Pipeline type micro-nano bubble generator

A nano-bubble and generating device technology, which is applied in transportation and packaging, gas/steam and liquid mixing, mixers, etc. It can solve the problems of unsatisfactory mixing effect of static mixer, inability to form gas residence area, poor bubble crushing effect, etc. , to achieve the effect of low price, convenient installation and disassembly, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

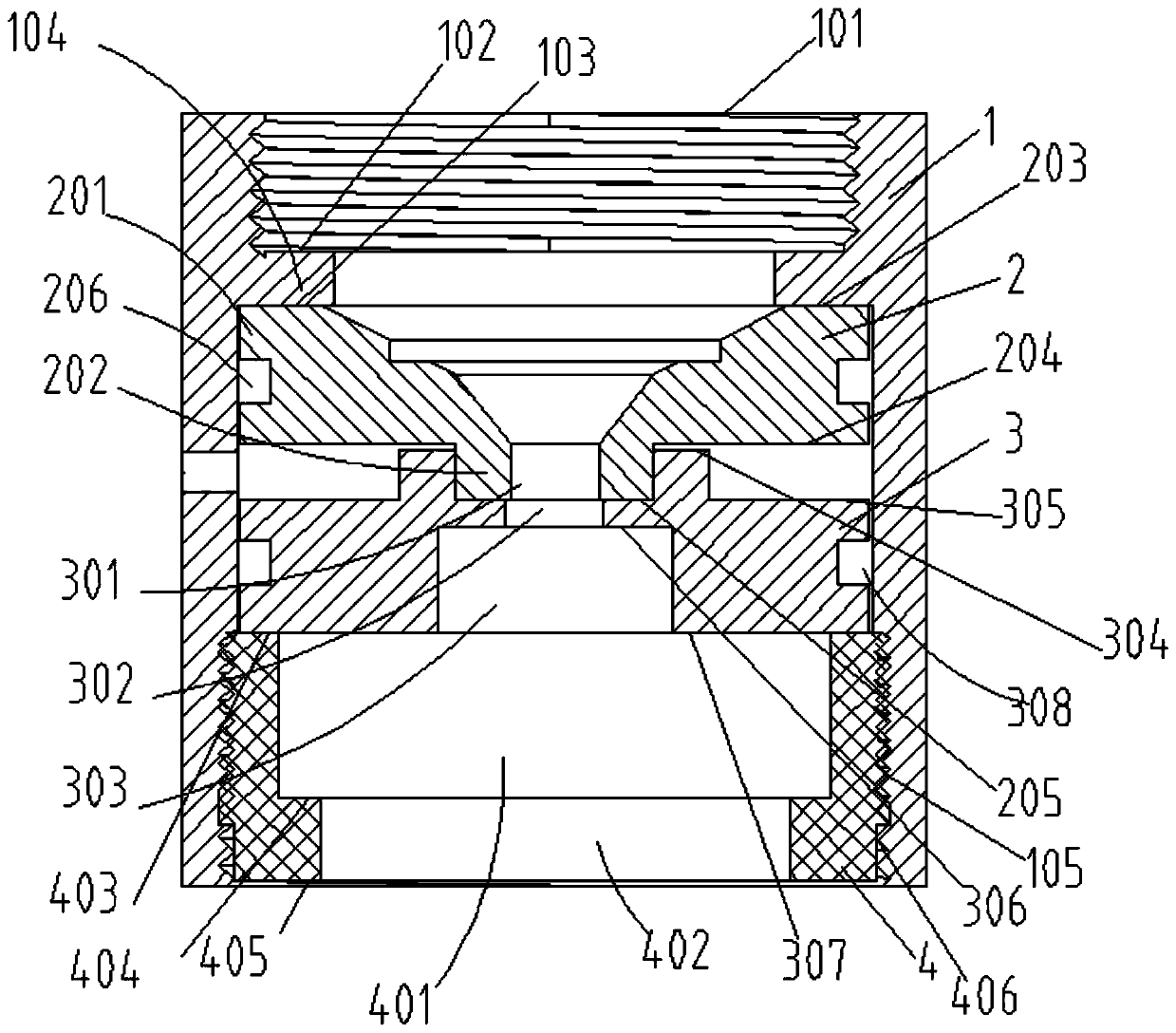

[0025] see figure 1 , a pipe-type micro-nano bubble generating device, comprising:

[0026] Cylindrical housing 1, water inlet pipe connection thread 101, and an annular protruding structure 104 facing the axial direction. The plane of the protruding structure facing the water inlet direction is called the first housing plane 102, and the plane facing the water outlet direction is called the housing second plane 103;

[0027] The first guide part 2, the first guide part is a two-section cylindrical structure, wherein the diameter of the cylindrical structure 201 close to the water inlet direction is larger than the diameter 202 of the cylindrical structure away from the water inlet direction, and in the axial direction There is an axisymmetric water channel on the top, and the diameter of the water channel is gradually reduced. Its function is to increase the water flow rate, reduce the hydrostatic pressure, and generate negative pressure; The plane is called the first plane...

Embodiment 2

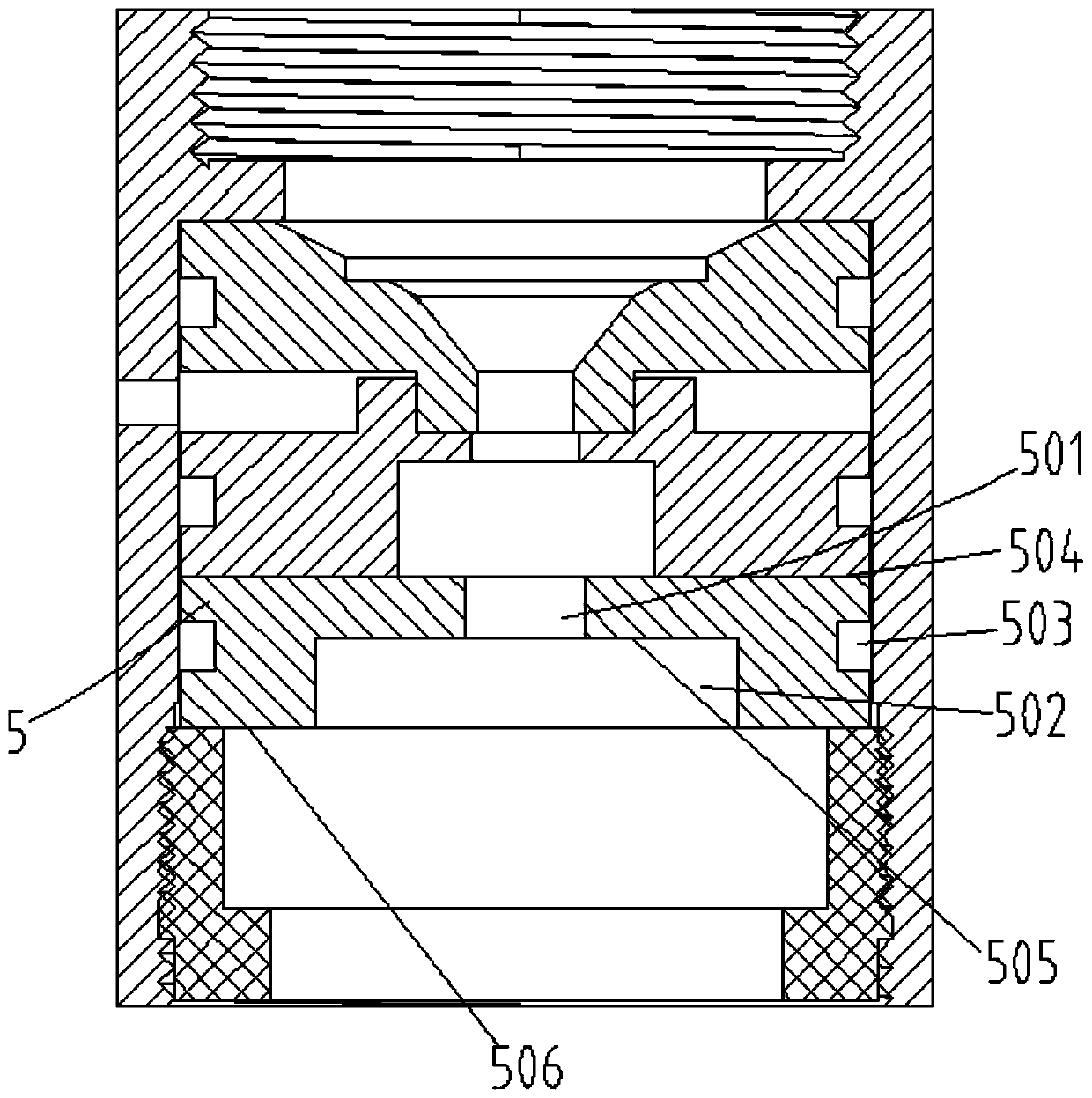

[0031] see figure 2 , in this embodiment, a third guide member 5 can be added between the second guide member 3 and the end cover member 4, which includes a first cavity 501, a second cavity 502, and an O-ring groove 503 ; The first plane 504, the second plane 505, and the third plane 506, the function of these accessories is to make the water channel smaller and then bigger, thereby improving the bubble breaking effect.

[0032] The invention effectively breaks large-sized air bubbles in the pipeline, and even breaks the air bubbles into micron levels, thereby greatly increasing the gas-liquid contact area; micron air bubbles with small diameters rise slowly in water, have large specific surface areas, and have negative charges on the surface , can comprehensively improve the cleaning ability of water for pesticide residues, oil stains, and detergent residues; at the same time, when cleaning with detergent, it can reduce the amount of detergent and improve the cleaning effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com