Patents

Literature

46results about How to "Large liquid holding capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenator and polymer hydrogenation method

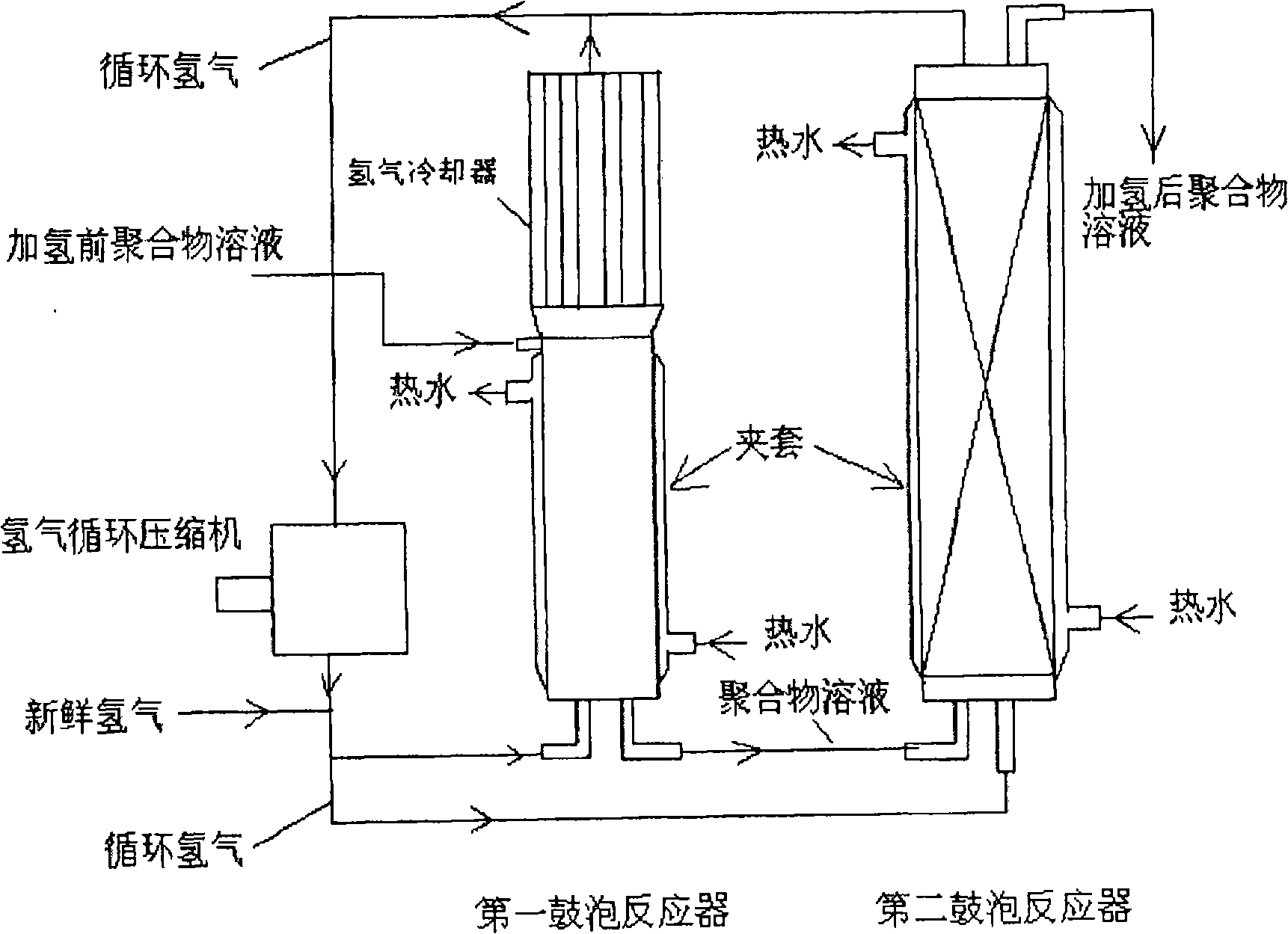

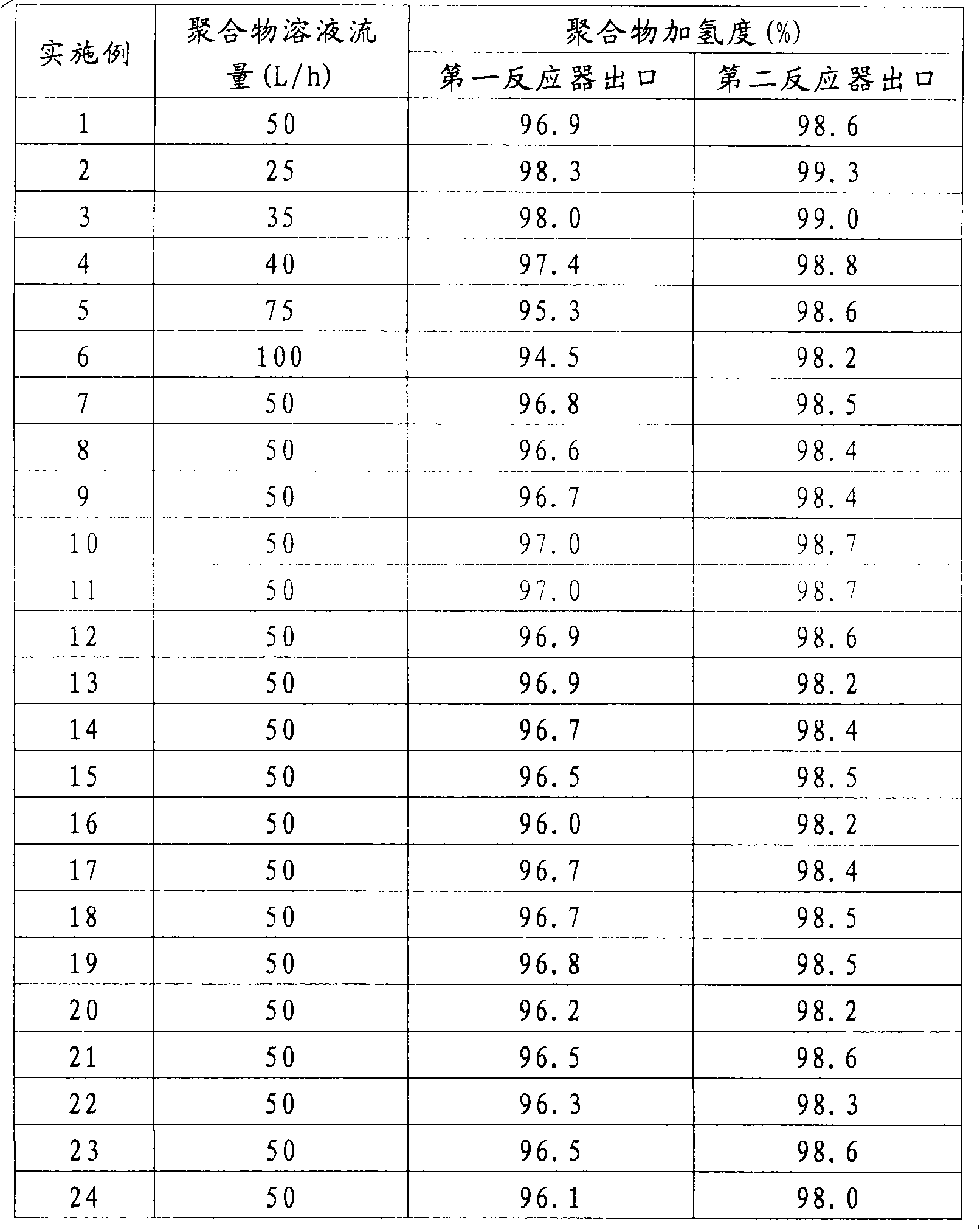

The invention relates to a hydrogenation reactor which is the combination of two or more bubbling reactors, wherein, a first bubbling reactor is arranged for causing the material flow state thereof to be close to totally mixed flow, and a second and the other bubbling reactors are arranged for causing the material flow states thereof to be close to laminar flow. The invention also relates to a method for utilizing the hydrogenation reactor to cause polymers with unsaturated bonds to be continuously hydrogenized. According the method, the temperature of the process of the hydrogenation can be stably controlled, the material consumption, energy consumption and operation cost of the reaction process are greatly reduced, the hydrogenation reaction efficiency is improved, the production cost is reduced, and simultaneously, products with ideal hydrogenation degree can be stably obtained within a longer operation period.

Owner:CHINA PETROLEUM & CHEM CORP

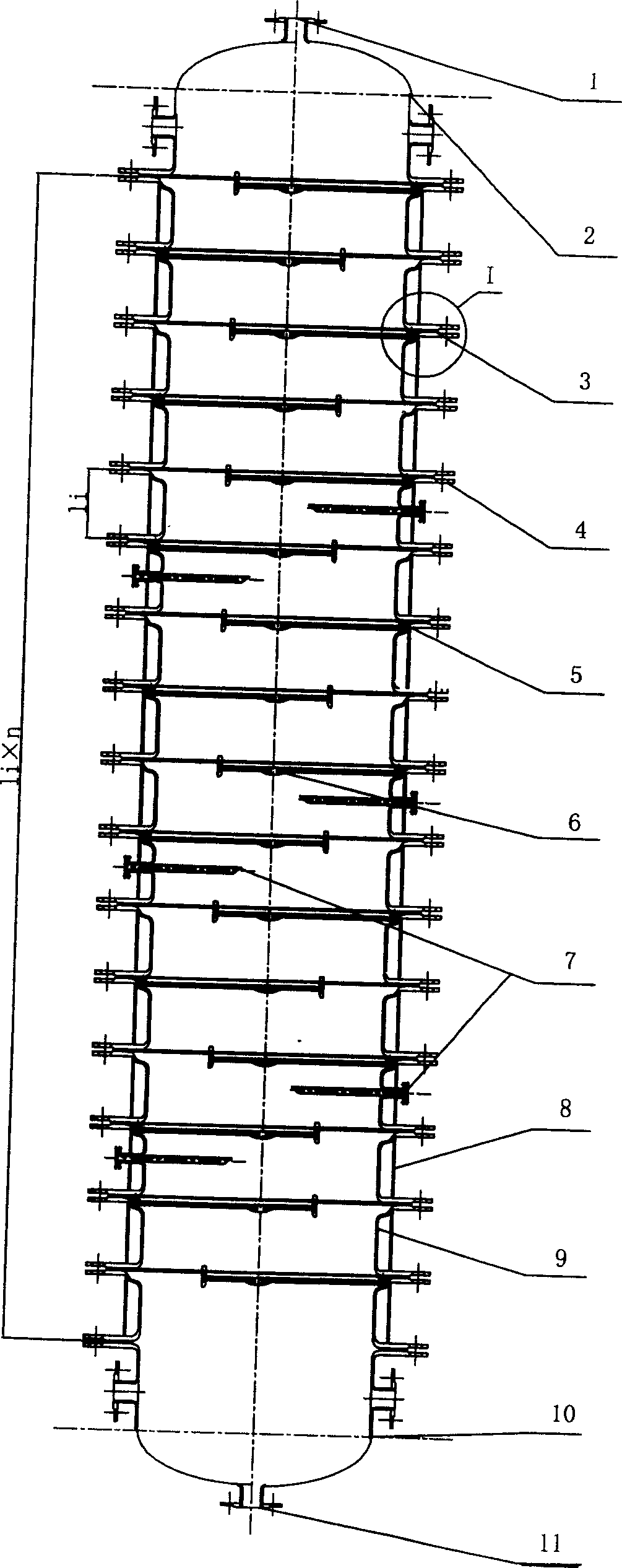

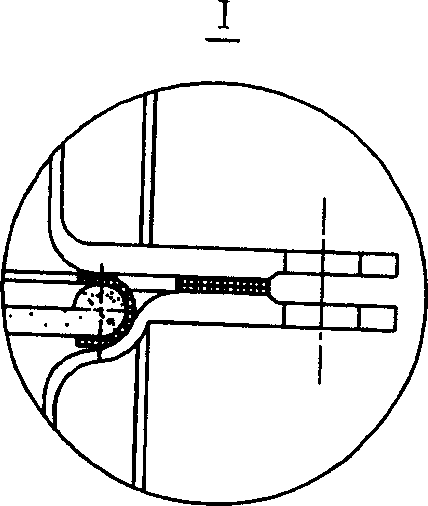

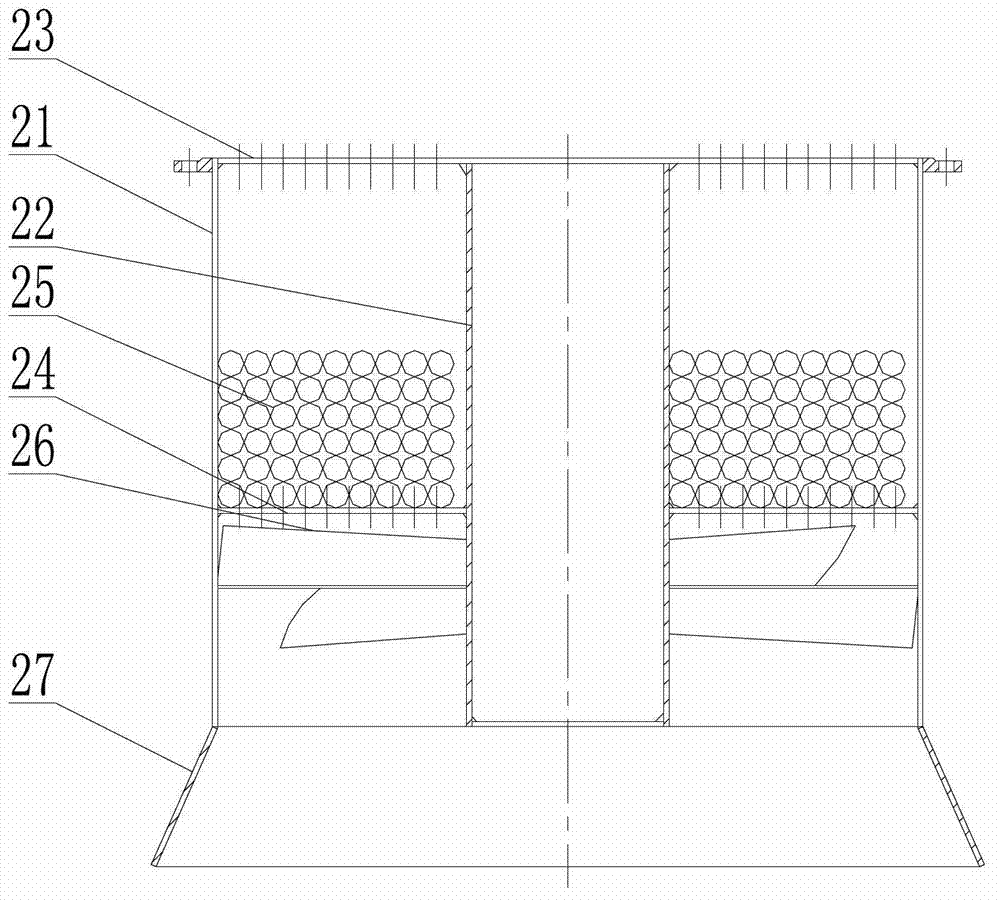

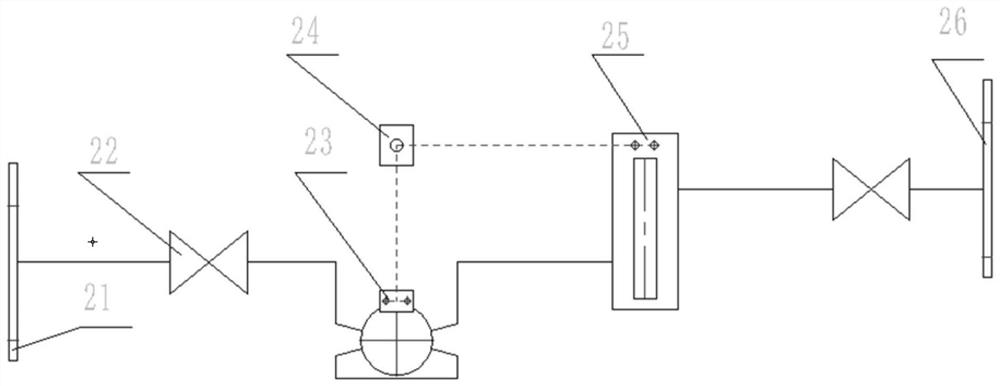

System and method for producing n-butyl acetate by using methyl acetate and n-butyl alcohol ester exchange reaction

InactiveCN101219950ASimple processEasy to operatePreparation by ester-hydroxy reactionChemical industryReboilerTransesterification

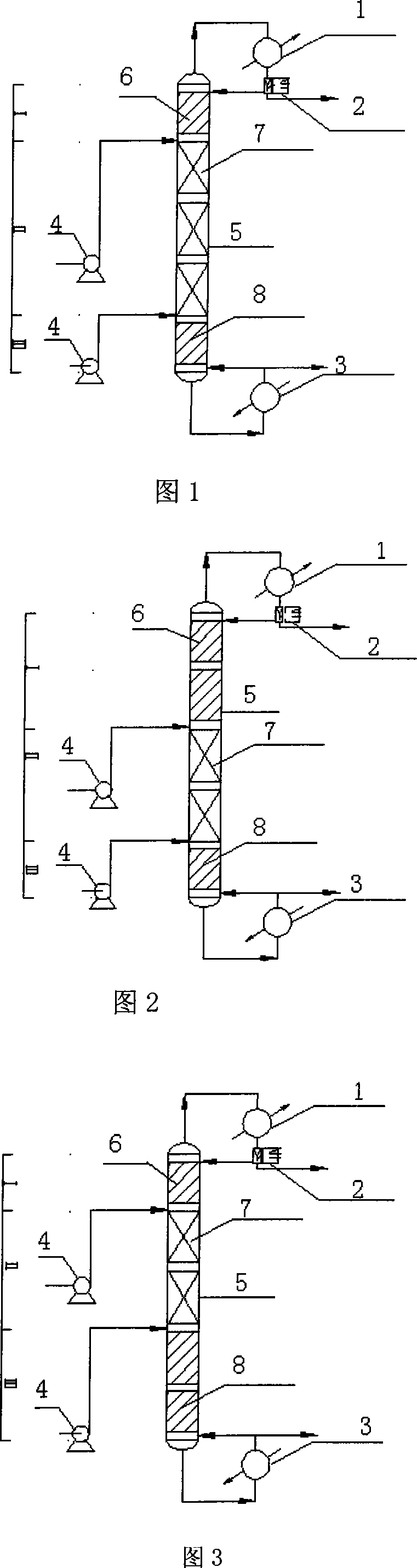

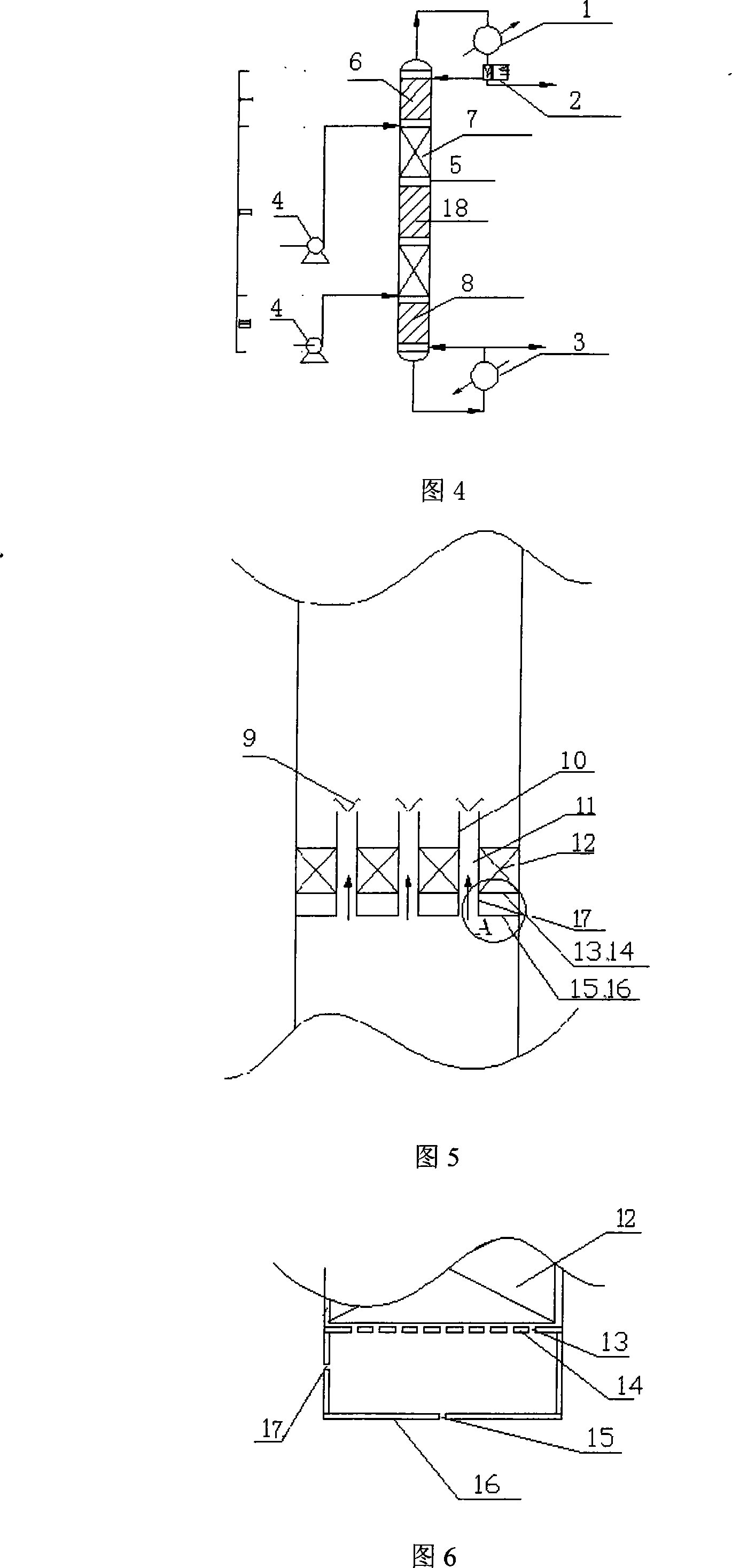

The invention discloses a method and a system for utilizing transesterification of methyl acetate and n-butanol to prepare n-butyl acetate. The reaction system substantially consists of a reboiler, a catalytic distillation column, a condenser, a feeding pump and a reflux ratio controller; among which, the catalytic distillation column is provided with a liquid collecting plate, a gas exit tube, a catalyst packet, a supporting plate and a catalytic reaction segment consisting of bottom plates. An overflow outlet is arranged on a tube wall of the gas exit tube at the lower end of the liquid collecting place and is higher than the catalyst packet. A lacrimal foramen is arranged on the bottom plate; the catalyst packet and a sieve hole is arranged on the supporting plate; a liquid leaking hole is arranged on the tube wall of the gas exit tube between the supporting plate and the bottom plate. The preparation method is to add the methyl acetate and n-butanol into the column respectively from the top and bottom of the catalytic reaction area. A molar ratio of the methyl acetate to the n-butanol is 0.5:5, a reaction temperature is 50 DEG C to 90 DEG C, and a reflux ratio is 0.5 to 30 under a normal pressure operation. The technical proposal of the invention enhances the conversion rate of the methyl acetate, simplifies the operation procedure and overcomes the problem of equipment corrosion.

Owner:TIANJIN UNIV

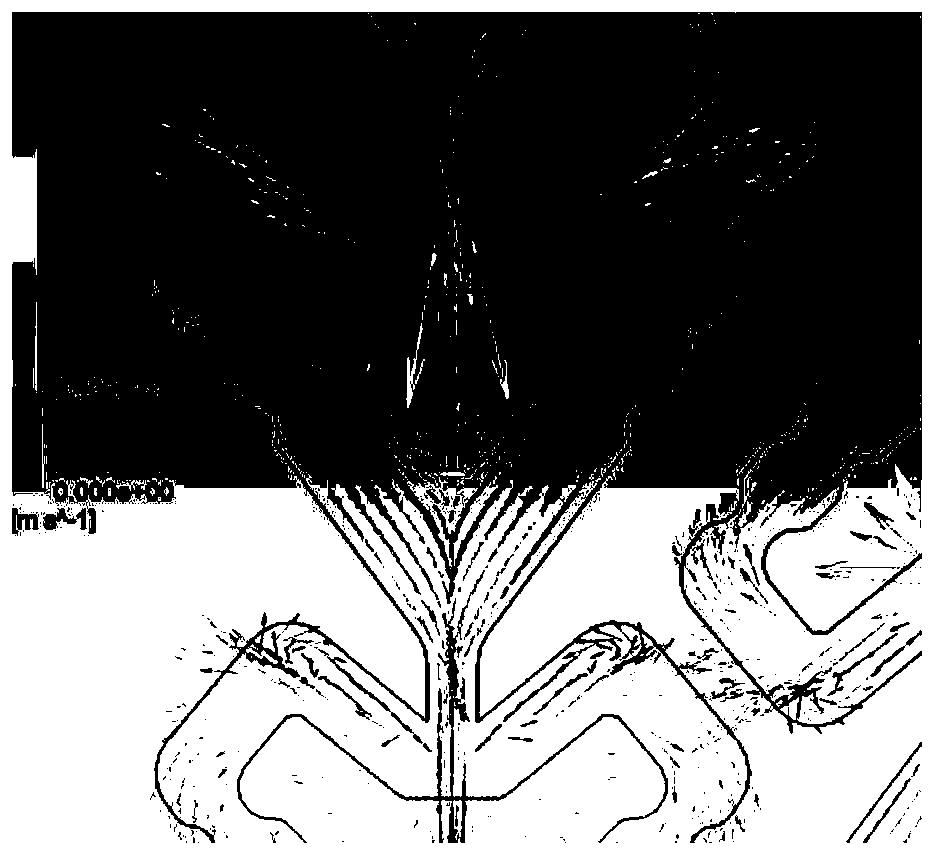

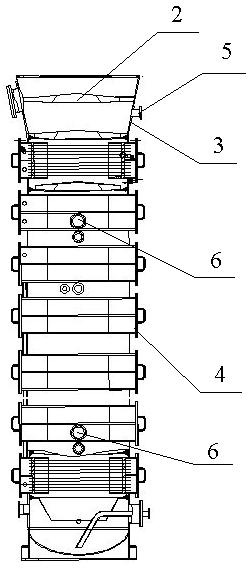

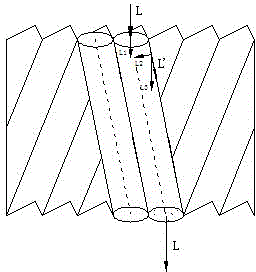

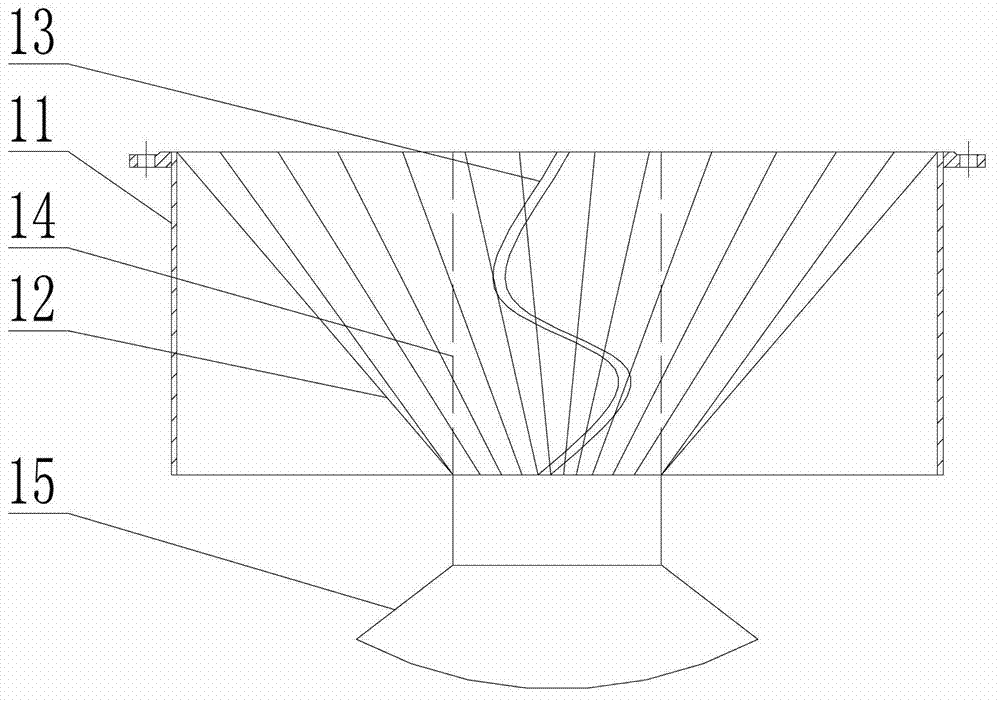

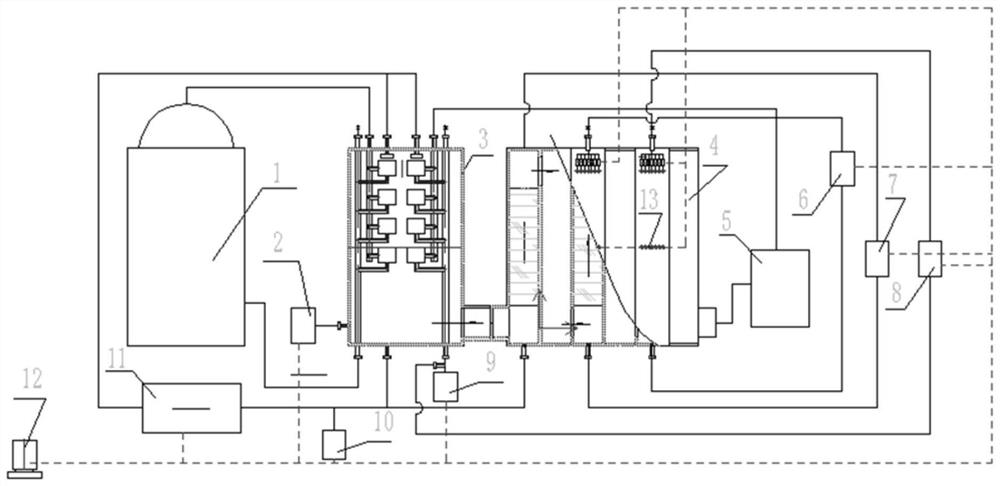

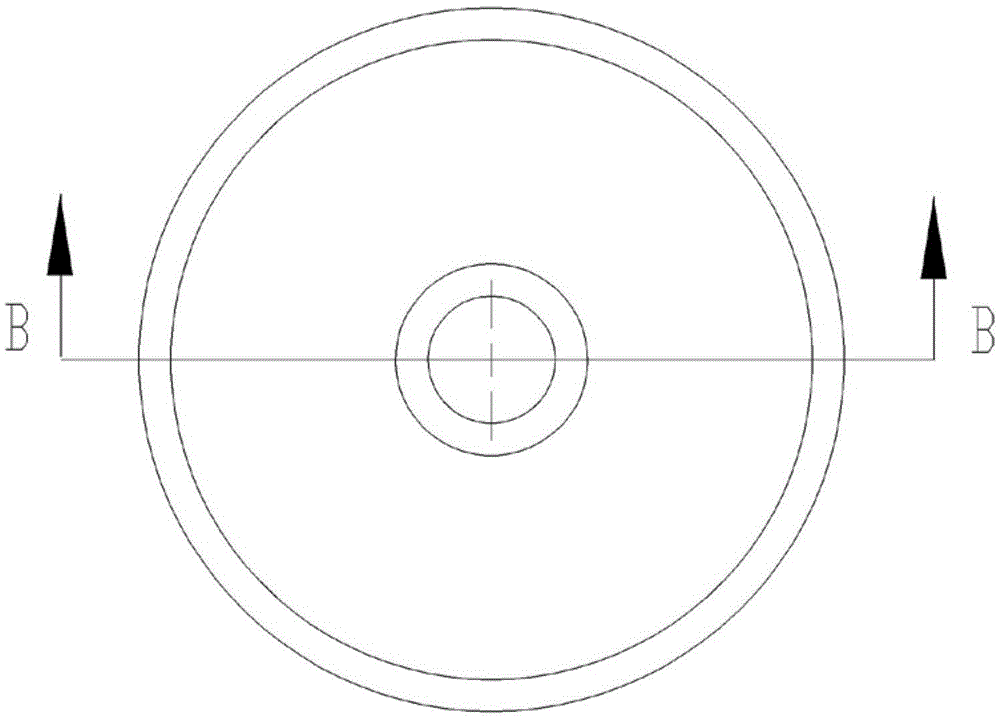

Boiling bed residual oil hydrocracking process

ActiveCN1952063AReduce the amount addedLarge liquid holding capacityHydrocarbon oil crackingHydrogenSolid particle

The invention disclosed a kind of dreg oil hydrogenating technology on bubbling bed. The invention disperses the scattered water-soluble catalyst uniformly in the heavy dreg oil; the catalyst enters the bubbling bed reactor from the top part of the loading catalyst's bed; at the same time, the heavy dreg oil together with hydrogen enters the bubbling bed reactor from the below part of the reactor; hydrogenating the material under proper conditions; fractionating the reacted product to get gas, distillate and end oil. The scattered catalyst can reduce the amount of loading catalyst in the bubbling reactor so as to increase the liquid holdup of the reactor and increase its handling ability; the scattered catalyst has strong adsorbability, it can adsorb the smuggled fine catalyst powder from the rising air current and liquid. The fine powder settled on the loading catalyst bed so it's easier to separate the solid granules and the liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

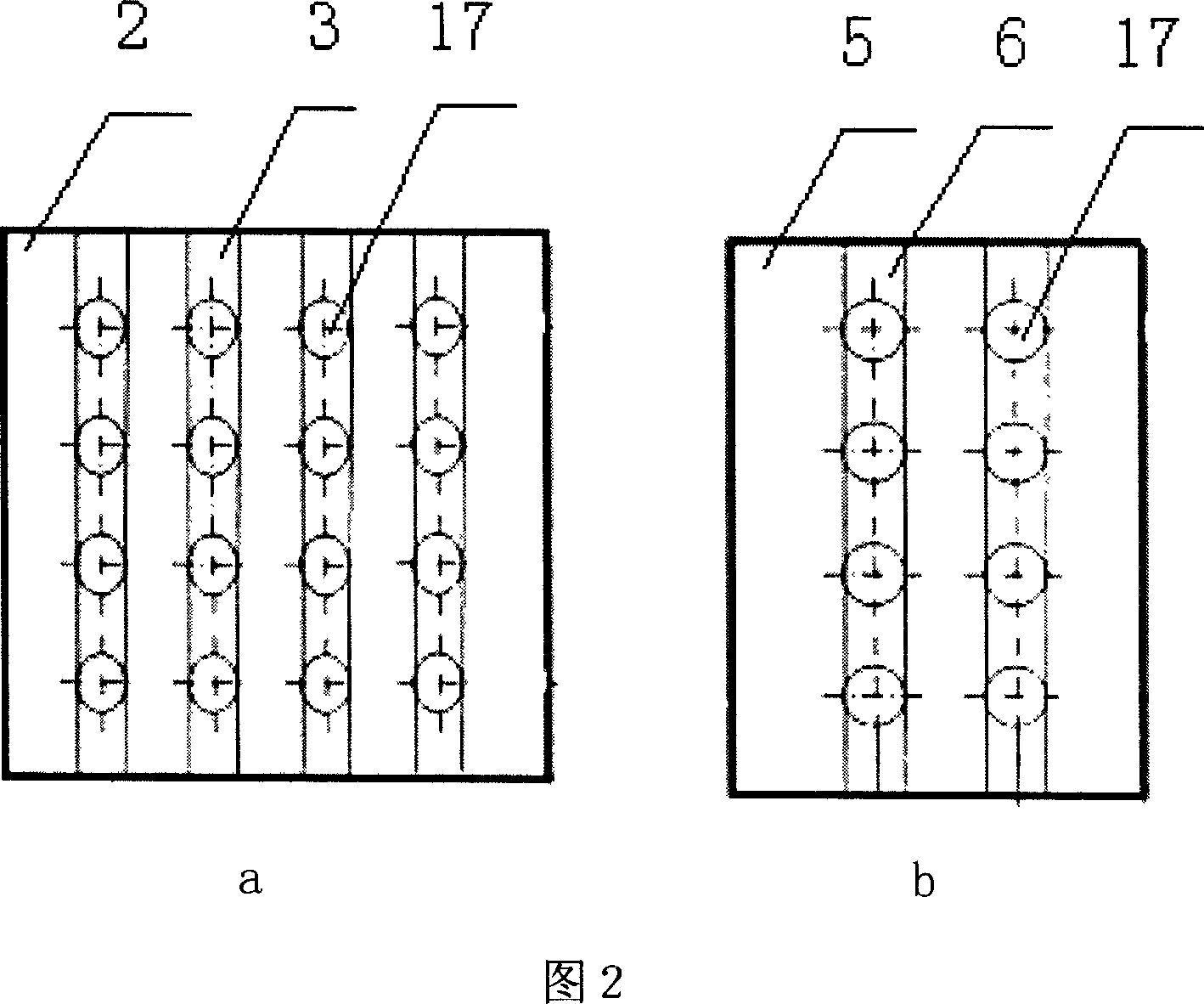

Gas-liquid mass transfer apparatus-plate tower

InactiveCN1709541AReliable mass transfer coefficient and mass transfer areaGreat operating flexibilityFractional distillationProduct gasEngineering

The present invention relates to gas liquid conduction equipment-board tower. The board tower consists of several tower burls where lays tower board. The liquid is flowing along the board weir and distributing dentation board by board like a curtain. When the gas and liquid meet and react, it will become adverse current. The tower tray is arc and there are sawtooth upside weir and underside distributing dentation. The tower burl and tower board are made from metal, acid-resistant pottery that are corrode-resistant or package steel corrode-resistant. The present invention can prevent from separating out and jam of the gas and liquid. The equipment can provide conduction value and conduction area. It operates flexibly and resistance value is little.

Owner:王健祥

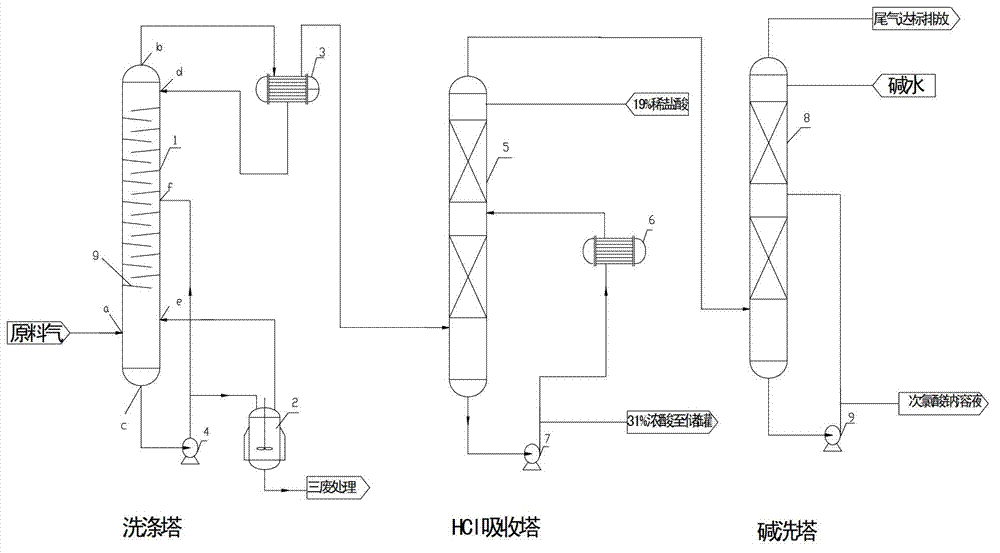

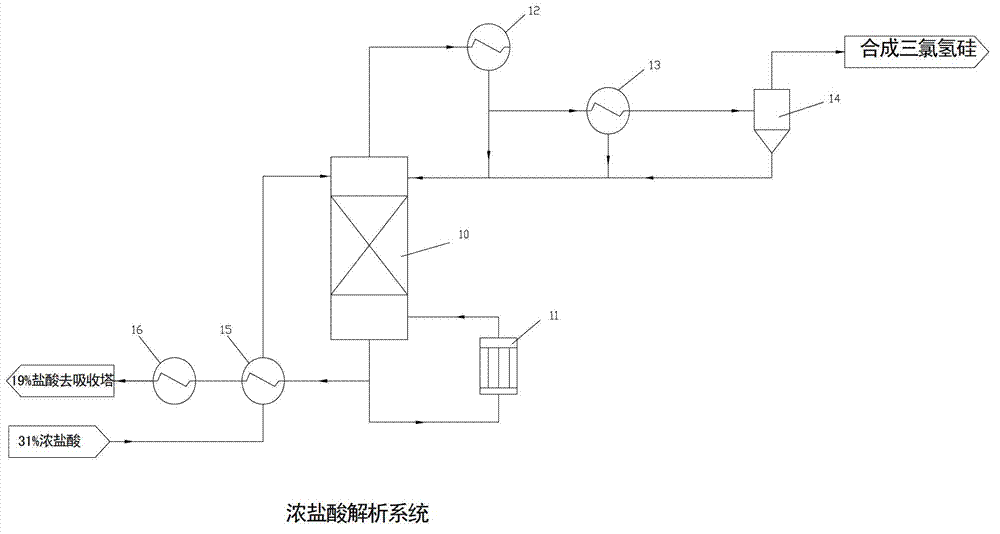

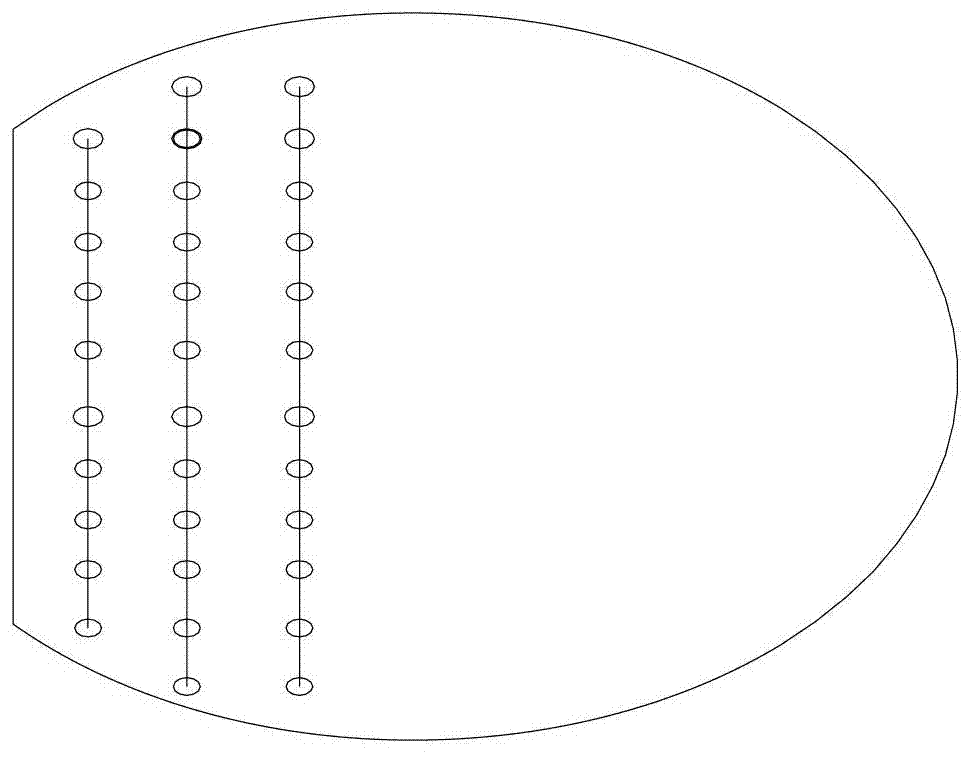

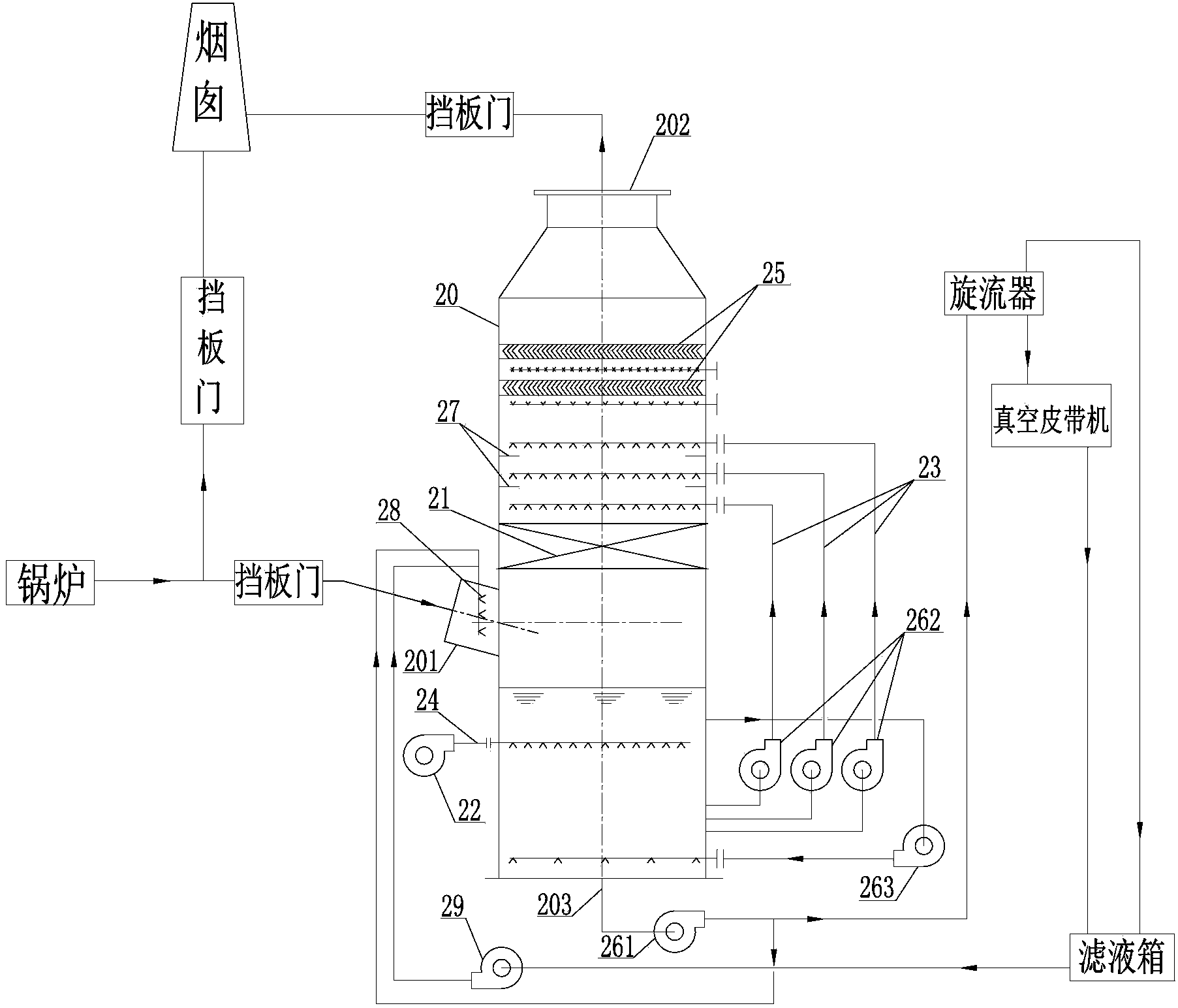

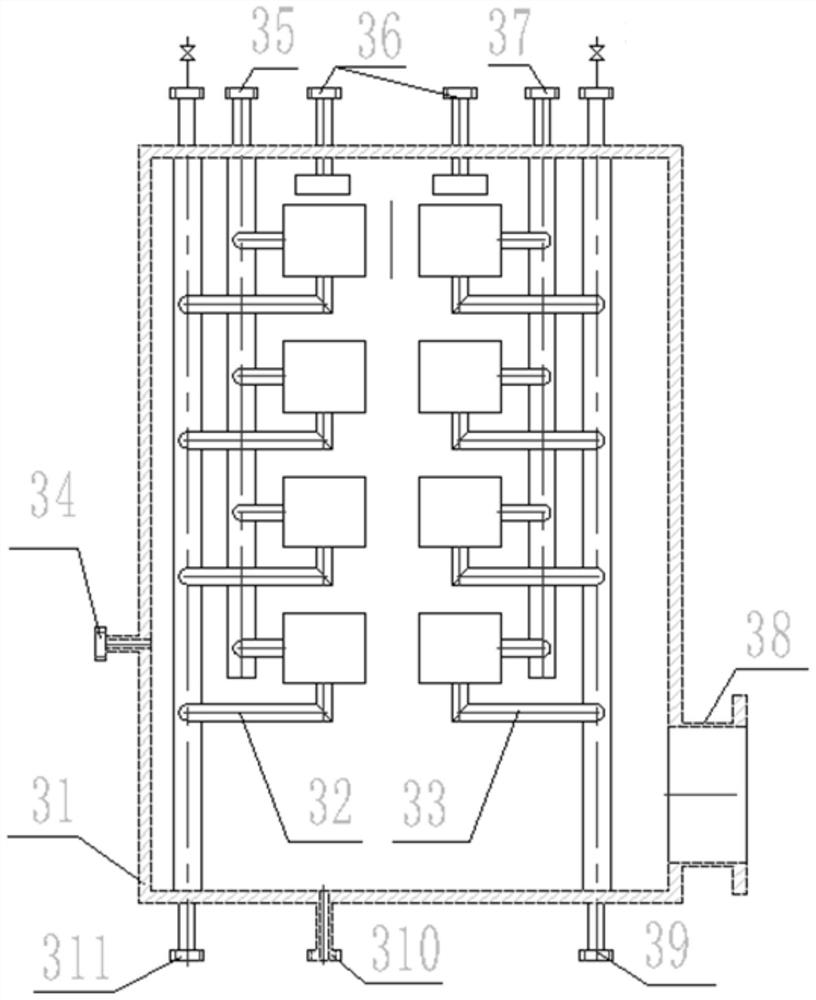

White carbon black tail gas processing method and washing tower

ActiveCN103708421ALarge liquid holding capacityPowerful flushingChlorine/hydrogen-chloride purificationGas phaseProcess engineering

The invention provides a white carbon black tail gas processing method. The method comprises the following steps: spraying white carbon black tail gas in a washing liquid in a plate type washing tower, wherein the plate type washing tower comprises tower plates and a tower body having an angle of 120-150DEG to each of the tower plates, and the surface of each of the tower plates is provided with holes; and separating the washed white carbon black tail gas from the used washing liquid. The invention also provides a washing tower. The washing tower comprises a tower body, a gas inlet, a gas phase outlet, a liquid phase inlet, a liquid phase outlet, a stirring kettle gas phase return port and tower plates, an angle between each of the tower plates and the tower body is 120-150DEG, and the surface of the tower plates is provided with the holes. The plate type washing tower is adopted in the invention, and the surface of each of the tower plates is provided with the holes, so white carbon black particles can be powerfully flushed by the washing liquid, thereby a problem that the washing tower is blocked by the white carbon black particles due to the aggregation of the white carbon black particles in the washing tower is avoided, and the white carbon black white carbon black tail gas is well dedusted in the washing process.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL +1

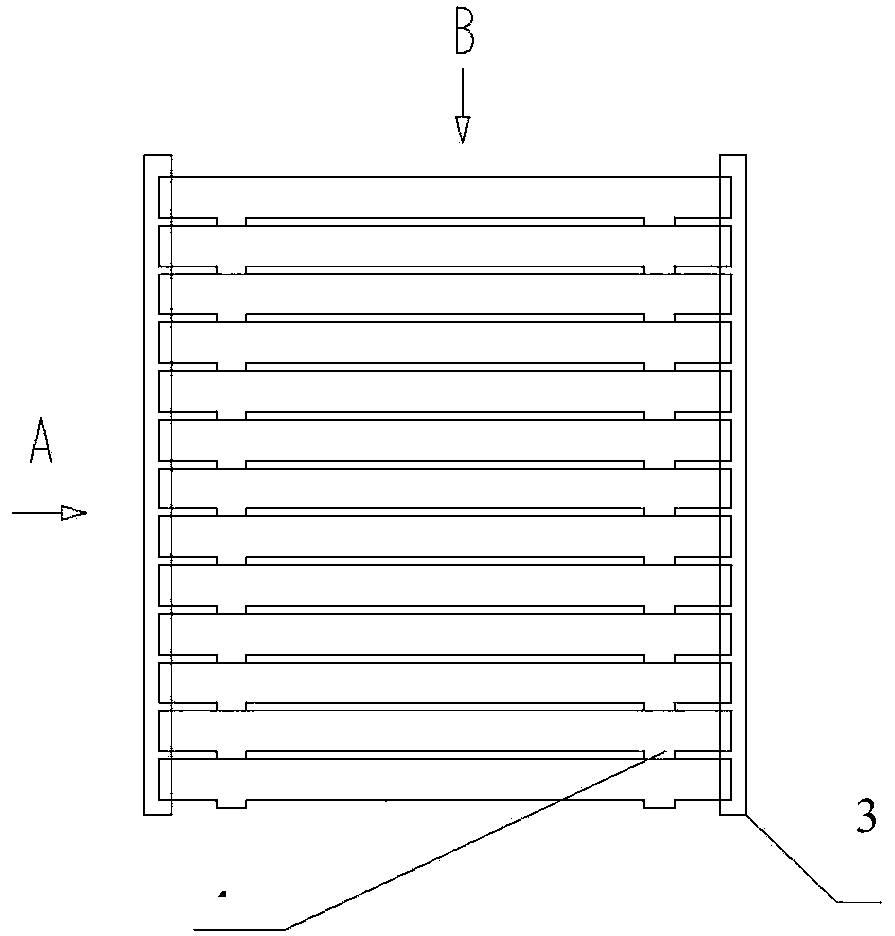

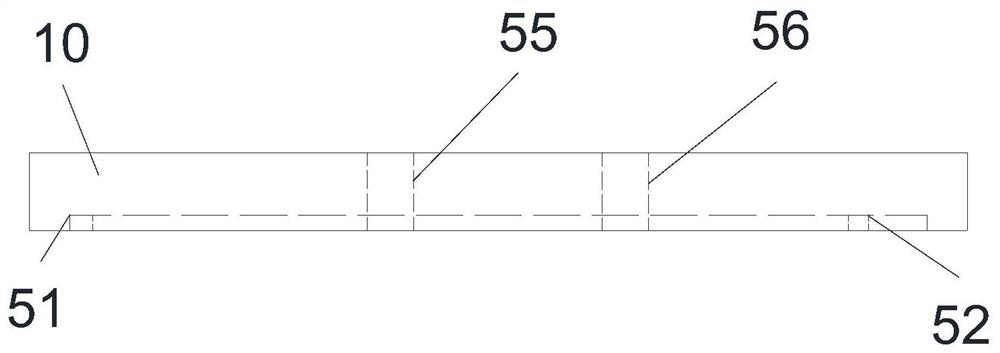

Microreactor

PendingCN110090607ALarge specific surface areaNo swirlChemical/physical/physico-chemical microreactorsMicroreactorEngineering

The invention discloses microreaction channel and relates to the field of chemical equipment. The microreaction channel comprises a reinforced mixing cavity which is left and right symmetrical along acentral symmetry axis, wherein the outlet part of the reinforced mixing cavity is provided with a confluent mixing region. A partition body is arranged in the reinforced mixing cavity. The partitionbody and the inner wall of the reinforced mixing cavity form a symmetrical first subchannel and a symmetrical second subchannel. And the first subchannel and the second subchannel extend outwards relative to the central symmetry axis to cross the inlet part of the reinforced mixing cavity and then are connected with the confluent mixing region. The microreaction channel has the advantages of a high specific surface area up to 10000-50000 m<2> / m<3>. A fluid in the channel belongs to a horizontal thrust flow, has no vortex and back mixing, and can effectively avoid the bad and uneven mixing effect in the channel caused by the pulse of a feed pump; the microreaction channel has a low pressure drop and good mixing effect. Under a same substrate area, a large channel area the can be arranged, and no area is wasted, so the liquid holdup is large and the residence time is long.

Owner:山东微井化工科技有限公司

Wet type static solid strip-shaped anode dust collecting plate

InactiveCN103406207ALarge liquid holding capacityPrevent static sedimentation tendencyElectrode constructionsEngineeringCapillary action

The invention provides a wet type static solid strip-shaped anode dust collecting plate. The strip-shaped anode dust collecting plate is characterized in that a pole plate is composed of solid strip-shaped bodies, the strip-shaped bodies are horizontally arranged and are woven through ropes or connected by a single layer of plywood, necessary gaps are formed among the strip-shaped bodies, and the sizes of the gaps are determined by liquid holdup, surface tension, liquid film thickness and solid-liquid characteristics. The strip-shaped anode dust collecting plate provided by the invention has the advantages that a horizontal water film is uniform by virtue of the capillary phenomena of the gaps; the gaps internally contain liquid to increase the liquid holdup of the pole plate so as to keep a liquid film stable; the gaps can penetrate through the two sides of the pole plate and can transmit the pressure fluctuation of airflow on the two sides of the pole plate, then the water film is driven to vibrate, and thus dust is prevented from precipitating on the pole plate.

Owner:SHANDONG UNIV +1

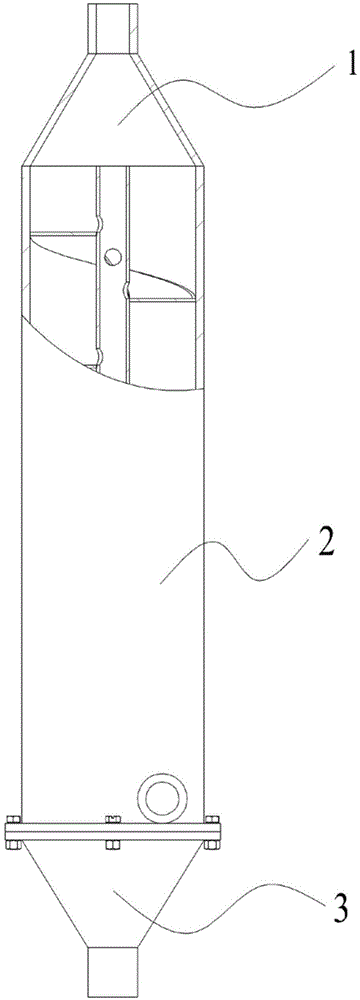

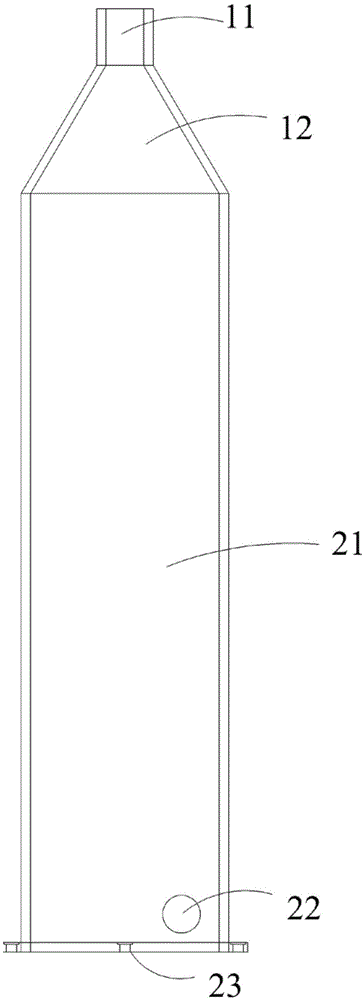

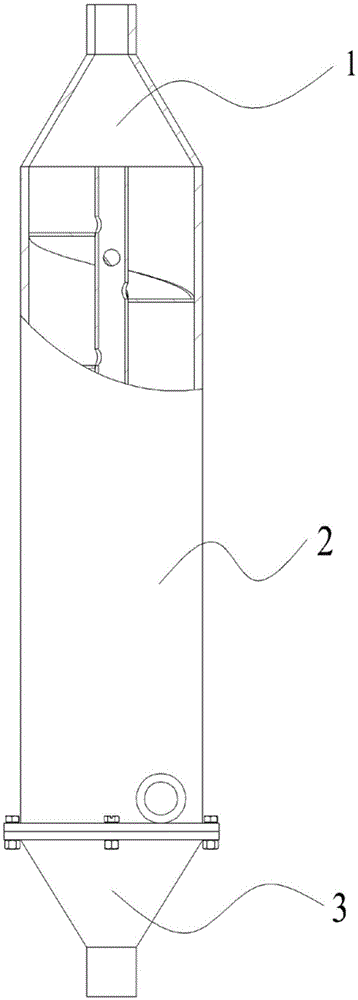

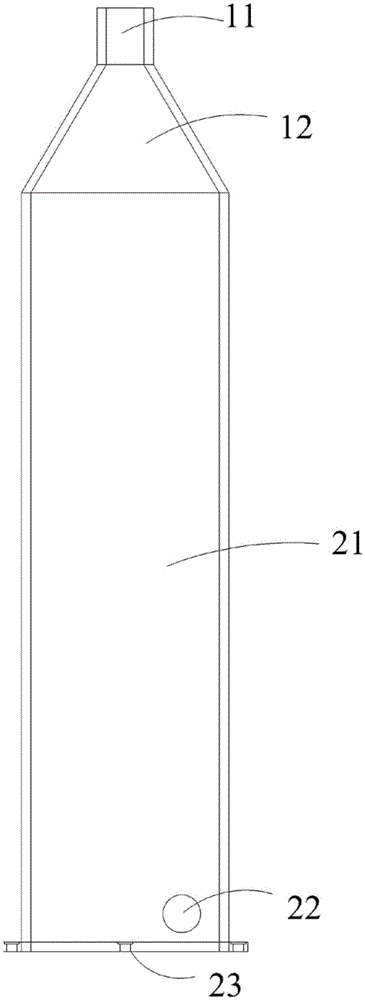

Aerosol collection and separation device and method

InactiveCN104548760ARealize capture and recoverySolve pollutionGas treatmentDispersed particle separationEngineeringVertical penetration

The invention discloses an aerosol collection and separation device, which comprises a separator, an exhaust hood and a liquid collection cone, wherein the separator is a cylinder, and comprises a barrel, a screw shaft, a screw blade, a baffle, an air inlet, liquid collection holes and a lower flange; the exhaust hood comprises a cone and an exhaust outlet; the liquid collection cone comprises an inverted cone, a liquid outlet and an upper flange; the exhaust hood, the separator and the liquid collection cone are connected in a vertical penetration manner; the exhaust hood is connected with the separator in a welding manner; the liquid collection cone is connected with the separator through the upper flange. The invention further provides a method for performing gas-liquid collection and separation by utilizing the aerosol collection and separation device. The device and the method have the characteristics of high separation speed, high separation efficiency, high liquid holdup, low pressure loss, low scaling and blocking rate and firm structure.

Owner:CHINA UNIV OF MINING & TECH

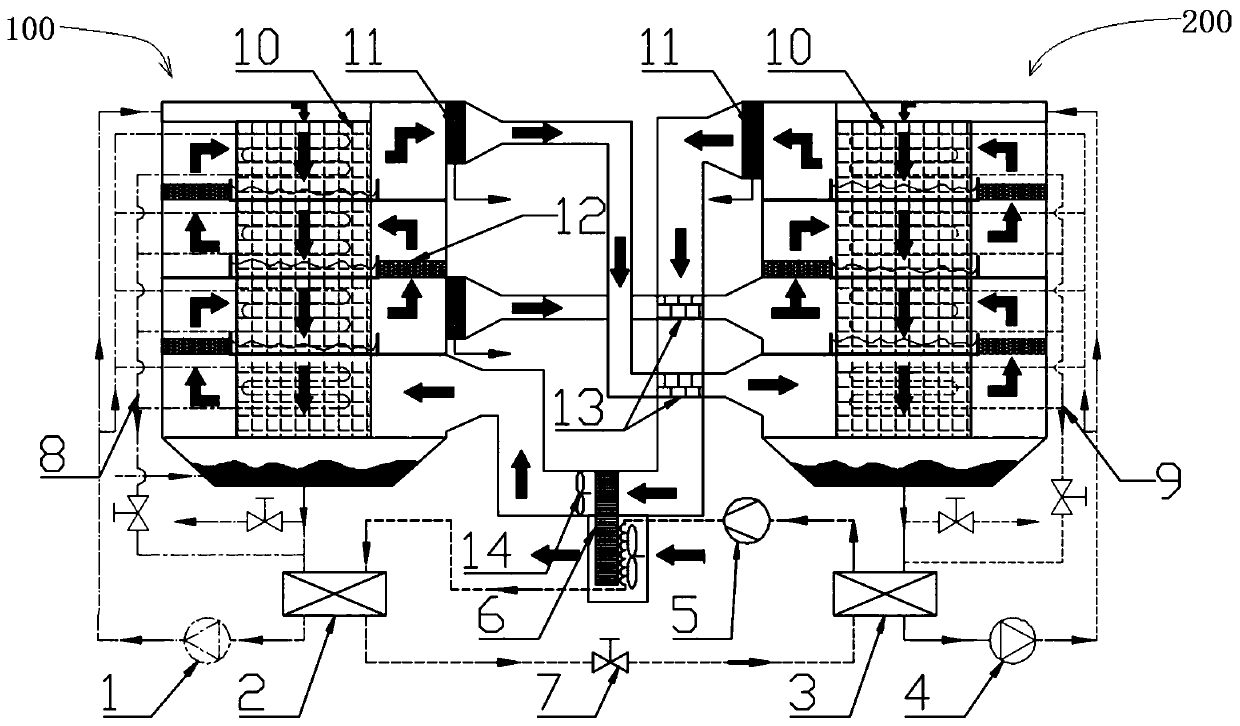

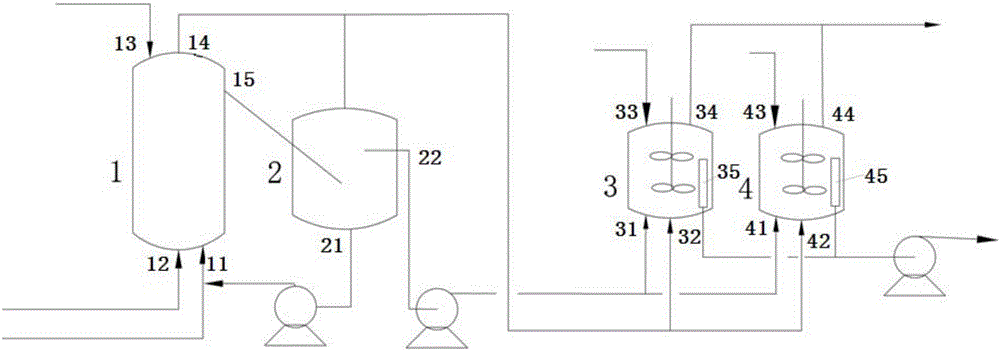

System and method for treating industrial waste liquid based on carrier gas extraction and low-temperature mass transfer

ActiveCN110498462AIncrease temperatureHigh trafficGas treatmentSpecific water treatment objectivesLiquid wasteDistributor

The invention provides a system and method for treating industrial waste liquid based on carrier gas extraction and low-temperature mass transfer. The system comprises an absorber, wherein the absorber is connected with a condenser, the condenser is connected with a waste liquid circulating pump, and the waste liquid circulating pump is connected with a liquid distributor of the absorber and a heater in the absorber; the system also comprises an analyzer, wherein the analyzer is connected with an evaporator, the evaporator is connected with a clean water pump, and the clean water pump is connected with a liquid distributor of the analyzer and a cooler in analyzer; an air outlet of the absorber is connected with an air inlet of the analyzer; an air outlet of the analyzer is connected with an air inlet of the absorber; and an air channel between the air outlet of the analyzer and the air inlet of the absorber is provided with a circulating fan and an adsorber. According to the invention,air can be utilized as a mass transfer medium to realize water migration in industrial waste liquid under the condition of a low temperature, and the system operates under normal pressure and is suitable for treatment of corrosive liquid which is crystallized easily and scaled easily, so that a series of pretreatment procedures such as precipitation, oil removal, pH value adjustment and the likerequired by conventional waste liquid treatment are greatly reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

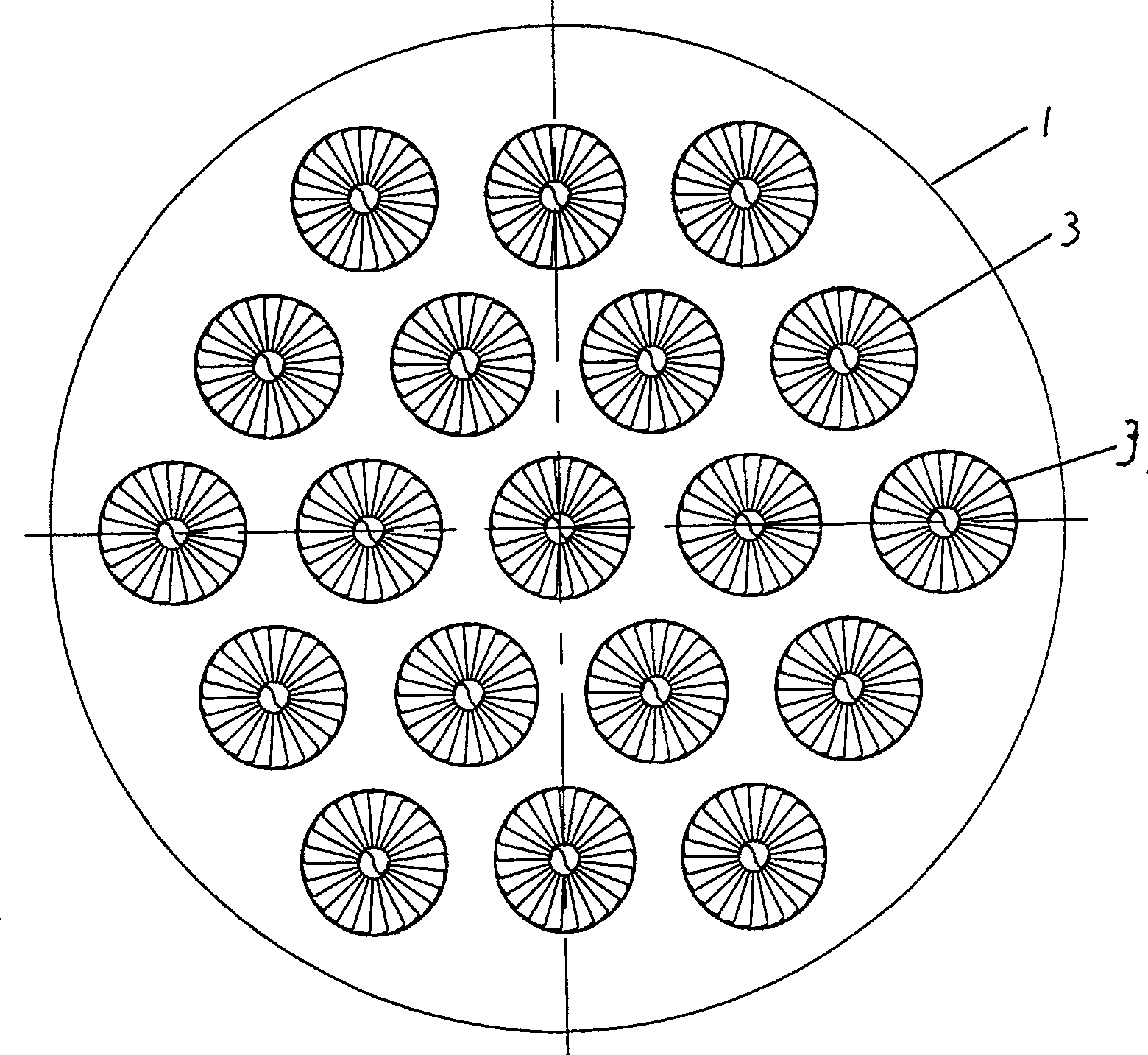

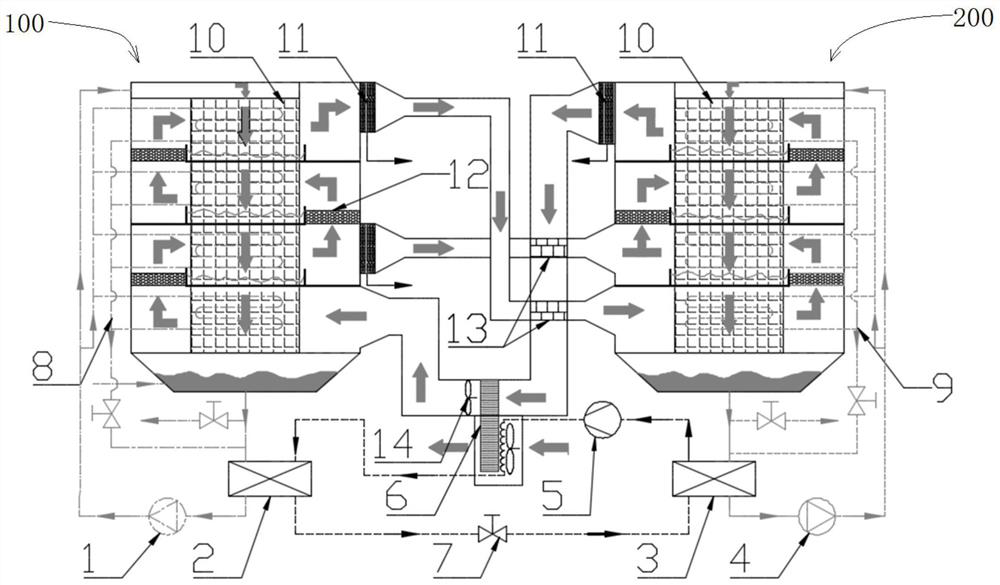

Design method of fluid curtain bed gas-liquid contact reaction device

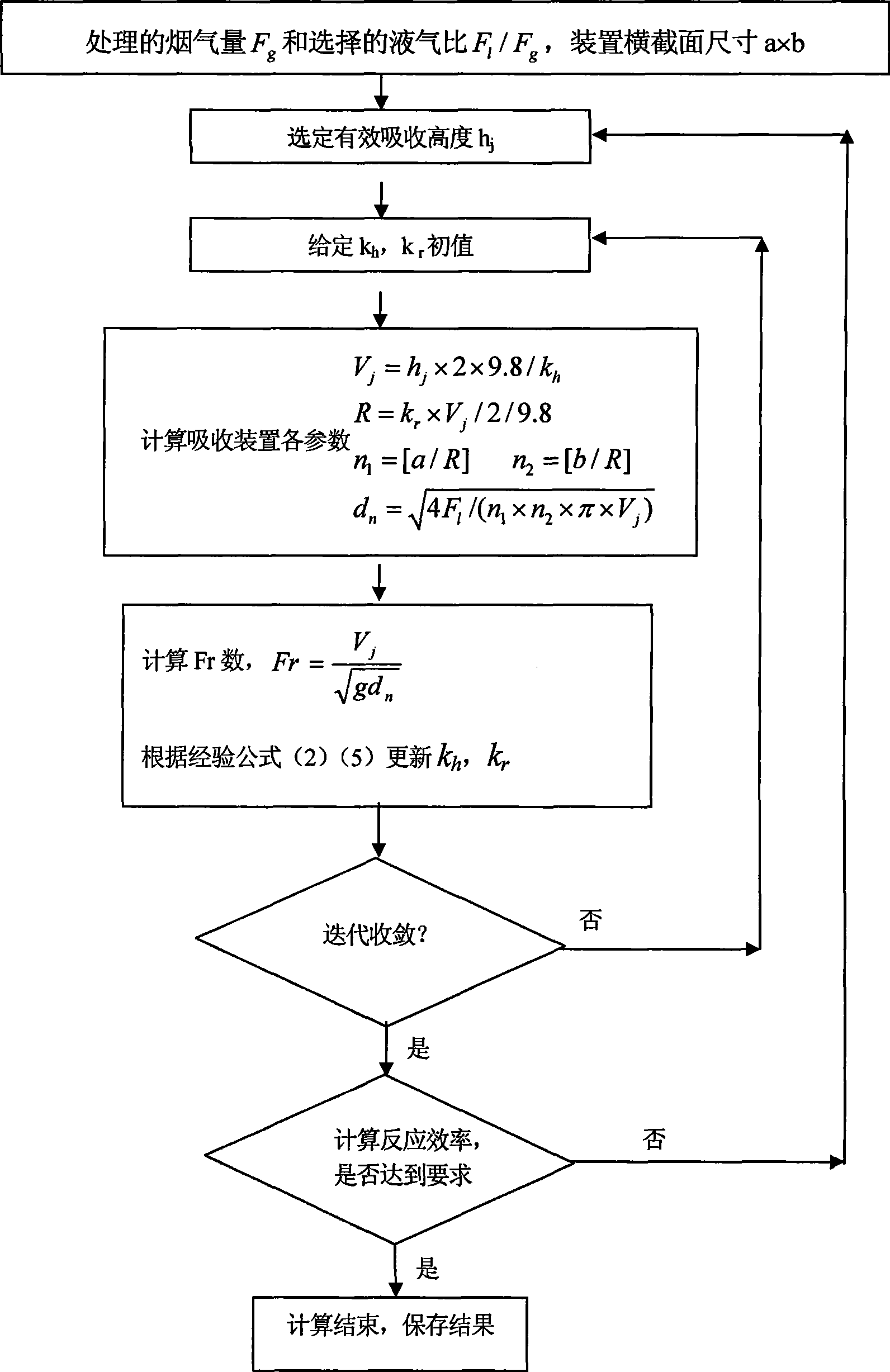

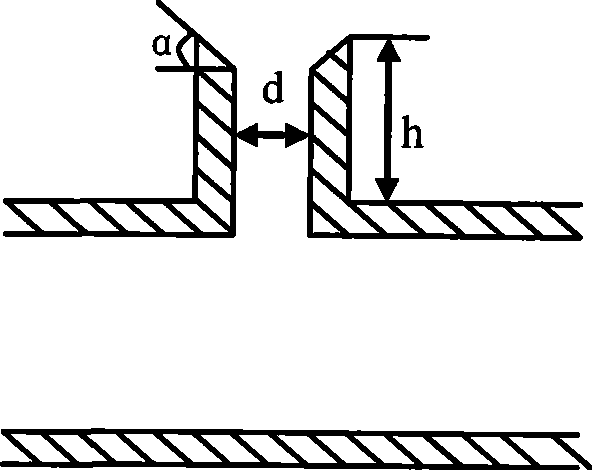

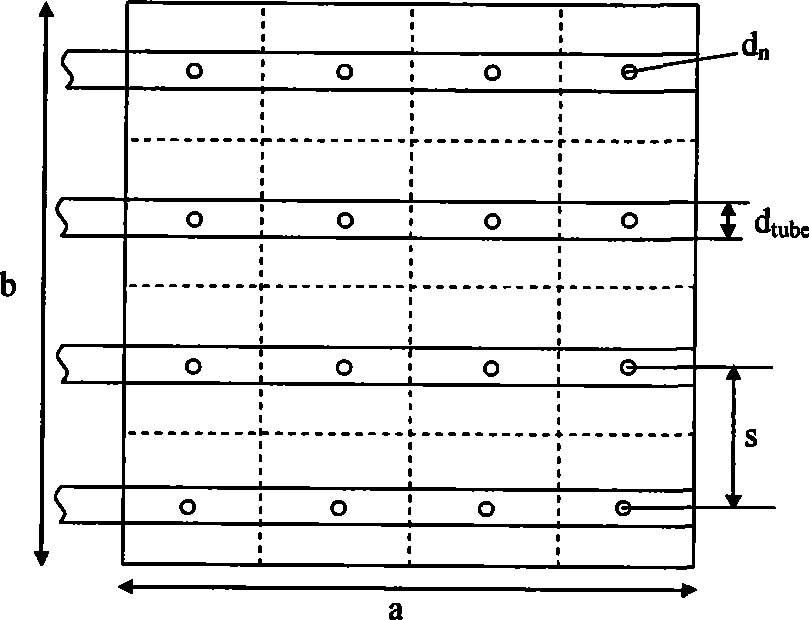

InactiveCN101391176AEasy to implementImprove accuracyDispersed particle separationChemical/physical/physico-chemical nozzle-type rreactorsGas liquid reactionAlgebraic solution

The invention discloses a design method of a fluid curtain bed gas-liquid contact reaction device, when designing the gas-liquid reaction device, the known quantities are: the liquid / gas ratio of the device (F1 / Fg), the amount of flue gas to be treated (Fg), the scale of the reaction device (cross-sectional dimension axb), parameters needing to be solved are all the parameters of an arrangement method and an apparatus of uniform fluid curtain of a liquid phase jet apparatus, which include the number of nozzles (n1xn2), the nozzle diameter dn, the space s between nozzles, the diameter of a jet main pipe d(tube), and the effective absorption height hj of the reaction device when meeting the requirement of reaction efficiency. A solving method bases on the experimental results of the unit, three empirical formulas are introduced, then the algebraic solution is adopted, and the device has advantages of easy implementation and high accuracy.

Owner:XI AN JIAOTONG UNIV

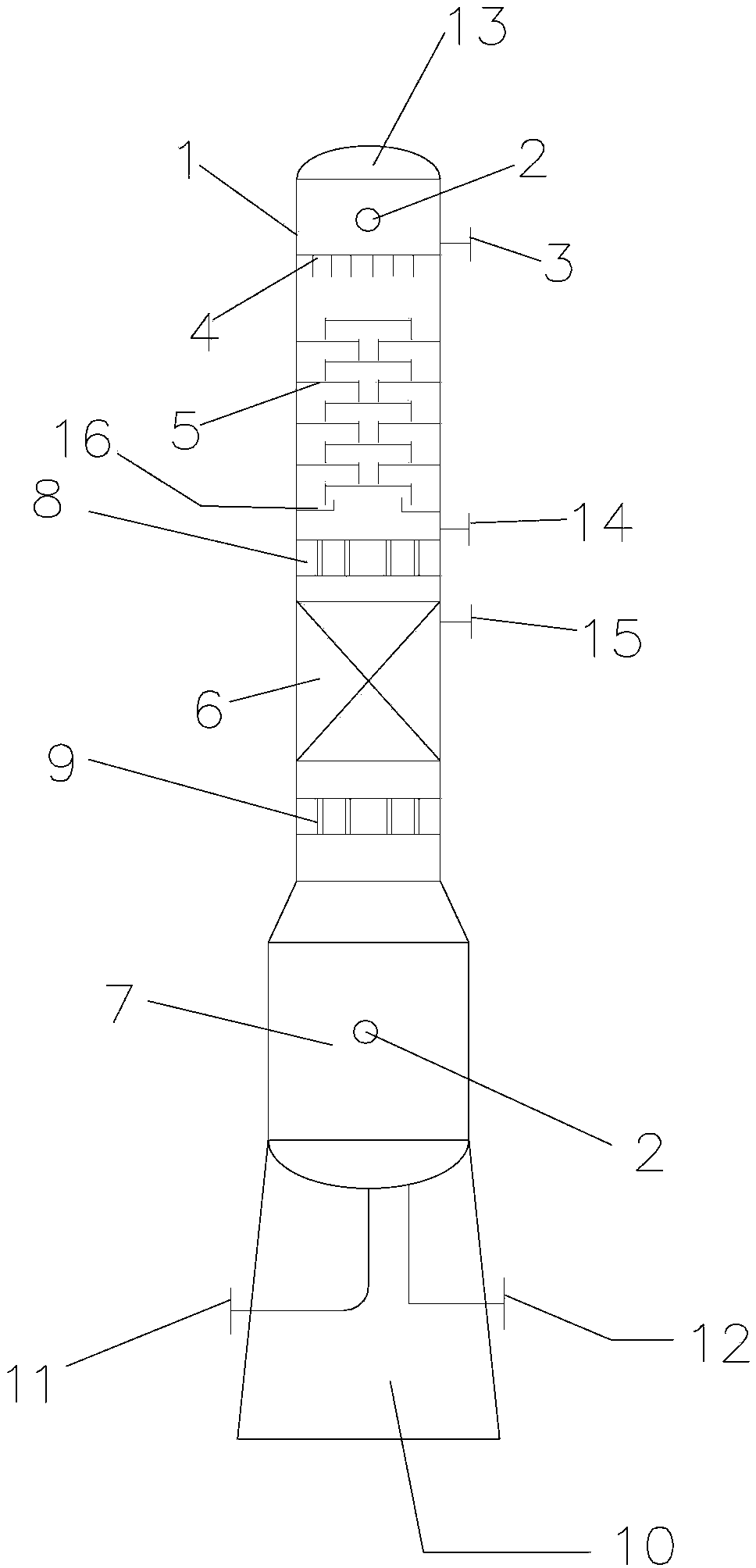

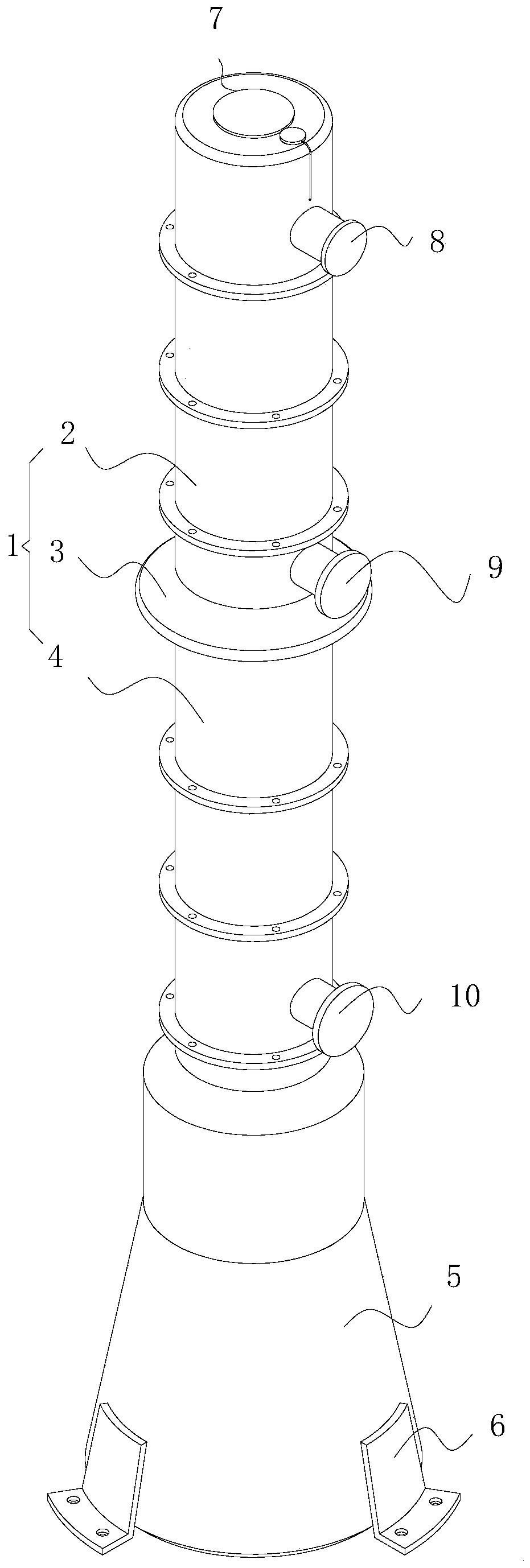

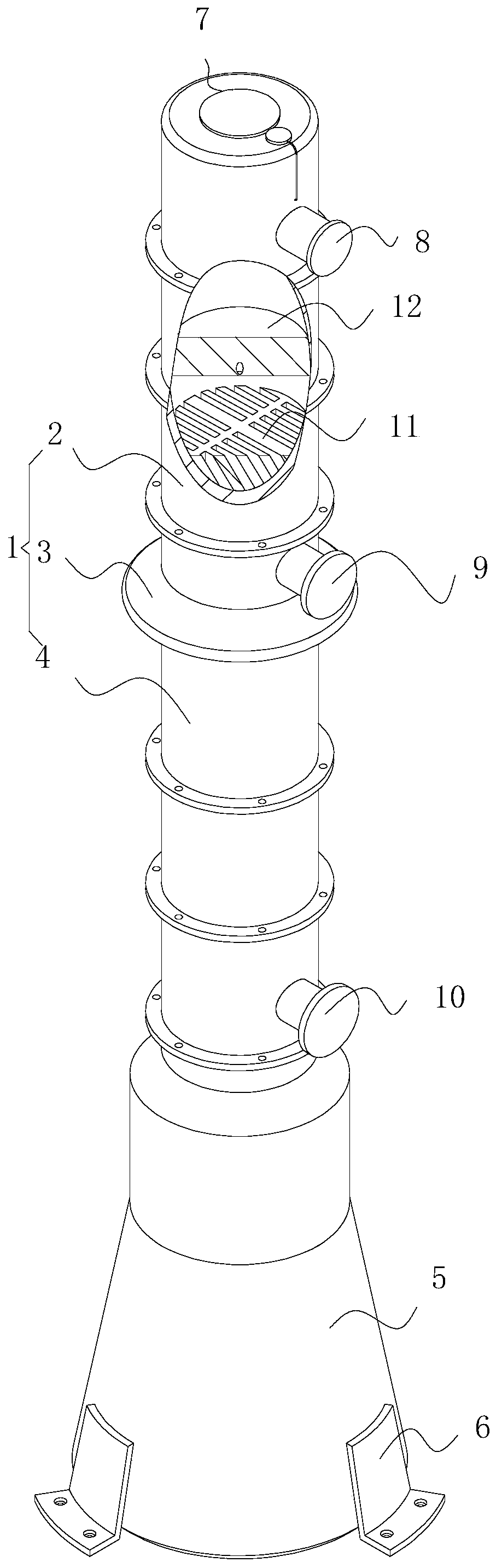

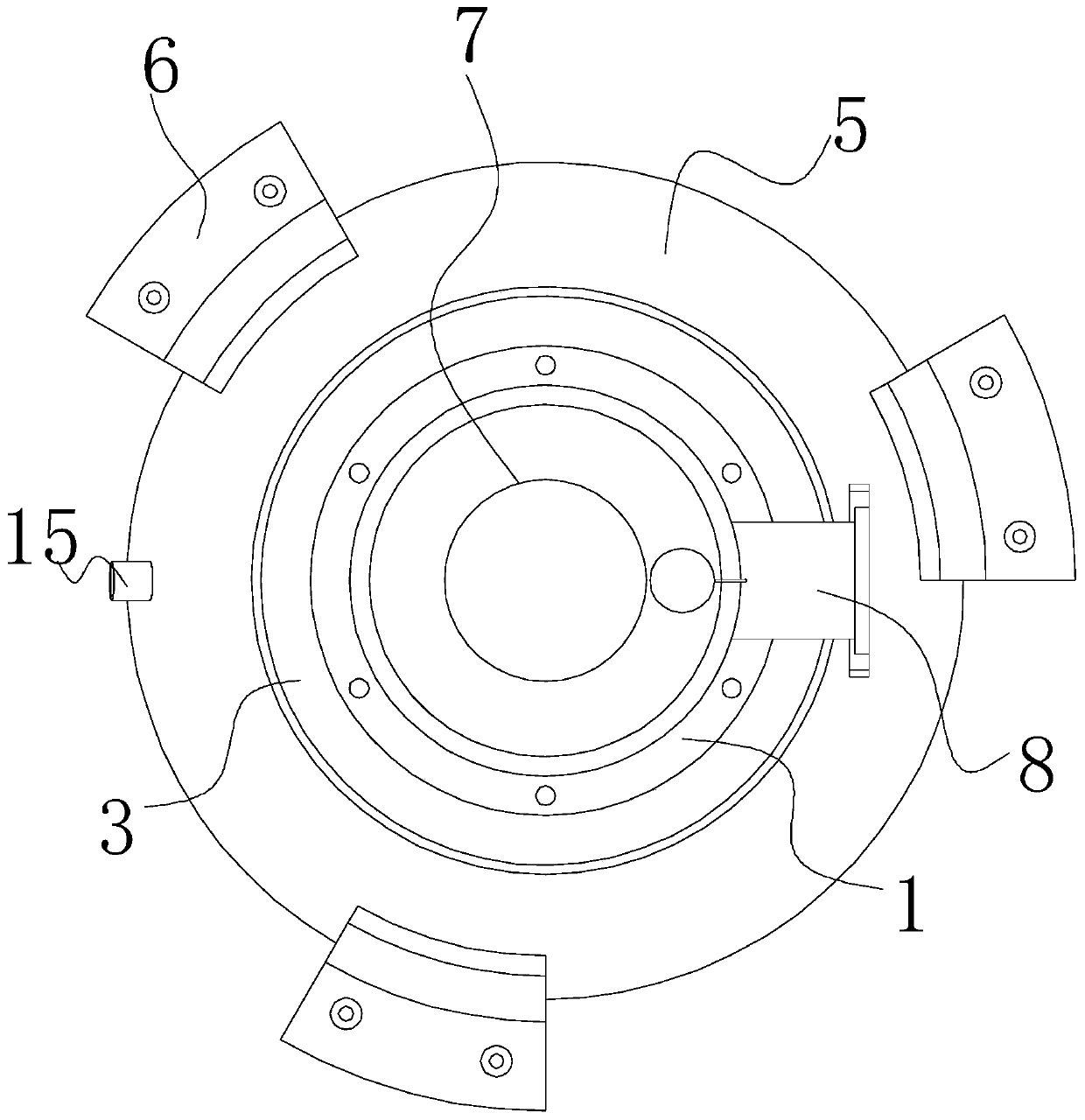

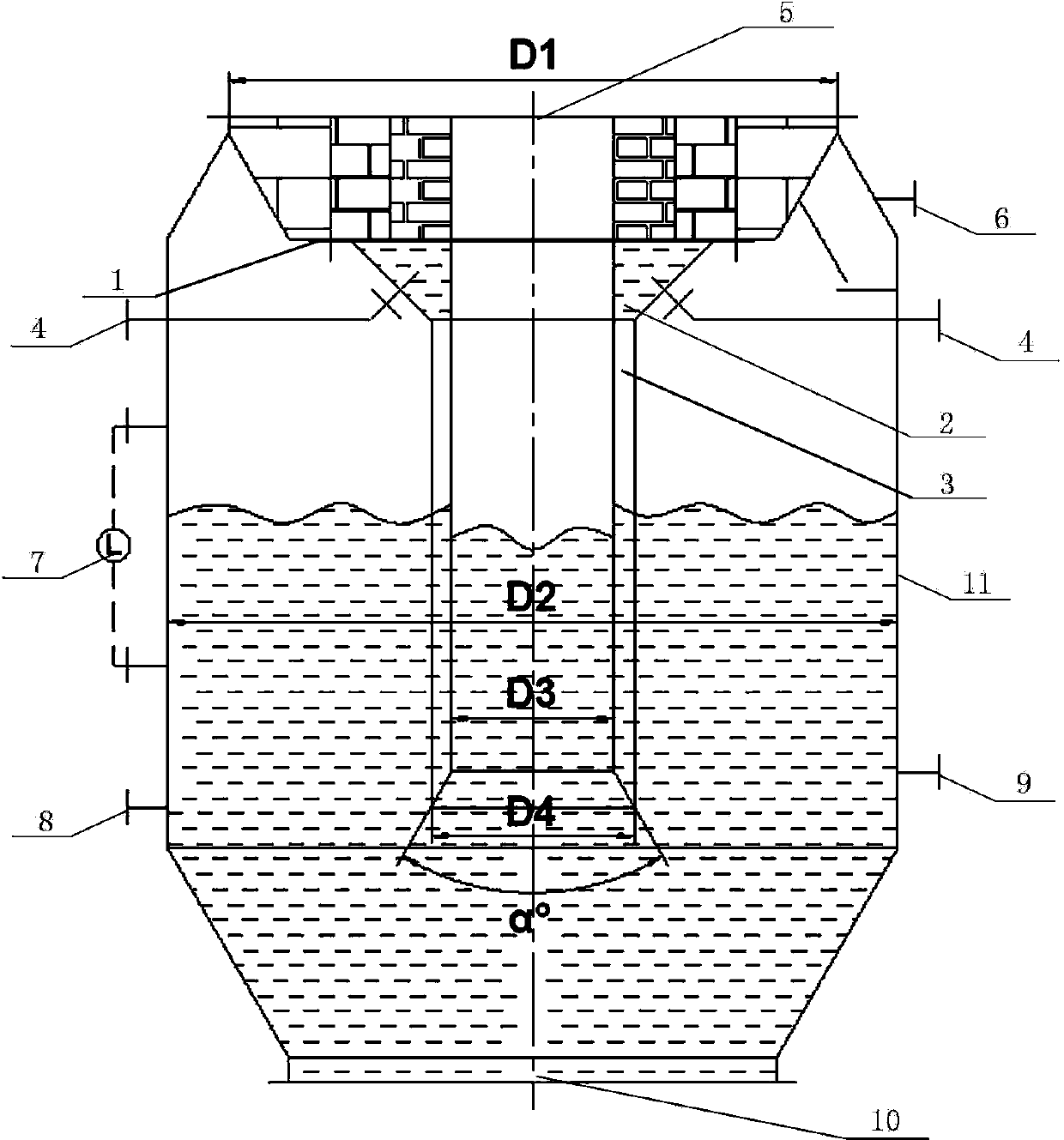

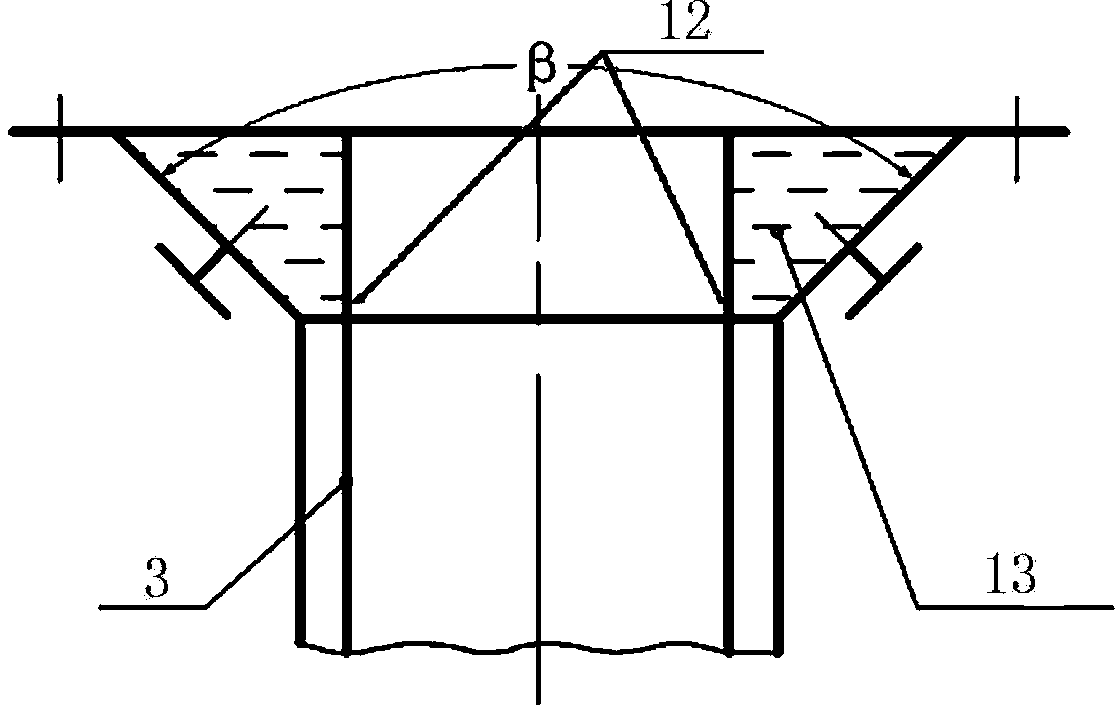

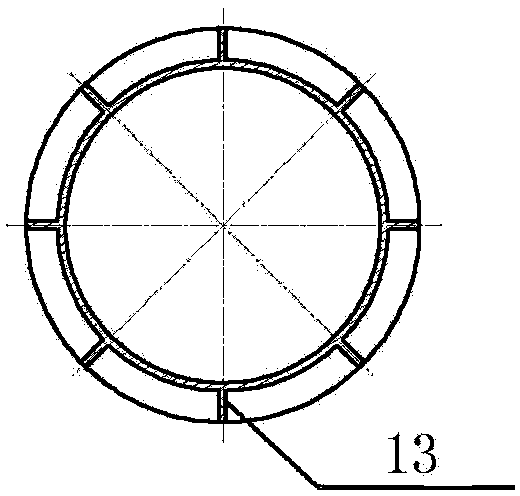

Large-scale pressure carbonization tower

ActiveCN102424405ALarge ventilationIncrease the gas-liquid contact areaCarbonate preparationSodium bicarbonateEngineering

The invention relates to a large-scale pressure carbonization tower which is characterized in that its bamboo rain-hat is composed of a base plate, a top cover and several rib plates; the rib plate is central symmetric and fixed on the base plate; the top cover is fixed on the rib plates; a through hole is arranged at the center of the base plate; the edge of the base plate equipped with the through hole is a zigzag edge; 24 bamboo rain-hats are arranged inside the upper portion of the tower; the opening rate of the first bamboo rain-hat to the 21st bamboo rain-hat from the top to the bottom is 9.8%, and the opening rate of the 22nd bamboo rain-hat to the 24th bamboo rain-hat is 12.8%; one bamboo rain-hat with the opening rate being 13.3% is arranged inside a central conical tower; an airintake is arranged on the central conical tower body; the base plates of the bamboo rain-hats at the bottom are all equipped with appropriate opening rate; and the second and seventh tower sections are respectively provided with two air intakes. According to the invention, ventilation volume and liquid holdup of each portion of the carbonization tower are enlarged; the reaction time and crystal growth time are prolonged; carbonization tower production power and carbonization conversion rate are raised; sodium bicarbonate crystalline particles become large and many unfavorable factors of original carbonization towers are improved.

Owner:赵祥海

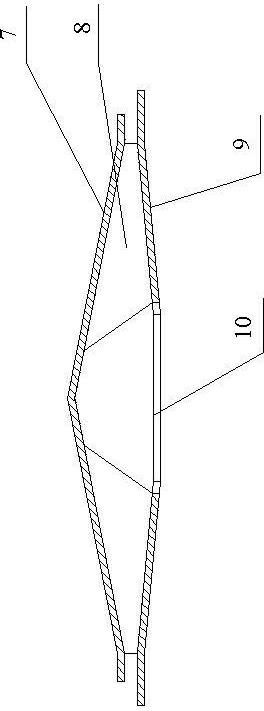

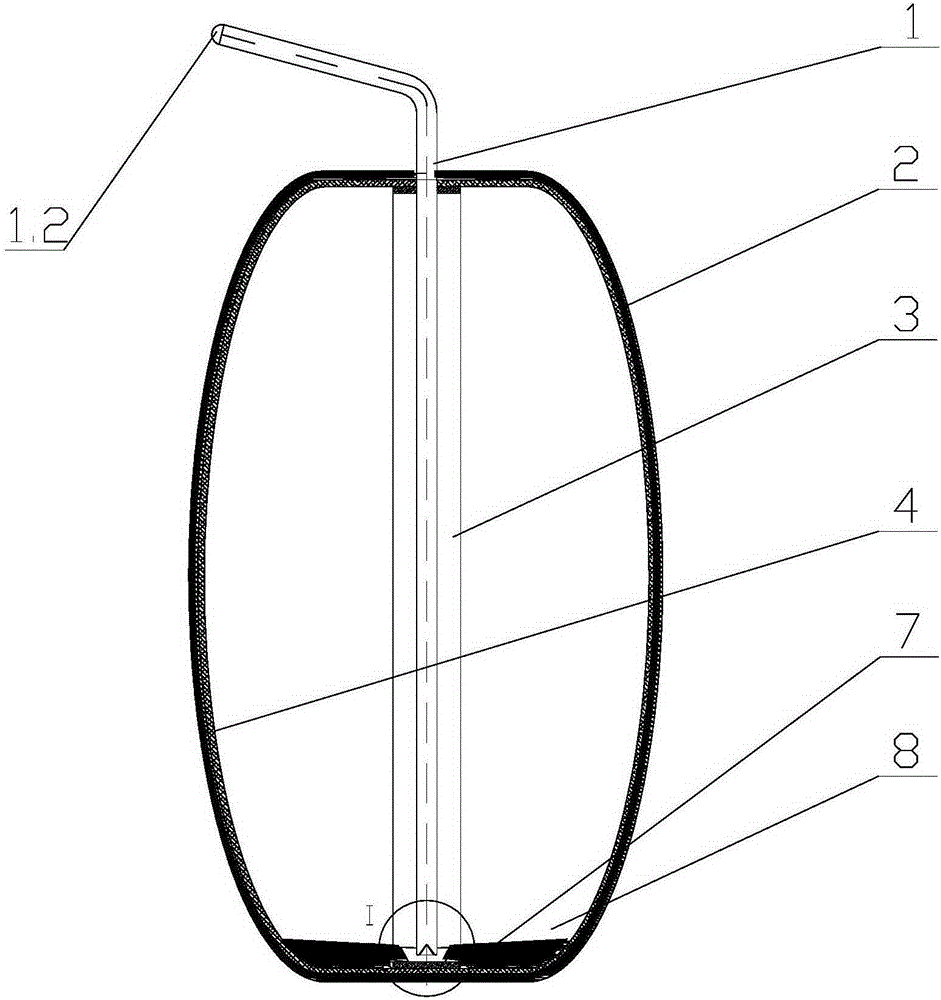

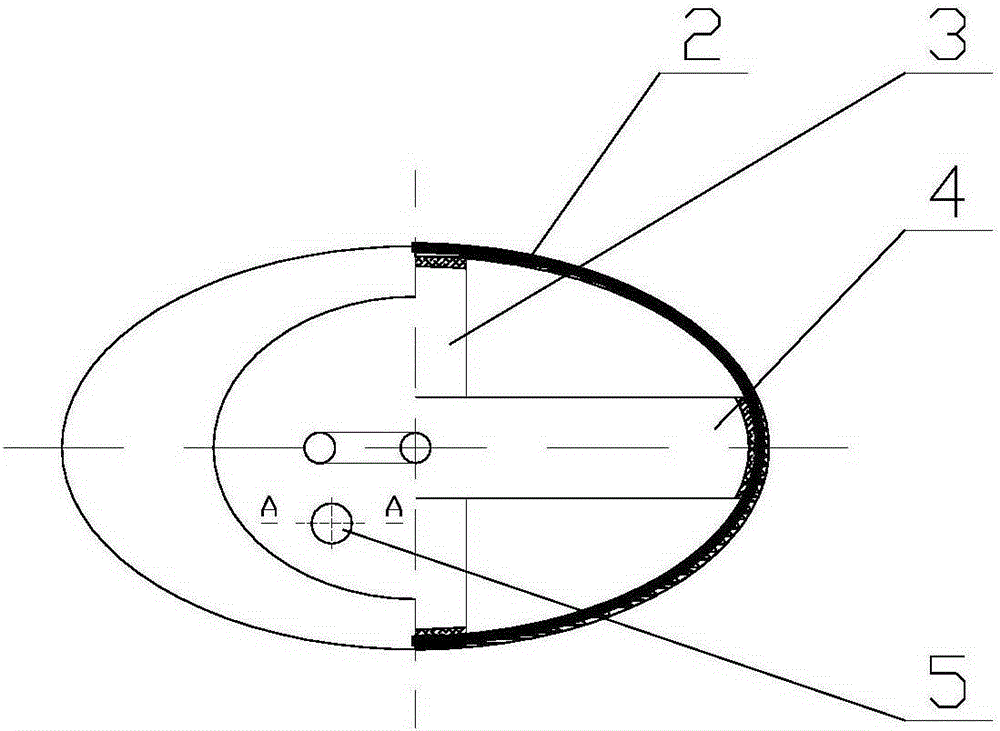

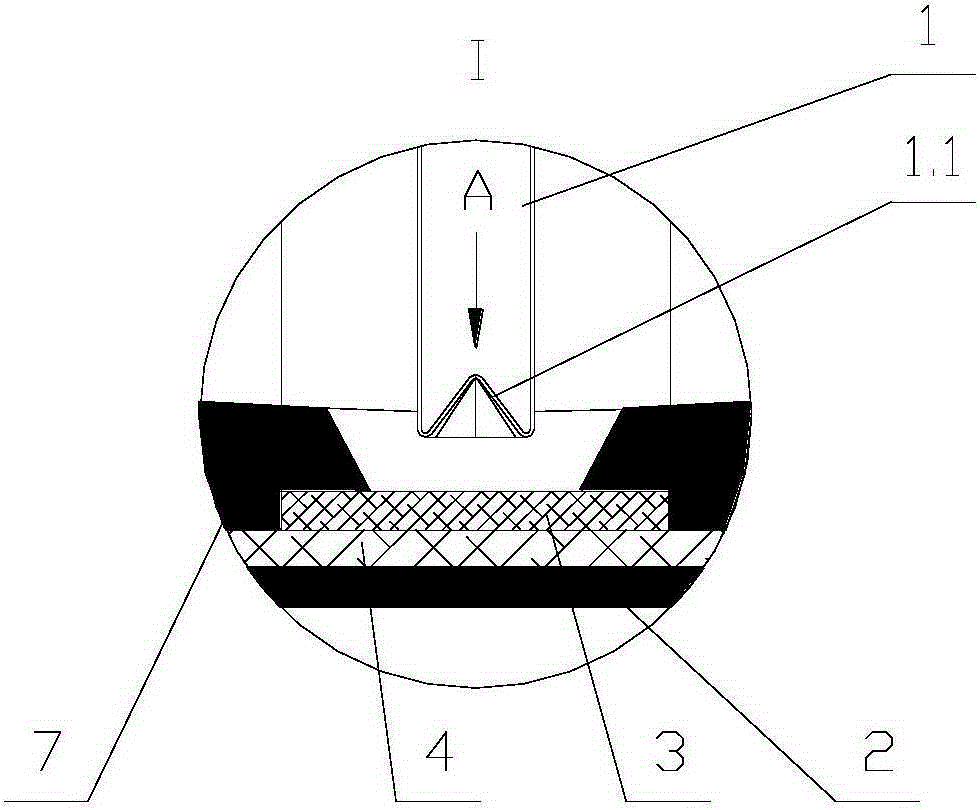

Rectifying tower for separating and purifying ethyl hexanoate

InactiveCN104338339AImprove efficiencyEasy to cleanOrganic compound preparationCarboxylic acid esters preparationContact timeEngineering

The invention discloses a rectifying tower for separating and purifying ethyl hexanoate. The rectifying tower includes a rectifying tower barrel (1), an internally arranged inner part, a sealing head (13), a support (7) and a skirt (10), the rectifying section of the rectifying tower adopts double overflow tray assignment, stripping section of the packing, the stripping section of the rectifying tower adopts a filler, and the bottoms of the rectifying section and the stripping section are provided with a first cyclone separator (8) and a second cyclone separator (9) respectively, a liquid distributor (4) is arranged below a refluxing hole and above the trays, a liquid sealing disk (16) is arranged between the trays and the first cyclone separator (8) at the bottom of the rectifying section, and the stripping section barrel is provided with a lateral line export (15). The rectifying section adopts the trays, and the stripping section adopts the metal corrugated structured filler, so a good separation effect is achieved, and the processing ability is strong; and the rectifying section adopts the trays, so the blocking of the filler by ester in the separation process is prevented, the tray efficiency is stable, the trays are convenient to clean, the liquid holdup is large, and the gas-liquid contact time is long.

Owner:常州市松盛香料有限公司

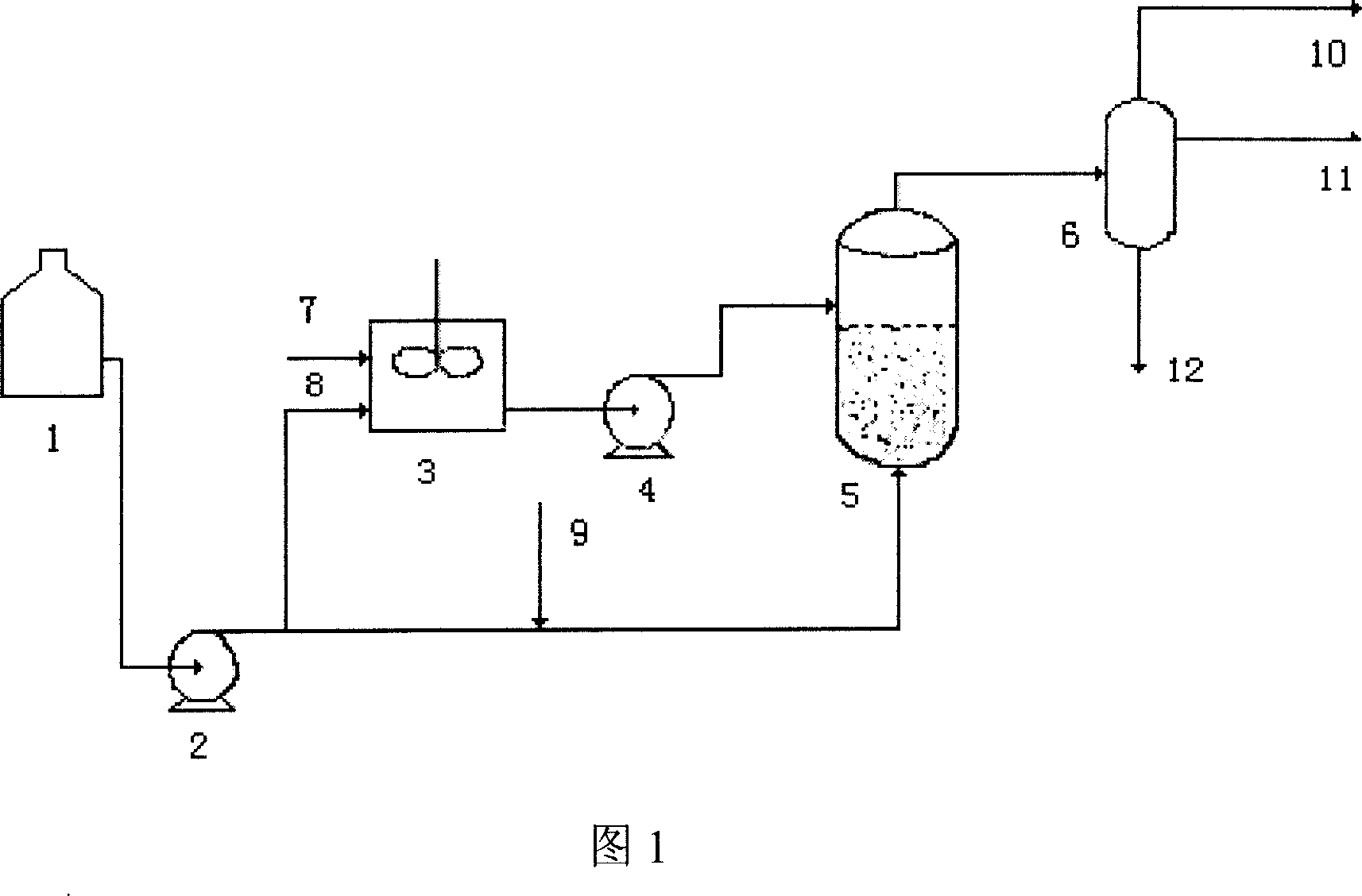

Device and method for preparing propylene oxide

ActiveCN106632148AEasy temperature controlAvoid the formation of hot spotsOrganic chemistryBulk chemical productionChemistryHydrogen peroxide

The invention discloses a device and a method for preparing propylene oxide. The device sequentially comprises a bubble tower slurry column reactor, a settling separation unit and a stirred tank slurry column reactor. According to the method, the bubble tower slurry column reactor and the stirred tank slurry column reactor are combined for epoxidation reaction under the reaction conditions of reaction pressure of 0.1 to 0.6MPa and reaction temperature of 40 to 70 DEG C. Local hot spots generated by strong reaction heat in a reaction process can be effectively avoided, and generation of a byproduct by back mixing of a liquid phase can also be effectively avoided. The advantages of high hydrogen peroxide conversion rate (more than or equal to 99 percent), high hydrogen peroxide effective utilization rate (more than or equal to 95 percent) and high propylene oxide product selectivity (more than or equal to 98 percent) are achieved.

Owner:CHINA CATALYST HLDG CO LTD

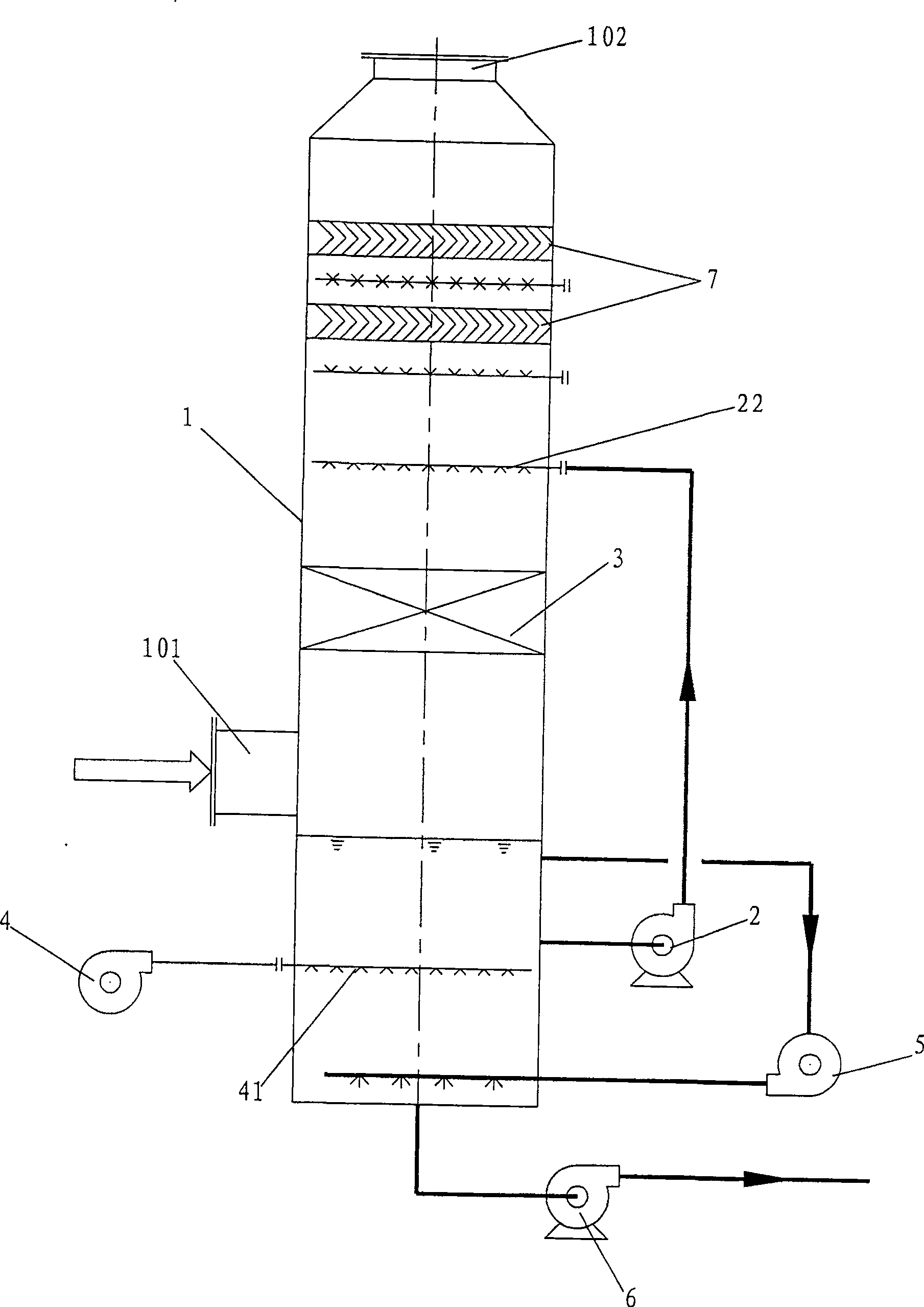

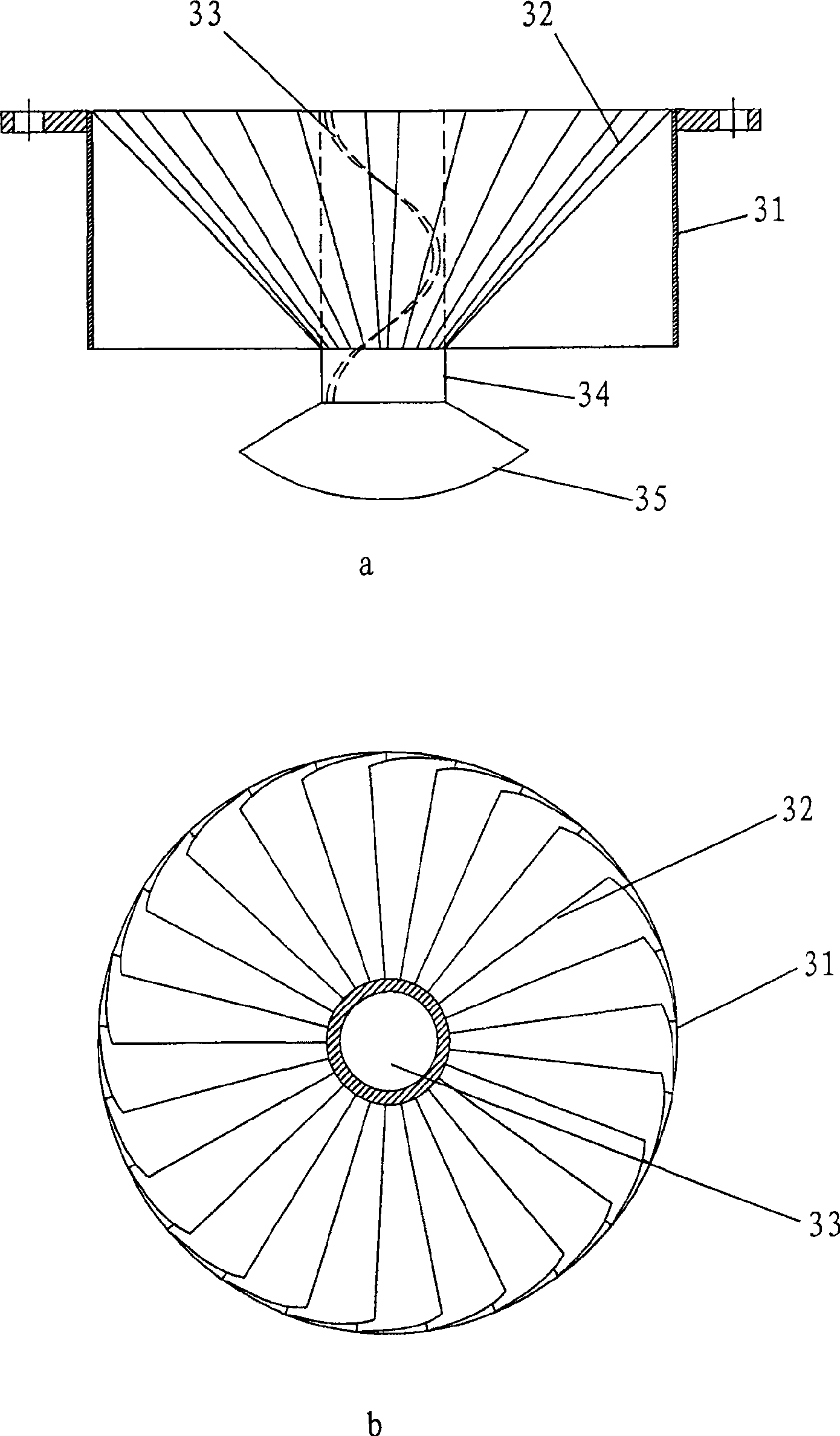

Turbine type pressure charging acceleration fuel gas desulfurization gas wash tower

InactiveCN100525885CIncrease contact timeIncrease contact spaceDispersed particle separationLiquid gasDust abatement

The invention relates to a turbine typed turbocharged accelerating flue gas desulfurization dust abatement tower, belonging to the field of gas purification technique, which includes a spray pump tower body, a slurry pump that is arranged on the tower from bottom to top and is connected with a slurry outlet at the bottom of the tower, a roots blower that is connected with a fall trachea and is arranged in a liquid storage district at the bottom in the tower, a spray pump pipe arranged over the liquid storage district, a circulating pump that is connected with and arranged in a circulating pipeline communicated with the spray pump pipe, and a demister arranged on the spray pump pipe; a flue gas inlet, a flue gas outlet and a slurry outlet are arranged on the lateral wall, on the top and at the bottom of the lower part of the spray pump tower body; a disturbance pump and a turbine typed turbocharged accelerating flue gas desulfurization dust abatement system are also included, wherein, the disturbance pump is connected with and arranged in the circulating pipeline communicated with the liquid storage district at the bottom of the tower, and the desulfurization dust abatement apparatus is arranged under the spray pump pipe in the tower and over the flue gas inlet. The invention has the advantages that sufficient connection of gas and liquid can be realized and high speed mass transfer can be carried out within the shortest time, in the smallest space and with the minimum liquid-gas ratio, thus improving high dust abatement and desulfurization efficiency with minimum energy consumption.

Owner:北京紫光威肯环保工程技术有限公司

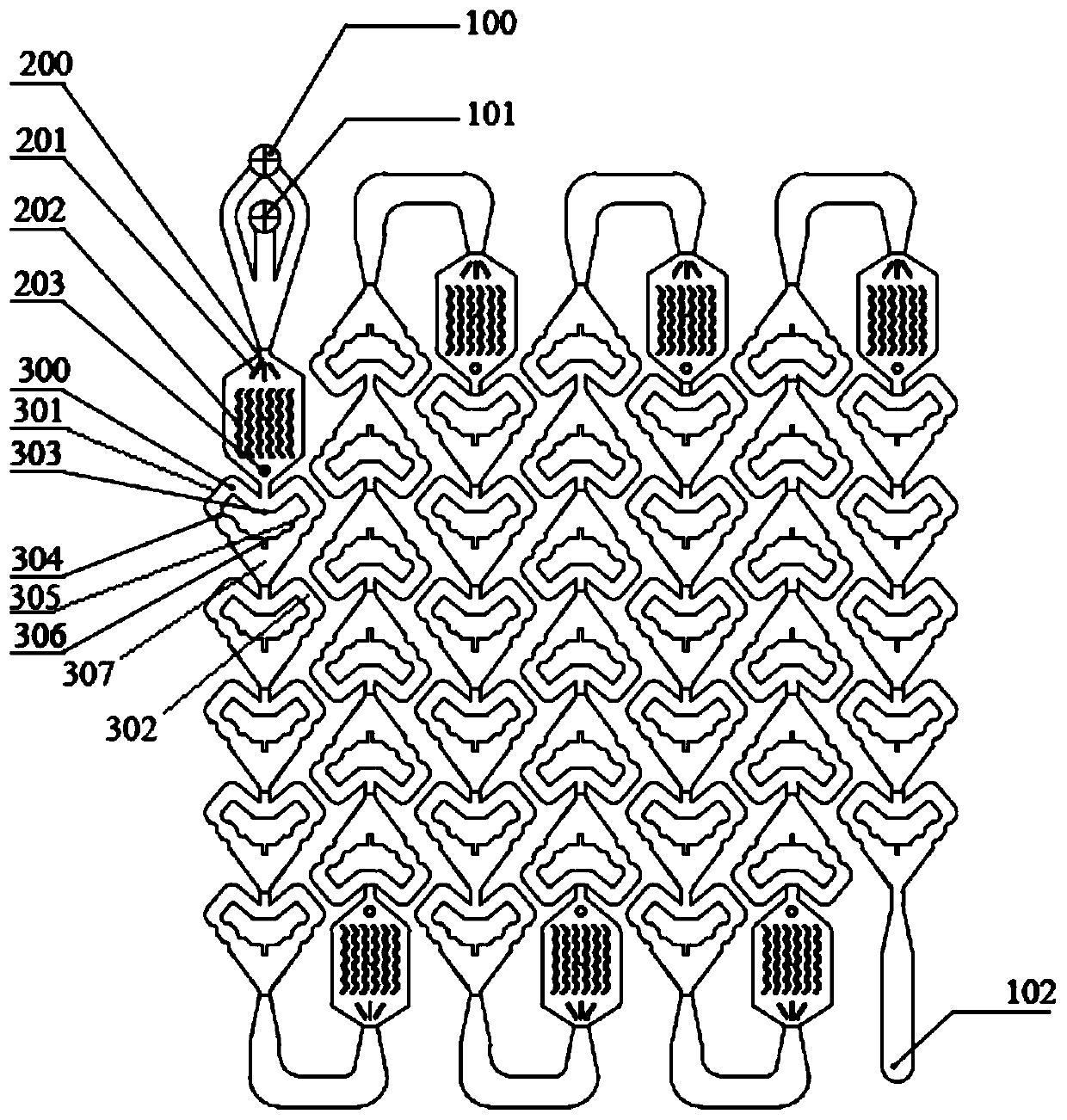

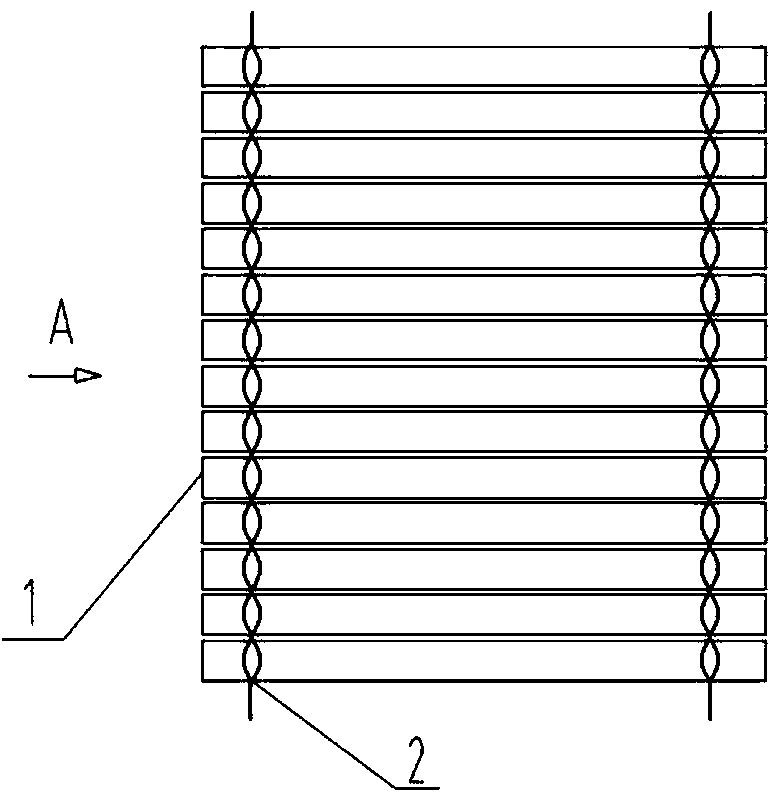

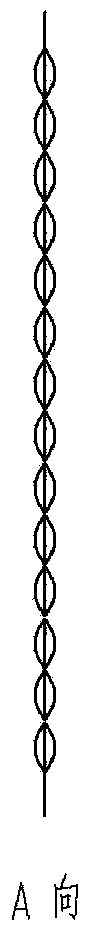

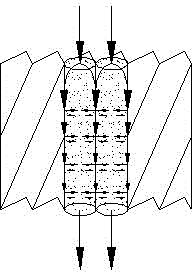

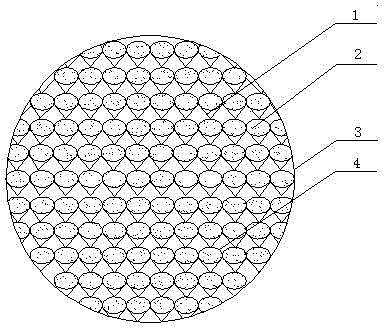

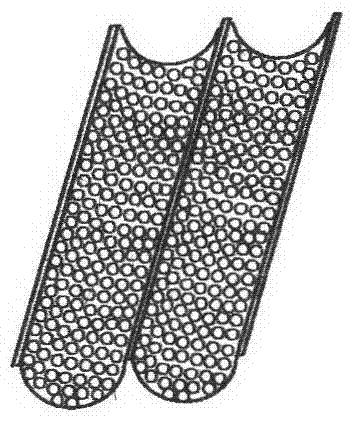

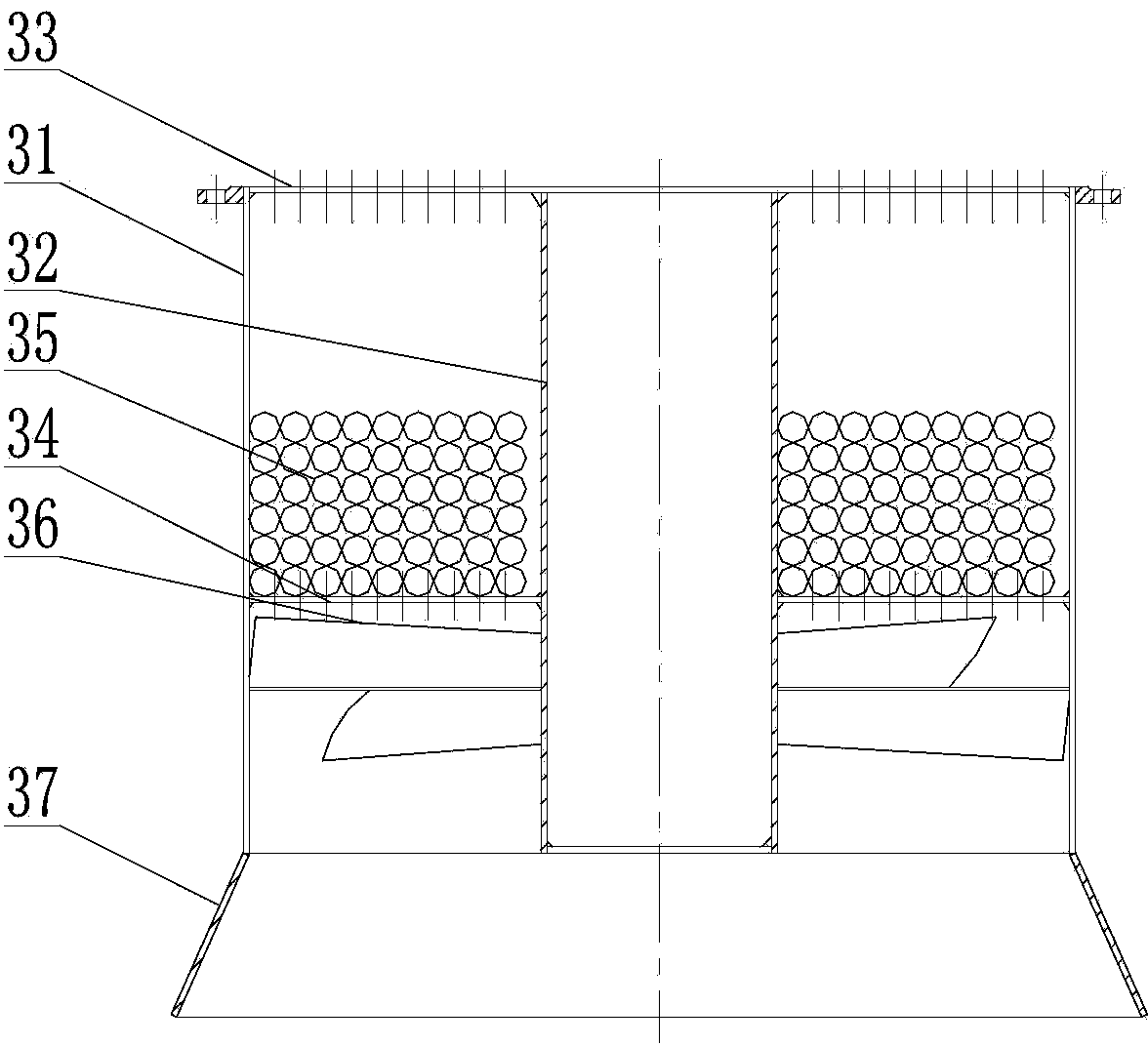

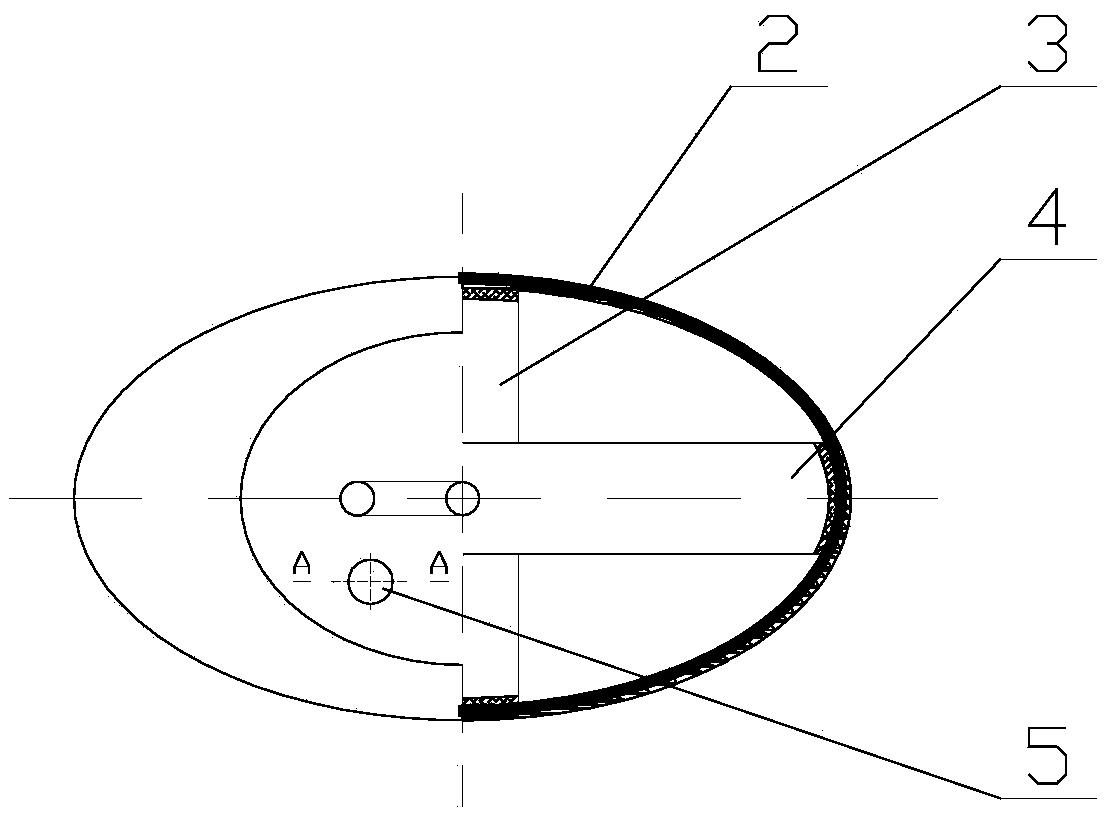

Regular catalytic packing in catalytic distillation column and preparation method of regular catalytic packing

InactiveCN104587945AImprove space utilizationReduce dosageChemical/physical/physico-chemical processesFractional distillationVapor liquidCatalytic distillation

The invention relates to a regular catalytic packing in a catalytic distillation column and a preparation method of the regular catalytic packing. The regular catalytic packing is prepared from a catalytic packing unit, wherein the catalytic packing unit consists a component I and a component II; the component II is a catalyst cloth bag which is sewed by spun silk cloth, nylon cloth or dacron cloth, the component I and the component II are alternately slantingly arranged in reverse directions respectively and are bound into a cylinder shape to form an efficient catalytic distillation packing unit. According to the regular catalytic packing and the preparation method disclosed by the invention, the catalyst cloth bag and a corrugated packing are slantingly arranged in reverse directions, so that the residence time of a reactant in the catalyst cloth bag can be prolonged, reaction is facilitated, the utilization ratio of the catalyst is increased, and the use amount of the catalyst is reduced; the reaction residence time of the reactant in the catalytic packing can be changed by regulating the inclination angle of the catalyst cloth bag; while, as the component I and the component II are alternately arranged, the vapor-liquid mass transfer process can be enhanced, and thus vapor and liquid alternately flow between a catalyst and a corrugated net repeatedly, and coupling action of separation and reaction is promoted.

Owner:FUZHOU UNIV

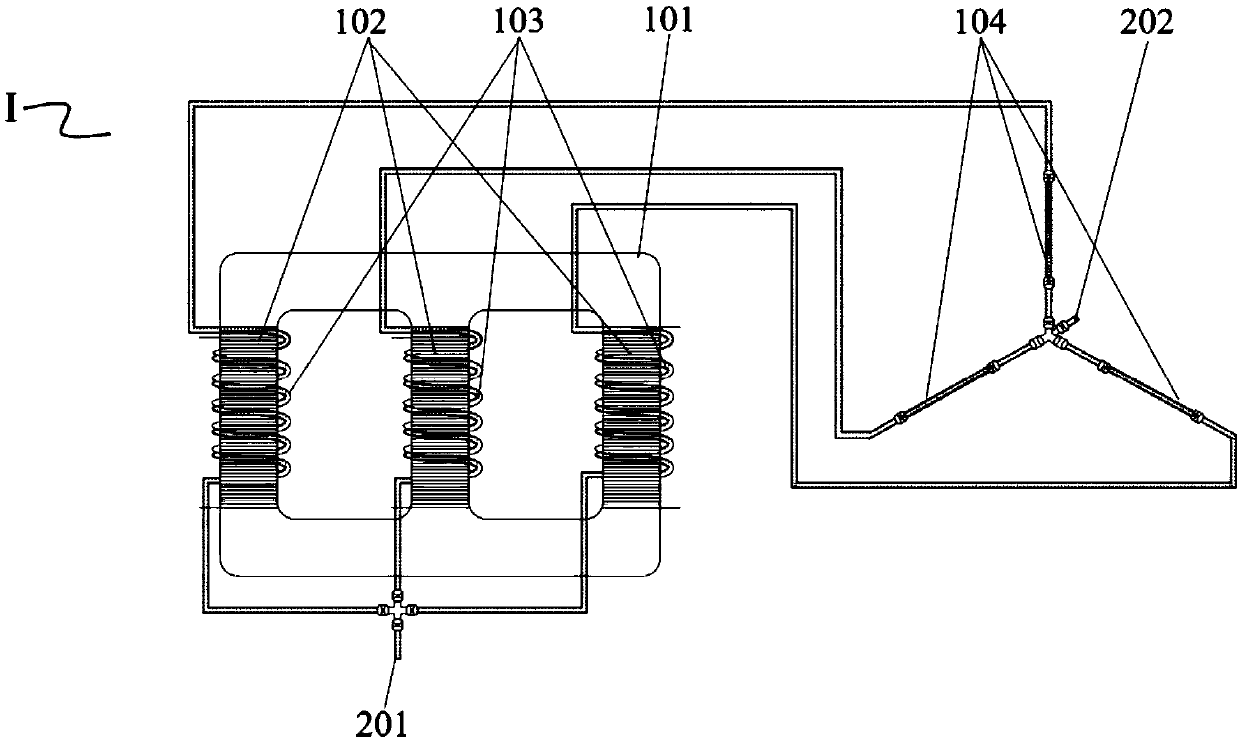

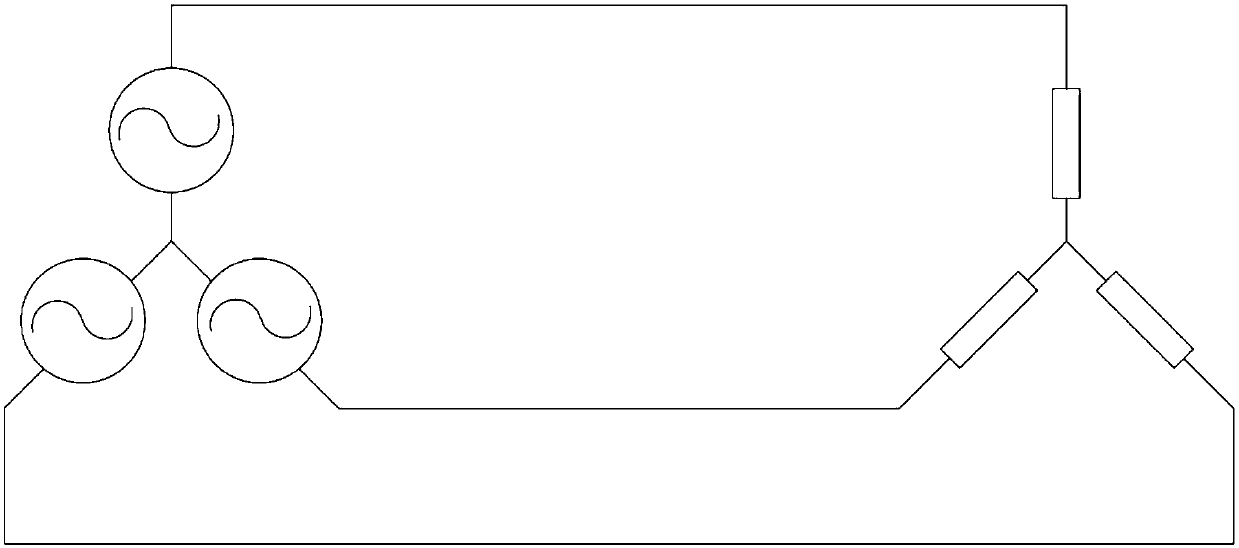

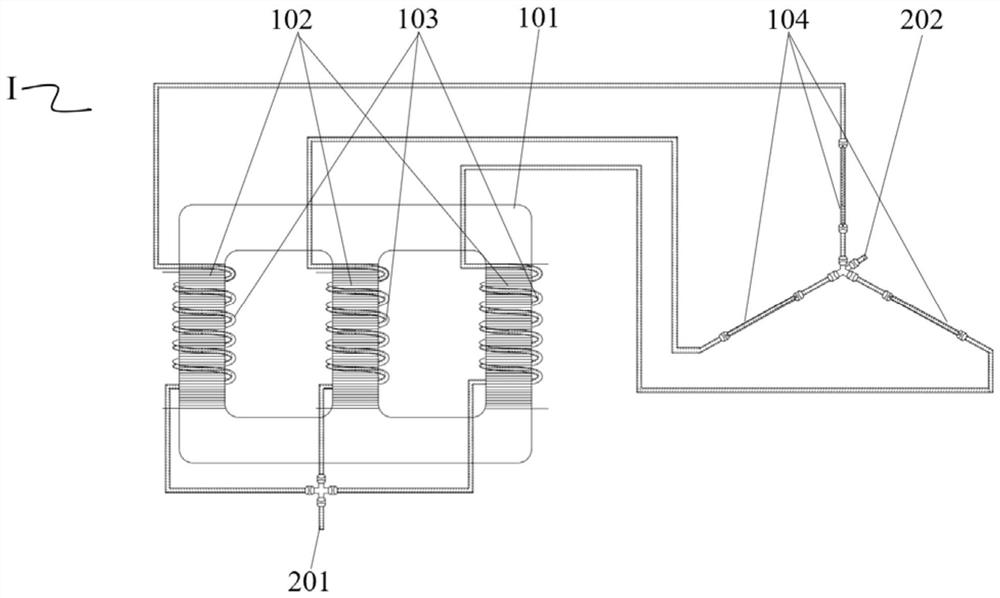

Star-star type three-phase induction heat reactor

ActiveCN109618439ASimple flow path structureLarge liquid holding capacityCoil arrangementsInduction heating apparatusEffective potentialInjection port

The invention discloses a star-star type three-phase induction heat reactor, and belongs to the technical fields of chemical engineering, food and environments. The star-star type three-phase induction heat reactor comprises a three-column magnetic circuit, a magnet exciting coil, magnetic coupling tubes and reaction cavities, wherein an injection port and a sample outlet are formed in the joint intersections of the groups of the magnetic coupling tubes or the groups of the reaction cavities; Each group of the magnetic coupling tubes and each group of the reaction cavities is of three-phase star joint, and the groups of the magnetic coupling tubes and the groups of the reaction cavities are connected in a star-star structure; higher effective potential difference can be generated by an electrically conductive material or a reaction medium inside the reaction cavities, the effective potential difference comes from the line voltage of a three-phase circuit, the value is square root of 3times of normal phase voltage, and then the temperature rise efficiency of feed liquid or the reaction medium is higher, no external heat source or radiation is realized, sample are efficiently heatedunder the effect of no eternal electrode, and the star-star type three-phase induction heat reactor is provided with the single injection port and sample outlet, the liquid holdup of the reaction cavity is large, and the handling capacity is relatively high under the same sampling flow rate.

Owner:INDUC SCI CO LTD

Methanol rectifying tower

ActiveCN110270121AReduce exposureEasy to recycleOrganic compound preparationHydroxy compound preparationRefluxPulp and paper industry

The invention belongs to the technical field of chemical production equipment, and particularly relates to a methanol rectifying tower. The methanol rectifying tower comprises a tower body, wherein the upper part of the tower body is a packing tower section, a connecting tower section is arranged in the middle of the tower body, a plate type tower section is arranged at the lower part of the connecting tower section, a concrete base is fixedly connected to the lower portion of the tower body, and a plurality of reinforcing angle steel seats are welded on the side surface of the concrete base; a steam outlet is formed in the top of the tower body, and a reflux liquid inlet, a methanol solution inlet and a mixture inlet are formed in the side face of the tower body from top to bottom in sequence; two groups of liquid distributors and a packing layer are arranged on the inner wall of the packing tower section; a plurality of groups of liquid reducing pipes are arranged on the inner wall of the plate type tower section. The methanol rectifying tower is better than the prior art, an ingenious design is utilized, the contact between liquid rectified methanol and the inner wall of the plate type tower section can be effectively reduced during flowing in a hydromechanical mode, and recycling and reutilization are facilitated; the liquid rectified methanol can be subjected to condensation, so that the recycling efficiency of the liquid rectified methanol is improved.

Owner:TANGSHAN XUYANG CHEM IND CO LTD

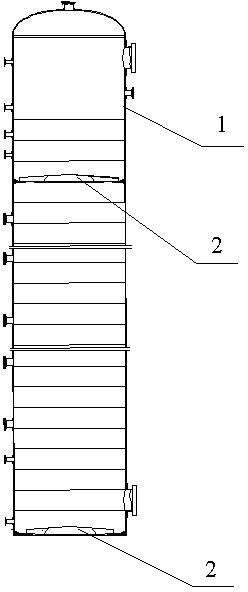

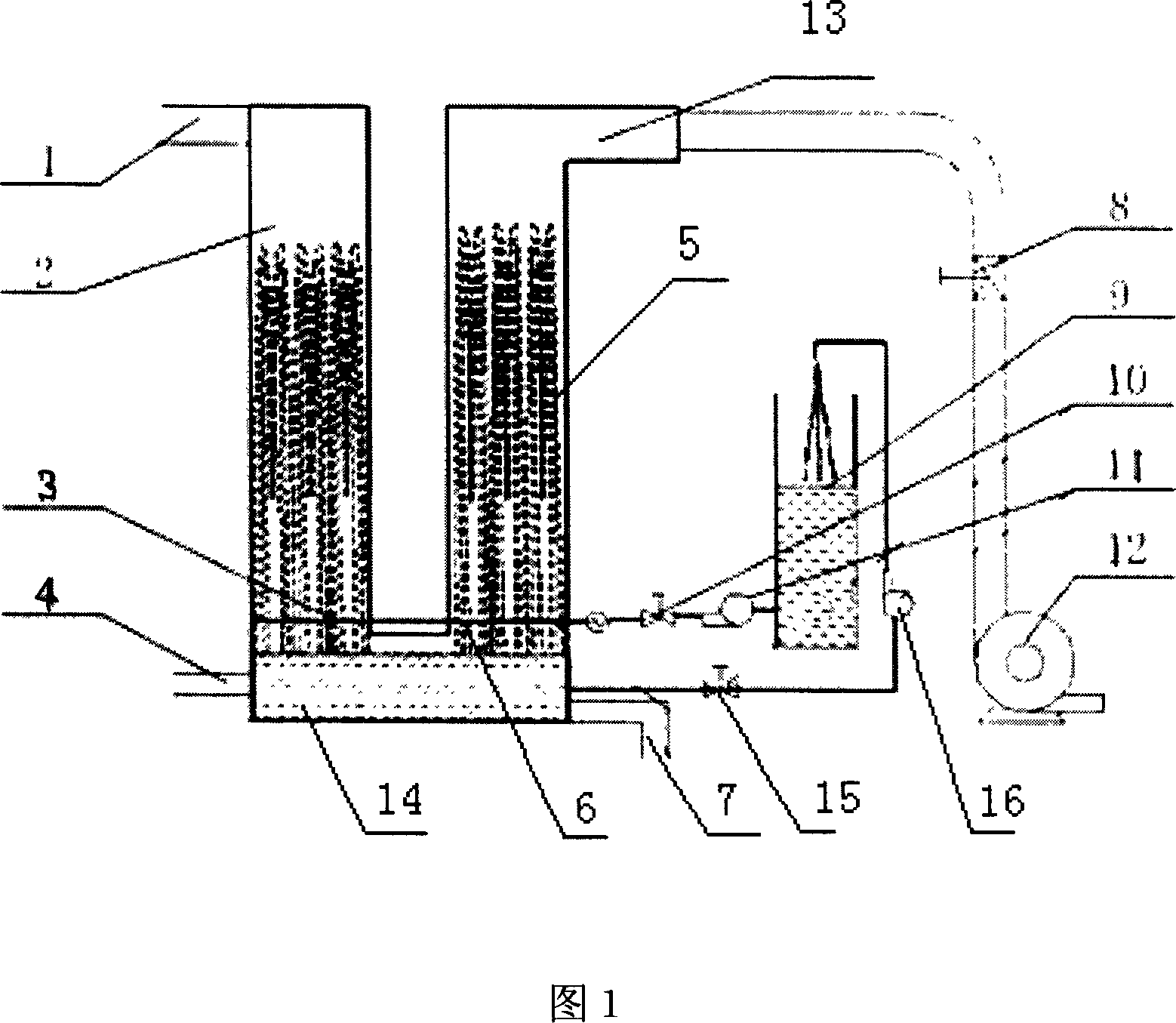

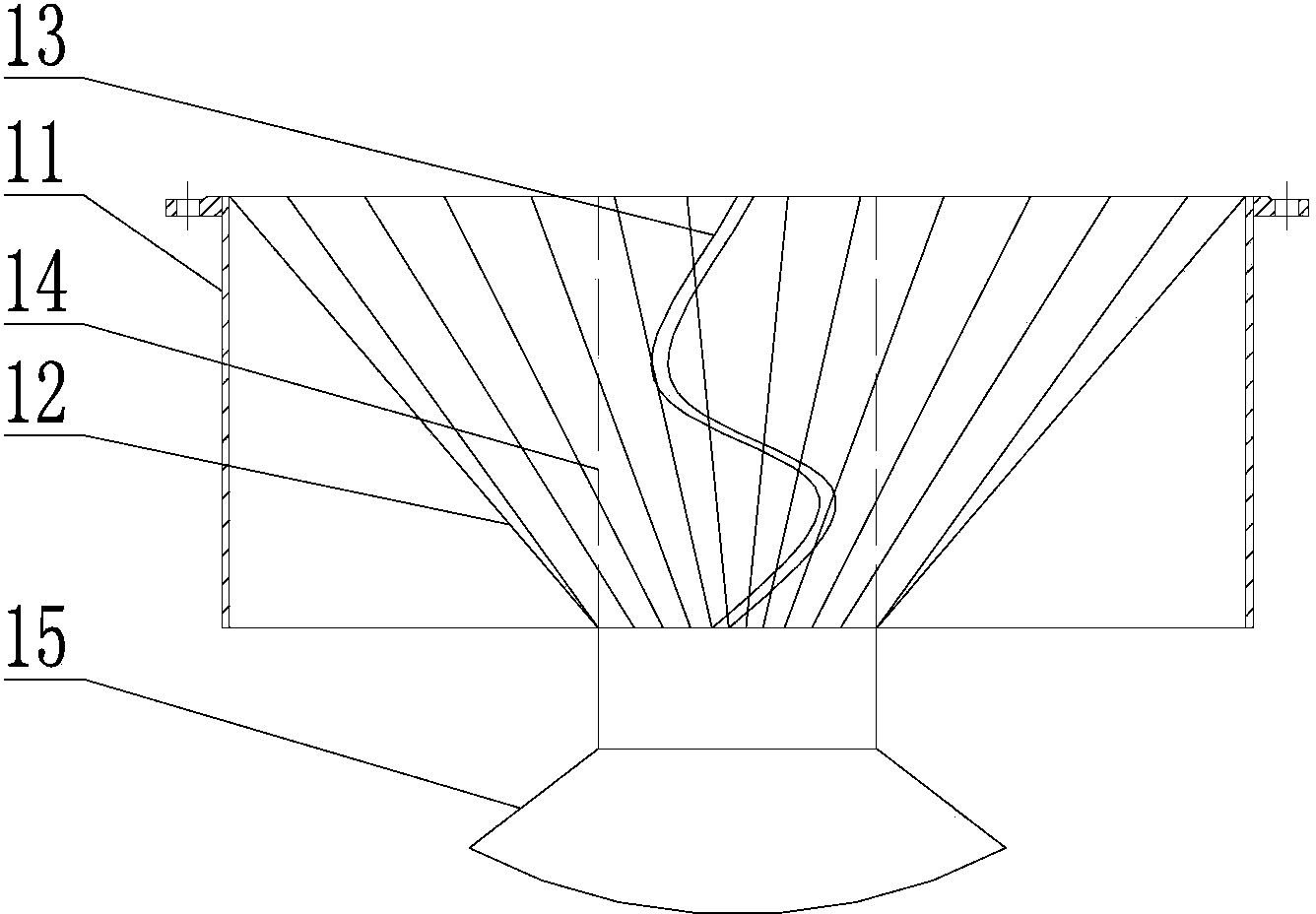

Gas-liquid contacting response operator of fluid curtain bed

InactiveCN1958131AHigh heat and mass transferHigh gas-liquid relative velocityDispersed particle separationLiquid-gas reaction processesSlurryTower

A gas-liquid contact reactor with liquid curtain bed is composed of a slurry pool with slurry inlet and outlet, a desulfurizing tower consisting of a forward-current tower and a counter-current two, whose bottoms have more than one row of nozzles and are communicated with each other, a draught blower connected via valve to the fume outlet of counter-current tower, and a circulating slurry tank communicated via regulating valve and circulating pump to said nozzles.

Owner:XI AN JIAOTONG UNIV

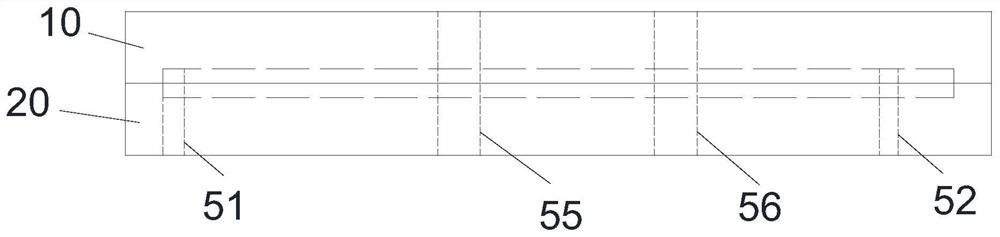

Reaction assembly and reactor with same

PendingCN112090389ALarge specific surface areaSmall pressure drop lossChemical/physical/physico-chemical stationary reactorsContinuous reactorEngineering

Owner:ASYMCHEM LIFE SCI TIANJIN

Smoke gas desulfurization dust removal device by turbulent ball type turbocharging acceleration

InactiveCN102805998AImprove efficiencyLarge capacityUsing liquid separation agentMass transferEngineering

The invention relates to a smoke gas desulfurization dust removal device by turbulent ball type turbocharging acceleration, which belongs to the technical field of gas purification and comprises a casing, a pipeline and a smoke shielding cover, wherein the pipeline is fixedly arranged in the center of the pipeline, and the lower end of the casing is connected with the smoke shielding cover. The dust removal device is characterized by also comprising upper and lower porous end plates, a turbulent ball and a plurality of blades, wherein the upper and lower porous end plates are respectively arranged at the upper end and the middle part of the casing, the turbulent ball is filled in the space between the upper and lower porous end plates of the casing, the blades are arranged between a porous separation plate and the pipeline, the upper end of each blade is connected with the inner wall of the casing, and the lower end of each blade is connected with the outer wall. The turbulent ball type turbocharging acceleration smoke gas desulfurization dust removal device has the advantages that the full gas and liquid contact can be realized under the conditions of the shortest time, the smallest space and the lowest liquid liquid-gas ratio, the high-speed mass transfer is carried out, and the high dust removal and desulfurization efficiency can be improved at the minimum energy consumption.

Owner:北京威肯泛联能源科技有限公司

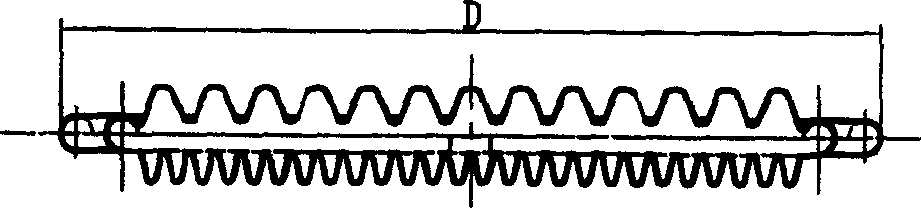

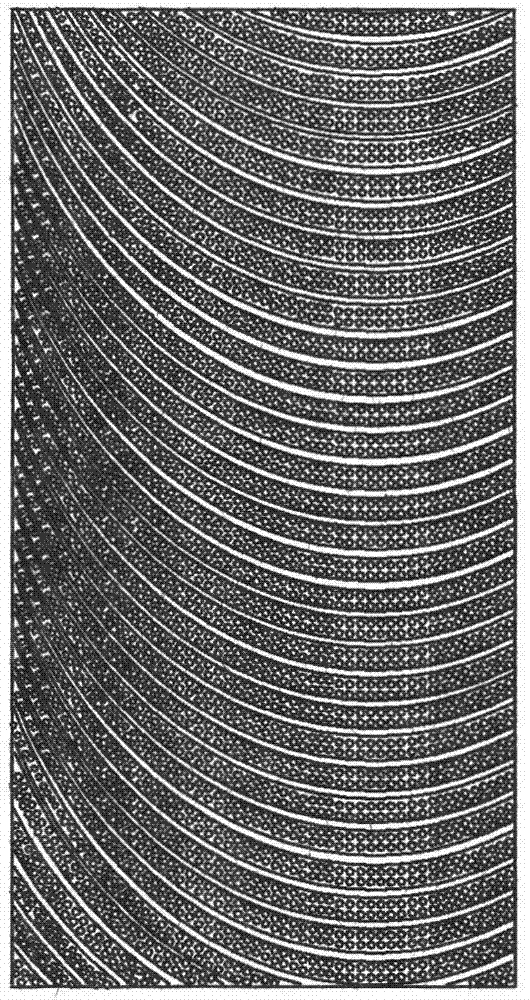

Spiral-plate corrugated structured packing

InactiveCN103611488AChange directionEvenly distributedChemical/physical/physico-chemical processesLayer interfaceMetallic materials

The invention relates to spiral-plate corrugated structured packing prepared from a metal material and belongs to the technical field of gas-liquid and liquid-liquid mass-transfer separation designs of oil refining, petrifaction, chemical engineering, light engineering and environment protection industries. The spiral-plate corrugated structured packing is mainly technically characterized in that the corrugated shape of conventional corrugated packing is changed from V into U, and a corrugated sheet is wound into spiral structured packing, so that flowing channels of gas fluid and liquid fluid are parallel and independent; liquid uniformly flows and is uniformly distributed on a whole packing layer interface, so that the distribution condition of the whole liquid in a tower is improved, and the surface of a liquid membrane can be further updated; under a condition that the specific area of the packing is not enlarged, the effective mass-transfer area is enlarged, so that the comprehensive performance of the packing is improved.

Owner:NANJING COLLEGE OF CHEM TECH

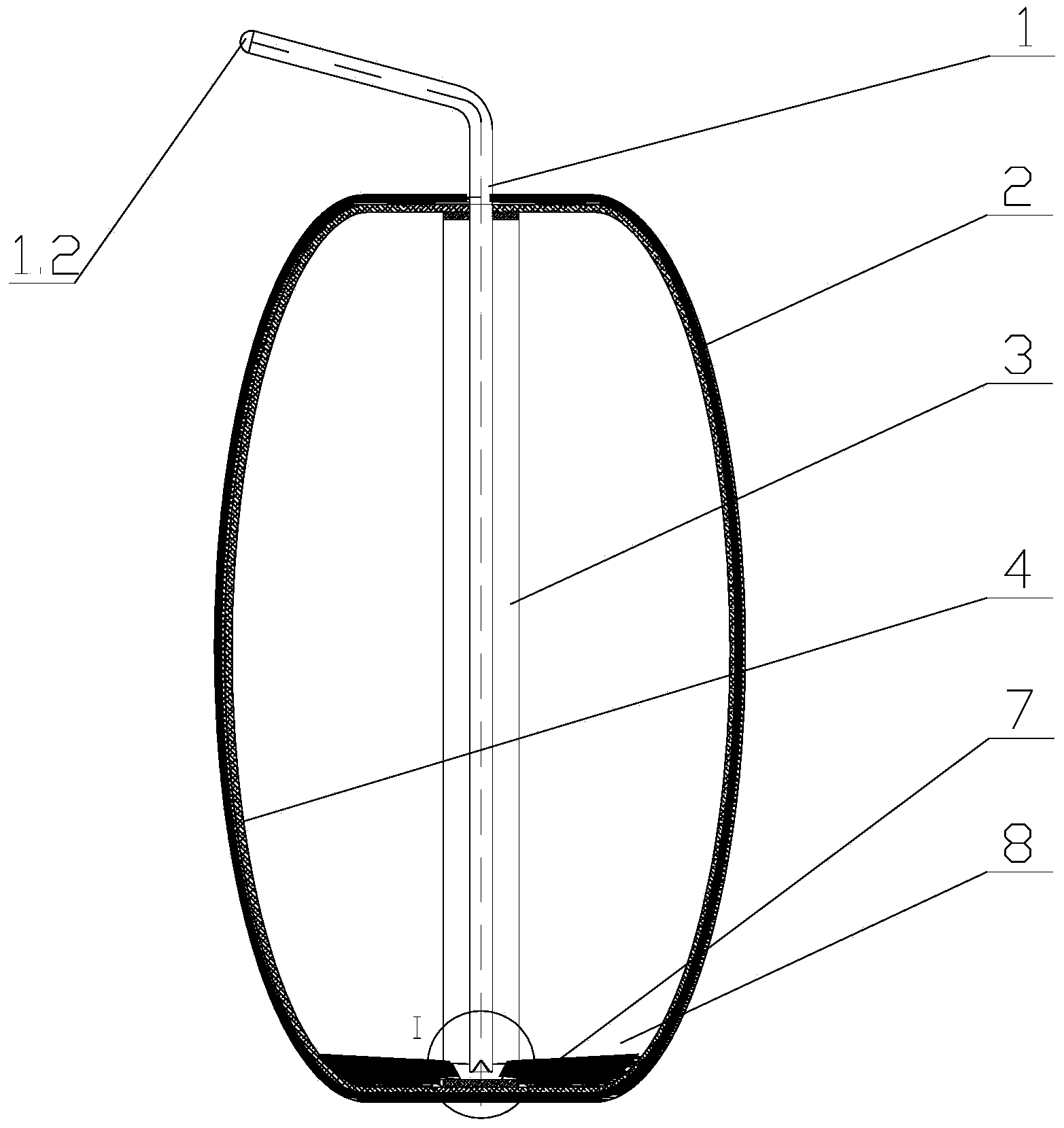

Environmental protection liquid storage tank for exterior wall paint

InactiveCN104029882BEasy to useNo pollution in the processDispensing apparatusBio-packagingEnvironmental resistancePlastic materials

An environment-friendly liquid storage tank for exterior wall paint relates to the technical field of colorful paint. Environmentally friendly liquid storage tank for exterior wall paint, including discharge pipe, discharge pipe check valve, collodion ball, shell, bamboo elastic support A, bamboo elastic support B, air inlet sealing sheet, air inlet pipe, inlet The trachea check membrane, the liquid reducing pad, and the liquid storage tank are characterized in that: the check valve of the discharge pipe is made of rubber and plastic material, the bottom of the discharge pipe is connected with the check valve of the discharge pipe, and the check valve of the discharge pipe It is an isosceles triangular membrane flap, which is in the shape of a regular pyramid. The bottom of the isosceles triangle is connected to the inner wall of the bottom of the discharge pipe. The top side of the shell is connected to an air inlet, and the air inlet pipe is sealed with an air inlet. piece, the top end of the discharge tube is fitted with a collodion ball. It has the characteristics of ecological environmental protection, degradable and non-polluting.

Owner:UNIV OF JINAN

An industrial waste liquid treatment system and method based on carrier gas extraction low-temperature mass transfer

ActiveCN110498462BNo secondary pollutionAchieve moisture purificationGas treatmentSpecific water treatment objectivesCirculator pumpProcess engineering

The invention proposes an industrial waste liquid treatment system and method based on carrier gas extraction low-temperature mass transfer. The system includes an absorber connected to a condenser connected to a waste liquid circulation pump connected to an absorber The liquid distributor of the resolver and the internal heater of the absorber; the resolver, which is connected to the evaporator, and the evaporator is connected to the clean water pump, and the clean water pump is connected to the liquid distributer of the resolver and the internal cooler of the resolver; the air outlet of the absorber is connected to the resolver The air inlet of the resolver, the air outlet of the resolver is connected to the air inlet of the absorber, and the air channel between the air outlet of the resolver and the air inlet of the absorber is provided with a circulating fan and an adsorber. The invention can use air as the mass transfer medium to realize the migration of water in the industrial waste liquid under the condition of relatively low temperature. A series of pretreatment processes such as precipitation, oil removal, and pH adjustment required for liquid disposal.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Turbulent ball type turbocharging compound desulfurization dust removal tower

ActiveCN102805999BIncrease contact timeFully contactedUsing liquid separation agentSpray towerEngineering

The invention relates to a turbulent ball type turbocharging compound desulfurization dust removal tower, which belongs to the technical field of gas purification and comprises a spraying tower body, a gas inlet, a smoke outlet, a slurry discharger, a slurry discharge pump, a Roots blower, multilayer spraying pipes, an annular separation plate, a circulation pump, a demister, a disturbance pump and a plurality of turbulent ball type turbocharging acceleration smoke gas desulfurization dust removal devices, wherein the turbulent ball type turbocharging acceleration smoke gas desulfurization dust removal devices are arranged in the tower and respectively comprise a casing, a pipeline, upper and lower porous end plates, a turbulent ball and a plurality of blades, the pipeline is fixedly arranged in the center of the casing, the upper and lower porous end plates are respectively arranged at the upper end and the middle part of the casing, the turbulent ball is filled in the space between the upper and lower porous end plates, the blades are arranged between the porous end plates and the pipeline, the upper end of each blade is connected with the inner wall of the casing, the lower end of each blade is connected with the outer wall of the pipeline, and the lower end of the casing is connected with a smoke shielding cover. The turbulent ball type turbocharging compound desulfurization dust removal tower has the advantages that the full gas and liquid contact can be realized under the conditions of the shortest time, the smallest space and the lowest liquid-gas ratio, the high-speed mass transfer is carried out, and the high dust removal and desulfurization efficiency can be improved at the minimum energy consumption.

Owner:北京威肯泛联能源科技有限公司

Multi-column series negative pressure rectification device

ActiveCN112807730BReduce the overall heightReduce manufacturing difficultyFractional distillationTowerIndustrial engineering

The invention discloses a multi-column series negative pressure rectification device and an application method thereof, comprising: an outer casing of a rectangular structure, in which a plurality of rectification columns are arranged, and adjacent rectification columns pass through a predetermined distance The empty column sections are spaced apart; wherein, the side of the lower end of the rectifying column located in the first section is provided with a steam inlet flange communicating with the evaporation unit; the side of the empty column section located at the end is provided with a steam outlet communicating with the steam evacuation equipment flange; the bottom of the two adjacent rectification columns is provided with an air inlet that matches the steam inlet flange in space, and a matching air outlet is arranged on the top of the opposite side of the air inlet, so that each fine The distillation columns are connected in series in the outer shell of the rectangular structure through empty column sections. The invention provides a multi-column series negative pressure rectification device and an application method thereof, which reduces the manufacturing difficulty of the rectification tower, reduces the equipment cost, and has more obvious cost advantages compared with the rectification tower with a height of more than 50m.

Owner:绵阳科大久创科技有限公司

Environmentally friendly liquid storage tank for exterior wall coating material

InactiveCN104029882ANo pollution in the processReduce white pollutionBio-packagingDispensing apparatusPlastic materialsAgricultural engineering

The invention discloses an environmentally friendly liquid storage tank for exterior wall coating material and relates to the technical field of colorful coatings. The environmentally friendly liquid storage tank for the exterior wall coating material comprises a discharging tube, a discharging tube non-return diaphragm clack, a collodion ball, a shell, a bamboo elastic support A, a bamboo elastic support B, an air inlet hole sealing piece, an air inlet tube, an air inlet tube non-return diaphragm, a liquid reducing gasket and a liquid storage tank body. The environmentally friendly liquid storage tank is characterized in that the discharging tube non-return diaphragm clack is made of rubber and plastic material. The bottom of the discharging tube is connected with the discharging tube non-return diaphragm clack which is an isosceles triangle clack and is in a regular pyramid shape, the bottom of the isosceles triangle is connected with the inner wall of the bottom of the discharging tube, an air inlet hole is connected with one side of the top of the shell, the air inlet hole sealing piece is arranged on the air inlet tube, and the collodion ball is installed at the tail end of the top of the discharging tube. The environmentally friendly liquid storage tank has the advantages of being ecologically environmentally friendly, degradable and free of pollution.

Owner:UNIV OF JINAN

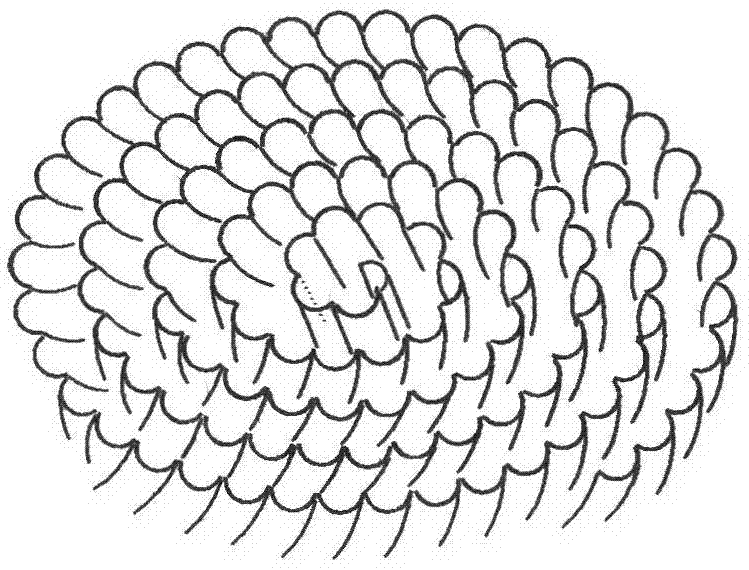

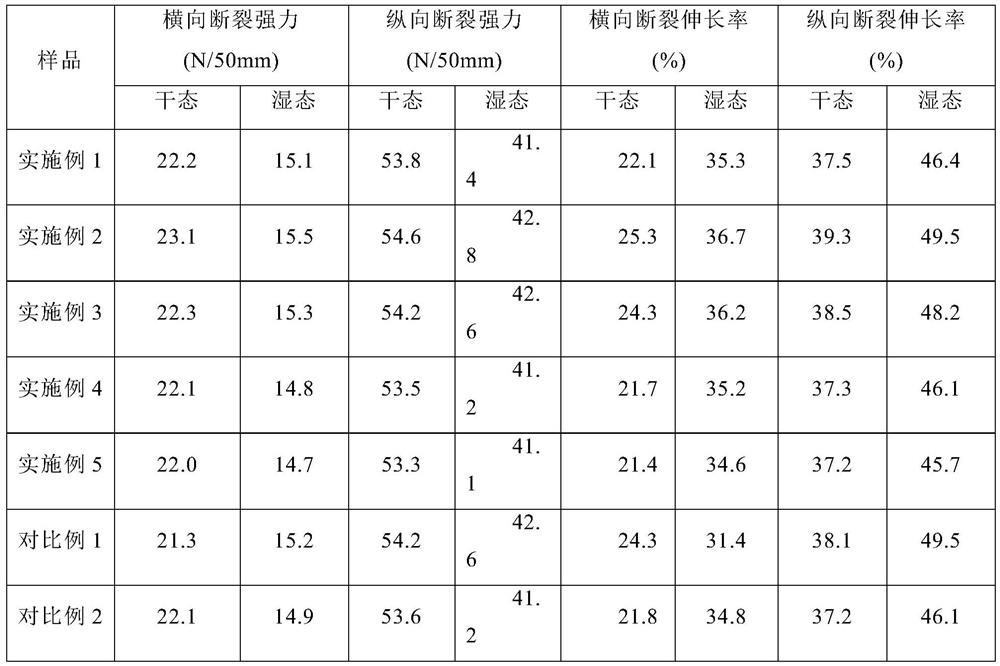

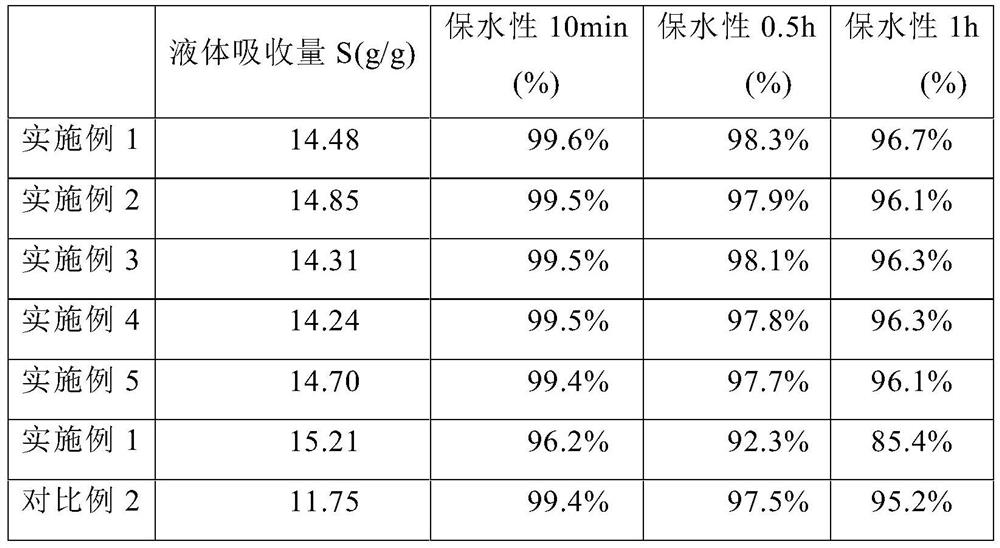

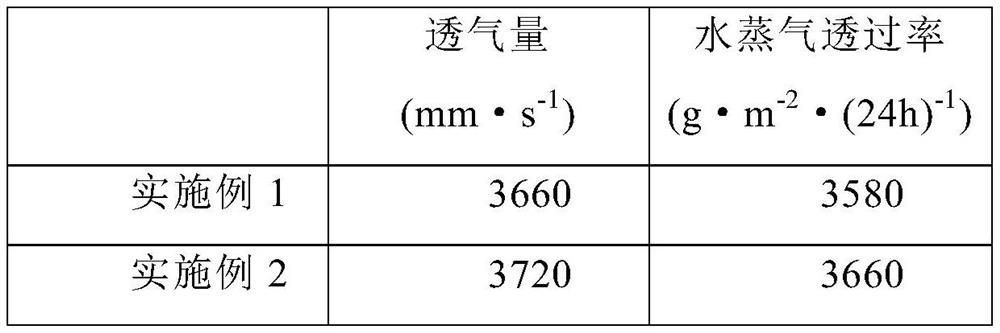

A kind of unidirectional water-conducting mask base material and preparation method thereof

ActiveCN112176525BMaximize nutrient absorption efficiencySoft and comfortableFibre typesNon-woven fabricsPolyesterFacial skin

The invention relates to a unidirectional water-conducting mask base material, which has a three-layer structure, the upper layer is hydrophobic modified polyester fiber, the middle layer is chitosan modified polyvinyl alcohol fiber, and the lower layer is viscose fiber; hydrophobic modified polyester fiber, The chitosan-modified polyvinyl alcohol fiber and the viscose fiber are combed into a net and compounded, and then reinforced by hydroentanglement. The present invention uses three fiber layers of different materials for compounding, and the obtained mask base material has one-way vertical water conduction, so that after the mask absorbs the nutrient essence, it can vertically transmit the nutrient essence from top to bottom in a directional manner, so that the absorption of nutrients The liquid efficiency is maximized, and the nutrient solution is not wasted. The surface density of each fiber layer and the angle of compounding, and the synergistic effect of the upper, middle and lower fiber layers make the resulting mask base material have excellent performance, unidirectional water-conducting performance, excellent water absorption and water retention performance, and good air permeability Moisture permeability and humidity. It ensures that the facial skin can fully absorb the nutrient solution, and the texture of the mask is comfortable and soft.

Owner:ZHEJIANG WANGJIN NONWOVENS CO LTD

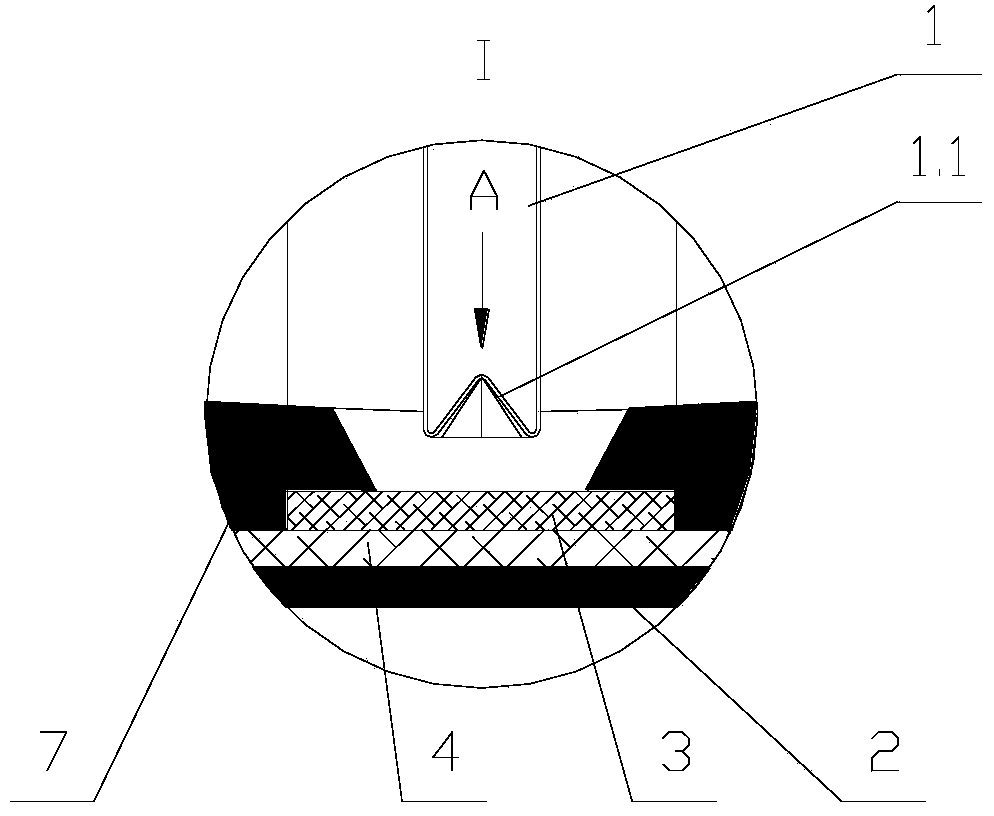

Quench cooler applied to entrained flow gasifier

ActiveCN102382685BLow costLarge liquid holding capacityGranular/pulverulent flues gasificationThermodynamicsSlag

The invention relates to a gasifier in coal chemical industry, and especially relates to a quench cooler of an entrained flow gasifier. The quench cooler is connected to the lower part of the gasifier, and comprises a shell and a quenched water distributor and a gas baffle tube; a firebrick support plate is provided at the upper part of the shell, the firebrick support plate is connected with the quenched water distributor through a flange, the lower part of the quenched water distributor is connected with the gas baffle tube; the quenched water distributor is in a hollow reverse round table shape, an annular cavity is formed between a lateral wall and an inside wall of the reverse round table shape, the lateral wall is communicated with a quenched water inlet arranged at the outboard of the shell of the quench cooler, a plurality of quenched water spray-holes are uniformly arranged on the inside wall of the reverse round table. The quench cooler has a simple structure which is capable of thoroughly solving the problem of slag hole blocking caused by a quenching ring; the gas baffle tube with a reinforcing rib has high deformation resistance which is capable of avoiding the deformation caused by large pressure difference between inside and outside of the quench cooler; the shell uses a material with temperature resistance level lower than that of the gasifier, so that the device cost can be reduced, and the gas can be fully cooled and the gas carrying water drops is avoided through the large liquid holdup and the heat exchange capability.

Owner:DONGFANG ELECTRIC CORP LTD

Star-star three-phase induction thermal reactor

ActiveCN109618439BSimple flow path structureLarge liquid holding capacityCoil arrangementsInduction heating apparatusChemical industryConductive materials

The invention discloses a star-star three-phase induction thermal reactor, which belongs to the technical fields of chemical industry, food and environment. Including: three-column magnetic circuit, excitation coil, magnetic coupling tube, and reaction chamber. Wherein the sample inlet and the sample outlet are arranged at the coupling intersection of the magnetic coupling tube group or the reaction chamber group. Each group of magnetic coupling tubes and reaction chambers are in a three-phase star connection, and the connection between the magnetic coupling tube group and the reaction chamber group is in a star-star structure; so that the conductive material or reaction medium in the reaction chamber will generate The effective potential difference is derived from the line voltage of the three-phase circuit, and its value is twice the normal phase voltage, which leads to a higher temperature rise efficiency of the material liquid or reaction medium, and realizes no external heat source or radiation. Without the action of external electrodes, the sample is heated efficiently, and the star-star three-phase induction thermal reactor has a single sample inlet and sample outlet, and the reaction chamber has a large liquid holding capacity. Under traffic, it has a higher processing capacity.

Owner:INDUC SCI CO LTD

An aerosol capture and separation device and method

InactiveCN104548760BRealize capture and recoverySolve pollutionGas treatmentDispersed particle separationTrappingEngineering

The invention discloses an aerosol collection and separation device, which comprises a separator, an exhaust hood and a liquid collection cone, wherein the separator is a cylinder, and comprises a barrel, a screw shaft, a screw blade, a baffle, an air inlet, liquid collection holes and a lower flange; the exhaust hood comprises a cone and an exhaust outlet; the liquid collection cone comprises an inverted cone, a liquid outlet and an upper flange; the exhaust hood, the separator and the liquid collection cone are connected in a vertical penetration manner; the exhaust hood is connected with the separator in a welding manner; the liquid collection cone is connected with the separator through the upper flange. The invention further provides a method for performing gas-liquid collection and separation by utilizing the aerosol collection and separation device. The device and the method have the characteristics of high separation speed, high separation efficiency, high liquid holdup, low pressure loss, low scaling and blocking rate and firm structure.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com