Surface modifying method for superfine paint powder

A technology of surface modification and paint powder, which is applied to the device and coating of the surface coating liquid, which can solve the problems of poor fluidity, inability to realize spraying, difficult fluidization, etc., to eliminate the agglomeration effect and avoid the defects of the sprayed coating , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

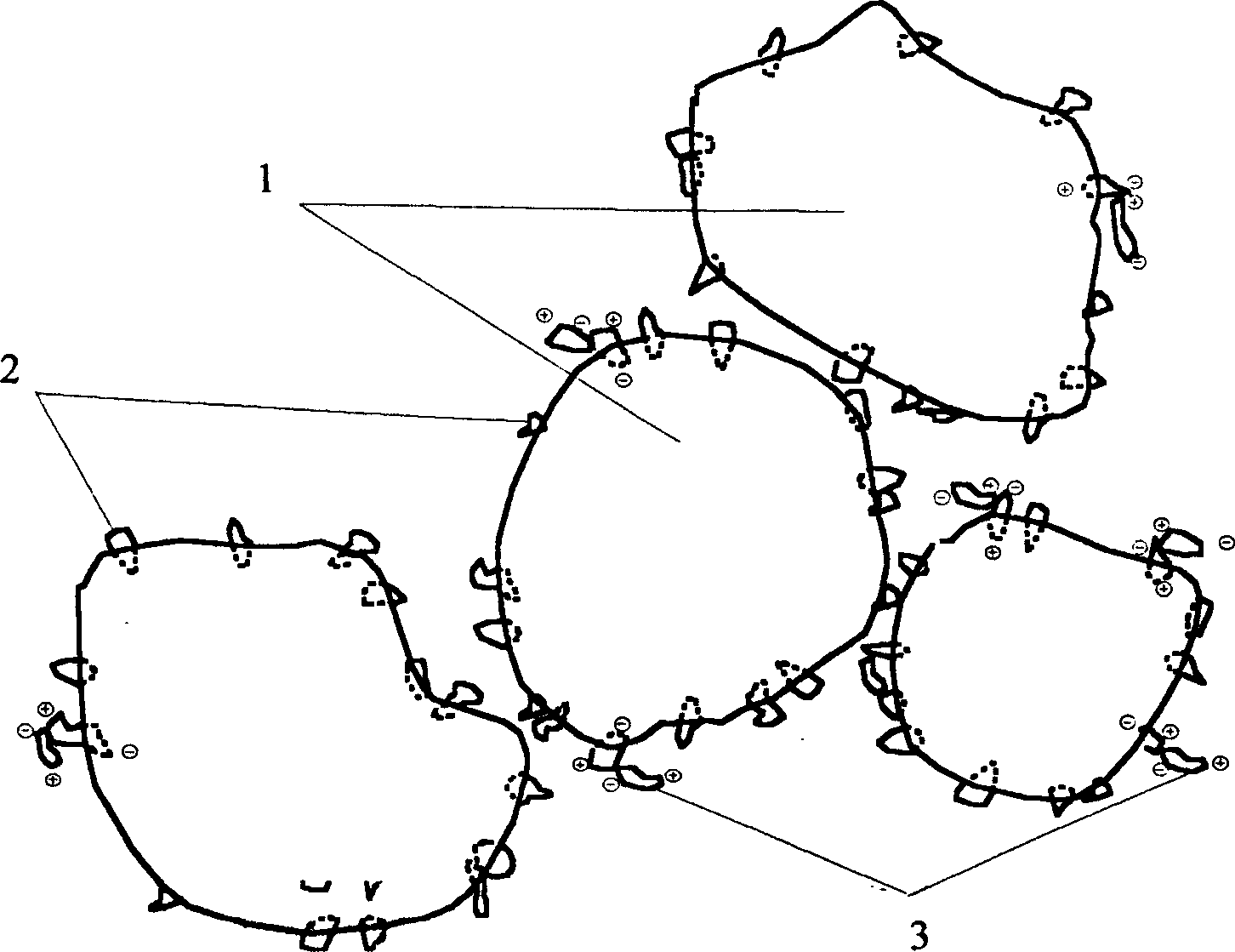

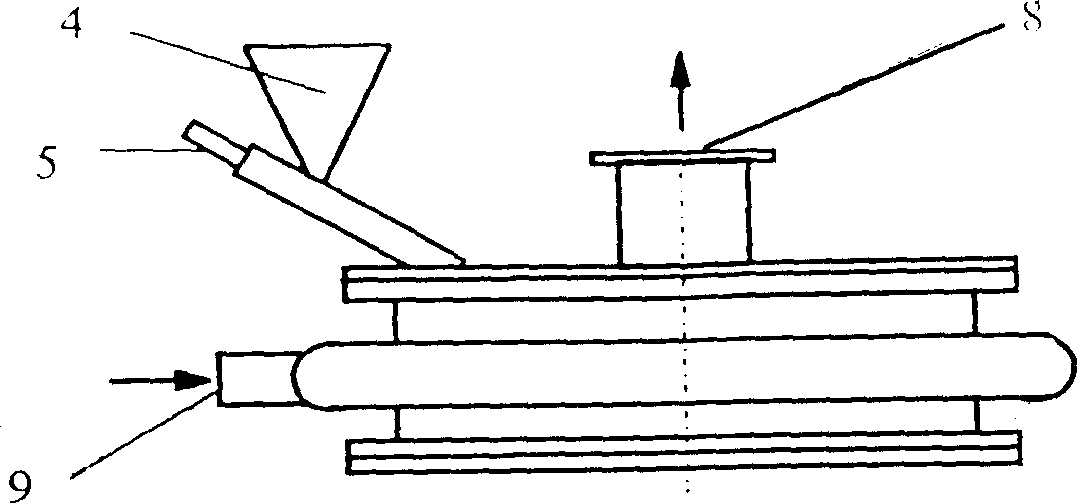

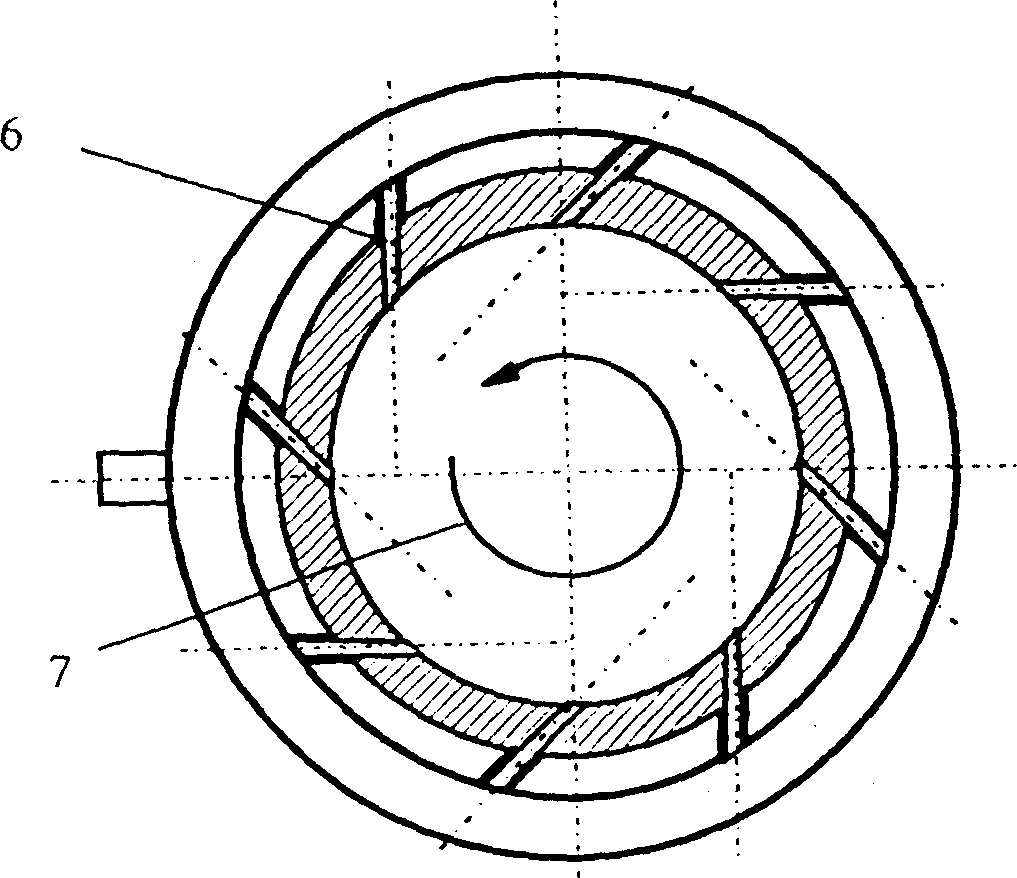

[0034] figure 2 , 3 , 4, and 5 are schematic diagrams of the three most common jet mills widely used in the powder industry. figure 2 , 3 It is a flat jet mill. The material to be crushed enters through the feeding port (4), is accelerated to supersonic speed through the Venturi pushing nozzle (5) and is introduced into the crushing chamber (7). At the same time, the high-pressure airflow is sprayed into the crushing chamber from the compressed air inlet (9) through the crushing airflow nozzle (6) at a speed of hundreds of meters or even thousands of meters per second. Since the crushing air nozzle and the radius of the crushing chamber form an acute angle, the high-speed airflow ejected from the nozzle exerts a very high drag force on the particles, pushing the particles to rotate in a circular motion, resulting in strong collision and friction between the particles and between the particles and the wall of the crushing chamber. smash. The pulverized particles are entr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com