Gas-liquid mass transfer apparatus-plate tower

A technology of gas-liquid mass transfer and plate tower, which is applied in the direction of fractionation, etc., can solve the problems of small liquid holdup, solid blockage, failure to reach, etc., and achieve the effect of large operating flexibility, small resistance, and good gas-liquid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

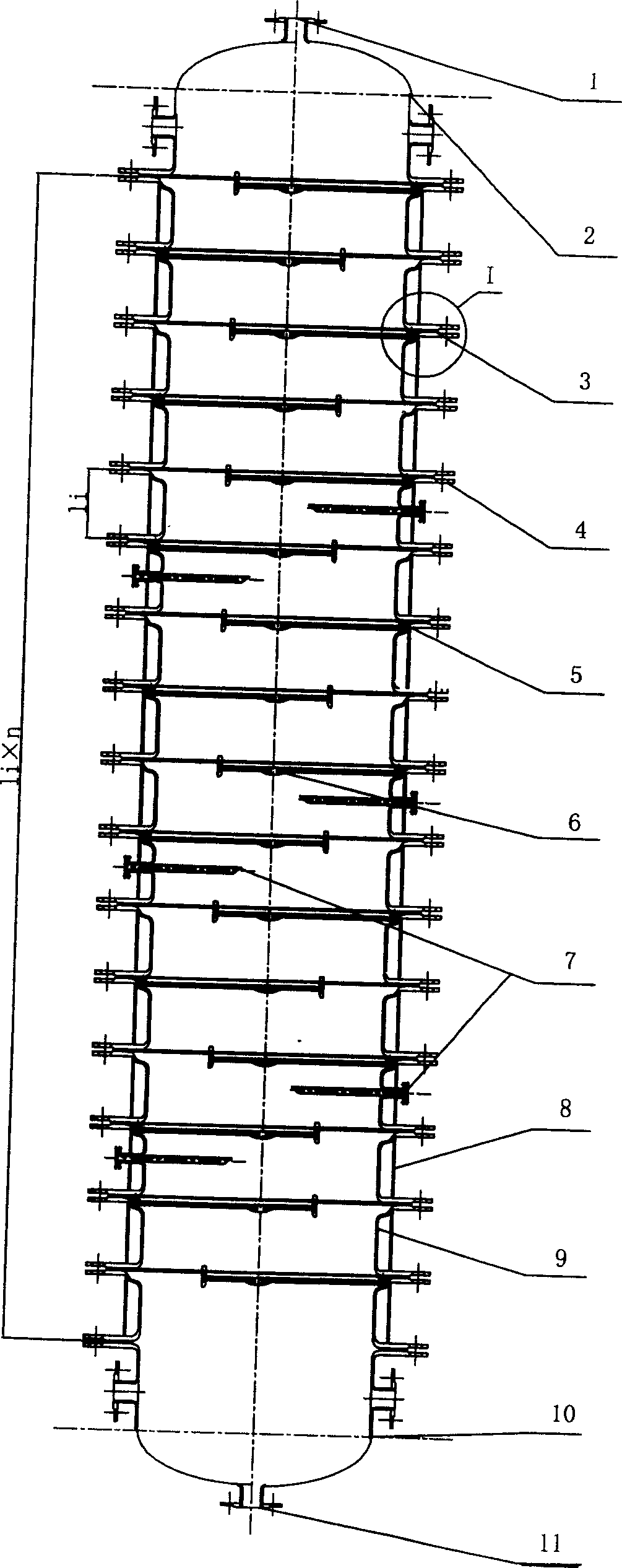

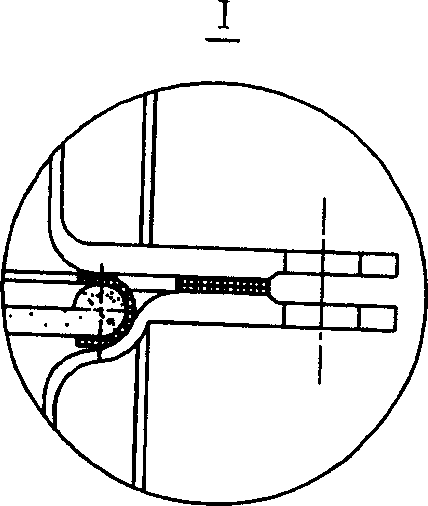

[0014] Such as figure 1 As shown, the upper head (2) and the tower section (9), the tower section (9) and the lower head (10) are connected through the flange (4), and the sealing ring (3) is arranged at the joint; on the upper head ( 2) There is an upper material port (1) on the top, and a lower material port (11) is provided on the lower head (10); the tray (6) is placed in the groove at the upper end of the tower section (9); the tray (6) The periphery is fixed with gasket (5) and plays a sealing role. The liquid material enters from the upper material port (1), and flows down step by step to form a liquid curtain to the lower tray (6), and the gas enters through the inlet pipe (7), and rises step by step around the plate from bottom to top to intersect with the liquid curtain. flow contact reaction. The tower section is provided with a jacket (8) for heat exchange.

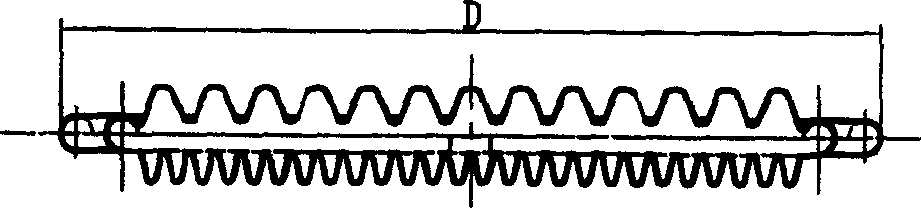

[0015] Tray (6) is directly made of materials such as metal, acid-resistant pottery, and also can be mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com