Patents

Literature

87results about How to "Improve fluidization quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for full methanation of carbon dioxide and preparation method thereof

ActiveCN101884927AImprove fluidization qualityHigh strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationThermal stability

The invention discloses a catalyst for full methanation of carbon dioxide, which belongs to the technical field of methanation of carbon dioxide. In the catalyst, spherical gamma-Al2O3 is used as a carrier, Ni and Fe are used as active ingredients, and MgO, La2O3 or CeO2 is used as an auxiliary agent. The catalyst is prepared by adopting an ordered soaking method through drying, roasting and reduction. The catalyst comprises the following components in percentage by mass: 60 to 80 percent of gamma-Al2O3, 10 to 20 percent of NiO, 5 to 15 percent of Fe2O3, 1 to 10 percent of MgO, and 1 to 10 percent of La2O3 or CeO2. Under the reaction conditions that the pressure is between 3.0 and 5.0MPa, the volume airspeed of the raw material gas is 5,000 to 10,000 per hour and the ratio of H2 to CO2 is 4.1, both the CO2 conversion rate and the CH4 selectivity can be close to 100 percent. The catalyst has the characteristics of high strength, good thermal stability, carbon deposition resistance, easy fluidization and the like.

Owner:TSINGHUA UNIV

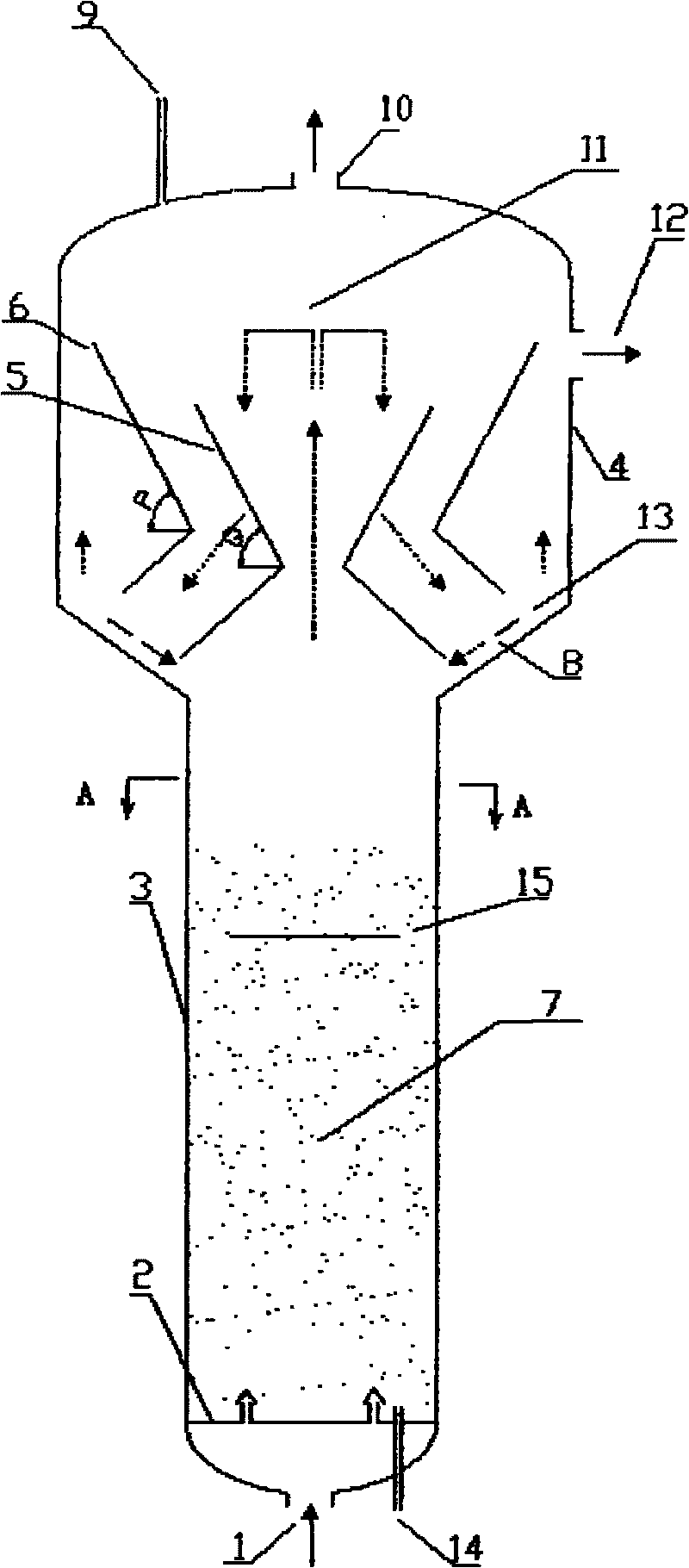

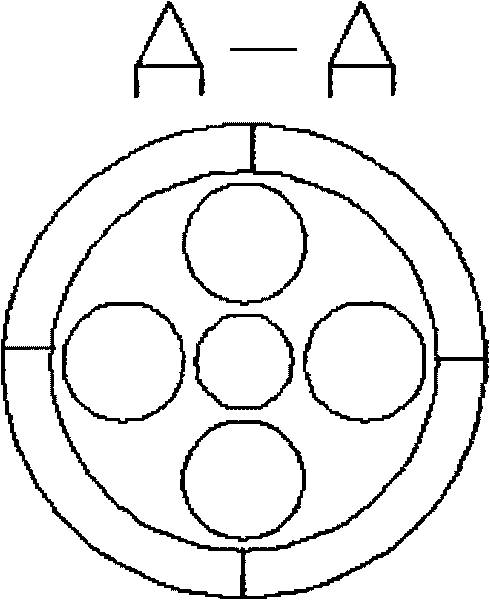

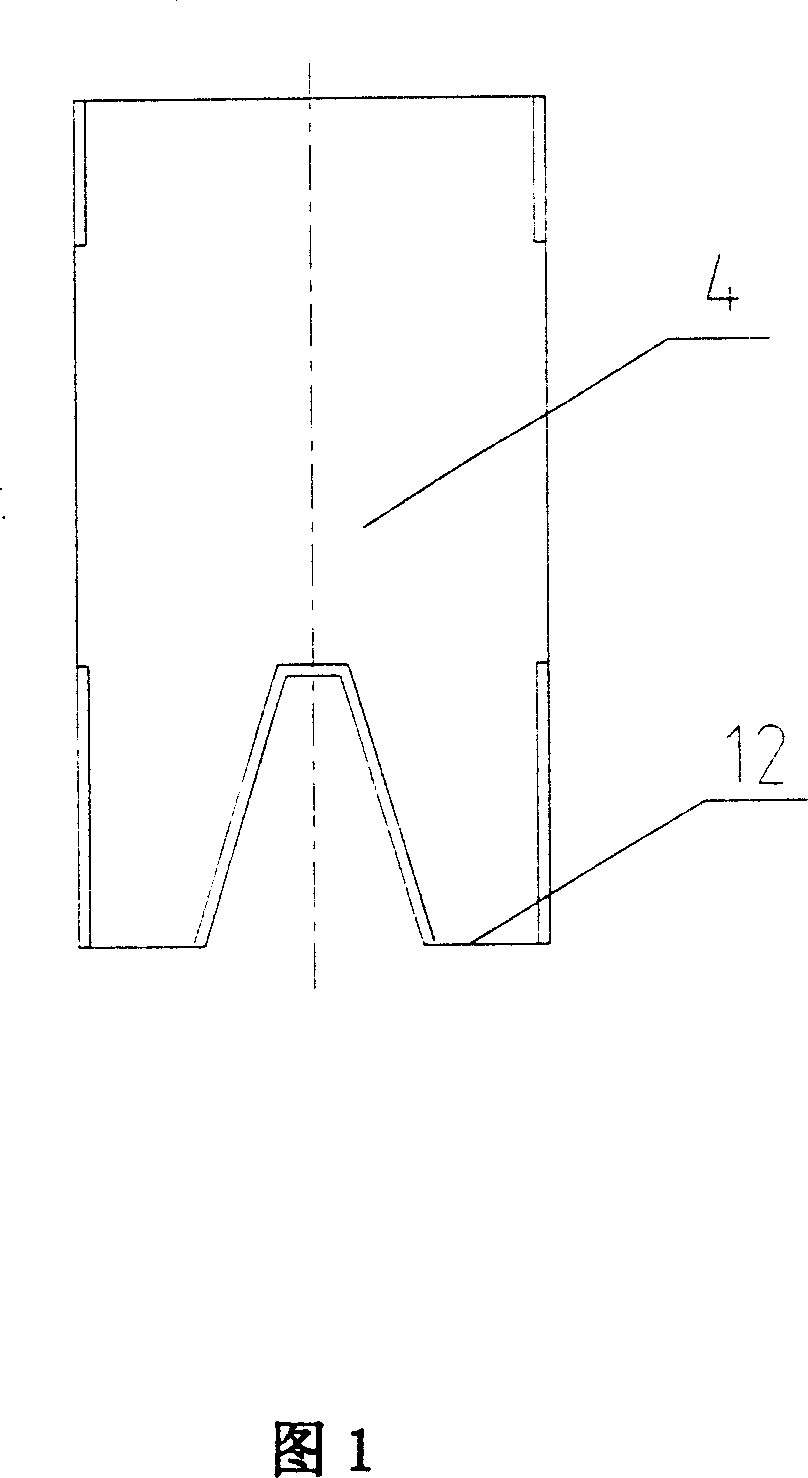

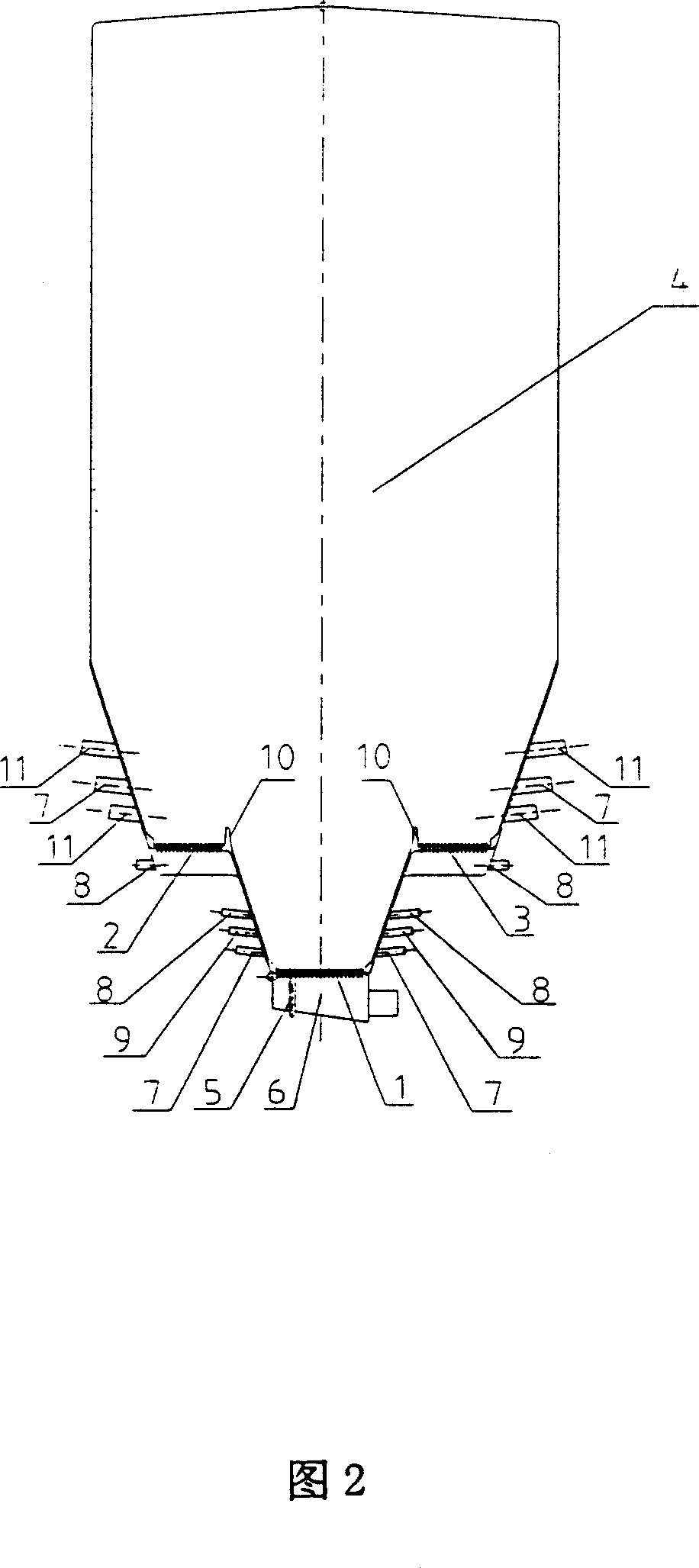

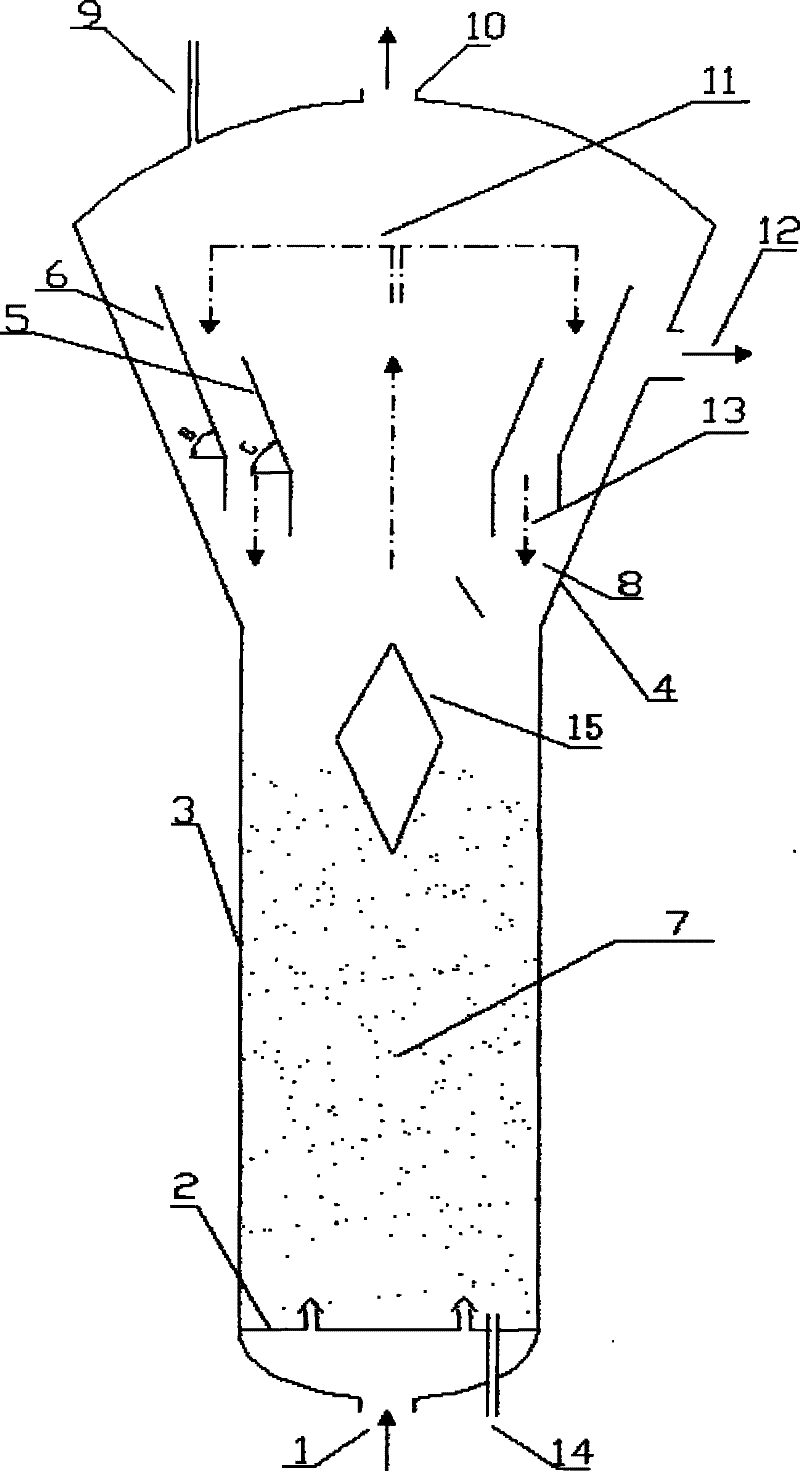

Fluidized bed reactor

ActiveCN101721960AGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

The invention discloses a fluidized bed reactor which comprises a reactor shell and a three-phase separator, the three-phase separator is arranged at the upper part inside the reactor shell and is of a sleeve structure comprising an inner sleeve and an outer sleeve, the upper ends and lower ends of the inner sleeve and the outer sleeve are both of opening structures, the inner sleeve and the outer sleeve are respectively composed of an upper section and a lower section, the upper sections of the inner sleeve and the outer sleeve are in reverse frustum structures, and the lower sections of the inner sleeve and the outer sleeve are in frustum structures. By designing a novel three-phase separating structure, the invention can further improve separating effect, reduce catalyst carrying-out amount, and enhance the operation elasticity of the three-phase separator. The reactor is mainly applicable to chemical reactions between liquid and gas substances of different types and solid particles under contact condition, and has the advantages of large catalyst inventory, high reactor use ratio, simple structure, easy operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

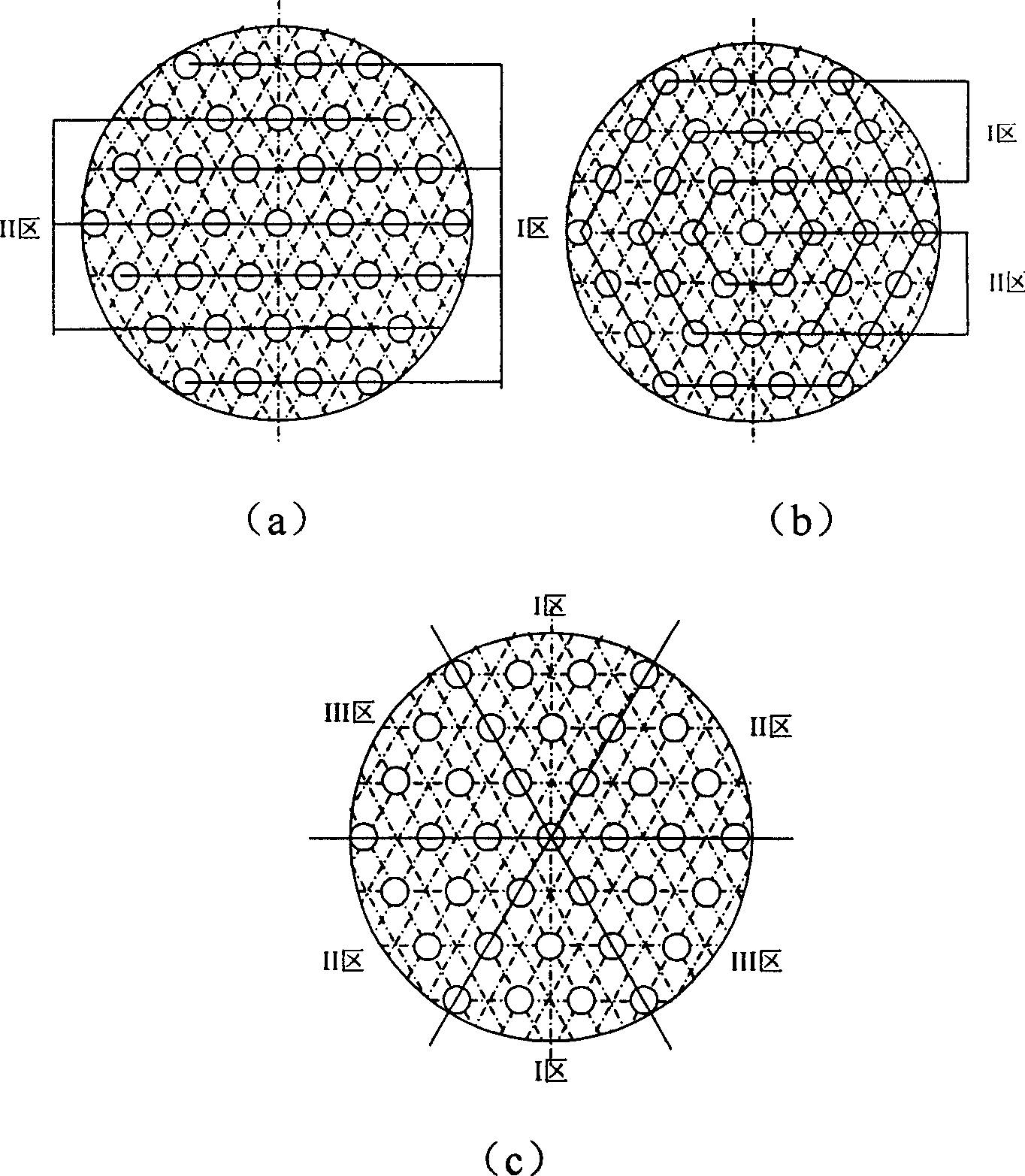

Arranging method of layered fluidization air distribution plate of fluidized bed boiler

ActiveCN1948831AImprove mixing conditionsRealize large-scaleFluidized bed combustionApparatus for fluidised bed combustionAir volumeCombustion

The invention adopts a multi-layer arrangement method of a fluidized-bed boiler bottom air-feeding plates and the integral hearth bottom consists of three independent air-feeding plates. One air-feeding plate is disposed in the lowerest part of the hearth and on the above air-feeding plate are overlaid the other air-feeding plates, so as to realize the step charging, the step air-supply and the fractional combustion of the recirculating fluidized-bed boiler. By regulating the blast volume and the fuel flow of each air-feeding plate, the uniform combustion and air-supply of the boiler can be realizer.

Owner:SHANGHAI BOILER WORKS

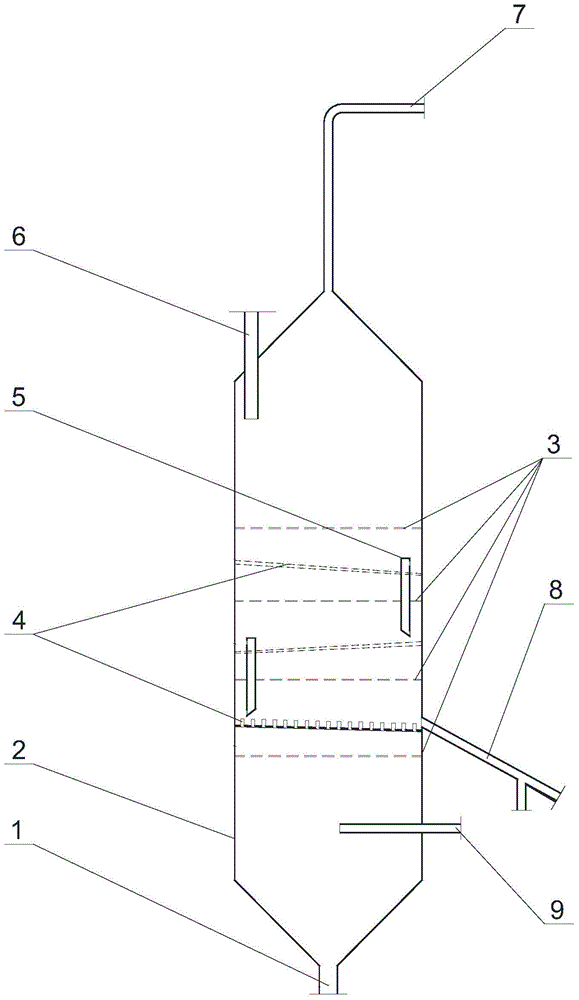

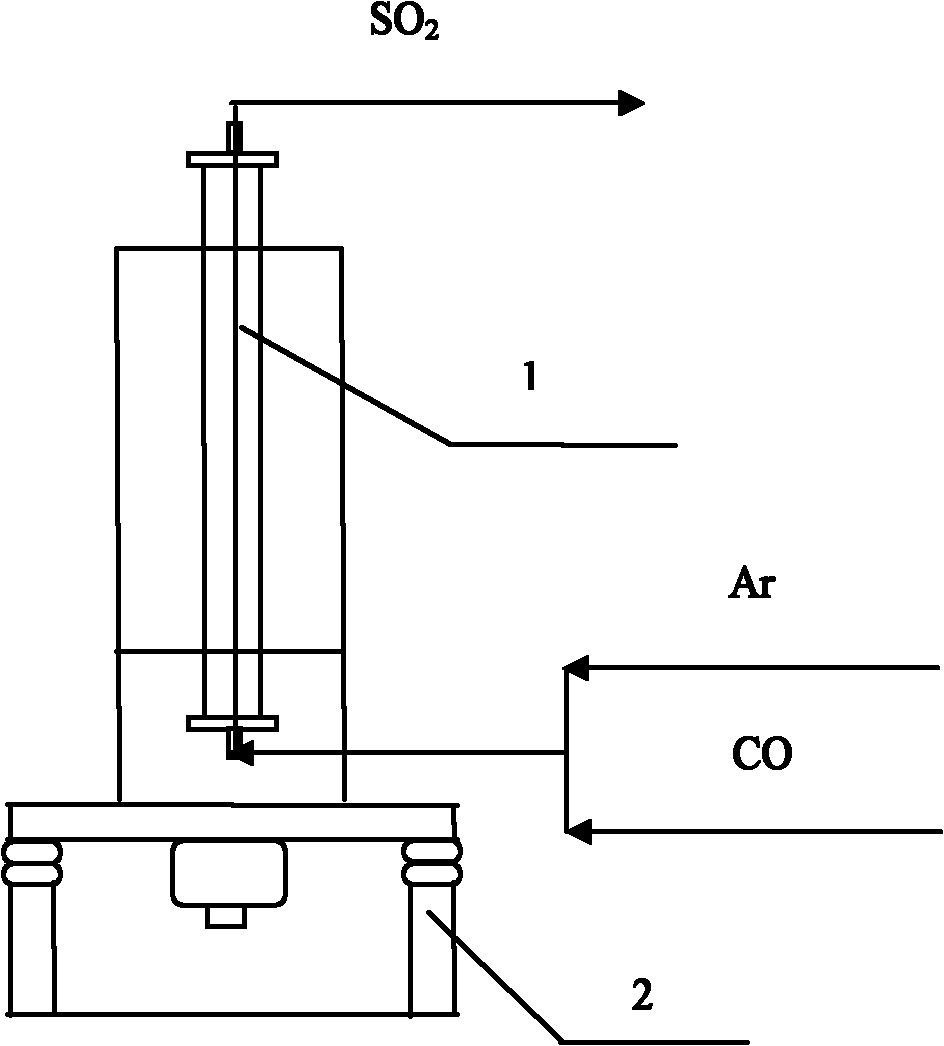

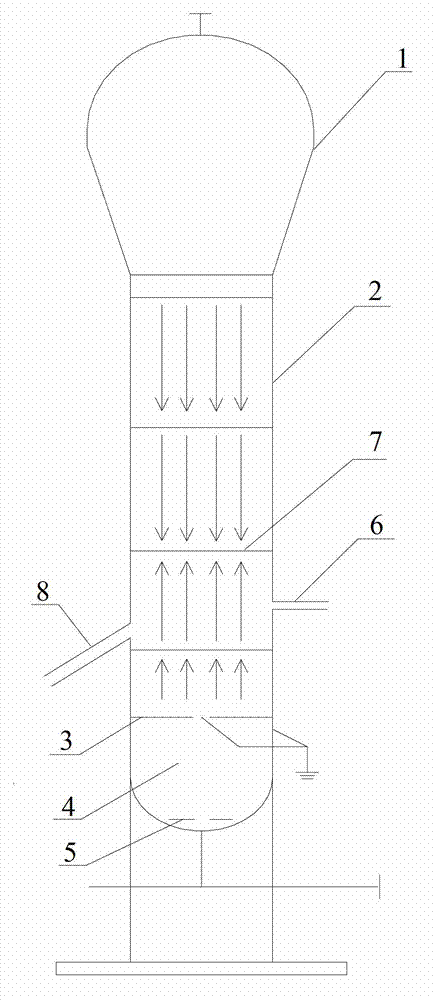

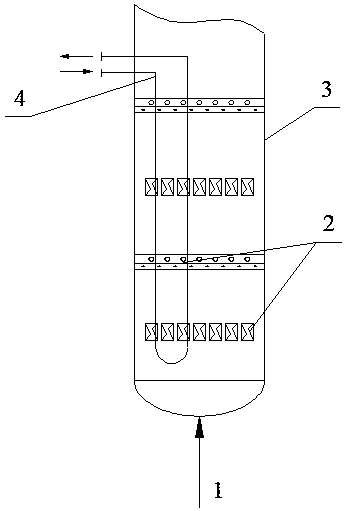

Vibratory fluidized bed reactor for continuous production of rare earth fluorides and production method

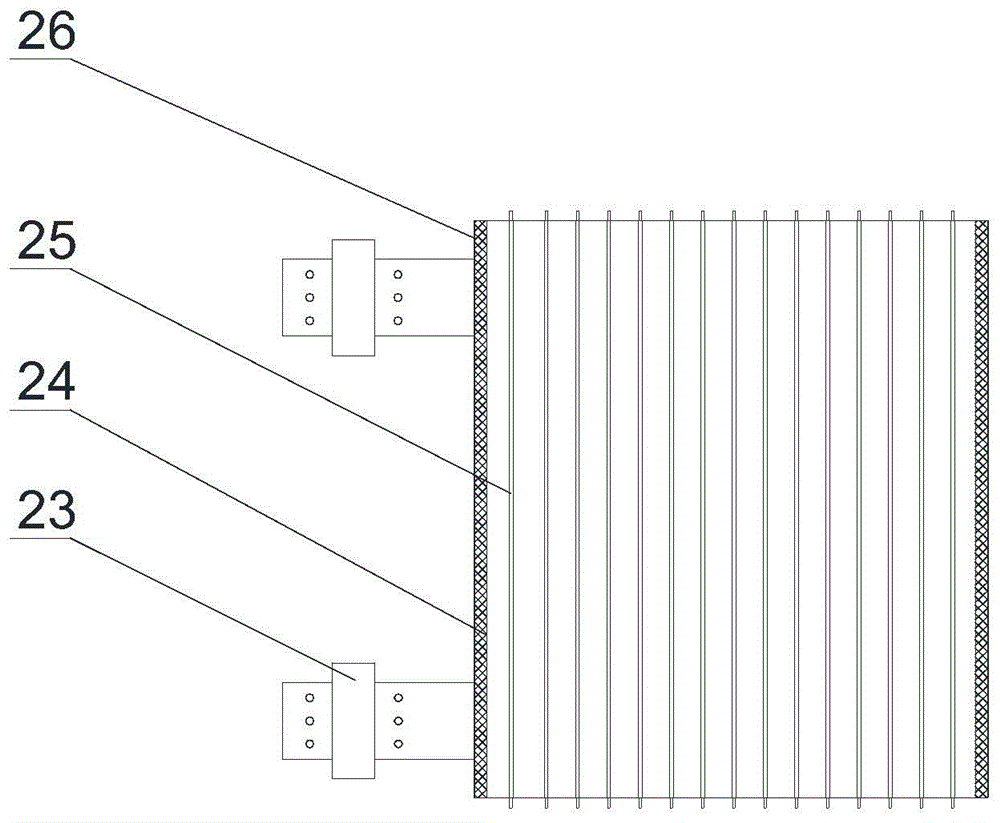

InactiveCN104084095AImprove fluidization qualityOptimizing the gas-solid fluidization reaction processRare earth metal compoundsChemical/physical processesHydrogen fluorideFluoride products

The invention discloses a vibratory fluidized bed reactor for continuous production of rare earth fluorides. The vibratory fluidized bed reactor comprises a feeding device, a discharging device, a fluidized bed, a vibrator and a heating device, wherein a rare-earth-containing material feeding hole is formed in the upper part of a fluidized bed body; a rare earth fluoride product discharge opening communicated with the discharging device is formed in the lower part of the fluidized bed body; a hydrogen-fluoride-containing gas inlet is formed in the bottom of the fluidized bed body; gas distribution plates through which hydrogen-fluoride-containing gas passes and uniform air distribution is realized are arranged in the cavity of the fluidized bed body; an exhaust pipe is arranged on the top of the fluidized bed body; the heating device is arranged on the outer side of the fluidized bed body and covers the fluidized bed body; the vibrator is arranged on the outer wall of the fluidized bed body; the bottom of the fluidized bed body is connected to supports through elastic supporting pieces. According to the scheme in the invention, the fluidization quality can be improved, the mass transfer and heat transfer effects are improved, the production efficiency is high, and the product is uniform and stable in quality, high in fluorination rate and low in process cost.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

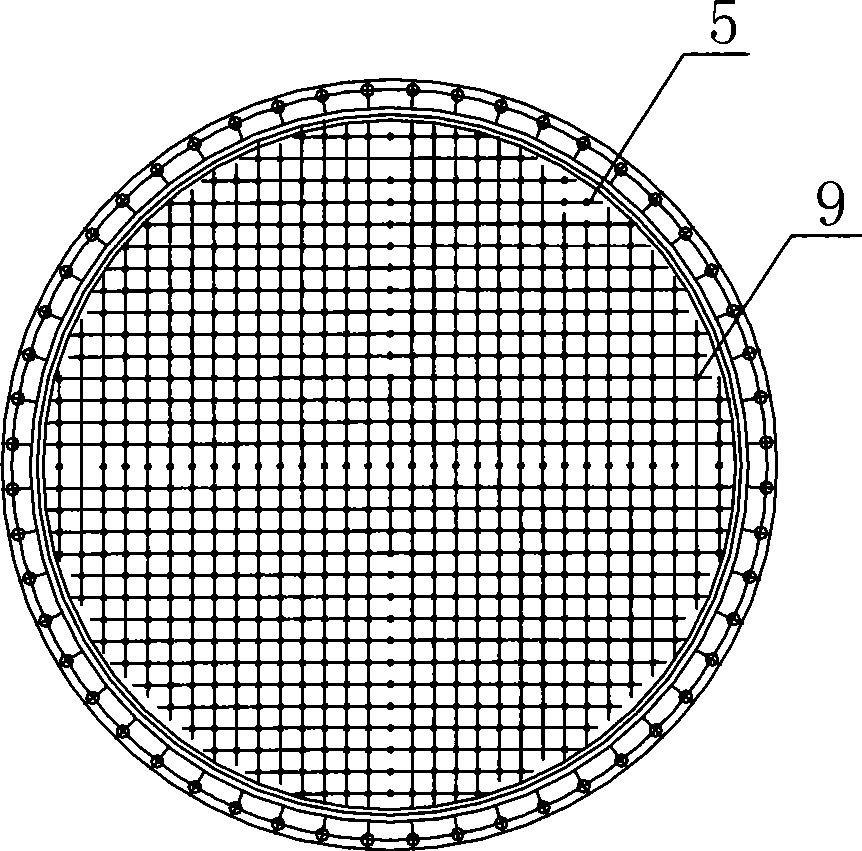

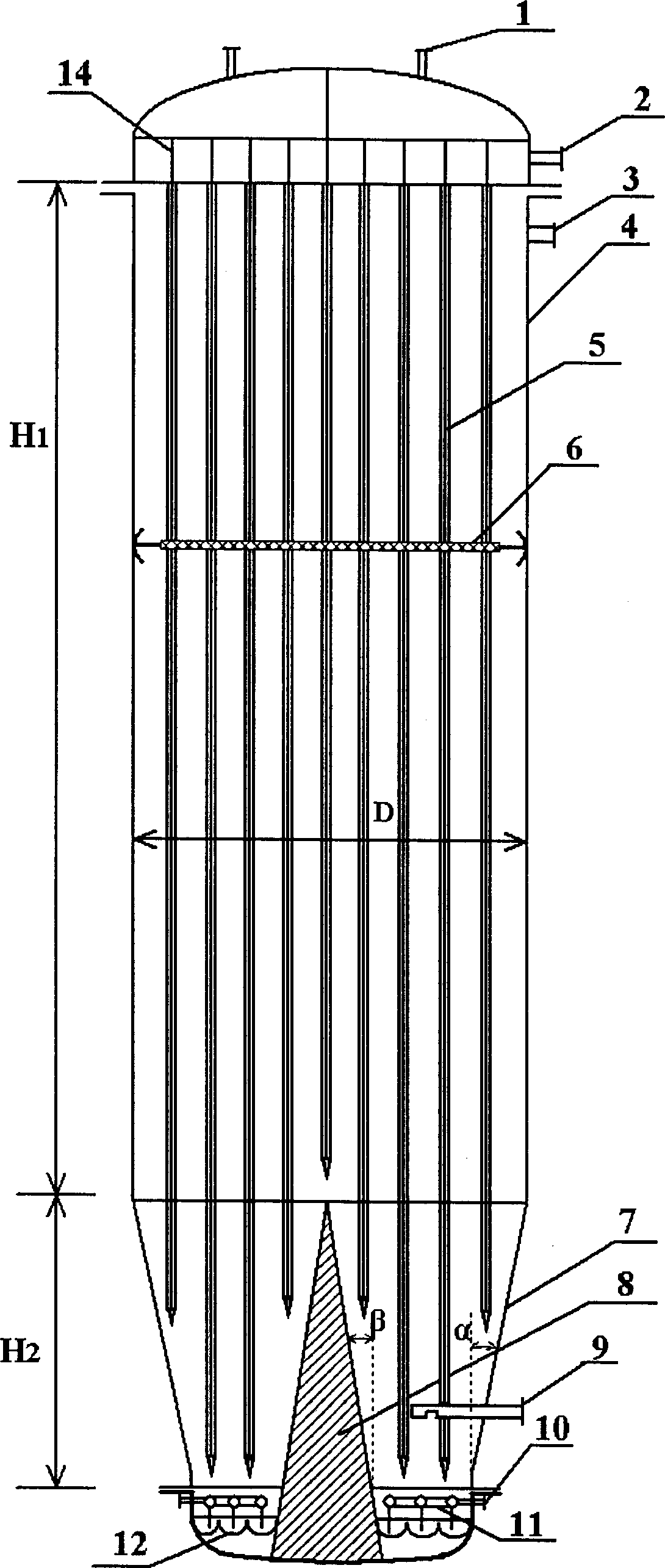

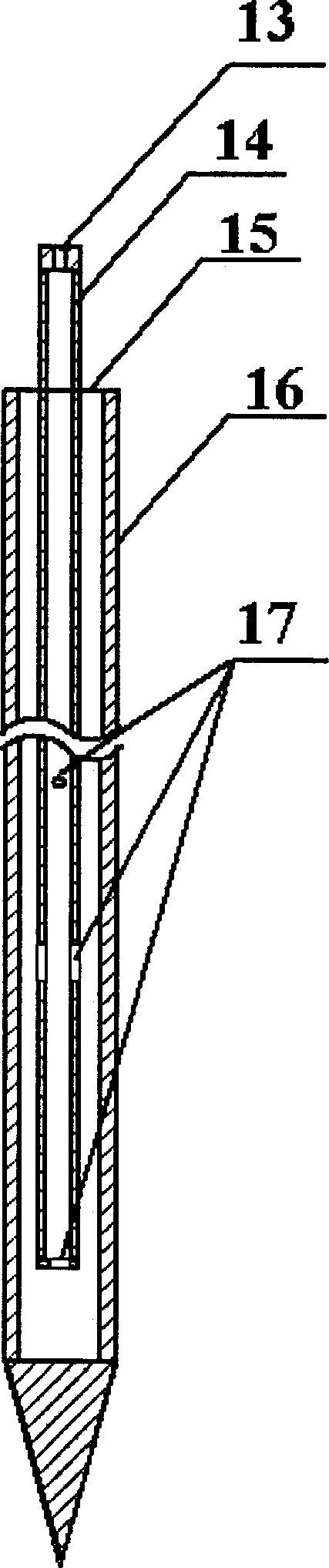

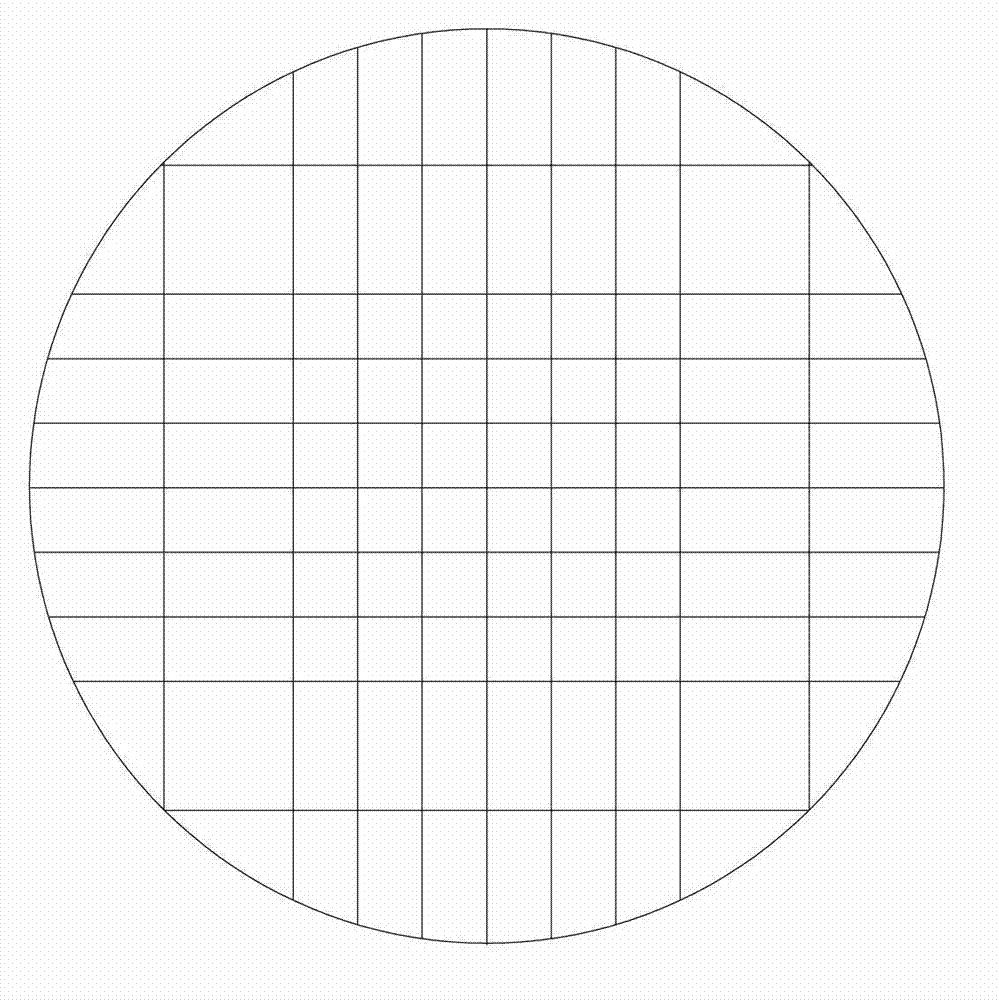

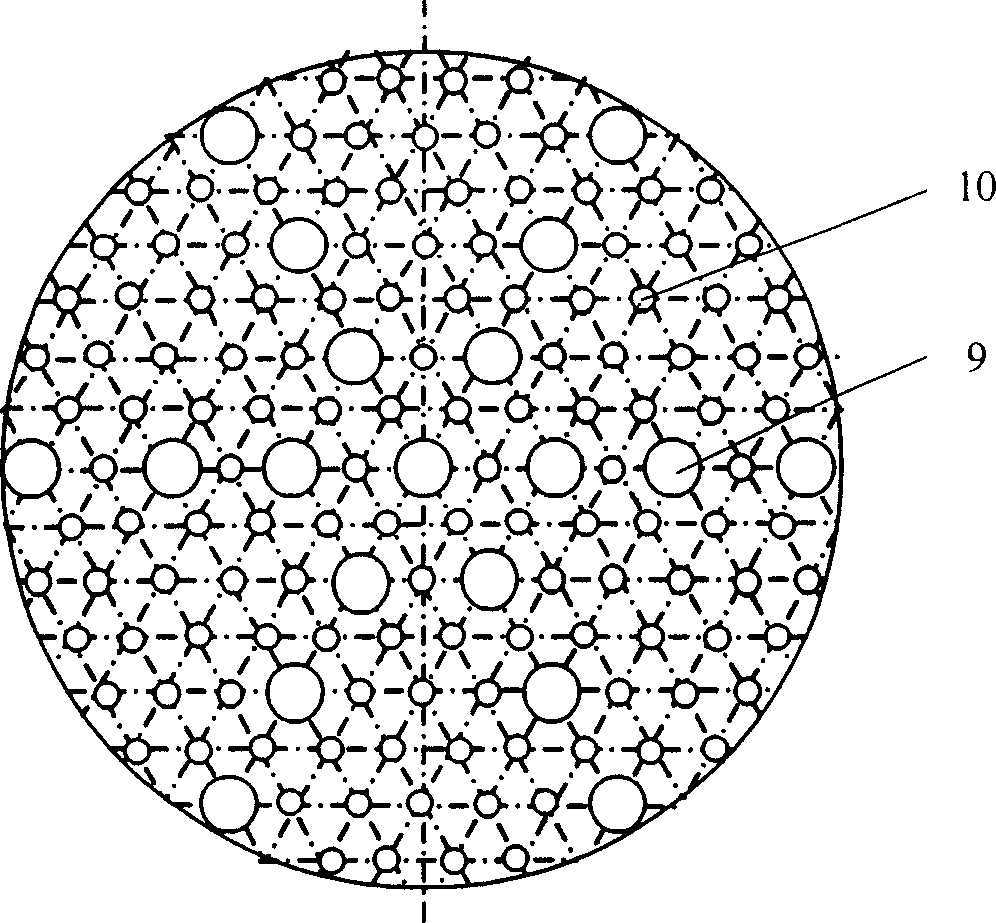

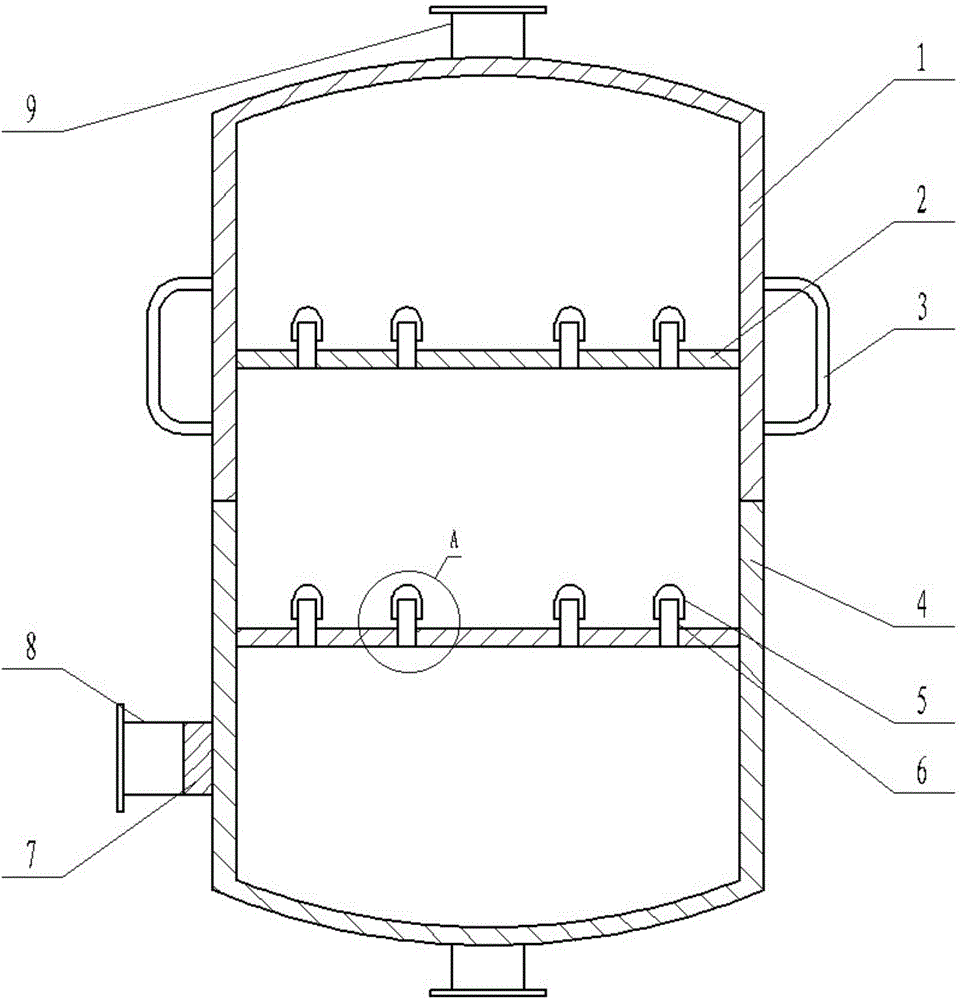

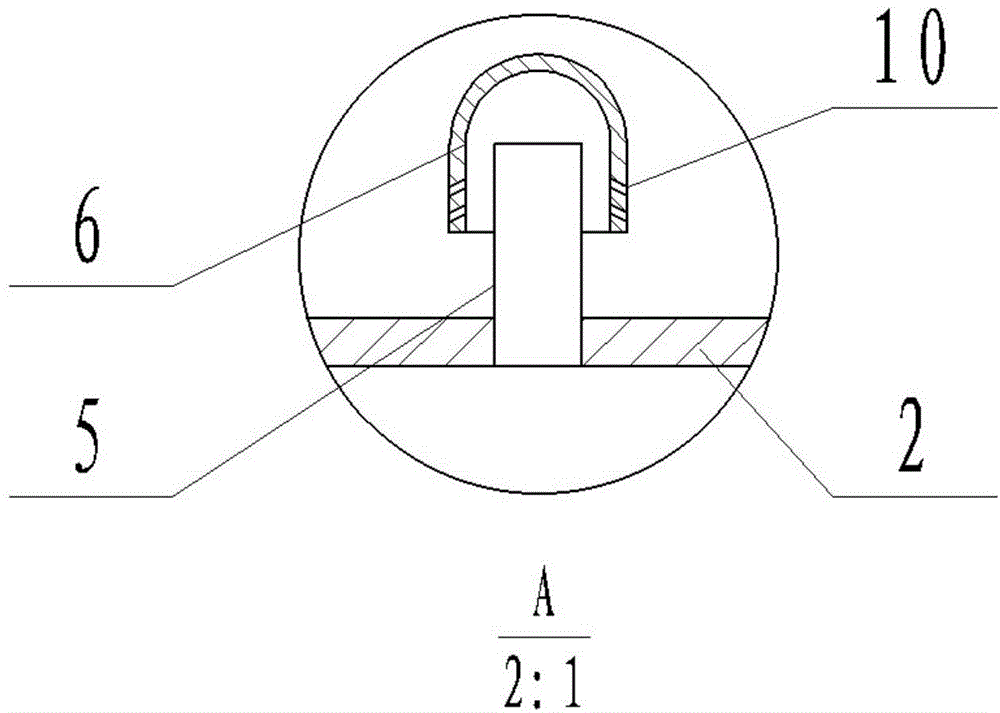

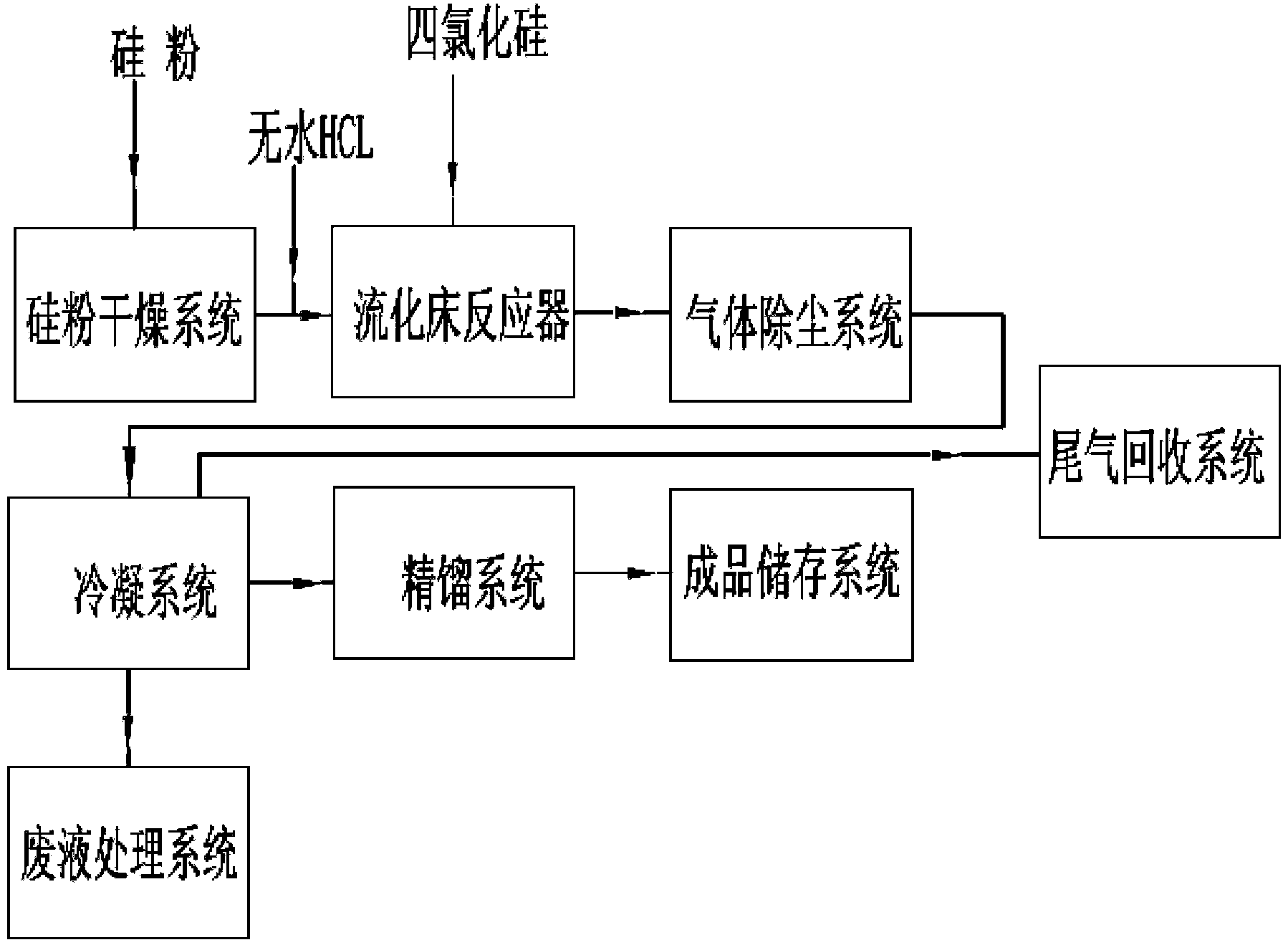

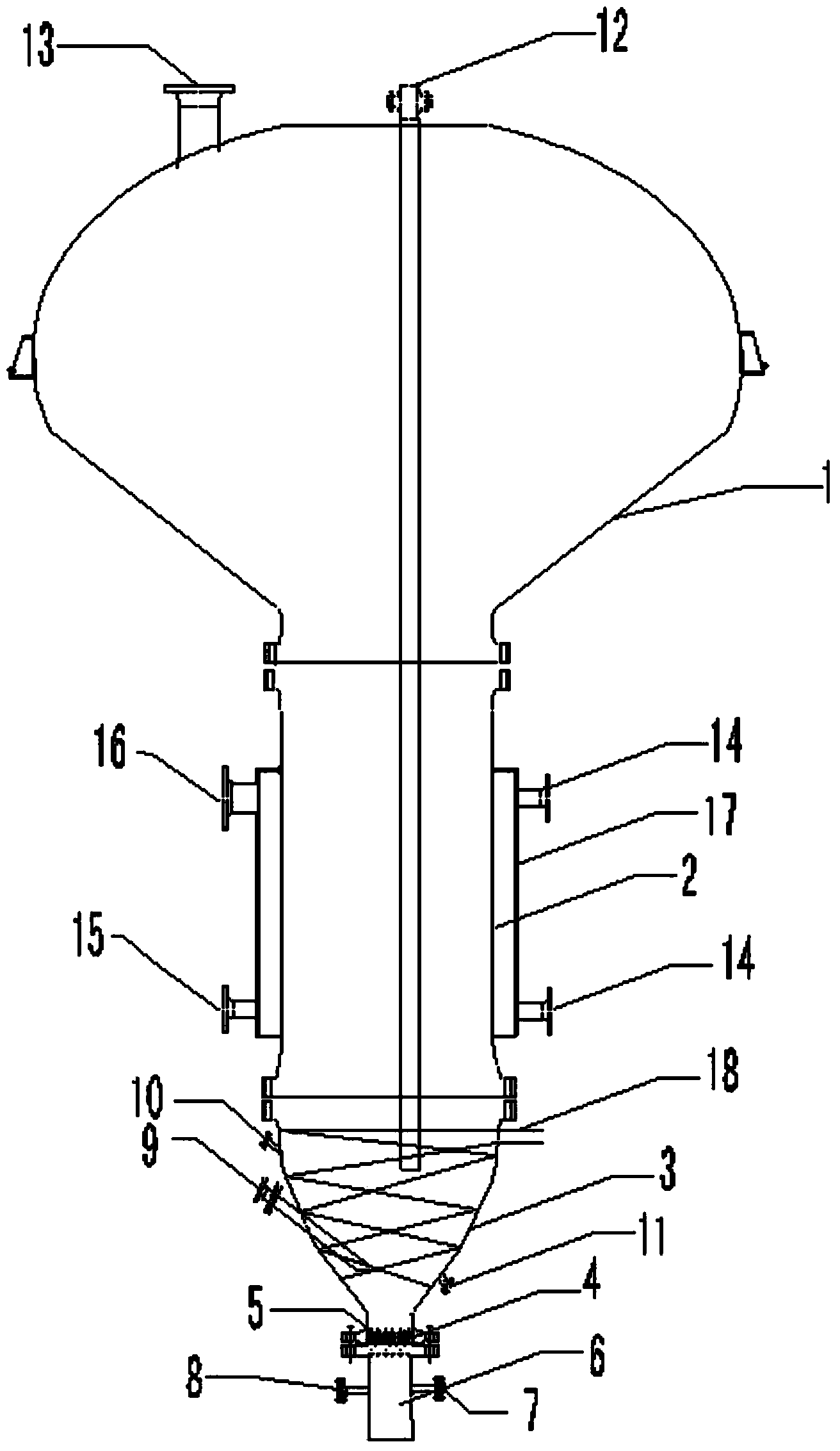

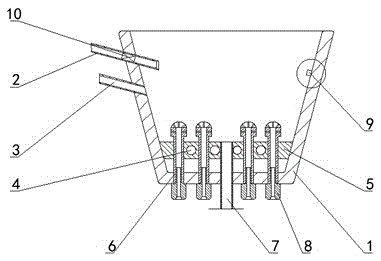

Fluid bed reactor for producing trichlorosilane and gas distributor thereof

ActiveCN101486466ASimple structureImprove fluidization qualityHalogenated silanesProcess engineeringDistributor

The invention relates to a fluidized bed reactor in the chemical technology field, in particular to a fluidized bed reactor used for the production of trichlorosilane, and a special gas distributor thereof. The gas distributor of the fluidized bed reactor used for the production of trichlorosilane comprises a distribution plate provided with a plurality of mounting through holes which are internally provided with blast caps internally provided with an axial gas vent; the lower end of the axial gas vent causes the lower part of the distribution plate to be conductive, the upper end of the axial gas vent is sealed, and the axial gas vent is provided with a plurality of radial gas outlets circumferentially along the side wall; and the radial gas outlets and the upper part of the distribution plate are conductive. The invention also discloses the fluidized bed reactor applying the gas distributor. By the improvement, the trichlorosilane fluidized bed reactor has simpler structure, higher fluidization quality, and larger production capability which can reach 10,000 ton / year to 30,000 ton / year.

Owner:浙江富士特硅材料有限公司

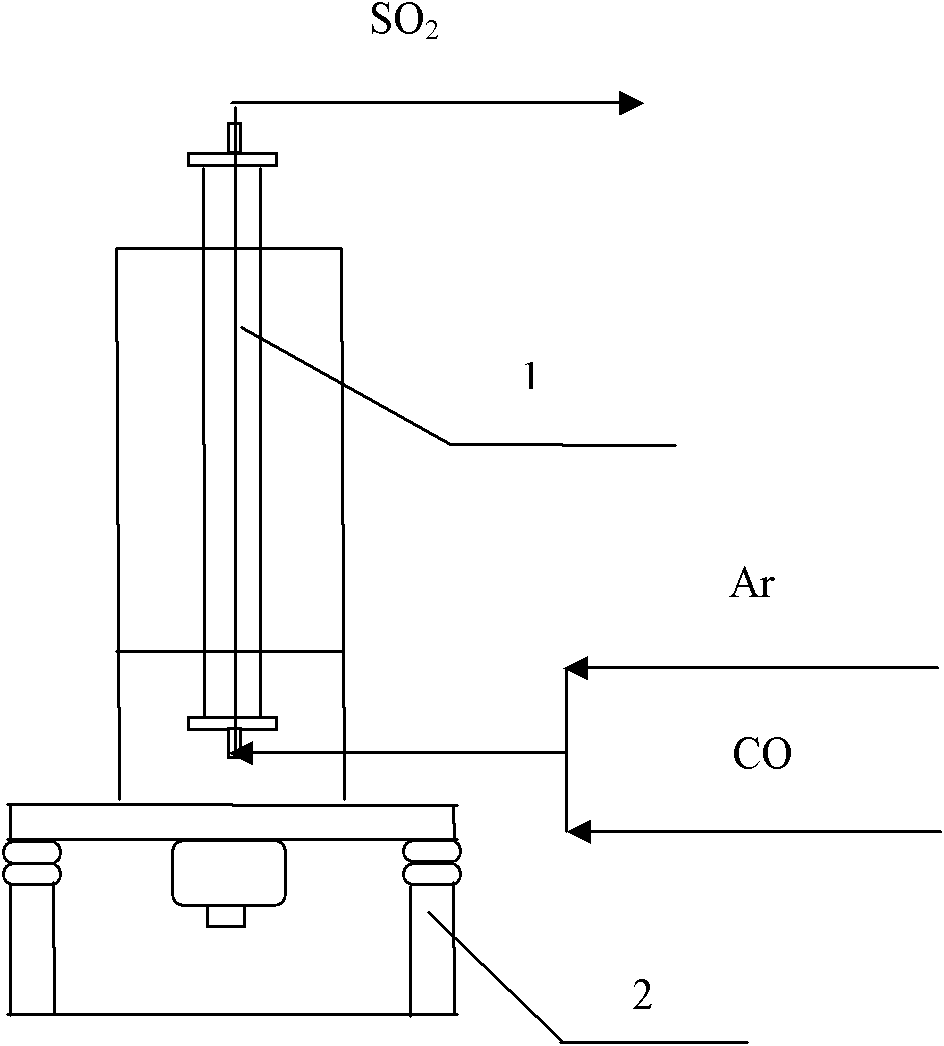

Method for vibrating, fluidizing and decomposing phosphogypsum

InactiveCN101891407AFacilitate reduction of production cost of sulfuric acidFacilitate the improvement of environmental qualitySulfur compoundsCement productionMass ratioAtmosphere

The invention relates to a method for vibrating, fluidizing and decomposing phosphogypsum. The method is characterized by comprising the following steps of: 1) pretreating the phosphogypsum; 2) preparing a composite additive; 3) uniformly mixing the composite additive and the phosphogypsum in a mass ratio of 1:7 to prepare a mixture; 4) preparing equipment; 5) reducing and decomposing, namely feeding the mixture into a uniform fluidizing decomposing furnace out of a kiln; heating to the temperature of between 850 DEG and 1,100 DEG C under the protection of Ar atmosphere; introducing CO at theflow rate of 5 to 50mL / min; making the volume flow ratio of the CO to the Ar to be 1:2-19; controlling the temperature to be between 850 and 1,100 DEG C; and starting a vibration energy loading device. The method has the characteristics of not easily agglomerated materials, high fluidizing quality, low fluidizing gas velocity, high SO2 concentration in tail gas, low dust content, low process energy consumption, contribution to industrial large-scale conduction production, and capability of reducing sulfuric acid production cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

CFB boiler inlaid type hood air distributing device and improving method thereof

InactiveCN106122952AAvoid the risk of cokingThe situation of ash leakage is solvedFluidized bed combustionApparatus for fluidised bed combustionSlagEngineering

The invention discloses a CFB boiler inlaid type hood air distributing device and an improving method thereof, and belongs to the technical field of heat-engine plant circulating fluidized bed boiler air distribution plate transformation. The CFB boiler inlaid type hood air distributing device comprises a tube nest, air distribution plate castable and the like. The tube nest is located at the upper portion of an air chamber. Hearth water wall tubes are evenly arranged below the tube nest. The air distribution plate castable is laid on the tube nest with reserved gaps. An air pipe B is inlaid in an air pipe A, penetrates the tube nest and extends into the air chamber. The air pipe A and the air pipe B are fixed through welding points. A strengthening casing pipe is fixed to the intersection position of the air pipe A and the tube nest. Small air holes of the air pipe B are formed in the upper portion, above the air pipe A, of the air pipe B. An I-shaped hood is buckled at the upper portion of the air pipe A, and I-shaped hood air outlet holes are formed in the I-shaped hood. According to the CFB boiler inlaid type hood air distributing device and the improving method thereof, welding and fixing points are broken by dismounting the hood, part of air pipes are cut, new air pipes are inserted, welding and fixing are conducted, and therefore the running resistance of an air distribution plate can be adjusted; and the problems that the air distributing uniformity is poor, temperature distribution is uneven, slag leaks in the air chamber, and the power consumption of a primary draught fan is large are solved.

Owner:山西平朔煤矸石发电有限责任公司

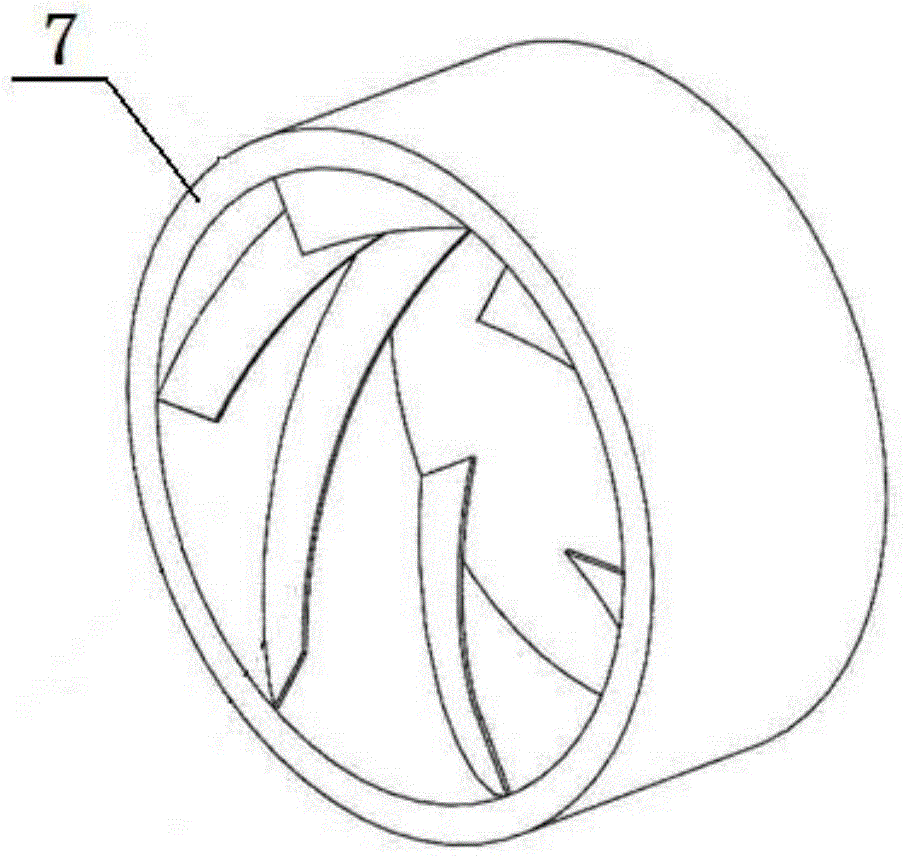

Solid particle player

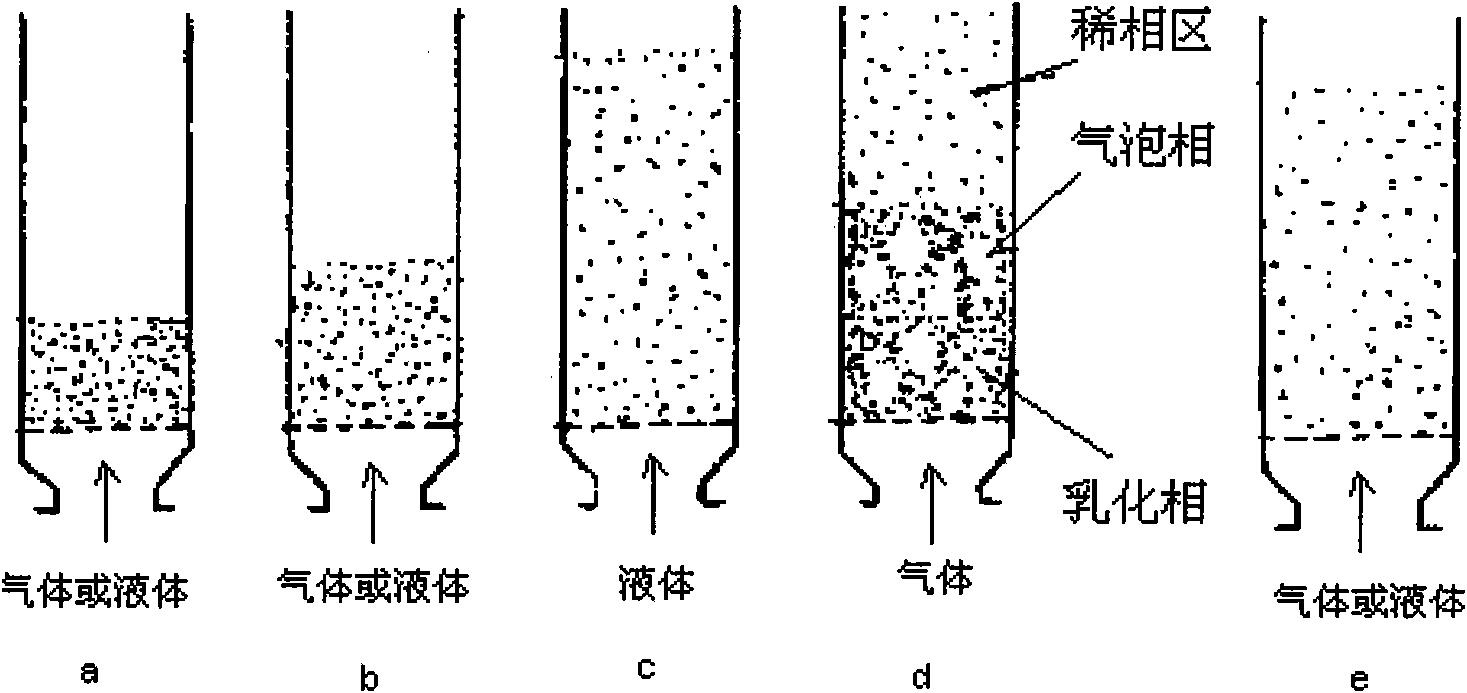

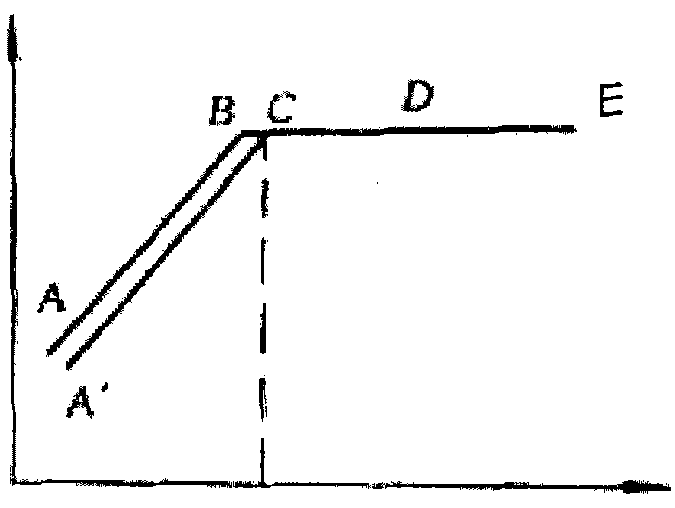

ActiveCN101912752AEvenly distributedAvoid wall effectChemical/physical processesSpray nozzleInstability

The invention discloses a solid particle player which is in a coaxial segmented sealing cylindrical structure and comprises a base plate, a spray nozzle, an acceleration section, a rectifying section, a fluidized section and a cover plate. A rectifying plate which is uniformly provided with millimeter grade through holes is fixedly arranged at the inner wall of the connected part of the acceleration section and the rectifying section; an air distribution plate which is uniformly provided with nano-grade gaps is fixedly arranged on the inner wall at the connection part of the rectifying section and the fluidized section; solid particles are stacked on the air distribution plate; a plurality of layers of fluidized substance outlets are machined at the positions in different heights at the upper side of the fluidized section; and an included angle of 15-50 degrees is formed between the axis of the fluidized substance outlets and the axis of the solid particle player. The solid particle player is formed by sintering metal powder; air current is diffused by the air distribution plate with nano-grade gaps so as to obtain the uniformly-distributed incoming current and avoid the wall-surface effect; and according to the distance among various sections and the opening mode of the air distribution plate and the side wall, the invention ensures enough flowing resistance, reduces the wall-surface effect due to the nonuniform air inlet speed and pressure distribution, overcomes the instability of focus fluidization and inhibits the abnormal phenomenon of channeling and slugging in a bed layer.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

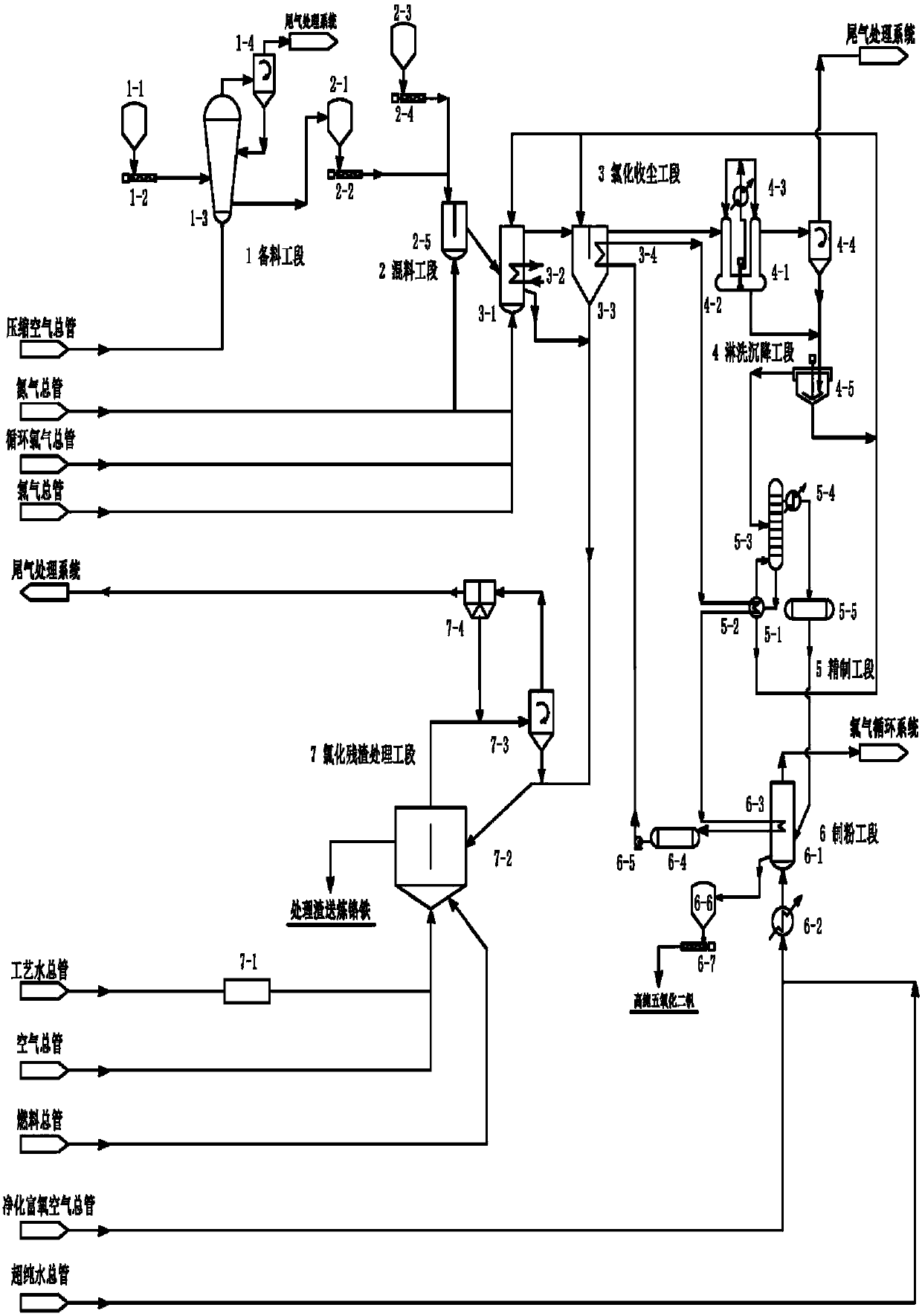

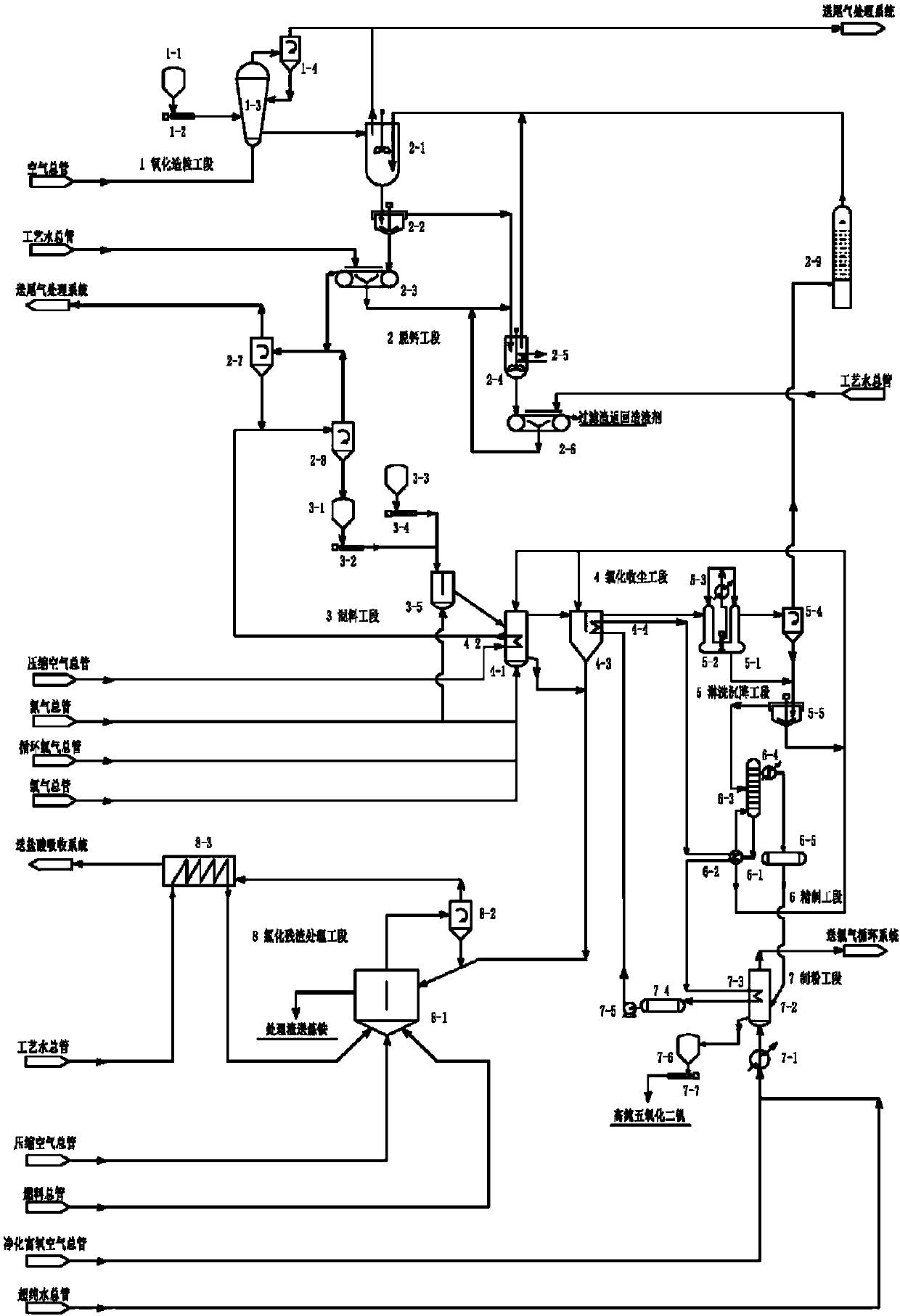

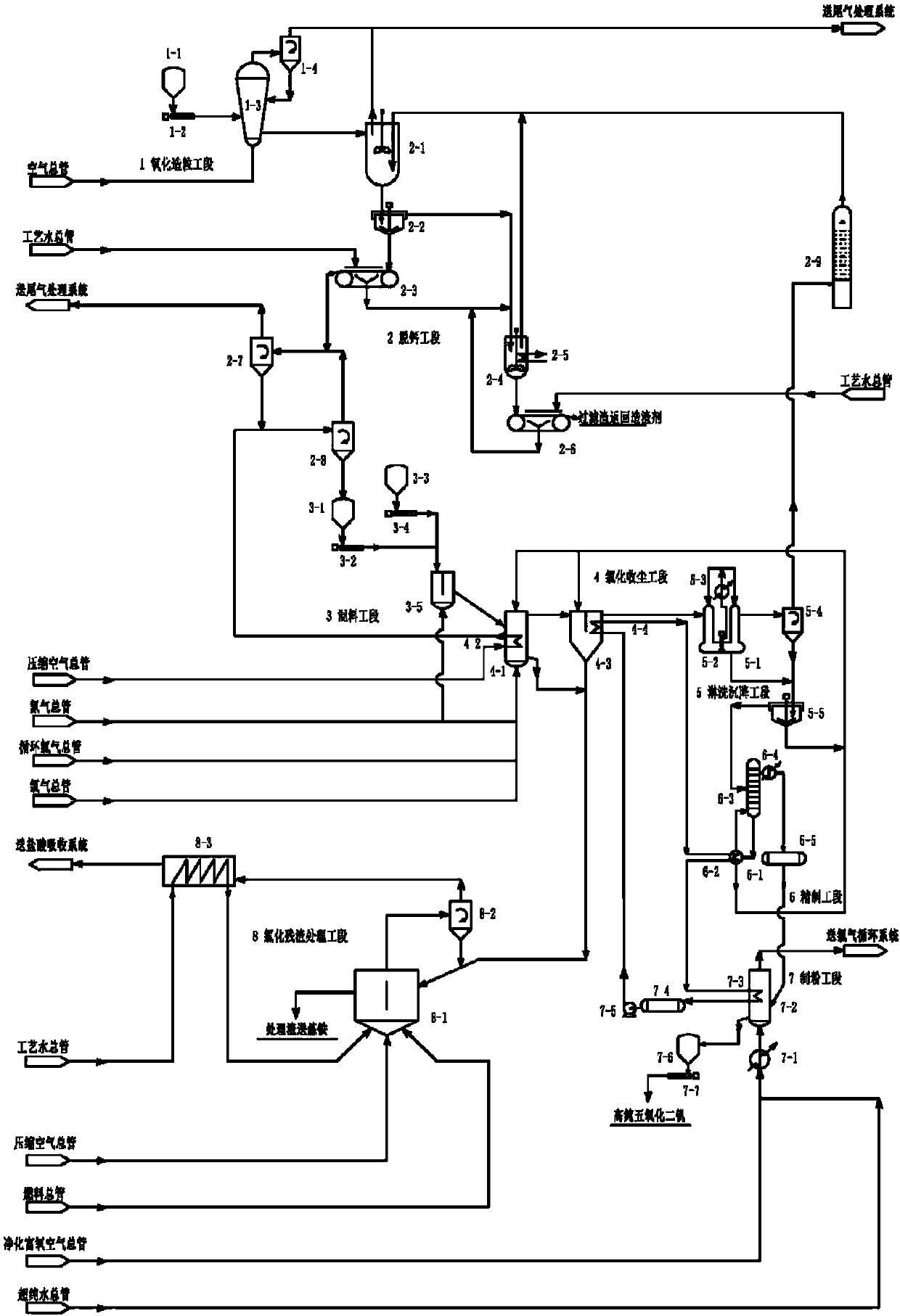

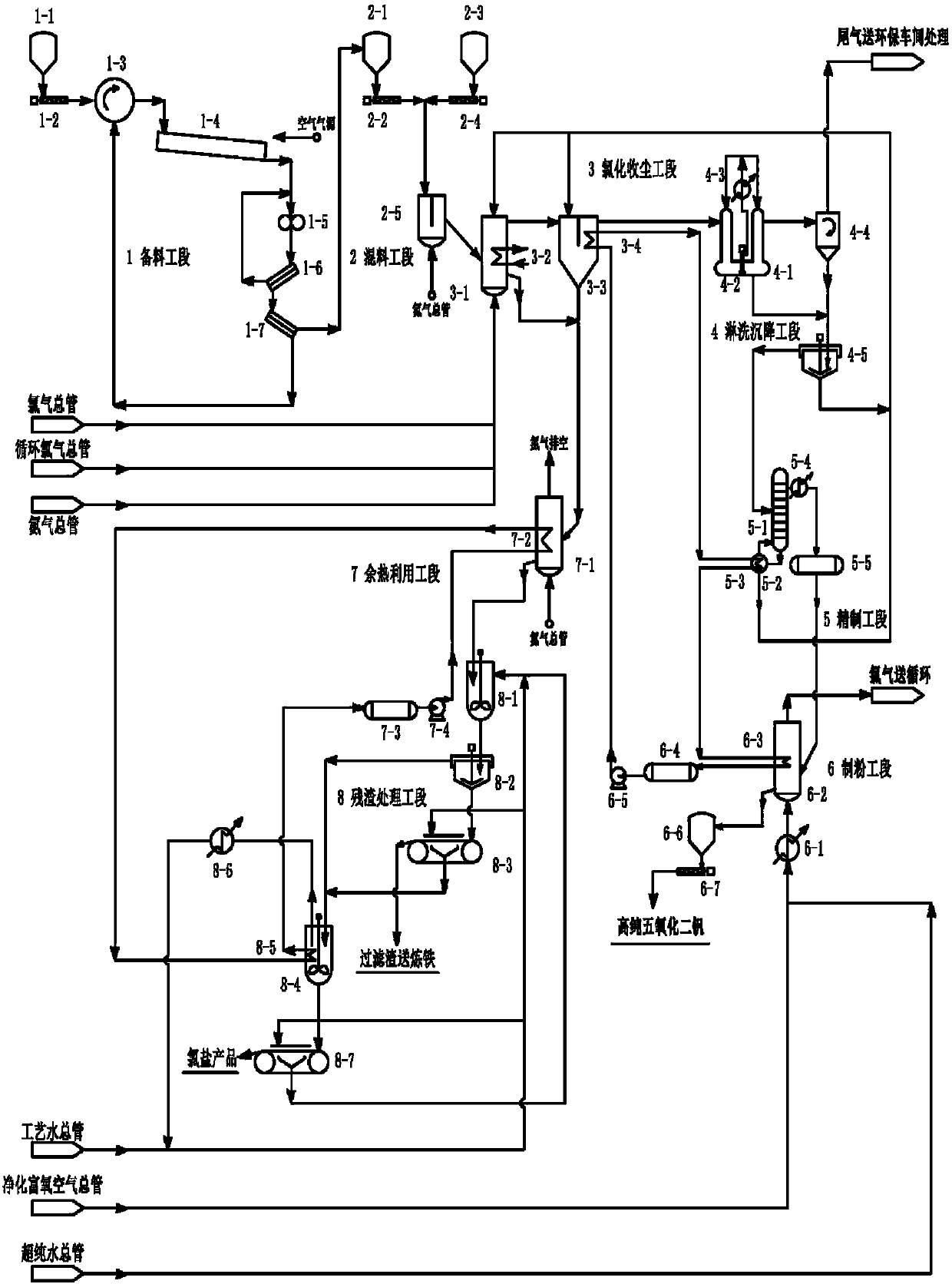

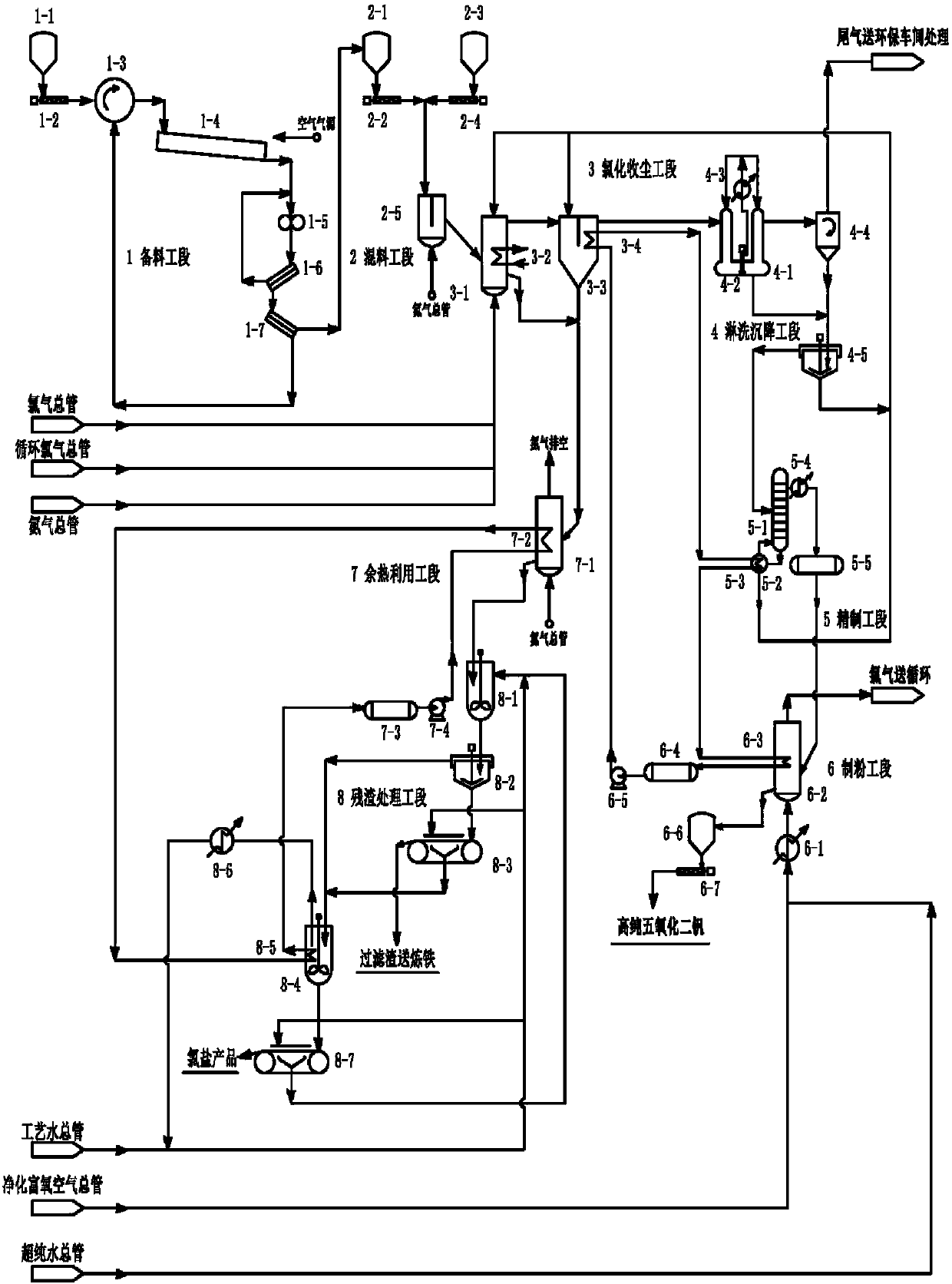

System and method for producing high-purity vanadium pentoxide through clean chlorination of vanadium residue

ActiveCN109835949AImprove chlorination selectivityAchieve separationChemical industryVanadium oxidesFlue gasFluidized bed

The invention discloses a system and a method for producing high-purity vanadium pentoxide through clean chlorination of vanadium residue. According to the present invention, through fluidized bed oxidative granulation treatment, the mineral phase reforming and the mineral particle growth of the vanadium residue are achieved; the vanadium in the vanadium residue is converted into gaseous vanadiumoxytrichloride through selective chlorination, and most of impurities such as chromium, iron, calcium, phosphorus, manganese, titanium, silicon and the like are remained in the chlorinated residue soas to achieve effective separation of other impurities such as vanadium, chromium and the like; the gaseous vanadium oxytrichloride is sequentially subjected to dust removal, leaching, settlement, rectification purification, catalytic oxidation and other processes to prepare the high-purity vanadium pentoxide; the chlorinated residue is subjected to gas phase hydrolysis dechlorination treatment, and the treated residue returns to ferrochromium smelting; and with the system and the method, the clean comprehensive utilization of vanadium residue is achieved, and the sensible heat of the high temperature flue gas of the chlorination furnace is effectively utilized so as to achieve the purposes of energy saving and consumption reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

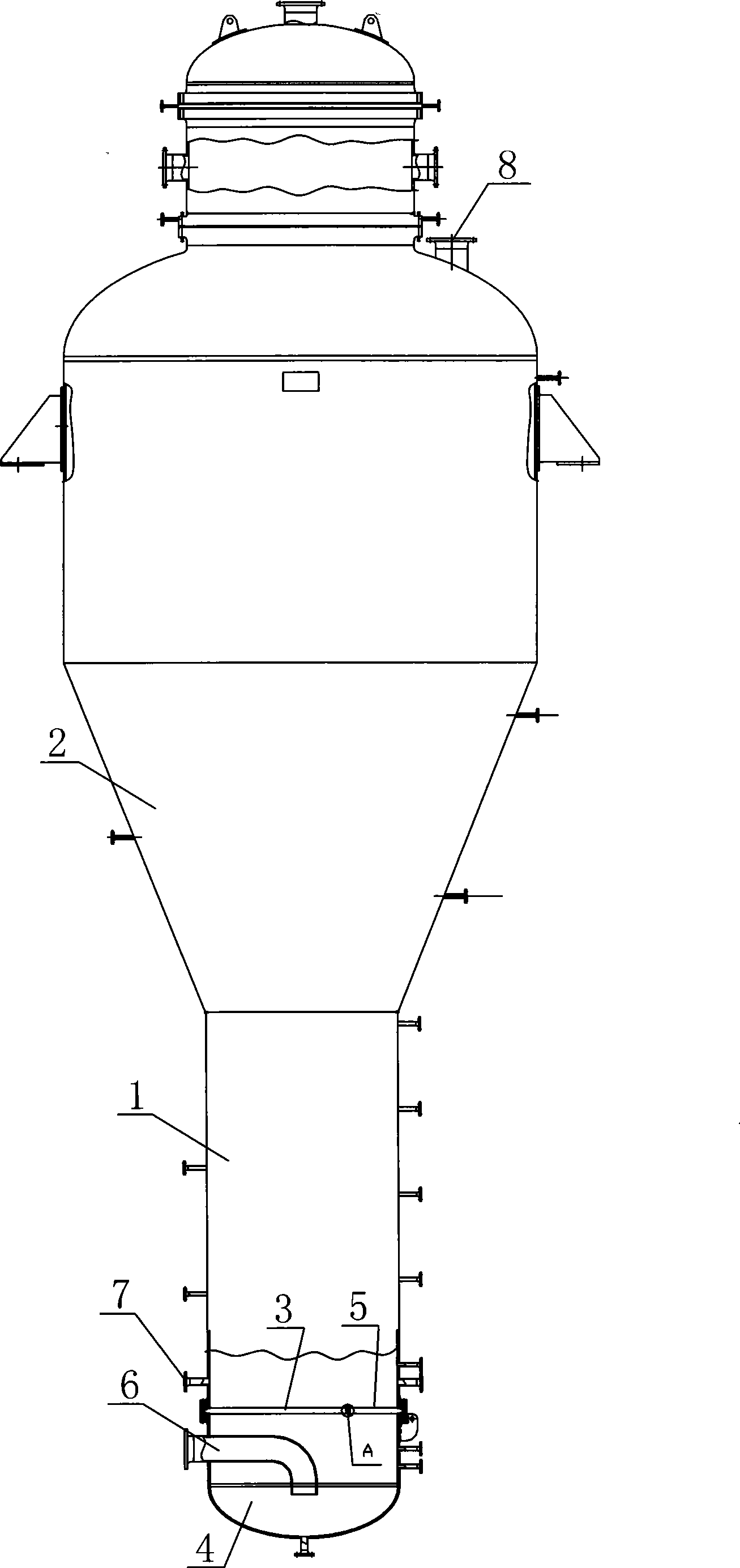

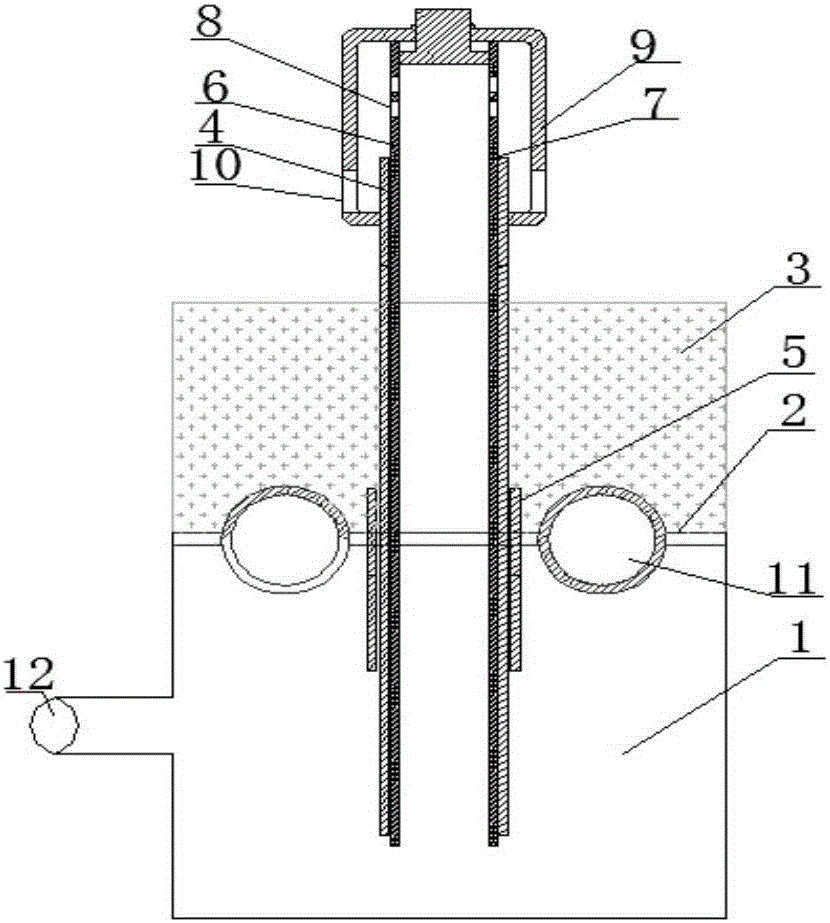

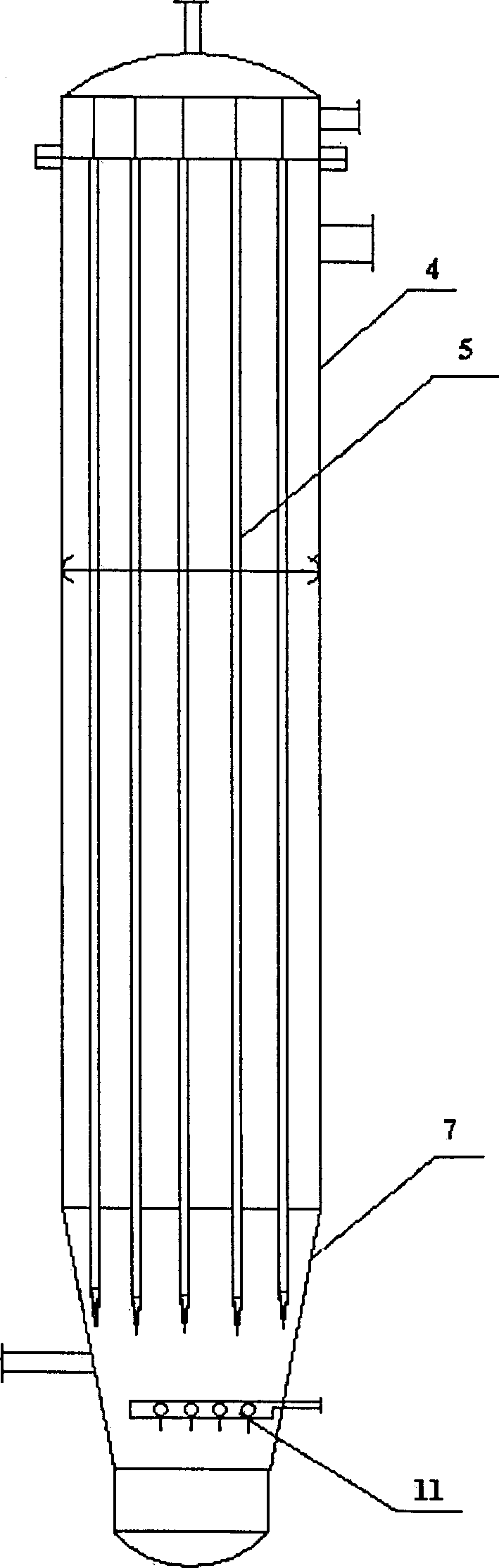

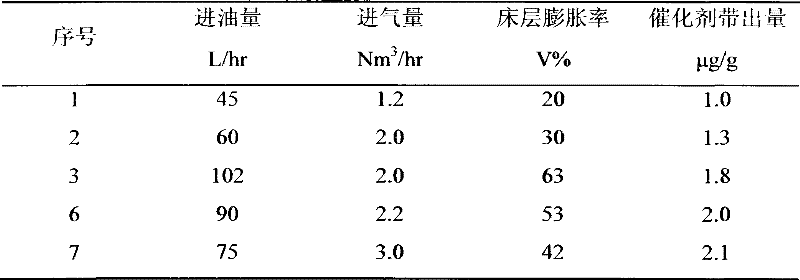

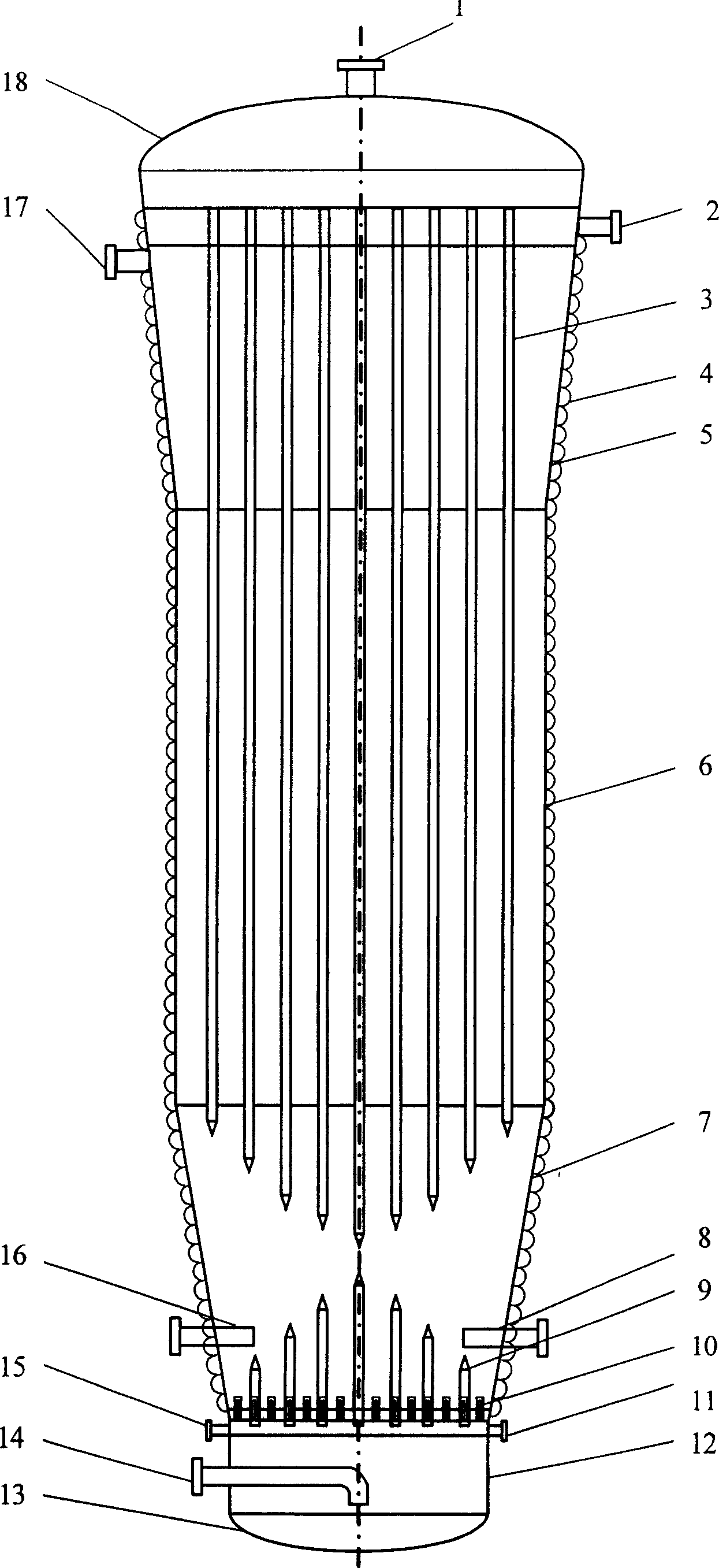

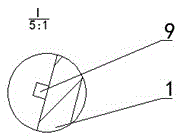

Large fluidized bed reactor for wide sieving fluidized particles

InactiveCN1425494AImprove fluidization qualityFulfilling magnification requirementsChemical/physical processesProcess engineeringProduct gas

The present invention relates to chemical equipment technology. The large fluidized bed reactor consists of main bed, conic bed, internal finger-shaped tube heat-exchange member and gad distributor, and features the inner cone structure in the conic bed and sectional introduction of heat-exchange medium to the heat exchange pipe. Using the fluidized bed reactor of the present invention can regulate effectively the fluidizing cross-section area, improve fluidizing quality and realize industrial application easily.

Owner:TSINGHUA UNIV

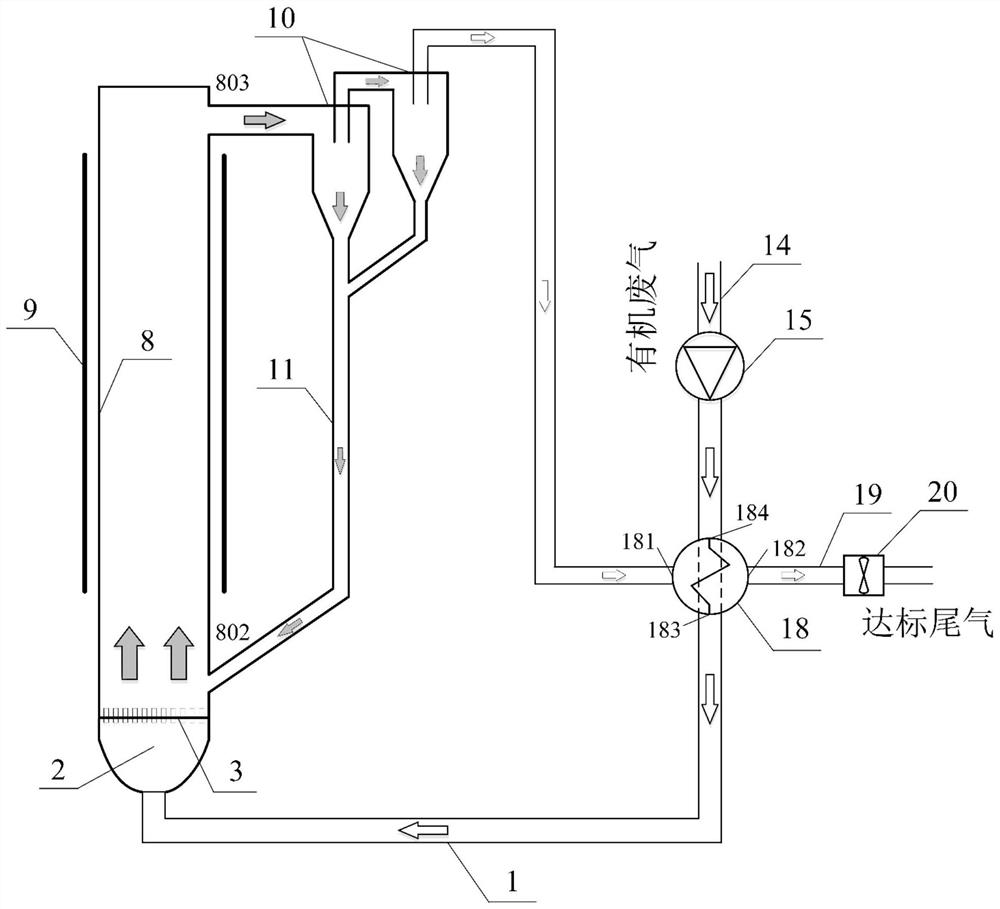

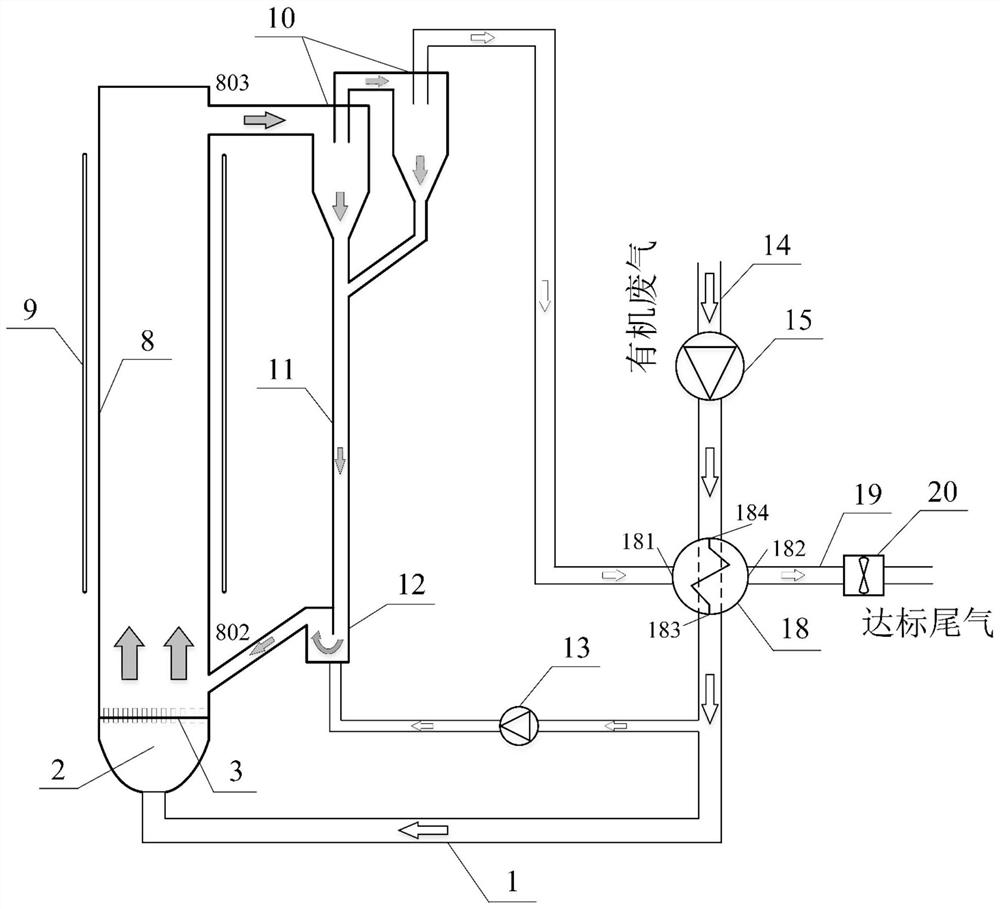

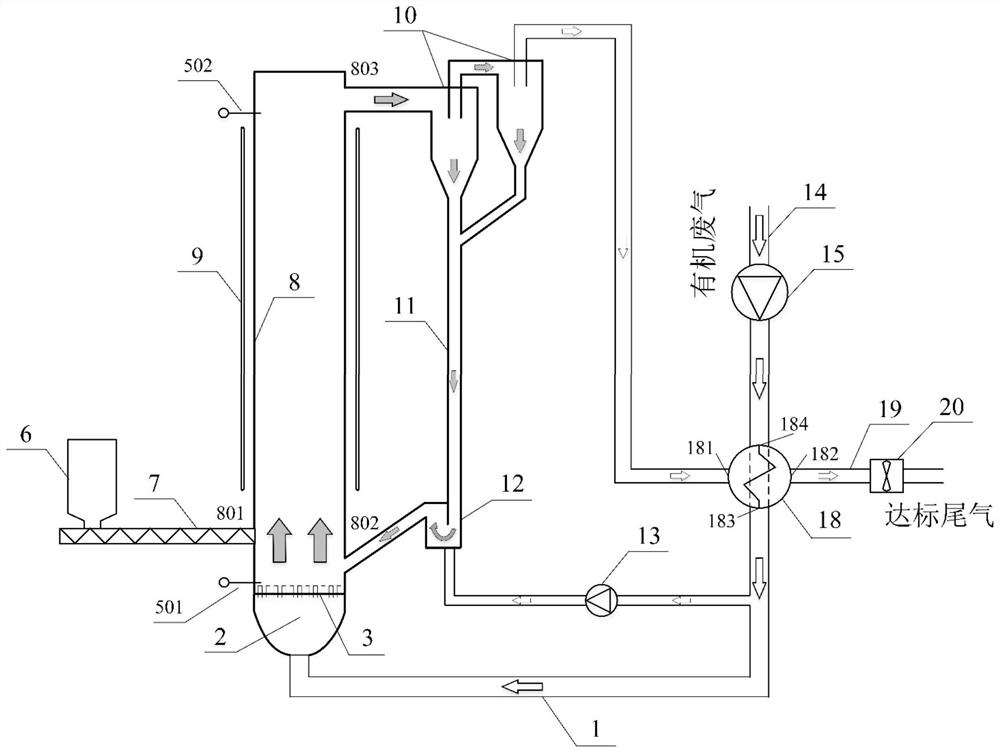

Circulating fluidized bed catalytic combustion method for treating organic waste gas

PendingCN111853834AIncreased gas-solid contact areaReduce consumptionIncinerator apparatusPtru catalystFluidized bed

The invention discloses a circulating fluidized bed catalytic combustion method for treating organic waste gas, and belongs to the field of environmental protection. The method comprises the followingsteps that A, the temperature of a raising pipe in a circulating fluidized bed catalytic combustion furnace is controlled within the set catalytic combustion temperature range; B, the organic waste gas to be treated is sent from a raising pipe intake manifold into the raising pipe, so that catalyst particles in the raising pipe are fluidized rapidly, and at the same time, VOCs components in the organic waste gas to be treated are catalyzed for oxidative decomposition; C, airflow after oxidative decomposition entrains part of the catalyst particles to move upwards into a separator, the catalyst particles are separated and return to the raising pipe through diplegs, and hot exhaust gas after purifying leaves the separator; and D, the hot exhaust gas after purifying enters a heat exchanger for exchanging heat to utilize exhaust gas heat, and the exhaust gas after heat exchange merges into an exhaust gas flue and is introduced into a factory exhaust manifold or exhausted into the atmosphere. The method is high in removal rate, simple in operation and high in heat utilization rate, and long-term continuous and stable operation of volatile organic waste gas can be achieved.

Owner:JIANGSU NANFANG COATING & ENVIRONMENT PROTECTION EQUIP +1

Surface modifying method for superfine paint powder

InactiveCN1472261ASimple production processIncrease profitLiquid surface applicatorsCoatingsLacquerMaterials science

A process for modifying the surface of superfine paint particle in order to improve the flowability of paint particles for airflow delivery features that the airflow or external mechanical force is used to make small and hard additive particles collide or squeeze with paint particles. Part of additive particles is anchored on the surface of paint particle and other additive particle is adsorbed by its exposed rest. Its advantages are high effect, low cost, and simple operation.

Owner:张伟

Fluidized bed reactor and inner constructional elements thereof

InactiveCN103446877AIncrease contact rateIncrease concentrationDispersed particle separationFluidized bedSolid particle

The application discloses a fluidized bed reactor and inner constructional elements thereof. The fluidized bed reactor comprises a tower cylinder, wherein a plurality of inner constructional elements are arranged in the tower cylinder; each inner constructional element comprises a junction surface, a contacting surface and a flow guide surface, and the junction surfaces are arranged on the inner wall surface of the tower cylinder; the contact surfaces and the flow guide surfaces are connected to the junction surfaces in an inclining manner, and an inflexion point is formed between each contact surface and each flow guide surface; when solid particles enter the tower cylinder through a feed port, the contact surfaces can guide the solid particles to flow along the radial direction of the tower cylinder and the directions of the inflexion points; when solid particles pass through an inverse region point, the flow guide surfaces can guide the solid particles to be distributed in the tower cylinder along the radial direction of the tower cylinder and flow facing to an exhaust port, and thus a solid-gas contact reaction is promoted, the solid-gas axial direction and radial direction mixing capability is strengthened, and a flow field in the tower cylinder is optimized.

Owner:中国大唐集团科学技术研究总院有限公司

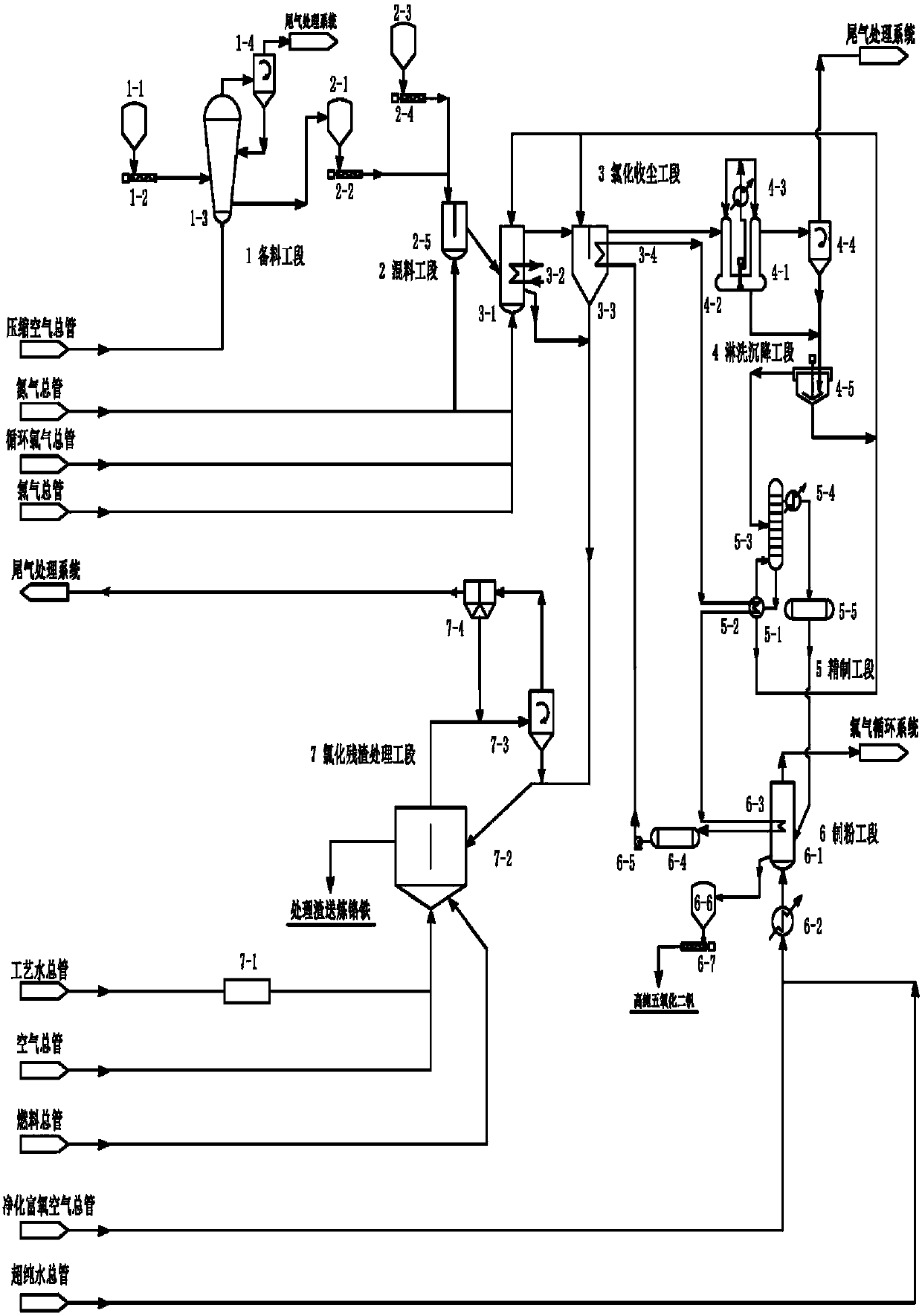

System and method for producing powdery vanadium by using chlorination process

ActiveCN109835951AImprove chlorination selectivityAchieve separationDispersed particle separationEnergy inputGas phaseCatalytic oxidation

The present invention discloses a system and a method for producing powdery vanadium by using a chlorination process. According to the present invention, through fluidized bed oxidative granulation treatment, the mineral phase reforming and the mineral particle growth of the vanadium residue are achieved; through calcium fixing treatment with carbon dioxide, the decalcification of the vanadium residue is achieved; the vanadium in the vanadium residue is converted into gaseous vanadium oxytrichloride through selective chlorination, and most of impurities such as iron, manganese, phosphorus, titanium, silicon and the like are remained in the chlorinated residue so as to effectively separate vanadium and other impurities; the gaseous vanadium oxytrichloride is sequentially subjected to dust removal, leaching, settlement, rectification purification, catalytic oxidation and other processes to prepare the high-purity vanadium pentoxide powder (powdery vanadium); the chlorinated residue is subjected to gas phase hydrolysis dechlorination treatment, and the dechlorination residue returns to iron making; and with the system and the method, the clean comprehensive utilization of vanadium residue is achieved while the sensible heat of the high temperature flue gas of the chlorination furnace is effectively utilized so as to achieve the purposes of energy saving and consumption reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Air impulsive motion dense medium fluidized bed and sorting method thereof

InactiveCN101468329ABest pulse frequencyGuaranteed to workGas current separationWet separationEngineeringMineral processing

The invention discloses an air pulse dense-medium fluidized bed and a separation method therefore, which belongs to the field of dry-process mineral processing and is particularly suitable for dry-process coal preparation. The air pulse dense-medium fluidized bed and the separation method therefore comprise the prior air dense-medium fluidized-bed and the separation method thereof, and are characterized in that the upflow for the fluidization of a dense-medium bed is kept to be unsteady airflow that alternately changes in a period according to a certain law. When the fluidized bed and the separation method are adopted for separation, the aim that the fluidized bed is stable, easy to control, high in reliability, good in effects, capability of popularization and wide in adaptation range can be achieved, and the effects that can not be achieved by the prior air dense-medium fluidized-bed and the separation method thereof can be achieved. The method is a novel dry-process separation method in the mineral processing industry.

Owner:唐山易通科技开发有限公司

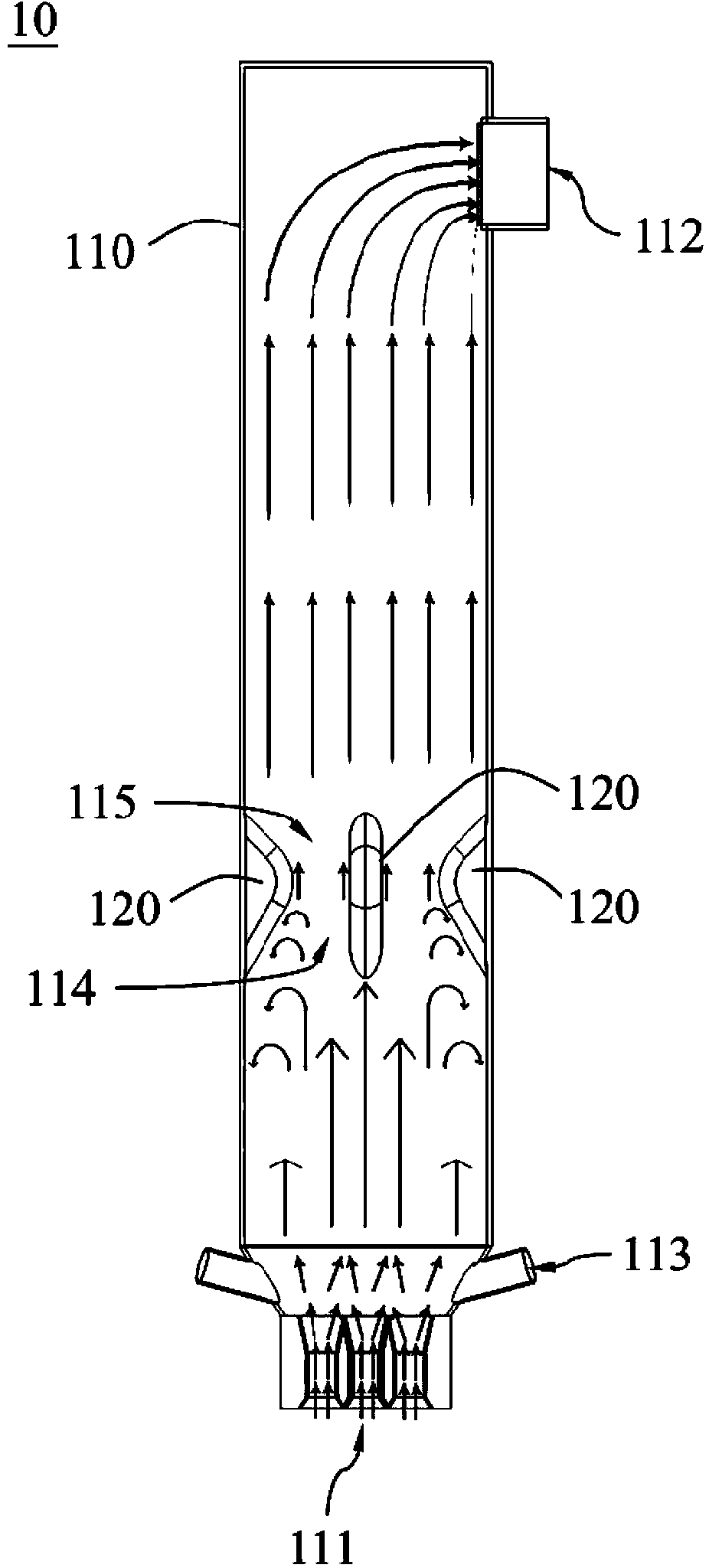

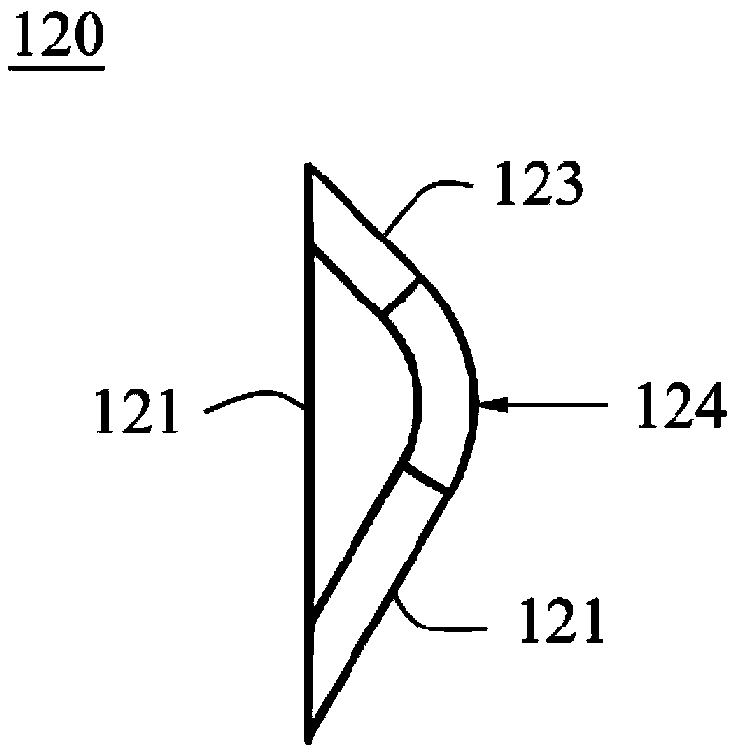

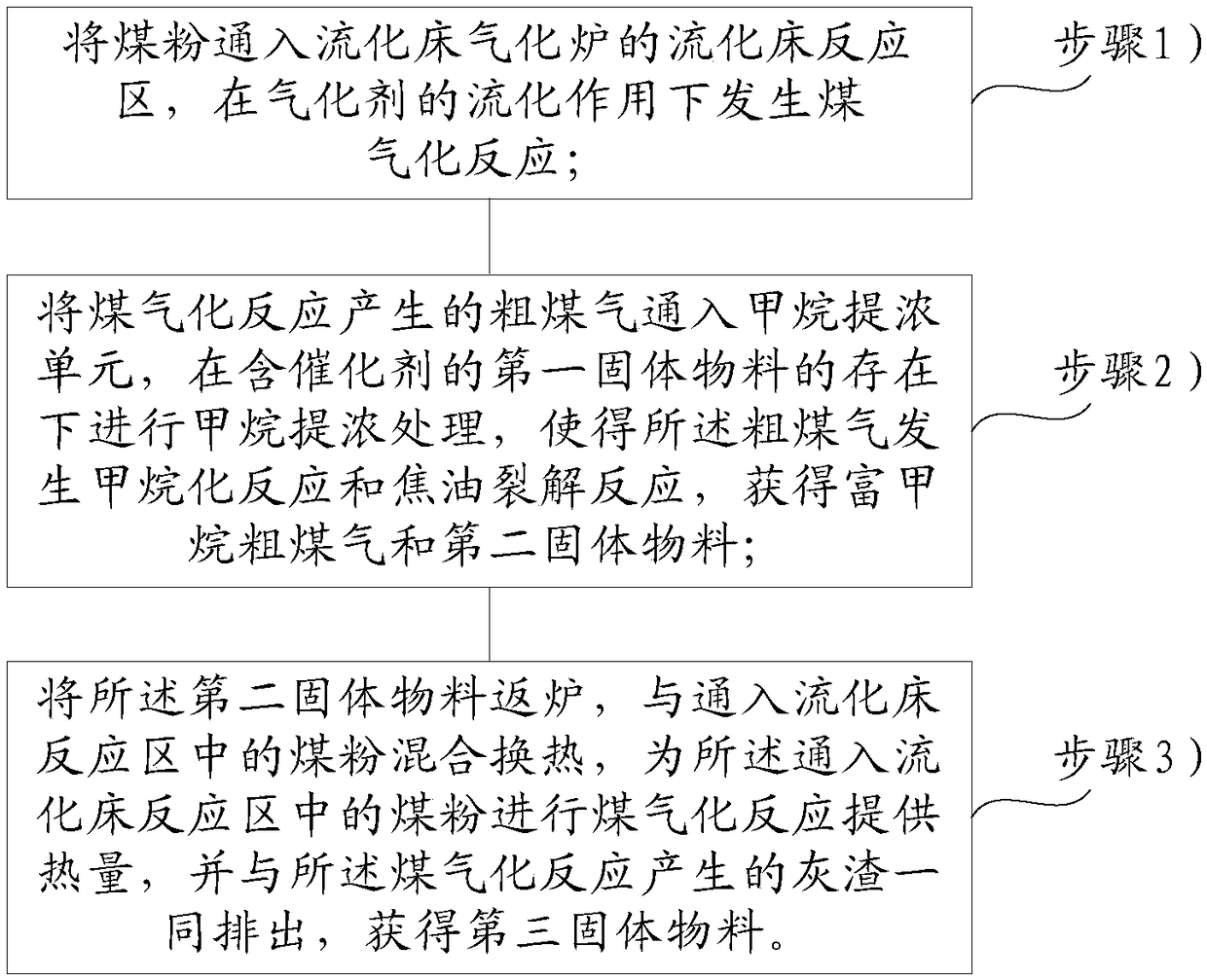

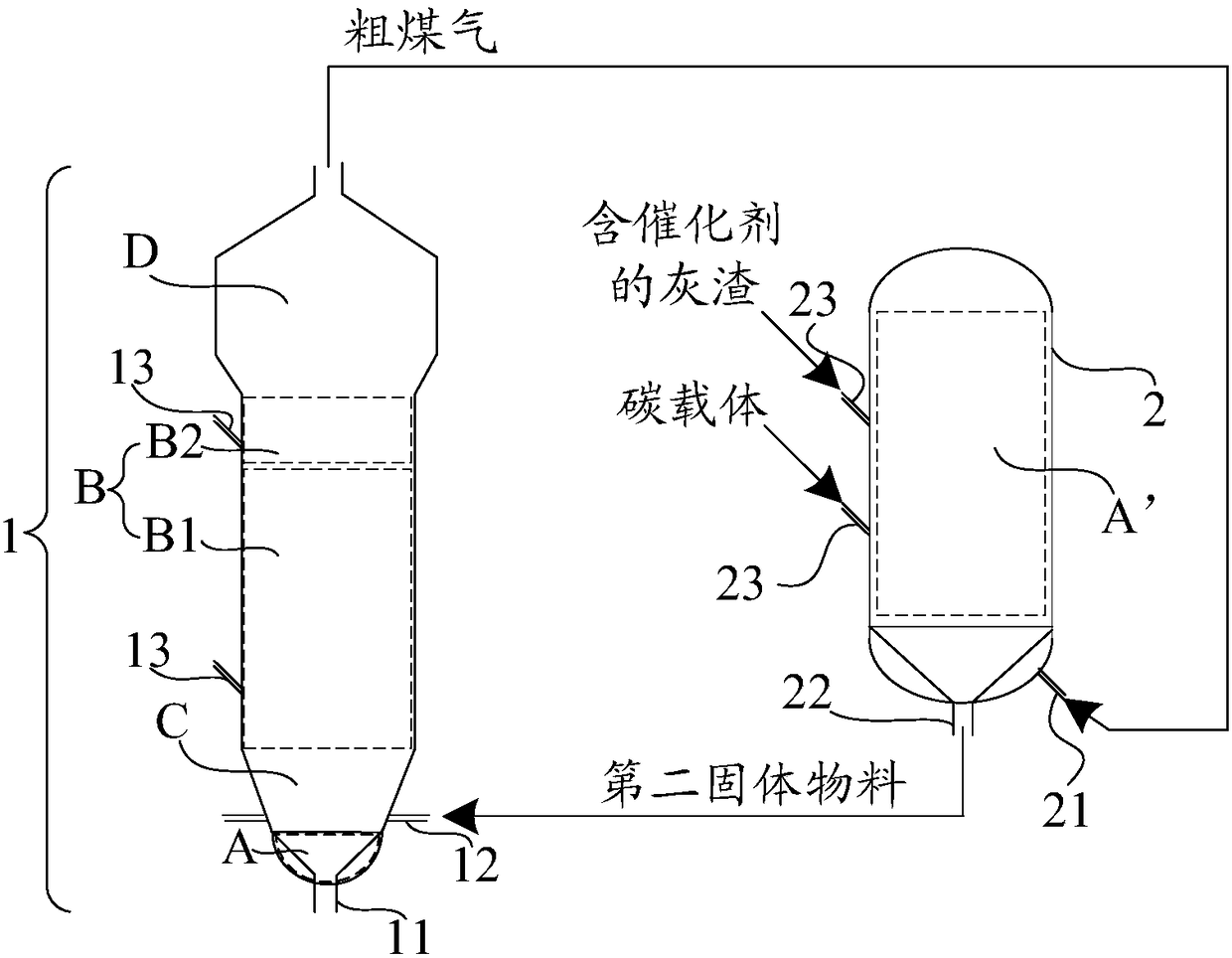

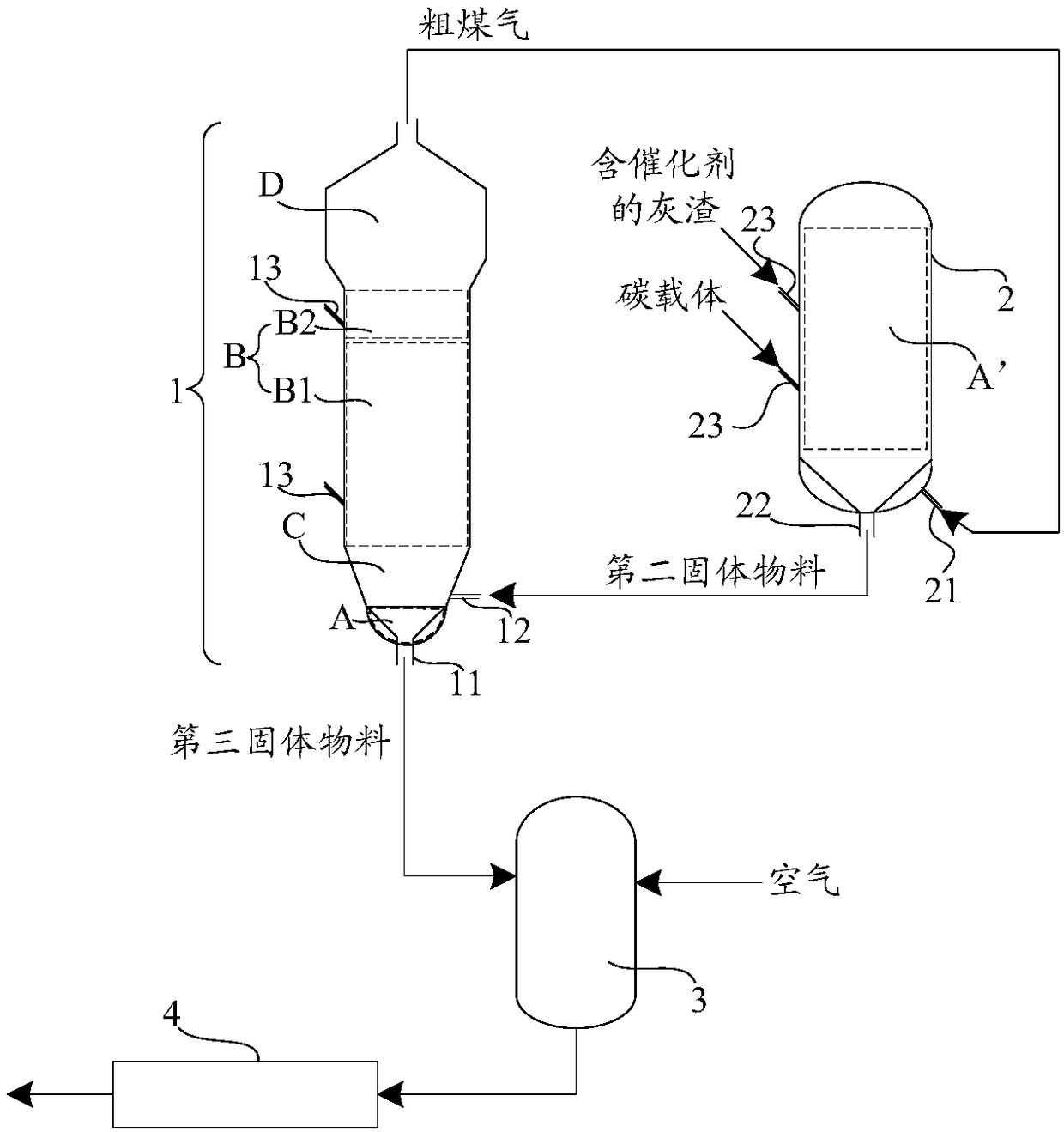

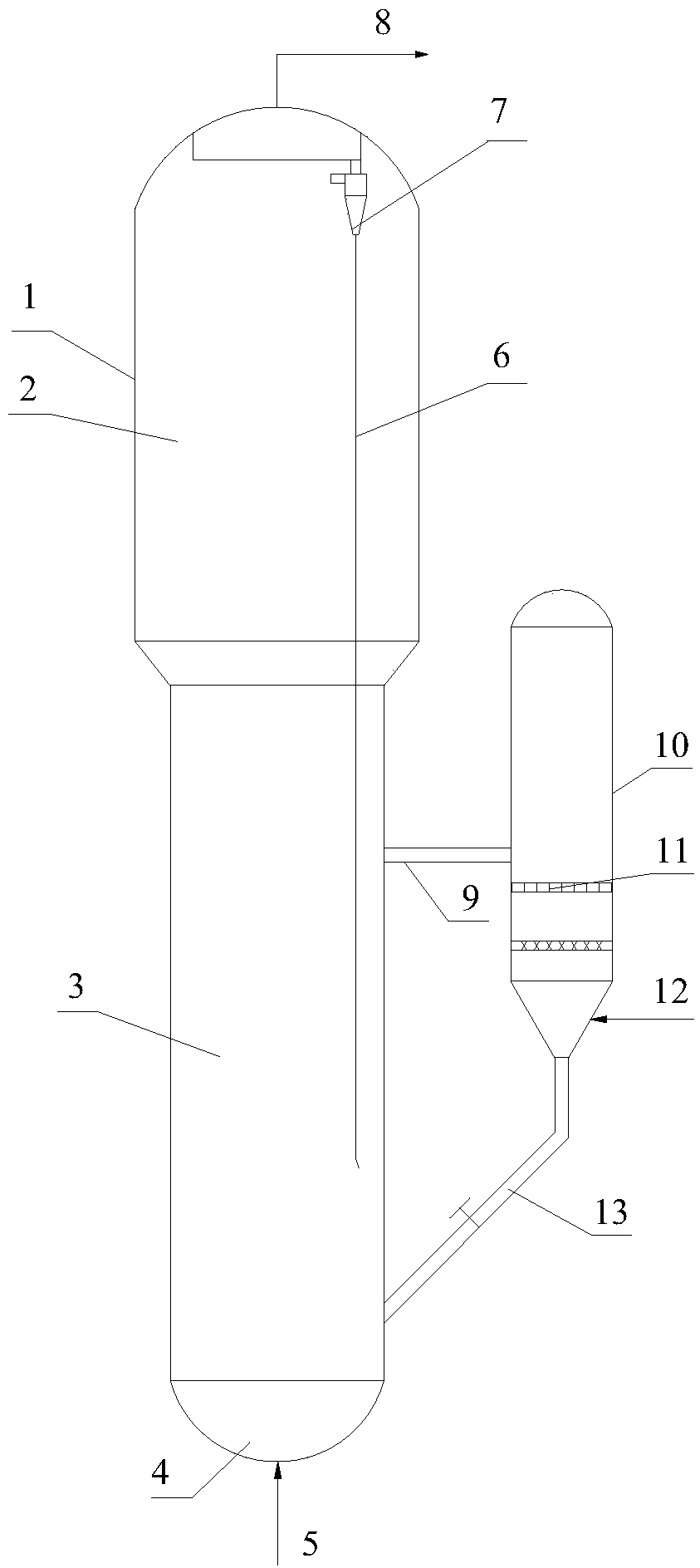

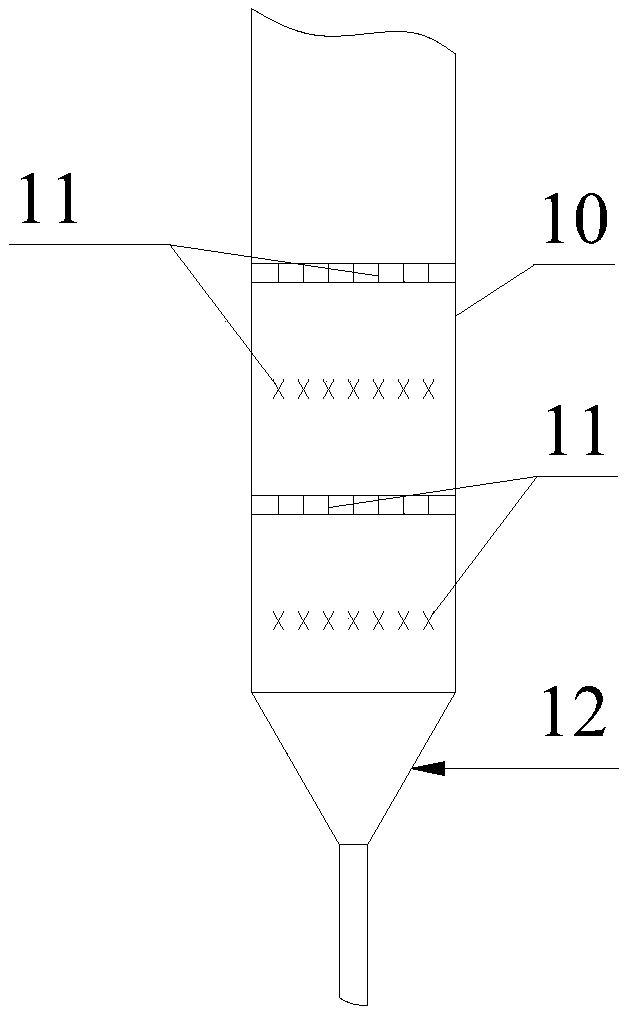

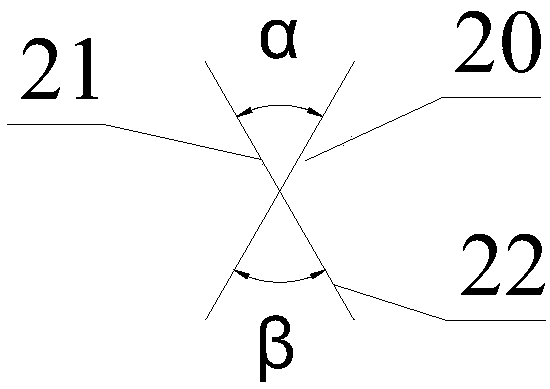

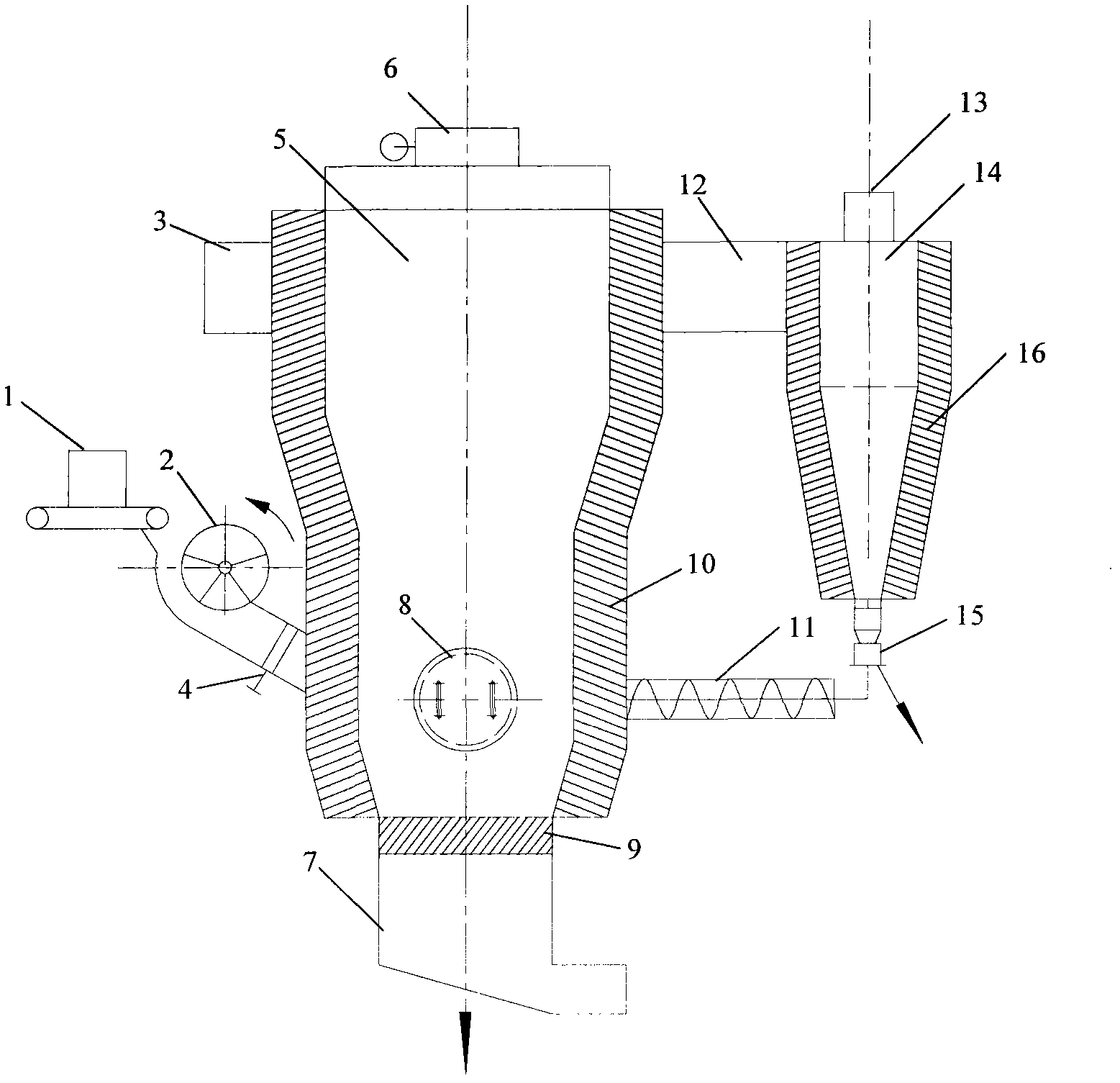

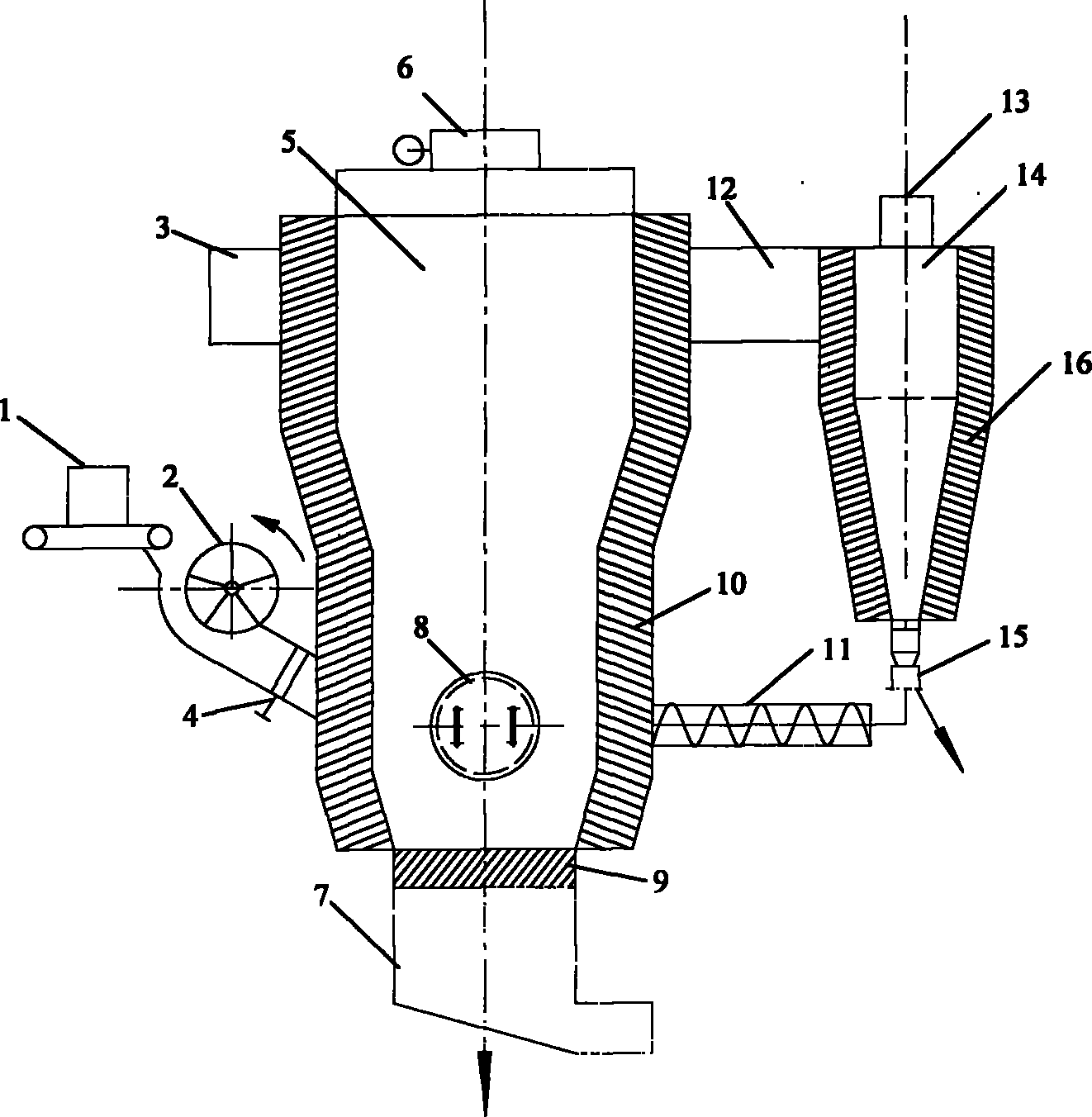

Coal gasification method and coal gasification system

ActiveCN108219851AImprove fluidization qualityImprove the flow fieldGasification processes detailsBulk chemical productionSlagMethanation

The invention relates to the technical field of coal gasification, and especially to a coal gasification method and a coal gasification system. The method and the system can improve the fluidization quality in a gasifier, improve the flow field in the gasifier, avoid slagging in the gasifier and improve the running stability and the methane yield of the gasifier. The coal gasification method comprises the following steps: introducing coal powder into a fluidized bed reaction zone, and performing a coal gasification reaction under the fluidization action of a gasifying agent; introducing raw gas generated by the coal gasification reaction into a methane concentration unit, and performing methane concentration treatment in the presence of a first solid material containing a catalyst to makethe raw gas undergo a methanation reaction and a tar cracking reaction in order to obtain methane-rich raw gas and second solid material; and returning the second solid material into the gasifier, performing mixing and heat-exchanging on the second solid material and the coal dust in the fluidized bed reaction zone to provide heat for the coal gasification reaction of the coal dusts in the fluidized bed reaction zone, and discharging ash and slag generated in the coal gasification reaction to obtain a third solid material.

Owner:ENN SCI & TECH DEV

System and method for producing high-purity vanadium pentoxide through clean chlorination of vanadium resources

ActiveCN109835950AImprove chlorination selectivityEfficient separationEnergy inputVanadium oxidesCatalytic oxidationManganese

The present invention discloses a system and a method for producing high-purity vanadium pentoxide through clean chlorination of vanadium resources. According to the present invention, vanadium resources are subjected to granulation, oxidation, crushing, screening and other pretreatment processes, the pre-treated vanadium resources enter a chlorination furnace and are selectively chlorinated, thevanadium in the vanadium resources is converted into gaseous vanadium oxytrichloride, and most of impurities such as iron, chromium, calcium, phosphorus, manganese, titanium, silicon and the like in the vanadium resources are retained in the chlorinated residue so as to achieve the effective separation of vanadium and other impurities; the gaseous vanadium oxytrichloride is sequentially subjectedto dust removal, leaching, settlement, rectification purification, catalytic oxidation and other processes to prepare the high-purity vanadium pentoxide; the chlorinated residue is sequentially subjected to waste heat recovery, water washing dechlorination, settlement separation, filtering washing and other processes to obtain filter residue and a washing liquid, the filter residue returns to ironsmelting, and the washing liquid is subjected to evaporation crystallization to obtain a chlorine salt; and with the system and the method, the clean comprehensive utilization of vanadium resources is achieved while the sensible heat of the high temperature flue gas of the chlorination furnace and the high temperature chlorination residue is effectively utilized so as to achieve purposes of energy saving and consumption reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

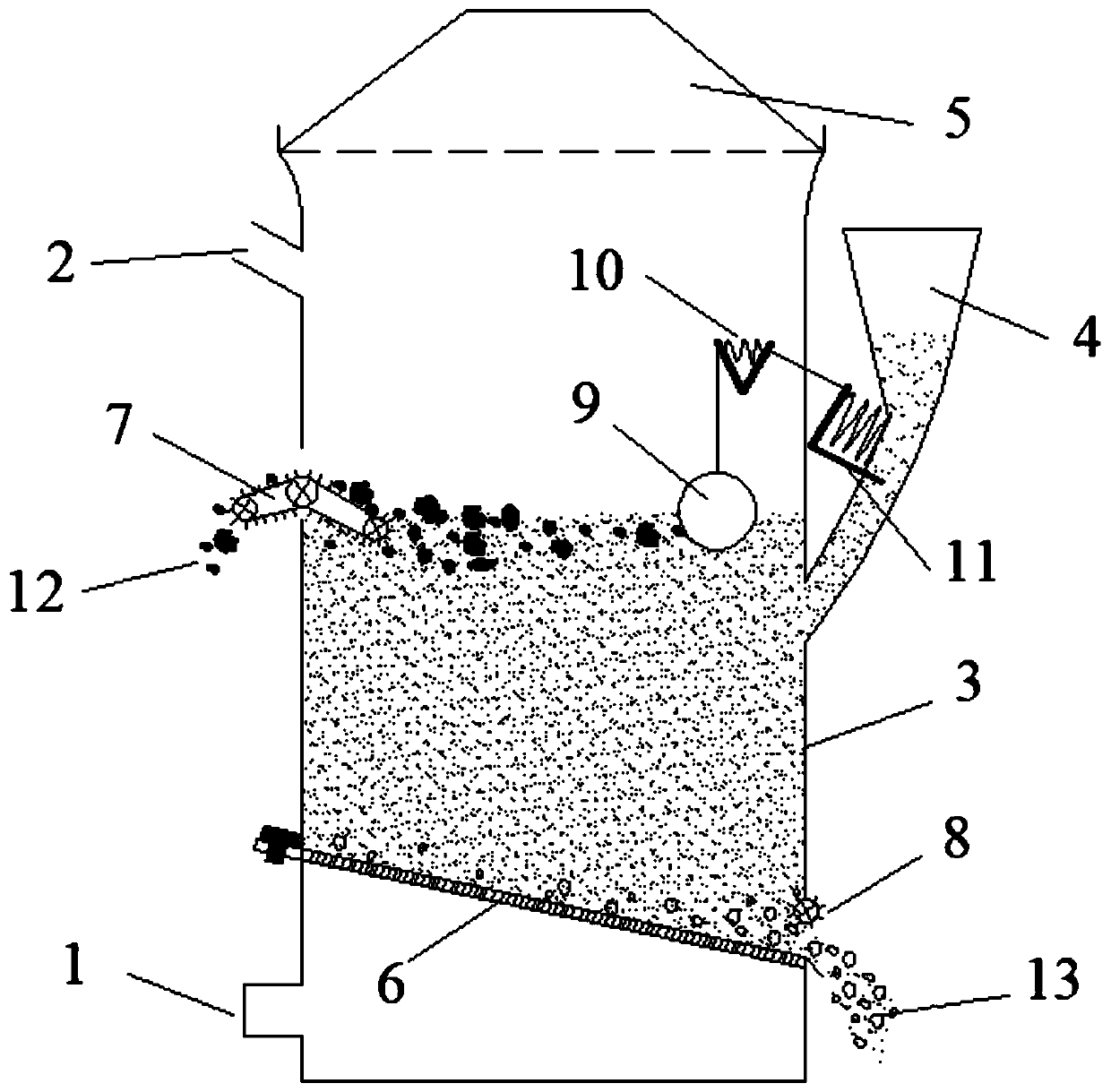

Fluidized bed sorting method and device for fine-grained coal sound field

The invention relates to a fluidized bed sorting method and device for a fine-grained coal sound field. The method and the device is suitable for dry coal selection operation in alpine area and arid water shortage area. The device is composed of an air inlet, an air outlet, a fluidized bed body, a material and medium feeding funnel, an acoustic wave generator, a gas distribution plate, a fine coalscraping plate, a material shifting wheel, a density automatic control assembly, a fine coal product and a gangue, wherein the acoustic wave generator is arranged at the top of a bed layer, the generated sound waves can reduce the acting force between fine particles, channeling and slugging can be effectively inhibited, the critical fluidization velocity is reduced, the fluidization quality of the particles is improved, a stable gas-solid two-phase separation fluidized bed is formed, the distribution plate is obliquely arranged at the bottom of the bed body and covered with two layers of filter cloth, the density automatic control assembly comprises a density ball, a V-shaped spring clamping rod and a valve, and can be used for effectively maintaining uniform and stable of density of thebed layer and improving the sorting precision of the fine-grained coal in the fluidized bed layer. The device is simple in structure, easy to operate and wide in practicability.

Owner:CHINA UNIV OF MINING & TECH

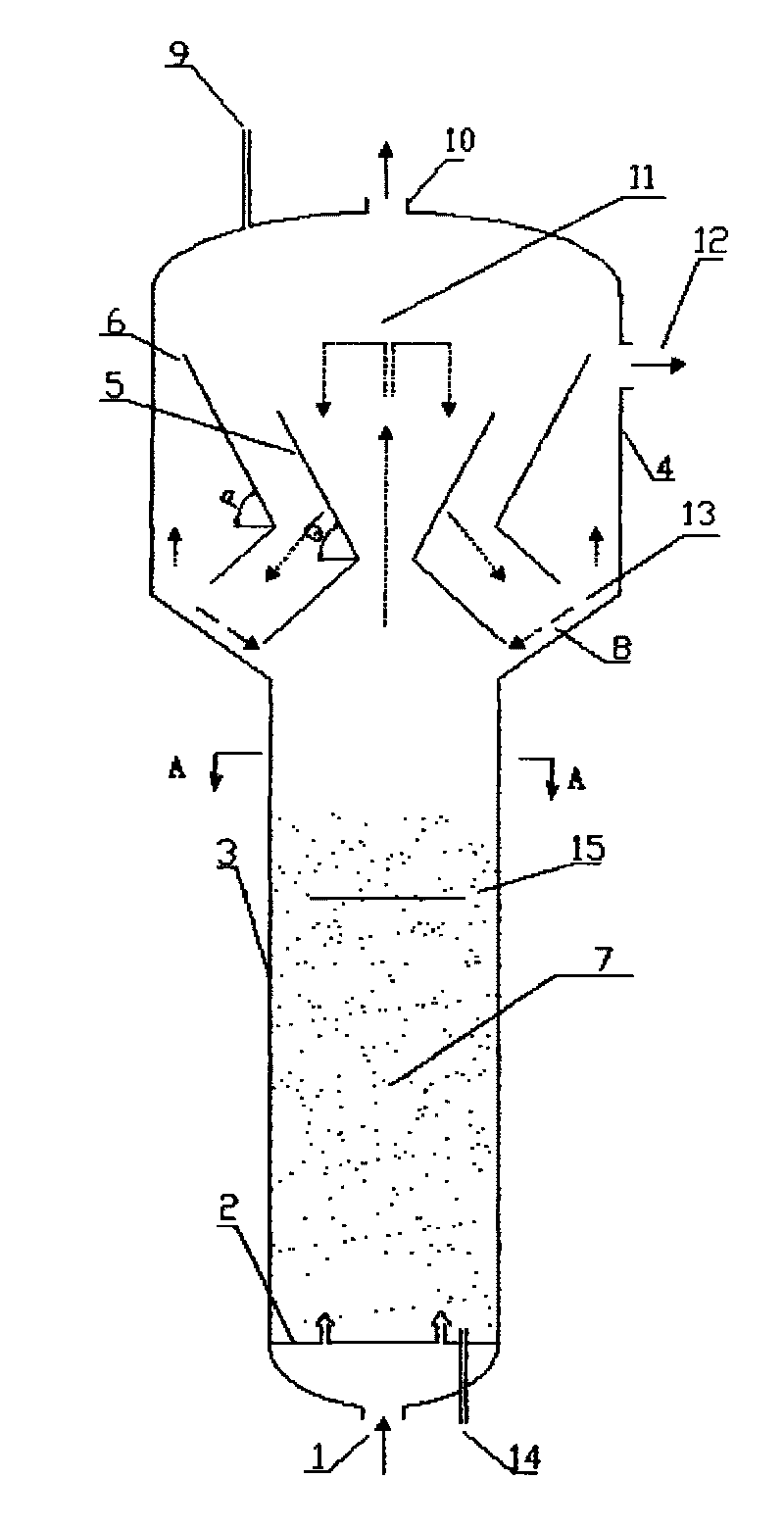

Fluidized bed reactor

ActiveCN101721961BGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

Owner:CHINA PETROLEUM & CHEM CORP +1

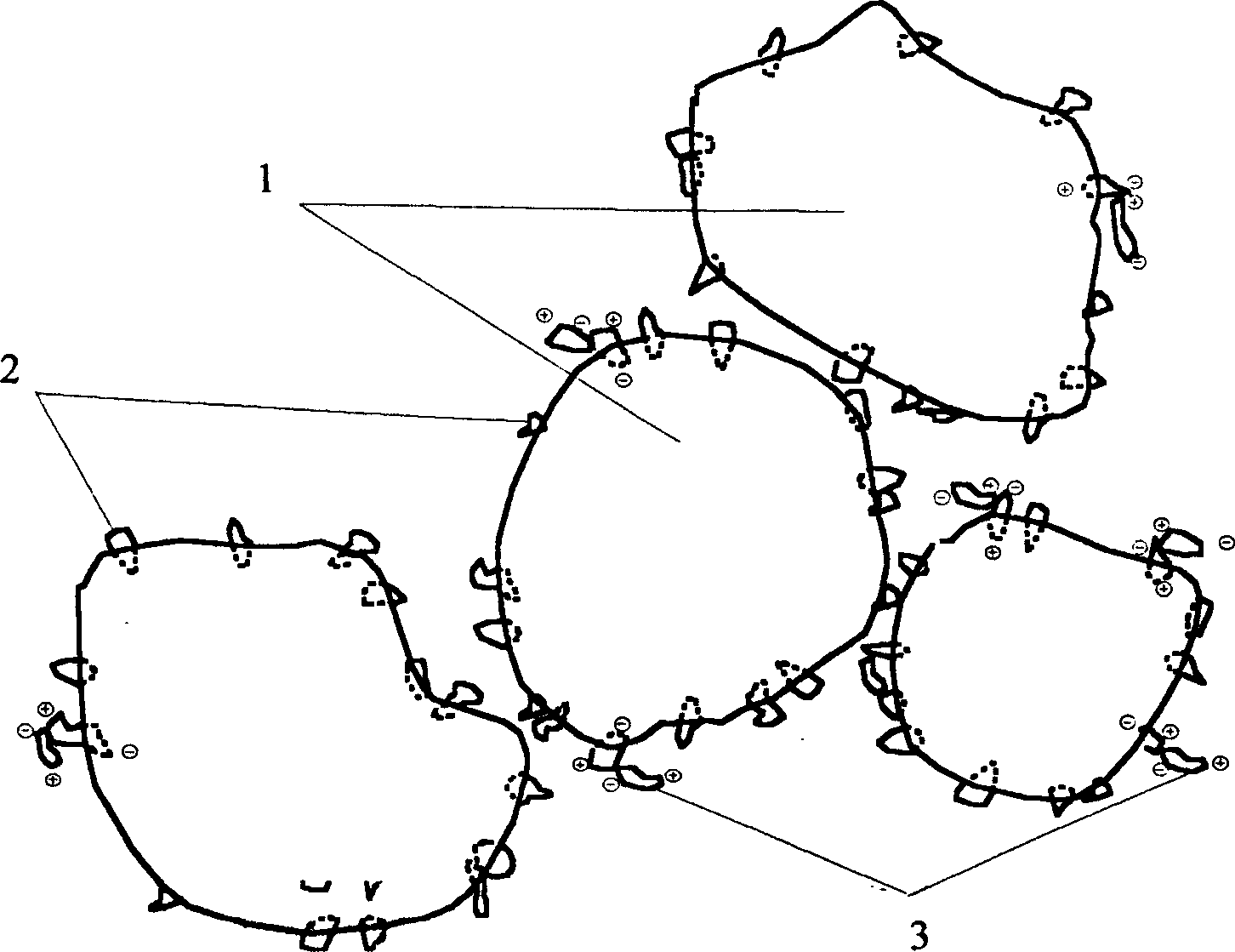

Method for controlling particles distribution by adopting electric field and gas phase polymerization fluidized bed reactor

The invention discloses a method for controlling particles distribution in a gas phase polymerization reaction system by adopting electric fields. The particles distribution is controlled by the application of the electric field including a first electric field and a second electric field whose directions are in parallel with the direction of gas flow, the first electric field and the second electric field being in opposite direction, so as to control the movement of particles, especially small particles, thereby realizing selective discharging and at the same time, decreasing entrainment of the small particles and reducing sizes of air bubbles. The invention also discloses a gas phase polymerization fluidized bed reactor to realize the method. The gas phase polymerization fluidized bed reactor comprises a base, a straight tube reaction section and a expansion section of a catalyst inlet arranged in the middle part of the reactor, one end of the straight tube reaction section being connected with the base, the other end of the straight tube reaction section being connected with the expansion section, the straight tube reaction section having a gas pre-distributor, a gas mixing chamber and a gas distribution plate arranged near a position where the base is arranged, a plurality of electrodes being arranged in the straight tube reaction section. The reactor capable of being realized easily, can break the air bubbles and improve fluidization quality.

Owner:ZHEJIANG UNIV

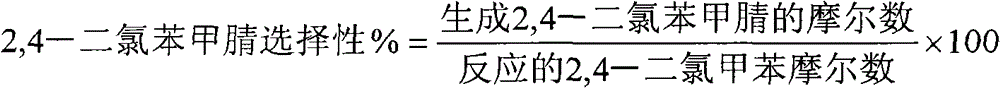

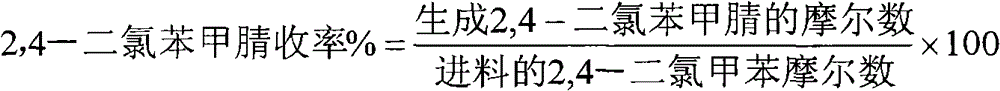

Method for ammoxidation preparation of 2,4-dichlorobenzonitrile

InactiveCN102746192AImprove wear resistanceExtend your lifePhysical/chemical process catalystsPreparation by hydrocarbon ammoxidationFixed bedReaction temperature

The invention relates to a method for the ammoxidation synthesis of 2,4-dichlorobenzonitrile to mainly solve problems of bad fluidization quality and low yield, or low yield and high production cost after using a fixed bed existing in fluidized bed reactors in present production technologies. The method which adopts 2,4-dichlorotoluene, ammonia and air as raw materials comprises a step that the raw materials contact and react with a catalyst in a fluidized bed under conditions that the raw material ratio of the 2,4-dichlorotoluene to the ammonia to the air is 1:2-10:4-40, the reaction temperature is 300-500DEG C, the reaction pressure is 0.01-0.1Mpa and the catalyst load (WWH) is 0.03-0.1h<-1> to generate the 2,4-dichlorobenzonitrile. The method well solves the problems and can be used for the industrial production of the ammoxidation synthesis of the 2,4-dichlorobenzonitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reactor of fluidized bed

InactiveCN1680012AEasy to handleAdjust the fluidized cross-sectional areaChemical/physical processesFluidized bedProduct gas

A fluidized-bed reactor is disclosed. A gas distributor is arranged between the lower conic body and gas predistributing chamber. The vertically arranged finger sleeve tube bank is symmetrically distributed above said distributor, and communicated with the heat exchanging medium inlet and outlet. The returned material and solid material feeding inlets are installed to said lower conic body. It has also the raw gas inlet, synthetic gas outlet, and heat exchanging medium inlet and outlet. Its advantage is the improved fluidizing quality.

Owner:ZHEJIANG UNIV

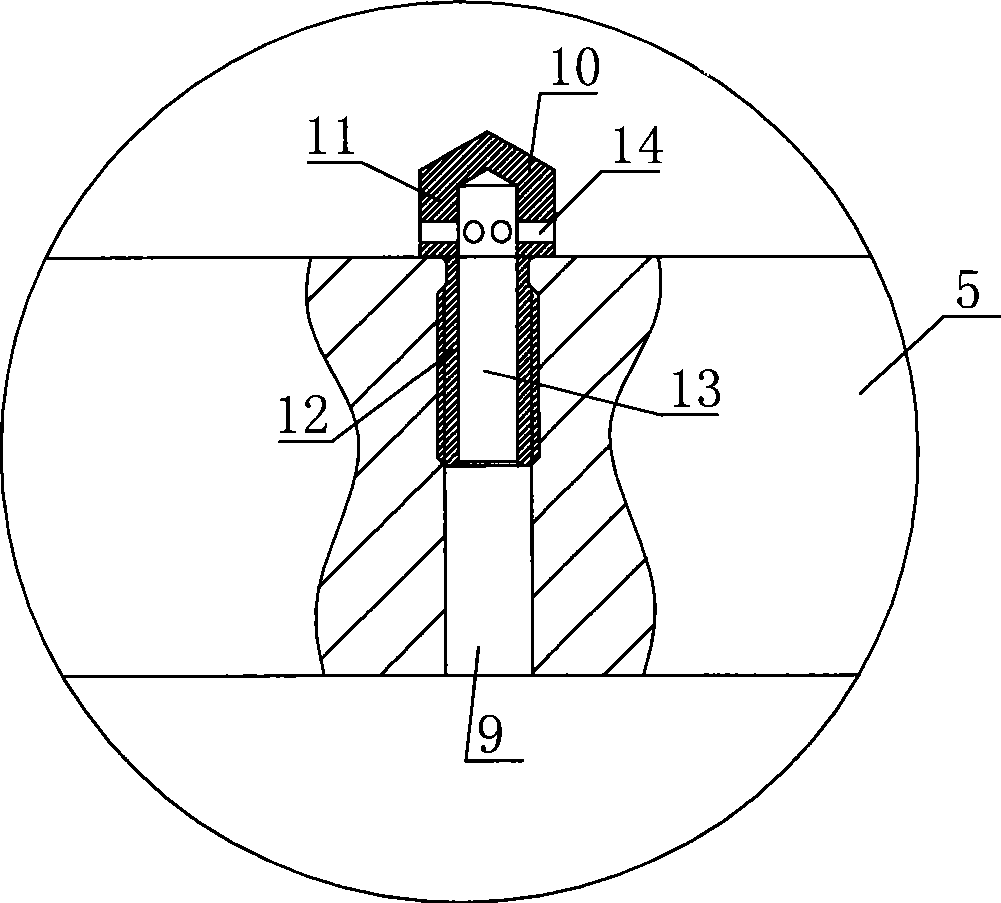

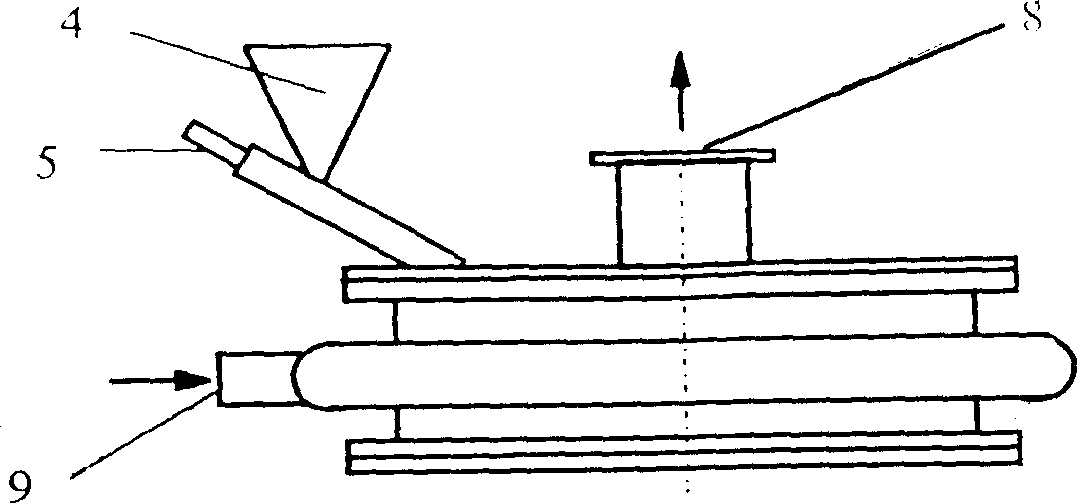

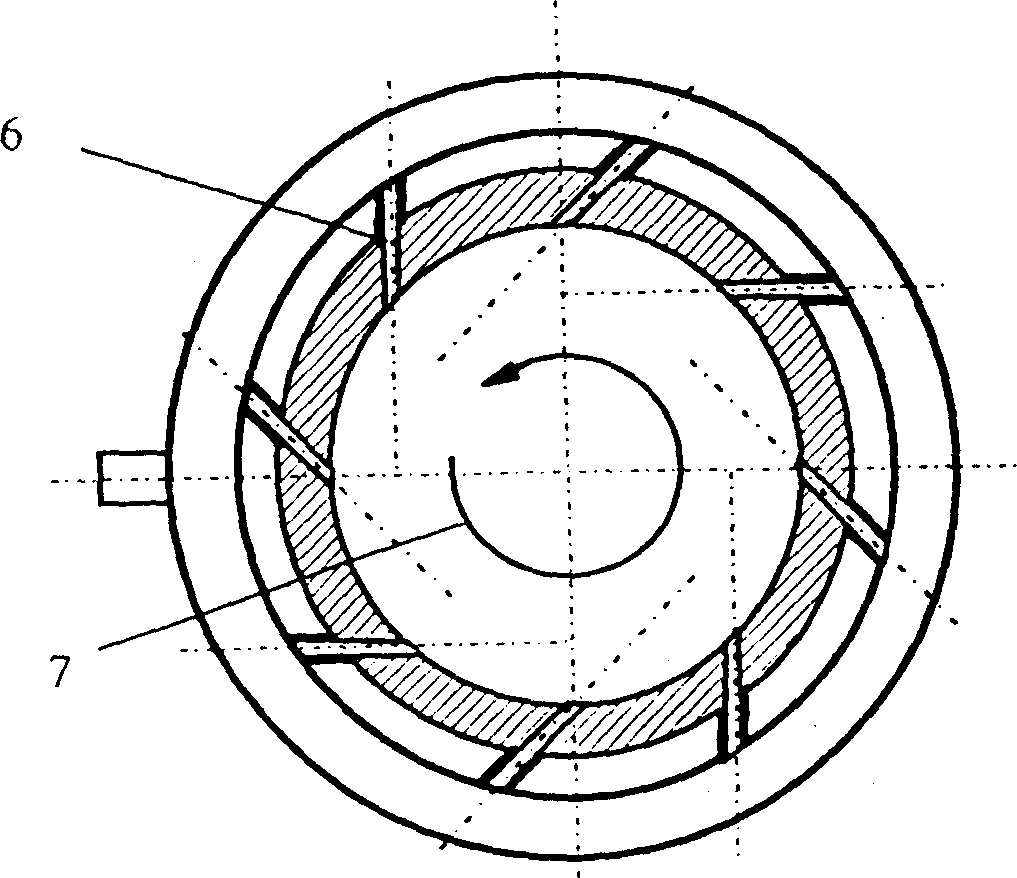

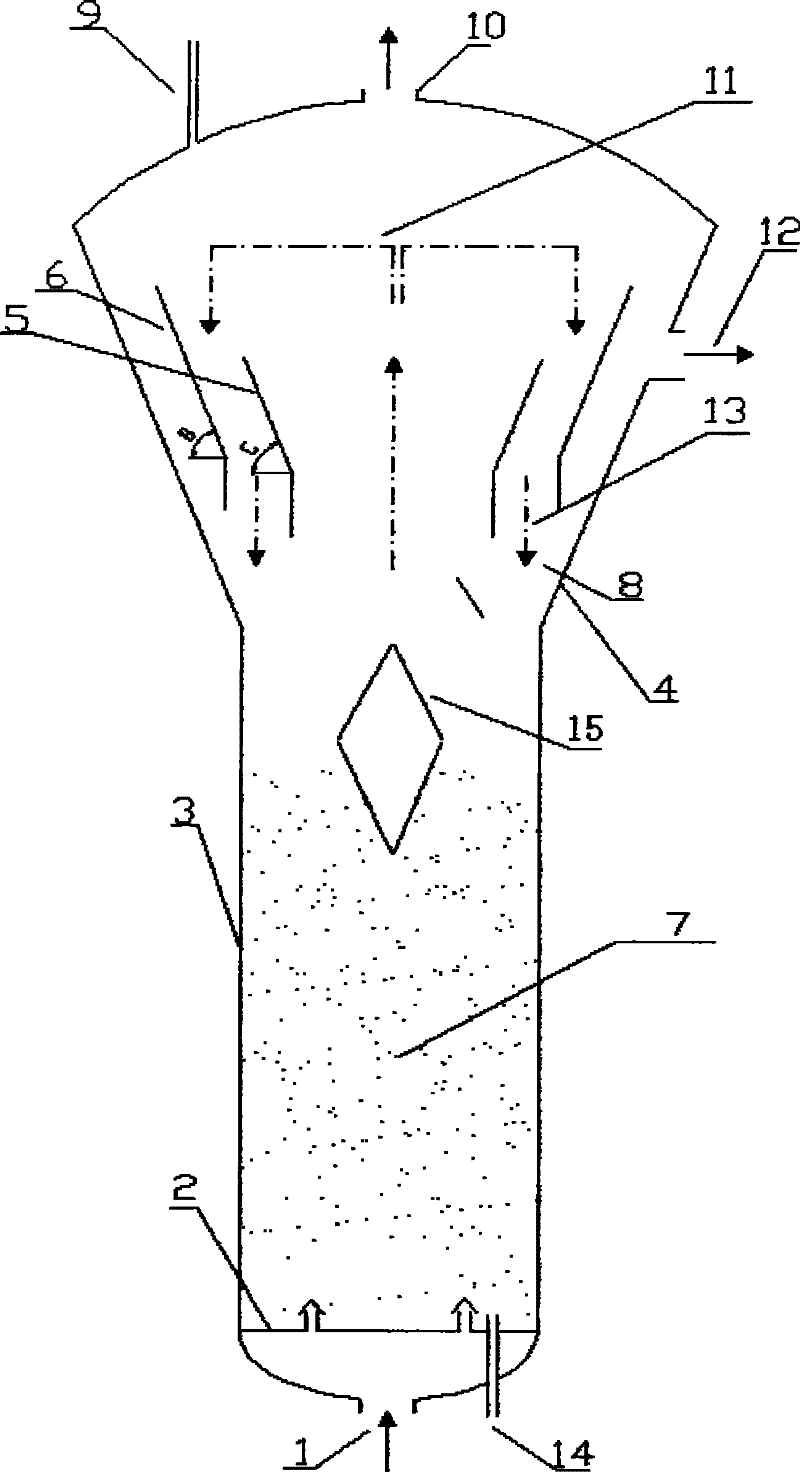

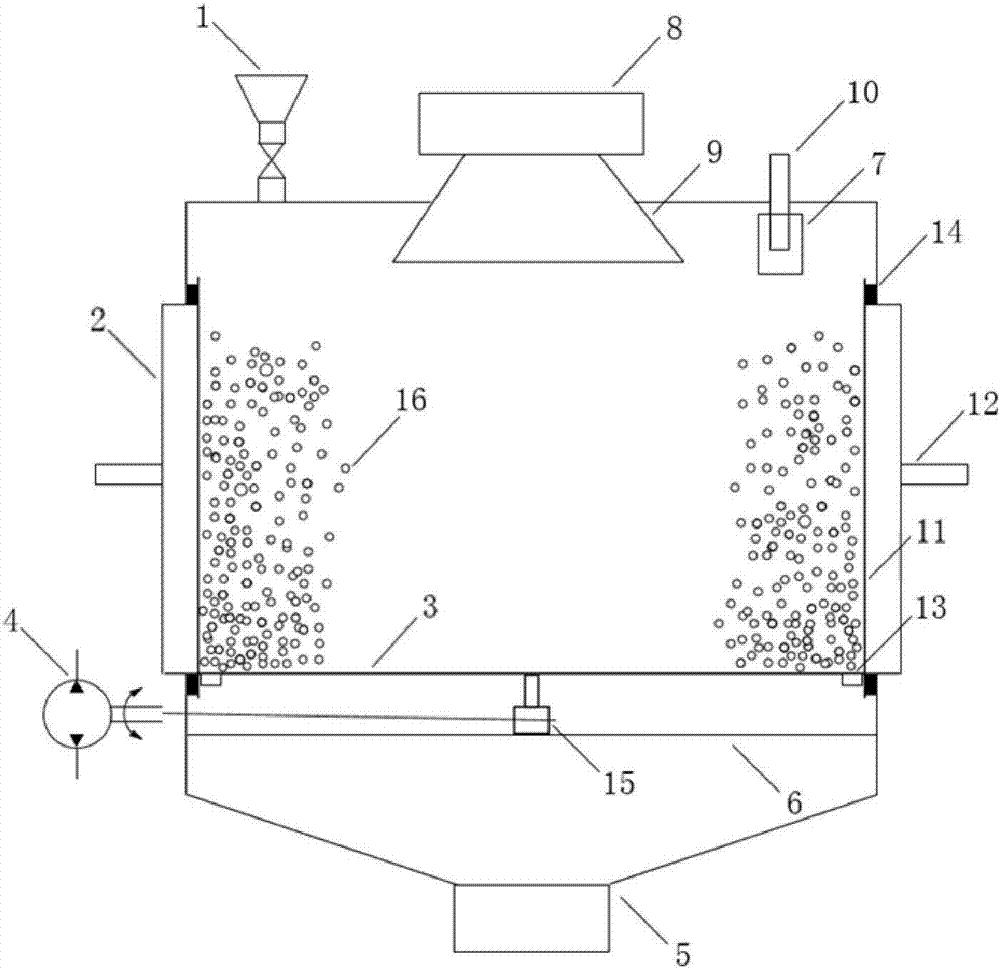

Device for cooperatively enhancing fluidization of nanoparticles by centrifugal field and sound field

InactiveCN106994322AOvercoming AdhesionGood fluidization behaviorEnergy based chemical/physical/physico-chemical processesBaghouseNanoparticle

The invention provides a device for cooperatively enhancing the fluidization of nanoparticles by a centrifugal field and a sound field. The device comprises a feeding hopper (1), an annular air inlet chamber (2), a centrifugal fluidized bed body (3), a stepping motor (4), a discharging hopper (5), a bed body supporting frame (6), a cloth bag dust collector (7), a sounder (8), a loudspeaker (9), an air outlet (10), an annular air distribution plate (11), an air inlet (12), an inner discharging hole (13), a sealing gasket (14) and a right-angle transmission gear box (15). According to the device provided by the invention, the fluidization of the nanoparticles is enhanced through the centrifugal field and the sound field, and abnormal fluidization phenomena including channeling, slugging even normal fluidization and the like of the nanoparticles in a fluidized bed can be effectively eliminated; an agglomeration-crushing process of particle agglomeration is enhanced and mixing between the particles is enhanced; the heat and mass transportation capability between the particles and a main body is improved; process application and amplification are easy to realize; the device has strong operation controllability and is stable to operate.

Owner:SOUTHEAST UNIV

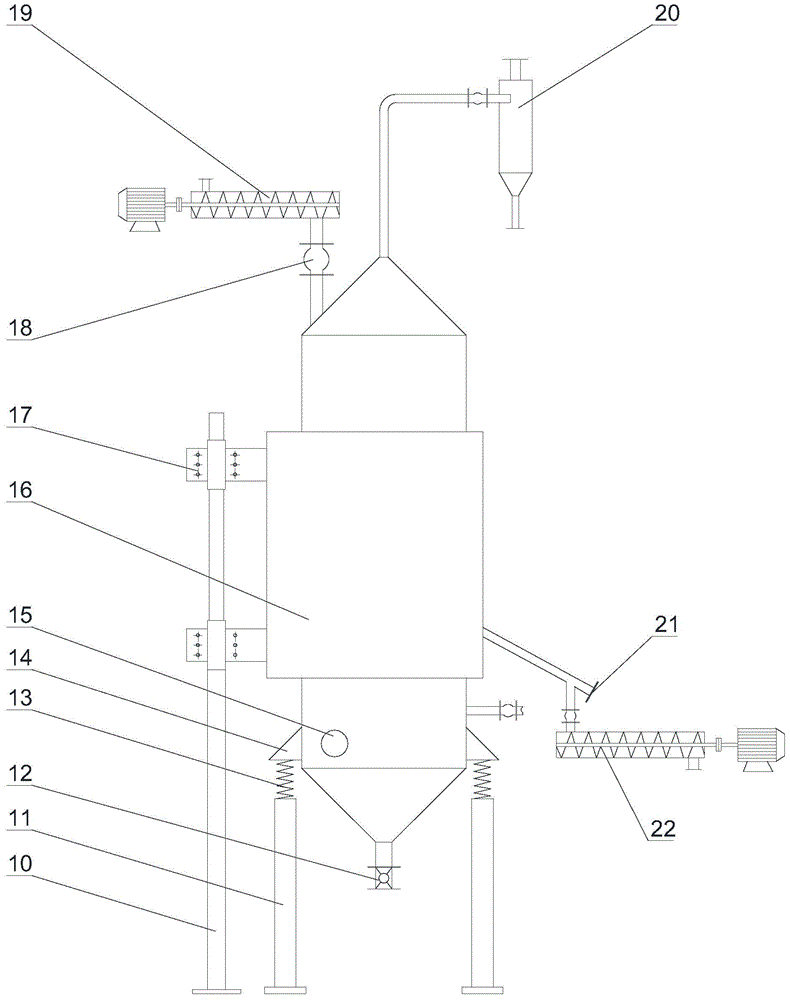

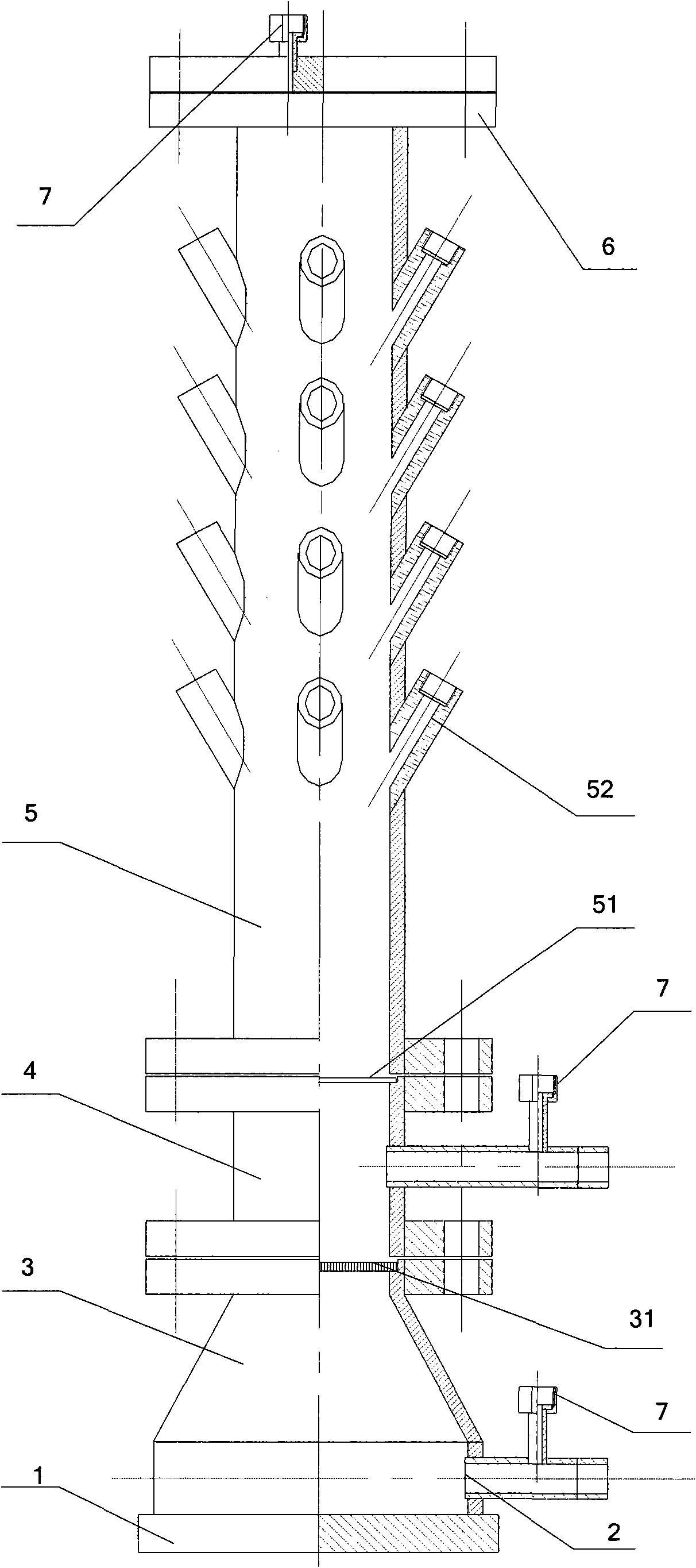

Aromatic hydrocarbon ammoxidation combined fluidized bed reaction device and aromatic hydrocarbon ammoxidation combined fluidized bed reaction method

ActiveCN111111562AHigh yieldAvoid oversupplyPreparation by hydrocarbon ammoxidationChemical recyclingPtru catalystFluidized bed

The invention relates to an aromatic hydrocarbon ammoxidation combined fluidized bed reaction device and an aromatic hydrocarbon ammoxidation combined fluidized bed reaction method. In the prior art,the heat regulation range in the reactor of the existing device is small, the heat collector cannot be repaired on line to keep production after being abraded, the ammonia ratio is large, the air ratio is large and the raw material utilization rate is low. A purpose of the invention is mainly to solve the problems in the prior art. The invention discloses an aromatic hydrocarbon ammoxidation combined fluidized bed reaction device and a reaction method thereof. According to the technical scheme, aromatic hydrocarbon / ammonia is vaporized and then enters a reactor together with air from a gas distribution chamber, an aromatic hydrocarbon ammoxidation reaction is carried out under the action of a catalyst, heat released in the reaction process is brought into an oxygen supply heat exchanger through the catalyst, efficient heat exchange is carried out under the action of a strong mixing member while catalyst lattice oxygen supplementing treatment is carried out, and then the low-temperaturehigh-lattice-oxygen catalyst circularly returns into the reactor to continuously participate in the aromatic hydrocarbon ammoxidation reaction. By adopting the technical scheme, the technical problems are well solved. The device and the method can be used in production of aromatic nitrile by aromatic ammonia oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

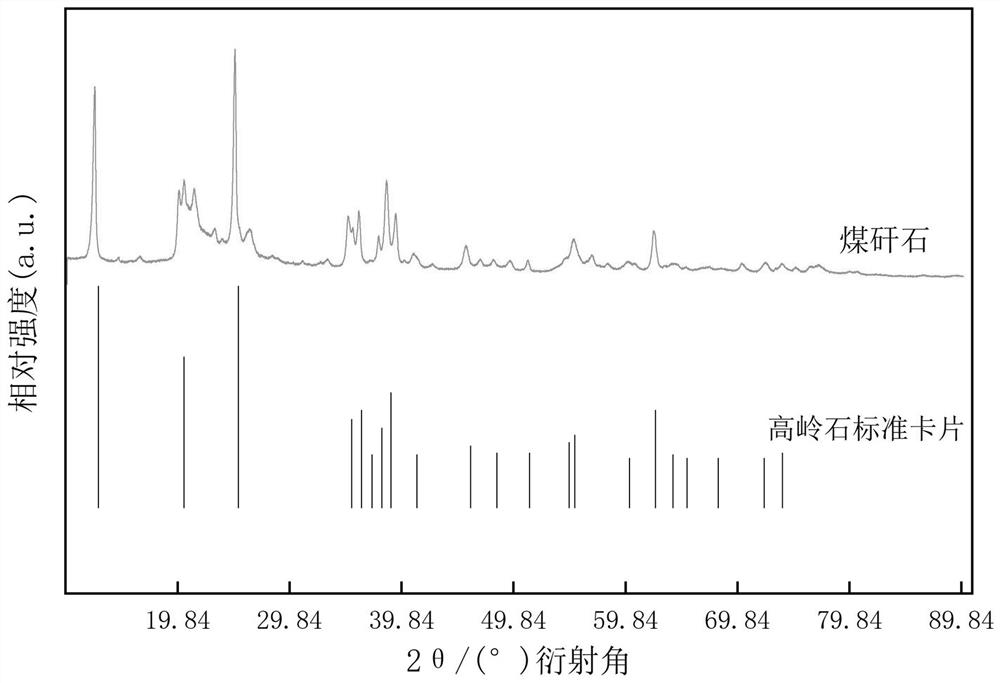

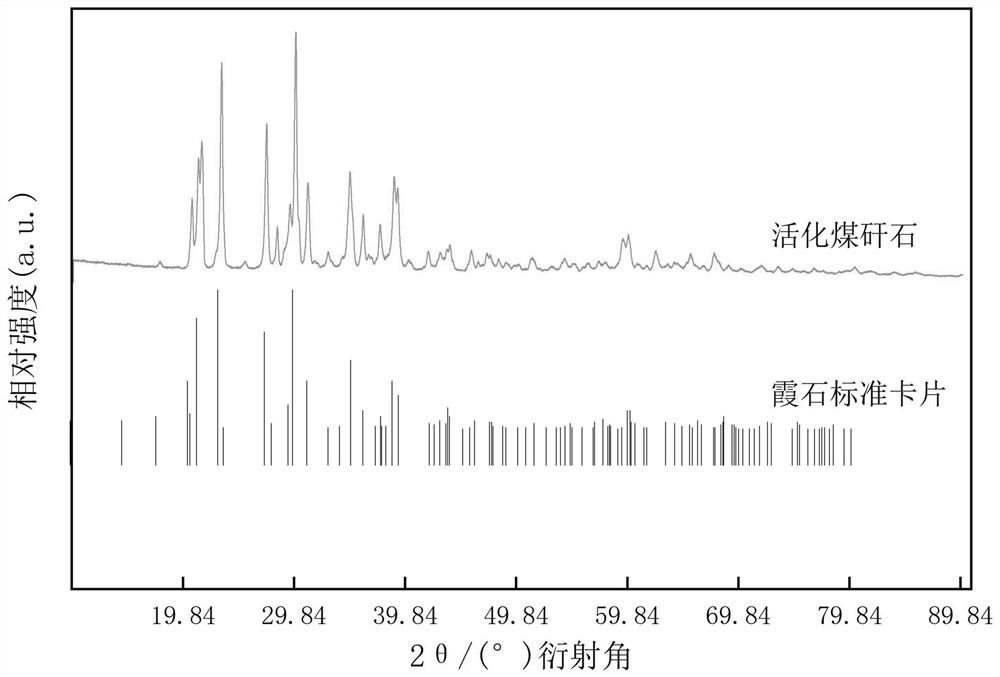

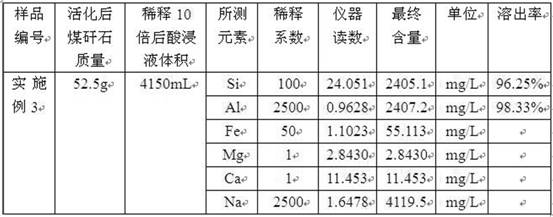

Method for extracting silicon and aluminum by activating coal gangue through plasma ball milling and vibration fluidization calcination

ActiveCN113213482AWell mixedImprove ball milling efficiencyProcess efficiency improvementSilicon compoundsSilicon oxideAluminium oxides

The invention belongs to the technical field of extraction of silicon and aluminum elements by activating coal gangue, and particularly relates to a method for extracting silicon and aluminum by activating coal gangue through plasma ball milling and vibration fluidization calcination, wherein the method comprises the steps: firstly, carrying out plasma ball milling treatment on a mixture of coal gangue and solid alkali to achieve the purposes of fully mixing and refining the coal gangue; meanwhile, mechanical pre-activation of the coal gangue can be achieved, then the coal gangue is calcined in the mode that air is introduced into the coal gangue solid powder to achieve solid fluidization, activation of the coal gangue can be achieved at the temperature lower than the traditional static calcination temperature, energy consumption in the coal gangue activation process is effectively reduced, and filtering and separating are carried out to obtain a silicon-aluminum mixed solution. The activation effect achieved at the temperature lower than the traditional static calcination activation temperature can reach the traditional static activation level, and the dissolution rate of aluminum oxide and silicon oxide is ideal.

Owner:TAIYUAN UNIV OF TECH

Two-tier fluidized bed

InactiveCN104482721AImprove heat utilizationAvoid uneven heatingDrying solid materials with heatDrying gas arrangementsFluidized bedEngineering

The invention discloses a two-tier fluidized bed comprising an upper part, a lower part, an air inlet and an air outlet. A distributing plate for holding material is transversely arranged in each of the upper part and the lower part. The air inlet is disposed on the sidewall of the lower part below the distributing plates. The air outlet is disposed above the upper part. A vortex guide plate is disposed at the air inlet. Each distributing plate is provided with air holes which are staggered. The vortex guide plate allows hot air, entering the bed, to be diverted along the vortex guide plate, and thus, the problem of uneven heating caused by direct blow of the hot air is avoided, heat utilization rate of the bed is increased and drying efficiency is good; the bed is simple in structure, convenient to mount, easy to maintain and cost saving.

Owner:林国友 +2

Fluidized bed gasification reaction method and reactor employing packed fuel

InactiveCN102002399AEasy to storeSmall footprintGranular/pulverulent flues gasificationProcess engineeringBubbling fluidized bed

The invention relates to a fluidized bed gasification reaction method and a reactor employing packed fuel, and belongs to the field of gasification utilization of biomass energy. In the device, rich biomass straw resources in China are packed to serve as gasification raw materials, the packs are scattered by a front-furnace scattering device for feeding, and the problem that the conventional auger feeding equipment is easily damaged. By adopting low-true density porcelain granule sand as bed materials, the problem of easy slagging of the traditional quartz sand bed materials is effectively solved. The gasification reactor is a bubbling fluidized bed, is low in fluidizing velocity and effectively reduces the combustible ratio in fly ash. By adopting the expanded design, a gasification reactor body can reduce a fluidized dead zone of the bed materials, accelerate the bed materials to form an inner cycle and improve the fluidization quality. Therefore, the high-efficiency utilization of biomass straws is realized, and the device can be used as an ideal device for combining pulverized-coal fired boilers with biomass in future.

Owner:GUODIAN CHANGYUAN ELECTRIC POWER CO LTD +1

Fluidized-bed reaction device and fluidization reaction method for hydrogenation of nitrobenzene

ActiveCN111298727AImprove fluidization qualityReduce air bubblesOrganic compound preparationAmino compound preparationNitrobenzeneCatalytic hydrogenation

The invention relates to a fluidized-bed reaction device and a fluidization reaction method for hydrogenation of nitrobenzene. The invention mainly aims to solve the problems of low gas-solid contactefficiency, large bubble size, low fluidization quality and the like in a fluidized bed. According to a technical scheme in the invention, at least one group of composite components are arranged in afluidized-bed reactor, so when gas and catalyst particles pass through the components, bubbles and particle clusters are broken, fluidization quality is effectively improved, and the above technical problems are well solved; and the device and the method can be applied to industrial production of gas-phase catalytic hydrogenation of nitrobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized bed reactor for producing trichlorosilane

InactiveCN104045088AEliminate potential safety hazardsReduce energy consumptionHalogenated silanesProduction rateFluidized bed

The invention discloses a fluidized bed reactor for producing trichlorosilane. The fluidized bed reactor comprises a reactor main body, wherein the reactor main body comprises a gas distribution section positioned at the lower part; the gas distribution section, a maintenance seal head, a reaction section and an expanding section are internally communicated with one another; the gas distribution section comprises a gas inlet pipeline, a gas distributor arranged in the gas inlet pipeline, and a silicon tetrachloride inlet and a hydrogen chloride inlet formed in the gas inlet pipeline; the reaction section comprises a gas reaction pipeline and a cooling water jacket coating the gas reaction pipeline; the expanding section comprises a gas synthesis pipeline and a synthesis gas outlet formed in the top of the gas synthesis pipeline; the maintenance seal head is connected with a material supply pipeline. The fluidized bed reactor for producing trichlorosilane, disclosed by the invention, can be used for improving the fluidized bed reactor, further removing potential safety hazards in the production process of trichlorosilane, improving the one-time conversion rate of hydrogen chloride, improving the production rate of trichlorosilane, and reducing the silicon consumption.

Owner:SHAANXI TIANHONG SILICON IND

Hood strengthening device of circulating fluidized bed

InactiveCN105485671AAvoid investmentImprove fluidization qualityFluidized bed combustionApparatus for fluidised bed combustionCooling pipeTuyere

The invention discloses a hood strengthening device of a circulating fluidized bed, and relates to the technical field of hood devices of circulating fluidized beds. The hood strengthening device comprises an operation furnace, a secondary air inlet, a feeding port, cooling pipes, an air distributing plate, hoods and a slagging port. The feeding port is formed in the left side of the operation furnace. The secondary air inlet is formed above the feeding port. The air distributing plate is arranged at the bottom of the operation furnace. The cooling pipes are arranged in the air distributing plate. The slagging port is formed in the middle of the air distributing plate and penetrates the bottom of the operation furnace. The air distribution plate is provided with the hoods. The huge input for the improvement of the fluidized bed and several months of construction are avoided, the work loadloads of dismounting castable and machining and installing novel hoods is are directly omitted, the field construction and improving flexibility is improved, equipment maintaining costs are reduced, and the fluidization quality of a boiler is greatly improved.

Owner:枣庄矿业(集团)有限责任公司蒋庄煤矿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com