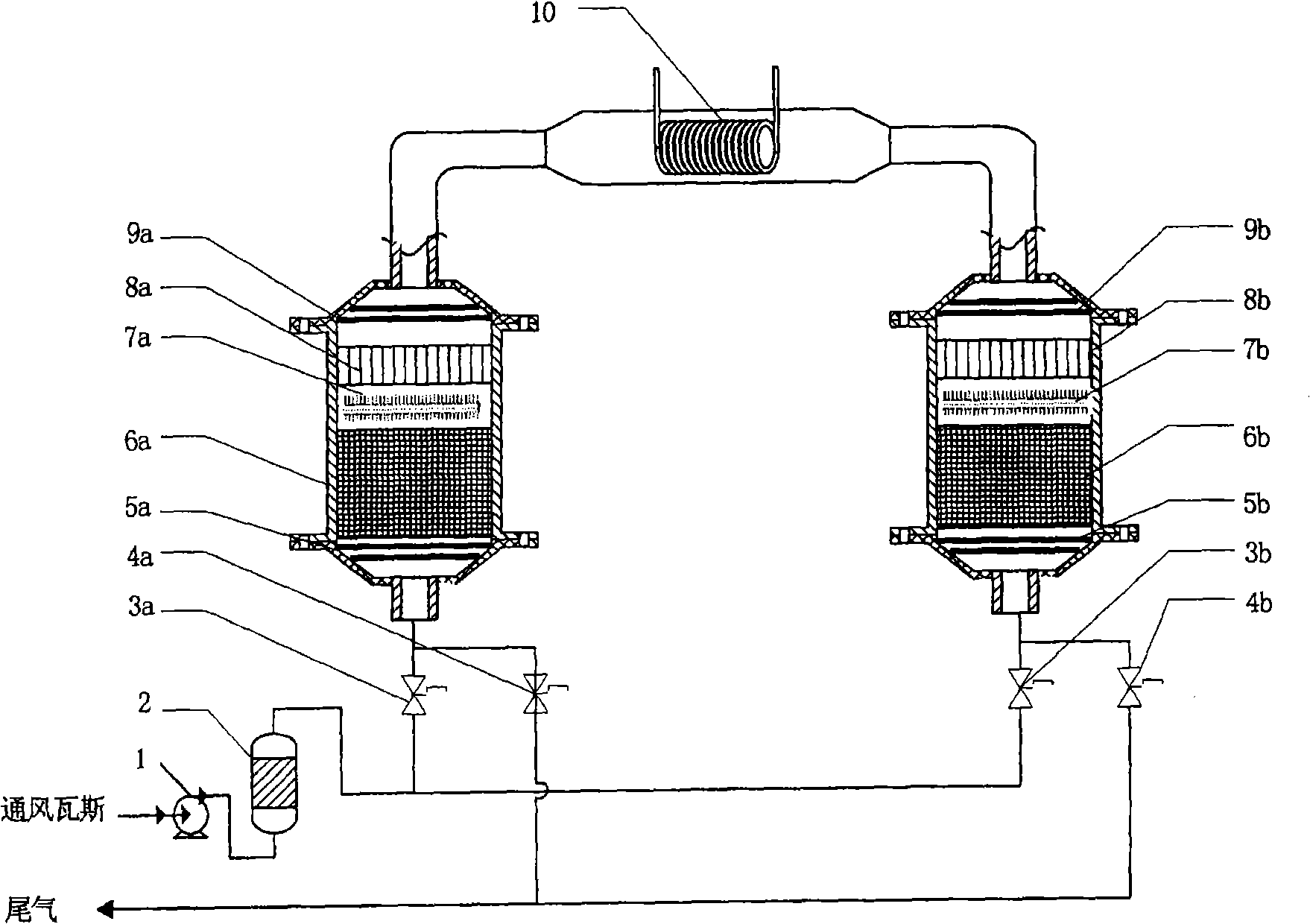

Apparatus for comprehensively utilizing coal mine to ventilate mash gas

A ventilation gas and coal mine technology, which is applied in the field of comprehensive utilization of coal mine ventilation gas, can solve the problems of not considering heat recovery and utilization, difficulty in meeting industrial applications, and difficult temperature control, achieving high strength, low resistance drop, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

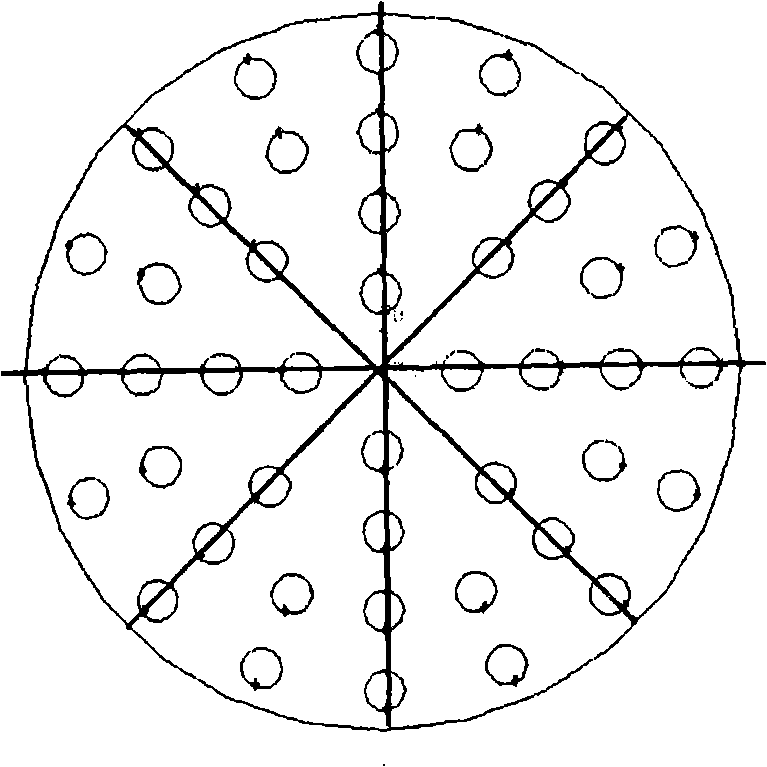

[0047] Applying the above design scheme, a set of processing capacity of 20m 3 / h ventilation gas comprehensive treatment device, its external dimensions are 934mm×420mm×120mm. In order to have a clearer understanding of the characteristics of the ventilation gas treatment device under different working conditions, 42 temperature measurement points were arranged in the device, see Figure 4 . When the inlet concentration of methane is 4000ppm and the flow rate of air is 333.3L / min, the axial temperature distribution of the reactor under different switching frequencies (0.5min~1.5min) (Figure 5), it can be seen that the axial temperature distribution of the reactor It is a typical "saddle-shaped" distribution; the temperature on the catalysts on both sides of the U-shaped reactor is controlled at 550 ° C, and the conversion rate of methane can be maintained above 95%, see Image 6 . And the pressure drop of the device is about 3kPa, see Figure 7 for details. At the same tim...

Embodiment 2

[0049] The reaction device, temperature measurement and pressure measurement scheme are the same as those in Example 1. The inlet concentration of methane is 3000ppm, the flow rate of air is 666.6L / min, and when the temperature on the catalysts on both sides of the U-shaped reactor is controlled at about 650°C, the conversion rate of methane can reach more than 98%; and it can produce 5 grams of superheated steam at 270°C. The resistance drop of the bed layer is about 5kPa, see Figure 7 for details. The temperature distribution in the axial direction of the reactor is the same as that in Example 1, showing a "saddle-shaped" distribution; the temperature of the regenerator, catalyst, intermediate heat-taking part, and combustion tail gas outlet is the same as that in Example 1, which changes periodically with the flow direction.

Embodiment 3

[0051] The reaction device, temperature measurement and pressure measurement scheme are the same as those in Example 1. The inlet concentration of methane is 3000ppm, the flow rate of air is 333.3L / min, the temperature on the catalyst on the left side of the U-shaped reactor is about 360°C, and the temperature on the right side is about 550°C, and the conversion rate of methane can reach 90%. left and right, see Image 6 ; And it can produce 3 grams of superheated steam at 200 ° C per minute. The temperature distribution in the axial direction of the reactor is the same as that of Example 1, showing a "saddle-shaped" distribution; the temperature of the regenerator, catalyst, intermediate heat-taking part, and combustion tail gas outlet is the same as that of Example 1, which changes periodically with the flow direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com