I-Doped BiOClBr photocatalyst and preparation method thereof

A photocatalyst and catalyst technology, applied in the field of photocatalytic materials, can solve the problems of low utilization rate of visible light, etc., and achieve the effect of neat stacking structure, orderly structure and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

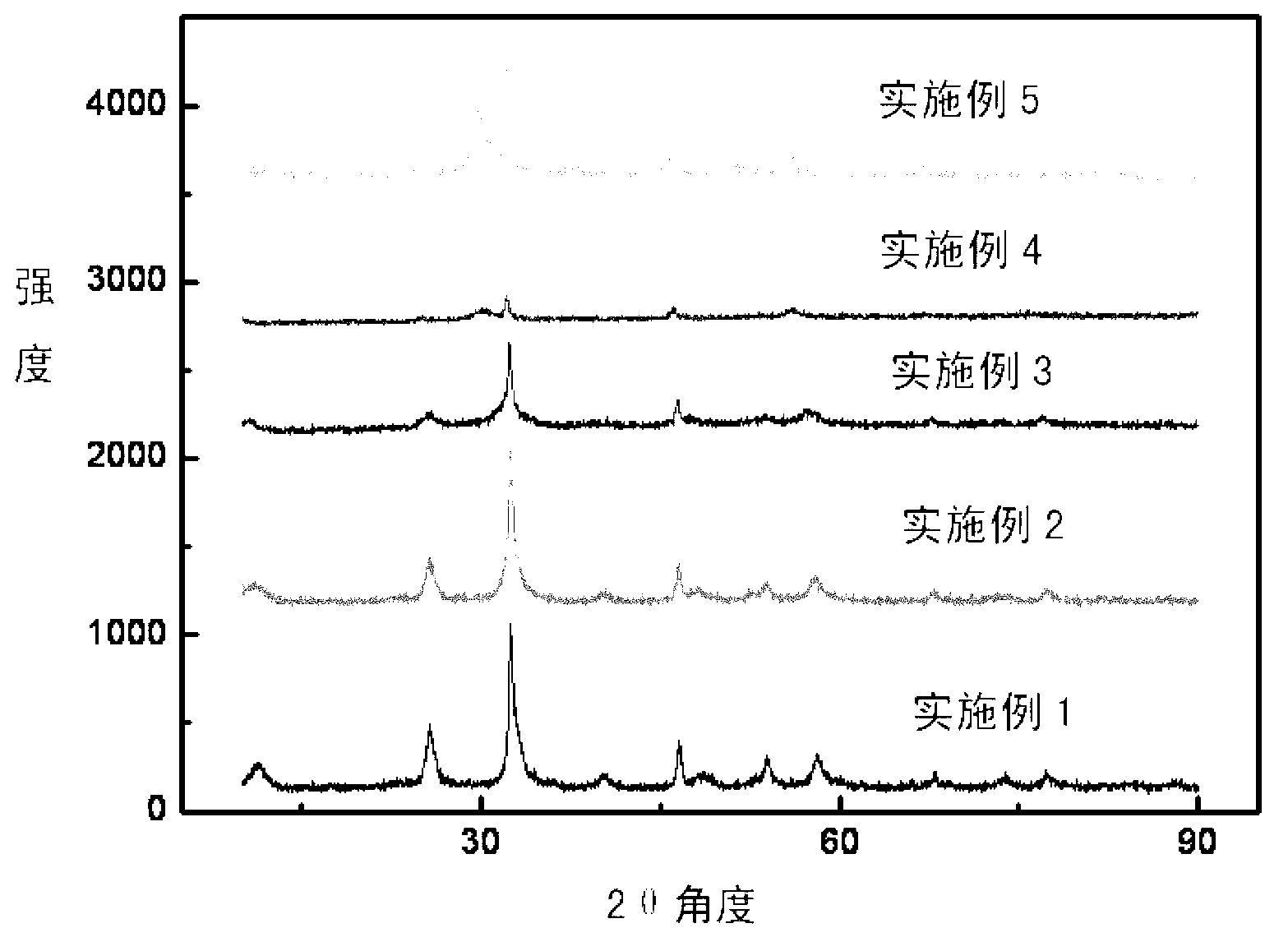

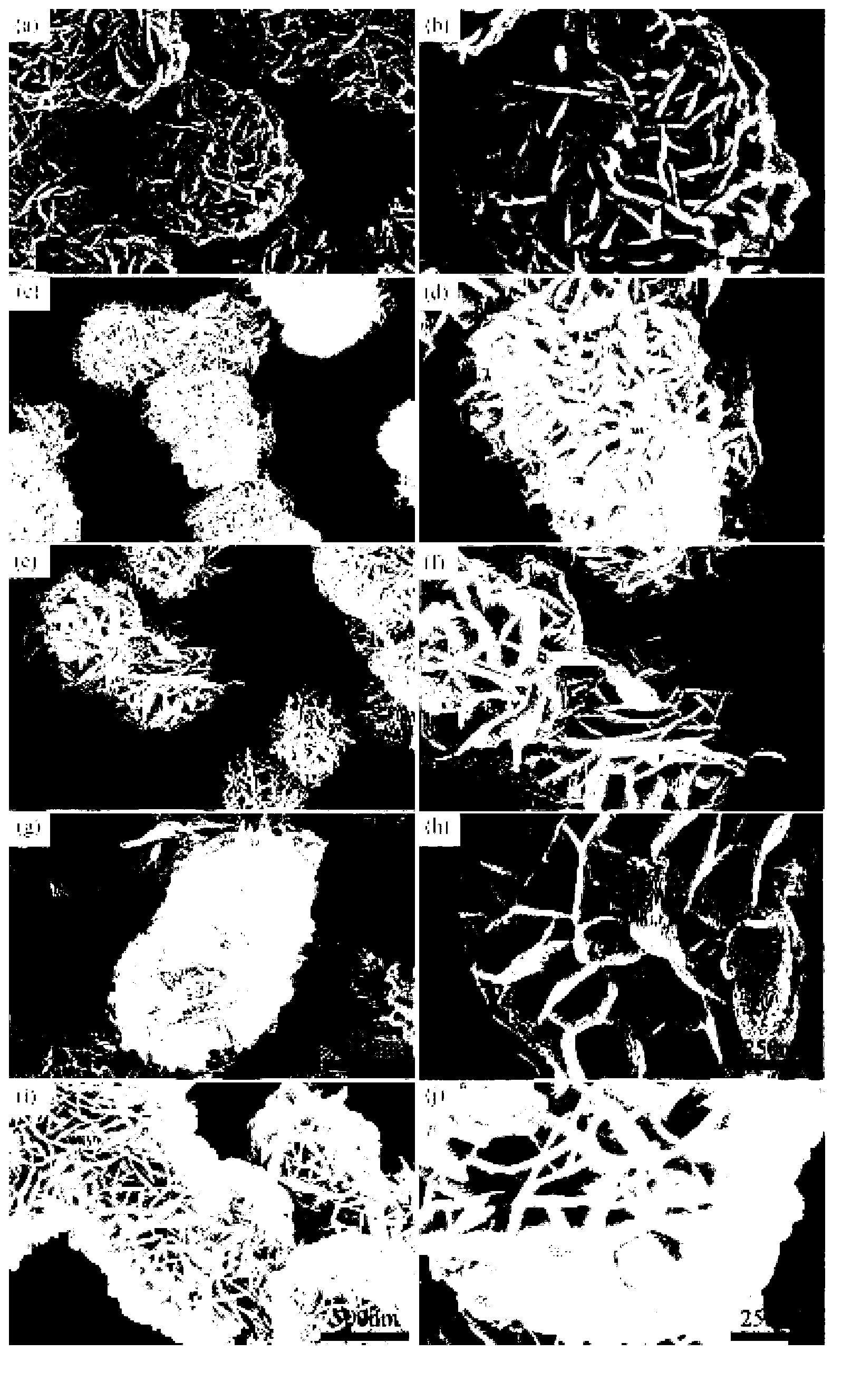

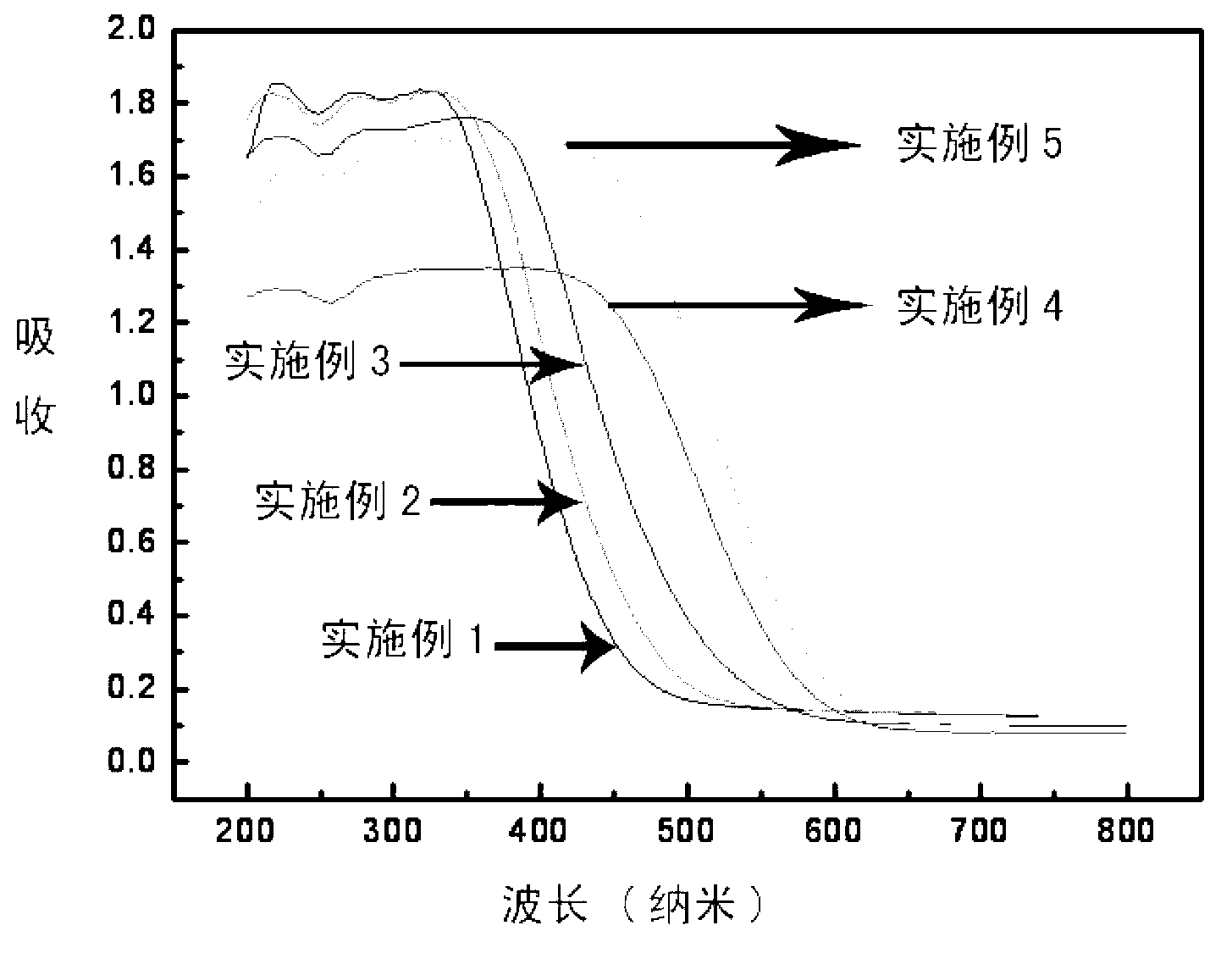

[0030] The preparation method of the BiOClBr photocatalyst with three-dimensional structure doping I: measure 60mL ethylene glycol solution, weigh Bi(NO) 3 2g, KCl0.5g, NaBr0.5g, KI0.5g, the weighed Bi(NO) 3, KCl, NaBr and KI were dissolved in ethylene glycol solution, stirred for 30 minutes, transferred the prepared solution to a polytetrafluoroethylene-lined autoclave, and reacted at 170°C for 8 hours. After the autoclave was cooled, the precipitate The sample was centrifuged and washed several times with absolute ethanol and distilled water, and the prepared sample was dried in a vacuum oven at 60 °C for 3 h to obtain the I-doped BiOClBr photocatalyst.

[0031] The photocatalytic performance test of the I-doped BiOClBr photocatalyst obtained by the above preparation method: put the above-mentioned 20 mg I-doped BiOClBr solid solution into 200 mL of 7.5 ppm RhB solution, firstly carry out 30 min of dark state adsorption, until the adsorption equilibrium, in the dark During ...

Embodiment 2

[0033] The preparation method of the BiOClBr photocatalyst with three-dimensional structure doping I: measure 65mL ethylene glycol solution, weigh Bi(NO) 3 2g, KCl0.375g, NaBr0.375g, KI0.75g, Bi(NO) 3 Dissolve it with KCl, NaBr, and KI into the ethylene glycol solution, and stir for 30 minutes. The prepared solution was transferred to a Teflon-lined autoclave, and reacted at 170°C for 9 hours. After the autoclave was cooled, the precipitate was centrifuged and washed several times with absolute ethanol and distilled water. The prepared The sample was dried in a vacuum oven at 60°C for 4 h to obtain the I-doped BiOClBr photocatalyst.

[0034] The photocatalytic performance test of the I-doped BiOClBr photocatalyst obtained by the above preparation method: put the above-mentioned 20 mg I-doped BiOClBr solid solution into 200 mL of 7.5 ppm RhB solution, firstly carry out 30 min of dark state adsorption, until the adsorption equilibrium, in the dark During the state adsorption p...

Embodiment 3

[0036] The preparation method of the BiOClBr photocatalyst with three-dimensional structure doping I: measure 70mL ethylene glycol solution, weigh Bi(NO) 3 2g, KCl0.3g, NaBr0.3g, KI0.6g, Bi(NO) 3 Dissolve it with KCl, NaBr, and KI into the ethylene glycol solution, and stir for 30 minutes. The prepared solution was transferred to a polytetrafluoroethylene-lined autoclave, and reacted at 170°C for 10 h. After the autoclave was cooled, the precipitate was centrifuged and washed several times with absolute ethanol and distilled water. The prepared The sample was placed in a vacuum oven at 60°C and dried for 5 hours to obtain the I-doped BiOClBr photocatalyst.

[0037] The photocatalytic performance test of the I-doped BiOClBr photocatalyst obtained by the above preparation method: put the above-mentioned 20 mg I-doped BiOClBr solid solution into 200 mL of 7.5 ppm RhB solution, firstly carry out 30 min of dark state adsorption, until the adsorption equilibrium, in the dark Durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com