Fluidized bed reactor and inner constructional elements thereof

A technology for fluidized bed reactors and internal components, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as uneven radial distribution of solid particles, unsatisfactory gas-solid contact reaction efficiency, etc., to achieve Improve the fluidization quality, increase the contact rate, and increase the effect of cross-sectional particle concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The implementation of the present application will be described in detail below in conjunction with the drawings and examples, so that the realization process of how the present application uses technical means to solve technical problems and achieve technical effects can be fully understood and implemented accordingly.

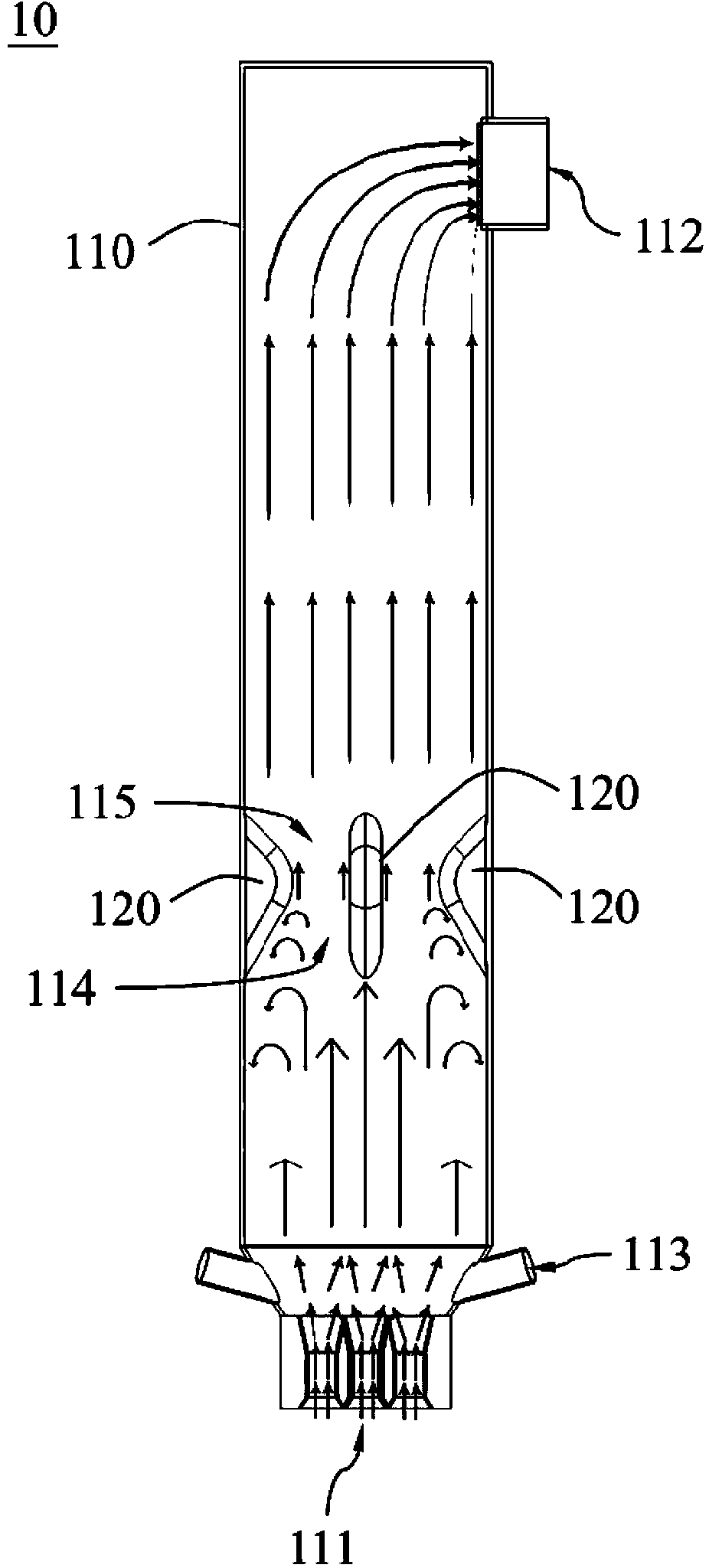

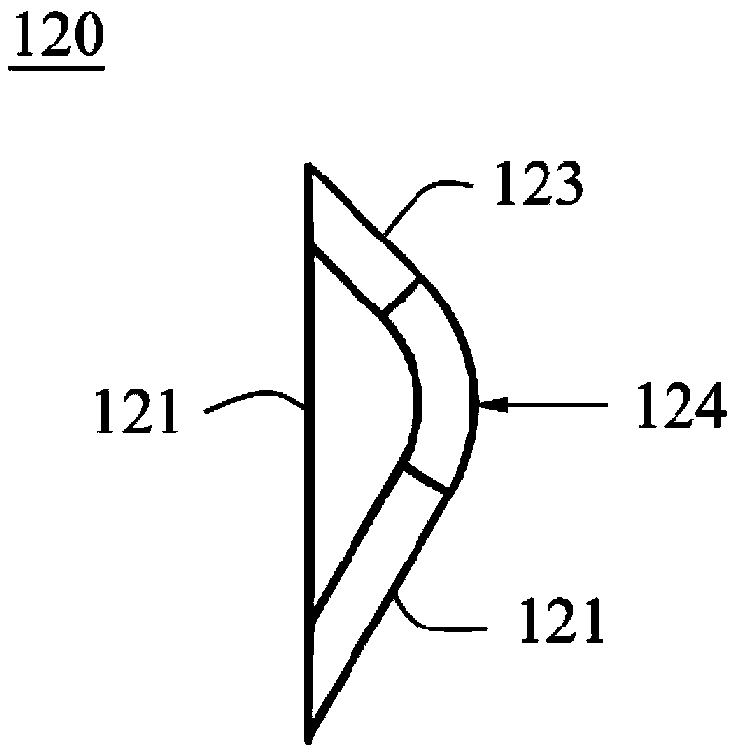

[0011] Please refer to figure 1 and figure 2 , The fluidized bed reactor 10 disclosed in an embodiment of the present application includes a tower 110 and a plurality of internal components 120, the tower 110 has an air inlet 111, an exhaust port 112 and a feed inlet 113, The air inlet 111 and the air outlet 112 are respectively arranged at opposite ends of the tower 110 , and the feed inlet 113 is arranged on a side of the tower 110 adjacent to the air inlet 111 . A plurality of internal members 120 are arranged at intervals in the tower 110 along the circumferential direction of the tower 110 . On the inner wall surface, the contact surface 122 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com