Combined cleaning device for waste gas of low speed marine diesel engine

A technology for washing devices and diesel engines, which is used in combination devices, exhaust devices, mufflers, etc., can solve the problems of insignificant removal of fine particles, unsatisfactory removal of particles, and increased resistance. The effect of increasing the gas-liquid contact area and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

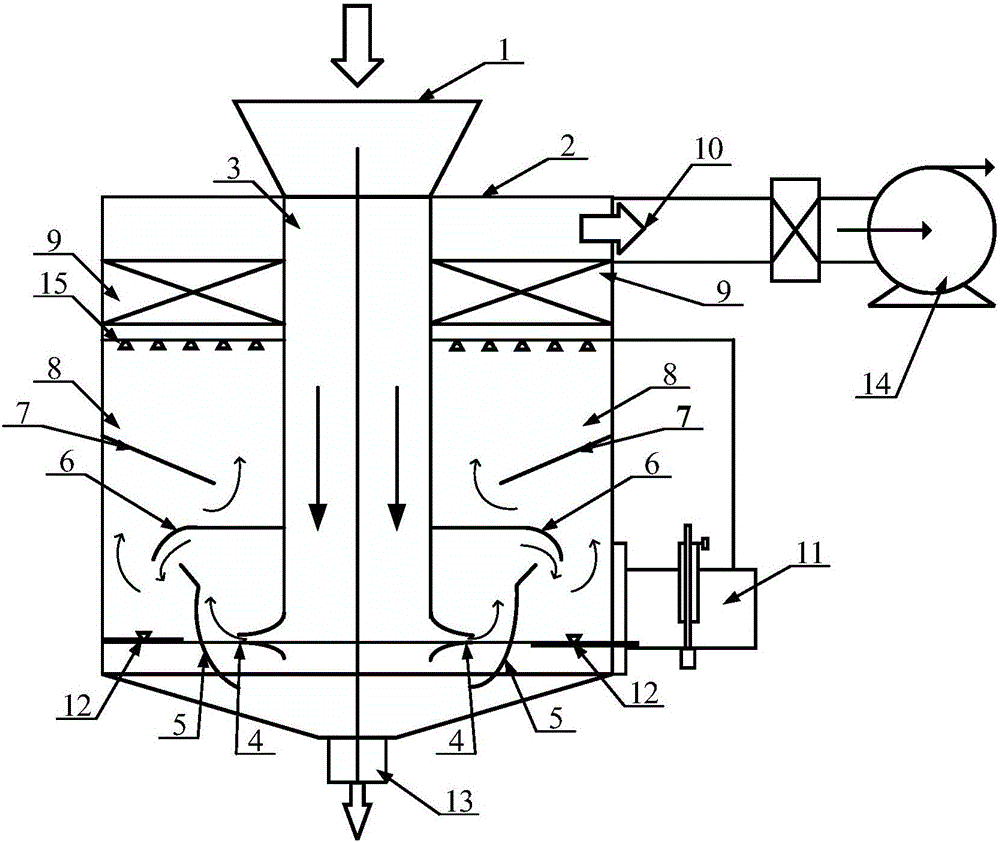

[0016] Combine figure 1 , The composite scrubbing device for low-speed diesel engine exhaust gas of a ship of the present invention mainly includes a scrubber 2 and a water supply system 11. The scrubber 2 includes an air inlet 1, an air inlet 3, a gas nozzle 4, a baffle 5-7, a washing zone 8, a liquid film nozzle 12, a spray layer 15, a mist eliminator 9, an exhaust port 10 and a drain 口13. In addition, the device also includes an induced draft fan 14. It is characterized in that: the air inlet 1 is connected with the air inlet 3, the air inlet 3 is connected to the washing zone 8 through the gas nozzle 4, and the liquid film nozzle 12, the baffle 5-7, and the spray nozzle are arranged in the washing zone from bottom to top. The shower layer 15 and the demister 9, the induced draft fan 14 are connected to the scrubber 2 through the exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com