Device for cooperating evaporation of desulfurized wastewater flue and enhancing removal of fine particulates and SO3 (sulfur trioxide) and method thereof

A technology for desulfurization of wastewater and fine particles, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation to achieve the effects of promoting evaporation, achieving synergistic removal, and promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

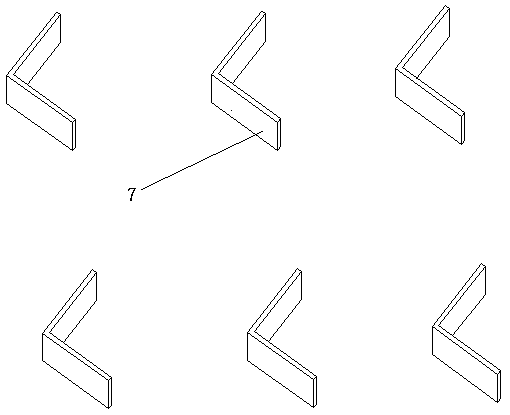

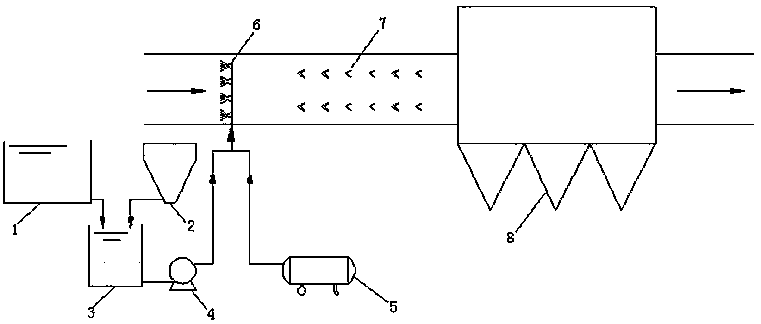

[0026] A device for coordinating desulfurization waste water flue evaporation and enhancing the removal of fine particles and sulfur trioxide, the device is installed on the flue of the boiler system, including desulfurization waste water storage tank 1, alkaline absorbent storage tank 2, injection system, production Vortex system and electrostatic precipitator 8, described injection system is made up of alkaline absorbent solution storage tank 3, metering pump 4, air compressor 5, two-fluid atomizing nozzle 6, wherein alkaline absorbent solution storage tank 3, metering The pump 4 and the two-fluid atomizing nozzle 6 are connected in sequence to form a liquid circuit, and the air compressor 5 is connected to the two-fluid atomizing nozzle 6 to form an air circuit; The distance between the nozzle 6 and the first-stage spoiler vortex is 1-3m, and the distance between the last-stage vortex and the entrance of the electrostatic precipitator 8 is 2-5m. Both the desulfurization was...

Embodiment 2

[0030] Dust-laden flue gas is produced by coal-fired boilers with a flue gas volume of 300Nm 3 / h, after the boiler runs stably, add a certain amount of fly ash and SO 3 , to ensure the required PM for testing 2.5 and SO 3 concentration. Before the method and device of the present invention are used, the flue gas directly enters the electrostatic precipitator, and the electric low-voltage impactor ELPI is used to test the PM online. 2.5 Concentration and particle size distribution, after testing, the PM at the inlet of the electrostatic precipitator 2.5 The particle size distribution is a typical bimodal distribution, the first peak appears at about 0.1um, and the number concentration is 7.1´10 6 / cm 3 , another peak appears at about 1um with a number concentration of 1.9´10 6 / cm 3 , PM 2.5 The mass concentration is 250mg / m 3 , with a number concentration of 1.5´10 7 / cm 3 ; PM at the outlet of electrostatic precipitator 2.5 The mass concentration is 30mg / m 3 , w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com