Patents

Literature

45results about How to "Synergistic removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

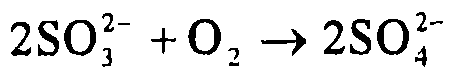

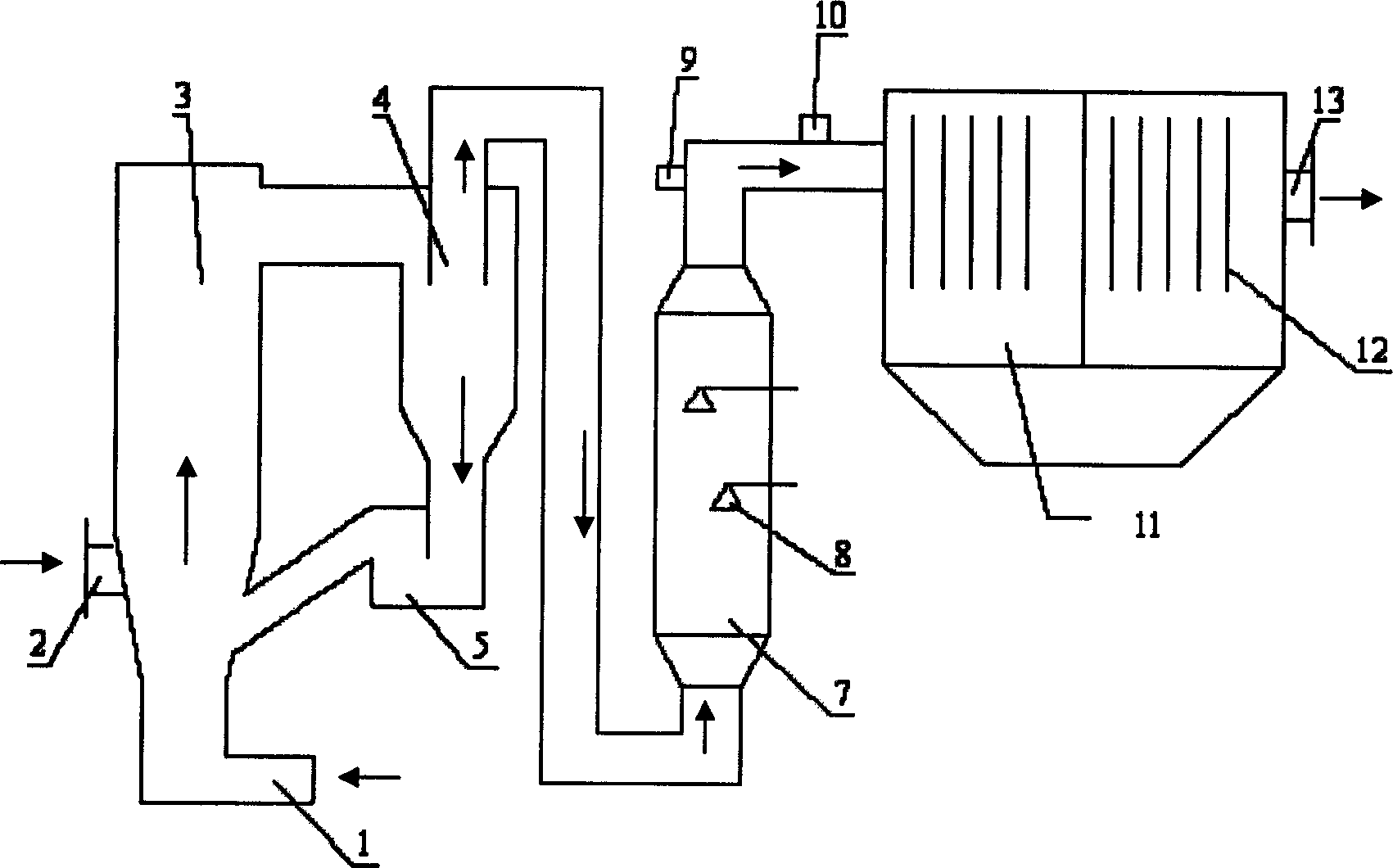

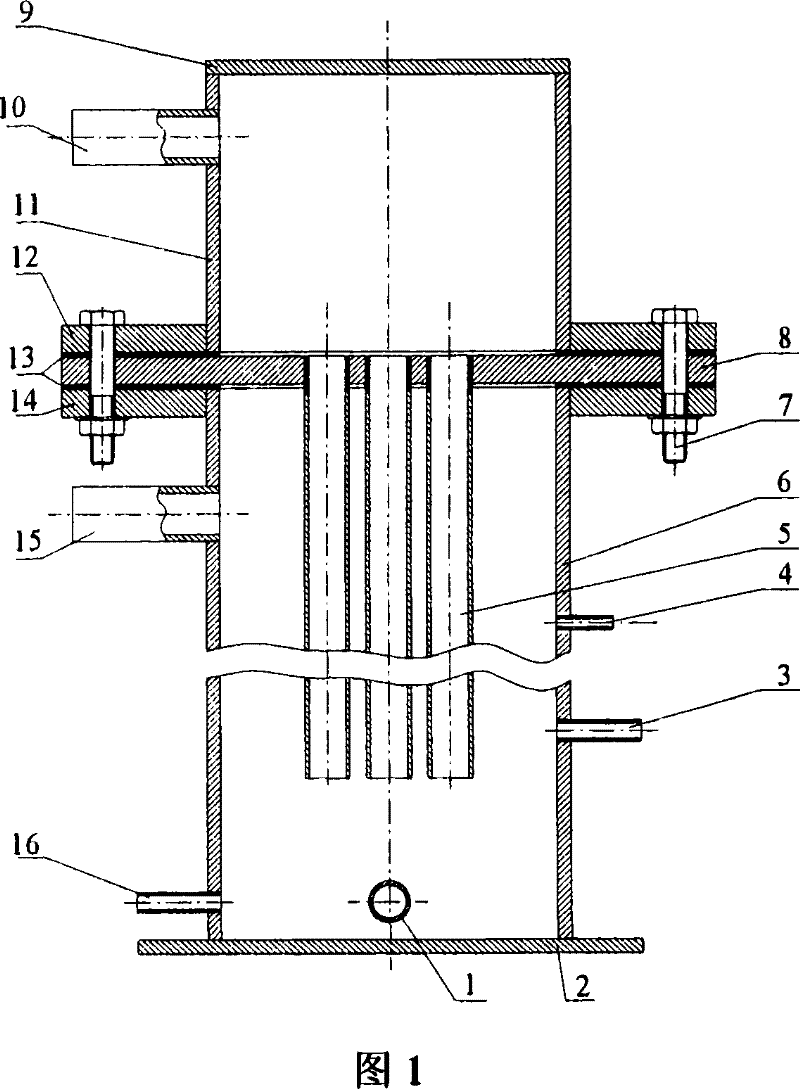

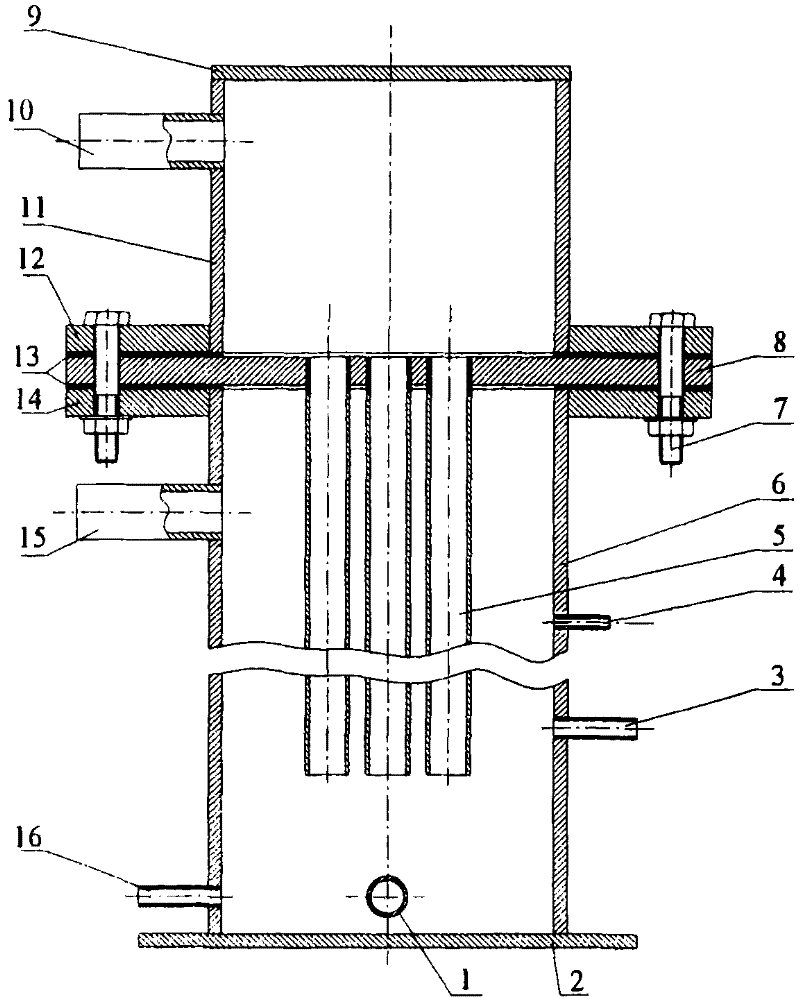

Integrative coordinated desulfurization, denitration, demercuration device and technique using spray bubbling method

ActiveCN101306322AReduce investment and operating costsSmall footprintDispersed particle separationInlet channelFlue gas

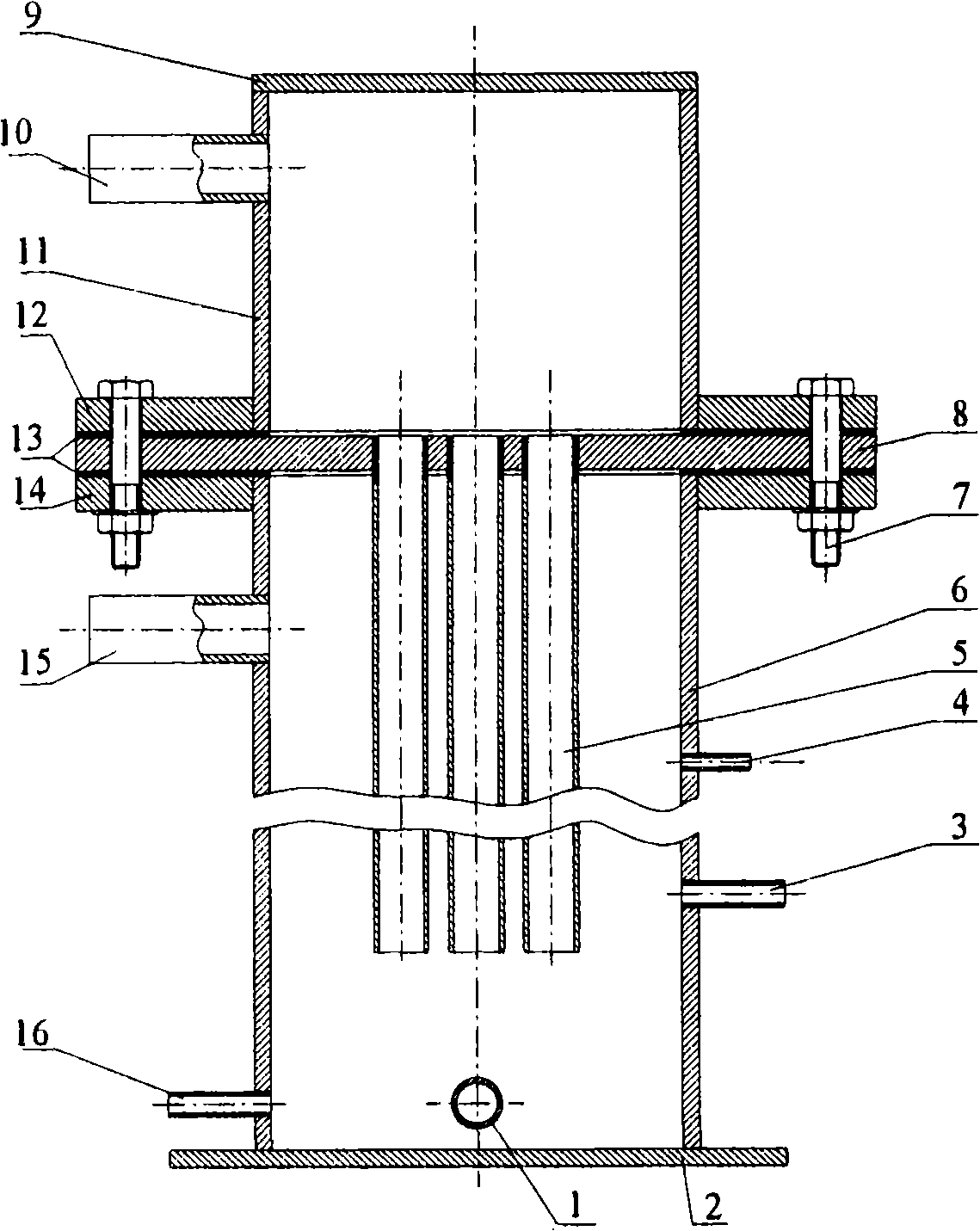

The invention relates to an integrated synergistic desulphurization, denitrification and demercuration device used for flue gas and a process for carrying out integrated synergistic desulphurization, denitrification and demercuration of the flue gas by using the device. The device comprises an original flue gas chamber (11), a tower body (6), a flue gas partition plate (8) and a bubbling jet pipe 5; wherein, the original flue gas chamber is fixed above the flue gas partition plate; the flue gas partition plate is fixed above the tower body; the three parts of the original flue gas chamber, the flue gas partition plate and the tower body are connected by an upper flange (12) and a lower flange (14); the upper end part of the bubbling jet pipe (5) is connected with the flue gas partition plate; the jet pipe communicates with the original flue gas chamber; an original flue gas inlet channel (10) is arranged outside the original flue gas chamber; and a purified flue gas outlet channel (15), a slurry discharge pipe (16), an oxidation wind pipe (1), a slurry return pipe (3) and a slurry adding pipe (4) are arranged outside the tower body.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

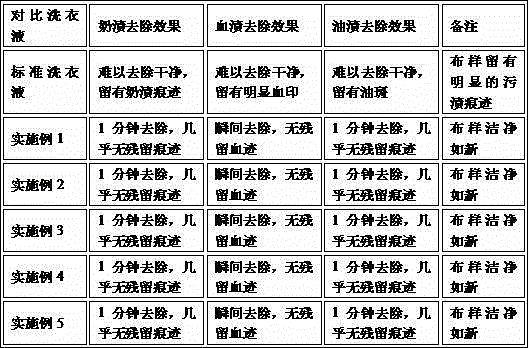

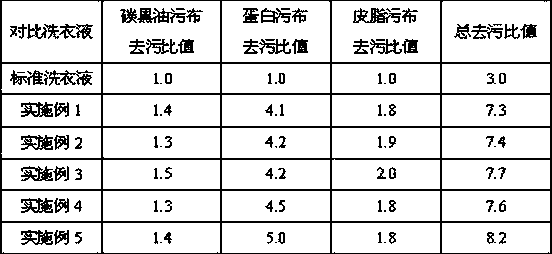

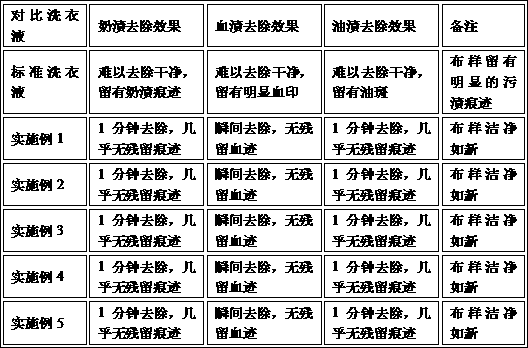

Protease super-concentrated laundry detergent and preparation method thereof

ActiveCN105062703AMild in natureGentle to the touchOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentBiology

The present invention discloses a protease super-concentrated laundry detergent, which mainly comprises, by mass, 3-38% of a non-ionic surfactant, 1-22% of an anionic surfactant, 0.1-1% of protease, 0.1-2% of triethanolamine, 0.1-2% of sodium citrate, 0.1-2% of refined salt and 60-70% of deionized water, wherein the protease comprises biological protease and compound protease. According to the present invention, the protease super-concentrated laundry detergent product is neutral and has characteristics of mild nature, no stimulation, soft hand-feeling, no alkaline residue after washing, no skin allergy and other symptoms, no damage on fabrics, water solubility, easy use, easy use amount control, easy storage, and easy use; and the process operation of the preparation method is simple, and the method is easily subjected to industrial production.

Owner:DONGGUAN XIANGYU CHEM

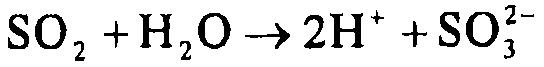

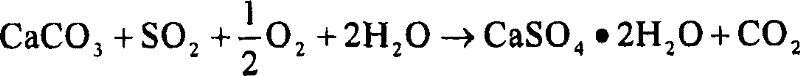

Spray bubbling method all-in-one synergetic desulfurization, denitration, demercuration absorption liquid

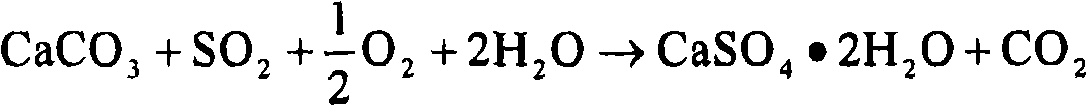

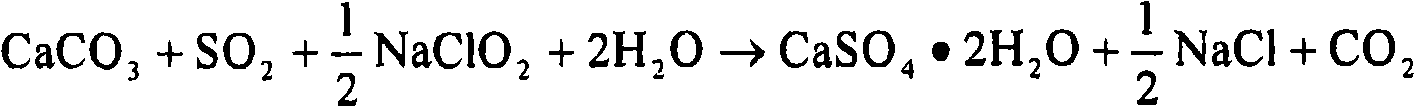

InactiveCN101310836ASynergistic removalImprove removal effectDispersed particle separationSlurryChemistry

The invention relates to an absorption liquid which is used for desulfurization, denitration and demercuration integrated and coordinated in a jet bubbling method, and comprises limestone slurry with the mass concentration of 5 percent to 30 percent. Furthermore, a strong oxidizer is added into the limestone slurry.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

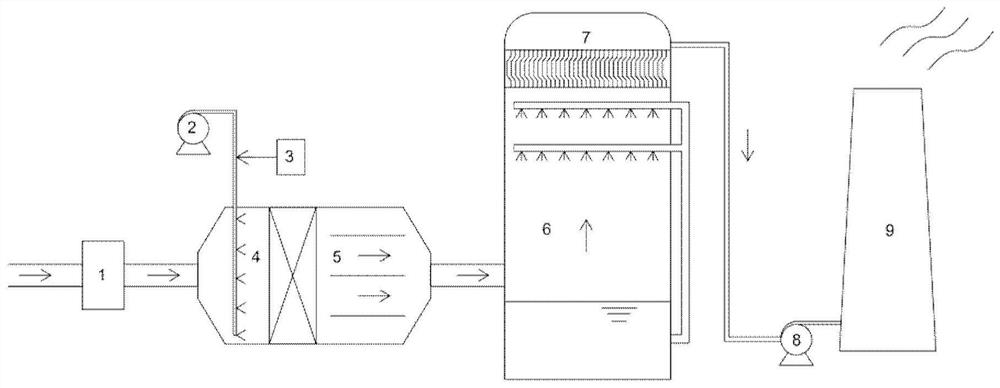

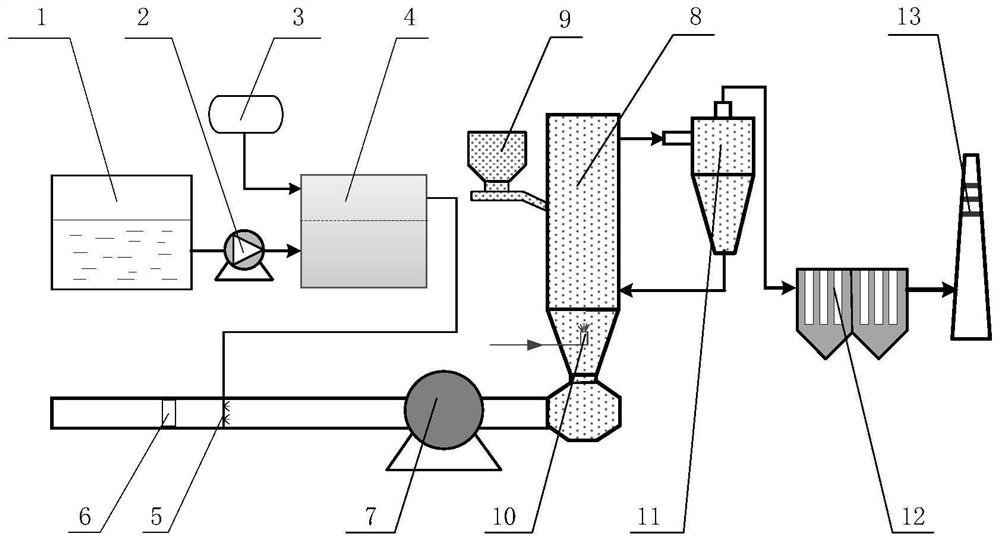

Synergistic gas-liquid-solid pollutant treatment system based on power plant wastewater zero-discharge technology

InactiveCN105967420AImprove economyImprove operational efficiencyElectrostatic separationDispersed particle separationDevice failureEconomizer

The invention provides a synergistic gas-liquid-solid pollutant treatment system based on a power plant wastewater zero-discharge technology and belongs to the technical field of coal-fired boiler pollutant control. The synergistic gas-liquid-solid pollutant treatment system includes a desulfurized wastewater zero-discharge treatment system, an SNCR + SCR united denitration system and a high-temperature electric dust removal system, wherein the desulfurized wastewater zero-discharge treatment system performs desulfurized wastewater pretreatment and pre-concentration, the SNCR + SCR united denitration system absorbs dissolved ammonia or urea of the treated desulfurized wastewater, uses the dissolved ammonia or urea as a reducing agent to be sprayed into an outlet of a boiler and a flue behind a coal economizer to complete denitration reaction, and the high-temperature electric dust removal system is arranged behind the coal economizer to collect and remove evaporated crystal substances of the wastewater. The synergistic gas-liquid-solid pollutant treatment system has excellent properties, is stable in process operation, achieves zero discharge of wastewater while achieving synergistic and coupled gas-liquid-solid pollutant treatment, reduces equipment investment by 10%-50% and the operation costs by 75%-90%, greatly reduces the equipment failure rate and maintains the working amount.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

Integrated plant of circulating fluid bed type boiler for burnning garbage and purifying tail gas

ActiveCN1796870ALess investment in equipmentSmall footprintDispersed particle separationIncinerator apparatusActivated carbonSmall footprint

An integral device of garbage burning and waste gas purifying is prepared as setting primary air inlet at bottom of boiler and garbage / lime powder inlet at middle ¿C bottom of boiler, connecting boiler top to cyclone through flue pipe, connecting cyclone bottom to material feedback mechanism with its bottom being connected to boiler bottom, connecting cyclone top to cooling tower bottom through flue pipe and setting water spraying nozzle opposite to flowing direction of smoke, connecting cooling tower top to bag ¿C type collector through neck flue pipe with inlets of iron fly ash and activated carbon, setting purified gas outlet and filtering material layer on bag ¿C type collector.

Owner:TSINGHUA UNIV +1

Electrostatic cooperative pollutant removing method and device

ActiveCN103463944AReduce energy consumptionGuaranteed uptimeElectrostatic separationDispersed particle separationParticulatesEngineering

The invention discloses an electrostatic cooperative pollutant removing method and device. The method comprises the following steps: firstly, conveying exhaust gas to an electrostatic dust collector for dust removal in advance, thus removing more than 90% of particles in the exhaust gas; secondly, generating low-temperature plasmas by a low-temperature plasma generating system, oxidizing and degrading pollutants in the exhaust gas subjected to dust removal in advance; thirdly, sucking or adsorbing the exhaust gas processed in the second step with a calcium oxide powder spraying method; fourthly, conveying the exhaust gas processed in the third step and used calcium oxide powder to a high-frequency impulse power supply electrostatic dust collector. The device is simple in system, compact in structure, high in pollutant removal efficiency, little in equipment investment, small in occupied space and low in operating cost.

Owner:SHANDONG UNIV +1

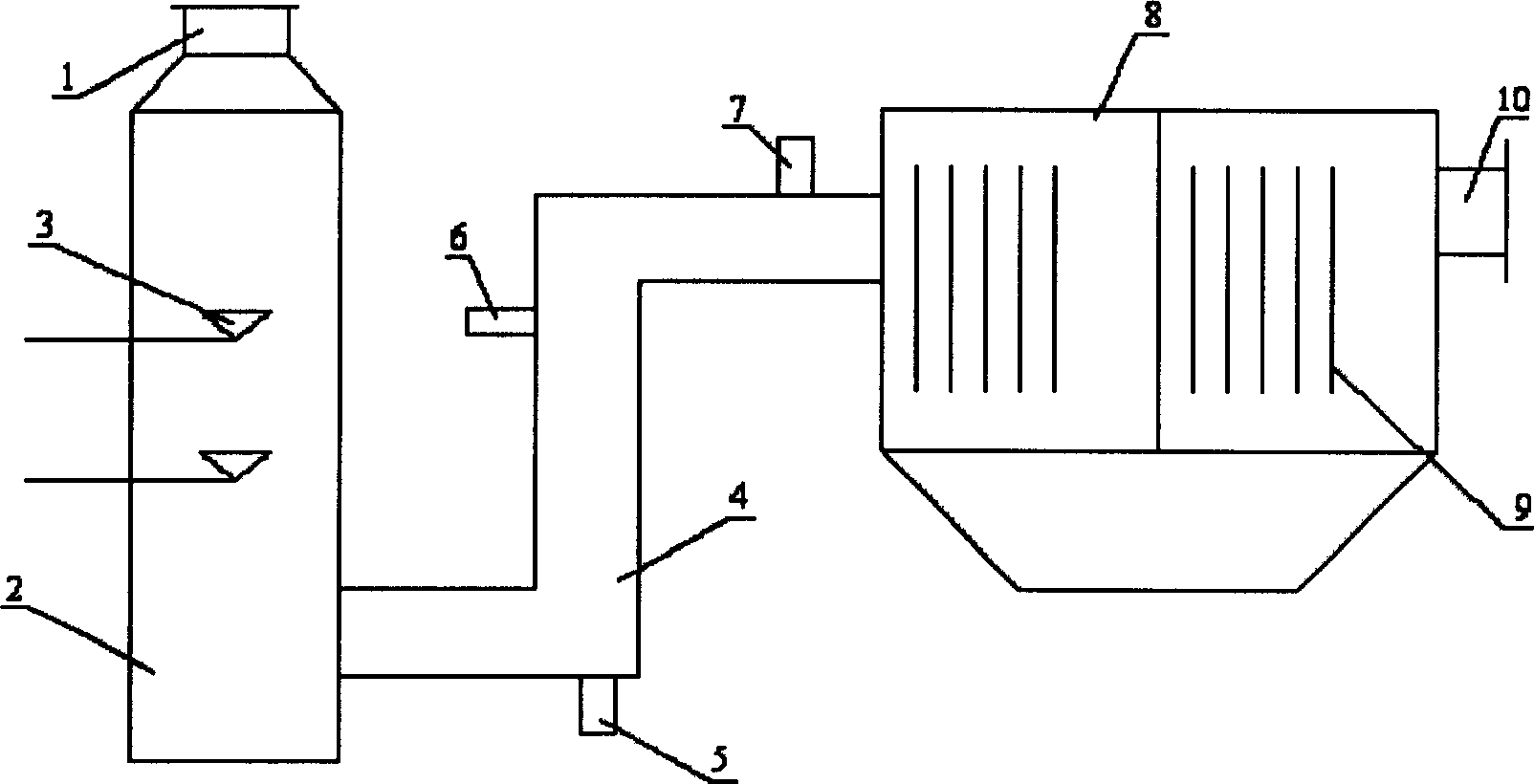

Method and equipment for purifying tail gas generated by burnning garbage

ActiveCN1796869AReduce the temperatureGood placeCombination devicesLighting and heating apparatusActivated carbonCooling tower

A device of purifying waste gas of garbage ¿C burning is prepared as setting smoke inlet at top end of cooling tower; setting water spraying nozzle opposite to flowing direction of smoke; setting S form flue pipe between cooling tower bottom and top of bag ¿C type collector; setting lime powder inlet at bottom section of said flue pipe, iron fly ash inlet at middle section of said flue pipe and activated carbon inlet at top section of said flue pipe; setting filter material layer in bag ¿C type collector and setting purified gas outlet at top side of bag ¿C type collector.

Owner:TSINGHUA UNIV +1

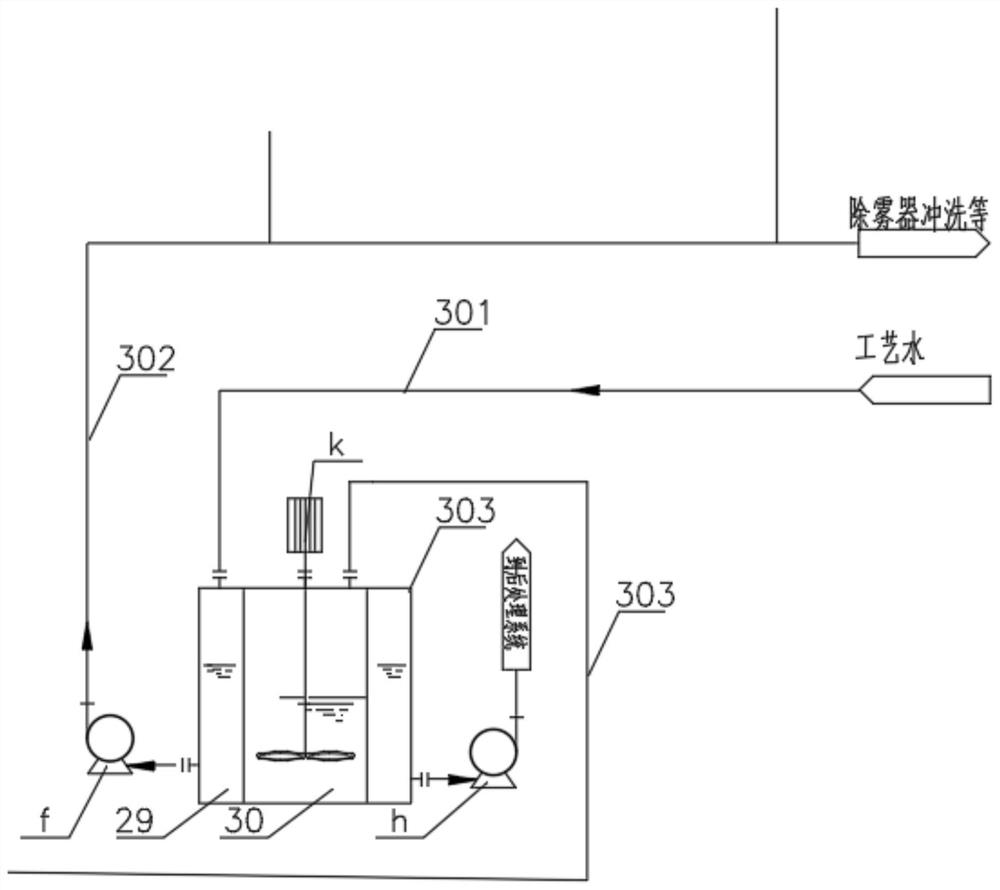

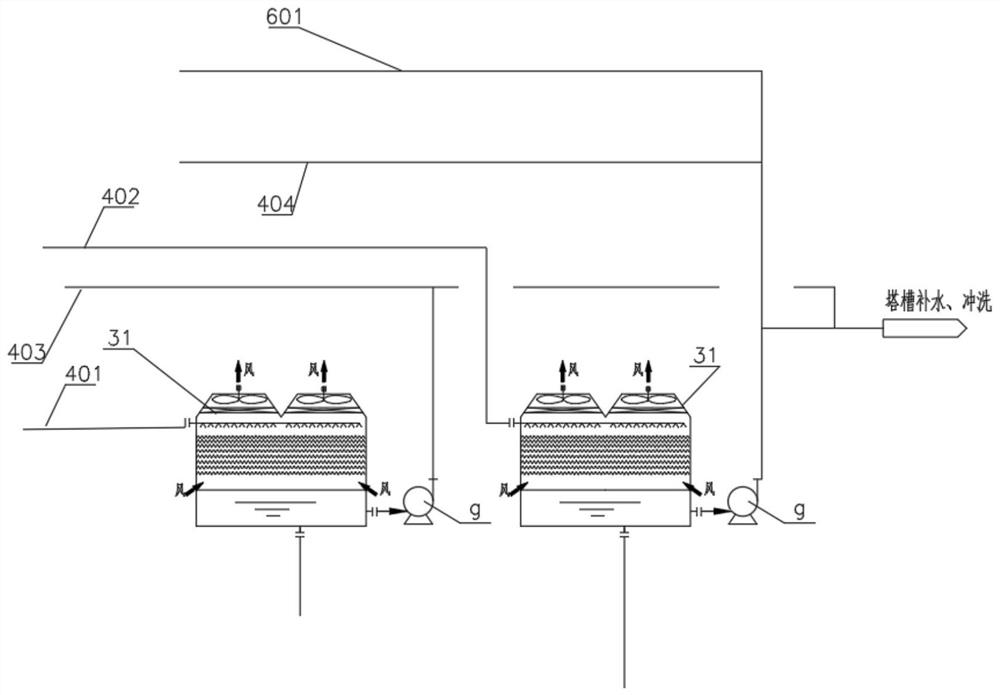

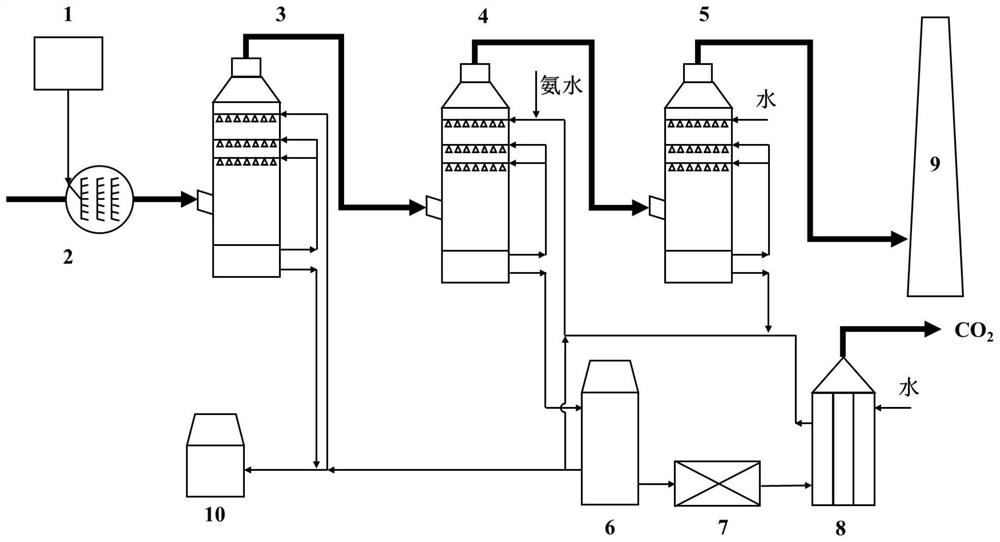

Water-saving and energy-saving ammonia desulphurization discharge process and system capable of preventing ammonia from escaping from aerosol

InactiveCN111841272APrevent escapeAvoid synergistic removalCombination devicesGas treatmentCooling towerSlurry

The invention discloses a water-saving and energy-saving ammonia desulphurization ultra-clean discharge system and process capable of preventing ammonia from escaping from aerosol. The system comprises a slurry disturbance system, a cooling concentration crystallization system, a sulfur oxide absorption system, an ammonia capture system, a washing purification system and a crystal particle enlarging system, circulating spray liquid of the desulfurizing tower from bottom to top adopts solutions with different components, and the concentration gradient is decreased progressively so that the desulfurizing efficiency is effectively improved, escape of aerosol and ammonia is avoided, and the phenomena of trailing and falling of ammonia-process desulfurized flue gas are eliminated. Different technologies such as multi-stage cyclone coupling, packing, a demister, an efficient cyclone water film dust collector and a wire mesh demister are combined, optimization of the distribution condition offlue gas in the tower is achieved, the retention reaction time of the flue gas is prolonged, further coagulation of fine particles and trapping of slurry droplets are promoted, the flue gas is washedthrough low-temperature washing liquid of the external cooling tower, cooperative removal of the fine particles is achieved, and ultra-clean emission is achieved.

Owner:江苏昆仑互联科技有限公司

Composite additive for synergistic removal of multiple pollutants and preparation method

ActiveCN102284242ASynergistic removalImprove removal effectDispersed particle separationFoaming agentMulti pollutant

The invention relates to an additive and a preparation method thereof, in particular to a composite additive for synergic removal of various pollutants and a preparation method thereof. In the composite additive for synergic removal of various pollutants and the preparation method thereof, the composite additive comprises the following components in parts by weight: 50 to 65 parts of a composite synergistic agent, 10 to 25 parts of high-efficiency cosolvent, 5 to 15 parts of high-efficiency oxidizing agent, 1 to 5 parts of high-efficiency anti-foaming agent, and 1 to 5 parts of high-efficiency corrosion inhibitor. The composite additive has the advantages of reasonable formula design, capability of removing various pollutants, good stain removal effect, energy-conservation performance and environmental friendliness, low cost, stable product quality, reasonable process design, and simple and easily operable method.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

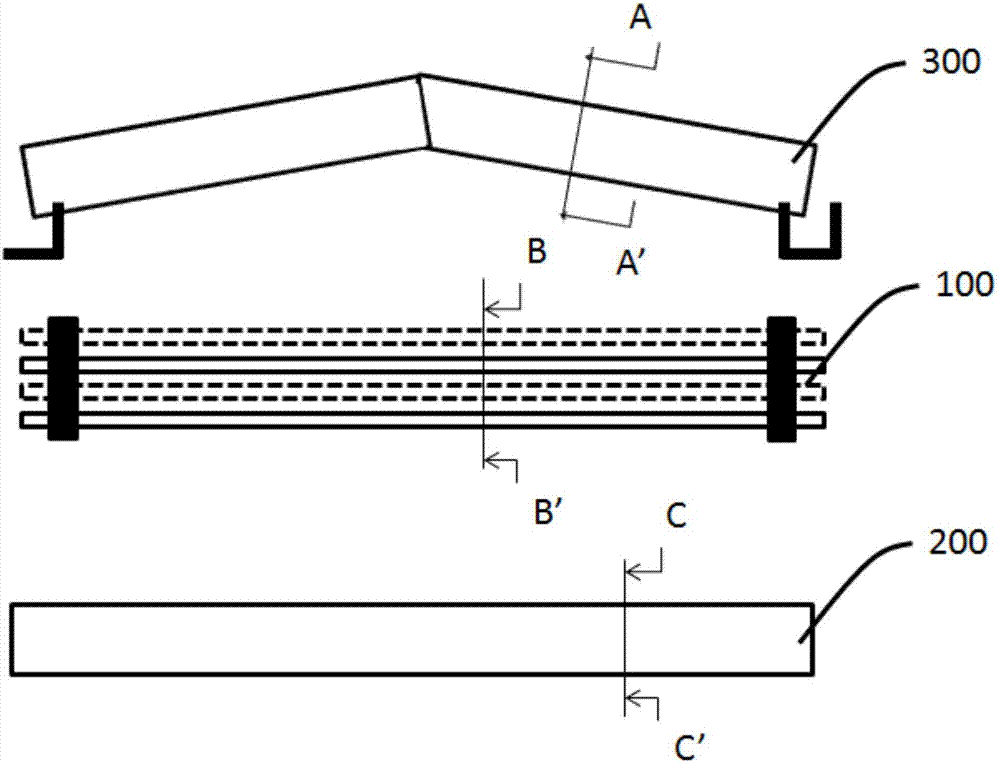

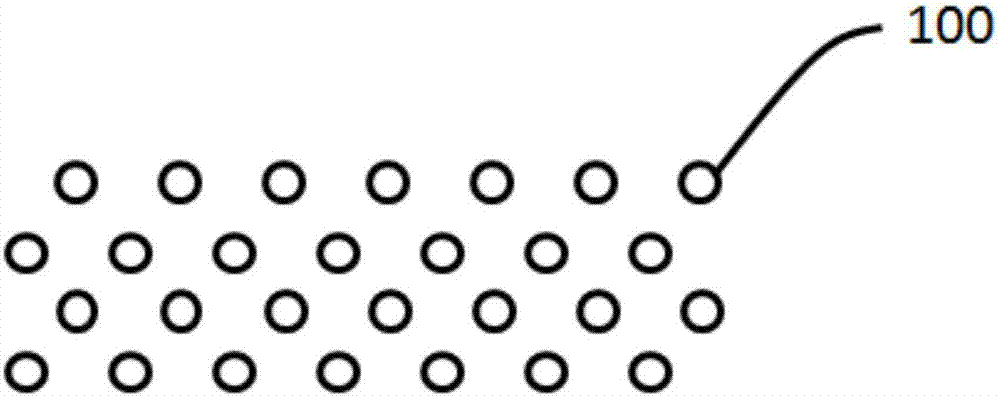

High-humidity flue gas purifying device

InactiveCN107485881AEfficient captureSynergistic removalCombination devicesGas treatmentHigh humidityWater vapor

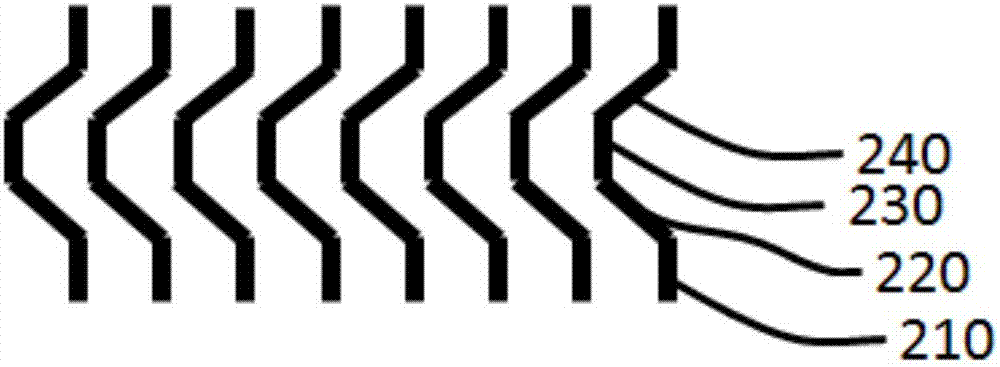

The invention relates to a high-humidity flue gas purifying device, which is used for purifying flue gas with water steam and fine particulate matters. The high-humidity flue gas purifying device comprises a heat exchange tube and a turbulence structure, wherein the flue gas can flow through a surface of the heat exchange tube and the turbulence structure, a refrigerant flows in the heat exchange tube, the water steam in the flue gas can be condensed on the surface of the heat exchange tube and surfaces of the fine particulate matters so as to form a water film and liquid drops, the turbulence structure has a bending part, and the flue gas can flow through the bending part and forms a turbulent flow, so that the liquid drops and the fine particulate matters are collided and agglomerated so as to be acquired and removed.

Owner:TSINGHUA UNIV

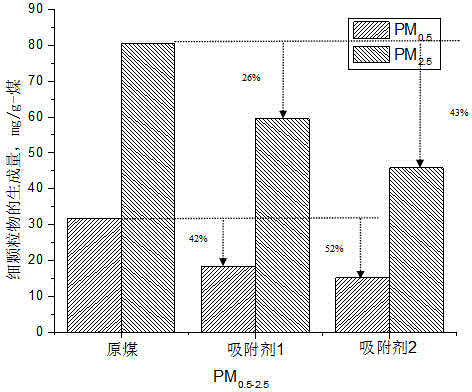

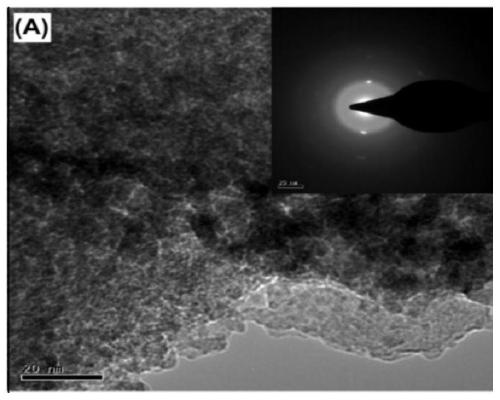

Ultrafine particle based on high-temperature-resistance titanium-based adsorbent and heavy-metal combined removal method

InactiveCN104399339AMature production technologyReduce generationUsing liquid separation agentFuel additivesCombustion chamberClay minerals

The invention discloses an ultrafine particle based on a high-temperature-resistance titanium-based adsorbent and a heavy-metal combined removal method. A titanium-based adsorbent is taken to be mixed with a fuel, the titanium-based adsorbent and the fuel are sprayed to a combustion chamber to be combusted, and the titanium-based adsorbent catches ultrafine particles, fin particles, particle type gas precursor contaminants and heavy metals. The titanium-based adsorbent comprises 50-100 percent by weight of main active component and 0-50 percent by weight of secondary active component, wherein the main active component is titanium dioxide (TiO2), and the secondary active component comprises one or more than two of clay mineral, metallic oxide and carbonate. According to the heavy-metal combined removal method, the high-temperature-resistance titanium-based adsorbent is used for catching ultrafine particles and heavy metals in smoke, and the thermal adaptability of the titanium-based adsorbent is strong; the titanium-based adsorbent excellently exerts the functions at low, middle and high temperatures, and can reduce the ultrafine particles, the fine particles, the particle type gas precursor contaminants and the heavy metals during combustion.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

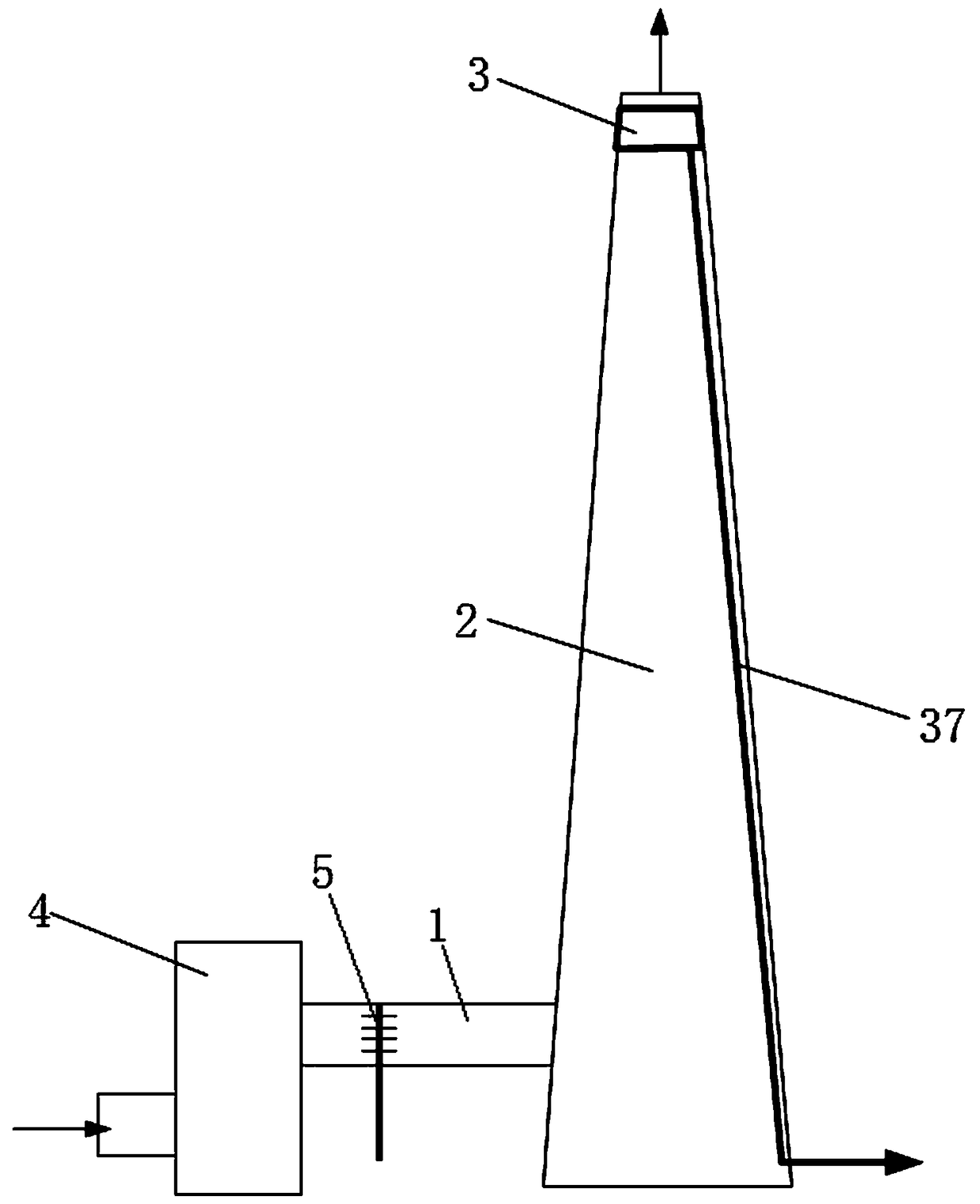

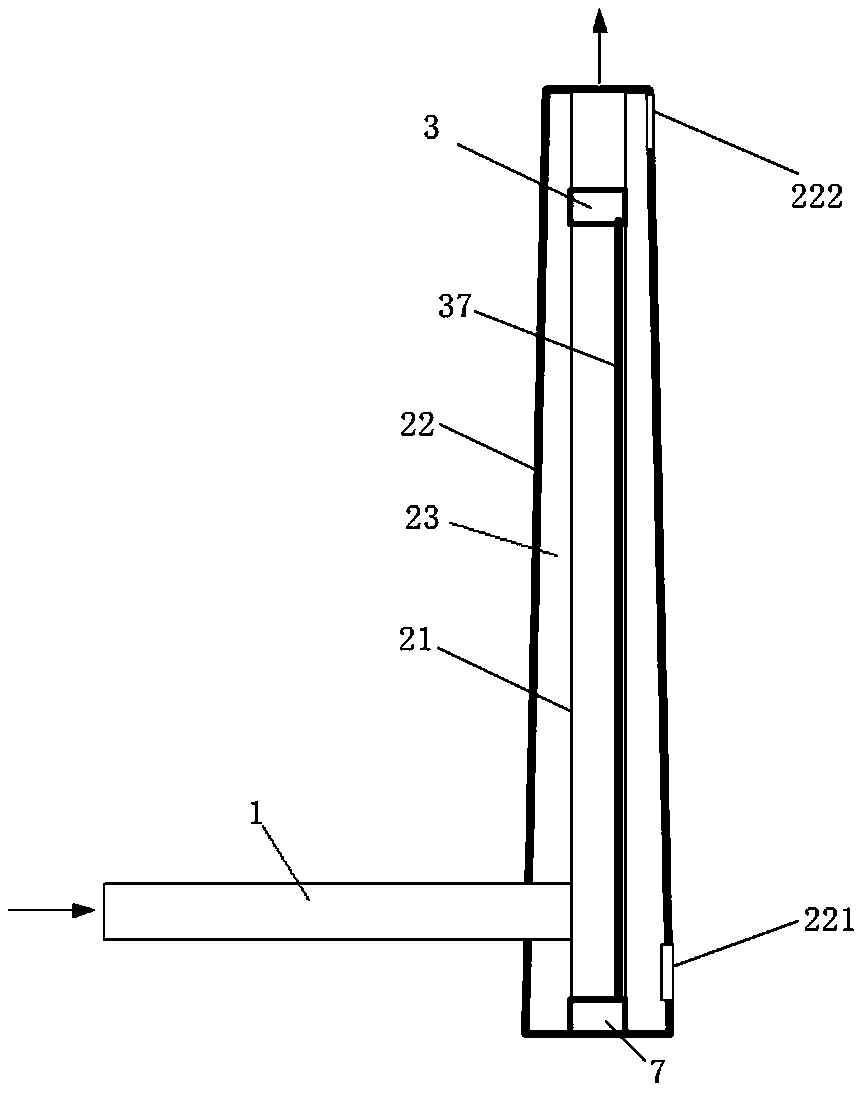

Flue gas pollutant treatment system and treatment method and chimney

InactiveCN108144383ASynergistic removalEasy to handleGas treatmentUsing liquid separation agentWater vaporMulti pollutant

The invention relates to the field of flue gas pollutant treatment devices, in particular to a flue gas pollutant treatment system and treatment method and a chimney. The flue gas pollutant treatmentsystem comprises the chimney and a humidifier for humidifying flue gas entering the chimney, the chimney is provided with a cooling wall for performing heat exchange with outside air and cooling watervapor in a smoke exhaust channel of the chimney, and a demister for removing condensed liquid drops is arranged in the smoke exhaust channel of the chimney. Flue gas is humidified by the humidifier,the water vapor in the humidified flue gas are condensed into the liquid drops under the cooling action of the chimney, pollutants such as harmful gas, dust, soluble salt and acid liquor in the flue gas are absorbed into the liquid drops, the liquid drops in the flue gas are removed by the demister arranged on the upper portion of the chimney, the removed liquid drops flow to the bottom of the chimney, various pollutants are cooperatively removed, pollutant treatment effects are improved, and the problem of poor removal effect of low-concentration pollutants in the flue gas in the prior art issolved.

Owner:苏跃进

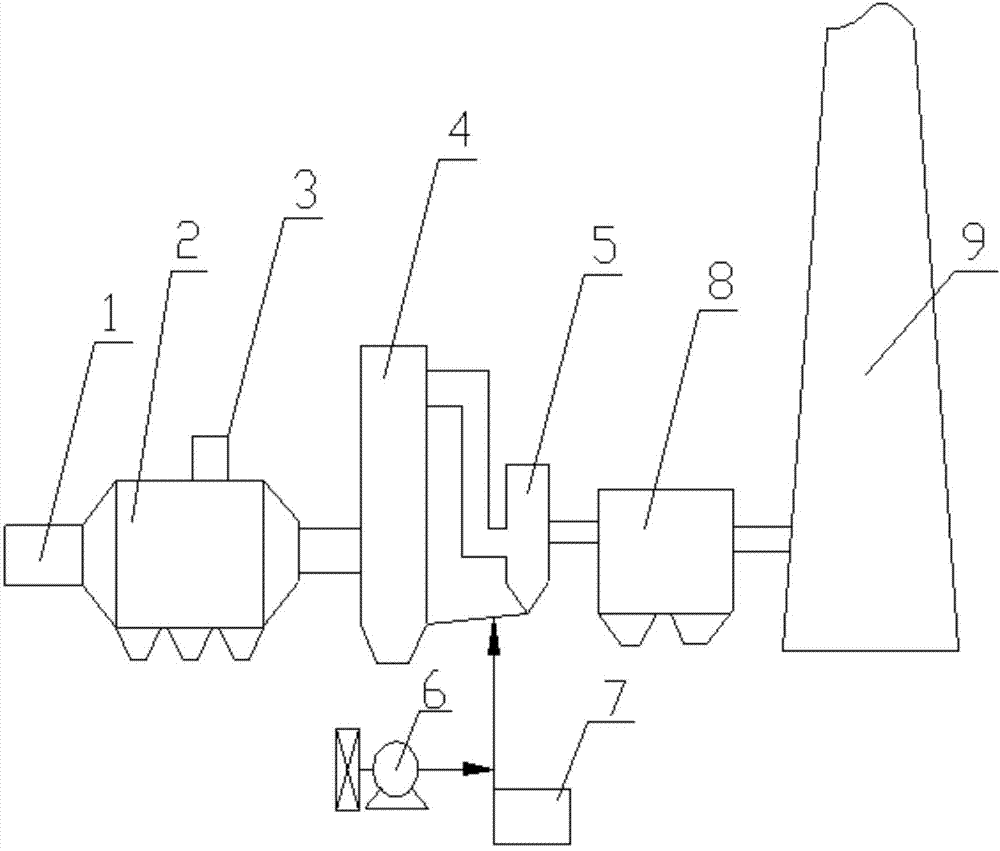

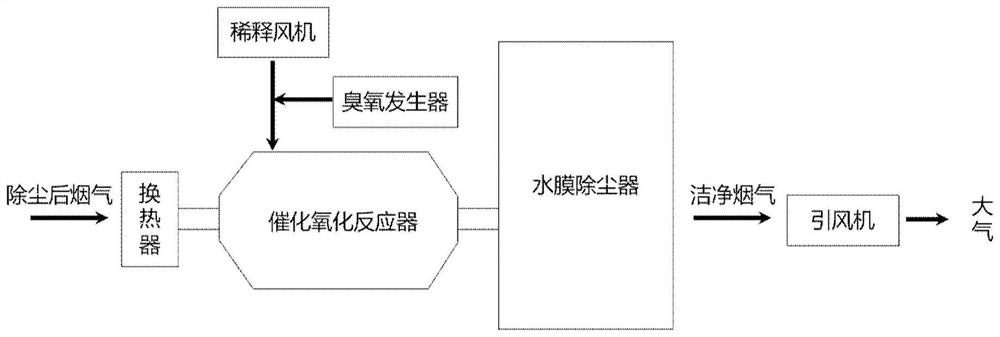

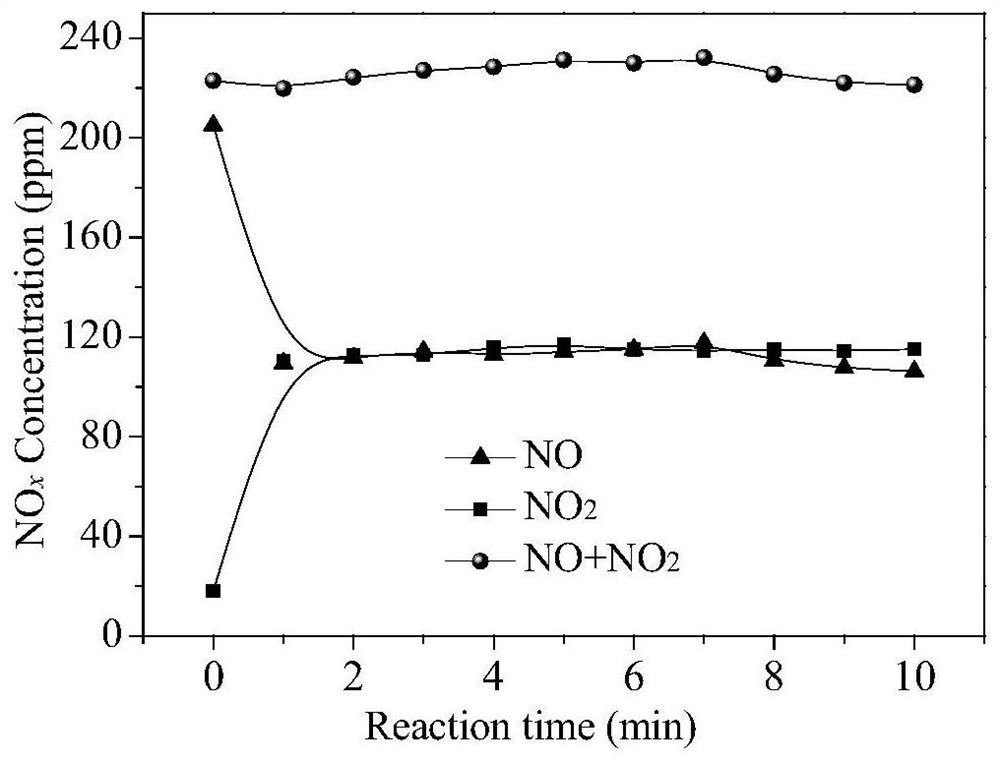

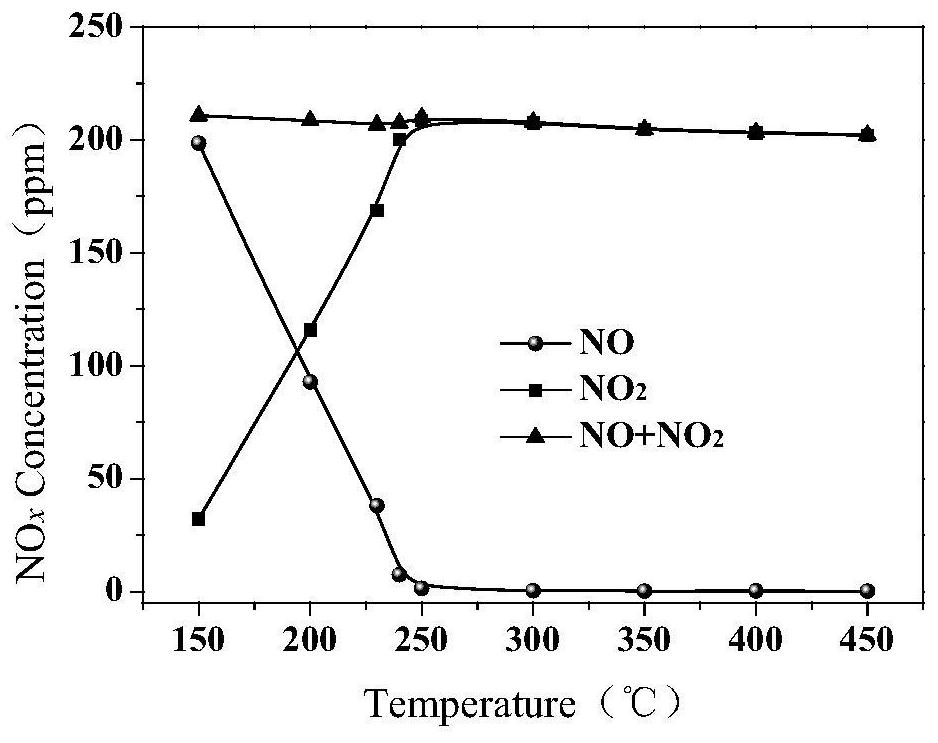

High-voltage narrow-pulse discharge and semi-dry process type cooperative pollutant control method and high-voltage narrow-pulse discharge and semi-dry process type cooperative pollutant control device

ActiveCN103495334ASynergistic removalImprove removal efficiencyDispersed particle separationMulti pollutantNitric oxide

The invention discloses a high-voltage narrow-pulse discharge and semi-dry process type cooperative pollutant control method and a high-voltage narrow-pulse discharge and semi-dry process type cooperative pollutant control device. The method comprises the following steps: (1) conveying dedusted flue gas to a high-voltage narrow-pulse discharge reactor through a flue gas inlet, and monitoring the concentrations of sulfur dioxide and nitric oxide at the flue gas inlet; (2) setting an energy input value of the high-voltage narrow-pulse discharge reactor according to the concentrations of the sulfur dioxide and the nitric oxide, and oxidizing and degrading the dedusted flue gas in the high-voltage narrow-pulse discharge reactor; (3) conveying the oxidized and degraded flue gas into a semi-dry process desulfurization system, absorbing or adsorbing the flue gas by quick lime or slaked lime, and removing original pollutants and newly-generated pollutants. Through the method and the device, a plurality of pollutants can be cooperatively removed. The method and the device have the advantages of high removal efficiency, flexibility in regulation, simple system, small occupied space and low investment.

Owner:SHANDONG UNIV +1

Method for synergically removing simple substance mercury and hydrogen sulfide from hot coal gas

InactiveCN102226114ASynergistic removalEfficient and Stabilized TreatmentGas purification by catalytic conversionGas purification with selectively adsorptive solidsSorbentPhysical chemistry

The invention relates to a method for synergically removing simple substance mercury and hydrogen sulfide from hot coal gas, which comprises the following steps: charging oxygen into unpurified coal gas with 50-300 DEG C so that the weight of oxygen is 0.8-1.7 times of that of hydrogen sulfide in the coal gas; and introducing the coal gas into an adsorber filled with adsorbent at volume space velocity of 1000-3000h<-1>, and adsorbing for 2.5-3 hours. The invention has the advantages of low cost and no secondary pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

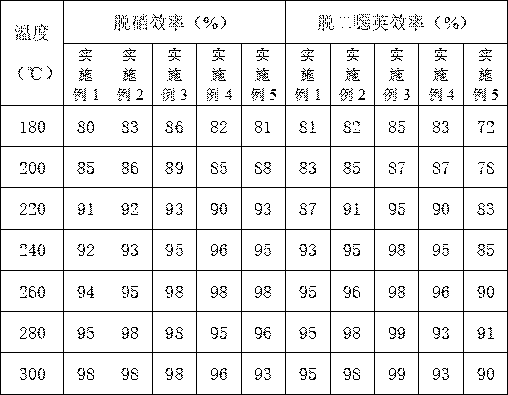

Medium/low temperature mesoporous nitrogen oxide and dioxin removal catalyst and preparation method thereof

InactiveCN110368923ALarge specific surface areaEffective co-removalDispersed particle separationCatalyst activation/preparationActive componentMetal particle

The invention discloses a medium / low temperature mesoporous nitrogen oxide and dioxin removal catalyst and a preparation method thereof. According to the catalyst, a mesoporous carbon-silicon composite material is adopted as a carrier, and one or more of vanadium pentoxide, tungsten oxide, cerium oxide and manganese oxide are adopted as active components. The catalyst disclosed by the invention iscapable of effectively achieving synergetic removal of NOx and dioxin within a medium / low temperature range of 180-300 DEG C, and in addition, the catalyst disclosed by the invention has the advantages of being large in specific surface area, ordered in pore height, small in active metal particle size and uniform in active metal particle size distribution.

Owner:LONGKING COALOGIX ENVIRONMENTAL PROTECTION TECH SHANGHAI CO LTD

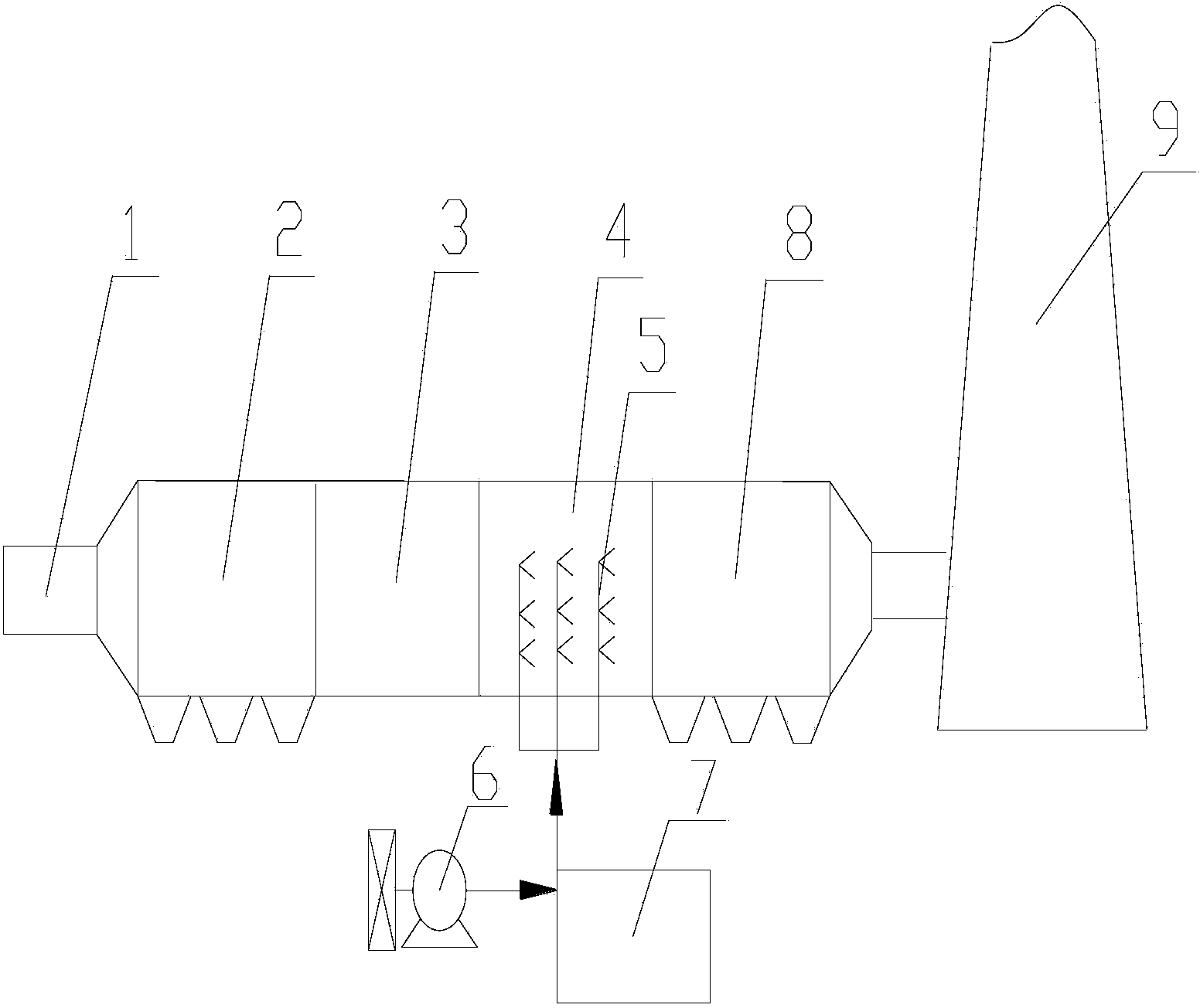

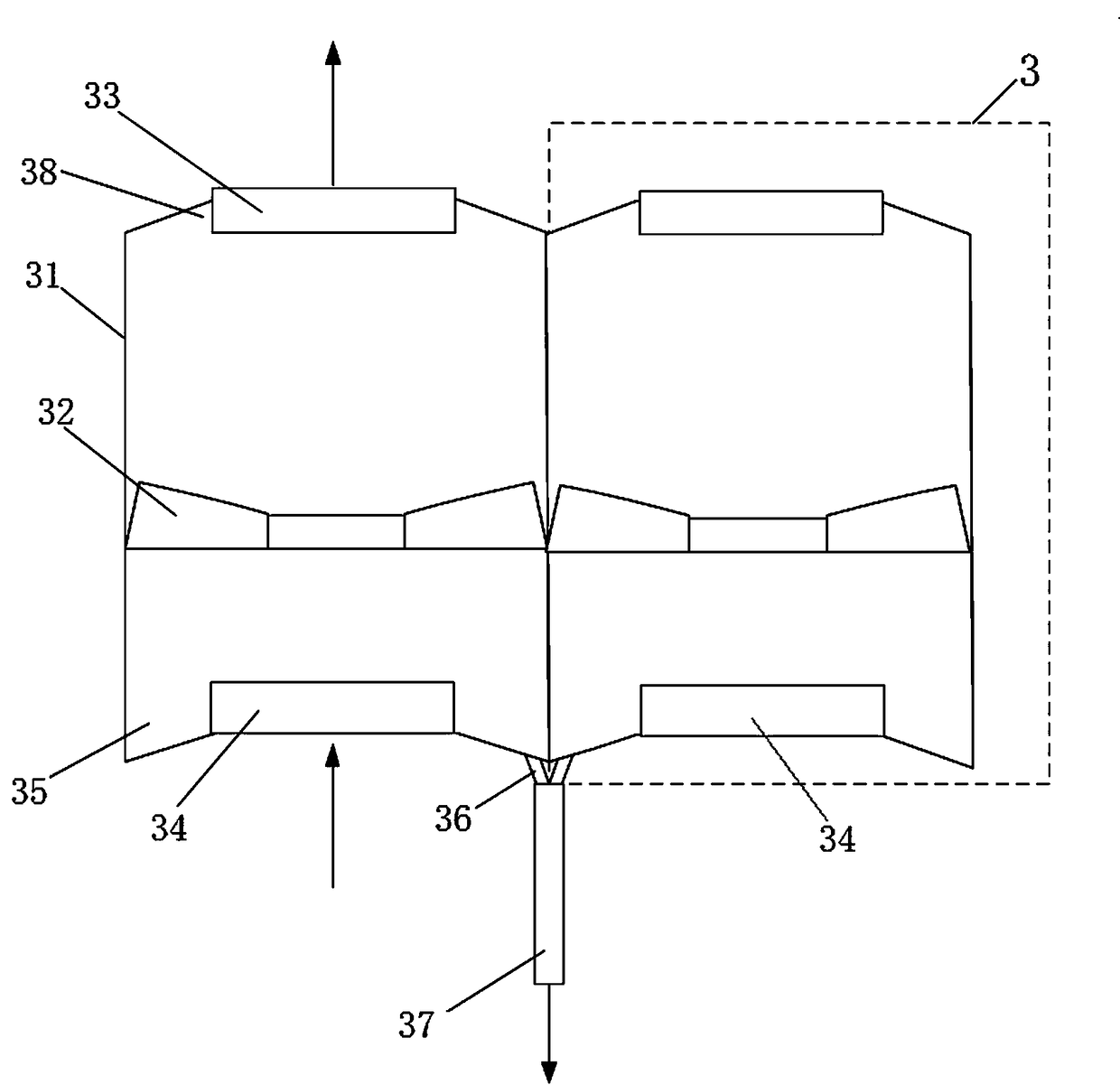

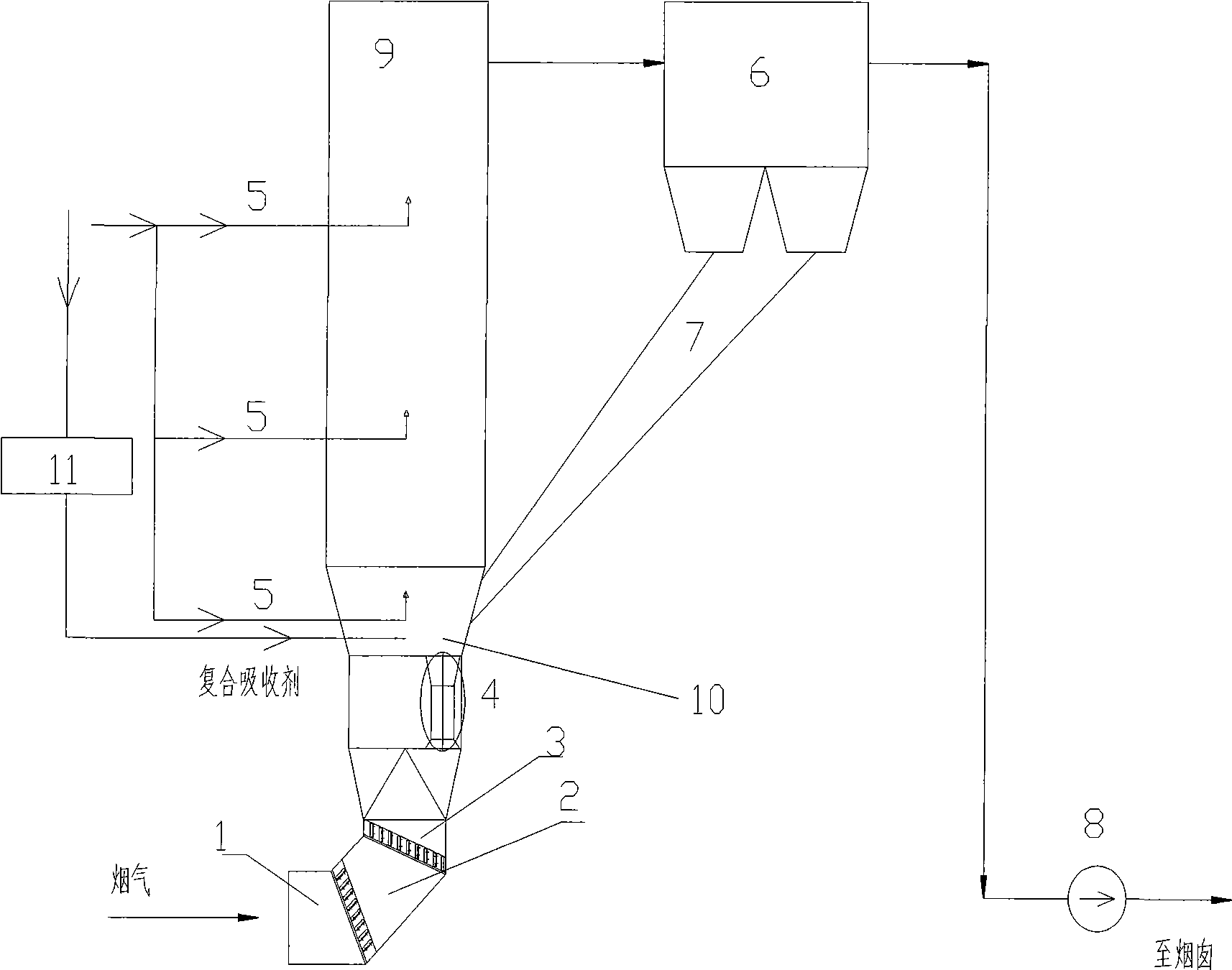

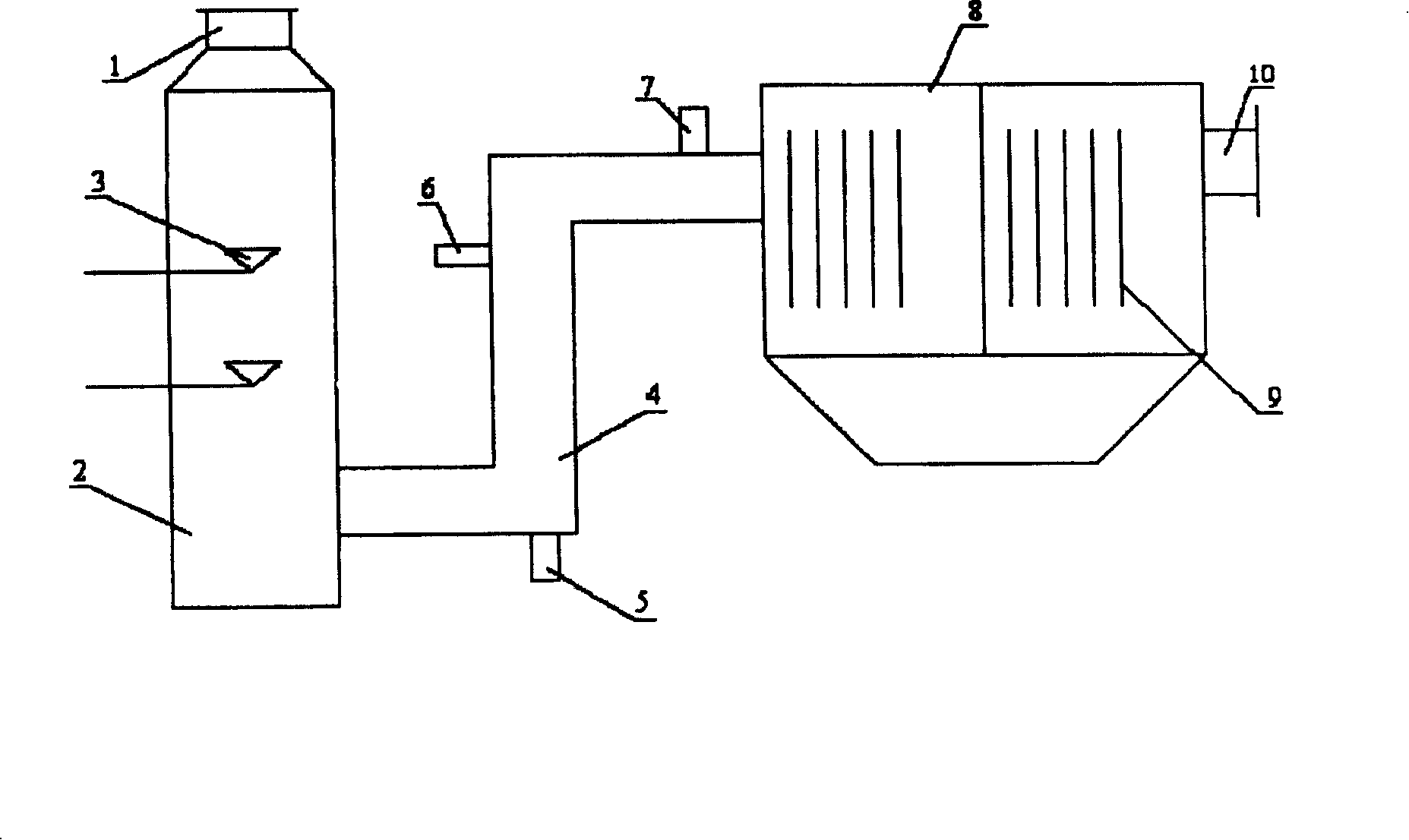

MCFB fuel gas purifying device capable of jointly removing various pollutants

InactiveCN101543712AMaintain moisture content uniformityEasy to removeCombination devicesMulti pollutantFluidized bed

The invention discloses an MCFB fuel gas purifying device capable of jointly removing various pollutants, which comprises a connecting flue, a primary fuel gas uniform distribution device, a secondary fuel gas uniform distribution device, a Venturi, multistage humidification and activation devices, a dust catcher, an ash circulation device, a draught fan, a fluidized bed reactor, a Venturi diffuser and a composite absorbent preparation device, wherein the lower end of the fluidized bed reactor is sequentially connected with the Venturi diffuser, the Venturi, the secondary fuel gas uniform distribution device, the primary fuel gas uniform distribution device and the connecting fuel; the upper part of the fluidized bed reactor is sequentially connected with the dust catcher and the draught fan; the bottom part of the dust catcher is connected with the Venturi diffuser through the ash circulation device; the multistage humidification and activation devices are arranged in the fluidized bed reactor and the Venturi diffuser; and the composite absorbent preparation device is connected with the Venturi diffuser. The multistage humidification and activation technology of the invention improves the pollutant purification efficiency, solves the problem of adhesion and blockage of materials in a tower, and realizes joint, high-efficiency and low-consumption removal of various pollutants in fuel gases.

Owner:ZHEJIANG UNIV

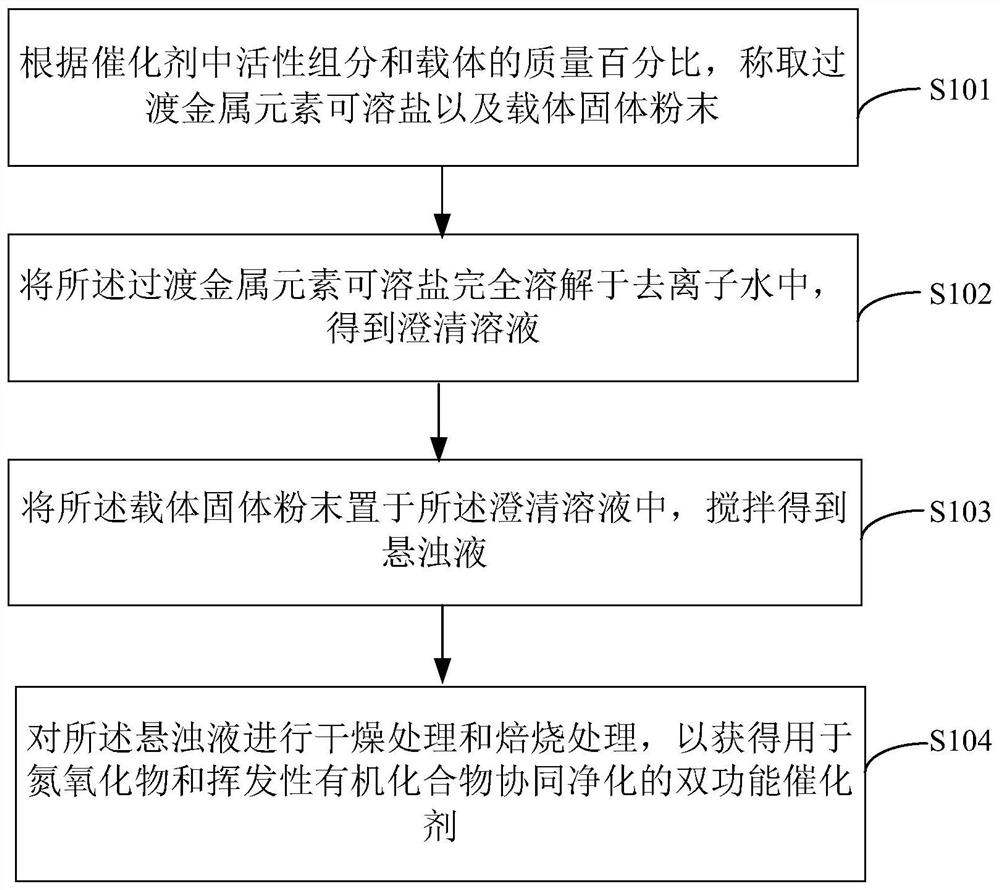

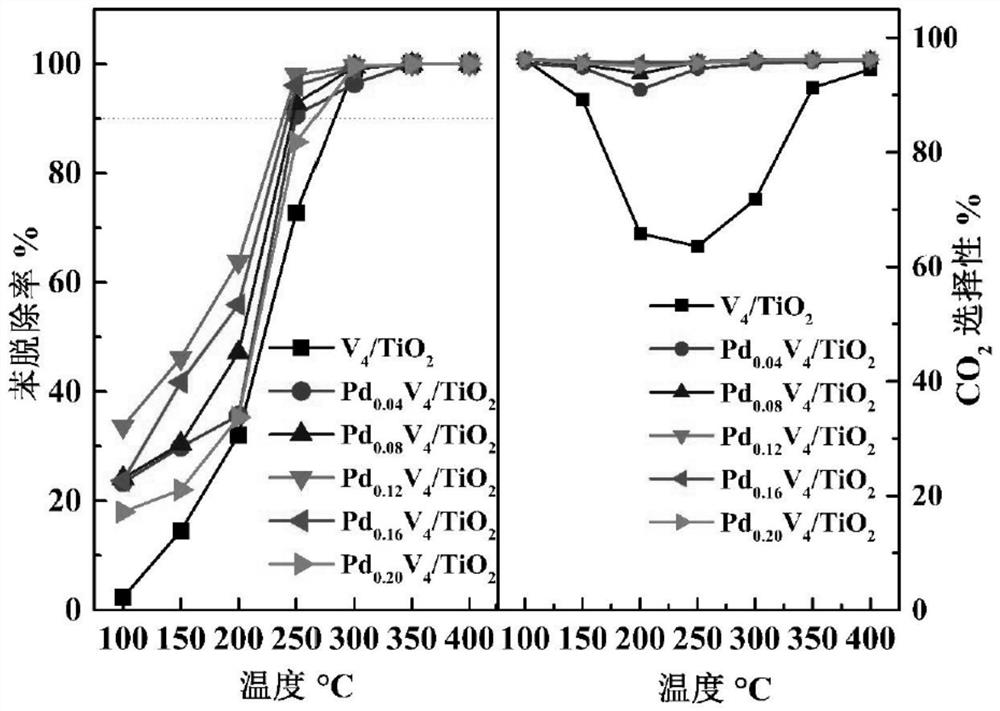

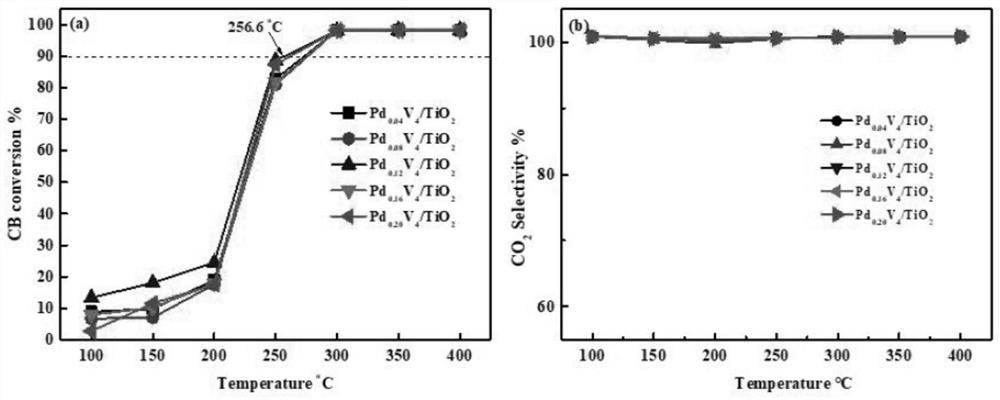

Bifunctional catalyst for synergistic purification of nitric oxides and volatile organic compounds and preparation method thereof

PendingCN112316941AReaction temperature and lowReduce reaction energy consumptionGas treatmentHeterogenous catalyst chemical elementsVolatile organic compoundNitric oxide

The invention discloses a bifunctional catalyst for synergistic purification of nitrogen oxides and volatile organic compounds and a preparation method of the bifunctional catalyst. The catalyst comprises a carrier and an active component, wherein the active component comprises a transition metal oxide. According to the bifunctional catalyst for synergetic purification of nitrogen oxides and volatile organic compounds provided by the invention, the transition metal oxide is used as the active component and is attached to the carrier, so synergetic removal of VOCs and NOx can be realized, highremoval rate and high selectivity of a target product are realized, reaction temperature is reduced, reaction energy consumption is lowered, and production cost is reduced.

Owner:光大环境修复(江苏)有限公司 +1

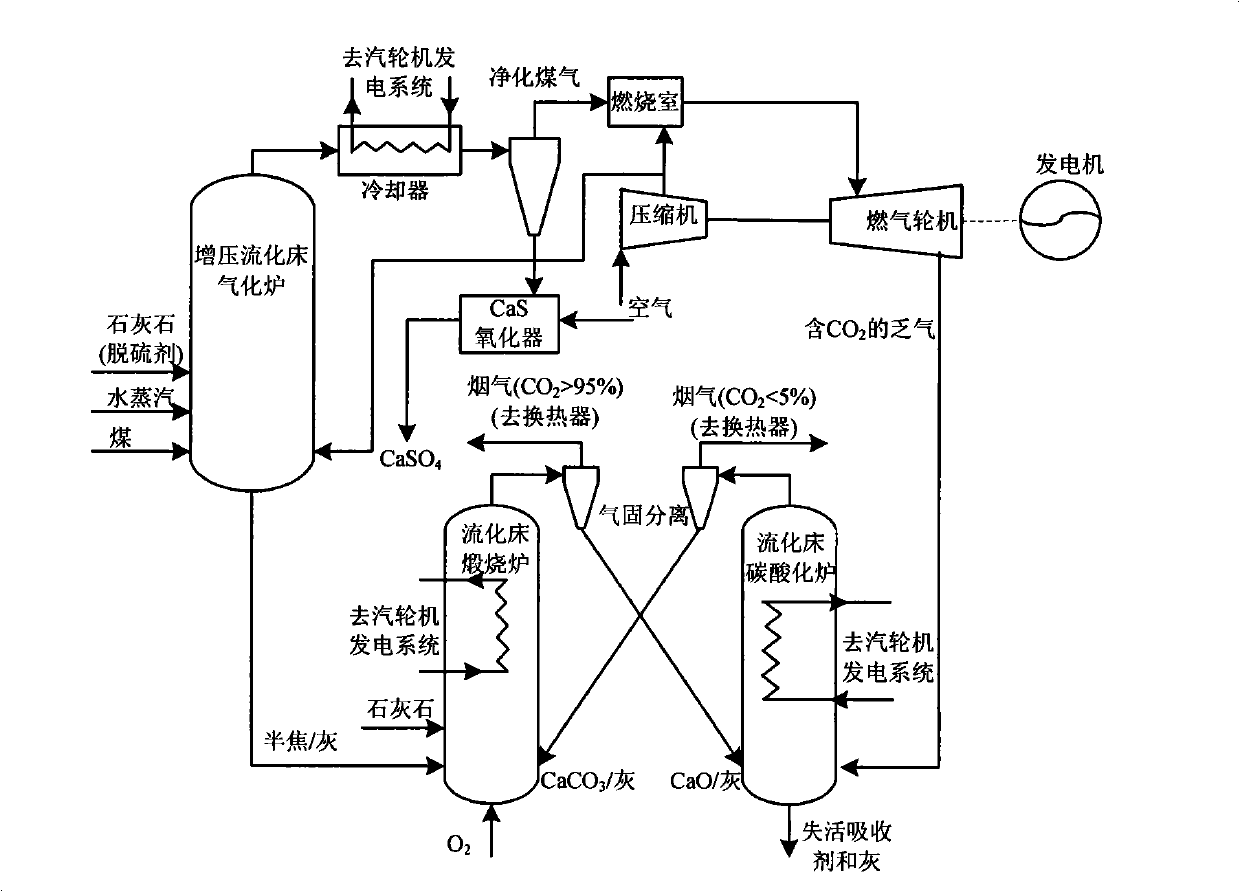

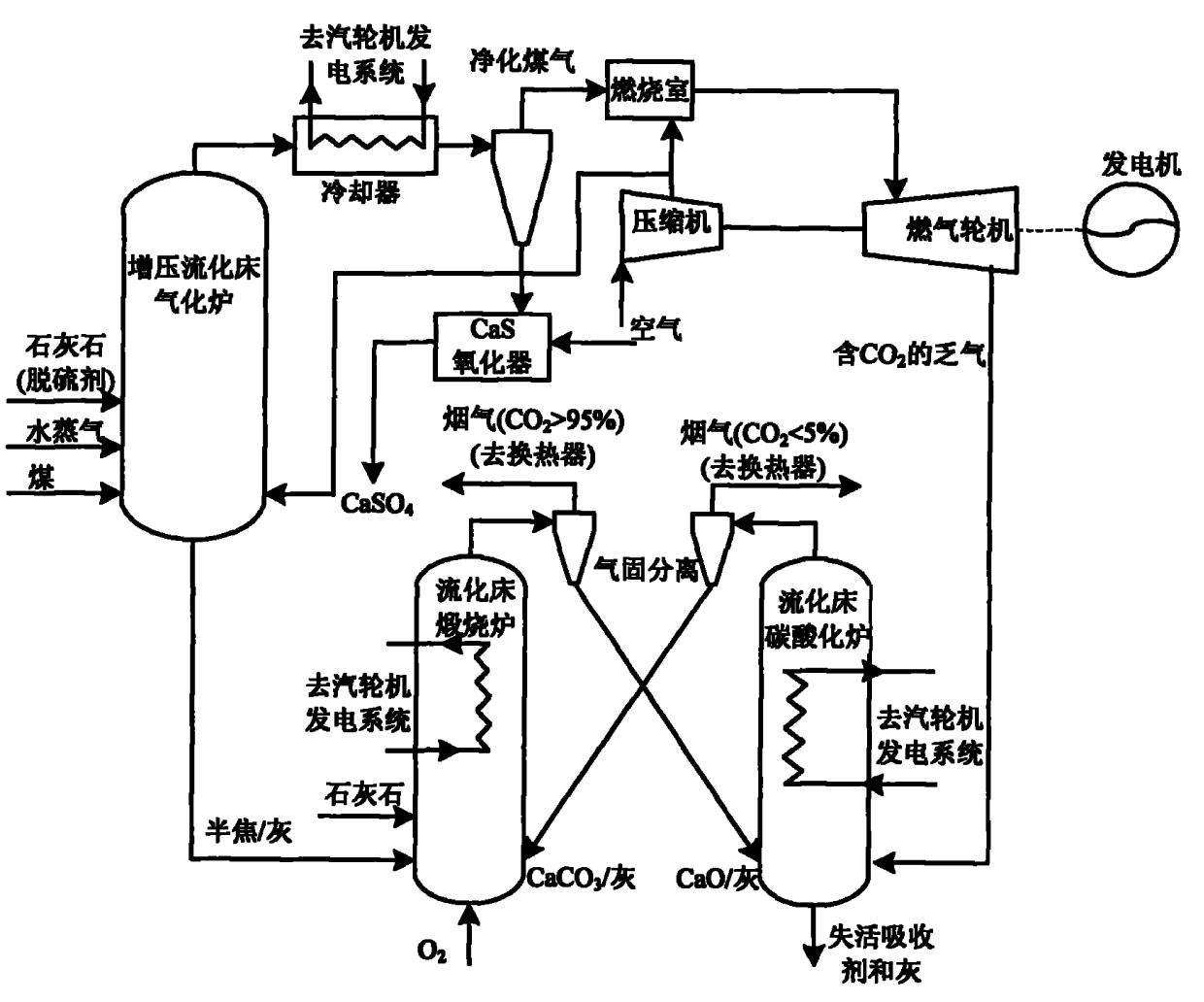

Method for catching carbon dioxide by pressurized fluidized bed combustion combined recycled generating system

InactiveCN101539037BReasonable realization of graded conversionRaise the inlet temperatureGas turbine plantsSteam engine plantsElectricityMulti pollutant

Owner:SOUTHEAST UNIV

Preparation method for pennycress and daisy tea cream

The invention discloses a preparation method for pennycress and daisy tea cream. The pennycress and daisy tea cream is prepared from main raw materials pennycress, daily leaves and oolong tea by the steps of raw material pretreatment, pulping treatment, tea powder extracting solution preparation, mixing, fermentation, enzyme treatment, homogenization, sublimation drying, crushing, tea cream preparation, drying sterilization, packaging and the like. According to the tea cream processed by the method, the pennycress, the daily leaves and the oolong tea, which are green, healthy, rich-nutrient and extensive, are taken as the raw materials, so that the production cost can be reduced, new varieties of the tea cream and nutritional components of the tea cream are richened, health effects of a tea cream finished product are improved, and obvious synergistic effects are achieved; the raw materials are steamed twice, so that bitterness and astringency in the raw materials can be removed, and the mouth-feel and the quality of the tea cream finished product can be improved; the tea cream finished product is convenient to carry and stable in color, tastes pure, and has the health effects of clearing away heat and toxic materials, inducing diuresis, reducing edema, regulating the middle warmer, promoting appetite, clearing liver-fire for improving eyesight and expelling wind to resolve the exterior, and the utilization efficiency and the economic value of the raw materials are improved.

Owner:柴华

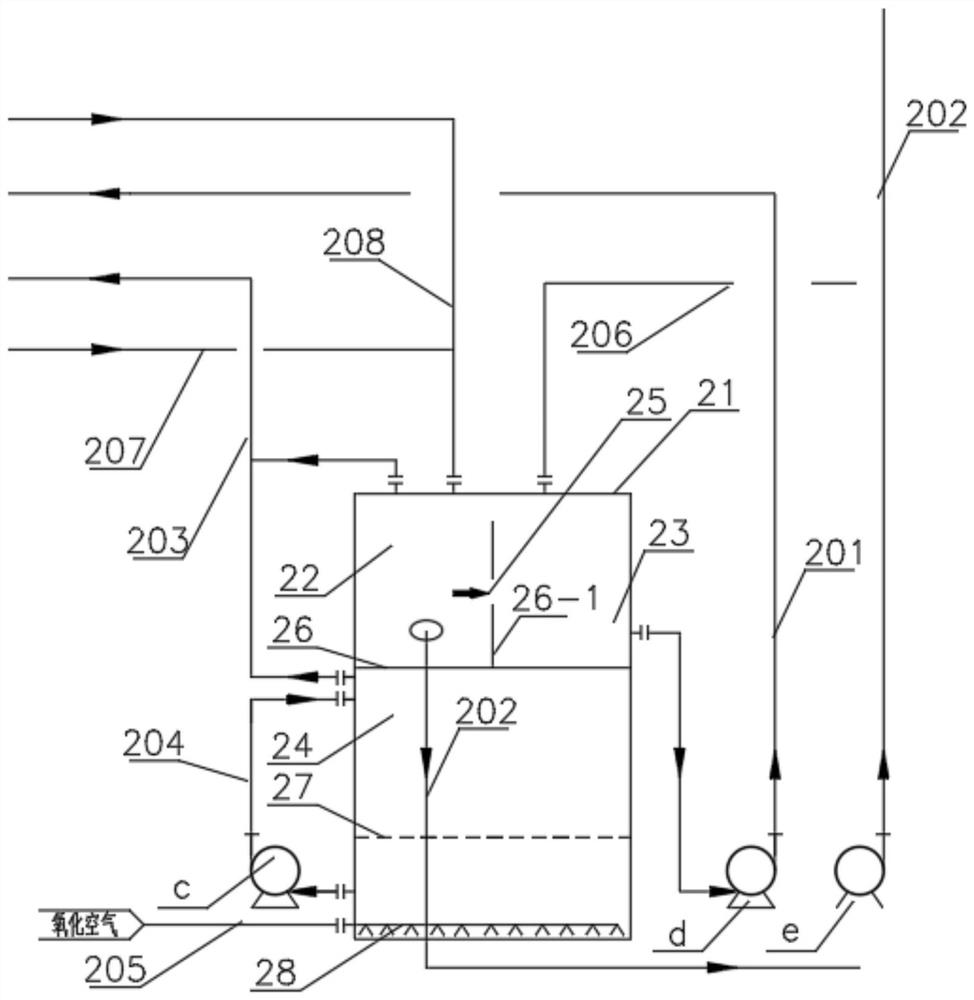

System device and method for desulfurization, denitrification and decarbonization of flue gas by ammonia process

PendingCN114146549ARealize resource utilizationSynergistic removalGas treatmentDispersed particle separationFlue gasEnvironmental engineering

The invention provides a flue gas ammonia process desulfurization, denitrification and decarbonization system device and method, the system device comprises a desulfurization and denitrification tower, a decarbonization tower and an ammonia gas escape recovery tower which are connected in sequence along a flue gas flowing direction, so that NOx, SO2 and CO2 in flue gas respectively react with ammonia in absorption liquid to generate ammonium nitrate, ammonium sulfate and ammonium bicarbonate, and the ammonium nitrate, the ammonium sulfate and the ammonium bicarbonate are separated from the absorption liquid. The method can be used for producing ammonium salt compound fertilizer to realize resource utilization; the system device further comprises a crystallization tower, a pyrolyzer and a washing tower, liquid discharged from the liquid outlet of the decarburization tower can be crystallized to obtain ammonium bicarbonate, and then the ammonium bicarbonate is pyrolyzed and washed, so that ammonia gas can be recycled to obtain ammonia water for circulation, and CO2 can be obtained for industrial utilization. A crystallization mother solution generated by crystallization is used as a desulfurization and denitrification absorption solution to be introduced into a desulfurization and denitrification tower for desulfurization and denitrification treatment; the system device and the method provided by the invention not only can realize collaborative removal of various pollutants, but also can realize resource recycling.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

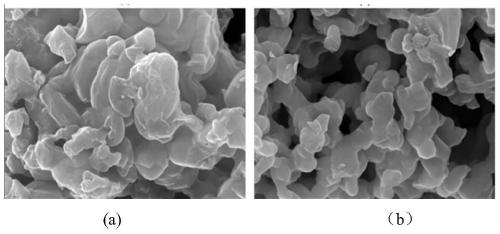

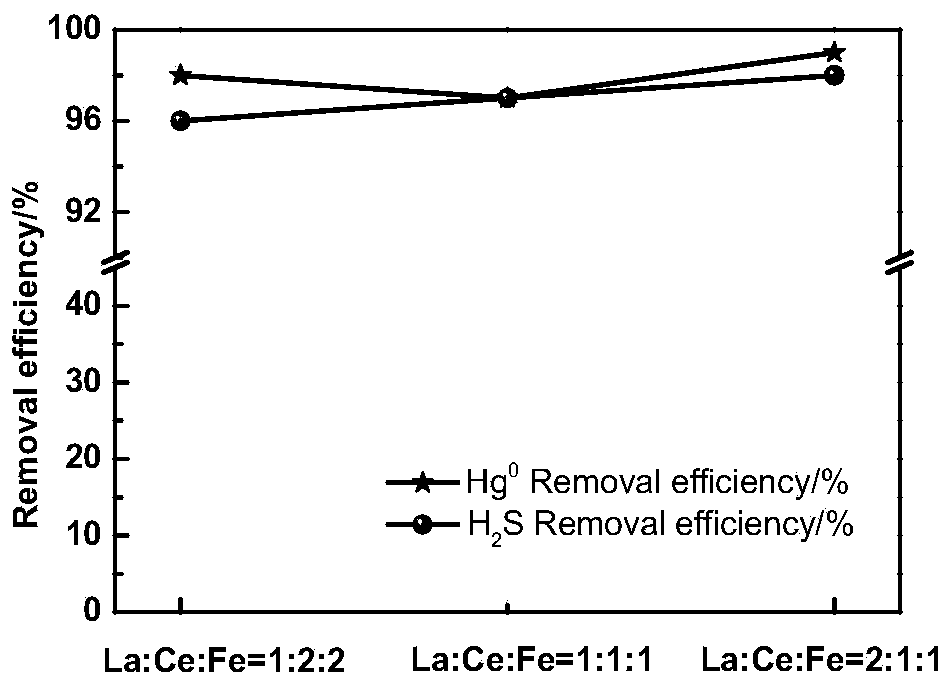

Preparation method of catalyst for synergistic removal of hydrogen sulfide and elemental mercury in garbage gasification pollutants

ActiveCN111215124AAvoid inactivationNarrow pore size distributionMolecular sieve catalystsDispersed particle separationPtru catalystLanthanum

The invention discloses a preparation method of a catalyst for synergistic removal of hydrogen sulfide and elemental mercury in garbage gasification pollutants, and belongs to the technical field of catalyst preparation. The preparation method comprises the following steps of: selecting an MCM-41 molecular sieve as a raw material, and introducing a hydrophobic group SiH4 to modify the outer surface of the molecular sieve; then removing a template agent by using a certain amount of anhydrous ethanol / HCl; introducing an -SH group to modify the inner surface of the molecular sieve; and then loading a salt solution of lanthanum, cerium and iron in the modified molecular sieve, performing drying, and then conducting high temperature roasting to obtain the multi-metal oxide molecular sieve composite material used for researching the synergistic control of garbage pyrolysis gasification pollutants. The prepared catalyst has good adsorption capacity and regeneration capacity within the temperature range of 150DEG C-200DEG C, H2S and Hg<0> can be efficiently and synergistically removed, and compared with the prior art, multiple pollutants are purified at the same time, and the investment cost and the operation cost can be effectively reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Integrative coordinated desulfurization, denitration, demercuration device and technique using spray bubbling method

ActiveCN101306322BReduce investment and operating costsSmall footprintDispersed particle separationInlet channelFlue gas

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

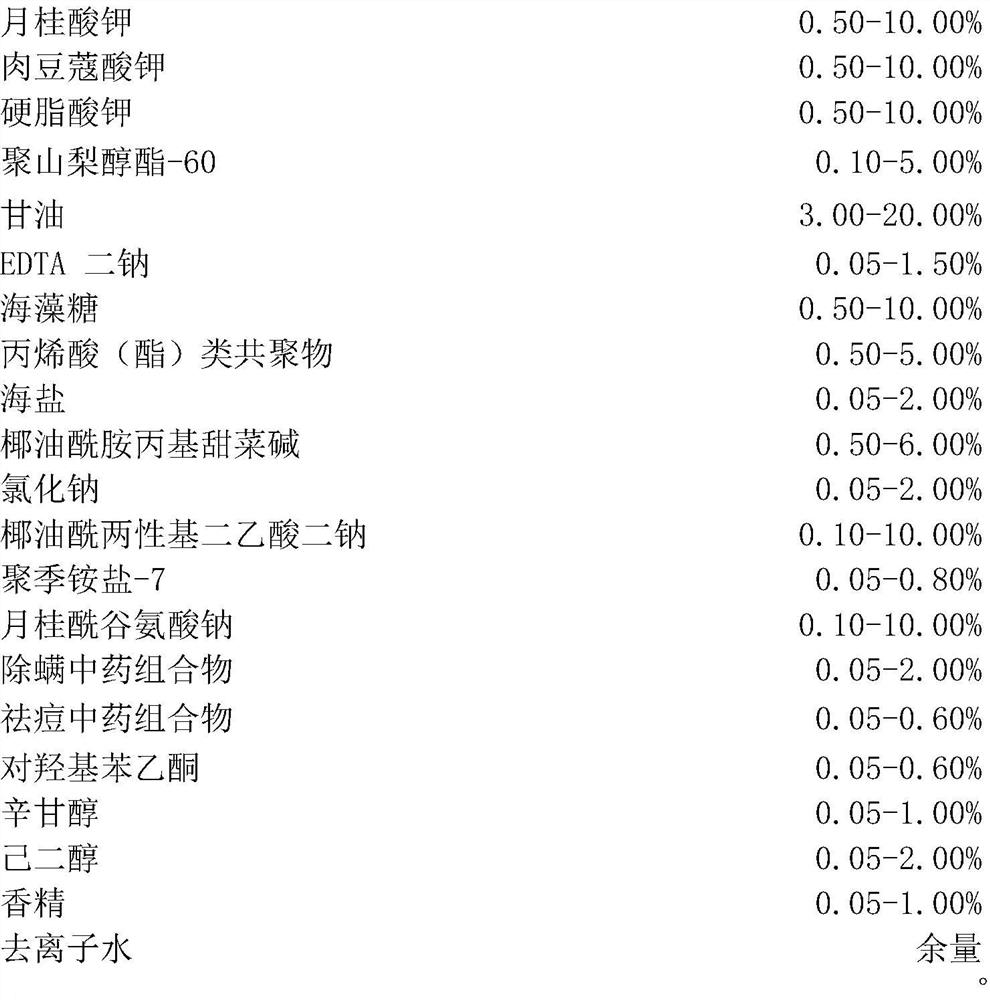

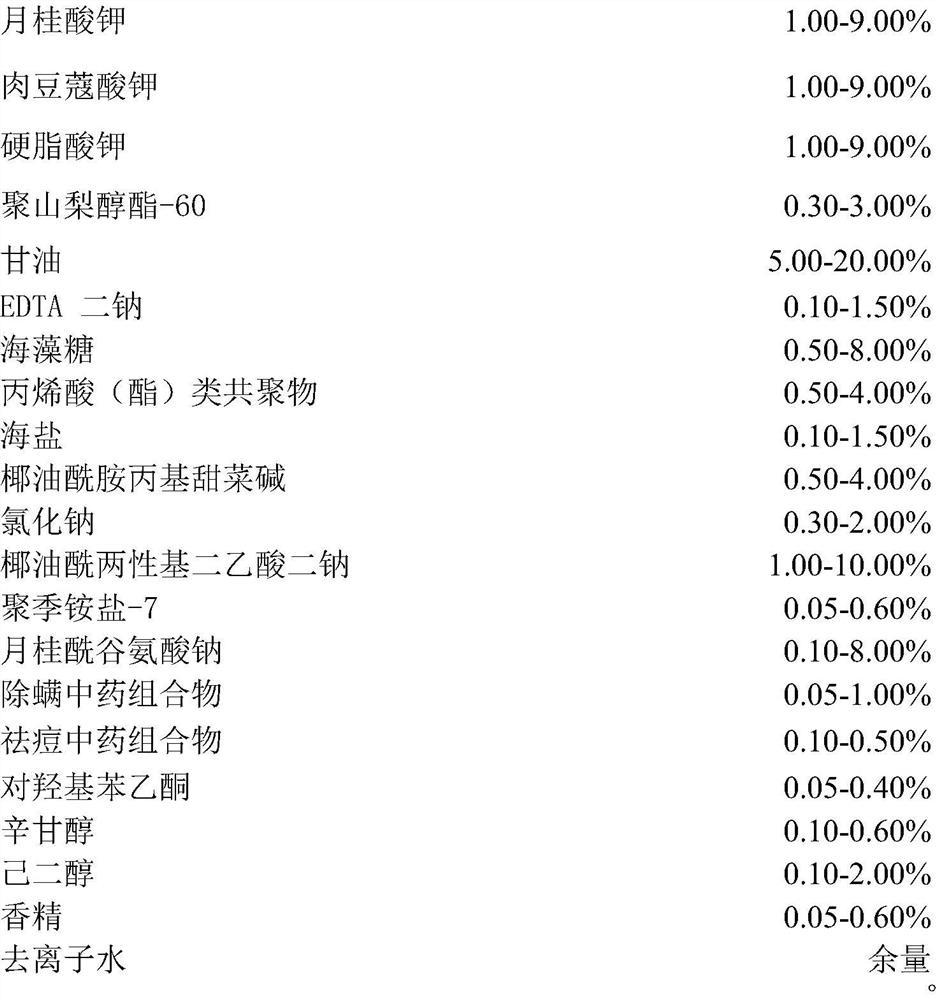

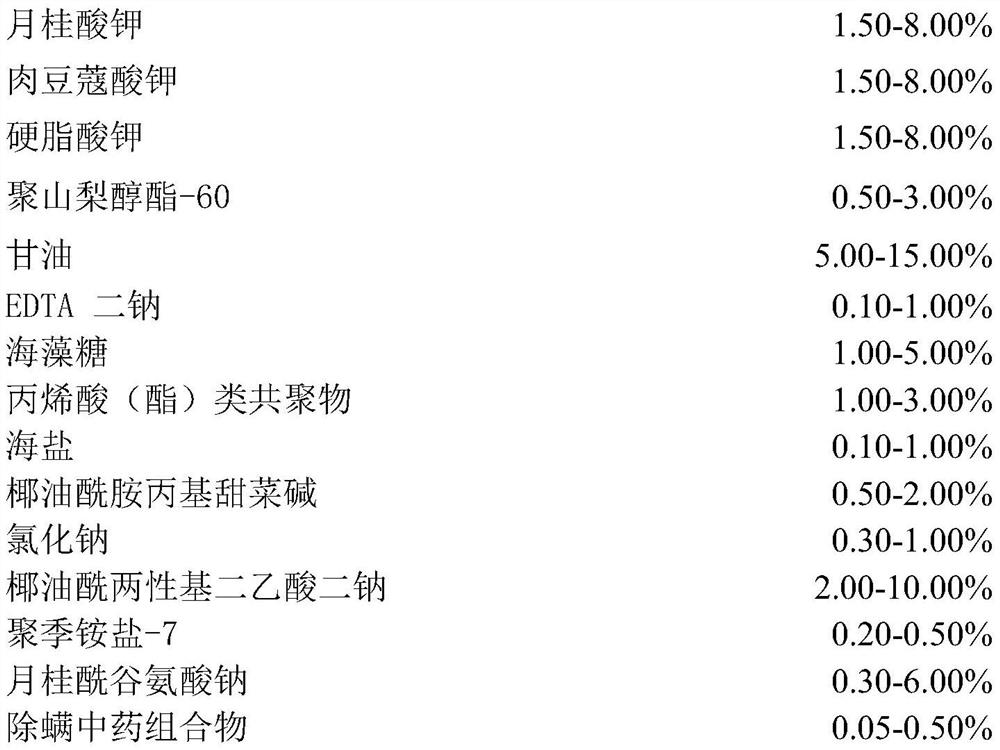

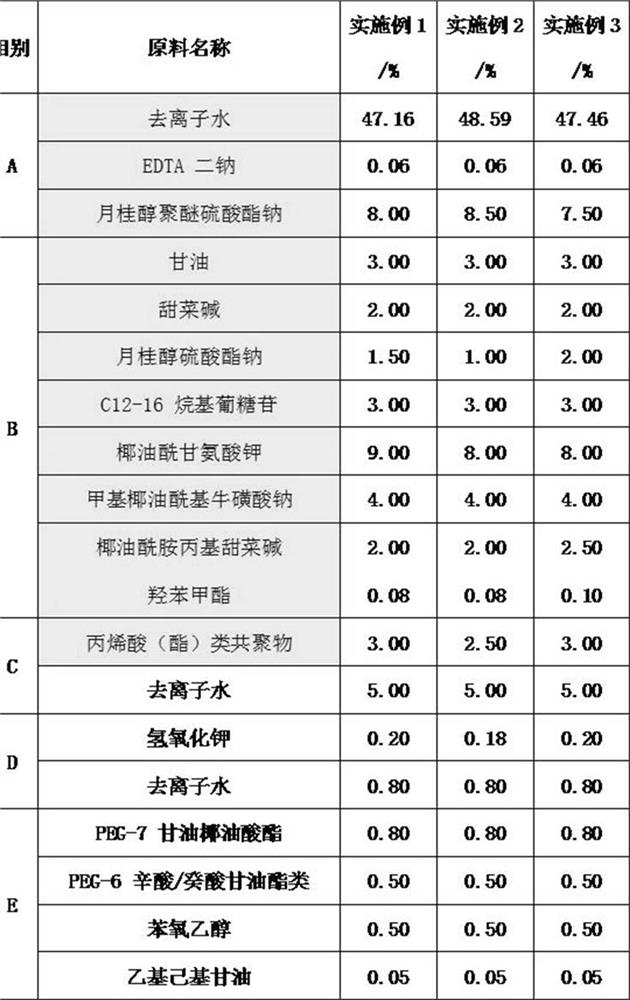

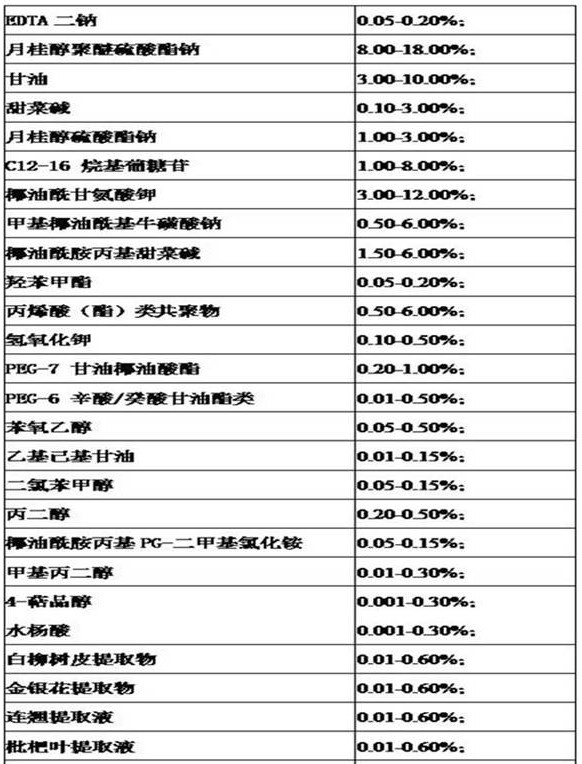

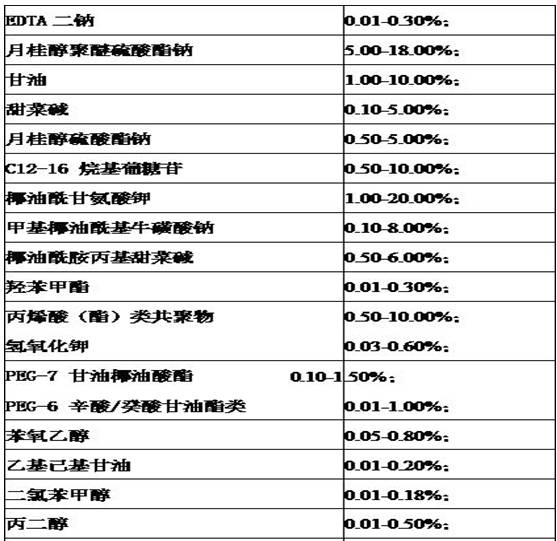

Oil-control acne-removing acarus-killing face-cleaning facial cleanser containing deep-sea salt

The invention discloses an oil-control acne-removing acarus-killing face-cleaning facial cleanser containing deep sea salt and a preparation method thereof. The acarus-killing traditional Chinese medicine composition contained in the facial cleanser can emit a special fragrance with a strong acarus-killing effect. The contained acne-removing traditional Chinese medicine composition has the effects of controlling grease secretion, dredging pores, inhibiting bacteria, disinfecting and removing acnes. The traditional Chinese medicine composition has a synergistic effect, shows strong oil control, sterilization, acarus killing and acne removing effects, also has good effects of scavenging free radicals and inhibiting tyrosinase activity, and has certain anti-aging and whitening functions. The sea salt from dead sea has the effects of promoting blood circulation of a human body, sterilizing, relieving itching, relieving swelling and pain, whitening, removing cutin, acne and blackhead. In conclusion, through the synergistic interaction among the components, the oil-controlling, sterilizing, acarus-killing and acne-removing effects are powerfully achieved.

Owner:广州极男化妆品有限公司

Plant mite eliminating deep skin clearing face cream for controlling oil, removing small poxes and moisturizing and preparation technology.

PendingCN111728911AAntipruriticAvoid breedingCosmetic preparationsToilet preparationsBiotechnologyNutrition

The invention discloses plant mite eliminating deep skin clearing face cream for controlling oil, removing small poxes and moisturizing and a preparation technology. A composition of plant extracts ofrosemary, dandelions, radix isatidis, isatis indigotica fortune, licorice roots, paris polyphylla and the like, contained in the face cream can emit special fragrance having efficacy of efficiently removing mites. Lipacide C8G ( Caprylylglycine ) contained in the face cream can deepen in pores and hair to clean dirt, and through cooperation of sodium shale oil sulfonat and plant extracts, the water-and-oil balance of skin can be efficiently adjusted, and obvious oil controlling efficacy is obtained. The composition of plant extracts, contained in the face cream has the efficacy of being efficiently nutritive and moisturizing, pure moistening and nourishing natural moisturizing force is provided for skin, and through cooperation of blue massaging granules, the skin environment can be awakened and moistened, nutrient absorption is facilitated, dryness, itch and discomfort symptoms of the skin can be relieved, and besides, the skin is full, and has elastic and healthy gloss. A white willow bark extract, a honeysuckle flower extract, a fructus forsythiae extracting solution, a white mulberry root bark extract and the like, which are contained in the face cream have the efficacy of efficiently resisting bacteria, dispelling small poxes, whitening and resisting ageing. The products can maintain week acid, and are mild and non-irritating.

Owner:广州天芝丽实业有限公司 +2

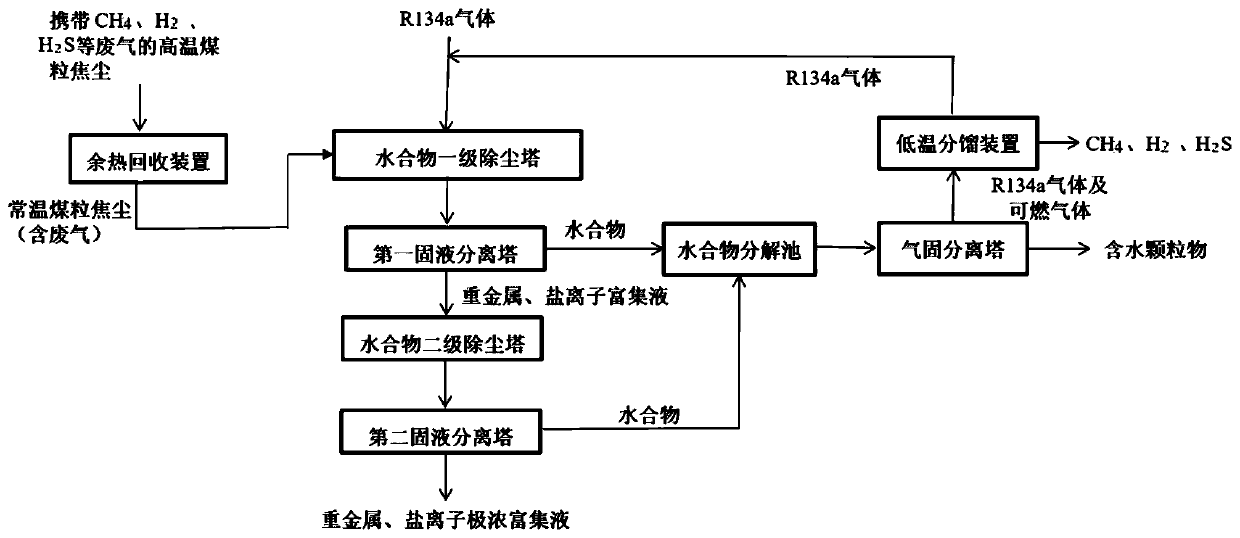

Hydrate-based particulate matter/waste gas synergistic removal system and method

ActiveCN110947262AReduced requirements for generating containersNon-irritatingGas treatmentMethane captureParticulatesHazardous substance

The invention discloses a hydrate-based particulate matter / waste gas synergistic removal system and method. Particulate matters / coking waste gas can be synthesized into a gas hydrate by utilizing R134a, so that particulate matters / coking waste gas synergistic removal can be realized in a pollution-free and low-energy-consumption manner. The system comprises a waste heat recovery device, a hydratefirst-stage dust removal tower, a solid-liquid separation first-stage tower, a hydrate second-stage dust removal tower, a solid-liquid separation second-stage tower, a hydrate decomposition tank, a gas-solid separation tower and a low-temperature fractionation device. According to the system, various harmful substances such as heavy metals and coking waste gas can be removed while particulate matters are removed, compared with an existing particulate matter control and waste gas treatment device, a hydrate method device is greatly simplified, various pollutants can be effectively removed, andenergy conservation and environment protection are achieved.

Owner:DALIAN UNIV OF TECH

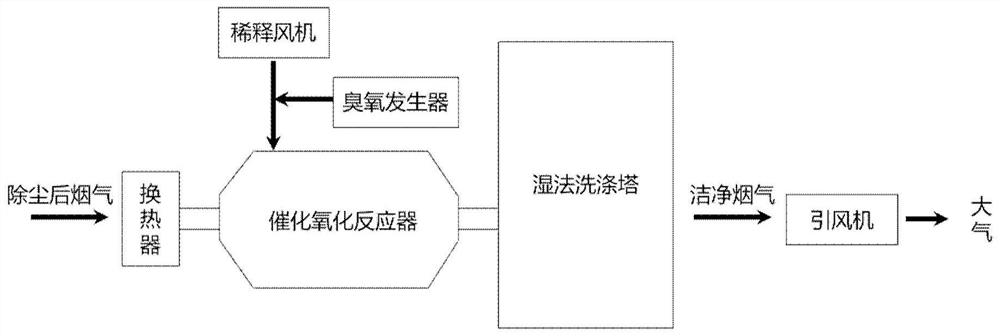

Method and device for removing chlorine-containing organic pollutants in flue gas through combination of ozone catalysis and wet process

PendingCN111841312AEfficient degradationCompletely degradedGas treatmentUsing liquid separation agentPtru catalystFlue gas

The invention relates to a method and a device for removing chlorine-containing organic pollutants in flue gas through a combination of ozone catalysis with a wet process. The method comprises the following steps: introducing to-be-treated flue gas and ozone into a reaction unit, and carrying out a catalytic ozonation reaction under the action of a catalyst; allowing oxidized flue gas to enter anabsorption unit to remove soluble pollutants so as to obtain clean flue gas. The invention provides a technology for efficiently, thoroughly and stably degrading chlorine-containing organic pollutantsin flue gas at a low temperature, an ozone coupled catalysis mode is adopted for conversion of the chlorine-containing organic pollutants into HCl, Cl2, CO2 and H2O , and then wet-process alkali liquor absorption is conducted so as to achieve a removal effect of 90% or more.

Owner:TIANJIN UNIV

A kind of protease super-concentrated laundry detergent and preparation method thereof

ActiveCN105062703BMild in natureGentle to the touchNon-ionic surface-active compoundsOrganic detergent compounding agentsSodium citrateLaundry

The invention discloses a protease super-concentrated laundry detergent, which is mainly composed of the following raw materials in mass percentage: 3% to 38% of nonionic surfactant, 1% to 22% of anionic surfactant, 0.1% to 1% of Protease, 0.1%-2% triethanolamine, 0.1%-2% sodium citrate, 0.1%-2% refined salt and 60%-70% deionized water; protease includes biological protease and compound protease. The protease super-concentrated laundry detergent of the present invention has mild neutral properties, no irritation, soft hand feeling, no alkaline residue left after washing, no skin allergies and other symptoms, no damage to fabrics, and at the same time Easily soluble in water, easy to use, easy to control the dosage, easy to store and easy to use. The preparation method of the invention has simple process operation and is easy to realize industrialized production.

Owner:DONGGUAN XIANGYU CHEM

Coal-fired flue gas semi-dry method combined desulfurization and denitrification system and method

PendingCN111905543AMolecular atomization particle size is smallAvoid invalid decompositionGas treatmentDispersed particle separationFlue gasFluidized bed

The invention provides a coal-fired flue gas semi-dry combined desulfurization and denitrification system and method. The coal-fired flue gas semi-dry combined desulfurization and denitrification system comprises a front oxidation system arranged on a flue, an absorption system arranged at an outlet of the flue, and a dust removal system and a chimney which are sequentially connected with the absorption system, wherein the front oxidation system comprises an H2O2 storage tank and an ultrasonic atomizer which are connected in sequence, and a compressed gas tank connected with an inlet of the ultrasonic atomizer; an outlet of the ultrasonic atomizer is connected into the flue; the absorption system comprises an absorption tower; the absorption tower adopts a circulating fluidized bed absorption tower, the top is provided with an absorbent supplementing bin, and the bottom is provided with a water-spraying humidifying device; the flue gas inlet of the absorption tower is connected with the flue outlet, the flue gas outlet of the absorption tower is sequentially connected with the dust removal system and the chimney, the system can effectively meet the requirement for integrated removal of pollutants, integrated removal of SO2 and NOx is achieved, meanwhile, the desulfurization and denitrification efficiency is high, the process is simple, and the investment and operation cost is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method and equipment for purifying tail gas generated by burnning garbage

ActiveCN100402926CReduce the temperatureControl flow rateCombination devicesIncinerator apparatusCooling towerDust control

A device of purifying waste gas of garbage-burning is prepared as setting smoke inlet at top end of cooling tower; setting water spraying nozzle opposite to flowing direction of smoke; setting S form flue pipe between cooling tower bottom and top of bag-type collector; setting lime powder inlet at bottom section of said flue pipe, iron fly ash inlet at middle section of said flue pipe and activated carbon inlet at top section of said flue pipe; setting filter material layer in bag-type collector and setting purified gas outlet at top side of bag-type collector.

Owner:TSINGHUA UNIV +1

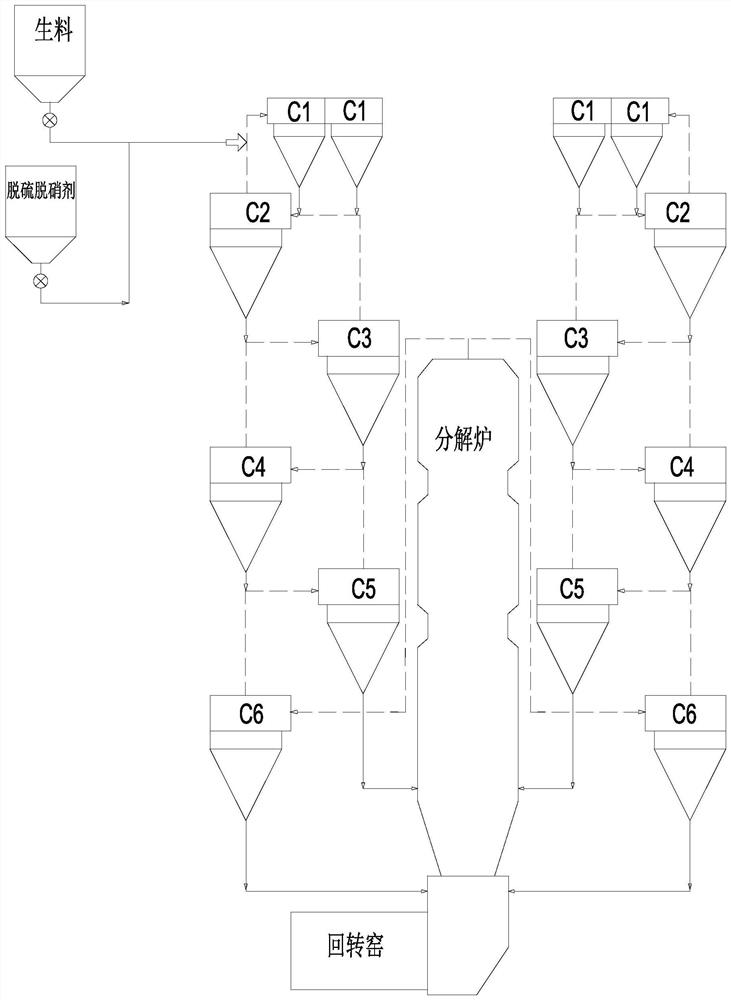

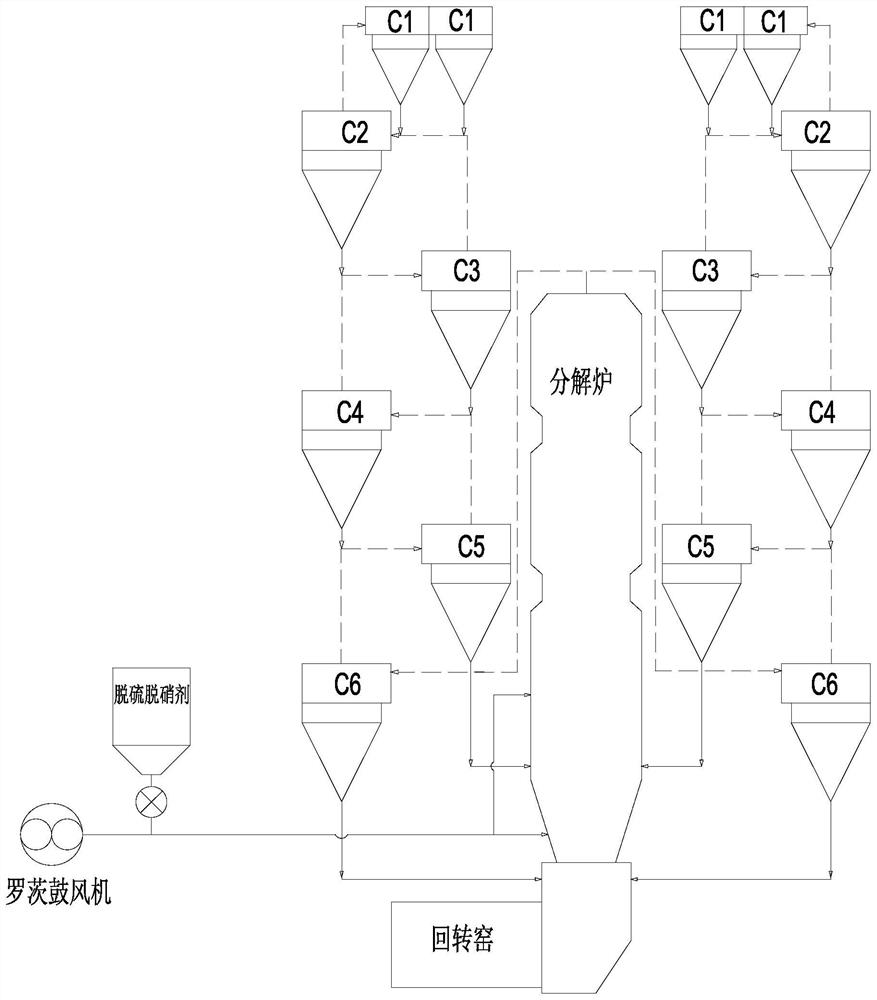

Method for preparing cement kiln synergistic desulfurization and denitrification agent through resource utilization of hazardous waste and solid waste

PendingCN114682085ASynergistic removalIncrease dosageDispersed particle separationCement productionPtru catalystNitrogen oxides

The invention relates to a method for preparing a synergistic desulfurization and denitrification agent for a cement kiln by recycling hazardous waste and solid waste. The method comprises the following steps: (1) mixing a crushed waste SCR (Selective Catalytic Reduction) denitrification catalyst, electrolytic manganese residues and carbide slag according to a certain mass ratio; (2) carrying out coarse grinding on the mixed material; and (3) adding an auxiliary agent into the material subjected to coarse grinding according to a certain proportion, and performing fine grinding to obtain the desulfurization and denitrification agent. According to the invention, nitrogen oxide and sulfur dioxide in the cement kiln tail gas can be synergistically removed, the emission standard is met, escape ammonia generated by an SNCR system can be eliminated, and increasingly strict ammonia escape supervision requirements are met; dangerous waste and solid waste can be treated while the desulfurization and denitrification cost is reduced, and resource reutilization is performed to create an environment-friendly value. Dust and waste liquid are not additionally generated, the technological process is easy to operate, and equipment and land occupation are not newly added.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com