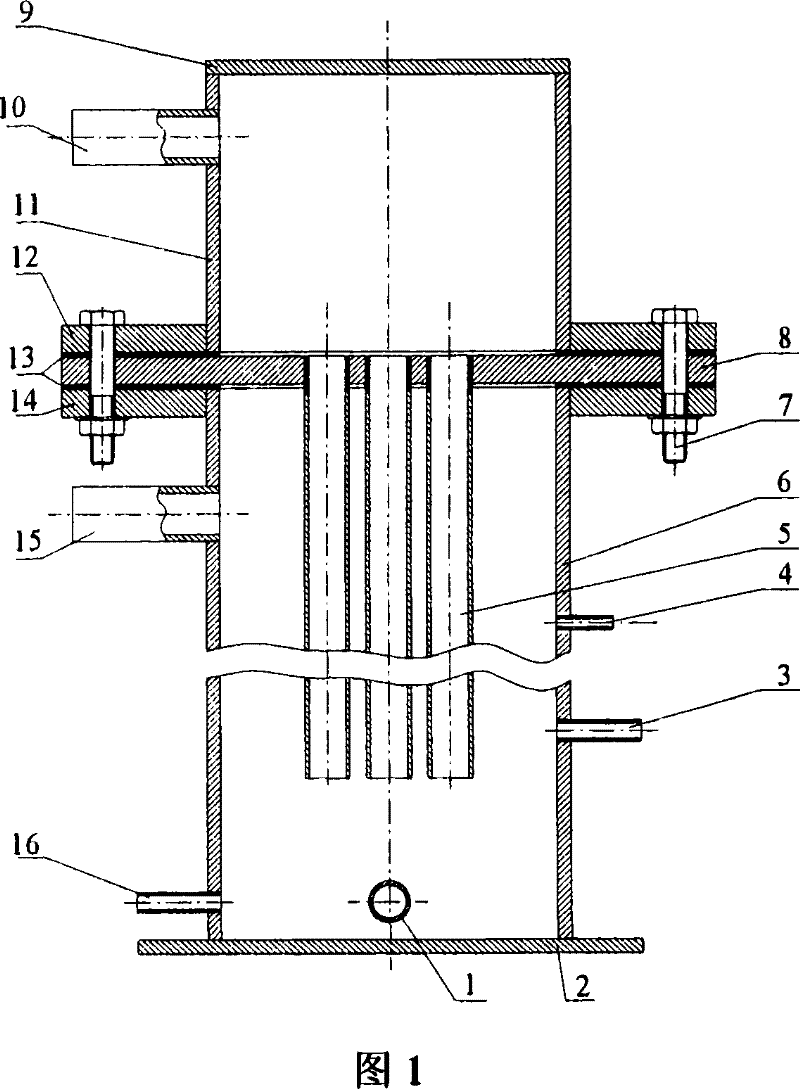

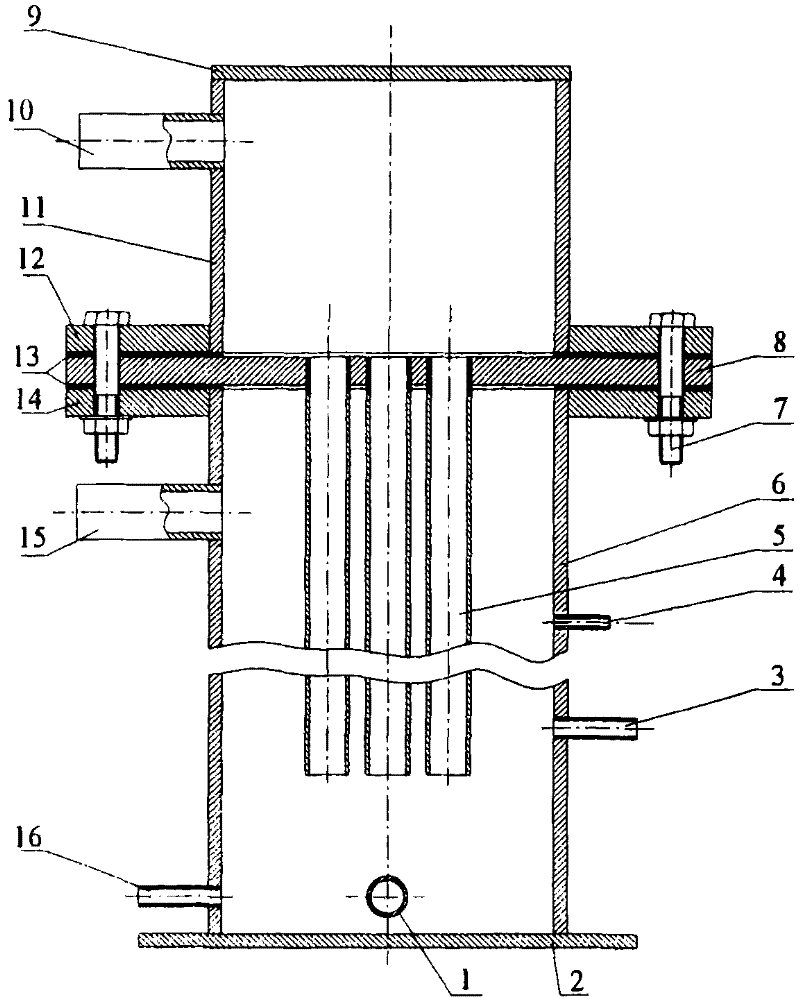

Integrative coordinated desulfurization, denitration, demercuration device and technique using spray bubbling method

A bubbling and denitrification technology, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of high investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

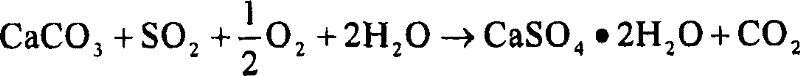

Method used

Image

Examples

Embodiment 1

[0031] The integrated synergistic desulfurization, denitrification, and mercury removal absorption liquid of the present invention includes a limestone slurry with a mass concentration of 5%, and KMnO is added to the limestone slurry 4 , its addition is 0.02% of the limestone slurry quality, the technical scheme described in the present embodiment, when flue gas flow rate is 5000Nm 3 / h, SO 2 The concentration is 5000mg / Nm 3 , NO concentration is 1500mg / Nm 3 At this time, the flue gas desulfurization efficiency can reach more than 60%, the denitrification efficiency can reach more than 30%, and the elemental zero-valent mercury Hg 0 The removal efficiency can reach more than 40%.

Embodiment 2

[0033] The integrated synergistic desulfurization, denitrification, and mercury removal absorption liquid of the present invention includes a limestone slurry with a mass concentration of 20%, and KMnO is added to the limestone slurry 4 , its addition is 0.15% of the limestone slurry mass, the technical scheme described in this embodiment, when the flue gas flow rate is 1 × 10 6 N m 3 / h, SO 2 The concentration is 5000mg / Nm 3 , NO concentration is 1500mg / Nm 3 At this time, the flue gas desulfurization efficiency can reach more than 85%, the denitrification efficiency can reach more than 60%, and the elemental zero-valent mercury Hg 0 The removal efficiency can reach more than 70%.

Embodiment 3

[0035] The integrated synergistic desulfurization, denitrification, and mercury removal absorption liquid of the present invention includes a limestone slurry with a mass concentration of 30%, and KMnO is added to the limestone slurry 4 , its addition is 0.25% of the limestone slurry mass, the technical scheme described in this embodiment, when the flue gas flow rate is 1 × 10 6 N m 3 / h, SO 2 The concentration is 5000mg / Nm 3 , NO concentration is 1500mg / Nm 3 At this time, the flue gas desulfurization efficiency can reach more than 95%, the denitrification efficiency can reach more than 80%, and the elemental zero-valent mercury Hg 0 The removal efficiency can reach more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com