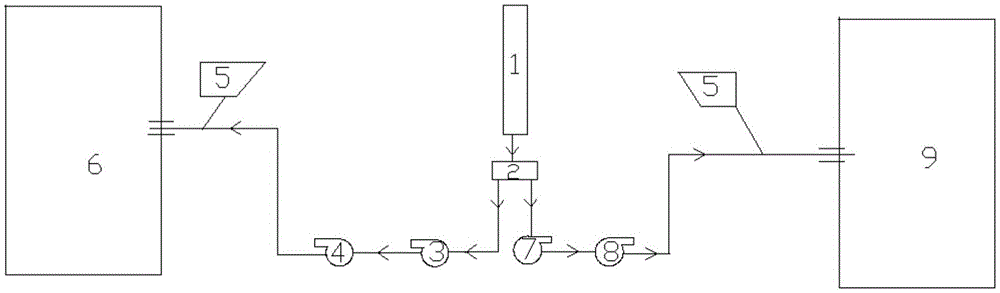

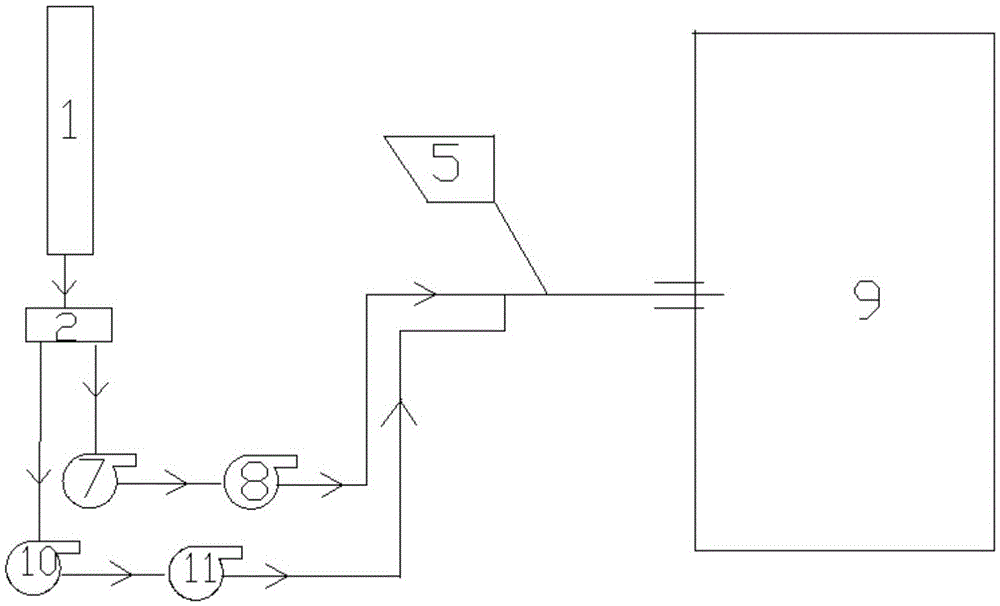

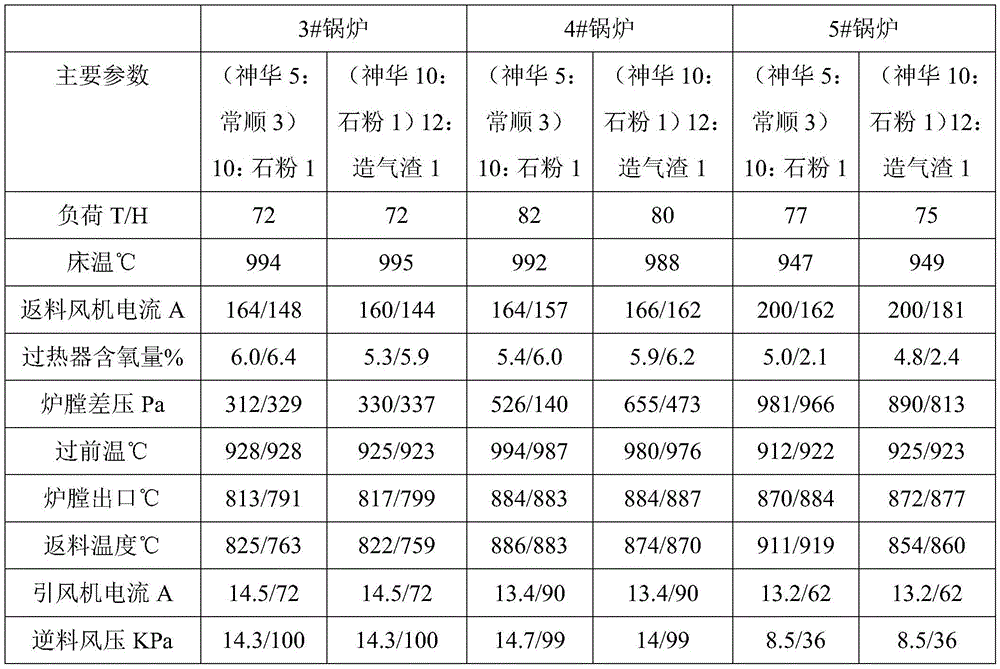

Method and system for waste recycling and treatment

ActiveCN105570908AImprove washing effectDoes not affect ignitionIncinerator apparatusLump/pulverulent fuel feeder/distributionCombustionSlag

The invention discloses a method and a system for waste recycling and treatment. The method comprises the following schemes: introducing oil fumes into a coal-fired boiler through a primary air fan and blowing primary air into the coal-fired boiler; or, introducing oil fumes into a coal-fired boiler through a primary air fan and blowing primary air into a boiler, meanwhile mixing waste coal slag generated by a gas-making furnace and coal in the coal-fired boiler so as to supply fuels to the boiler. The method and the system for waste recycling and treatment have the beneficial effects that the method is simple, convenient to operate and suitable for alteration of fume combination treatment of large and small boiler devices; the economic cost in construction of flue gas treatment facilities is reduced, the qualified flue gas emission is guaranteed as well, the environmental pollution is avoided; meanwhile the method is suitable for environment protection alteration of small-sized boilers without flue gas treatment process in the serious environment protection situation at present. Through blending combustion of coal slag in the boiler, the load capacity of the boiler maintains stably.

Owner:LUXI CHEM GRP

Smoke recirculation device for separating primary air and secondary air

PendingCN110657439AReduce unit consumptionReduce the amount of fly ashAir supply regulationIndirect carbon-dioxide mitigationCombustionEnvironmental engineering

The invention provides a smoke recirculation device for separating primary air and secondary air. The smoke recirculation device comprises an incinerator, a smoke purification device, a primary fan and a secondary fan. The incinerator is configured to incinerate biomass to generate smoke. The smoke purification device is configured to purify the smoke, and one part of purified smoke discharged bythe smoke purification device serves as recirculation smoke. The primary fan is configured to drain air, so that the air serves as primary air of the incinerator. The secondary fan is configured to drain air and the recirculation smoke, and the air and the recirculation smoke serve as secondary air of the incinerator. According to the provided smoke recirculation device for separating the primaryair and the secondary air, the primary fan drains the air as the primary air, the secondary fan drains the air and the recirculation smoke as the secondary air, thus the flying ash quantity and the flying ash carbon content are lowered, fuel unit consumption is lowered, high-temperature corrosion is reduced, and the combustion condition is optimized.

Owner:光大绿色环保管理(深圳)有限公司

Method for improving W-type flame boiler efficiency

InactiveCN107355803ABurn fullyImprove efficiencyAir supply regulationIndirect carbon-dioxide mitigationAnthraciteEngineering

The invention relates to a method for improving W-type flame boiler efficiency. The method comprises steps of conducting coaly element and industrial analysis to a selected coal type, presetting a boiler combustion strategy, conducting boiler fuel combustion simulation according to the preset combustion strategy to acquire a boiler work condition, comparing and analyzing boiler work conditions upon different combustion strategies to acquire an optimal boiler grading combustion coaly proportion and coal grinding machine coal powder injection way. A proportion of the burning coal and anthracite can be well determined during the boiler grading combustion by the use of the method.

Owner:中国大唐集团科学技术研究总院有限公司

Efficiency-improving method for W-type flame boiler grading combustion

InactiveCN107355804ABurn fullyIncreased burning distanceAir supply regulationIndirect carbon-dioxide mitigationAnthraciteEngineering

The invention relates to an efficiency-improving method for W-type flame boiler grading combustion. The efficiency-improving method comprises steps of analyzing coaly element and proximate analysis to selected coal, presetting a boiler combustion strategy, simulating boiler fuel combustion according to the preset combustion strategy to acquire a boiler work condition, and conducting comparison analysis to boiler work conditions according to different combustion strategies to acquire an optimal boiler grading combustion coal proportion and a coal injection way of a coal grinding machine. Burning coal and anthracite proportion during the boiler grading combustion process can be well determined.

Owner:中国大唐集团科学技术研究总院有限公司

How to Improve Furnace Efficiency of W Type Flame Boiler

InactiveCN107355803BBurn fullyImprove efficiencyAir supply regulationIndirect carbon-dioxide mitigationBoiler furnaceProcess engineering

The invention relates to a method for improving W-type flame boiler efficiency. The method comprises steps of conducting coaly element and industrial analysis to a selected coal type, presetting a boiler combustion strategy, conducting boiler fuel combustion simulation according to the preset combustion strategy to acquire a boiler work condition, comparing and analyzing boiler work conditions upon different combustion strategies to acquire an optimal boiler grading combustion coaly proportion and coal grinding machine coal powder injection way. A proportion of the burning coal and anthracite can be well determined during the boiler grading combustion by the use of the method.

Owner:中国大唐集团科学技术研究总院有限公司

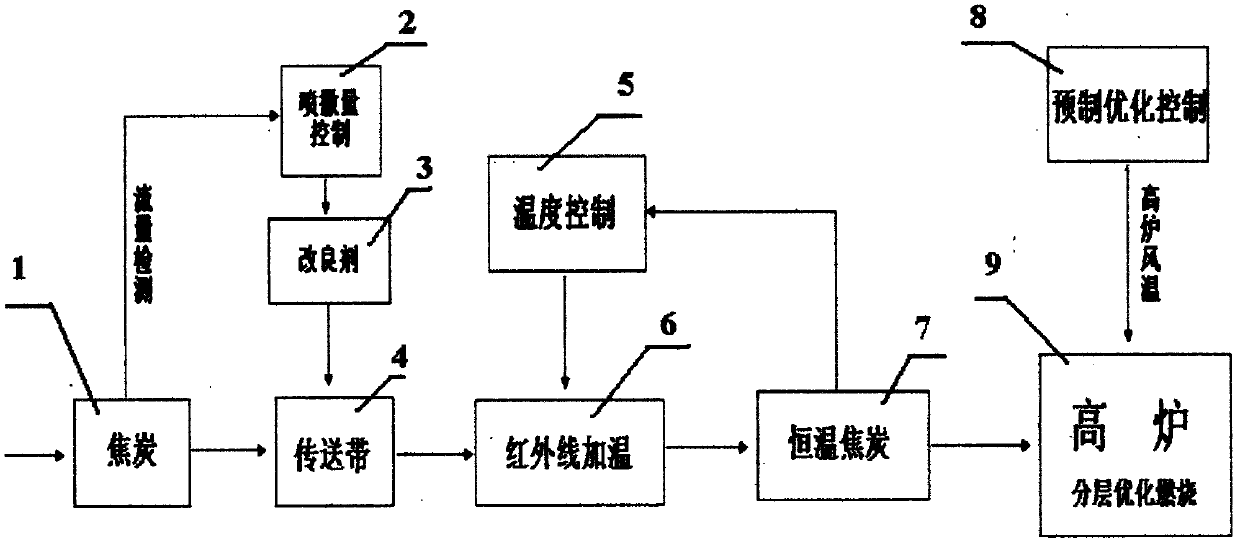

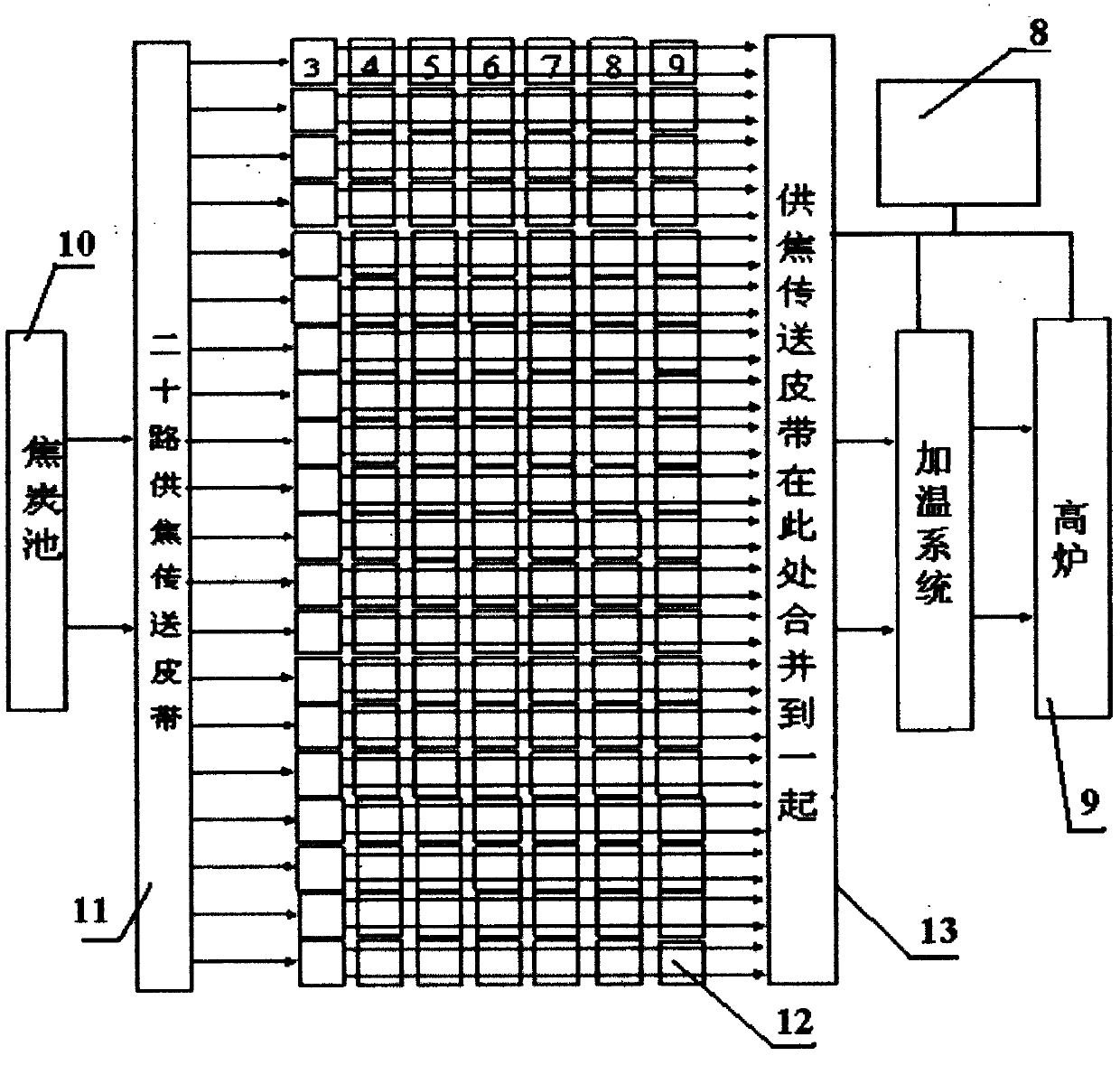

Coke-saving precast optimization control system for coke put into furnace

InactiveCN102297606BSolve the problem of maximum combustion efficiencyIncreased thermal efficiency of blast furnaceBlast furnace detailsControl devices for furnacesSlagControl system

The invention relates to a coke-saving precast optimization control system for coke put into a furnace, which comprises a coke input system, a conveyor belt system, a blast furnace and a precast optimization control module, wherein a modifying agent control unit is arranged between the coke input system and the conveyor belt system; a heating system is arranged between the conveyor belt system and the blast furnace; and the precast optimization control module is connected with the coke input system, the conveyor belt system, the heating system, the modifying agent control unit and the blast furnace through a signal line. The thermal efficiency of the coke-saving precast optimization control system for the coke put into the furnace is greatly improved, and the coal-saving rate is 30-50 percent. By adopting the control system, the emission is reduced, and the emission loads of dust, slag, SO2 and the like are respectively and greatly reduced, thus, the neighboring environment is purified.

Owner:宋群

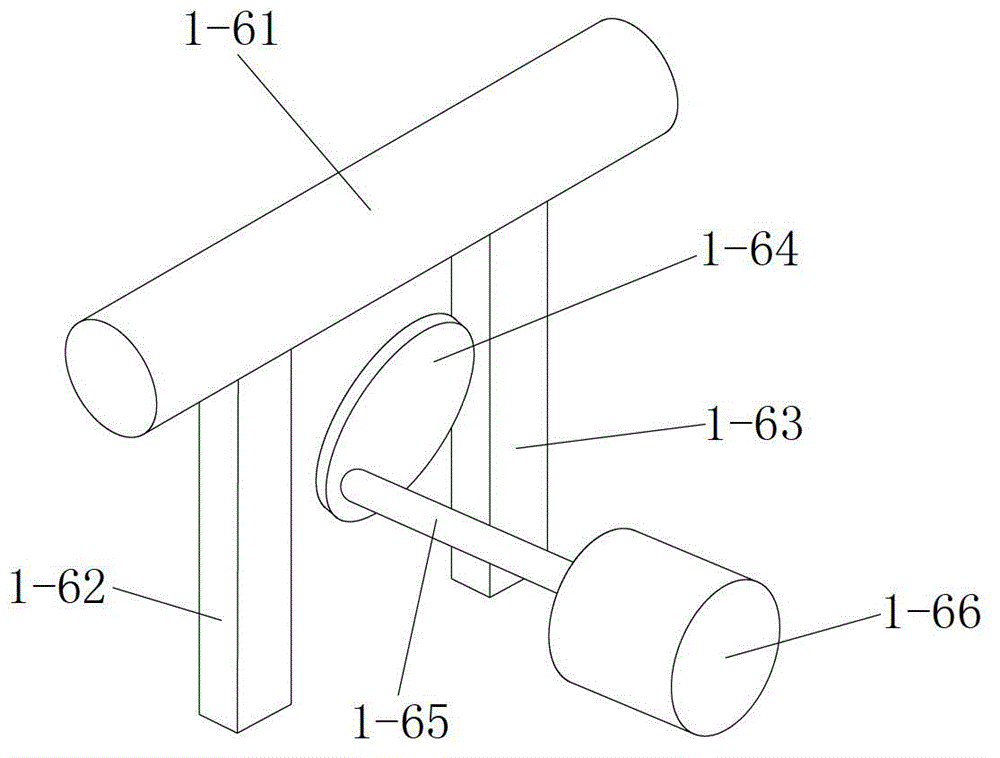

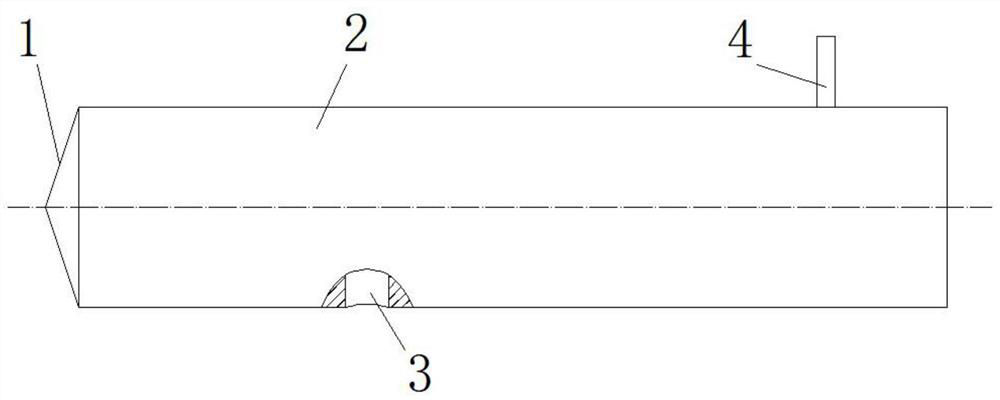

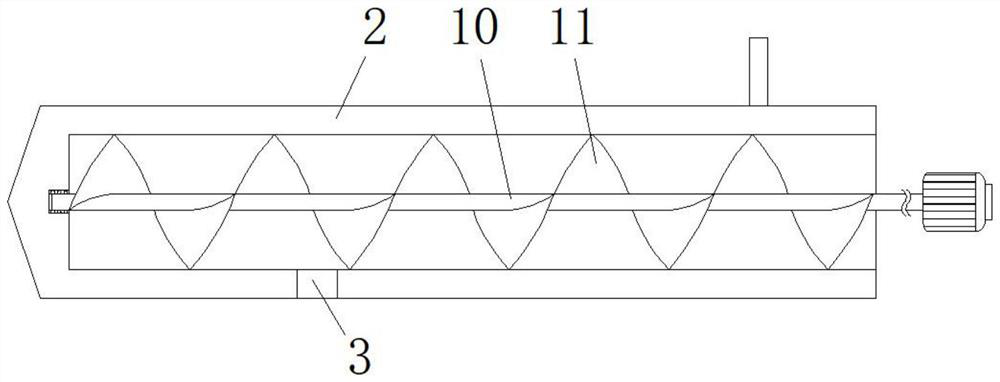

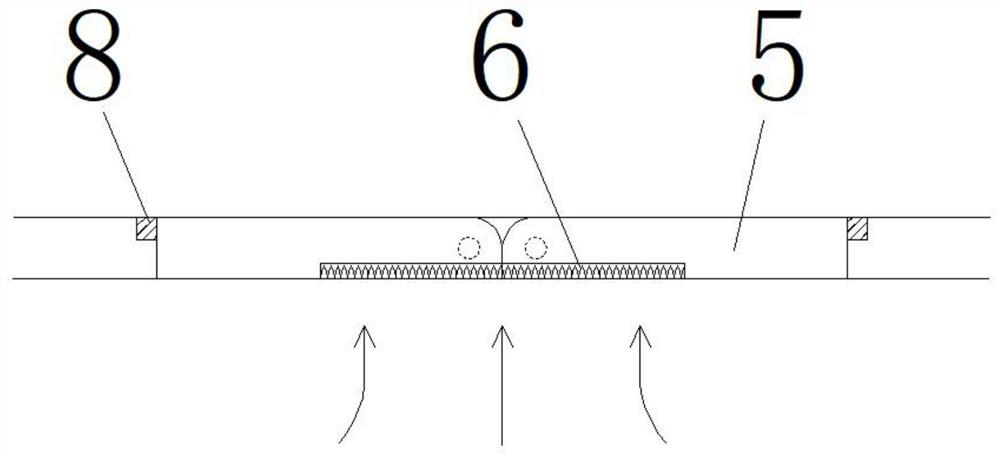

Boiler porous pulverized coal sampling gun and design method thereof

PendingCN112229686AEasy to operateSampling is convenientWithdrawing sample devicesProcess engineeringCoal

The invention discloses a boiler porous pulverized coal sampling gun and a design method thereof. A sampling hole is formed in the sampling gun, a conical plug is arranged at the gun head of the sampling gun, and a positioning pointer is arranged on the outer wall of the sampling gun; a sampled pulverized coal pushing device is arranged in the sampling gun; and a pulverized coal leakage preventiondevice is arranged in the sampling hole. Through the implementation of the sampling gun, the problems that the existing single-hole pulverized coal sampling time is long and a rotary sampling systemis complex can be effectively solved. Through a porous pulverized coal sampling pipe, pulverized coal sampling can be performed representatively. The porous pulverized coal sampling pipe is simple andpractical. Pulverized coal sampling operation is simple, sampling is convenient, the sampling position does not need to be calibrated in advance, and pulverized coal sampling representativeness is high. A baffle plate is arranged at the sampling hole of the porous pulverized coal sampling gun, so that pulverized coal in the pipeline can enter the sampling gun by pushing the baffle plate through forward wind pressure. Through the arrangement of a spring, the collected pulverized coal is prevented from reversely flowing out of the sampling gun, and the effect of maintaining the sampling resultis achieved.

Owner:LIAONING DONGKE ELECTRIC POWER

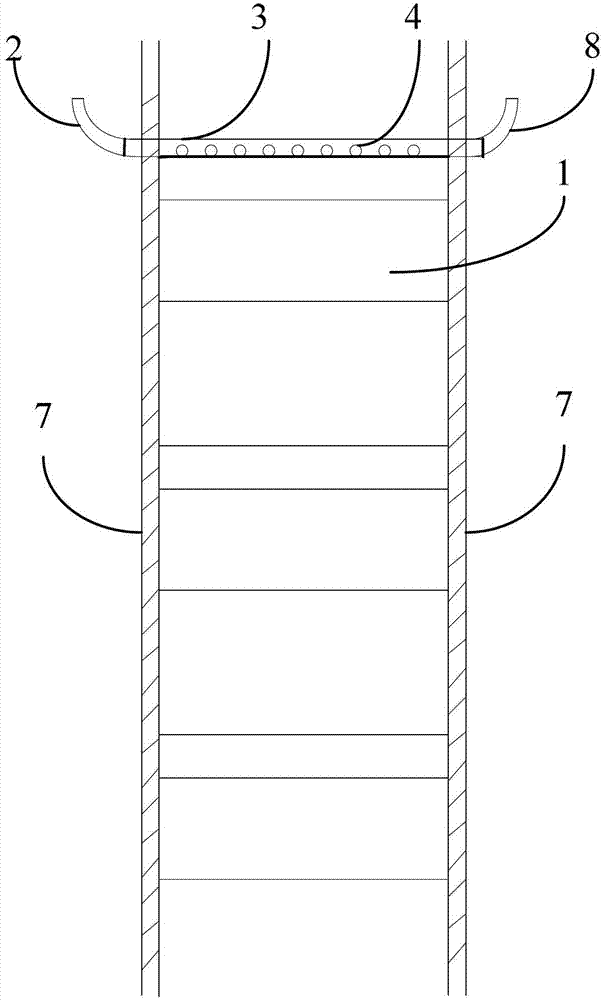

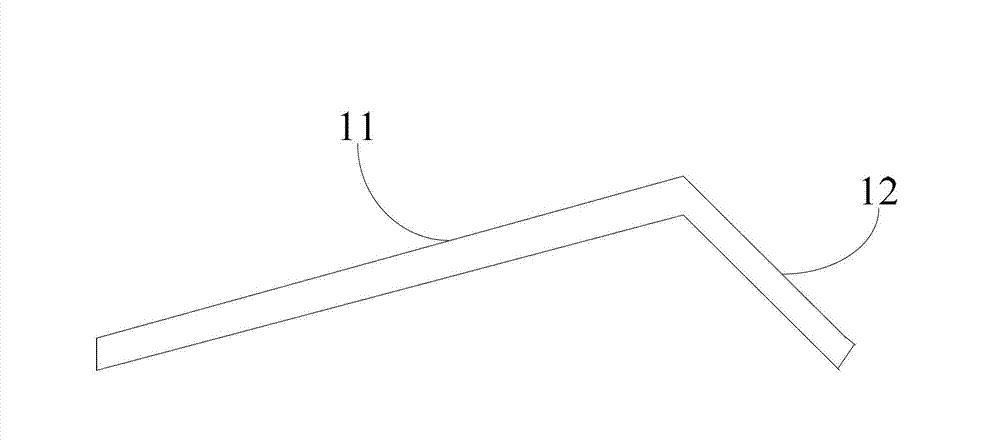

Waveform separation rotary fly ash burnout device

InactiveCN103032885AIncrease disturbanceExtended stayNon-combustible gases/liquids supplyBafflesFlue gasCombustible gas

The invention discloses a waveform separation rotary fly ash burnout device, which comprises a first air connecting pipe, a second air connecting pipe, an air lance and a plurality of cyclone air nozzles. Folded plates respectively comprise a first wing and a second wing; the first wings are respectively longer than the second wings; the folded plates are respectively and obliquely arranged at highest points of a front arch of a chain-grate boiler in a structure that the first wings are respectively lower than the second wings; both ends of each first wing and both ends of each second wing are respectively and fixedly arranged on two side walls of the chain-grate boiler to form a suspension space burning zone together with the front arch of the chain-grate boiler, a rear arch of the chain-grate boiler and the two side walls of the chain-grate boiler; the air lance is welded at the upper edges of the second wings; both ends of the air lance horizontally extend to pass through the two side walls of the chain-grate boiler to be respectively connected with the two air connecting pipes; and the cyclone air nozzles are evenly arranged in the length direction of the air lance located in the chain-grate boiler. According to the waveform separation rotary fly ash burnout device disclosed by the invention, the problems that the combustible gas content is high and the carbon content in fly ash is high in flue gas of the coal chain-grate boiler, the heat efficiency is low and black smoke is emited from a chimney are solved.

Owner:北京中煤神州节能环保技术开发有限公司

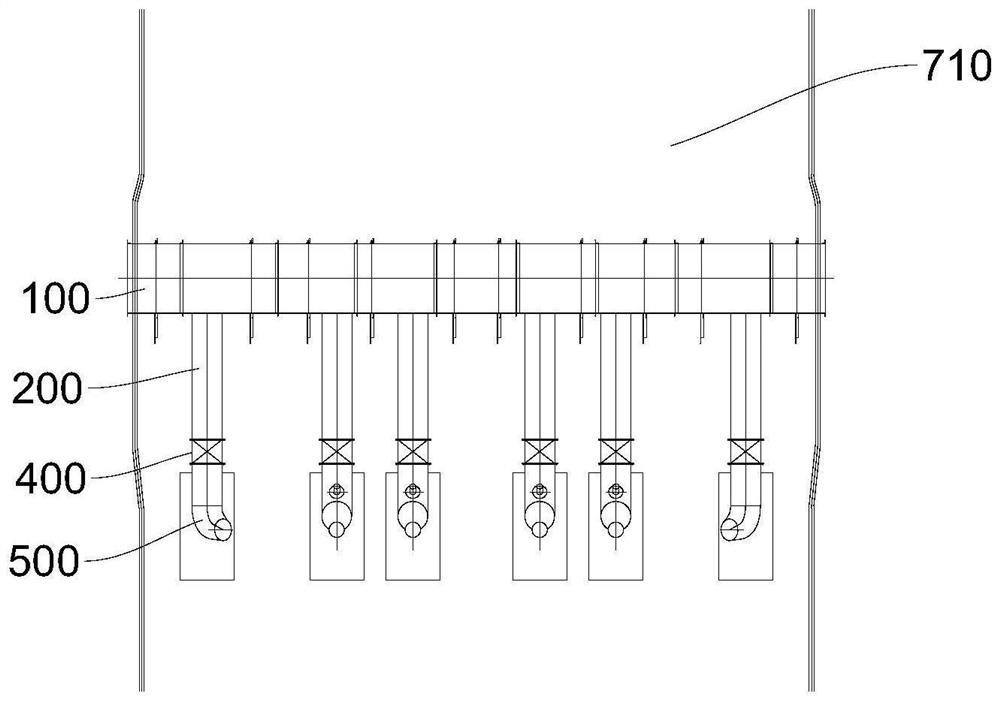

Circulating fluidized bed boiler

PendingCN113639263AHigh thermal efficiencyIncrease profitFluidized bed combustionNon-combustible gases/liquids supplyFluidized bedFly ash

The embodiment of the invention provides a circulating fluidized bed boiler, and relates to the field of combustion parts of circulating fluidized bed boilers. The combustion efficiency of the boiler is improved. The circulating fluidized bed boiler comprises a boiler body and a secondary air nozzle; the secondary air nozzle is a conical pipe, the secondary air nozzle is provided with a large end and a small end which are opposite in position, the secondary air nozzle is arranged on the boiler body, and the small end of the secondary air nozzle extends into the boiler body; the secondary air nozzle comprises a first nozzle arranged at the corner of the boiler body; the center line of the first nozzle and the center line of a hearth of the boiler body form an included angle; the secondary air nozzle adopts a conical structure, so that the kinetic energy of secondary air can be increased; the first nozzle is obliquely arranged towards the center line of the hearth, abrasion of secondary air to a side wall water cooling wall tube can be prevented, meanwhile, the influence of the secondary air to wall-attached downflow can be reduced to the maximum extent, the material mixing effect is guaranteed, the boiler heat efficiency is improved, and therefore the carbon content of fly ash is reduced, the heat loss of the boiler is reduced, and the use cost is reduced.

Owner:蒋俊芳

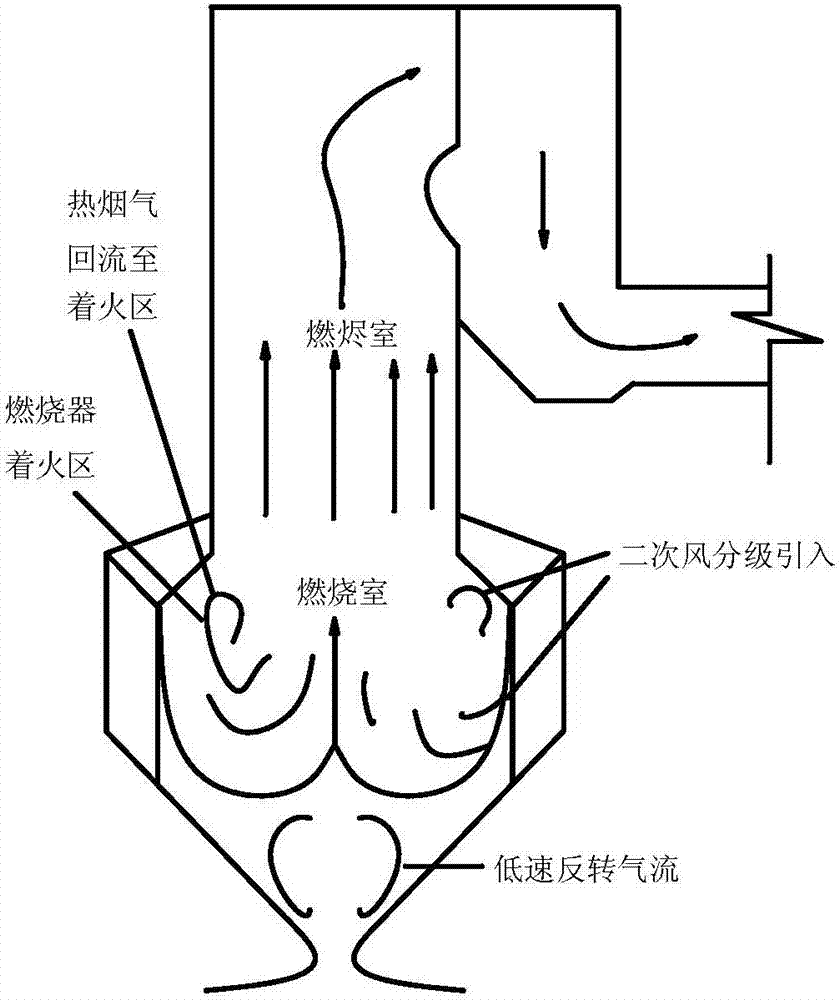

Low NOx coal dust combustion method and device based on underfire air and overfire air

InactiveCN102003701BEmission reductionReduce carbon content in fly ashCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBottom ashNitrogen oxides

The invention relates to a combustion improvement technology of an industrial fire coal boiler, aiming to provide a low NOx coal dust combustion method and device based on underfire air and overfire air. The method comprises: injecting parts of two-strand air required for combustion into a hearth from a boiler bottom ash hopper; strongly mixing with aslant downward injected fuel jet flow; fully utilizing the space of the bottom ash hopper to prolong smoke dwell time; burning fuel in a low-temperature oxidation zone; preventing volatile components from converting to nitric oxide; upwards and aslant injecting upper-layer fuel to form a reducing zone, so as to reduce generated nitric oxide into N2; and lowering nitric oxide emission amount. The invention also provides a boiler device for realizing the method. Under the condition that the original combustion condition is not influenced essentially, the invention effectively lowers the emission of nitric oxide and is easy to reform the existing boiler.

Owner:ZHEJIANG UNIV

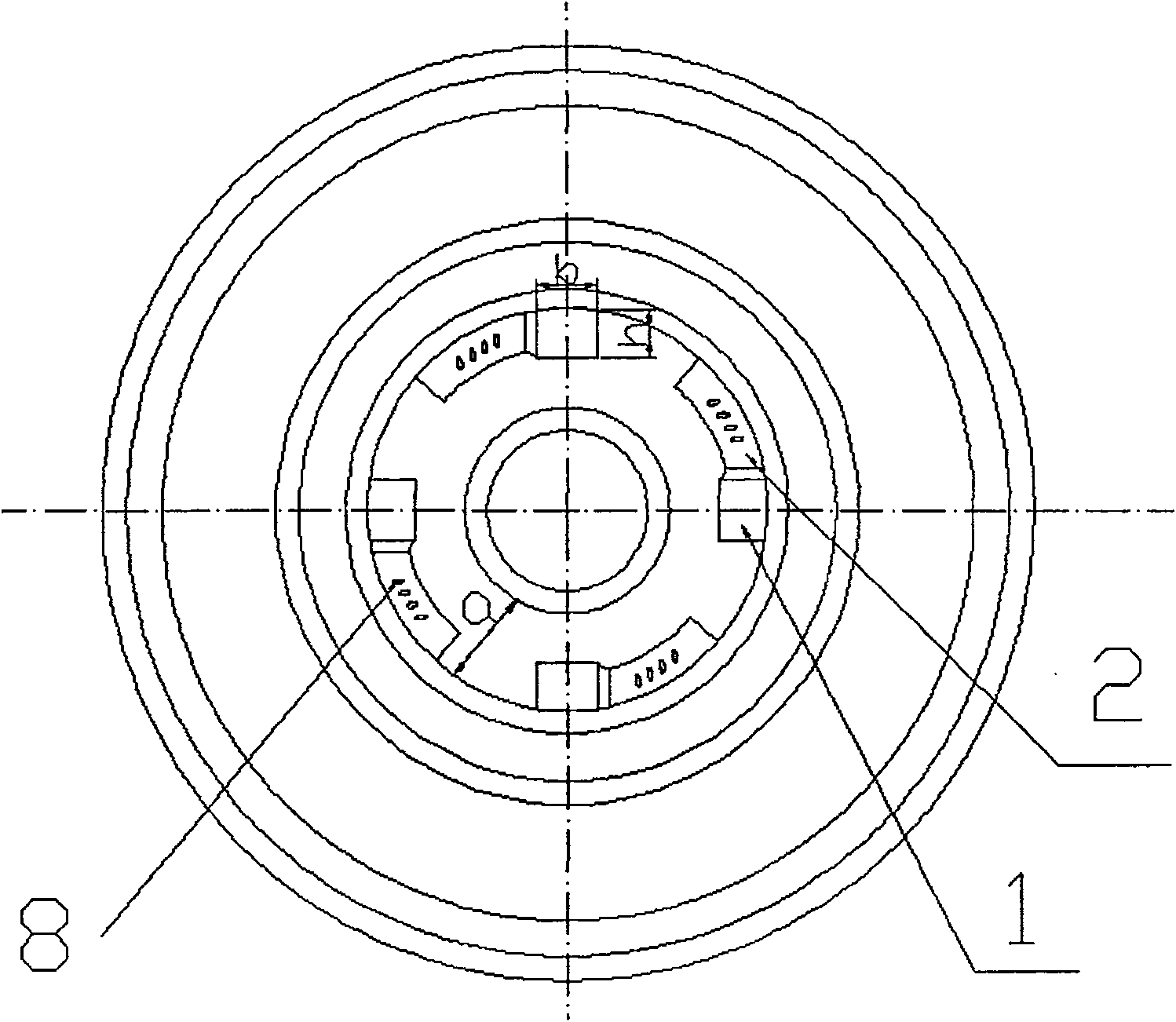

Vortex combustor of coal fines circumferential direction concentration sectional stopping whorl

InactiveCN101280921BGood effectEasy to controlPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustorFlue gas

The present invention provides a vortex combustor of coal powder circumferential compression space-sharing standing vortex, comprising a center air duct, a primary air duct, an internal secondary air duct and external secondary air duct arranged on periphery of a the center air duct from inside to outside in turn, a circumferential compression stream apparatus arranged inside secondary air duct, and a wedge-shaped circulation reflux standing vortex steady combustion body arranged at tail of the circumferential compression apparatus. After the primary air flows through the circumferential compression stream apparatus and the circumferential compression stream apparatus, the opening of the combustor forms an evident coal powder circumferential shade section and a strong standing vortex steady on-combustion section, and combustion condition of high temperature whirling current flue gas and poor-oxygen rich-fuel. Great on-combustion stabilization is provided. The invention is especially suitable for combustion of meagre coal, kilkenny coal and coarse coal, and for improving combustion flame stabilization of various coal.

Owner:XI AN JIAOTONG UNIV

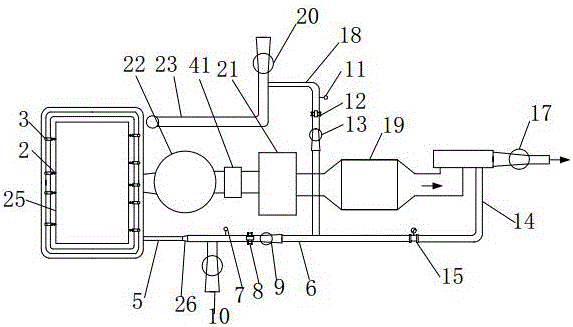

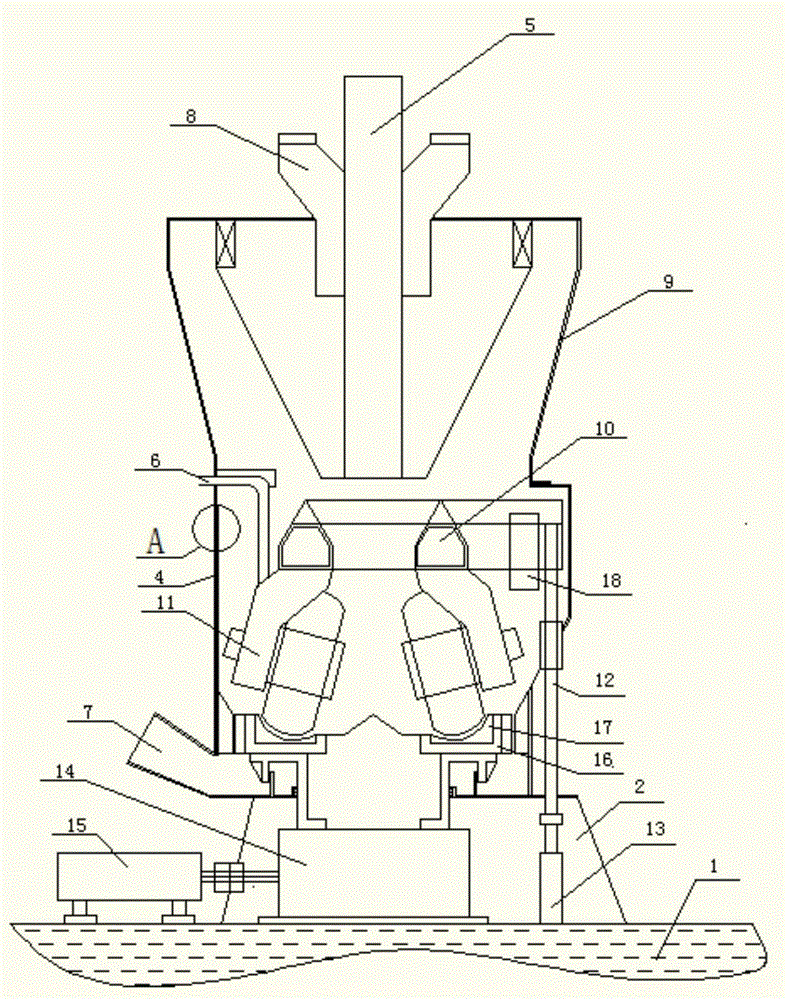

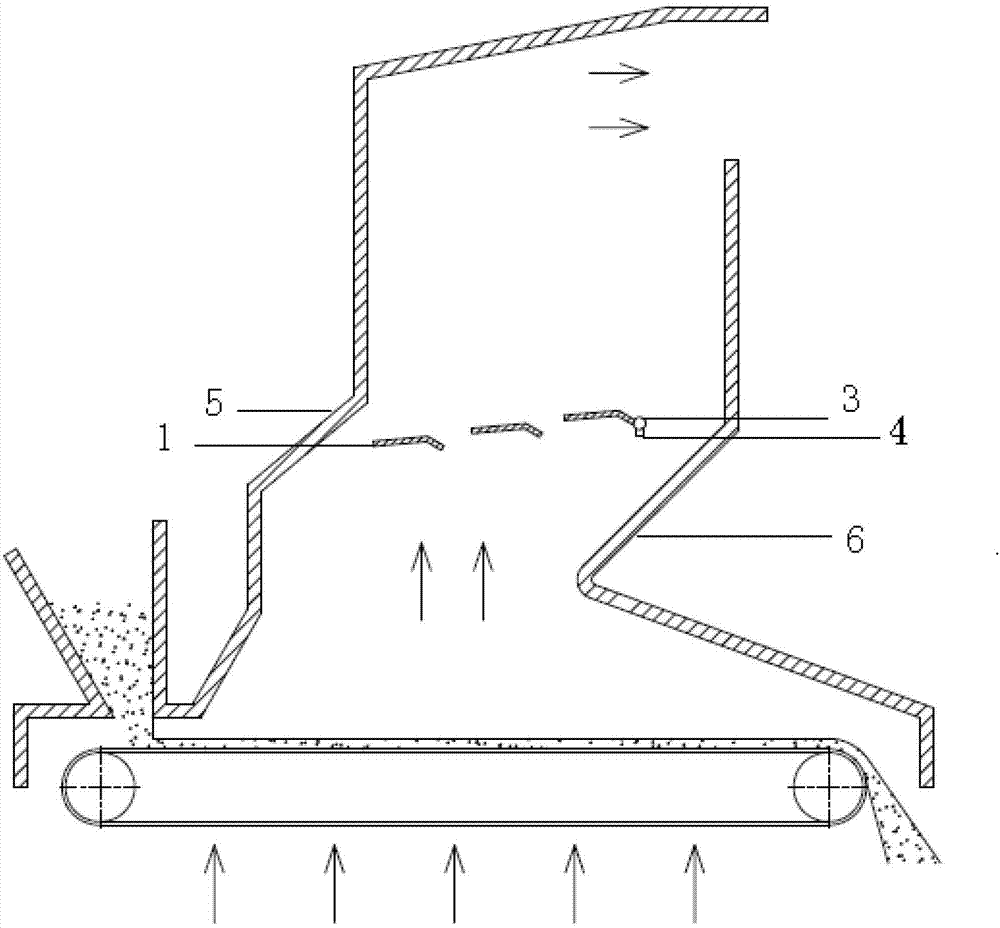

A combined denitrification device and method for a layer-fired boiler

ActiveCN105020700BEmission reductionAchieve staged combustionDispersed particle separationSolid fuel combustionAir preheaterCyclone

The invention belongs to the field of coal layer combustion boiler pollutant discharge control and discloses a layer combustion boiler combination denitration device and method. The invention aims to enable NOx discharged by layer combustion boilers to reach the standard. A vaporizing chamber is arranged below the front arch in a hearth, and the partition of the hearth is provided with a gas outlet. A vaporization air chamber, a first air chamber, a second air chamber, a third air chamber, a fourth air chamber and a fifth air chamber are sequentially formed below a fire grate from front to back. A secondary air port is formed in the part, above the front arch, of the front wall of the hearth. The outlet of the hearth is communicated with the inlet of a horizontal type cyclone separator with an acceleration section, and the bottom of the horizontal type cyclone separator with the acceleration section is communicated with a main combustion zone of the lower part of the hearth through a return valve. The horizontal type cyclone separator with the acceleration section is sequentially communicated with a convection calandria, an economizer and an air pre-heating device, the air pre-heating device is communicated with a dust remover, the dust remover is communicated with a recycling fan and a draught fan, and the recycling fan is communicated with a smoke channel. An air supply fan is communicated with the vaporization air chamber, the first air chamber, the second air chamber, the third air chamber, the fourth air chamber, the fifth air chamber and the secondary air port. The layer combustion boiler combination denitration device and method are used for layer combustion boiler combination denitration.

Owner:HARBIN INST OF TECH

Coal-fired boiler staged combustion air depth air staged combustion low NOx control method

ActiveCN111306533BReduce emission concentrationPrevent slaggingAir supply regulationCombustion apparatusEmberAir volume

Owner:SHANGHAI JIAOTONG UNIV +1

An Ende pulverized coal gasifier with a steam booster

ActiveCN103965968BNo flow phenomenonIncrease cycle ratioGranular/pulverulent flues gasificationChemical synthesisFuel oil

The invention relates to an Undok pulverized coal gasification furnace, and particularly relates to an Undok pulverized coal gasification furnace with a steam pressurizing device for solving the problems that in the running process of an existing Undok pulverized coal gasification furnace, carbon content in combustible materials in fly ash is 20%-80%, resulting in high specific coal consumption and low carbon conversion rate of the coal gasification furnace. A cyclone separator is communicated with the gasification furnace through an inlet of the cyclone separator, two ends of a discharging channel are respectively communicated with the cyclone separator and the gasification furnace, a steam pipeline is arranged on the discharging channel, a steam nozzle is arranged in the discharging channel and installed on the steam pipeline, a spout of the steam nozzle faces an outlet of the discharging channel, a steam flow regulating valve is installed on the steam pipeline, and a descending channel pressure measuring point is arranged between the steam nozzle and the outlet of the discharging channel and installed on the discharging channel. The Undok pulverized coal gasification furnace provided by the invention is used for producing feed gas through chemical synthesis and fuel oil synthesis, industrial fuel gas, domestic gas, metallurgical reducing gas, fuel gas for combined cycle power generation, and the like.

Owner:HARBIN INST OF TECH

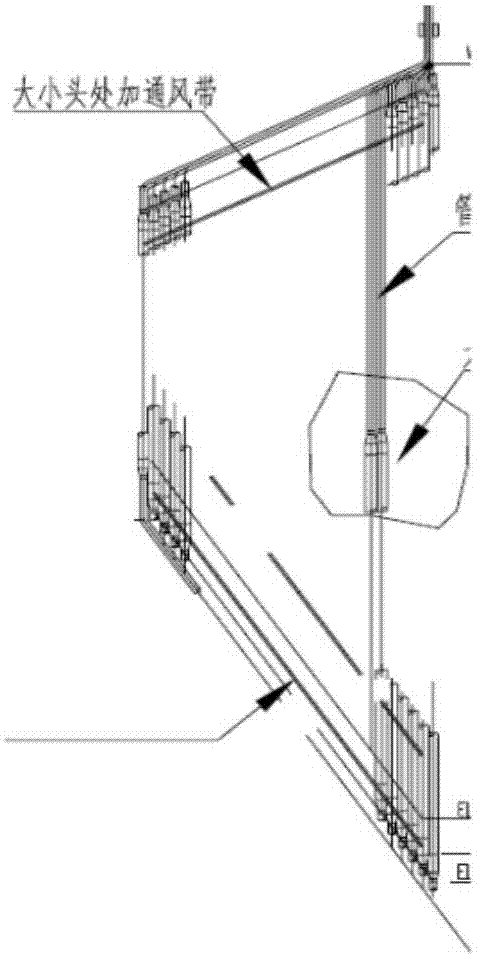

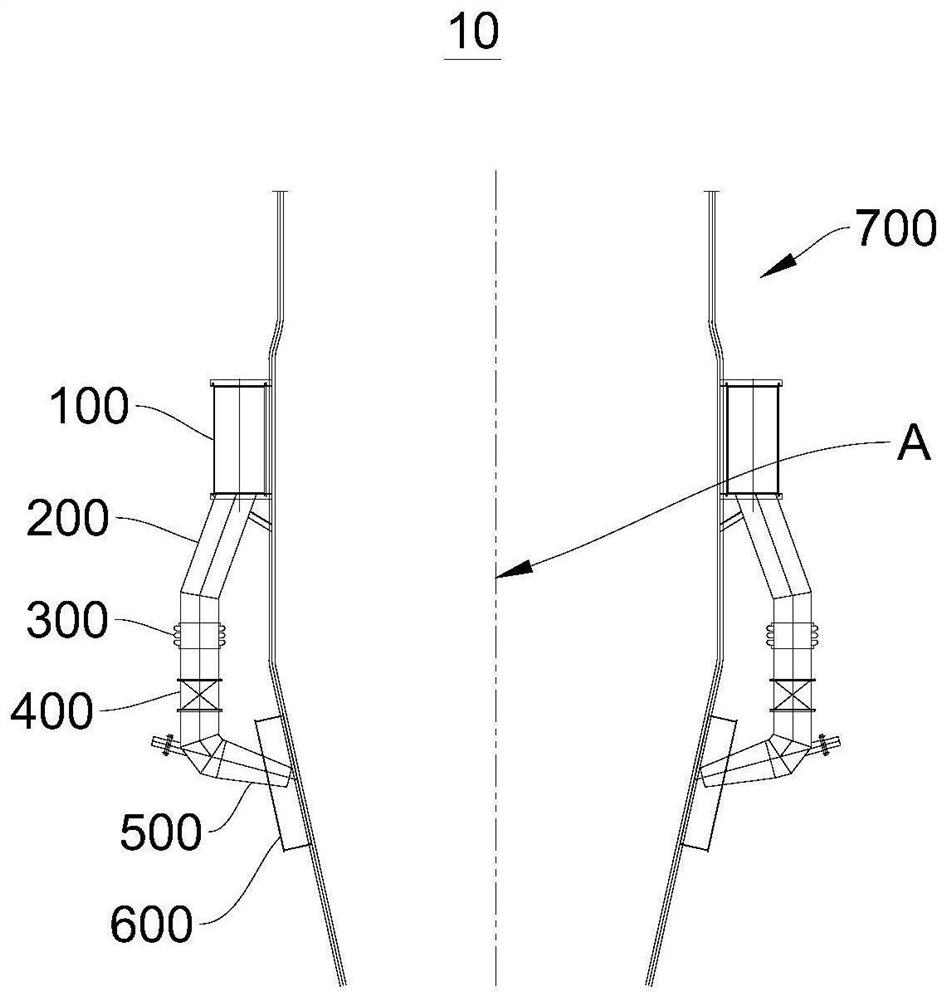

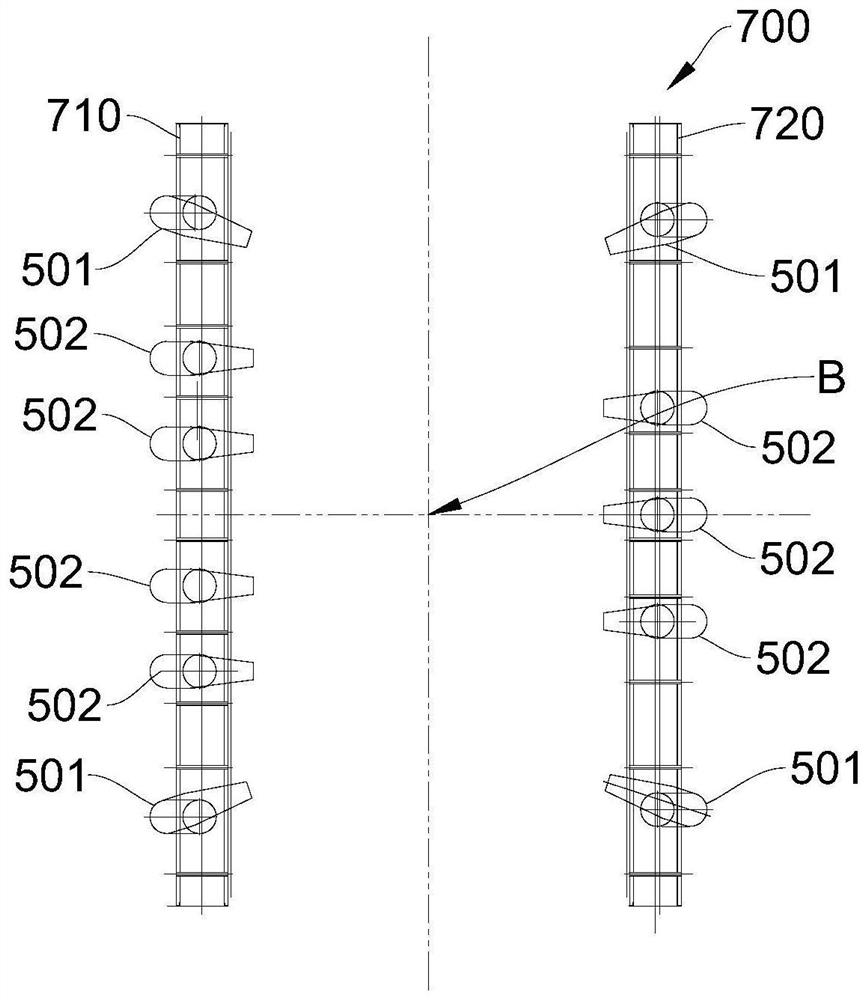

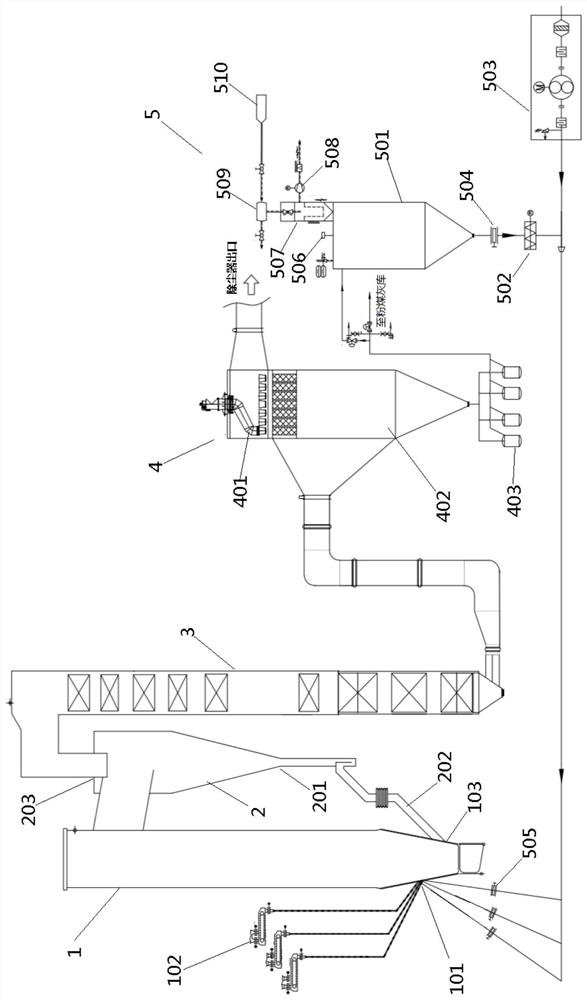

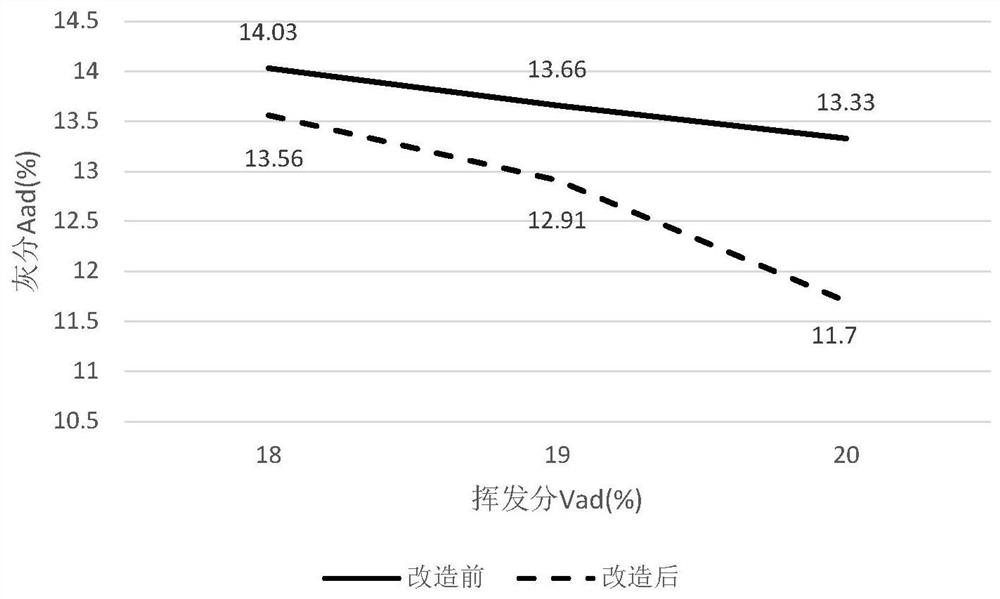

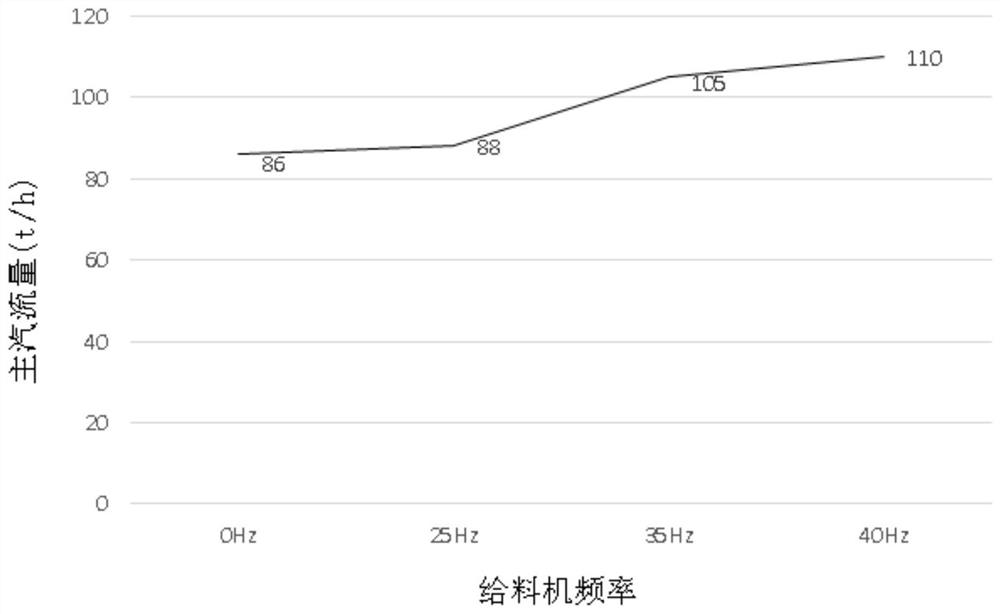

Fly ash circulating device and circulating fluidized bed boiler comprising same

PendingCN111878801AReduce carbon content in fly ashGood economic and environmental benefitsFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringCirculating fluidized bed boiler

The invention provides a fly ash circulating device and a circulating fluidized bed boiler comprising the same. The fly ash circulating device comprises a middle ash bin, a feeding machine and a pneumatic conveying device; the middle ash bin is used for containing fly ash to be circulated, an inlet of the middle ash bin is connected with a dust remover, and an outlet of the middle ash bin is connected with a coal feeding port of a hearth through a fly ash circulating pipeline; the feeding machine is arranged on the fly ash circulating pipeline and is used for supplying fly ash to the hearth from the middle ash bin; and the pneumatic conveying device is arranged on the fly ash circulating pipeline and used for conveying fly ash provided by the feeding machine into the hearth. By means of the device, the carbon content of the fly ash can be reduced, and the economic benefit and the environmental protection benefit are improved.

Owner:北京永博洁净科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com