Patents

Literature

39results about How to "Increase the gas-liquid contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

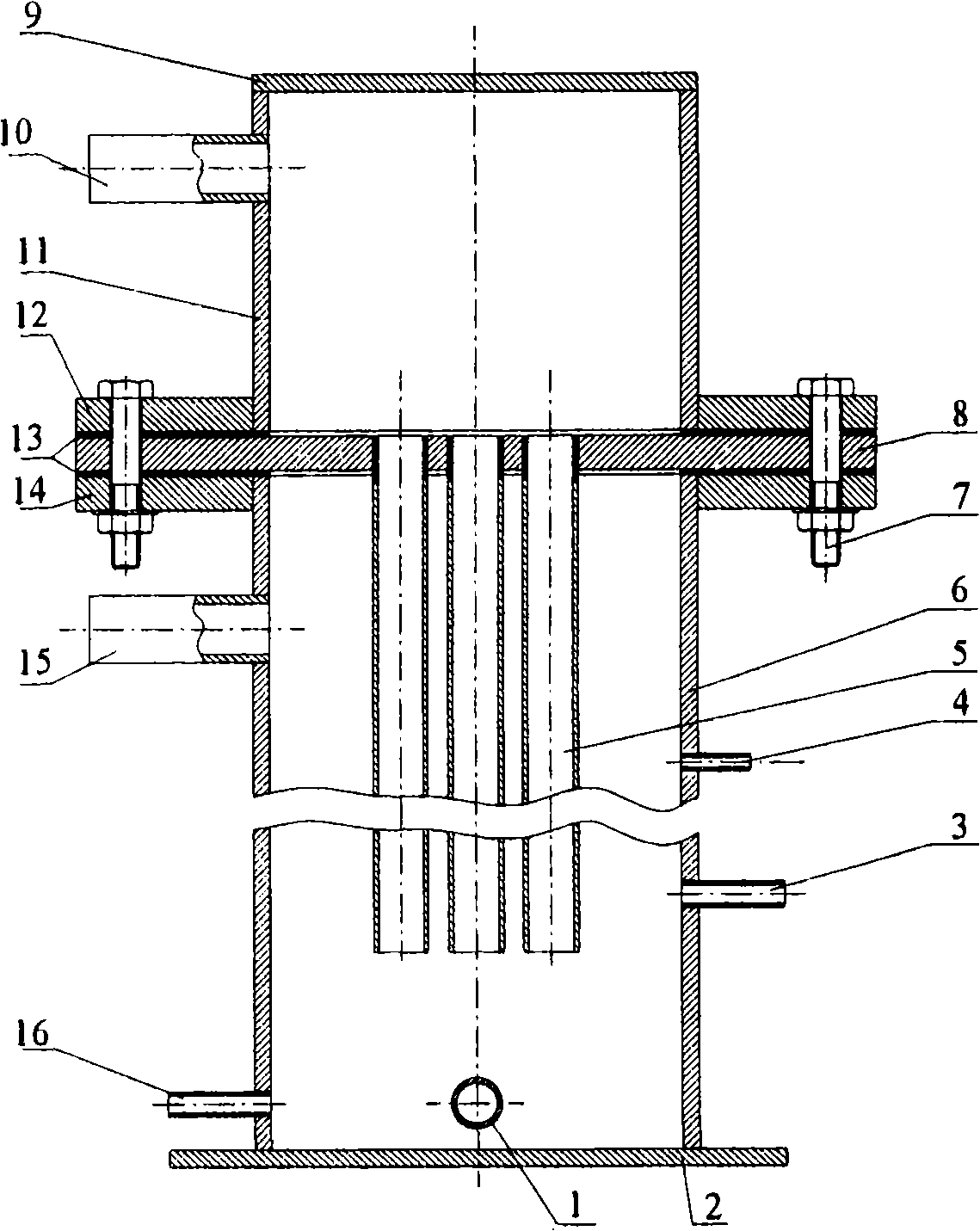

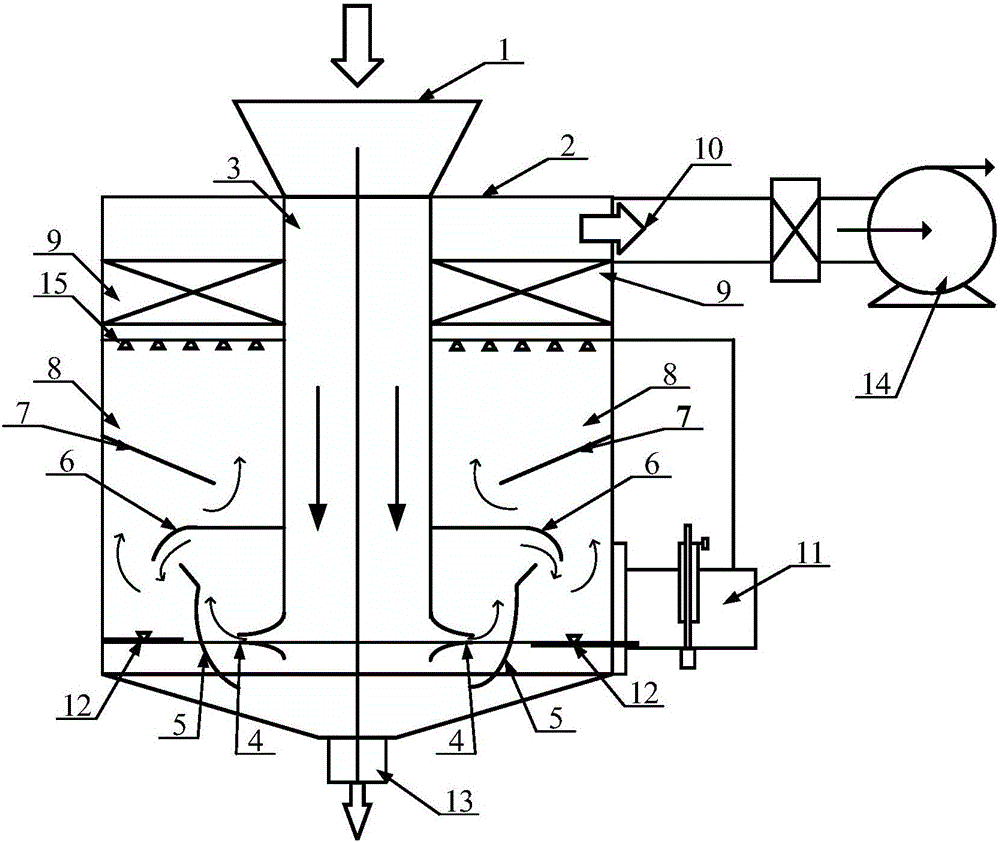

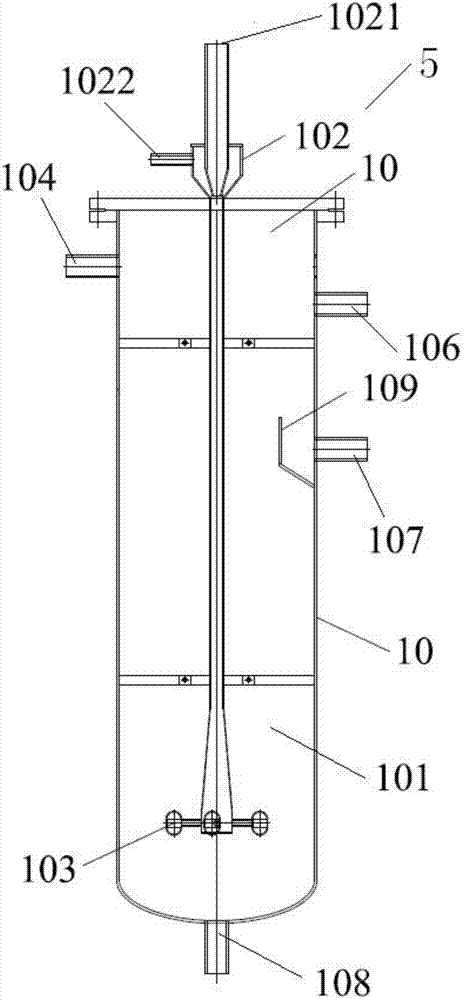

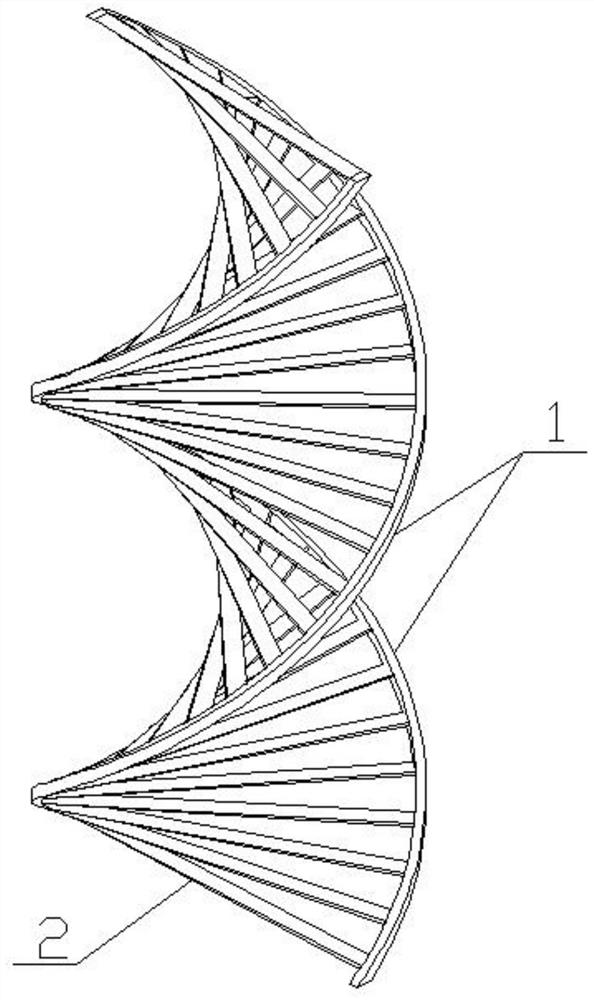

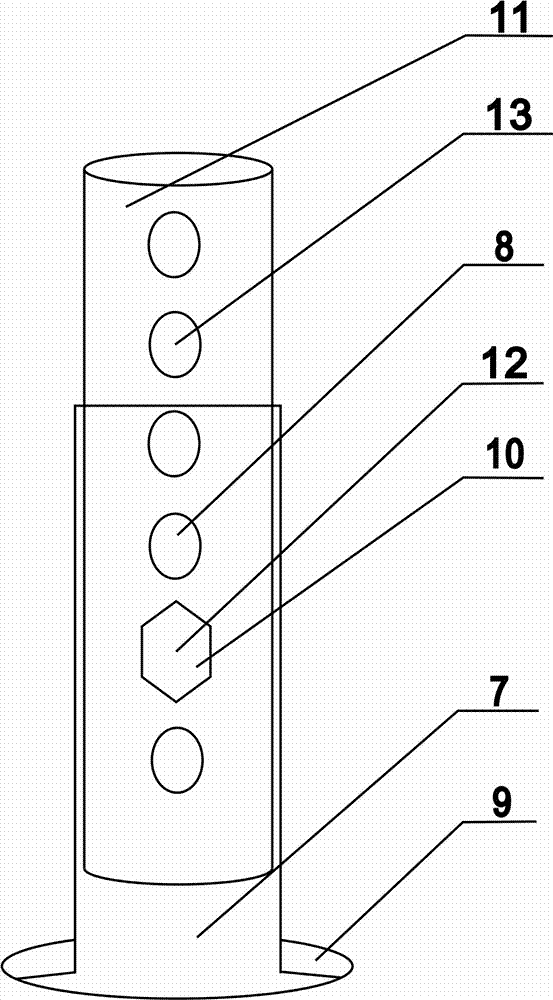

Integrative coordinated desulfurization, denitration, demercuration device and technique using spray bubbling method

ActiveCN101306322AReduce investment and operating costsSmall footprintDispersed particle separationInlet channelFlue gas

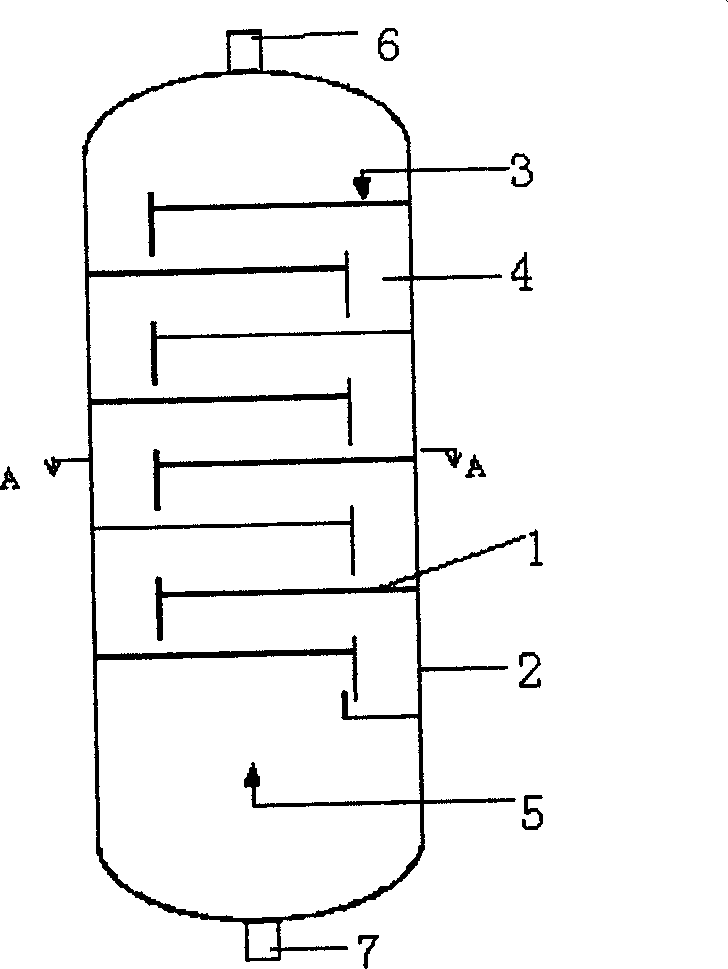

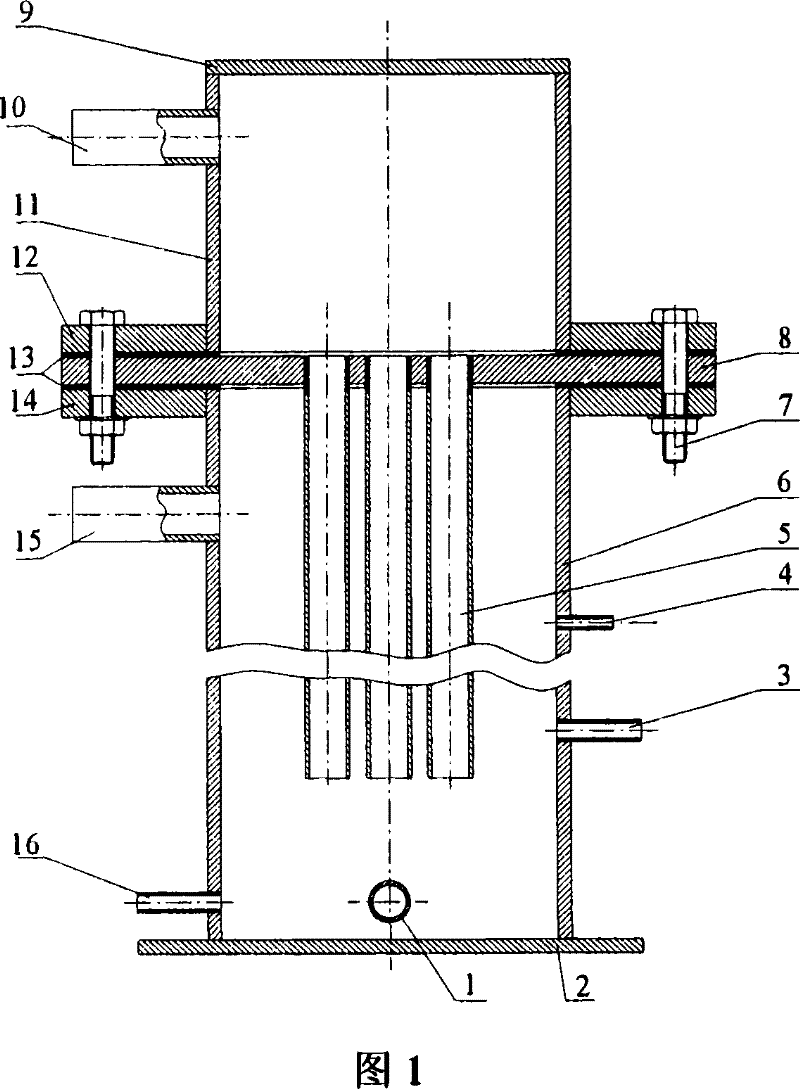

The invention relates to an integrated synergistic desulphurization, denitrification and demercuration device used for flue gas and a process for carrying out integrated synergistic desulphurization, denitrification and demercuration of the flue gas by using the device. The device comprises an original flue gas chamber (11), a tower body (6), a flue gas partition plate (8) and a bubbling jet pipe 5; wherein, the original flue gas chamber is fixed above the flue gas partition plate; the flue gas partition plate is fixed above the tower body; the three parts of the original flue gas chamber, the flue gas partition plate and the tower body are connected by an upper flange (12) and a lower flange (14); the upper end part of the bubbling jet pipe (5) is connected with the flue gas partition plate; the jet pipe communicates with the original flue gas chamber; an original flue gas inlet channel (10) is arranged outside the original flue gas chamber; and a purified flue gas outlet channel (15), a slurry discharge pipe (16), an oxidation wind pipe (1), a slurry return pipe (3) and a slurry adding pipe (4) are arranged outside the tower body.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

Method for removal of unreacted alcohol from reaction mixture of ester product with rotating packed beds

InactiveUS20050022666A1Short timeIncrease centrifugal forceUsing liquid separation agentAlcoholChemistry

A method is used to remove an unreacted alcohol from an ester product mixture by a gas stripping. The method involves the feeding of the ester product mixture into proximity of an axis of a rotating packed bed, so as to enable the ester product mixture to flow radially to come in contact with a gas which is introduced into the rotating packed bed. The unreacted alcohol and any other volatile component of low molecular weight are thus stripped from the ester product mixture by the gas entrainment, thereby resulting in production of a purified ester product which is collected at the bottom of the rotating packed bed. The unreacted alcohol and the volatile component, which are entrained in the gas, are discharged via an exit located at the top of the rotating packed bed.

Owner:IND TECH RES INST

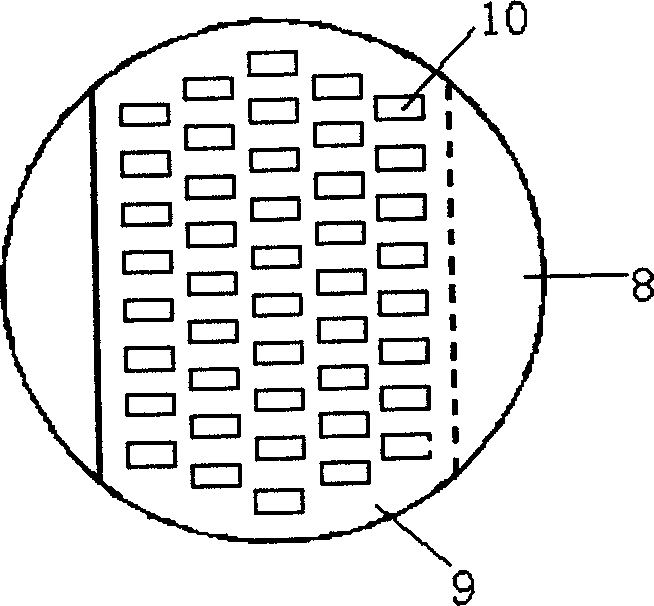

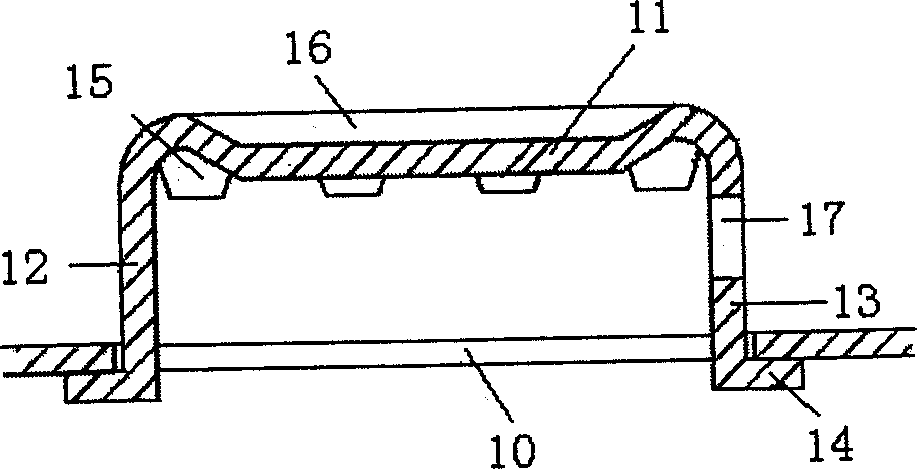

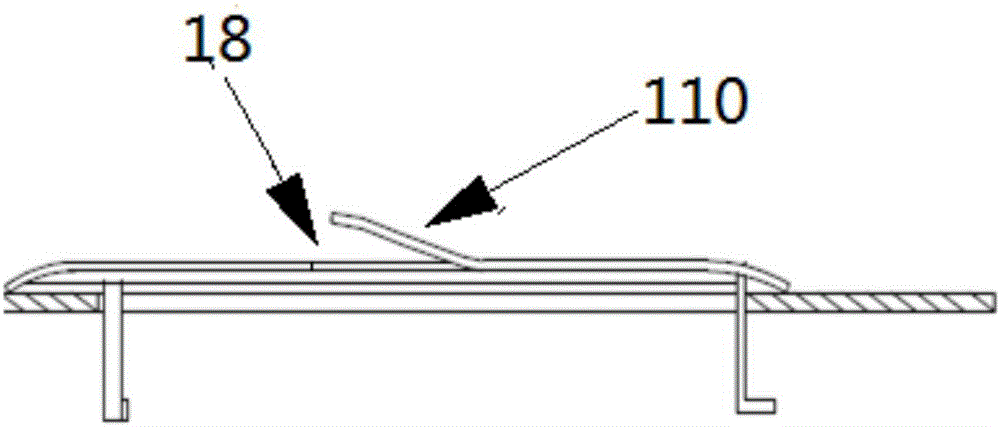

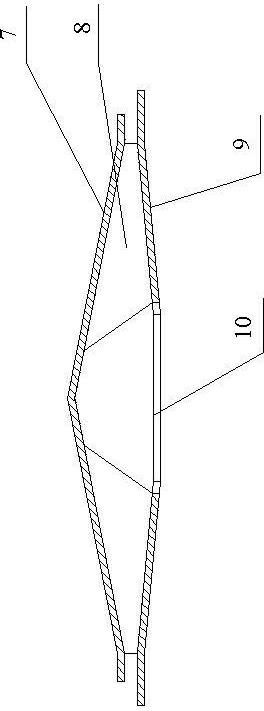

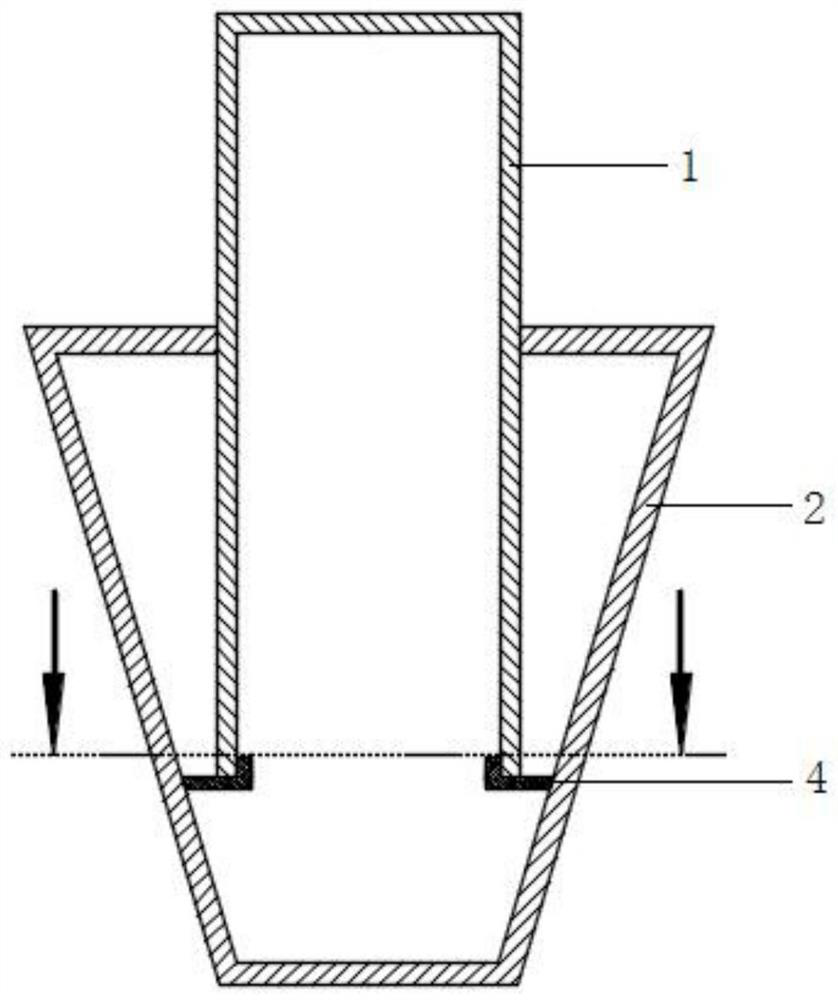

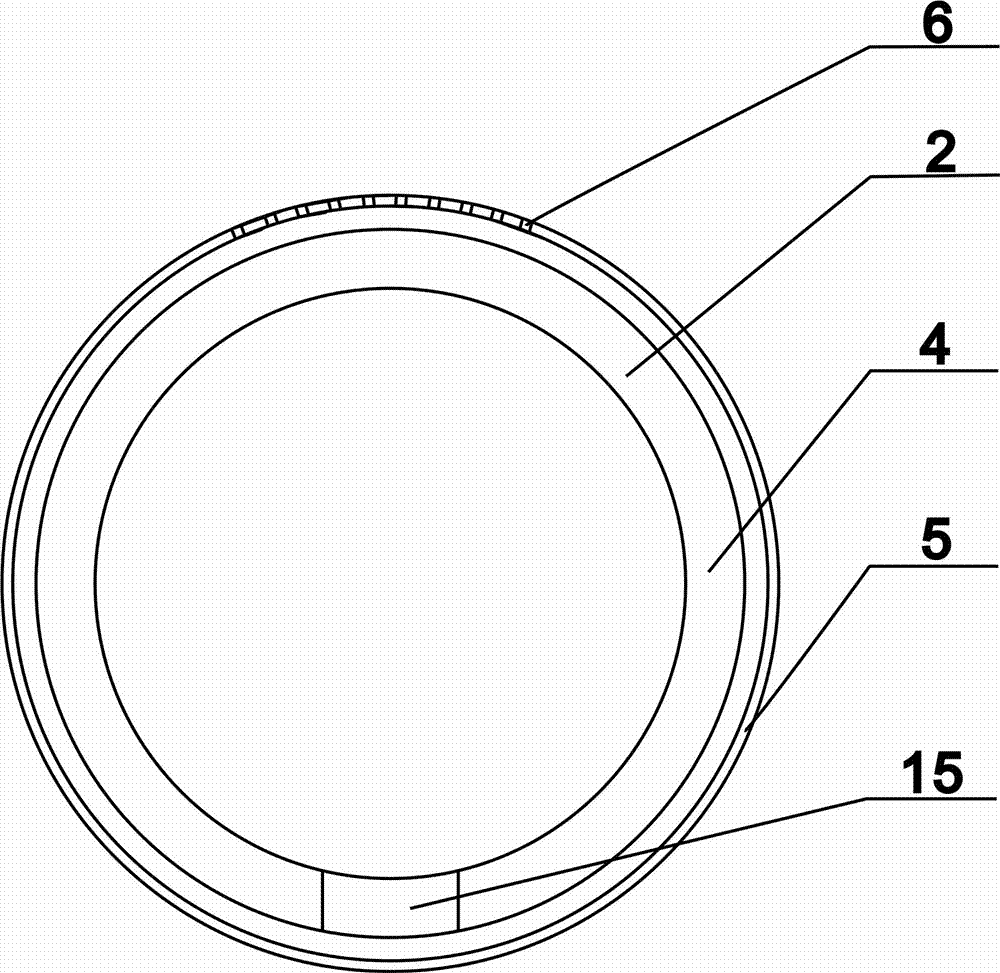

Tooth edge float valve

ActiveCN1683043ASmall bubble diameterIncrease the gas-liquid contact areaDistillation separationAirflowEngineering

The tooth edge float valve includes tabulated valve cover, liquid facing valve leg on one end of the valve cover and in the upstream position, liquid backing valve leg on the other end of the valve cover and in the downstream position, and valve feed fixed separately to the lower ends of the liquid facing valve leg and the liquid backing valve leg. The valve cover has downward bending toothed structures in the sides and the downward bending toothed structures can reduce the bubble diameter, raise the stability of the foam layer and avoid the direct spray of gas and liquid. In addition, the valve cover is provided with wedged slot to avoid the formation of gas flow eddy below the float valve, decrease liquid back mixing and lower the gas resistance of the float valve; and the liquid backing valve leg is provided with liquid guide hole for gas to drive liquid towards the outlet dam so as to reduce the liquid surface fall and decrease liquid back mixing.

Owner:CHINA PETROLEUM & CHEM CORP +1

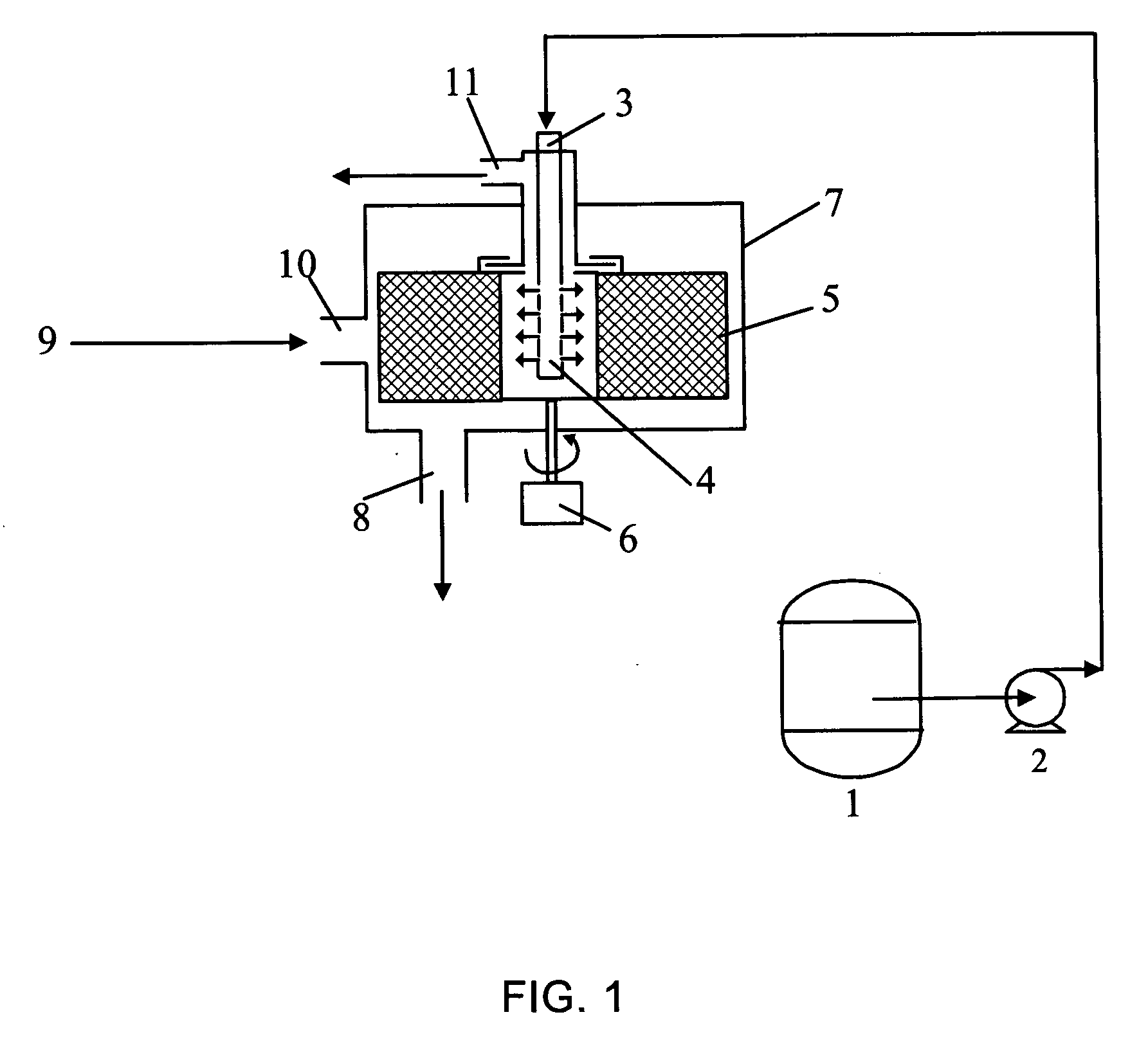

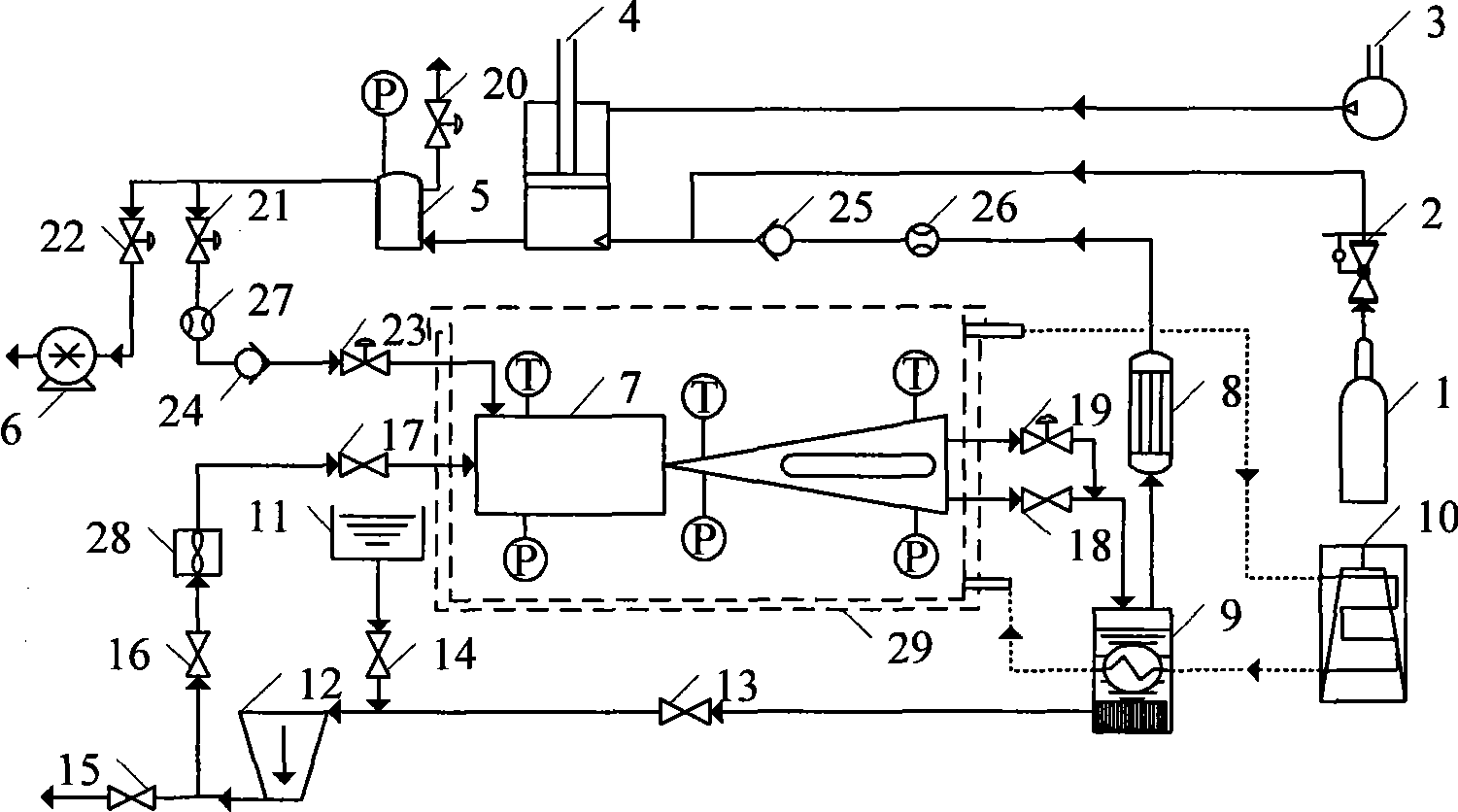

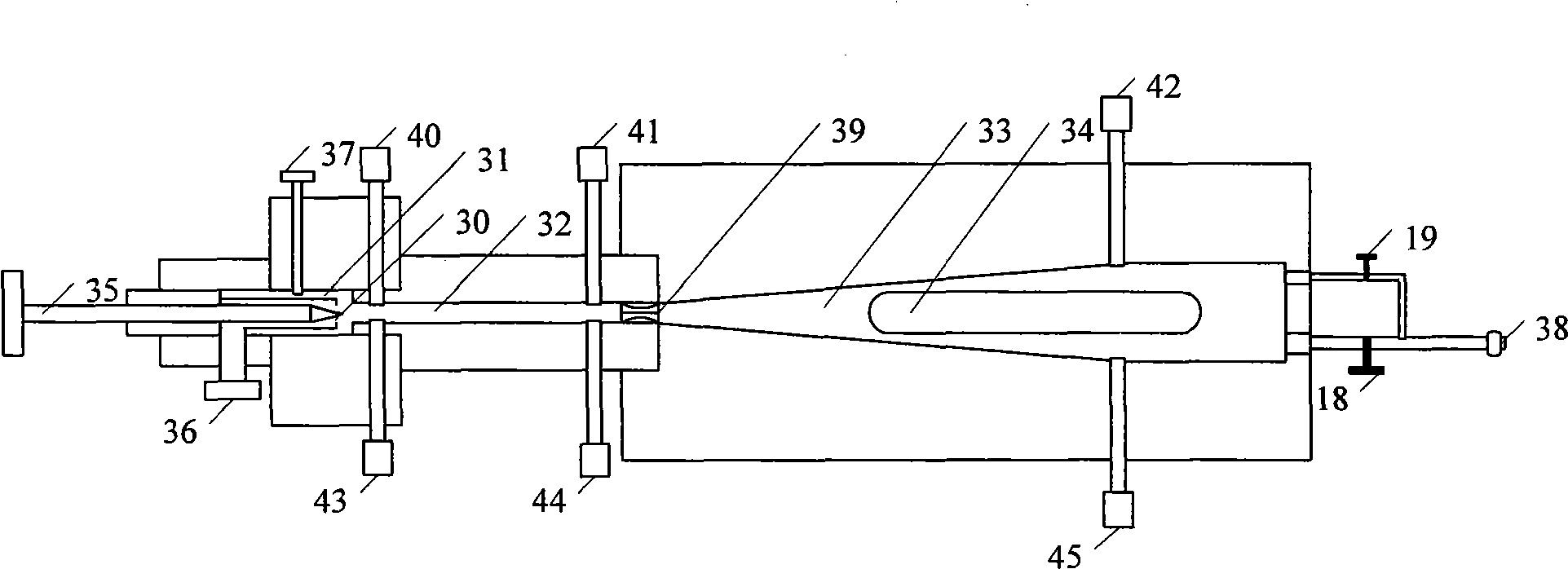

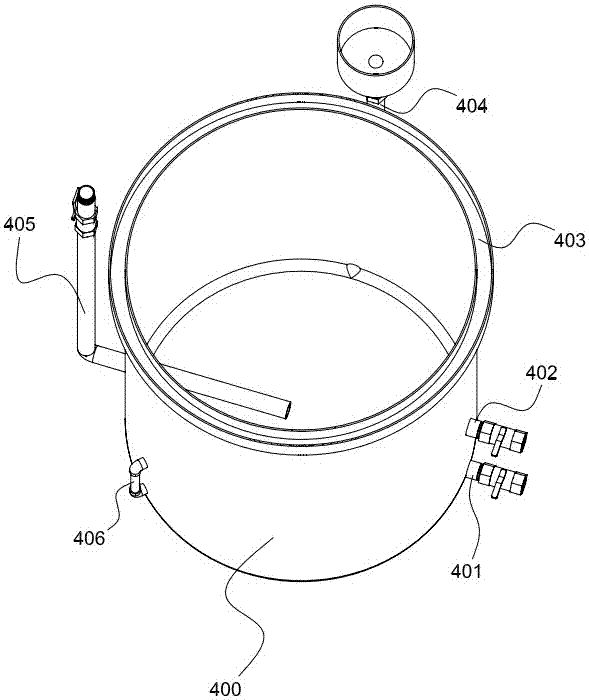

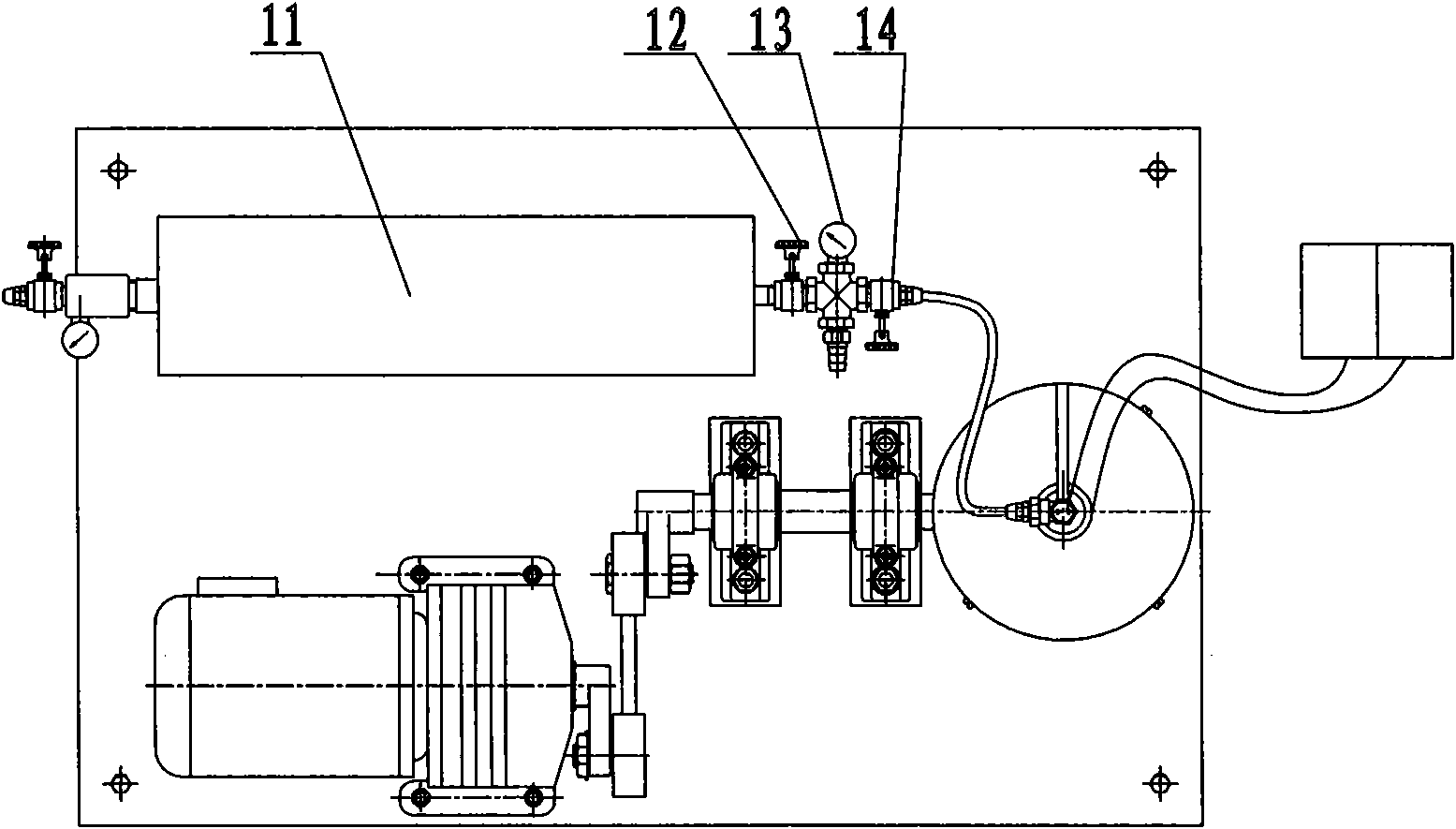

Visualization device for preparing gas hydrate in a spraying way

InactiveCN101543736AImprove solubilityIncrease the gas-liquid contact areaFlow mixersPlunger pumpWater cycle

The invention discloses a visualization device for preparing gas hydrate in a spraying way, which comprises a gas circulating loop, a reaction water circulating loop, a cooling medium liquid circulating loop, a spraying reactor and a cooling medium thermotank. A gas pressure reducer, an air bottle and an air compressor are additionally connected to the front of a gas pressure pump; a vacuum pump and a pressure meter are connected outside a buffer tank; the reaction water circulating loop is connected with a plunger pump, a liquid flow meter, a valve, a reactor and a storage tank, and the front of the plunger pump is additionally connected with a water tank and a valve; the cooling medium liquid circulating loop is provided with a low temperature thermotank, and can provide cooling medium liquid for the buffer tank, the storage tank and the cooling medium thermotank. The invention can lead gas to fully contact with redaction water and be sprayed and atomized, increases gas-water contact area, shortens the induction time of the hydration reaction, greatly improve the generation speed of the gas hydrate, and realizes the quick generation of the gas hydrate, thereby being the device for efficiently preparing the gas hydrate.

Owner:SOUTH CHINA UNIV OF TECH

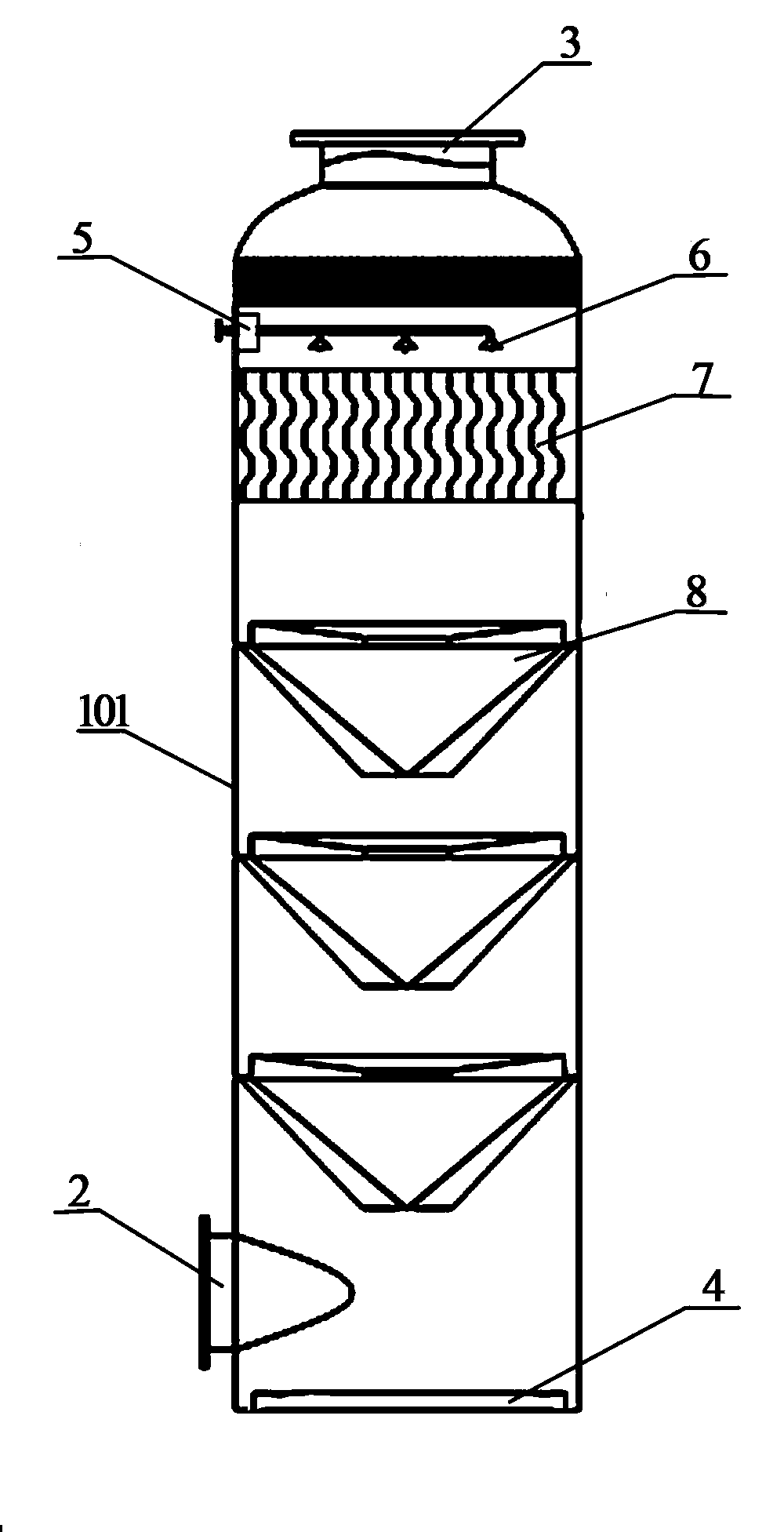

Combined cleaning device for waste gas of low speed marine diesel engine

ActiveCN105879555AIncrease the gas-liquid contact areaExtended reaction timeCombination devicesGas treatmentScrubberDiesel engine

The invention aims to provide a combined cleaning device for waste gas of a low speed marine diesel engine. The combined cleaning device comprises a cleaning device and a water supply system. The cleaning device comprises a shell and an air inlet duct wall arranged in the shell, an air inlet duct is formed in the air inlet duct wall, a cleaning region is formed between the air inlet duct wall and the shell, a demister and a spray layer are arranged in the cleaning region from top to bottom, a drainage opening is formed in the lower end of the shell, liquid membrane nozzles are arranged above the drainage opening and fixed to the inner wall of the shell, air nozzles are arranged between the liquid membrane nozzles and the air inlet duct wall, a first baffle is arranged on each gas nozzle, a second baffle is arranged above each first baffle, a third baffle is arranged above each second baffle, and an exhaust opening is formed in the portion, above the demister, of the shell. The water supply system is connected with the spray layer and the liquid membrane nozzles. An atomization spray device is omitted, strong vortexes are formed by the baffles many times, the liquid atomization and air-liquid contact area is increased, reaction time is prolonged, and the collection efficiency of SO2 and particles is improved.

Owner:HARBIN ENG UNIV

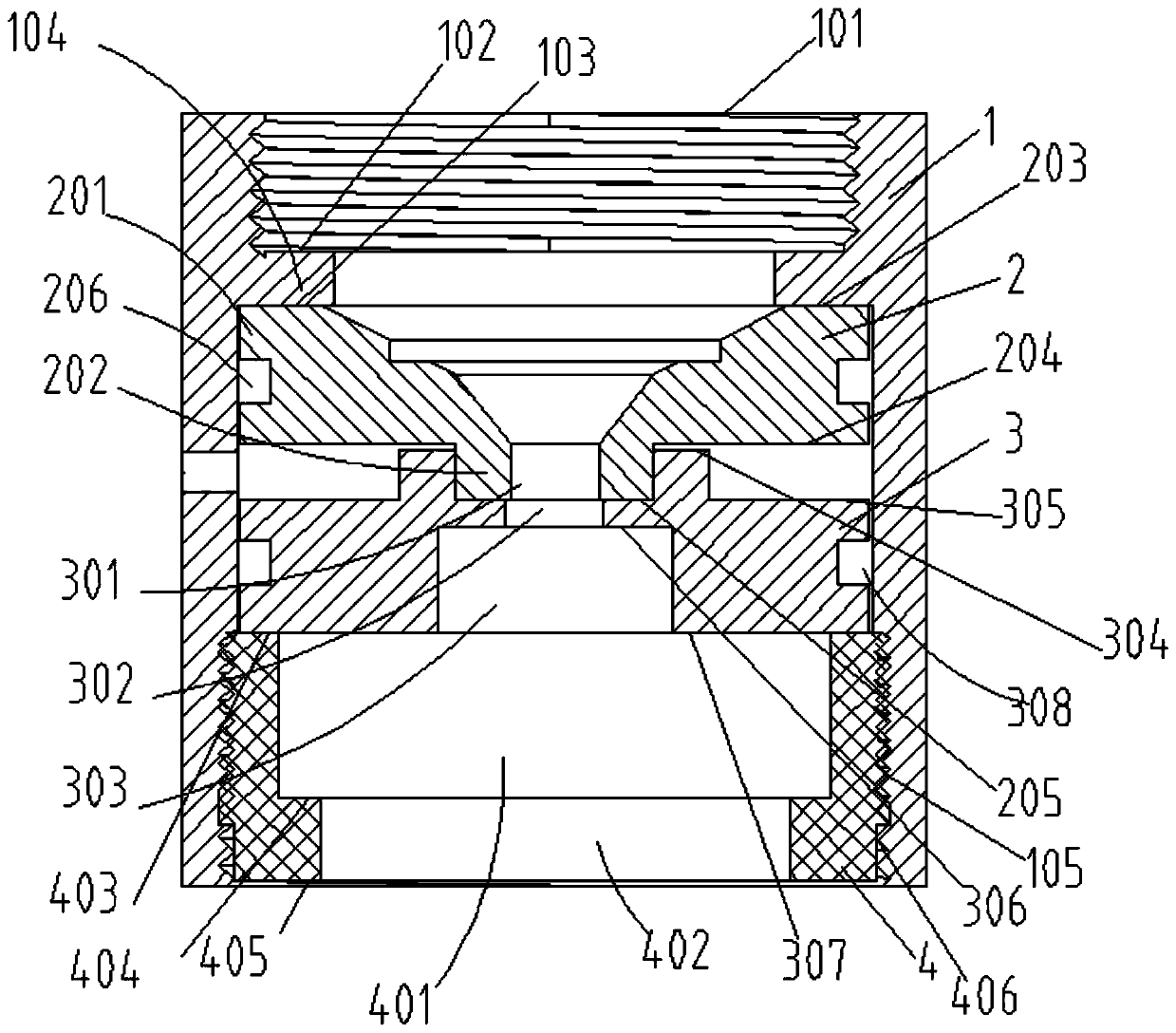

Micro-nano bubble gas-liquid reactor

ActiveCN111346589AIncrease the gas-liquid contact areaImprove mass transfer efficiencyChemical/physical/physico-chemical stationary reactorsPhysicsMass transfer

The invention provides a micro-nano bubble gas-liquid reactor. The invention belongs to the technical field of gas-liquid mass transfer. The reactor comprises a reactor shell, wherein a nano-bubble generation area, a gas-liquid mixing cavity, a micron-bubble generation area and a millimeter-bubble generation area are sequentially arranged in the reactor shell; the nano-bubble generation area is adopted to generate nano-bubbles and carry out mass transfer in the gas-liquid mixing cavity; gas is sucked into the nano-bubble generation area, bubbles are broken into nano-bubbles through negative pressure cavitation effect, the nano-bubbles are introduced into the gas-liquid mixing cavity for mass transfer for a certain time, the nano-bubbles sequentially pass through the micron-bubble generatiion area and the millimeter-bubble generation area, the diameters of the bubbles are gradually increased, and the bubbles can reach the size capable of being separated by a cyclone separator. A Venturitype nanobubble generator based on the cavitation effect is used for generating nanobubbles with the extremely large specific surface area, the gas-liquid contact area is increased, the mass transferefficiency is greatly improved, the structure is simple, the cost is low, and the application range is wide.

Owner:SHANGHAI JIAO TONG UNIV

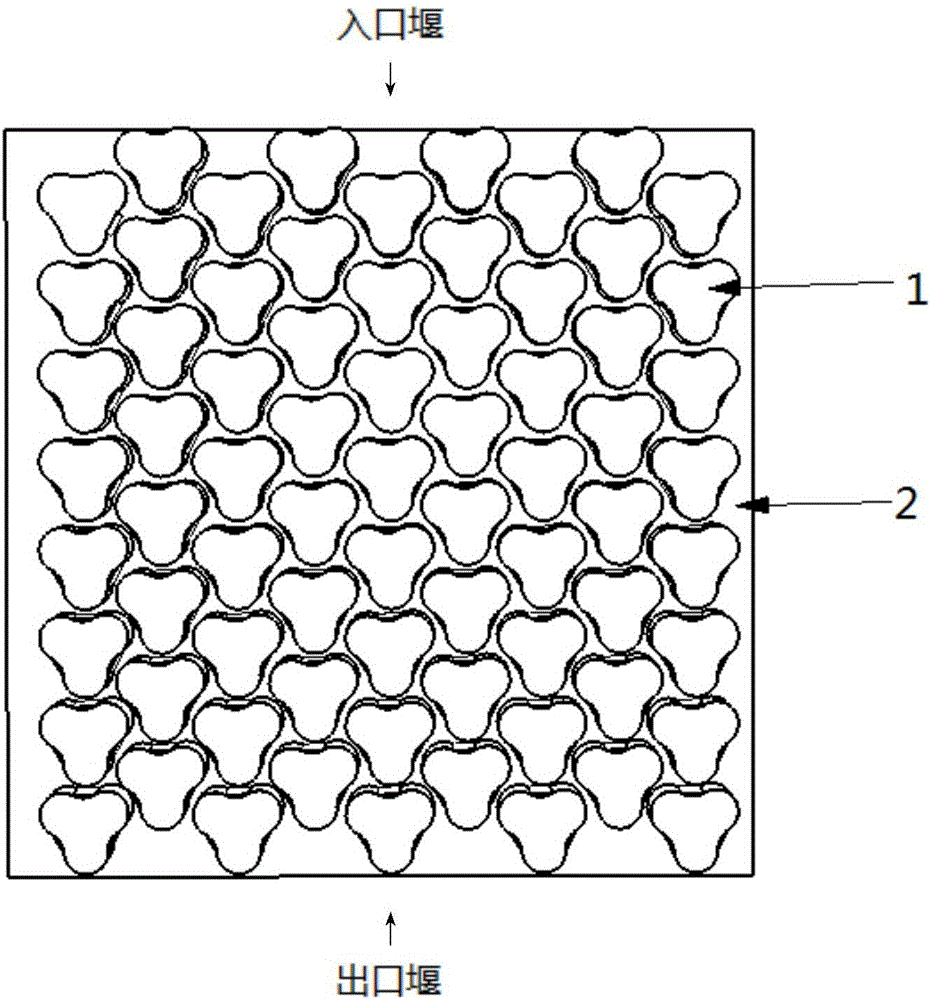

Column plate with porous surface

ActiveCN1754605AEnhanced heat transferIncrease the gas-liquid contact areaFractional distillationEngineeringHeat transmission

This invention discloses one tower panel with multiple hole surface, which uses tower surface of gas liquid tower panel with one layer of multiple hole with gap rate of15-45% and with even hole radium of 10 to 200 micro meter with even thickness of 0.2 to 0.8 mm. The tower in this invention can keep effect core boiling status in small temperature difference to strengthen the heat transmission quality and to improve fine stilling rate at 8 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

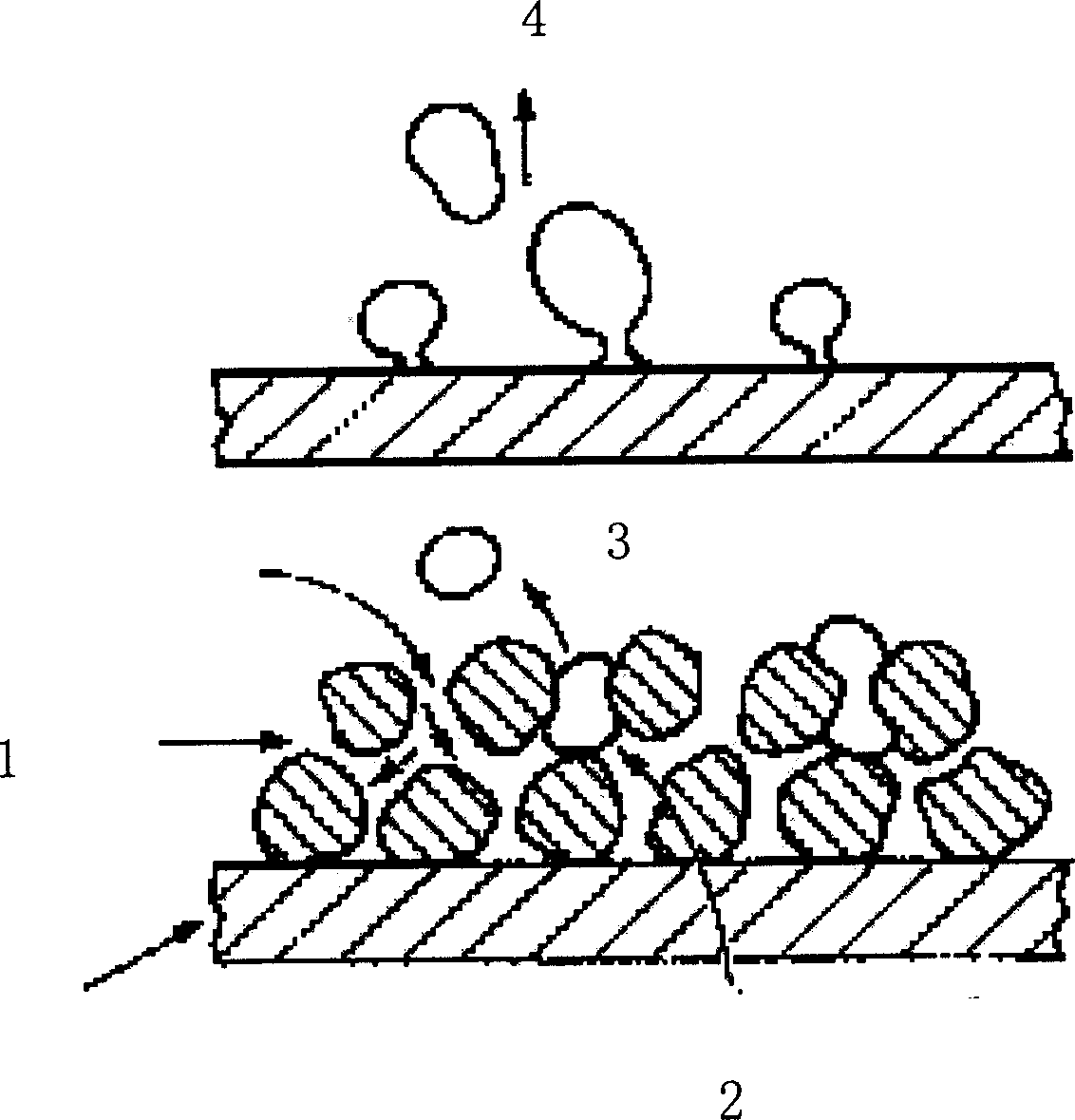

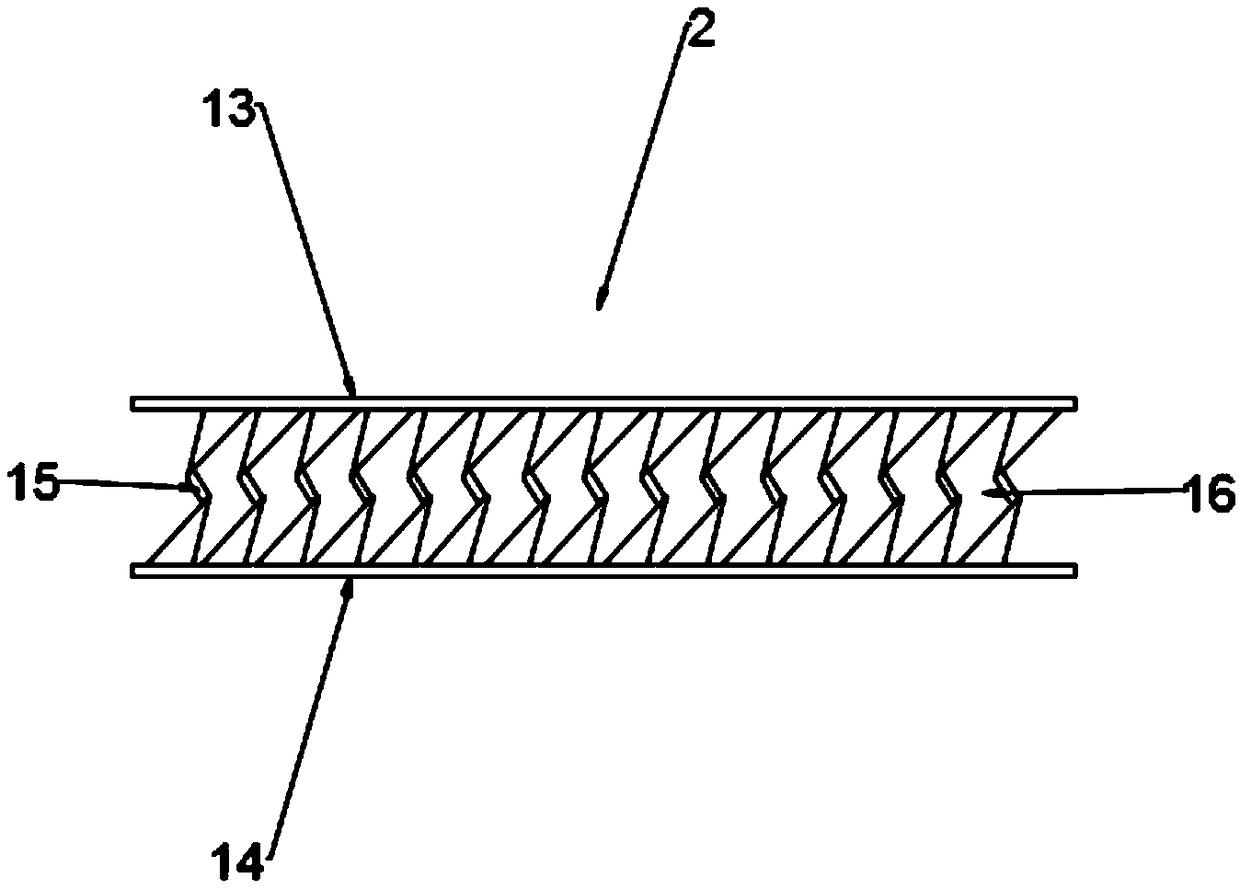

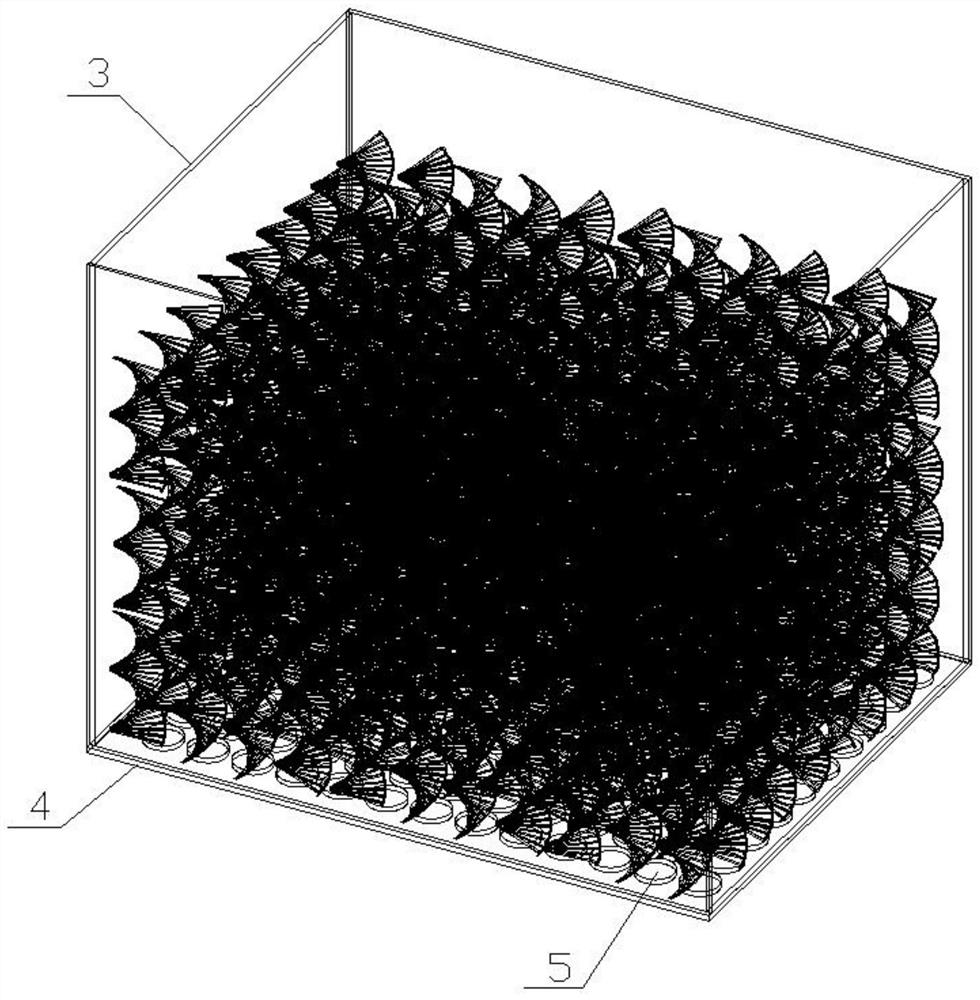

Novel plastic filler

InactiveCN101940907APromotes even distributionIncrease the gas-liquid contact areaChemical/physical/physico-chemical processesPolymer sciencePolymer chemistry

The invention discloses a filler sheet. The filler sheet comprises a strength support layer and is characterized by further comprising a hydrophilic layer which is compounded on the surface of the strength support layer. The filler sheet has the advantages of high uniform distributivity of liquid on the surface of a filler, larger gas-liquid contact area and improvement on mass transfer efficiency due to the hydrophilic layer on the surface of the filler sheet. The invention also discloses the filler made of the filler sheet.

Owner:BEIJING SINOREFINE AIR CONDITIONING TECH

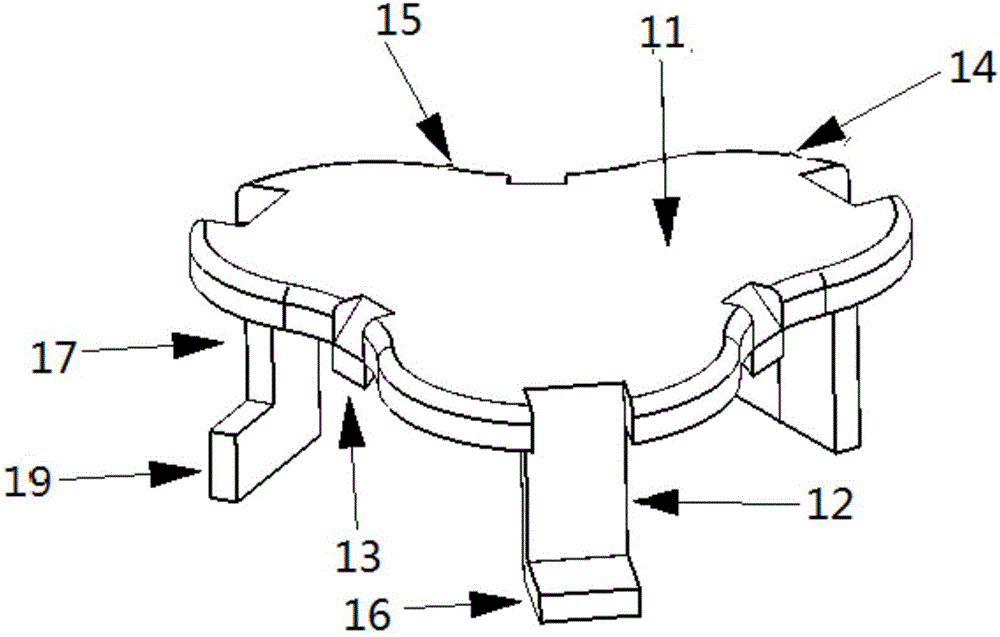

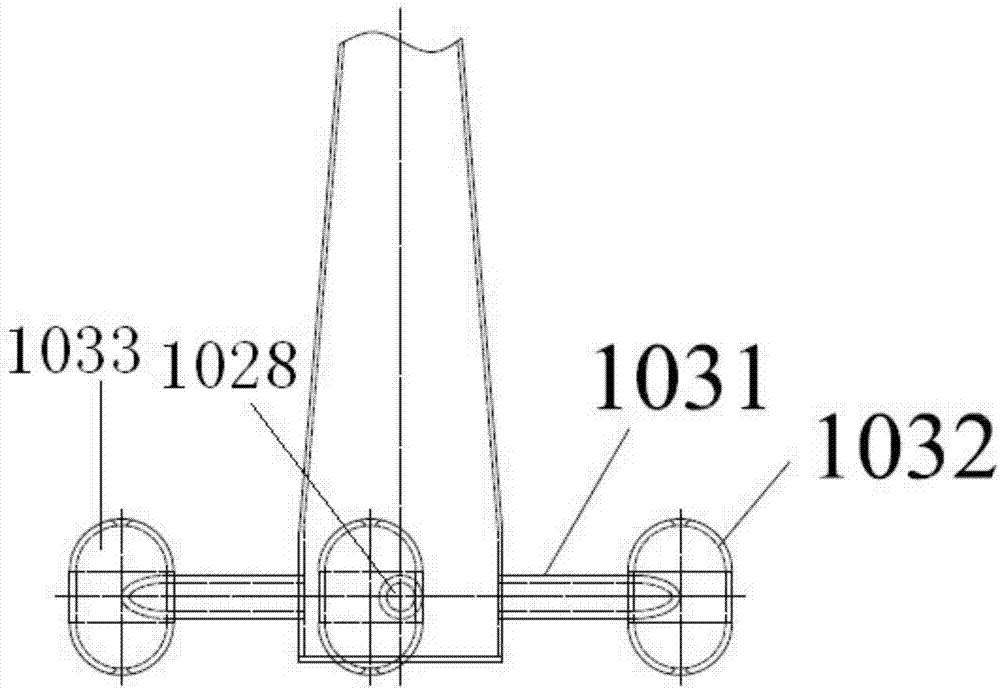

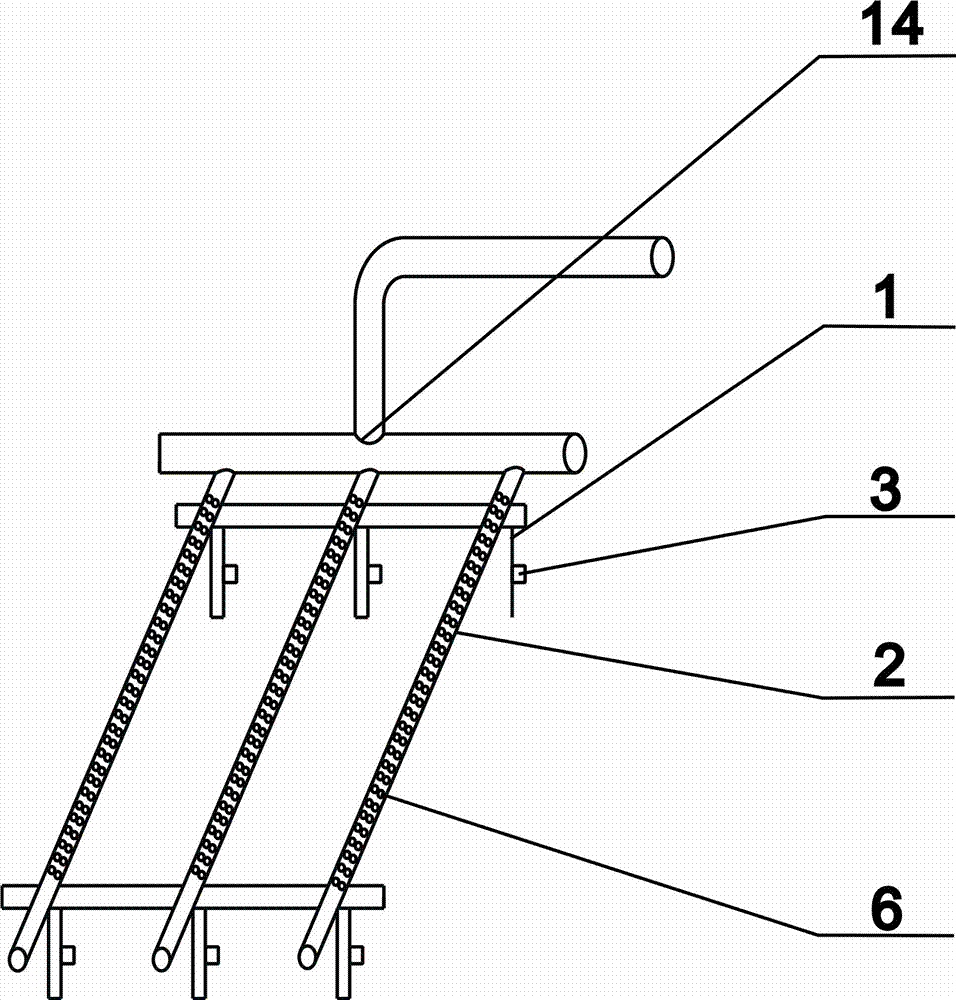

Novel high-flux gas-liquid uniform tower tray

ActiveCN106140075AIncreased wetted perimeterIncrease the gas-liquid contact areaChemical/physical/physico-chemical processesInterval distributionValve opening

The invention provides a novel high-flux gas-liquid uniform tower tray which comprises a tower plate, valve openings and floating valves. The edge of the valve block of each floating valve is arranged in a manner that convex arches and concave arches are arranged in intervened arrangement, the number of convex portions formed by the convex arches and the number of concave portions formed by the concave arches are respectively three, and the curvature radius of the convex portions is smaller than / equal to that of the concave portions; valve legs of each floating valve are perpendicularly fixed on the lower end surface of each convex portion, and the number of the valve legs is three which are in equidistant interval distribution; a spacing strip is arranged at the edge of each valve block. The novel high-flux gas-liquid uniform tower tray is high in operational flexibility, high in mass transfer efficiency, even in airflow dispersion and sufficient in gas-liquid connection.

Owner:TIANJIN AOZHAN XINGDA TECH

Integrative coordinated desulfurization, denitration, demercuration device and technique using spray bubbling method

ActiveCN101306322BReduce investment and operating costsSmall footprintDispersed particle separationInlet channelFlue gas

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

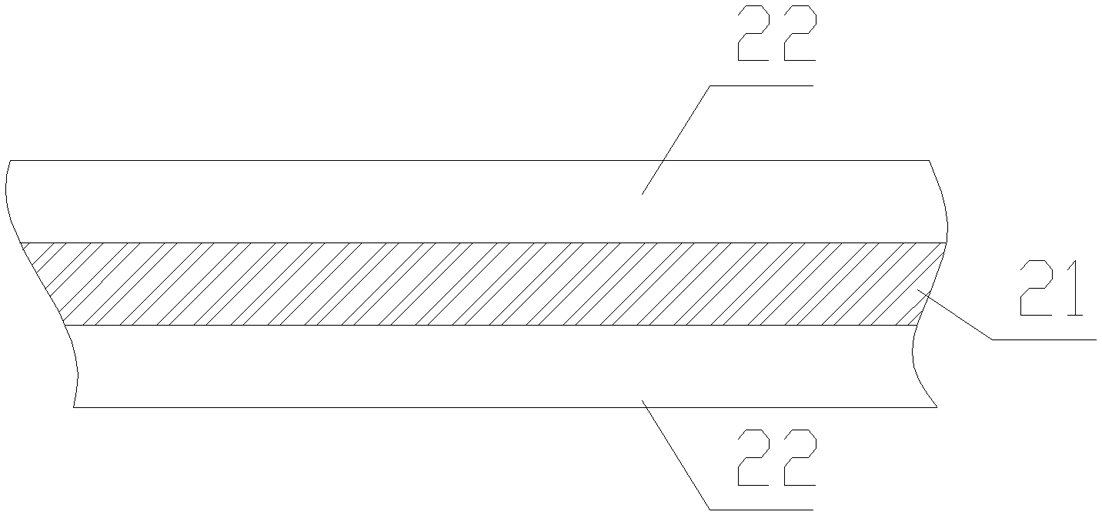

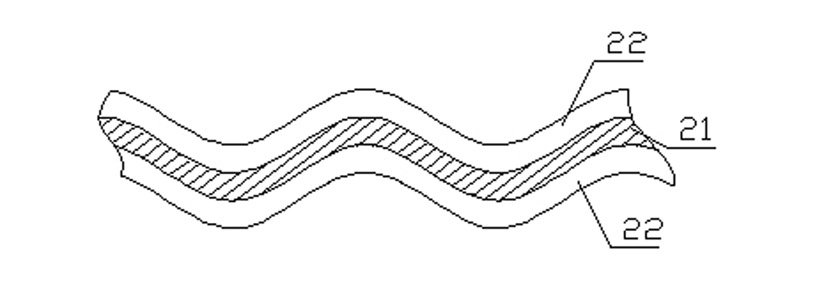

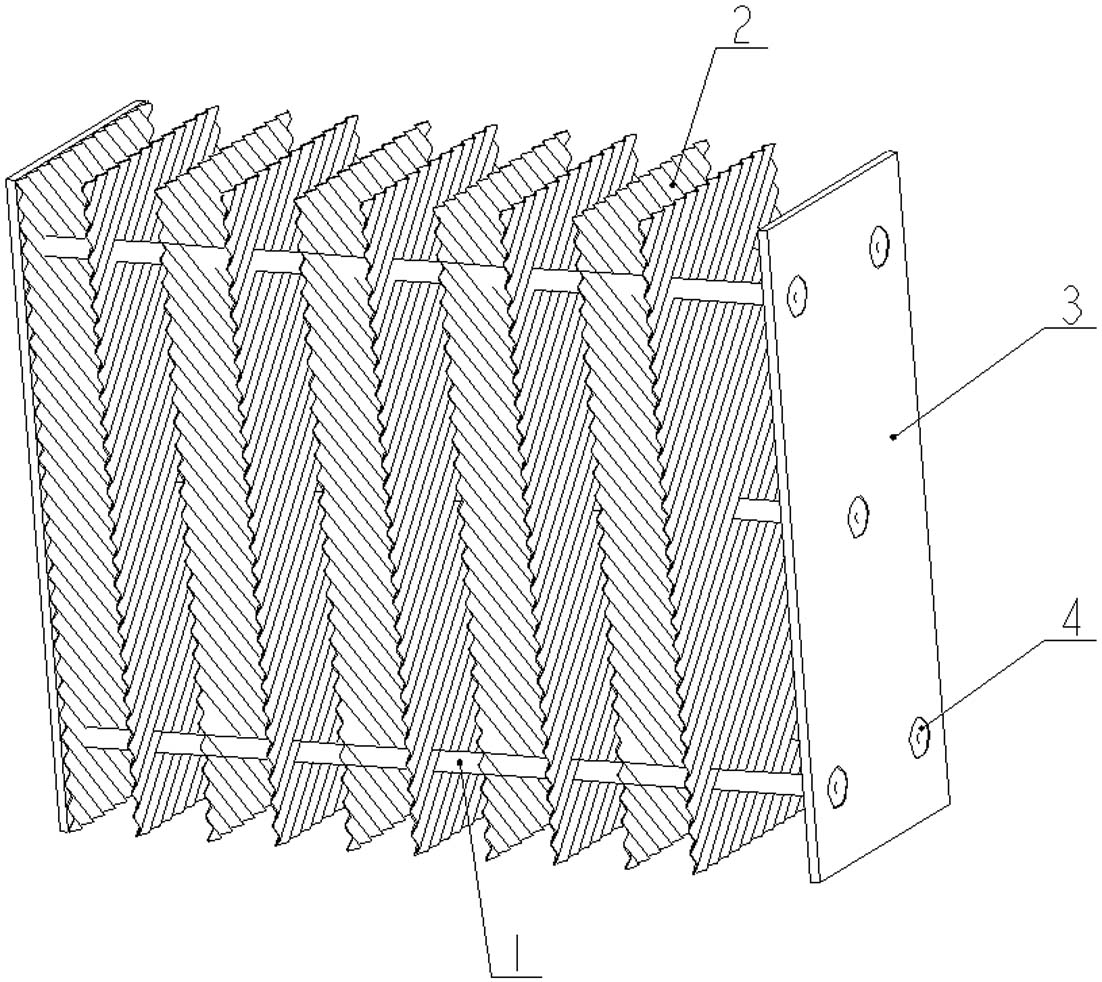

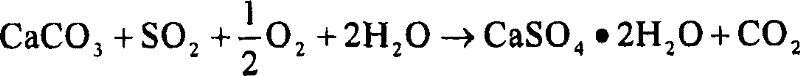

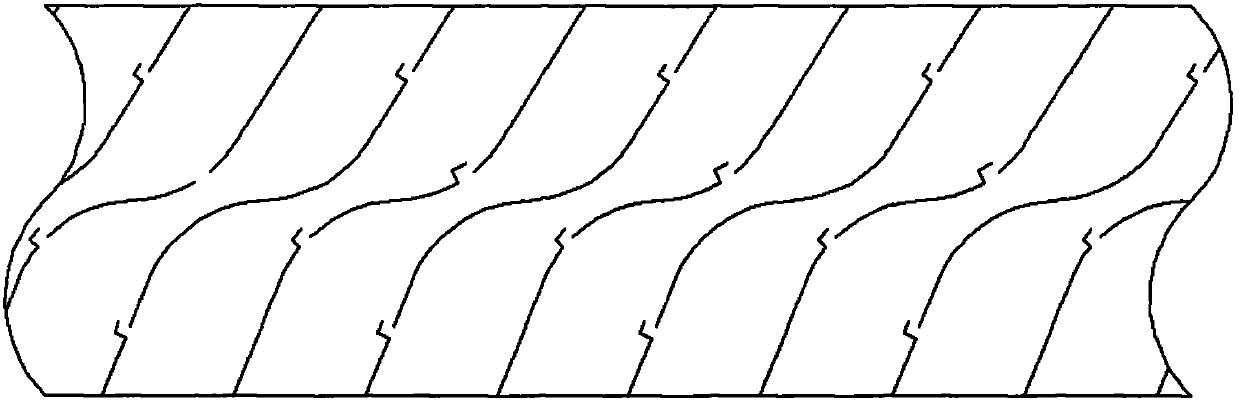

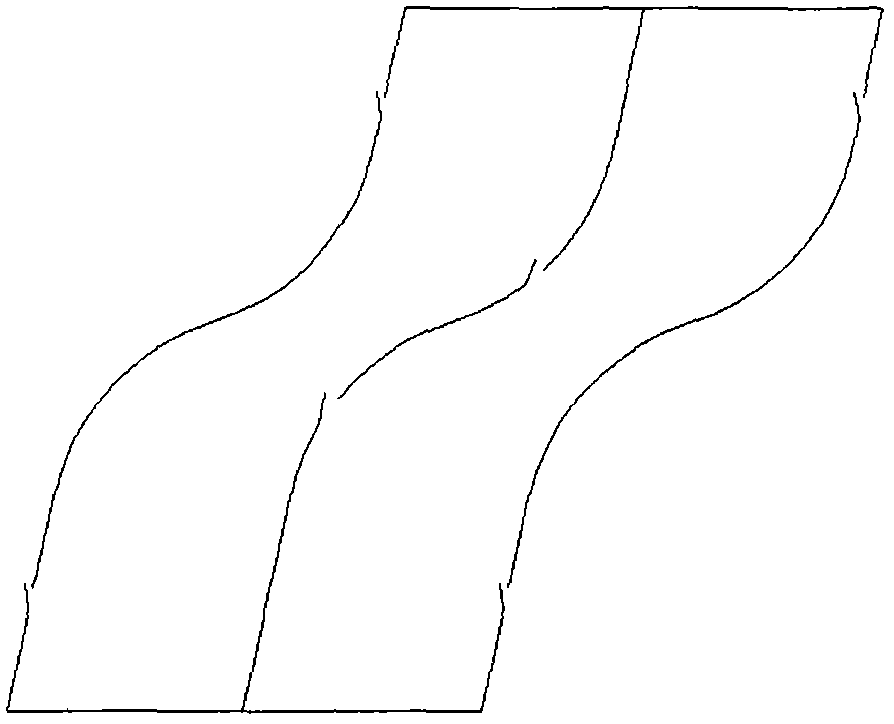

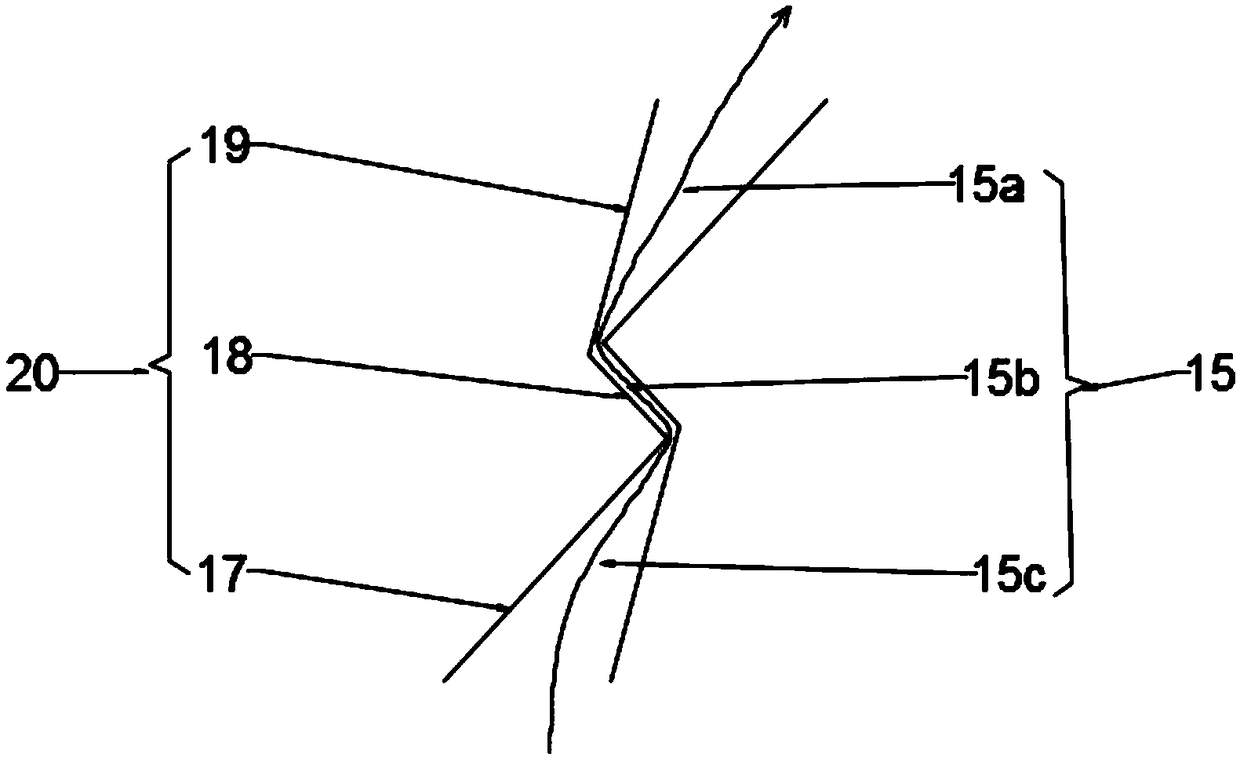

Flow guide filler

ActiveCN103691388AFully contactedIncrease disturbanceChemical/physical/physico-chemical processesChemical industryEngineering

The invention relates to a flow guide filler which is formed by stacking a plurality of layers of filler sheets, wherein two symmetrically-reversed curves are arranged in the middle parts of corrugated ridges of the filler sheets; the upper and lower ends of the corrugated ridges are straight lines; the two curves are tangent to each other; the curves at the upper end are tangent to the straight lines at the upper part; the curves at the lower end are tangent to the straight lines at the lower part; a height ratio of the curve parts of the corrugated ridges of the filler sheets to the straight line parts is 0.5-5; a series of rectangular, triangular and arc-shaped boss flow guide holes are punched in the filler sheets; the area of the boss flow guide holes punched in the filler sheets is 5-30% of the area of the filler sheets; regular diamond particles are adopted on the surfaces of the filler sheets, and vibrate and scour regularly in a liquid flow direction to perform surface roughening treatment; the filler is filled through combined filler discs with different inclination angles. The filler is good in surface film forming effect, so that an effective specific surface area is increased; gas-liquid phase perturbation is enhanced; meanwhile, a liquid surface updating rate is increased, so that gas-liquid mass transfer is full; mass transfer efficiency is greatly improved; the filler can be widely used in fields of petroleum, chemical industry, biology, pharmacy and environmental protection, and the like.

Owner:河北化大科技有限公司

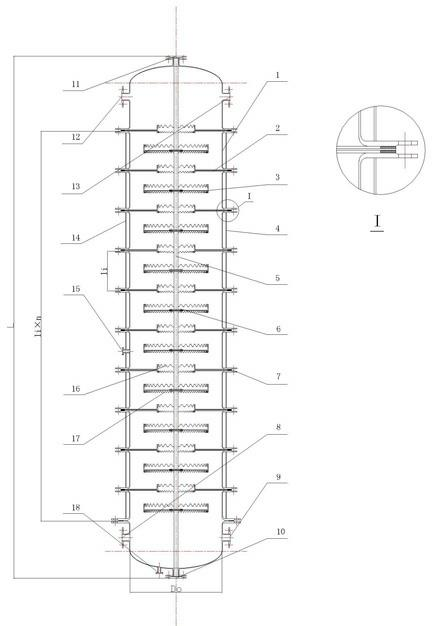

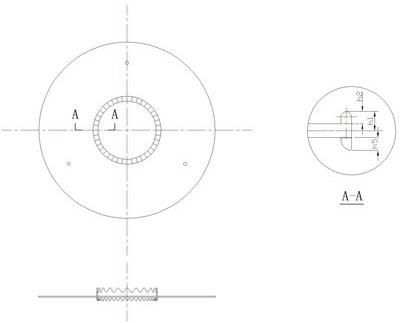

Large-scale pressure carbonization tower

ActiveCN102424405ALarge ventilationIncrease the gas-liquid contact areaCarbonate preparationSodium bicarbonateEngineering

The invention relates to a large-scale pressure carbonization tower which is characterized in that its bamboo rain-hat is composed of a base plate, a top cover and several rib plates; the rib plate is central symmetric and fixed on the base plate; the top cover is fixed on the rib plates; a through hole is arranged at the center of the base plate; the edge of the base plate equipped with the through hole is a zigzag edge; 24 bamboo rain-hats are arranged inside the upper portion of the tower; the opening rate of the first bamboo rain-hat to the 21st bamboo rain-hat from the top to the bottom is 9.8%, and the opening rate of the 22nd bamboo rain-hat to the 24th bamboo rain-hat is 12.8%; one bamboo rain-hat with the opening rate being 13.3% is arranged inside a central conical tower; an airintake is arranged on the central conical tower body; the base plates of the bamboo rain-hats at the bottom are all equipped with appropriate opening rate; and the second and seventh tower sections are respectively provided with two air intakes. According to the invention, ventilation volume and liquid holdup of each portion of the carbonization tower are enlarged; the reaction time and crystal growth time are prolonged; carbonization tower production power and carbonization conversion rate are raised; sodium bicarbonate crystalline particles become large and many unfavorable factors of original carbonization towers are improved.

Owner:赵祥海

Liquor distilling equipment

InactiveCN107043687ASpeed up evaporationIncrease the gas-liquid contact areaAlcoholic beverage preparationEngineeringDistillation

The invention discloses a liquor distilling equipment. The liquor distilling equipment comprises a distillation barrel, a distillation cover, a liquor steam pipe, and a condenser; a steam guide device is detachably arranged at the lower part of the inner side of the distillation barrel; the steam guide device comprises a separating plate, and a steam guide pipe arranged on the separating plate; the inner side space of the distillation barrel below the separating plate is designed to be a steam generation space; the inner side space of the distillation barrel above the separating plate is designed to be a fermented grains distillation space used for storing fermented grains; the steam generation space and the fermented grains distillation space are communicated via the steam guide pipe; a steam space is composed of the steam generation space and the space in the steam guide pipe; the liquor distilling equipment is also provided with a gas guide pipeline and a blower; one end of the gas guide pipeline is communicated with the steam space, and the other end of the gas guide pipeline is connected with a gas outlet of the blower.

Owner:RUIAN MAITENG ELECTRONICS COMMERCE CO LTD

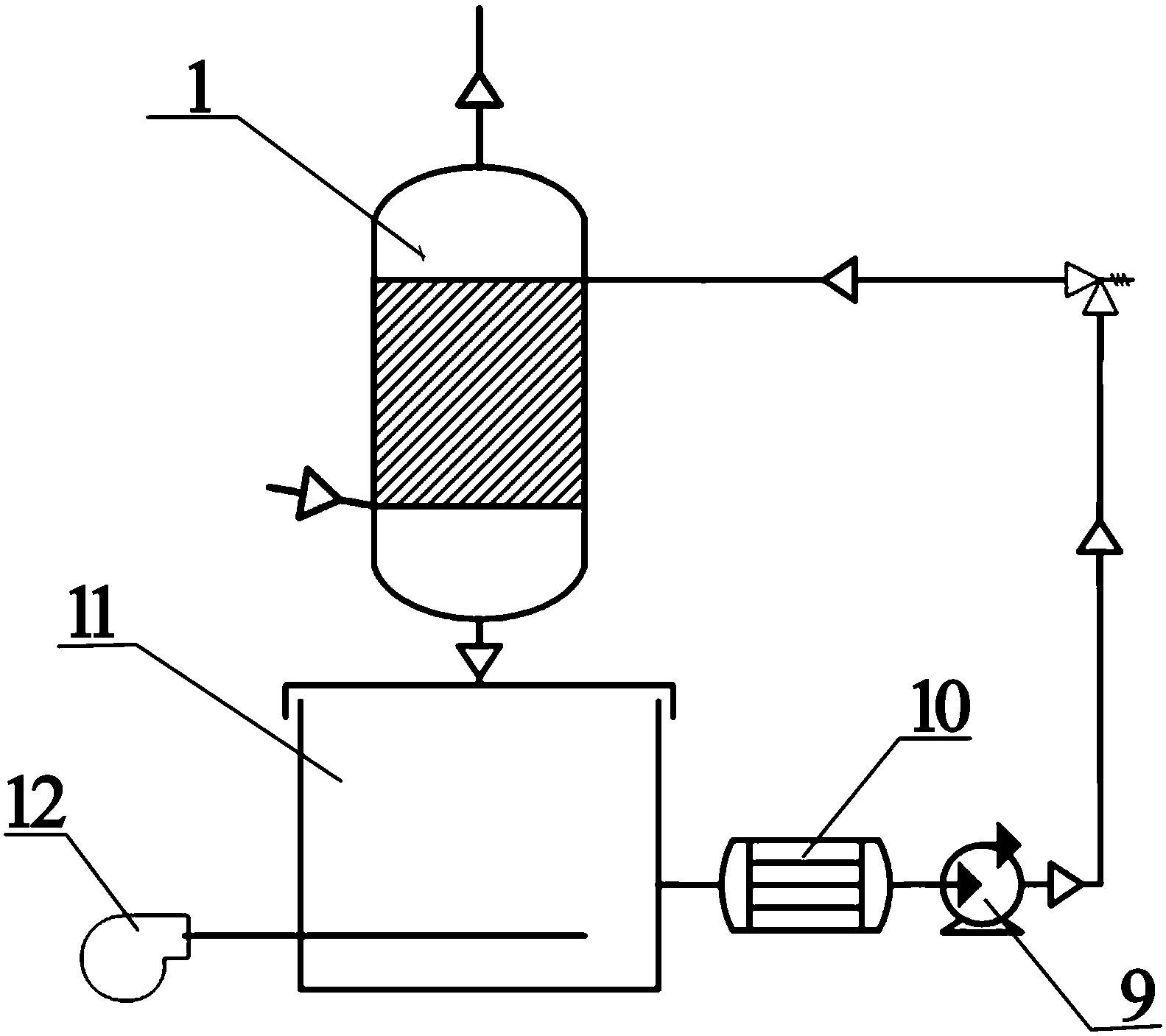

Device for absorbing and purifying SO2 in diesel engine tail gas by utilizing seawater and absorption method

InactiveCN104162361AIncrease the gas-liquid contact areaEfficient and stable removalDispersed particle separationContactorExhaust gas

The invention relates to a device for absorbing and purifying SO2 in diesel engine tail gas by utilizing seawater and an absorption method. The device includes a flue gas washer, a liquid circulating pump, a heat pipe heat exchanger, a seawater regeneration tank and an aeration fan; the flue gas washer is connected with a diesel engine tail gas exhaust system; the seawater regeneration tank is connected with a water inlet of the flue gas washer successively through the heat pipe heat exchanger and the liquid circulating pump; the seawater regeneration tank is connected with the aeration fan and is connected with a water outlet of the flue gas washer. With use of cyclone contactors in the flue gas washer, the gas-liquid contact area is increased, so that high efficiency and stable removal of SO2 is achieved, the absorption efficiency is higher, and the cost is saved.

Owner:JIANGSU NANJI MACHINERY

Waste gas absorption and purification equipment

InactiveCN109157951AStrong capture capacityIncrease the gas-liquid contact areaCombination devicesExhaust gasEngineering

The invention relates to the technical field of purification machinery equipment, in particular to waste gas absorption and purification equipment and solves the problem that liquid is carried in exhaust gas. The invention has the technical key points that the waste gas absorption and purification equipment comprises a gas outlet, a gas inlet, a liquid outlet and a liquid inlet; the liquid inlet is connected with a liquid distributor, and a gas-liquid separation device is arranged above the liquid distributor and is positioned between the gas outlet and the liquid inlet; the gas-liquid separation device comprises a first supporting piece and a second supporting piece, and first baffles, second baffles and third baffles are arranged between the first supporting piece and the second supporting piece; one first baffle, one second baffle and one third baffle form a baffle; the gas-liquid separation device comprises a plurality of baffles arranged in parallel, and a first overflow passage and a second overflow passage which are arranged in a staggered manner are formed between the adjacent baffles. As the waste gas absorption and purification equipment is provided with the gas-liquid separation device, the gas-liquid separation device can more thoroughly separate the gas from the liquid carried in the gas.

Owner:霸州市辉月网络技术有限公司

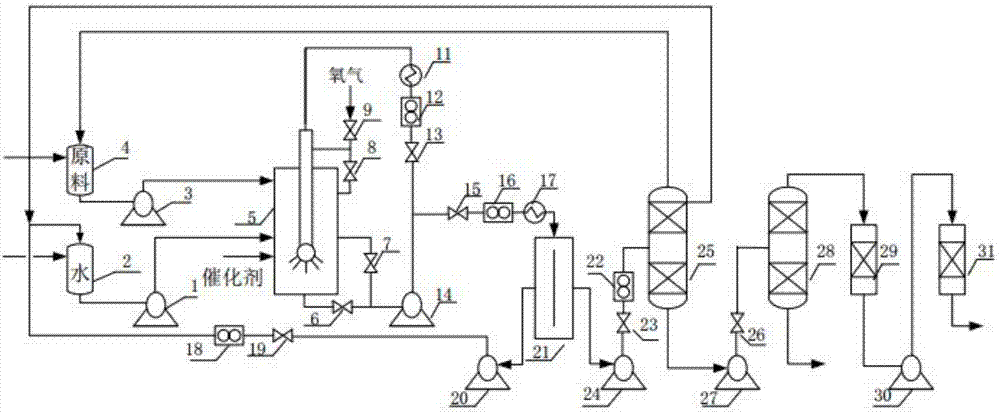

Preparation method and preparation apparatus of high-grade 4-tert-butylbenzaldehyde

PendingCN106977379AIncrease profitIncrease the gas-liquid contact areaOrganic compound preparationCarbonyl compound preparationHalogenP-tert-Butyltoluene

The invention discloses a preparation method of high-grade 4-tert-butylbenzaldehyde and a preparation apparatus of high-grade 4-tert-butylbenzaldehyde. The preparation method of high-grade 4-tert-butylbenzaldehyde comprises the following steps: A) 4-tert-butylbenzaldehyde, water and a catalyst without halogen are mixed in a micrometer bubble reactor for carrying out an oxidation reaction, in order to obtain reaction feed liquid; B) oil-water separation is carried out for reaction feed liquid in order to obtain water phase and oil phase, water phase contains the catalyst, and the oil phase contains 4-tert-butylbenzaldehyde and impurities; and C) 4-tert-butylbenzaldehyde and the impurities are separated in order to obtain high-grade 4-tert-butylbenzaldehyde. 4-tert-butylbenzaldehyde prepared by the preparation method of high-grade 4-tert-butylbenzaldehyde according to an embodiment does not contain halogen, and can be applied to the fields of foodstuff, medicine, perfume and the like.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

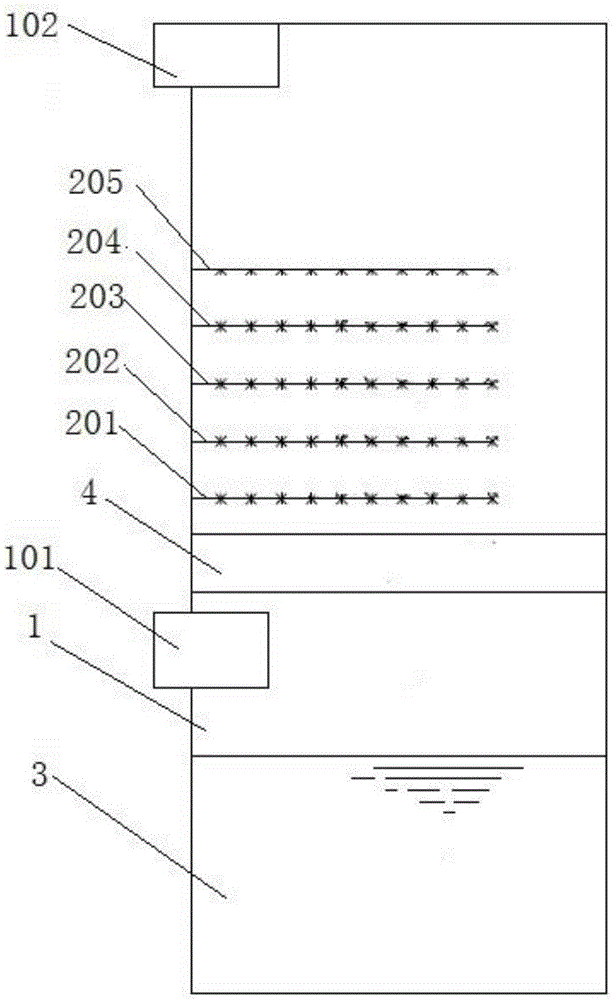

Desulfuration spray tower

InactiveCN105536491AImprove desulfurization efficiencyIncrease the gas-liquid contact areaGas treatmentDispersed particle separationSpray towerSpray nozzle

The invention discloses a desulfuration spray tower. The desulfuration spray tower comprises an absorption tower, a slurry tank and a flow disturbing device, wherein the upper part of the absorption tower is provided with a first spraying layer, a second spraying layer, a third spraying layer, a fourth spraying layer and a fifth spraying layer, and each of the first, second, third, fourth and fifth spraying layers is provided with a plurality of spray nozzles; the slurry tank is arranged at the lower part of the absorption tower; the flow disturbing device is arranged between an entrance of the absorption tower and the first spraying layer. The desulfuration spray tower has the beneficial effects that through arranging the five spraying layers, of which each is provided with the spray nozzles, the coverage of slurry of the spray nozzles reaches 250%, the slurry can be in full contact with fume, and thus, the desulfuration efficiency of a system is increased; through arranging the flow disturbing device, gas flow can flow towards the internal central position of the tower, the area of gas-liquid contacting is enlarged, and the utilization ratio of a desulfurating agent and the removal rate of sulfur dioxide are increased; the stable operation for a power plant host is guaranteed, and the stable operation for a desulfuration system is guaranteed, so that the occurrence of unit failure is effectively avoided; the cost is relatively low, so that the desulfuration spray tower has great economic significance.

Owner:DATANG ENVIRONMENT IND GRP

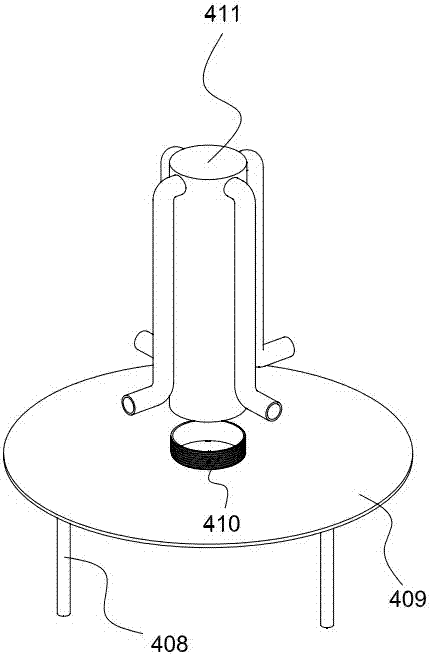

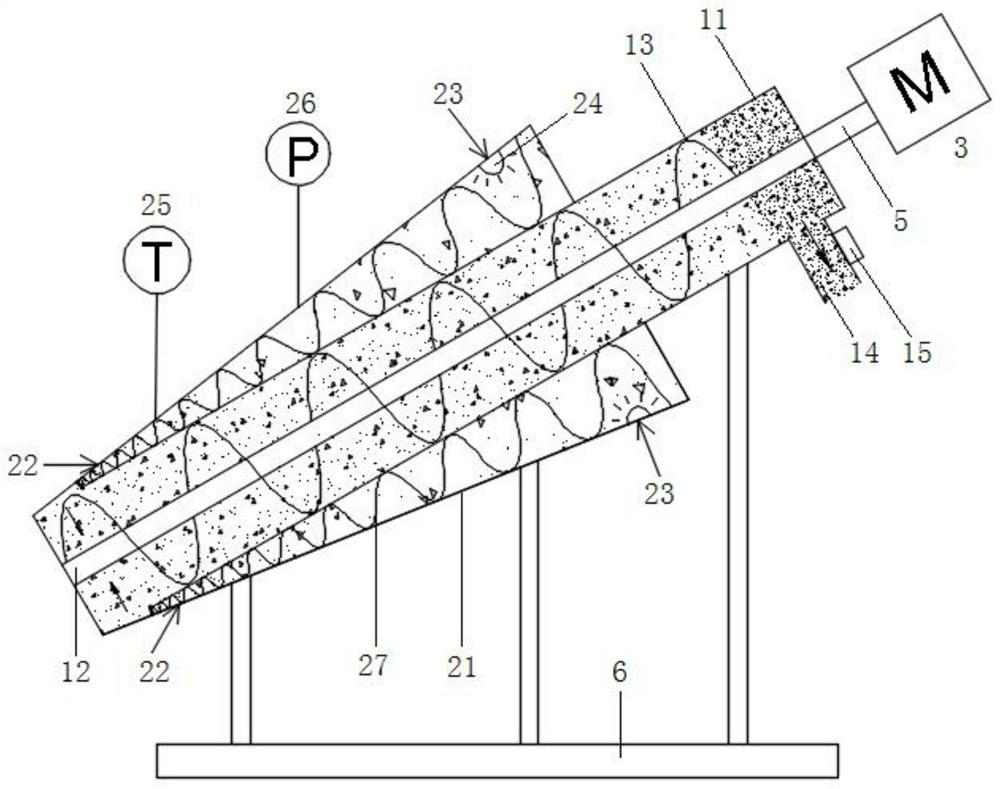

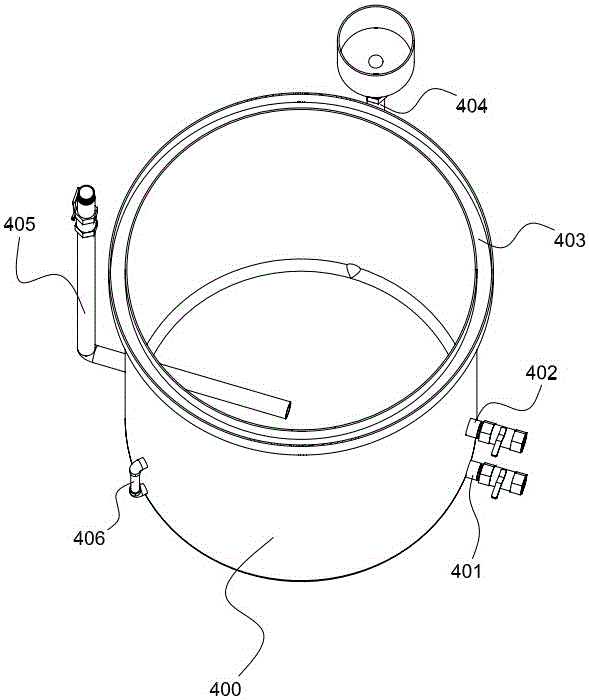

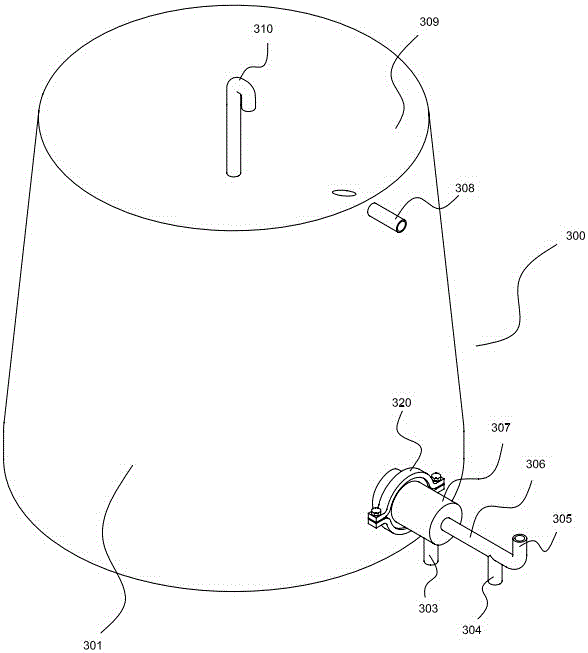

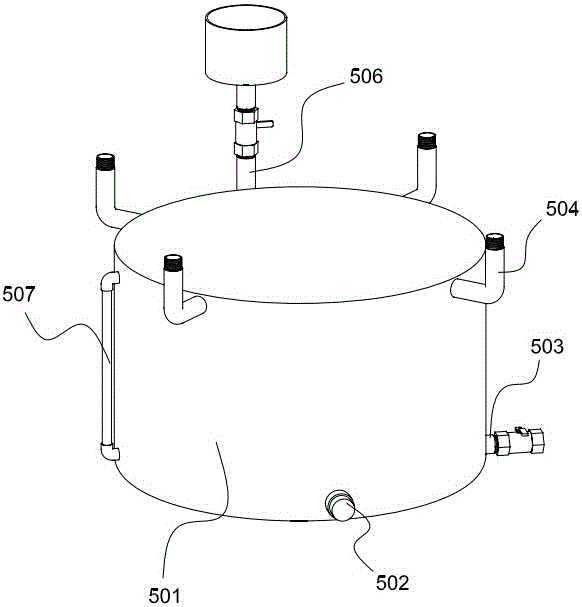

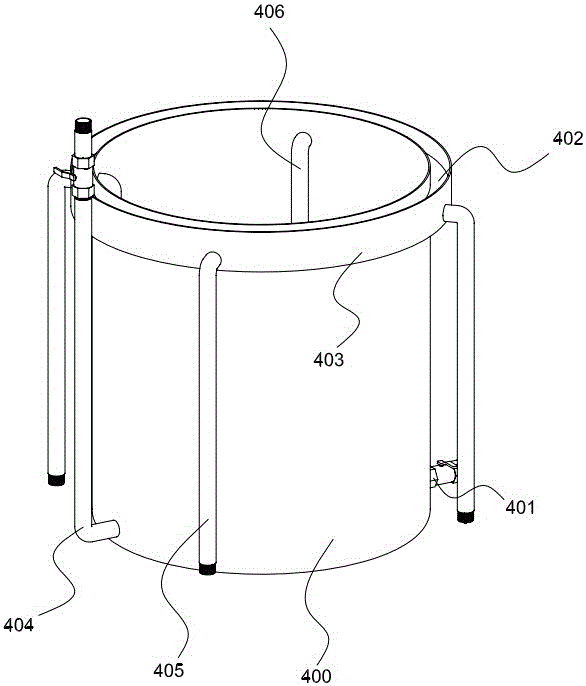

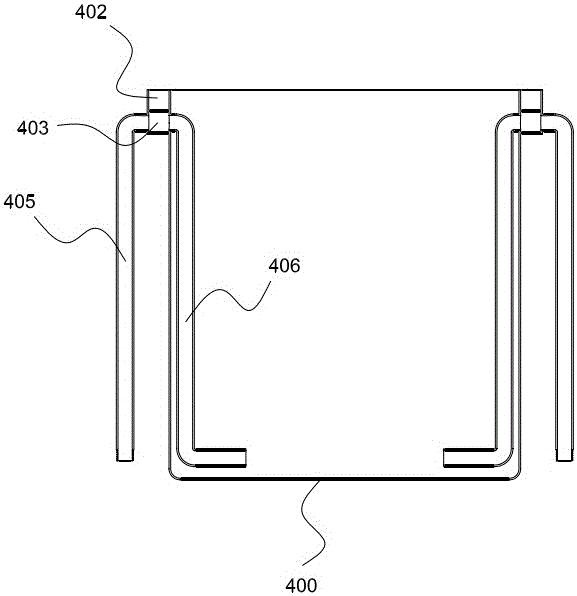

Production-transportation integrated continuous reaction device for hydrate

ActiveCN112111308AIncrease the gas-liquid contact areaSlow down the fallGaseous fuelsPhysicsEngineering

The invention belongs to the technical field of production and application of natural gas hydrate, and particularly relates to a production-transportation integrated continuous reaction device for hydrate. The device structurally comprises an inner spiral reaction kettle, an outer spiral reaction kettle, a motor, a clamping ring and a magnetic transmission rod, wherein the inner spiral reaction kettle and the outer spiral reaction kettle are assembled in a nesting mode. A spraying method is introduced into the outer spiral reaction kettle, and micro-droplets are generated by utilizing the spraying method; through the buffering effect of external spiral blades, a gas-liquid contact area is increased, so the falling speed of the micro-droplets is reduced, the dispersion degree of the micro-droplets is increased, the conversion time of the micro-droplets is prolonged, the conversion time of hydrate is prolonged, and a conversion rate and a gas storage rate are increased; and the generatedhydrate is output through the conveying function of stirring rods and inner spiral blades, and secondary reinforced conversion is conducted in the process, so the conversion rate is further increased, the gas storage rate is increased, and continuous, rapid, efficient and continuous production and conveying of the natural gas hydrate are achieved.

Owner:QINGDAO UNIV OF SCI & TECH

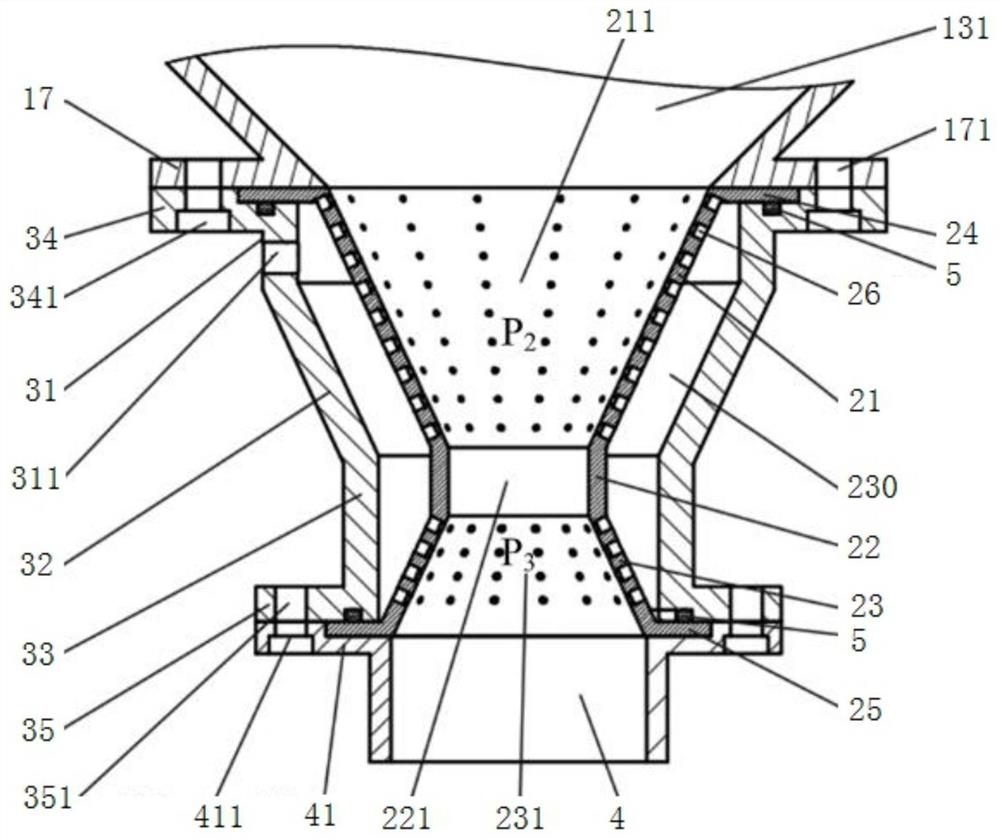

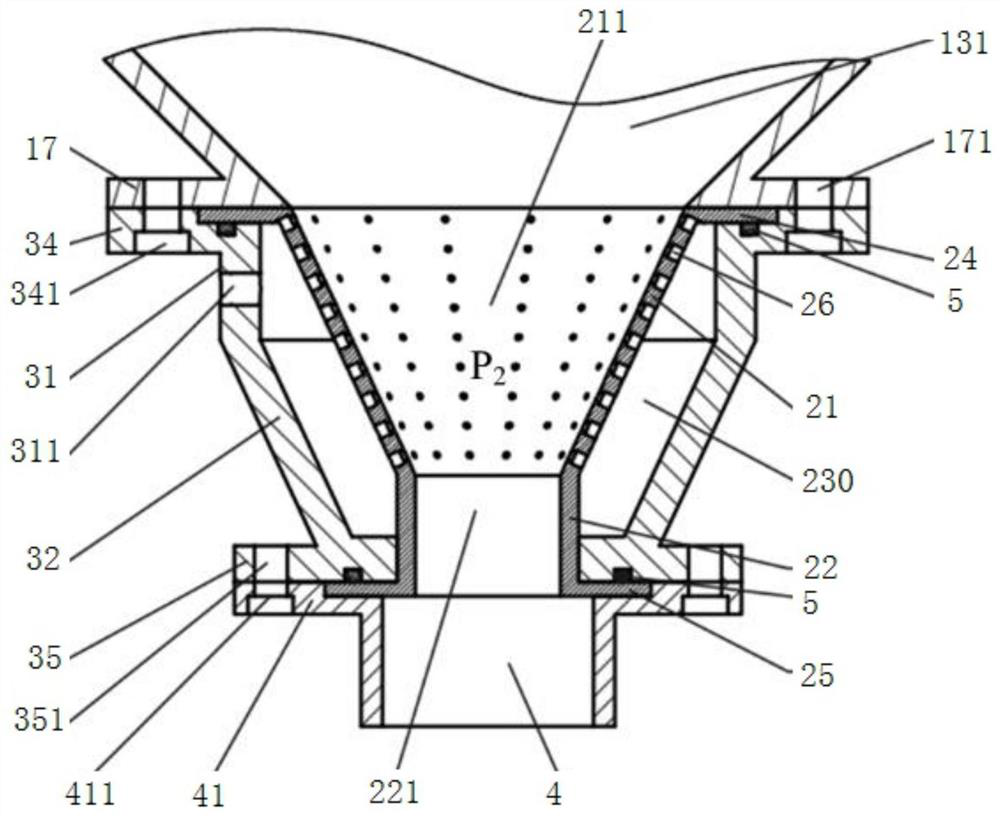

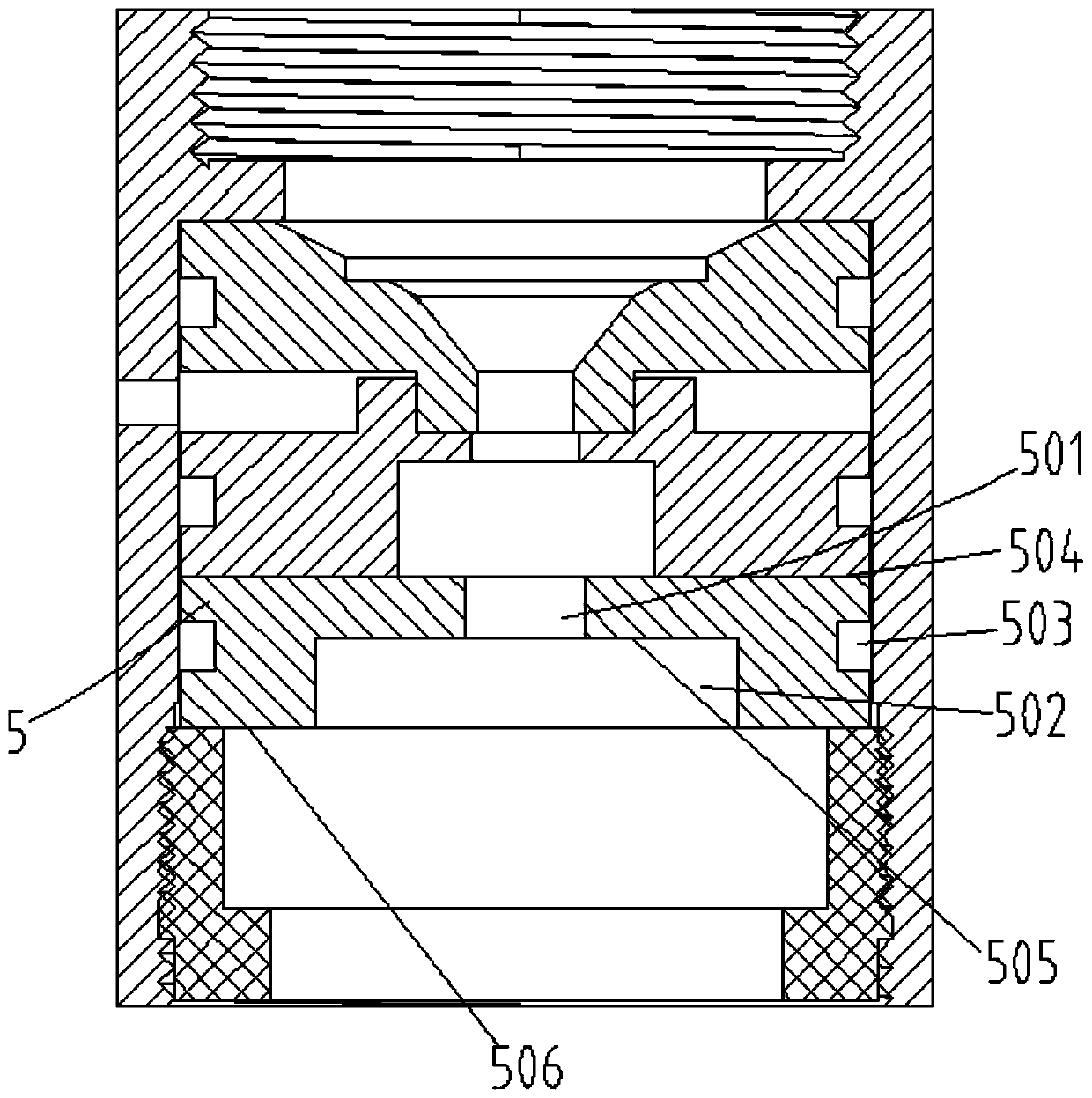

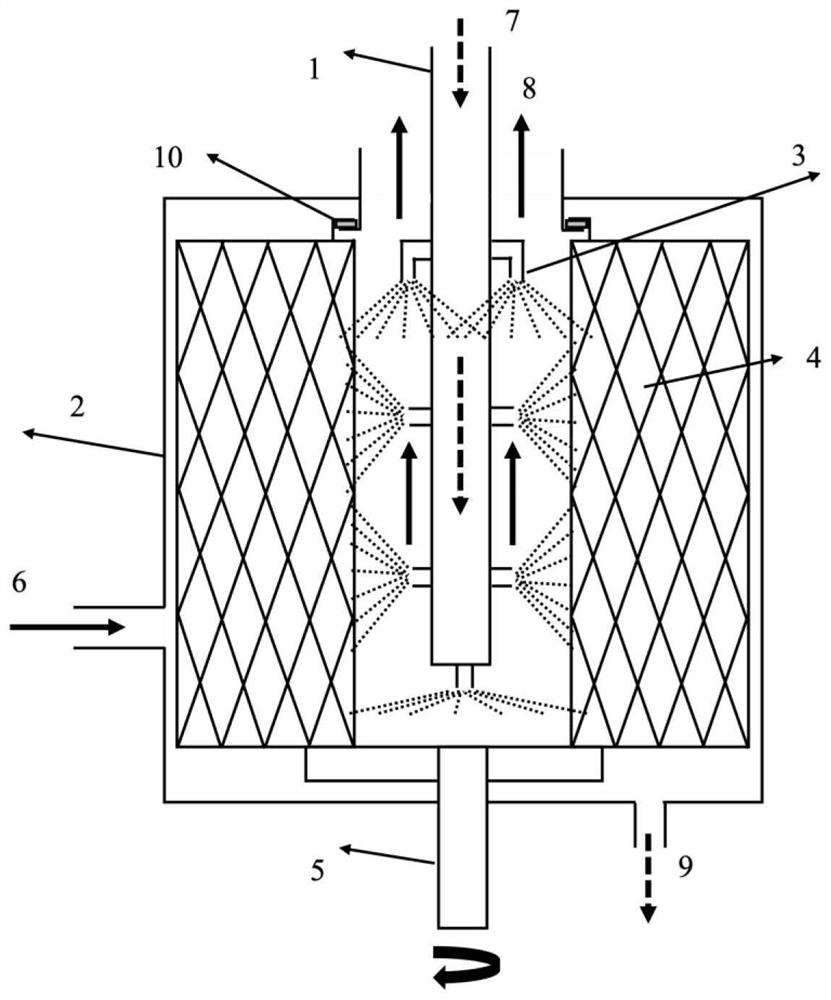

Spraying type hydrate continuous reaction device

ActiveCN113000004AEnhanced mass transferIncreased hydration reaction rateGaseous fuelsChemical/physical/physico-chemical stationary reactorsPhysicsHigh energy

The invention belongs to the technical field of hydrate reaction equipment, and particularly relates to a spray-type hydrate continuous reaction device, which adopts a spray-type hydrate reaction mode, atomized droplets and gas have a large gas-liquid contact area, which can enhance mass transfer, remarkably improves the hydration reaction speed, and can effectively improve the hydration reaction efficiency, in the reaction process, by means of the pressure difference between the high-pressure environment in the reaction kettle and the low-pressure environment outside the reaction kettle, the small hydrate particles are continuously conveyed out of the reaction kettle, continuous production of the hydrate is achieved, by means of the mode of conveying the small hydrate particles through the pressure difference, the problems of complex mechanical structure and high energy consumption of a traditional screw extrusion conveying mode can be avoided; the device is simple in structure and scientific and reliable in principle, and by means of the pressure difference between the high-pressure environment in the reaction kettle and the low-pressure environment outside the reaction kettle and the action of the fluidization throttler, small hydrate particles and unreacted reaction liquid and unreacted gas which can be repeatedly utilized are continuously conveyed outwards from the inside of the reaction kettle.

Owner:QINGDAO UNIV OF SCI & TECH

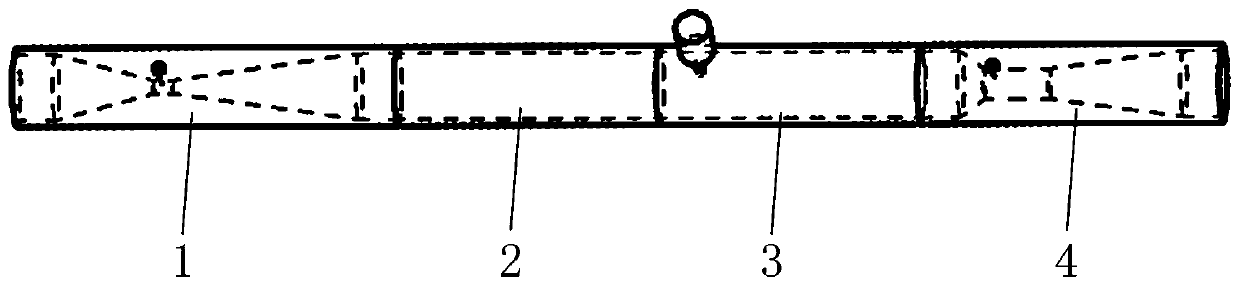

Pipeline type micro-nano bubble generator

PendingCN110433678AIncrease the gas-liquid contact areaReduce ascent speedFlow mixersTransportation and packagingMicro nanoEngineering

The invention relates to a pipeline type micro-nano bubble generator. The pipeline type micro-nano bubble generator comprises a columnar shell, one end of the columnar shell is a water inlet end, andthe other end of the columnar shell is a water outlet end; a flow guiding component group is arranged in the columnar shell from the water inlet end to the water outlet end; and the flow guiding component group includes at least two flow guiding components, every flow guiding component has a hollow cavity, and the adjacent flow guiding components are attached to each other in order to make the internal diameters of the hollow cavities alternately contract and expand within the length range of the flow guiding component group. The pipeline type micro-nano bubble generator has the advantages ofgreat increase of the gas-liquid contact area, comprehensiveness in improvement of the ability of water to remove pesticide residues, oil stains and detergent residues, easiness in manufacturing, convenience in mounting and dismounting, and realization of free expansion of the quantity and the total length direction of the flow guiding components as needed.

Owner:SHANGHAI XINGHENG SCI & TECH

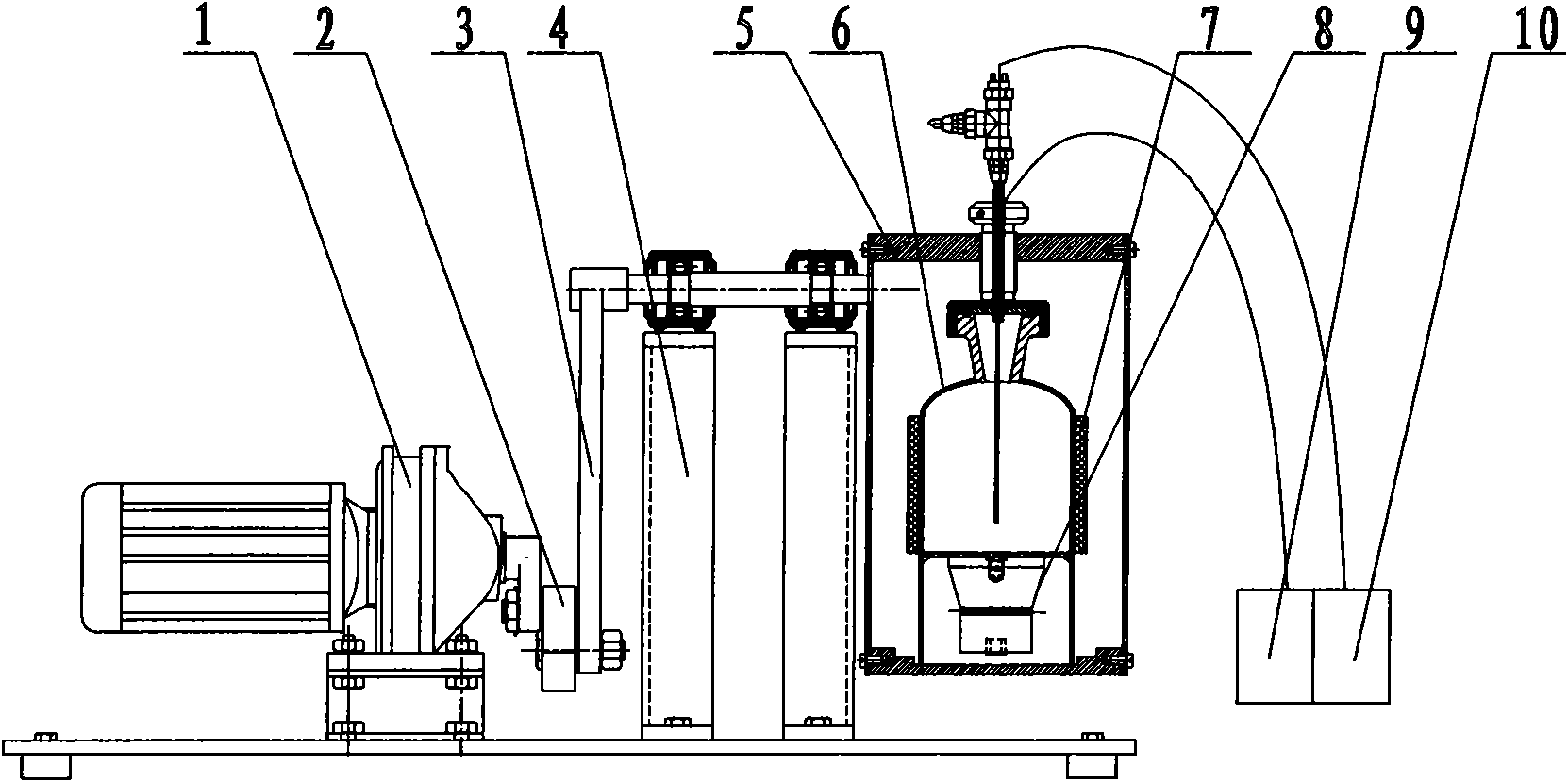

Ultrasonic exciting hydrogenation reactor

InactiveCN101579619AIncrease the gas-liquid contact areaHigh transmission speedEnergy based chemical/physical/physico-chemical processesChemical/physical/physico-chemical moving reactorsUltrasonic generatorProcess engineering

The invention relates to an ultrasonic exciting hydrogenation reactor, which comprises a reaction container and a hydrogen storage tank. The reaction container is arranged in a swinging cover, and the swinging cover is connected with a swinging mechanism; an adjusting valve and a pressure meter are connected between the reaction container and the hydrogen storage tank, the adjusting valve is respectively provided with an air inlet, an operating port and an exhaust port communicated with the hydrogen storage tank, the reaction container and the outside, and the pressure meter is communicated with an inner cavity of the adjusting valve; the reaction container is provided with a heating device and a temperature control device; and the bottom of the reaction container is provided with an ultrasonic vibrator, and the ultrasonic vibrator is in signal connection with an ultrasonic generator. The invention provides the ultrasonic hydrogenation reactor with high transfer efficiency, strong sealability and correct measurement.

Owner:ZHEJIANG UNIV OF TECH

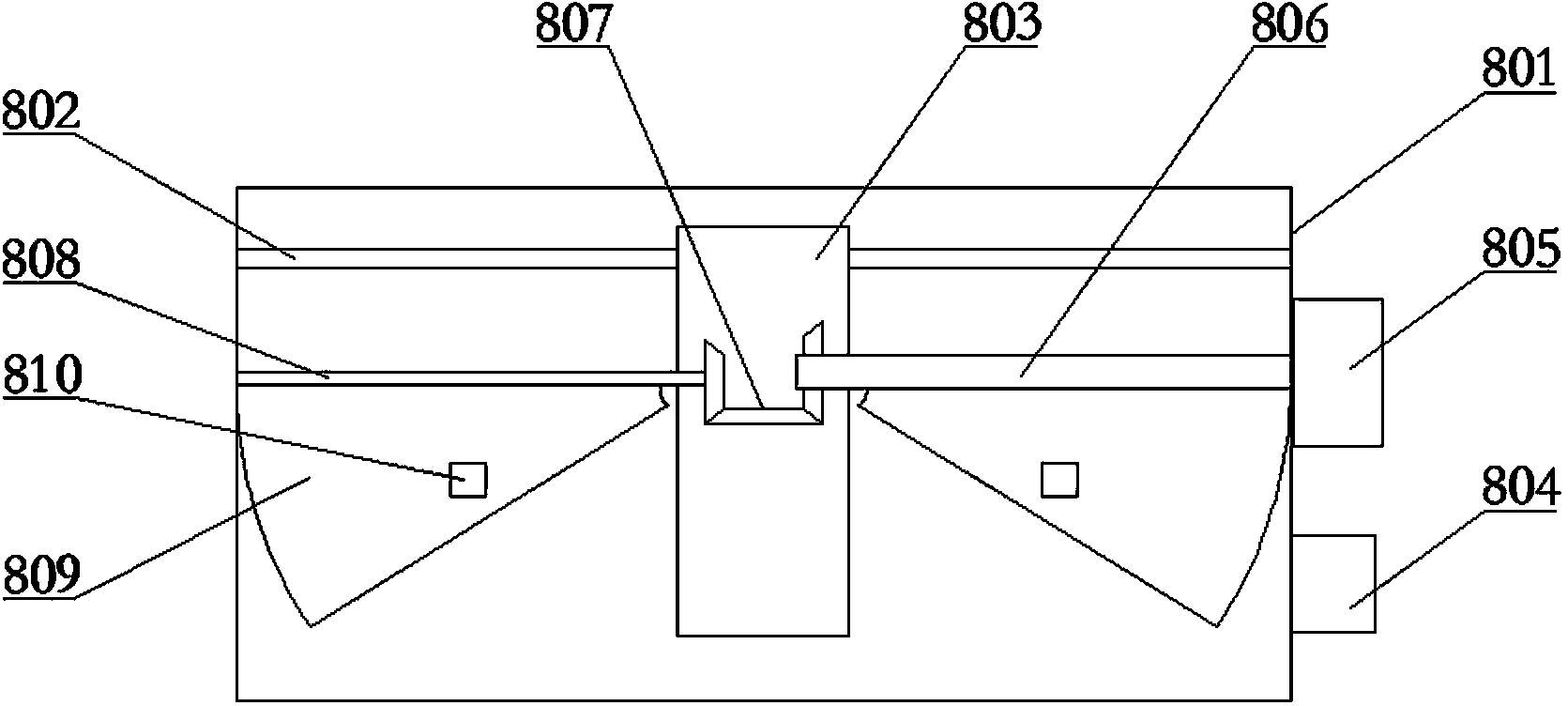

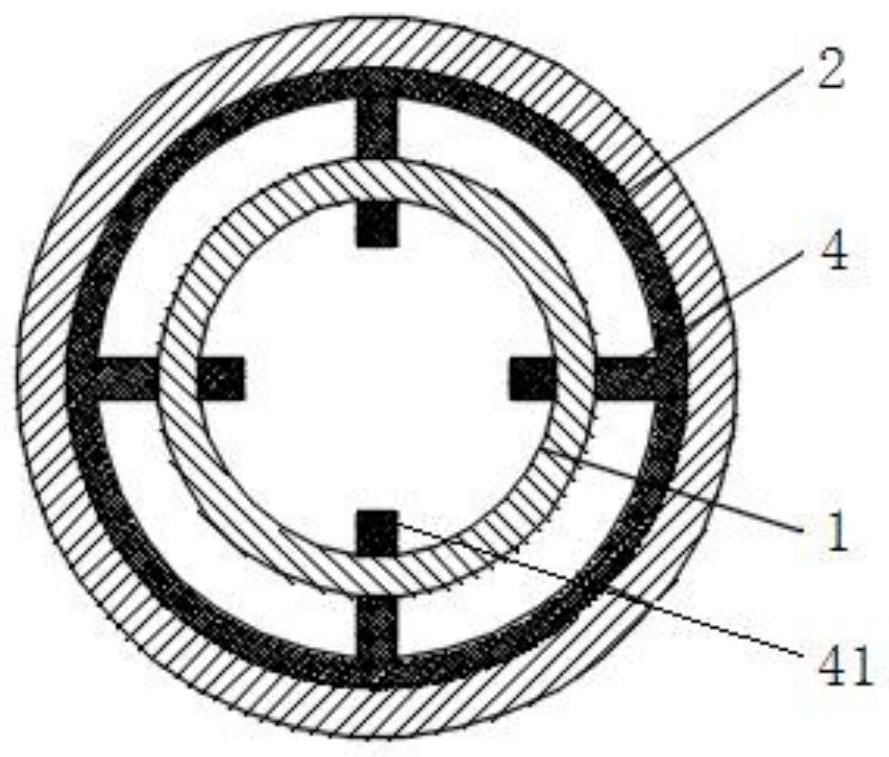

Double-circular plate tower

InactiveCN102580631AIncrease the gas-liquid contact areaReduce resistanceDispersed particle separationLiquid-gas reaction processesMass transferContact time

The invention discloses a double-circular plate tower, which comprises a tower wall, a gas inlet, a gas outlet, a liquid inlet, a liquid outlet, a tower column and tower plates, wherein two types of tower plates are provided, the tower plate A is circular, and an outer ring is connected with a tower body closely; and the tower plate B is circular, and an inner ring is closely connected with the tower column. The double circular tower plates are adopted to form two circular liquid curtains which have different sizes, so a larger gas-liquid contact area can be provided under the same tower diameter. Upper weirs and lower weirs are all arranged on the tower plates, so the liquid holdup of the plates is increased, and the double circular liquid curtains are ensured to be formed. The gas-liquid contact area and contact time are increased, the heat and mass transfer efficiencies are improved, and the tower plates have simple structures and are simple to manufacture and operate.

Owner:王健祥

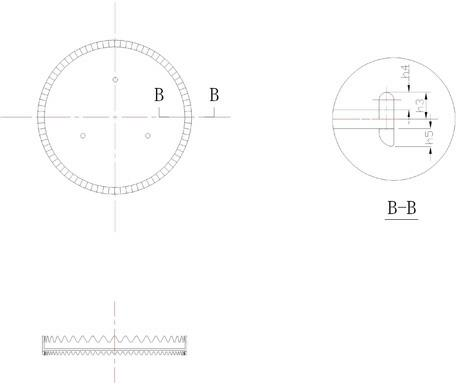

Mosquito coil type heterogeneous reactor and mosquito coil type heterogeneous reactor group

InactiveCN110465247AIncrease the gas-liquid contact areaUniform mass transferChemical/physical processesMass transferEngineering

A mosquito coil type heterogeneous reactor includes a cavity, the top of the cavity is provided with a liquid phase medium inlet, the bottom of the cavity is provided with a liquid phase medium outlet, the upper part of the sidewall of the cavity is provided with a gas phase medium outlet, and the lower part of the sidewall of the cavity is provided with a gas phase medium inlet; a first mosquitocoil type liquid distributor group, a first catalyst layer, a second mosquito coil type liquid distributor group, a second catalyst layer and a gas phase medium distributor are sequentially arranged in the cavity at intervals from top to bottom; the liquid phase medium inlet is communicated with a six-way joint, four inverted L-shaped liquid phase medium distribution tubes are evenly distributed on the peripheral surface of the six-way joint and communicate with the six-way joint, the lower bottom surface of the six-way joint is communicated with a vertical liquid phase medium distribution tube, and the liquid medium distribution tube passes through the first mosquito coil type liquid distributor group, the first catalyst layer, the second mosquito coil type liquid distributor group and the second catalyst layer from top to bottom, and extends into the lower part of the cavity; and the tube wall of every liquid phase medium distribution tube is provided with a plurality of through holes for mounting atomizers. The mosquito coil type heterogeneous reactor increases the contact area of the gas-liquid phase medium and increase the gas-liquid phase mass transfer speed.

Owner:JIANGSU UNIV OF SCI & TECH

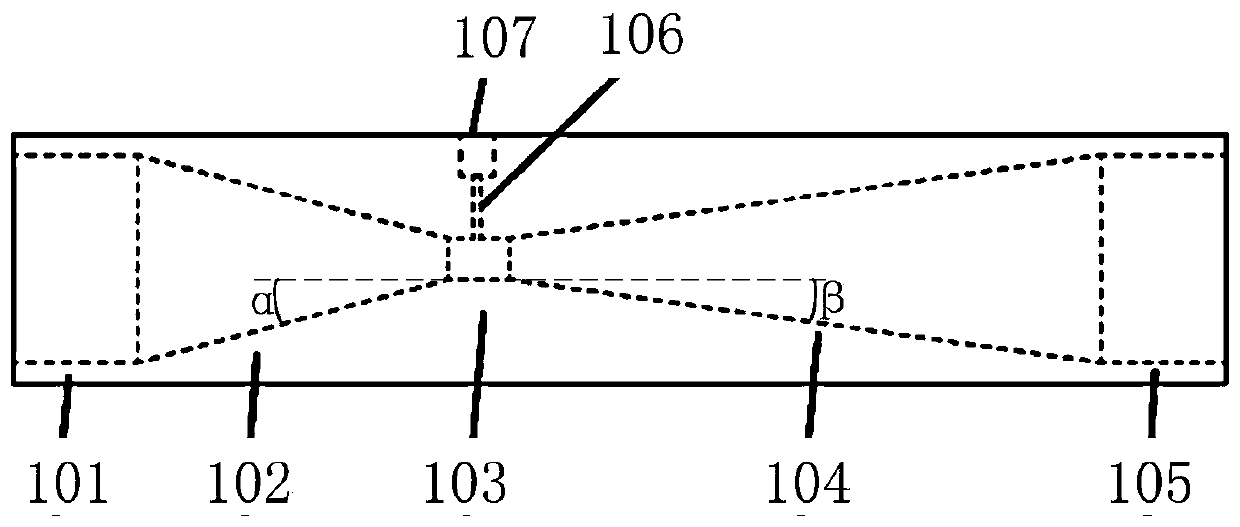

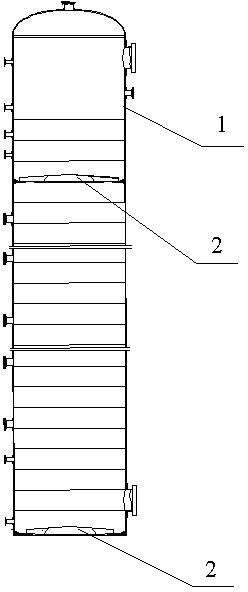

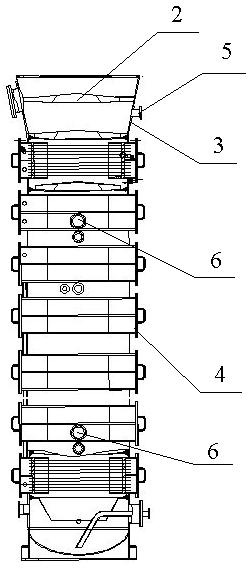

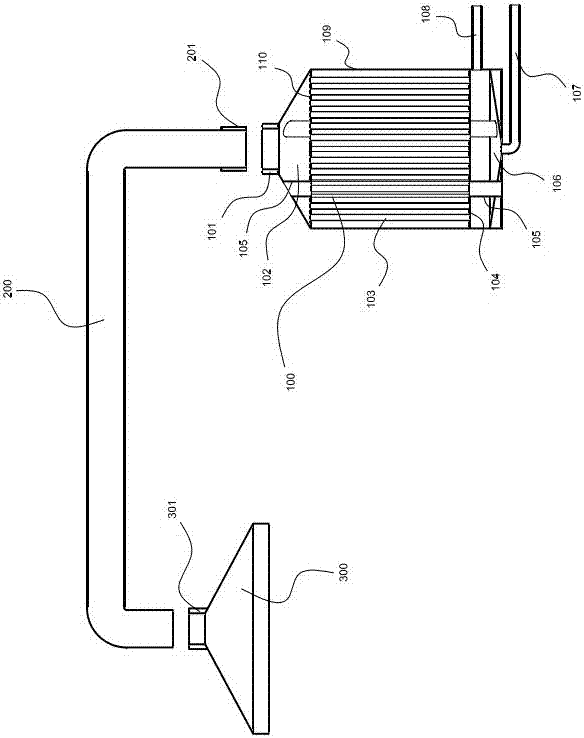

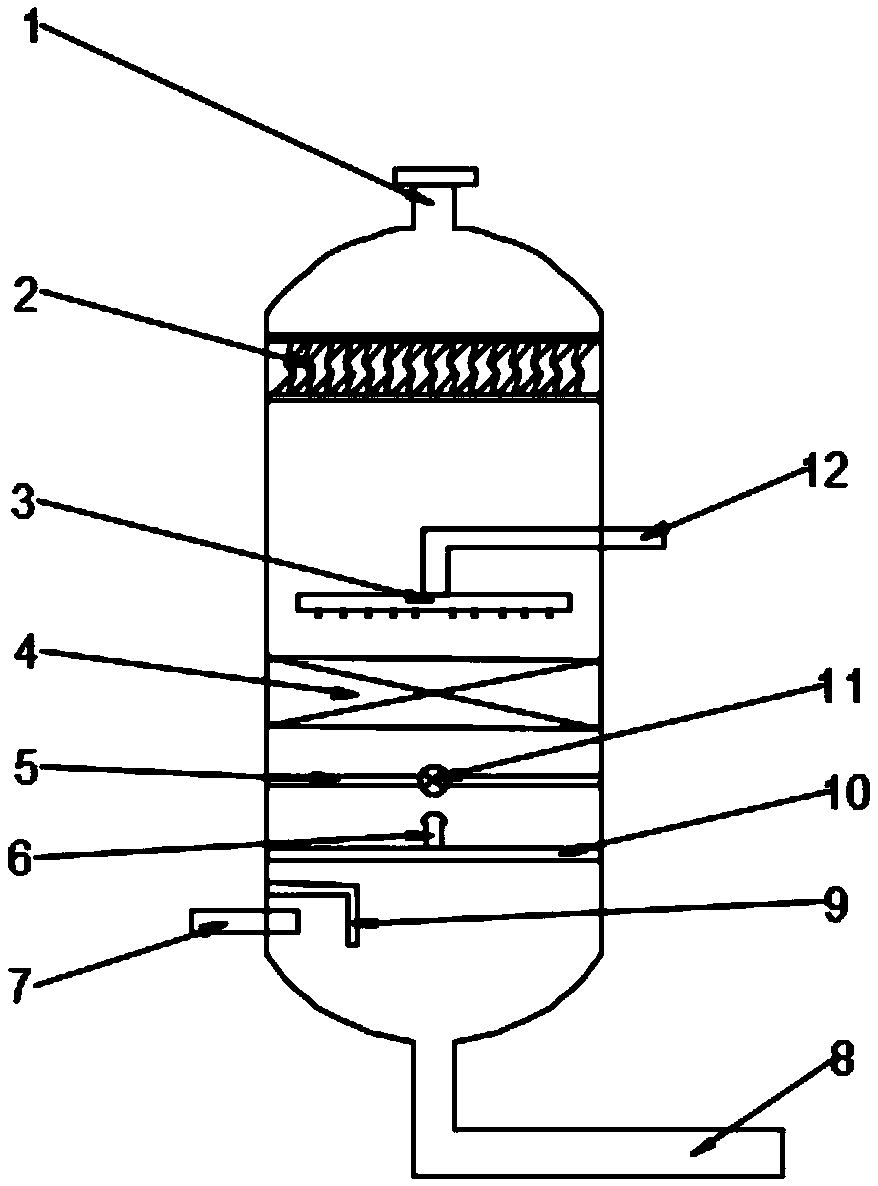

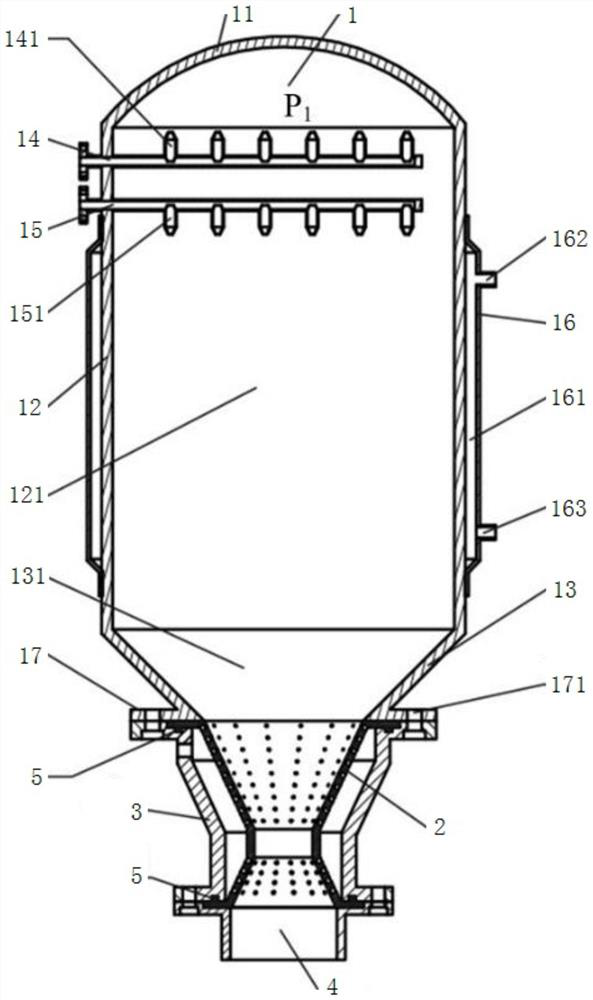

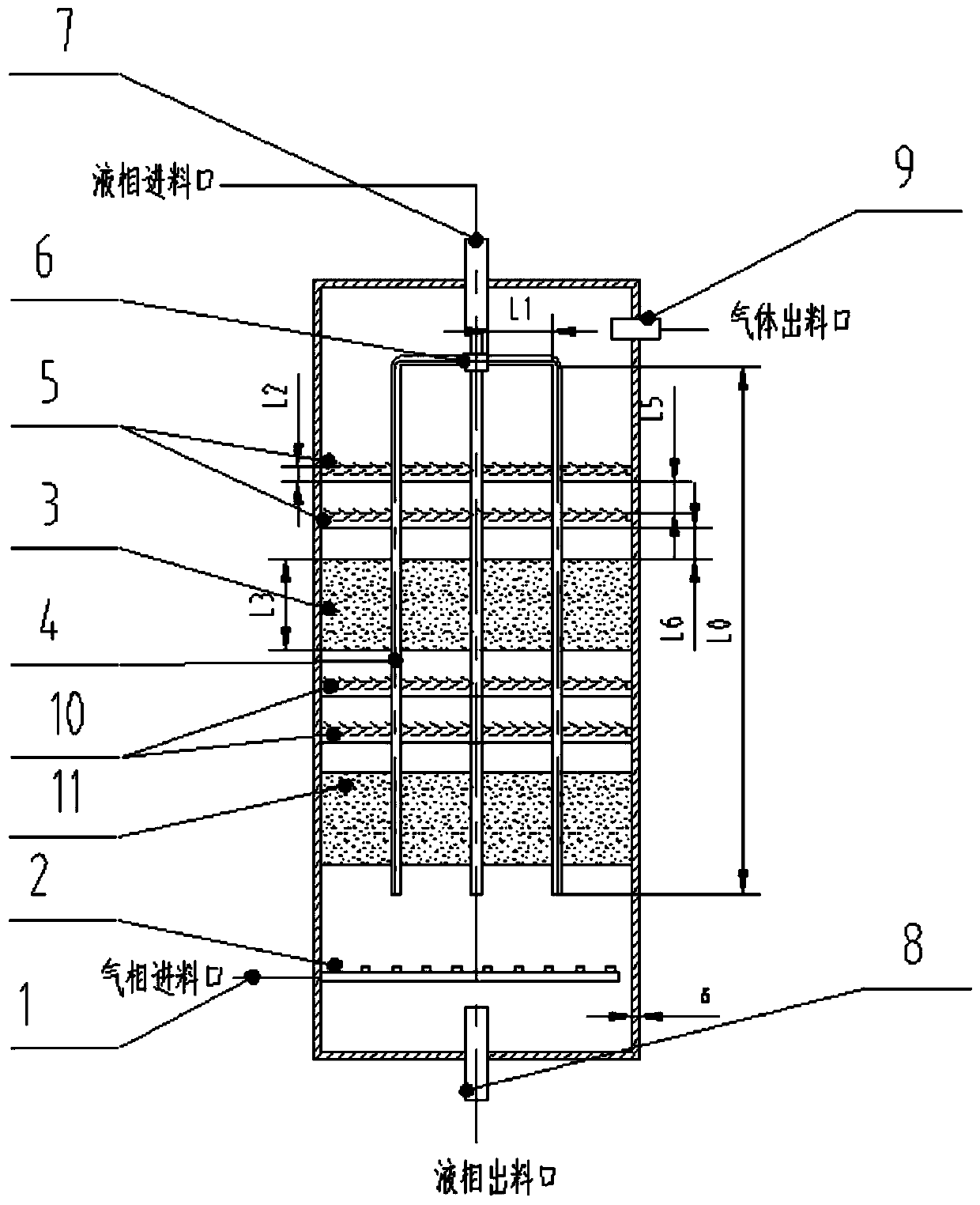

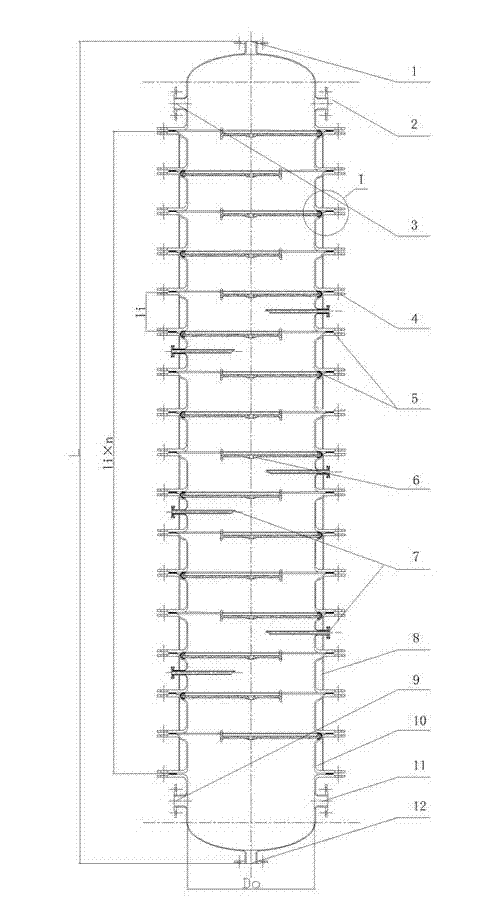

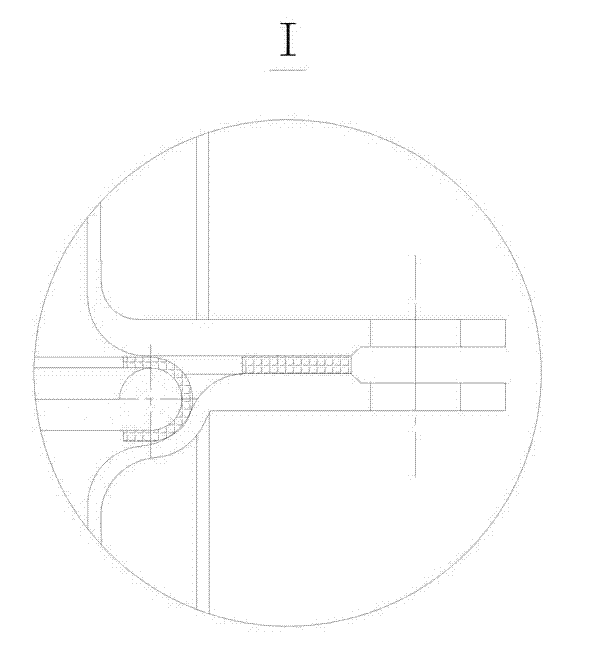

Gas absorption apparatus

InactiveCN102961949AIncrease the gas-liquid contact areaReduce resistancePhosphorus halides/oxyhalidesCarbon compoundsEngineeringTower

The invention discloses a gas absorption apparatus. The gas absorption apparatus comprises an upper seal (1), liquid inlets (2), gas outlets (3), tower sections (4), sealing washers (5), tower plates (6), observation ports (7), outer walls (8) of tower wall interlayers, gas inlets (9), tower bodies (10), liquid outlets (11) and a lower seal (12); the gas absorption apparatus is formed by the at least two tower bodies which are prolate and connected with on another through pipelines; and the tower plates (6) are rectangular. The gas absorption apparatus provided by the invention has the advantages of large mass transfer area, small resistance and relatively high mass transfer efficiency on the premise of ensuring great liquid holdup.

Owner:TAIZHOU POLYTECHNIC COLLEGE +1

Method for absorbing and separating ammonia-containing gas by using supergravity enhanced ionic liquid

InactiveCN113041788ARun smoothlyIncrease the gas-liquid contact areaGas treatmentDispersed particle separationNonferrous metalMass transfer rate

The invention relates to a method for absorbing and separating ammonia-containing gas by adopting supergravity enhanced ionic liquid. The method is suitable for absorbing and separating ammonia in industrial ammonia-containing gas such as synthetic ammonia purge gas, melamine tail gas, non-ferrous metal chemical tail gas and the like. According to the method, an atomizing and supergravity environment is provided by utilizing a spray rotating packed bed, and ammonia-containing gas and an ionic liquid absorbent are introduced into the spray rotating packed bed according to a certain proportion at a certain temperature and pressure; and the ionic liquid absorbent and the ammonia-containing gas are in countercurrent / cross-flow contact in the spray rotating packed bed, so that the phase contact area and the interface update rate of the ionic liquid absorbent and the ammonia-containing gas are enhanced, the problem of low mass transfer rate caused by high viscosity of the ionic liquid is solved, and efficient selective absorption of the ionic liquid to ammonia is realized. By adopting the method, the absorption efficiency of ammonia can reach more than 90%. Compared with a traditional packing absorption tower, the method has the advantages of small equipment size, high mass transfer efficiency, low investment and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Liquor steaming equipment

InactiveCN106834061ASpeed up evaporationIncrease the gas-liquid contact areaAlcoholic beverage preparationEngineeringDistillation

The invention discloses liquor steaming equipment. The liquor steaming equipment comprises a distillation barrel for holding fermented grains and a ceiling condenser covering the distillation barrel, wherein a steaming plate capable of being taken out is arranged at the lower part of the inner side of the distillation barrel. The liquor steaming equipment further comprises a blower used for blowing air into the distillation barrel and an air guiding pipeline used for guiding air blown out by the blower into the distillation barrel, wherein one end of the air guiding pipeline is connected with the air outlet of the blower; the other end of the air guiding pipeline enters the inner side of the distillation barrel and is communicated with the space on the inner side of the distillation barrel.

Owner:RUIAN MAITENG ELECTRONICS COMMERCE CO LTD

Wine distillation device

InactiveCN106754201ASpeed up evaporationIncrease the gas-liquid contact areaAlcoholic beverage preparationChemistryDistillation

The invention discloses a wine distillation device, which comprises a steam generator, a distillation bucket containing fermented grains, and a ceiling pocket condenser covering the distillation bucket, wherein the steam generator is in a hollow cylindrical form; a steam generation space containing water and water steam is arranged in the inner side of a cylinder; a space, containing the fermented grains, in the inner side of the distillation bucket is a fermented grains distillation space; the wine distillation device is also provided with an air guide pipe and a blower; and one end of the air guide pipe is communicated with the fermented grains distillation space and the other end of the air guide pipe is connected with an air outlet of the blower.

Owner:RUIAN MAITENG ELECTRONICS COMMERCE CO LTD

Gas-liquid heat transfer device based on ceramic matrix composite resin filler and preparation method of filler

ActiveCN111744453BHydrophilicIncrease the gas-liquid contact areaChemical/physical/physico-chemical processesResin-Based CompositeUltimate tensile strength

The invention discloses a gas-liquid heat transfer device based on a ceramic-based composite resin filler and a preparation method for the filler; in the filler, a high-efficiency ceramic-based composite resin is formed by adding resin fibers and heat-conducting fibers to the ceramic matrix. Corrosion packing. Compared with ordinary fillers, ceramic matrix composite resin corrosion-resistant fillers have better tensile strength and flexibility, better thermal conductivity, and stronger corrosion resistance.

Owner:安徽国微华芯环境科技有限公司 +1

Flue gas desulfurization absorption tower with twin-stage air flow distribution device

PendingCN108970383AIncrease the gas-liquid contact areaImprove mass transfer performance and absorption efficiencyGas treatmentDispersed particle separationMass transferAirflow

The invention discloses a flue gas desulfurization absorption tower with a twin-stage air flow distribution device. The flue gas desulfurization absorption tower comprises a tower body, a slurry pondlocated at the bottom of the tower body and the twin-stage air flow distribution device, a spray pipe and a demister which are sequentially arranged at the position, above the slurry pond, in the tower body from bottom to top; the tower body is provided with an absorption tower inlet communicated with the slurry pond, and the top end of the tower body is provided with an absorption tower outlet. The flue gas desulfurization absorption tower achieves rectification and uniform distribution of smoke entering the tower through the twin-stage air flow distribution device, when the smoke passes through the twin-stage air flow distribution device, the air liquid generates the strong impact effect: in the falling process of absorption slurry drops, the drops are broken again by the smoke which isaccelerated to go up when the drops pass through the twin-stage air flow distribution device, a new mass transfer absorption surface is generated, which is amount to, a spray layer without a circulation pump is additionally arranged, thus the mass transferring efficiency and the absorption efficiency are increased, and the operation energy consumption is saved.

Owner:HEFEI CEMENT RES DESIGN INST +1

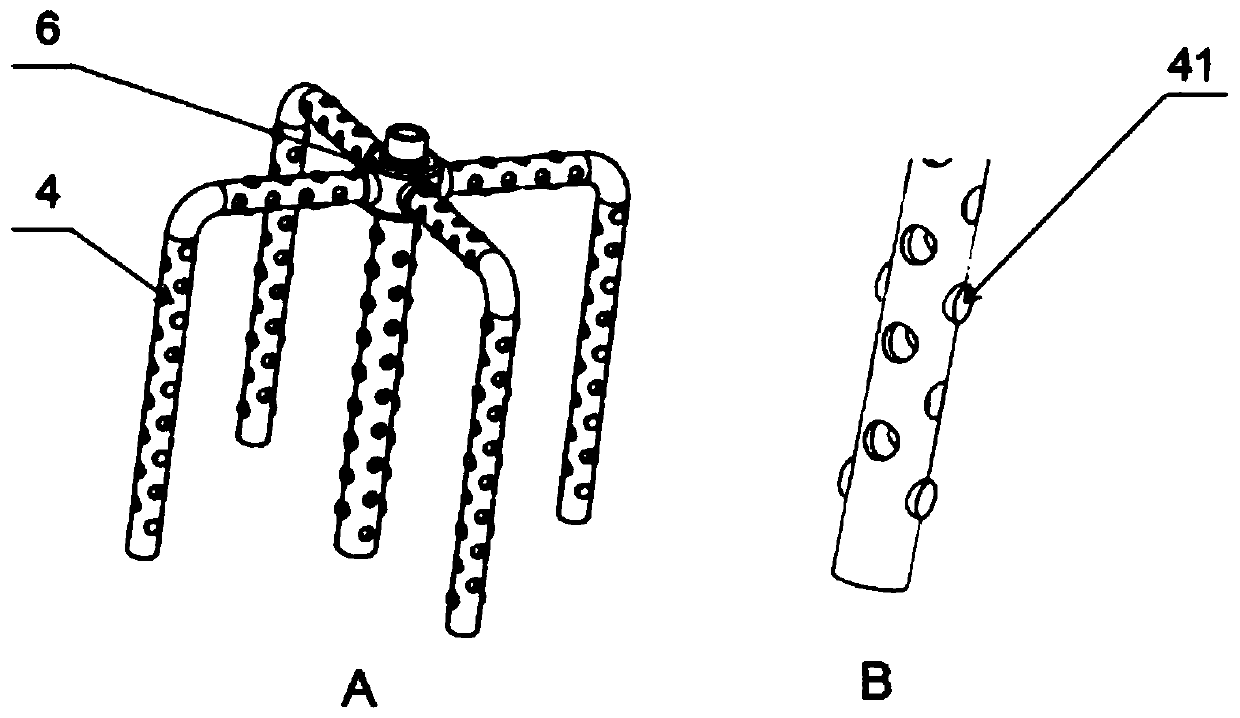

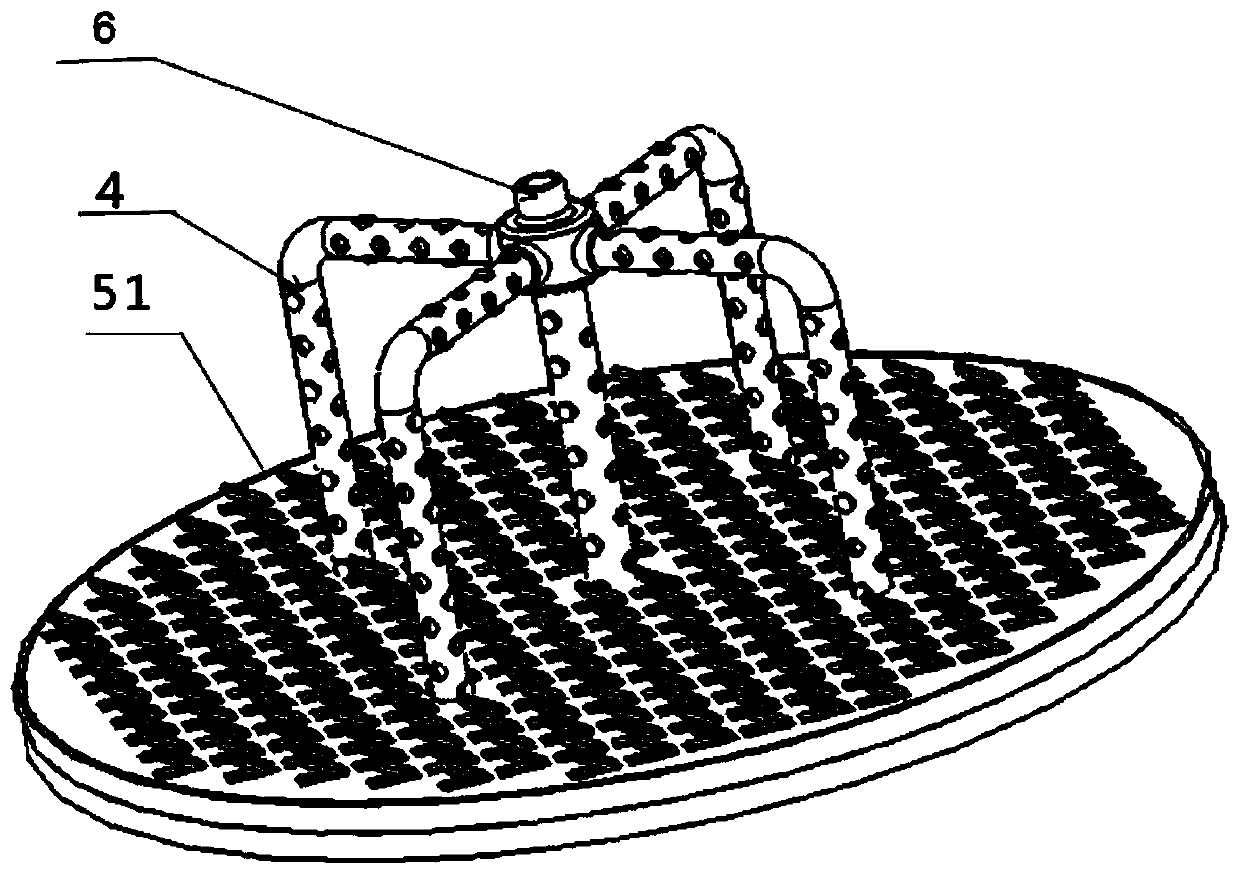

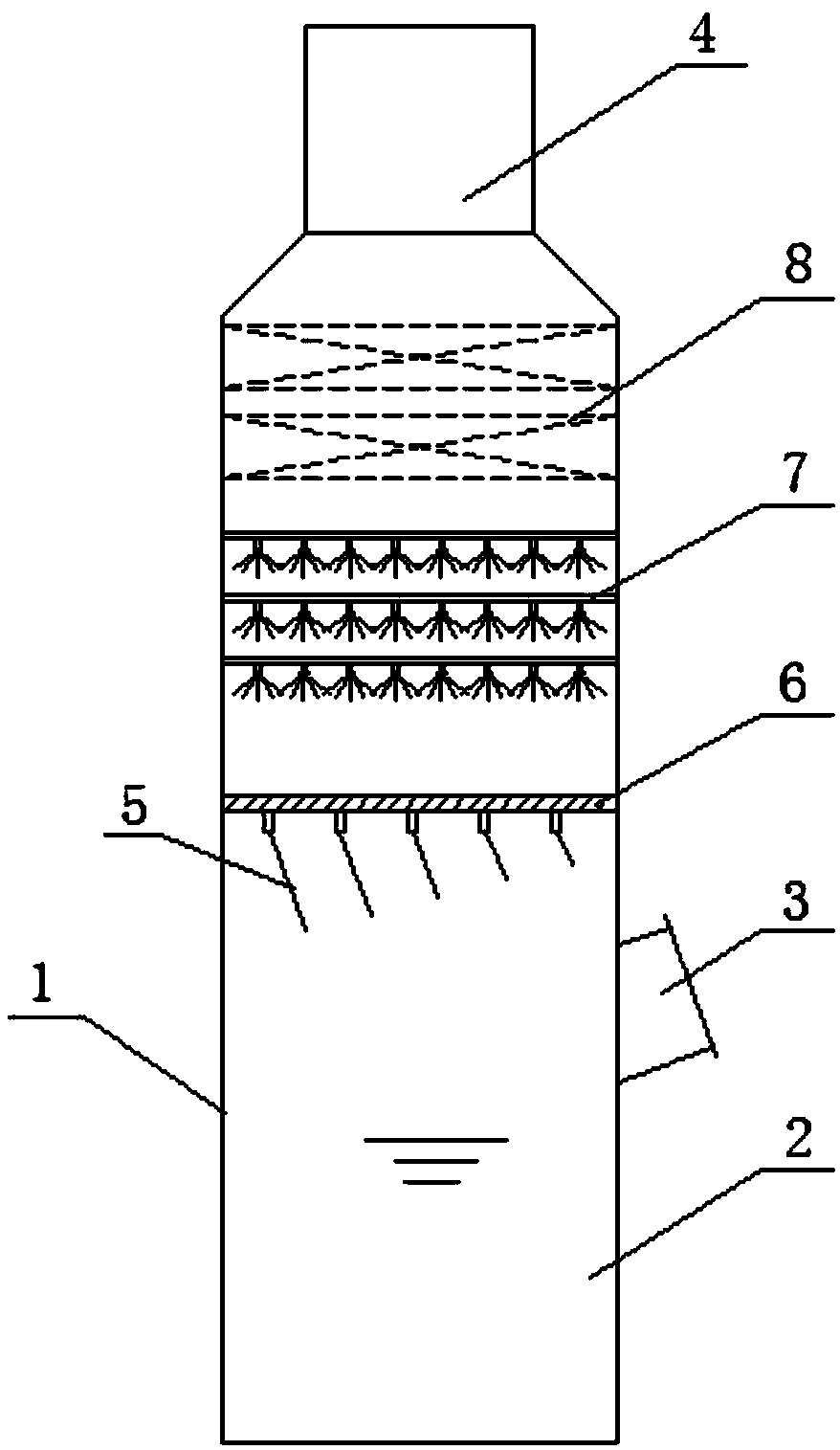

Novel oxygenized air distributor for desulfurizing tower

InactiveCN107213762AIncrease contact areaOvercome CorrosivityGas treatmentTransportation and packagingEngineeringTower

The invention discloses a novel oxygenized air distributor for a desulfurizing tower. Aerator pipes are parallelly and uniformly arranged on a bracket, one ends of the aerator pipes are fixedly connected with an air inlet main pipe, and the other ends of the aerator pipes are closed. The aerator pipe comprises a frame pipe and a distributor pipe, the frame pipe is arranged inside the aerator pipe, a vent hole is formed at the lower part of the frame pipe, the distributor pipe is arranged outside the frame pipe, and aeration holes are uniformly arranged just over the distributor pipe; a regulating device is arranged on a support bar of the bracket, support regulating holes are uniformly formed in the support bar of the bracket, two regulating plates are symmetrically arranged, and regulating holes are uniformly formed in the regulating plates. The novel oxygenized air distributor for the desulfurizing tower, disclosed by the invention, greatly increases the gas-liquid contacting area between oxygenized air and desulfurizing liquid, improves the desulfurization efficiency of SO2 and effectively overcomes the defect of blockage of the novel oxygenized air distributor.

Owner:LUOYANG GREEN ENVIRONMENTAL PROTECTION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com