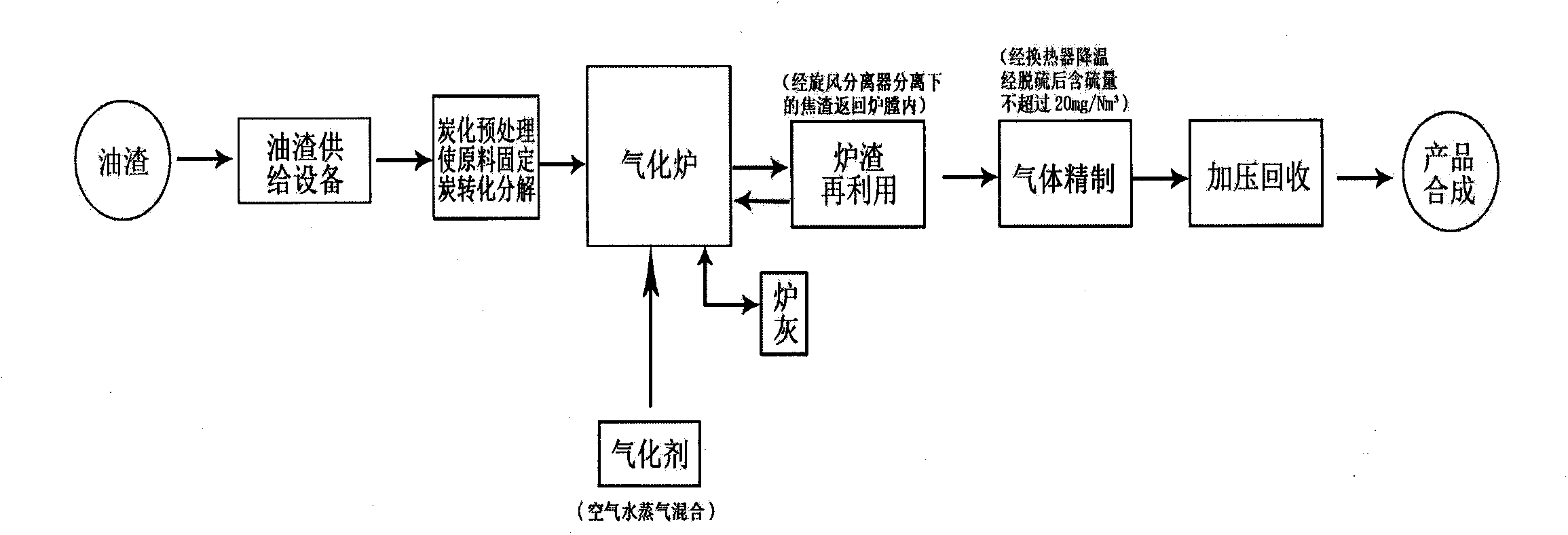

Secondary gasification treatment method for oil residue caused in gas production

A technology of secondary gasification and treatment method, which is applied in the petroleum industry, manufacture of combustible gas, energy input, etc. It can solve the problems of low carbon conversion rate, small gas production, high cost, etc., and achieve high gasification efficiency and high gasification efficiency. The effect of high and effective utilization rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

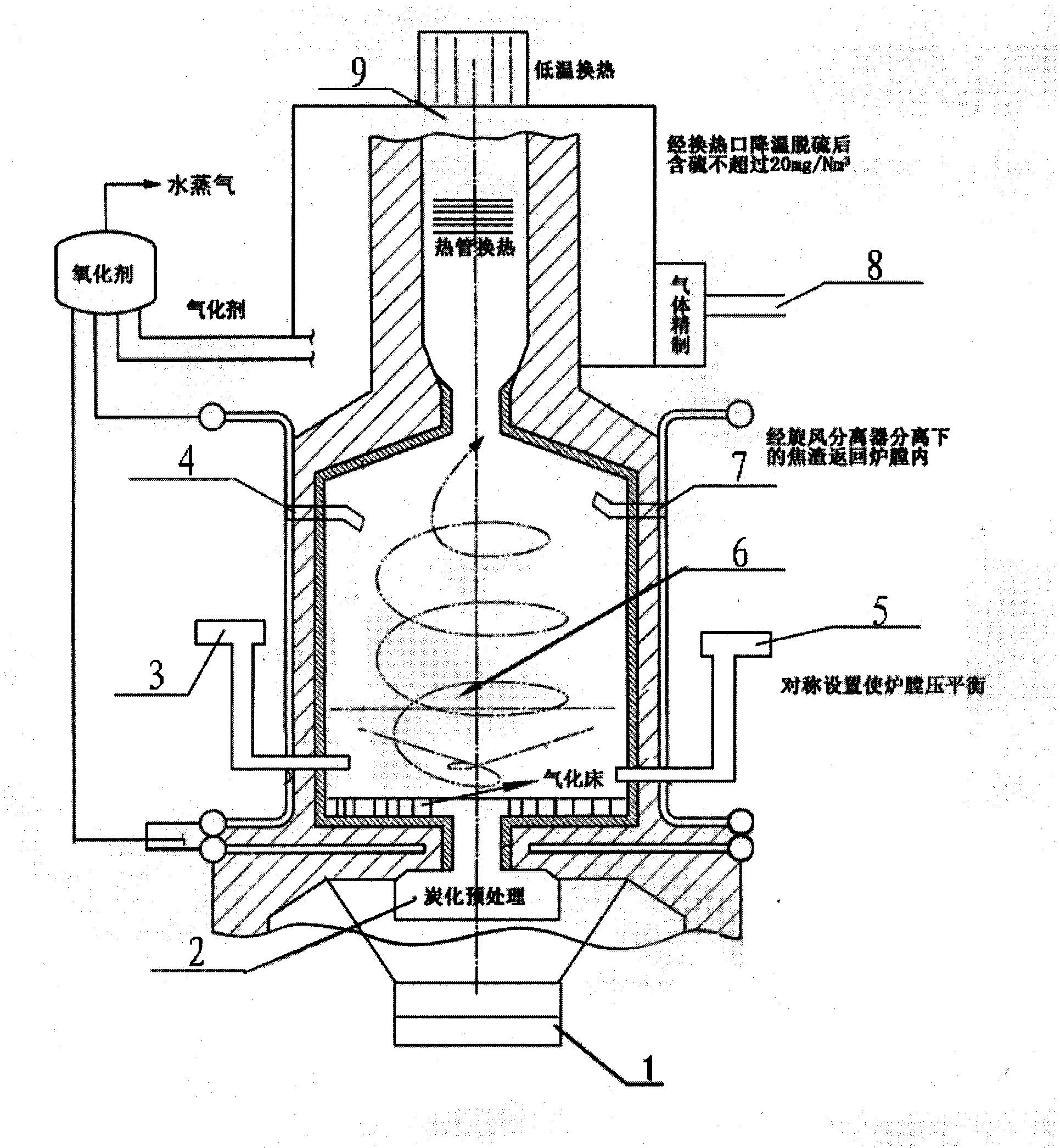

[0022] A raw coal gasification oil residue treatment method, as follows: the oil residue raw material with a diameter of less than 10 mm is transported from the feed port 1 to the oxygen-free carbonization furnace 2 coal hopper, and the oil residue raw material is further gasified into CO and CH 4 and H 2 The mixed gas is then sent to the cone section at the bottom of the gasifier to react with the gasification agent. The gasification agent is air, water vapor mixture or oxygen-enriched air water vapor mixture. The gasification agent is supplied from the primary tuyere 3 and the secondary The tuyere 5 enters the hearth 6 of the gasifier. Before the gasification agent enters the hearth 6, it exchanges heat with the coal gas discharged from the furnace in a high-temperature heat exchanger. The temperature of the gasification agent rises to 750°C. The pressure at the top of the gas furnace is 15Kpa and the temperature is 980°C. , the coal gas flows out from the top of the gasifie...

Embodiment 2

[0024] Parameters of oil residue gasification system

[0025] Gas output 8500-11000Nm 3 / nY;

[0026] Oil residue gas production 1500Nm 3 / nY;

[0027] Calorific value of gas 1300-1600cal / Nm 3 ;

[0028] Calorific value of oil residue gas 800-1100cal / Nm 3 ;

[0029] Steam output 1.5-2 tons, pressure 0.5MPA;

[0030] Coal consumption 2.5-3 tons;

[0031] Oil residue consumption is 3 tons.

[0032] Table 1 is the gasification system parameter list

[0033] General fuel

tar residue

Furnace granularity

<10mm

Vaporization rate

1.5-2.0Nm 3 / Kg

SO 2 emissions

3

steam volume

0.7-1 ton

Dust emissions

3

[0034] Table 2 is the volume percentage comparison table of various gases of gas and oil residue (percentage)

[0035] Element

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com