Water-saving and energy-saving ammonia desulphurization discharge process and system capable of preventing ammonia from escaping from aerosol

An ammonia desulfurization and emission system technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as visual pollution, smoke trailing and falling, and secondary environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

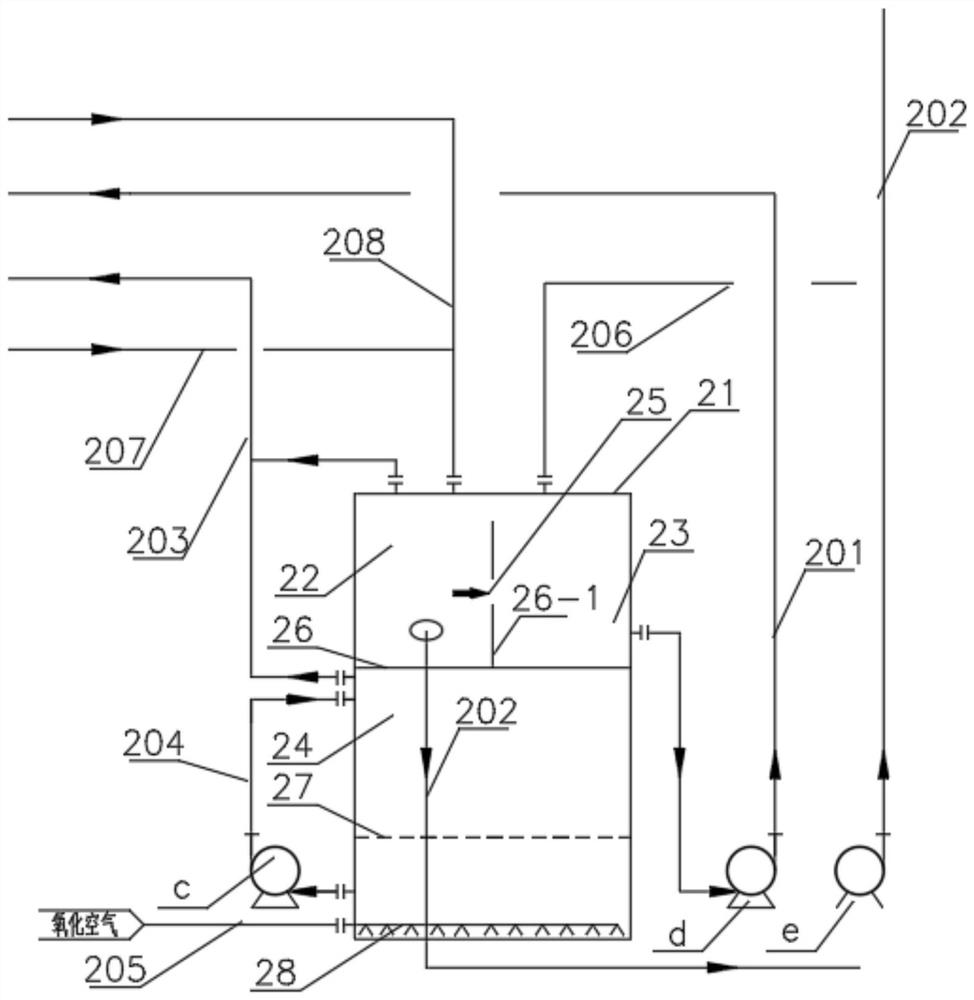

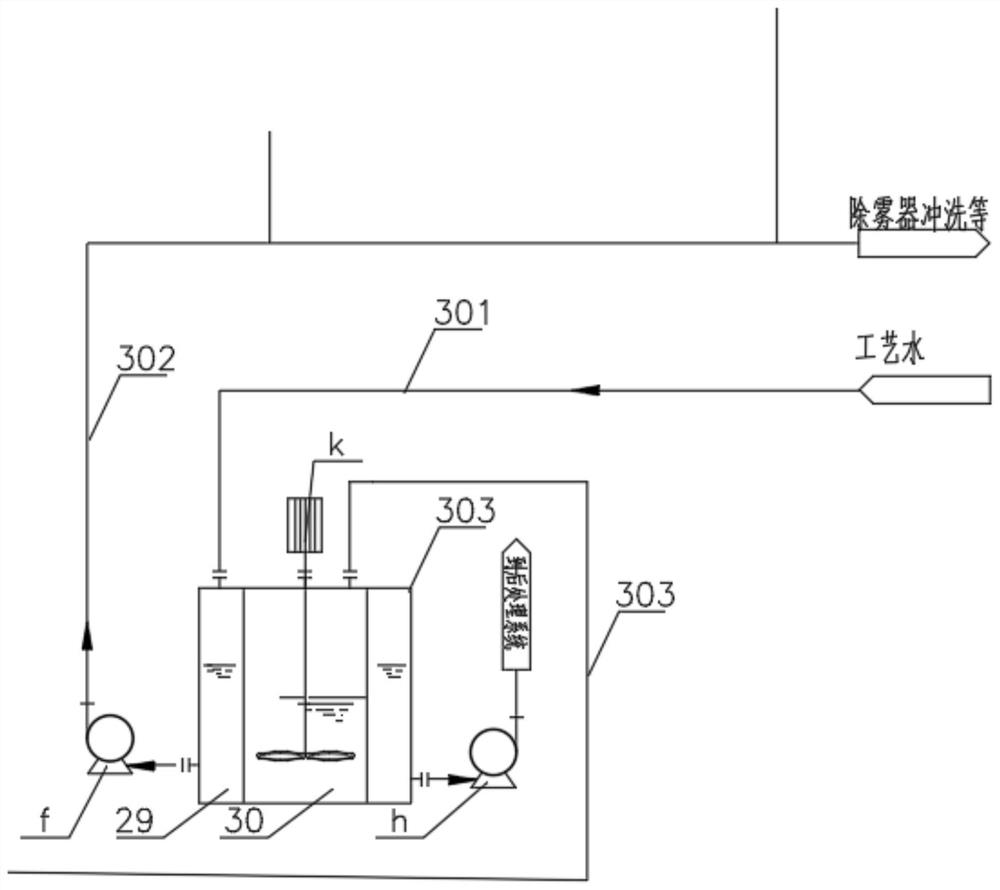

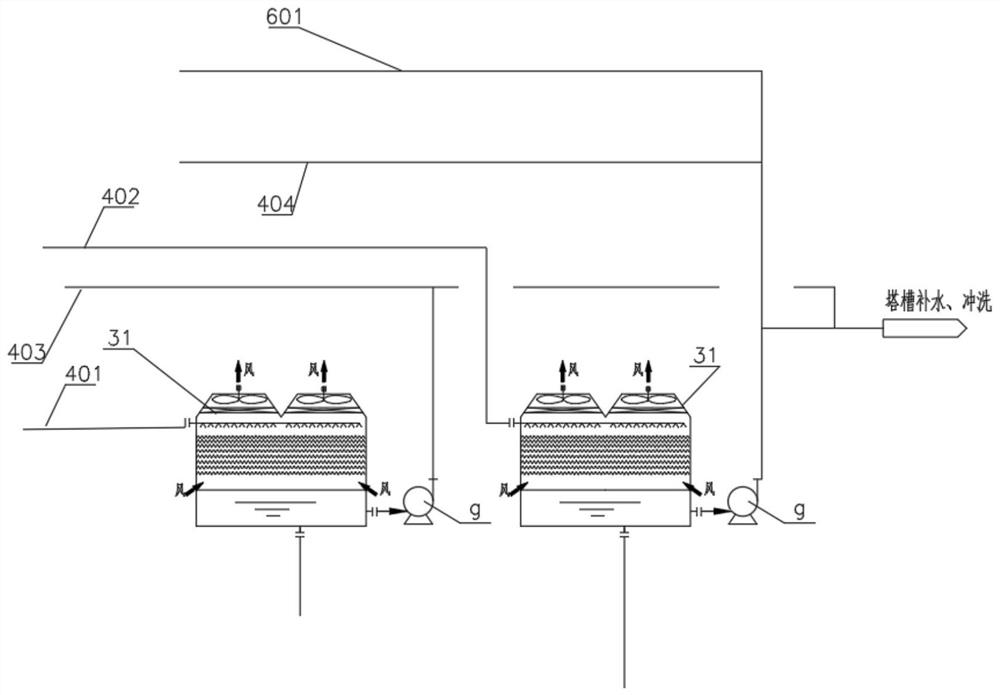

[0061] Such as figure 1 As shown, a water-saving and energy-saving ammonia desulfurization ultra-clean discharge system that prevents ammonia from escaping aerosols includes a desulfurization tower 20, a multifunctional circulation tank 21, a crystallization particle enlargement system 32, and a cooling tower 31. The desulfurization tower 20 passes through The pipelines are respectively connected with the multi-functional circulation tank 21 , the crystal grain increasing system 32 and the cooling tower 31 .

[0062] The desulfurization tower 20 includes a flue gas inlet 33, an absorption zone spray layer 9, and an absorption zone 10; the upper part of the absorption zone 10 is also provided with an ammonia capture zone spray layer 11 and an ammonia capture zone 12; the upper part of the ammonia capture zone 12 is also There are washing and purification zone 15, a spraying layer 14 for the first stage of washing, a second zone for washing and purification 15, and a spraying la...

Embodiment 2

[0083] The present invention also proposes a water-saving and energy-saving ammonia-based desulfurization ultra-clean discharge process that prevents ammonia from escaping aerosols, such as figure 1 As shown, the original flue gas enters the desulfurization tower cooling concentration crystallization zone 3 from the flue gas inlet 33 of the multi-section desulfurization tower 20, and enters the absorption zone 10 through the first breathable liquid collection cap 501 after being sprayed and cooled by the concentrated spray layer 4. The sulfuric acid gas in the flue gas is absorbed by the absorption liquid, and the flue gas enters the ammonia capture area 12 through the second breathable liquid collection cap 502, and the escaped ammonia gas is absorbed by the spray liquid, and the flue gas entrained with liquid droplets is removed by the high-efficiency demister 13 After the mist, it enters the washing and purification area 15 and the washing and purification area 17 successive...

Embodiment 3

[0101] Such as figure 1 As shown, the technical implementation steps of the process of the present invention are as follows: the flue gas enters the cooling concentration crystallization zone 3 from the flue gas inlet 33 of the multi-section desulfurization tower 20, and the slurry extracted from the concentrated slurry pool by the concentrated circulation pump a is passed through the concentrated spray layer 4 Spraying, reverse contact, mass transfer and heat transfer, the water in the slurry is evaporated to form a supersaturated slurry, and ammonium sulfate crystals are precipitated, falling into the concentrated slurry pool 2, and so on. Concentrated slurry tank 2 is provided with disturbance pipe network 1, and the slurry is pumped by disturbance circulation pump b and sprayed through the pipeline network to disturb the slurry tank to prevent the precipitation and hardening of ammonium sulfate crystals. It is more optimal, and at the same time, it avoids the cavitation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com