Large-scale pressure carbonization tower

A carbonization tower, a large-scale technology, applied in the field of pressurized carbonization reaction equipment, can solve the problems of small amount of synthetic conversion gas in single tower processing, low production capacity of single tower, restricting enterprise development, etc., to prolong reaction time and crystal growth time, increase gas The liquid contact area and the effect of improving unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

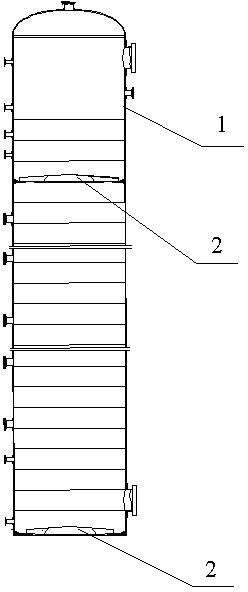

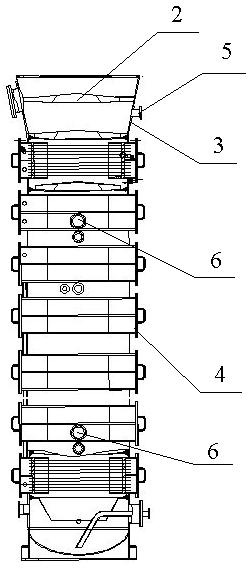

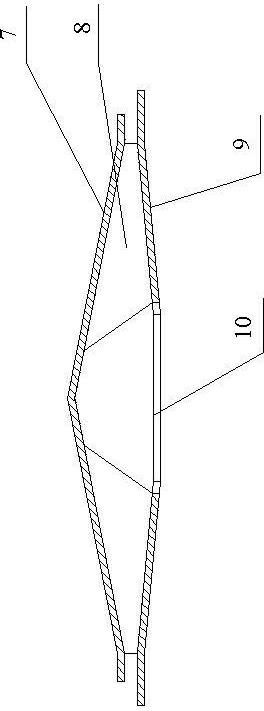

[0030] Embodiment 1, with reference to Figure 1-3 A large-scale pressurized carbonization tower, including an upper tower body 1, a lower water tank 4 and a middle conical tower body 3 connecting the upper tower body 1 and the lower water tank 4, and several sets of hats 2 are respectively arranged in the upper tower body 1 , the lower water tank 4 is provided with several tower sections, and a hat 2 is arranged above each tower section; the hat 2 is composed of a bottom plate 9, a top cover 7 and several ribs 8; the ribs 8 are in the center Symmetrically fixed on the bottom plate 9, the top cover 7 is fixed on the rib plate 8; a through hole 10 is provided in the middle of the bottom plate 9, and the edge of the bottom plate 9 where the through hole 10 is provided is a serrated edge;

[0031] There are 24 sets of hats 2 installed in the tower body 1 of the upper section, among which, the opening rate of the bottom plate 9 of the first to 21st sets of hats 2 from top to botto...

Embodiment 2

[0034] Embodiment 2, in the large pressurized carbonization tower described in Embodiment 1: the bottom plate 9 is in the shape of an inverted cone, and the top cover 7 is in the shape of a cone.

Embodiment 3

[0035] Embodiment 3, in the large-scale pressurized carbonization tower described in embodiment 1: the nominal diameter of the upper tower body 1 is 2700mm; the height of the carbonization tower is 26.4m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com