Novel oxygenized air distributor for desulfurizing tower

A technology for oxidizing air and sparger, applied in chemical instruments and methods, gas treatment, gas dissolution, etc., can solve the problems of clogging the aperture of oxidizing air sparger, reducing the oxidation effect of desulfurization liquid, uneven distribution of oxidizing air, etc. The effect of blocking the oxidizing air distributor, overcoming easy corrosion, convenient and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

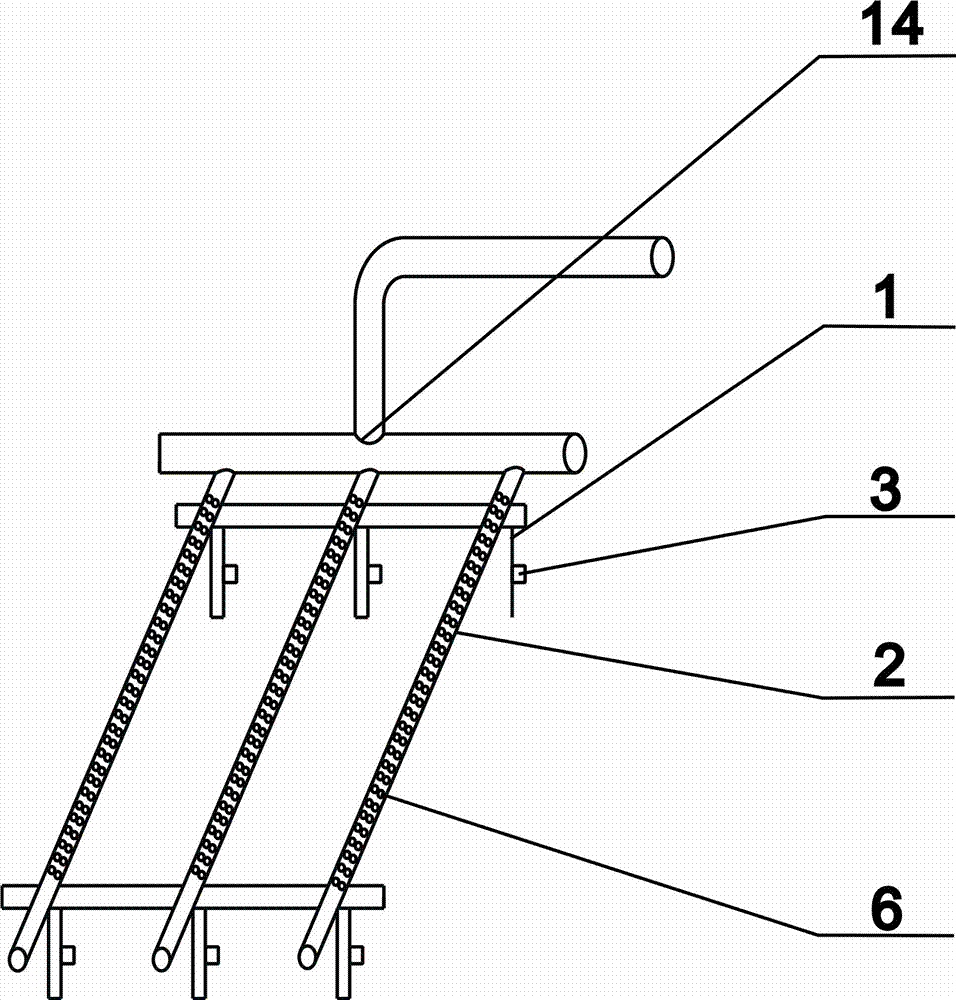

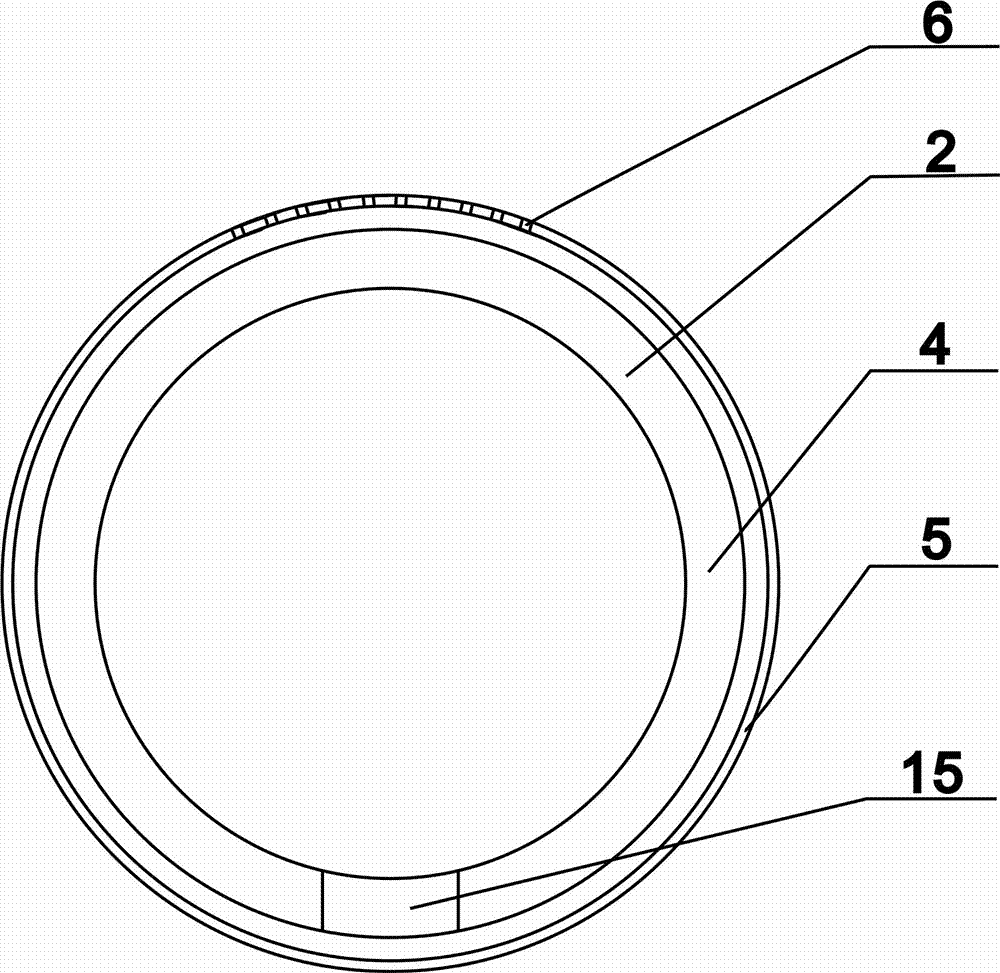

[0045] The aeration pipe 2 is composed of a skeleton pipe 4 and a distribution pipe 5. The inner diameter of the skeleton pipe is 80mm and the thickness is 8mm. The distribution pipe 5 is arranged on the outside of the skeleton pipe 4, and the upper part of the distribution pipe 5 is evenly provided with aeration holes 6. The diameter of the aeration holes 6 is 2mm. The distance between the aeration holes 6 and the aeration holes 6 The distance between them is 5 mm; the gap between the skeleton tube 4 and the distribution tube 5 is 1 mm.

Embodiment 2

[0047] The aeration pipe 2 is composed of a skeleton pipe 4 and a distribution pipe 5. The inner diameter of the skeleton pipe is 100mm and the thickness is 9mm. The diameter of the aeration hole 6 is 3mm, and the distribution pipe 5 is arranged on the outside of the skeleton pipe 4. The aeration hole 6 is evenly arranged on the upper part of the distribution pipe 5. The diameter of the aeration hole 6 is 3mm. The distance between them is 10 mm; the gap between the skeleton tube 4 and the distribution tube 5 is 1.5 mm.

Embodiment 3

[0049] The aeration pipe 2 is composed of a skeleton pipe 4 and a distribution pipe 5. The inner diameter of the skeleton pipe is 120mm and the thickness is 10mm. The distribution pipe 5 is arranged on the outside of the skeleton pipe 4, and the upper part of the distribution pipe 5 is uniformly provided with aeration holes 6. The diameter of the aeration holes 6 is 4mm. The distance between the aeration holes 6 and the aeration holes 6 The distance between them is 15 mm; the gap between the skeleton tube 4 and the distribution tube 5 is 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com