Patents

Literature

74results about How to "Less drag drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

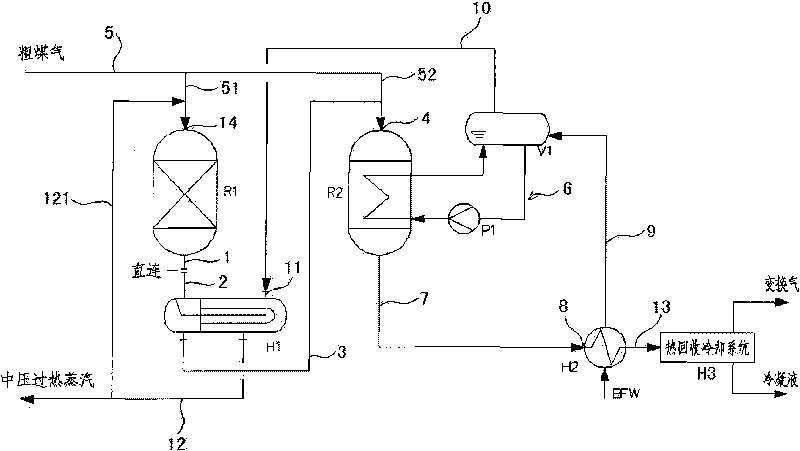

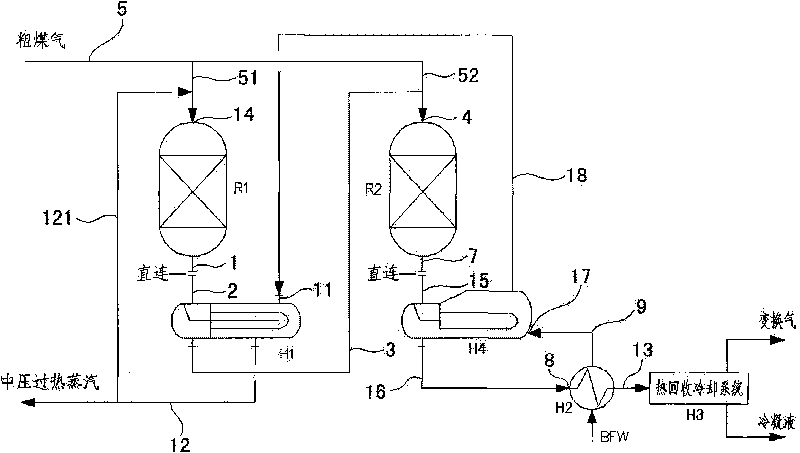

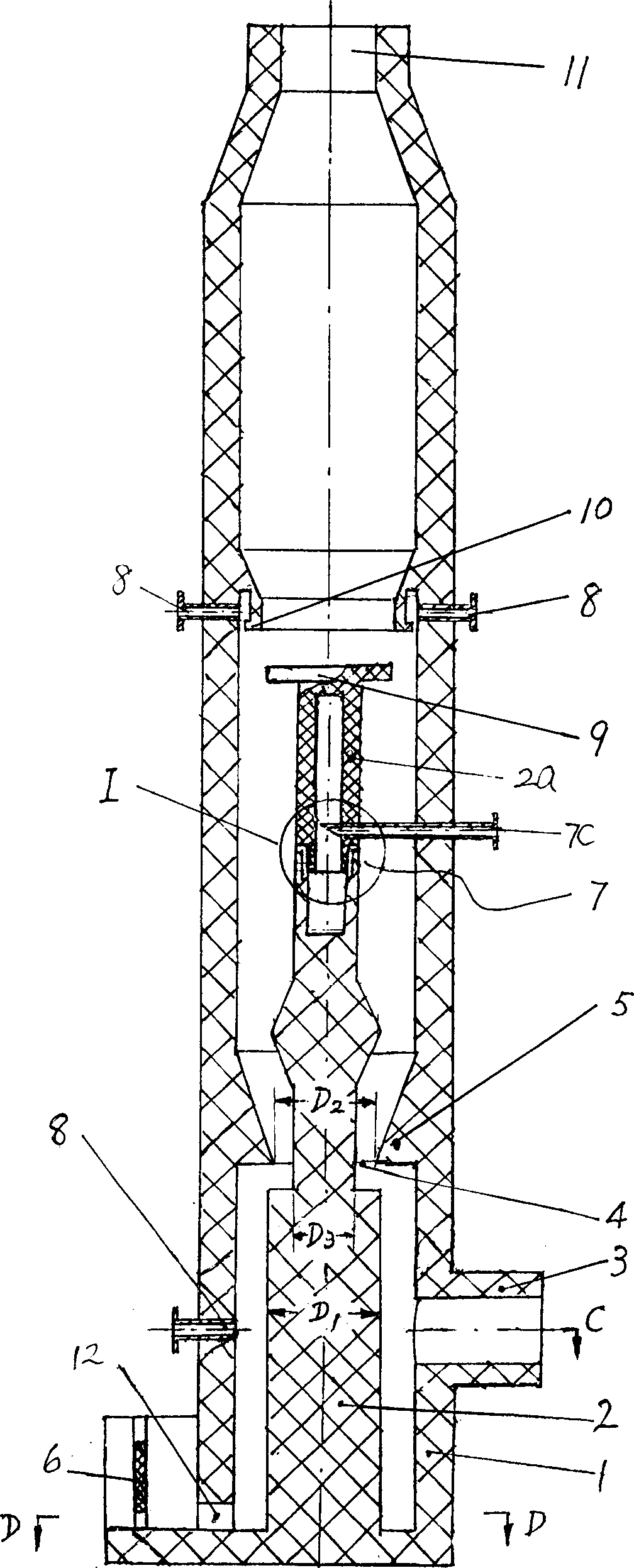

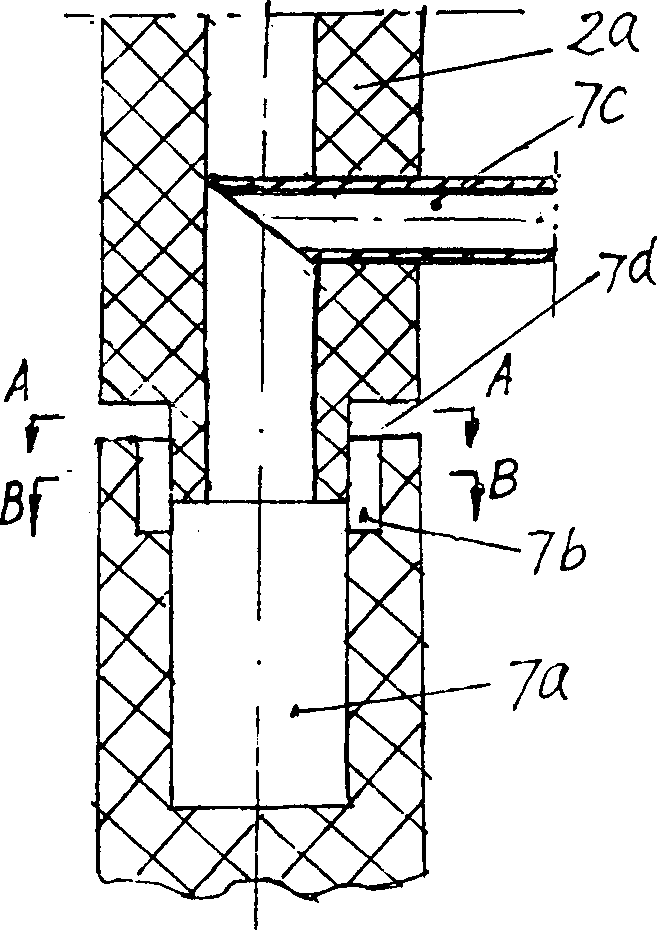

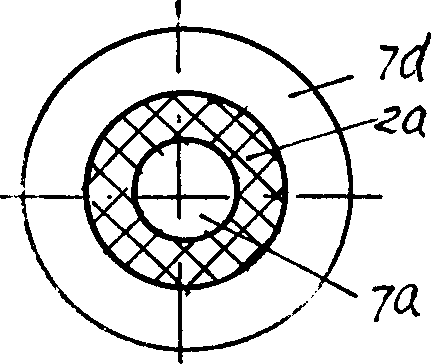

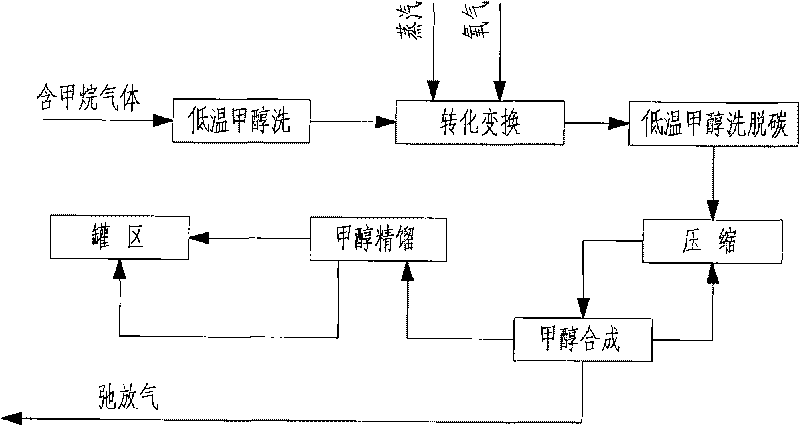

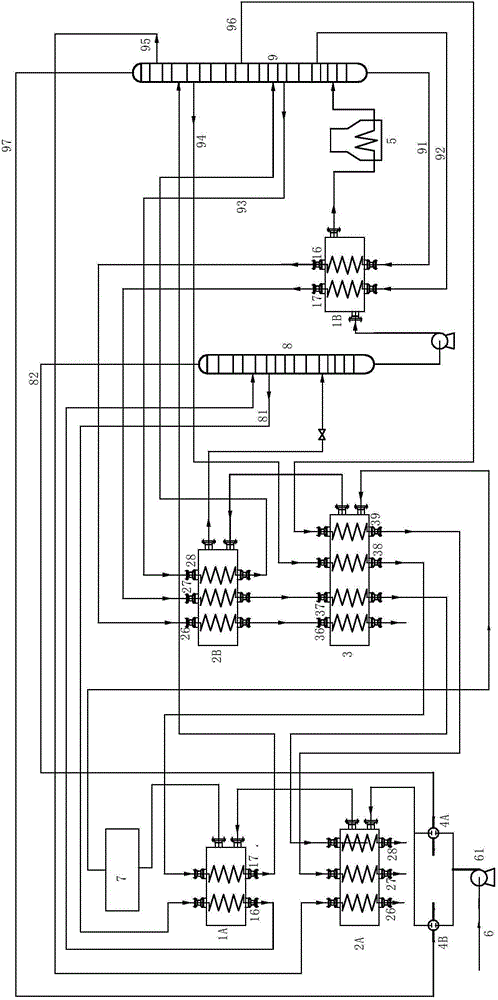

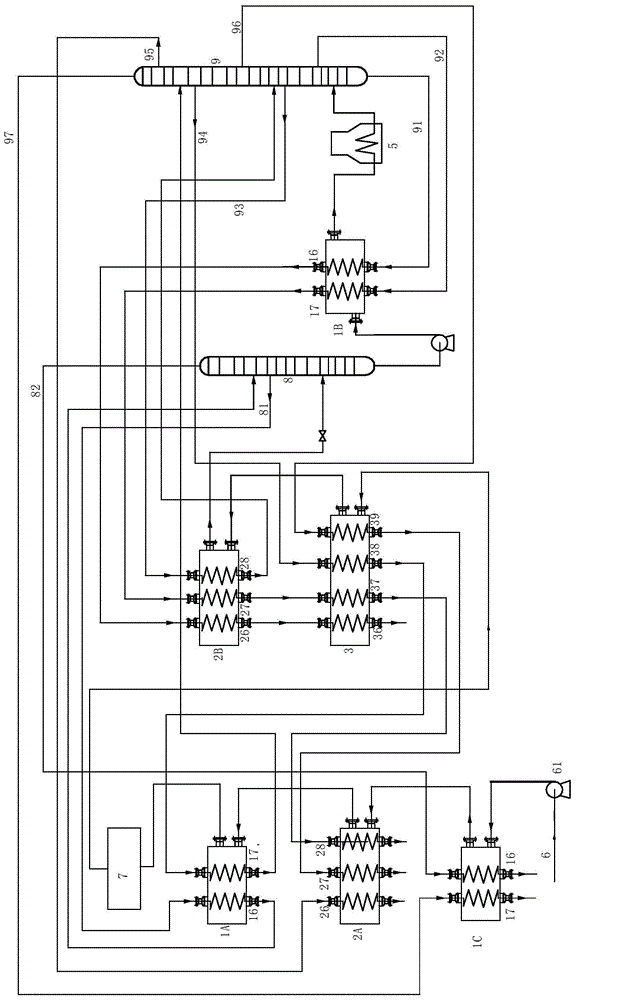

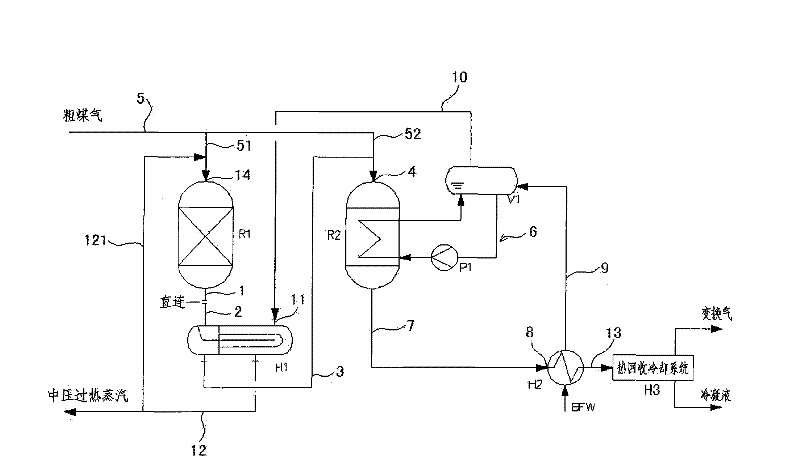

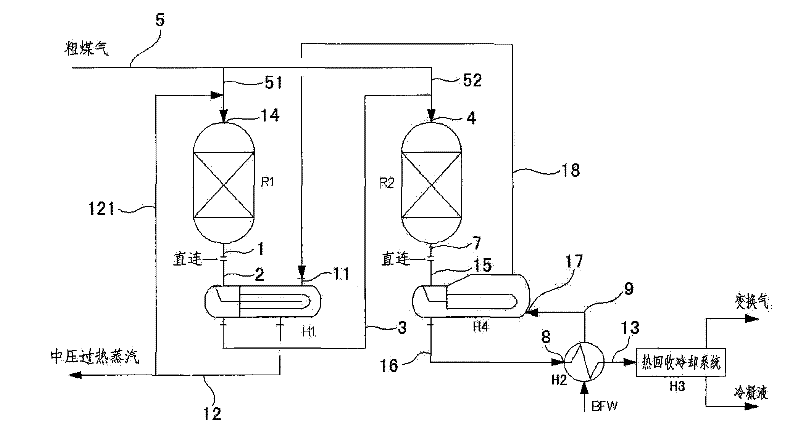

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

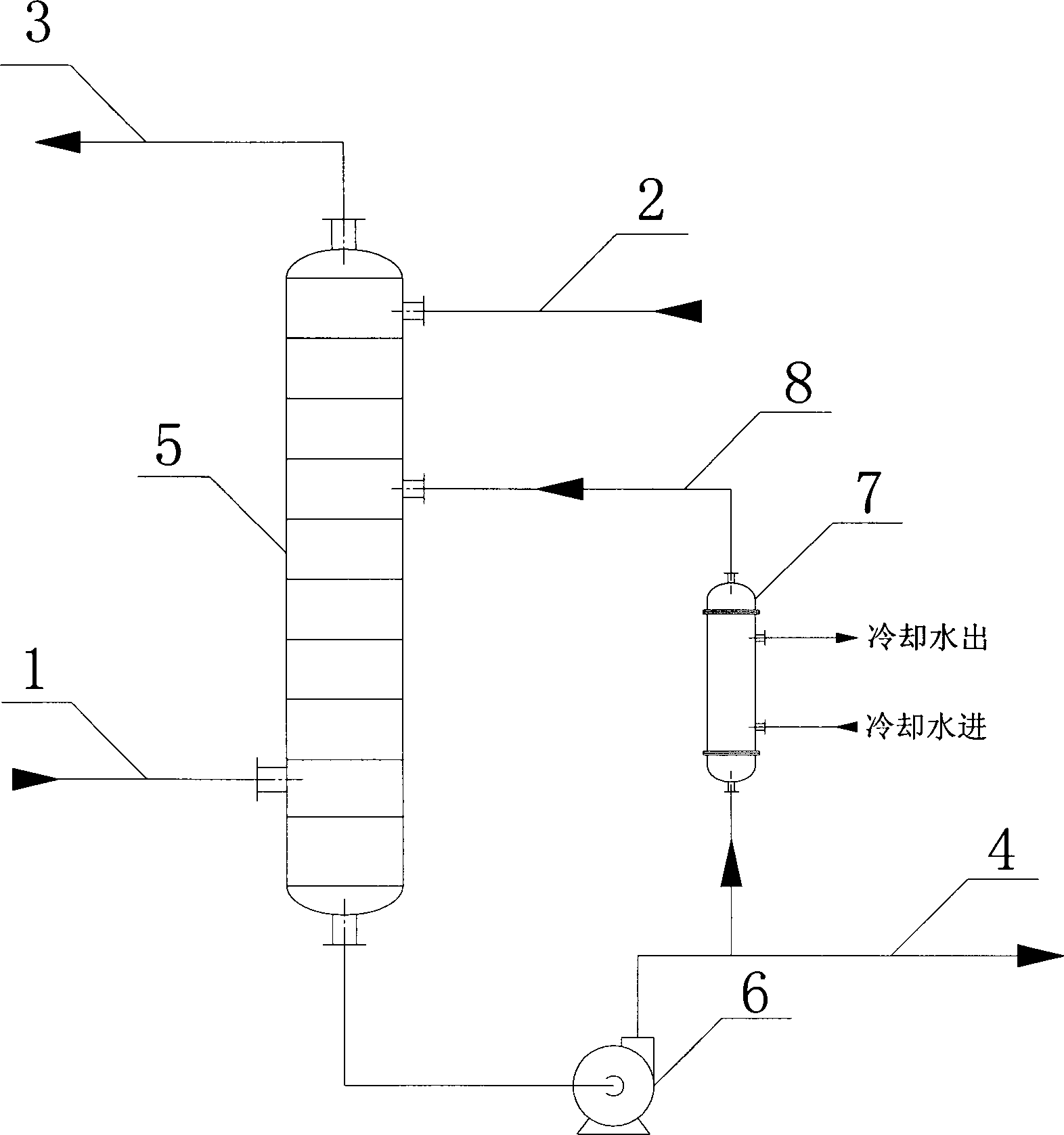

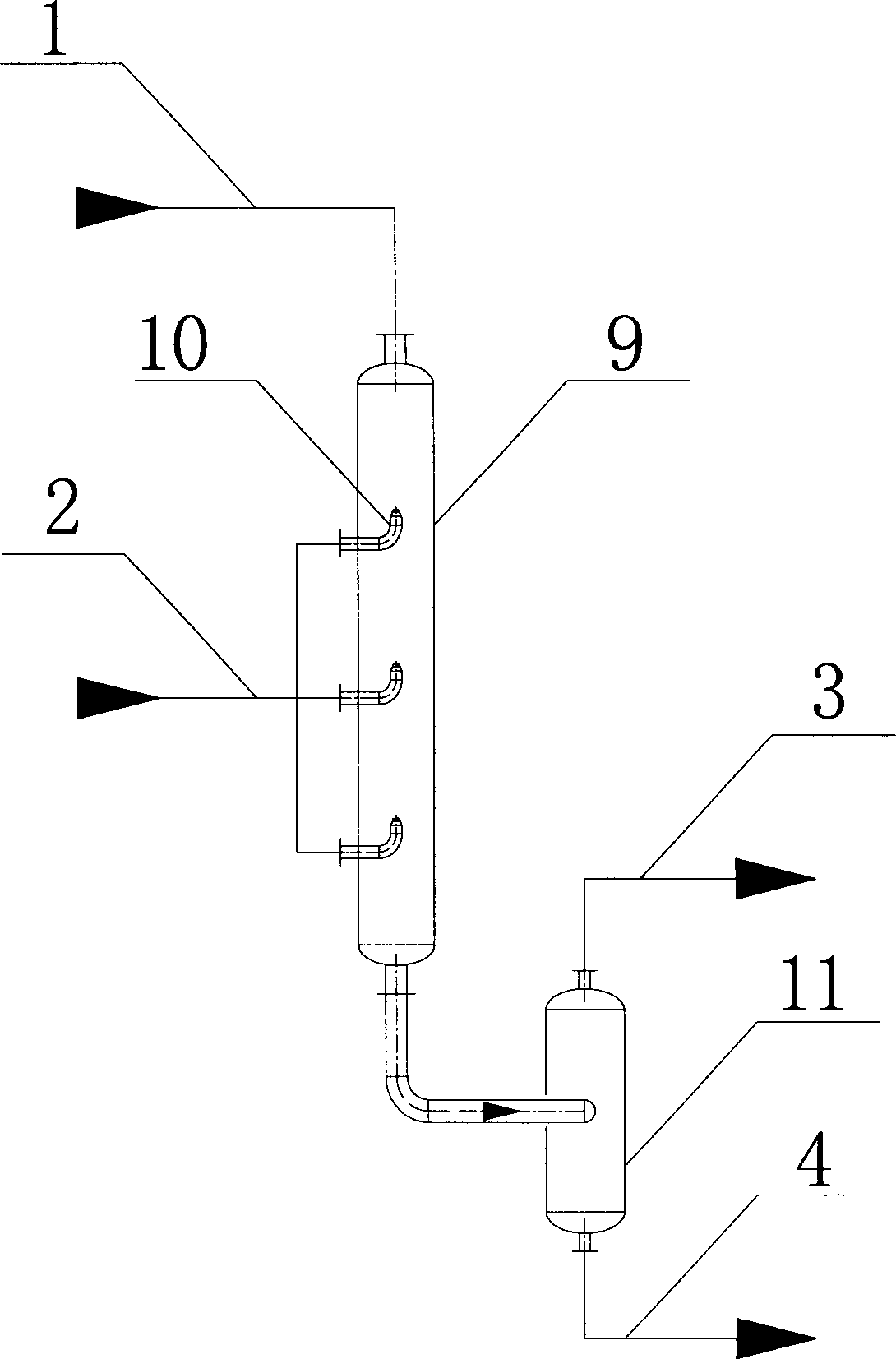

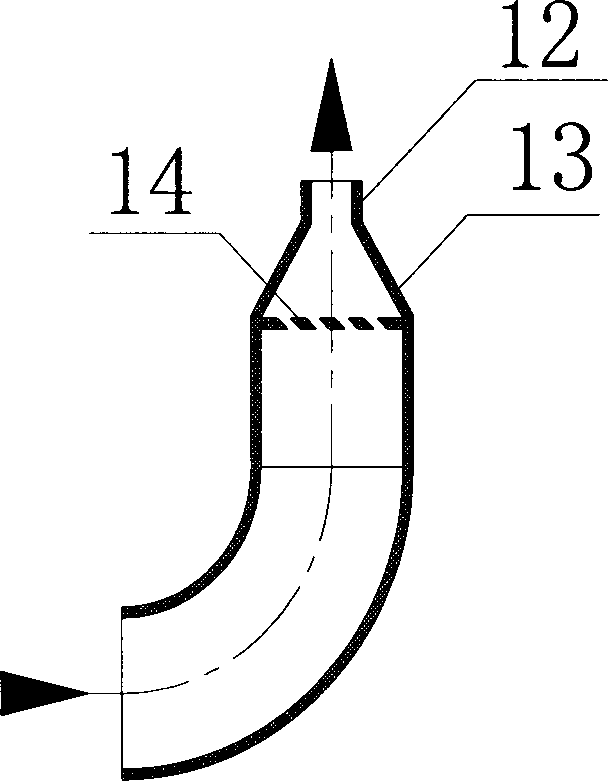

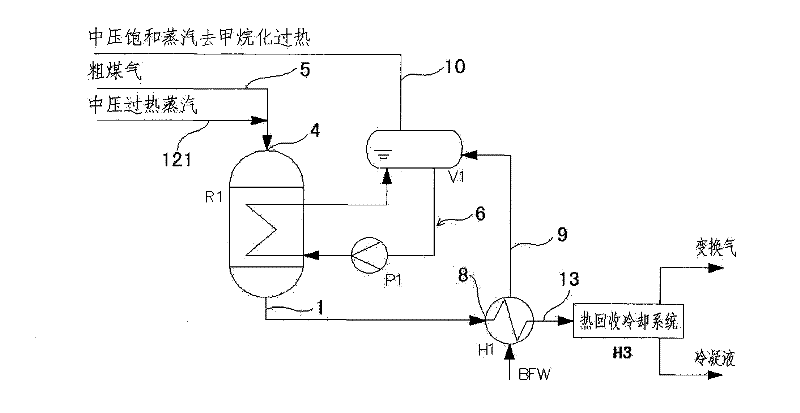

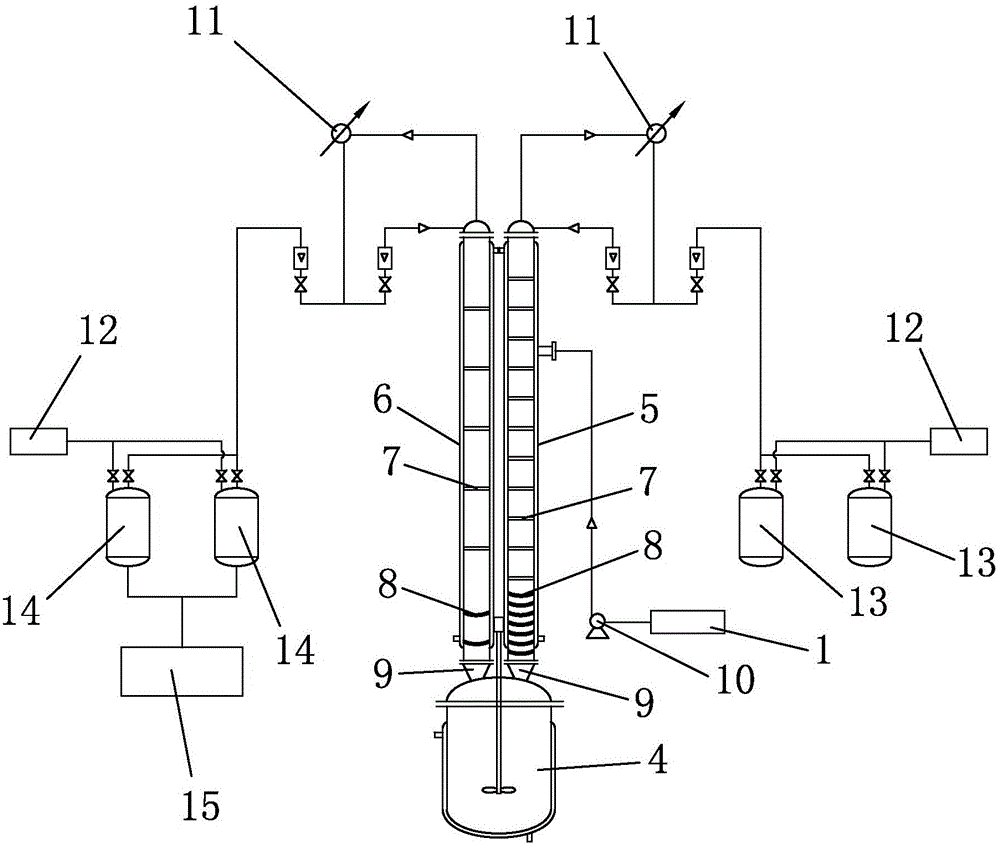

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

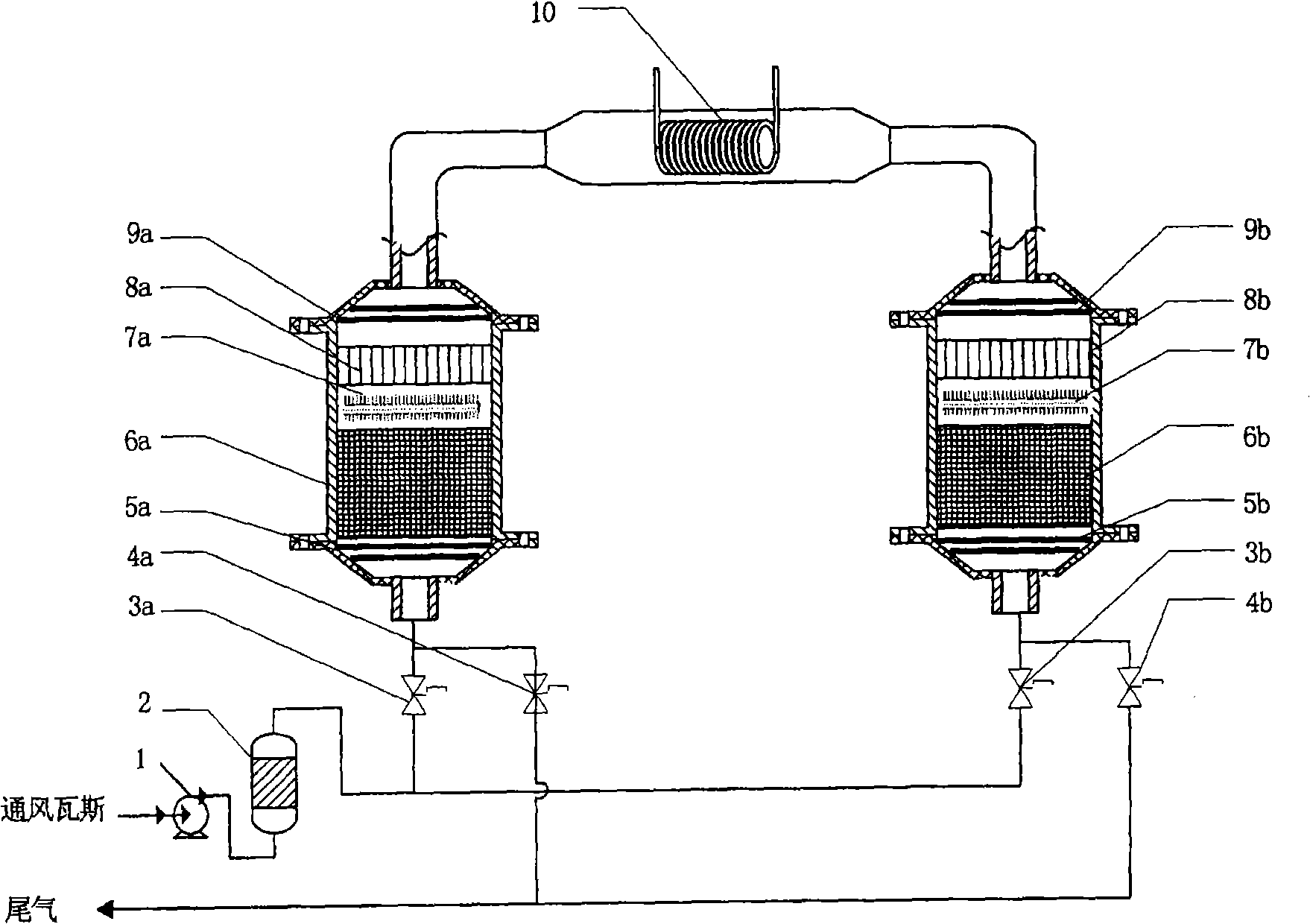

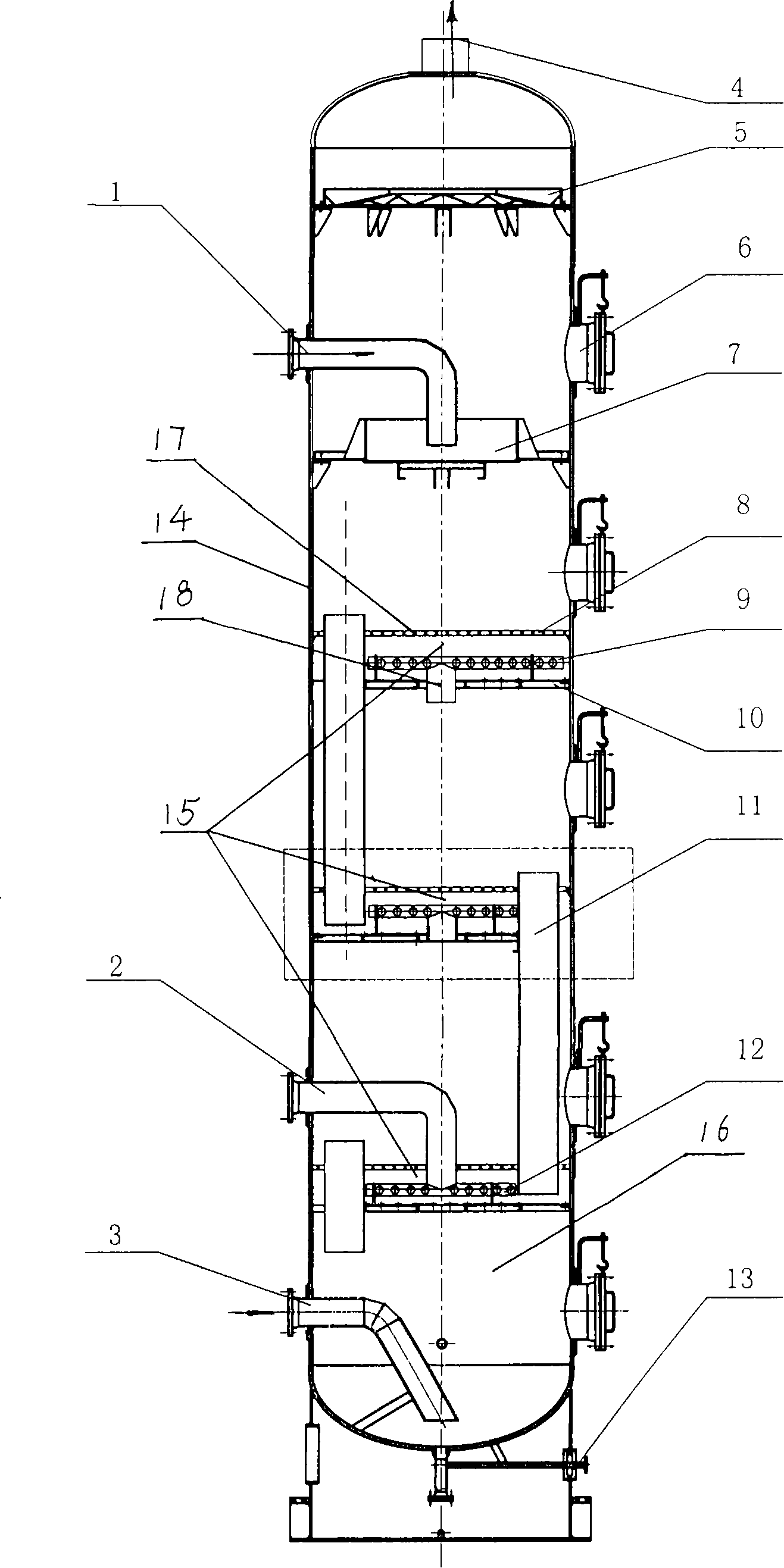

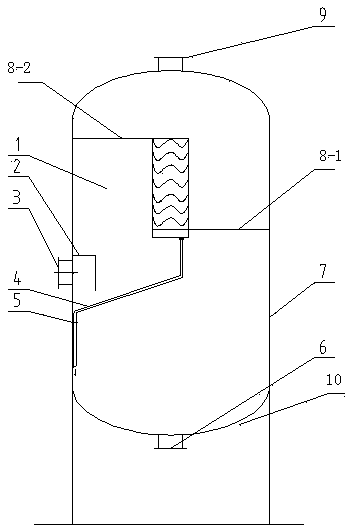

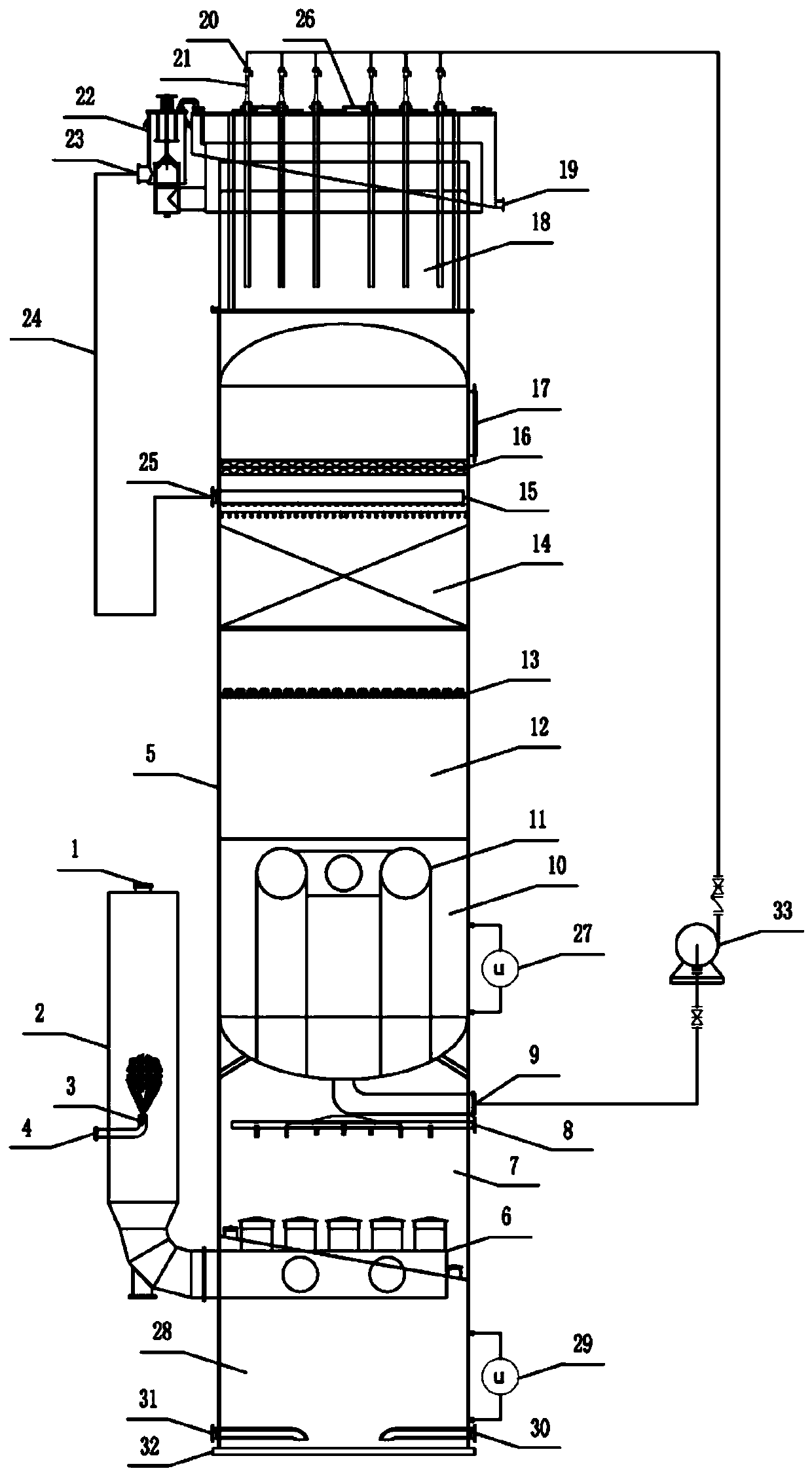

Apparatus for comprehensively utilizing coal mine to ventilate mash gas

InactiveCN101275744AImprove anti-blocking performanceHigh strengthIncinerator apparatusHoneycombProcess engineering

A device for the coal ventilation gas comprehensive utilization, a reactor outlet end with the same structure is connected into a U-shape reactor through a heat taking device; the entrance of the reactor is filled with a honeycomb heat retaining mass; the outlet end is a catalyst bed layer; an electric heater is arranged between the heat retaining mass outlet end and the catalyst bed layer; the entrance of the raw gas is provided with a valve set for controlling the conversion of the current direction in the reactor; the raw gas enters the reactor, and generates the catalytic combustion on the catalyst bed layer; a saddle type bed temperature distribution is realized in the reactor by processing the periodic switch through the current direction of the reaction gas, the burning end gas is fetched out by the heat taking device. The invention has higher heat reclaim efficiency; when the concentration of the methane in the ventilation gas and the flow of the ventilation gas change, the high efficiency selfheating operation can be realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

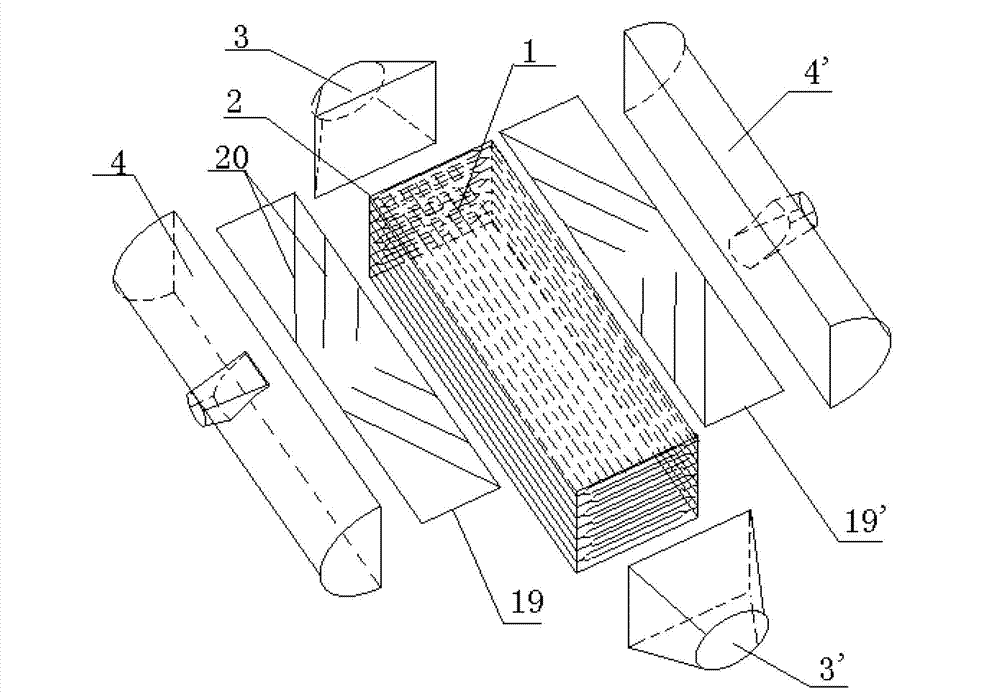

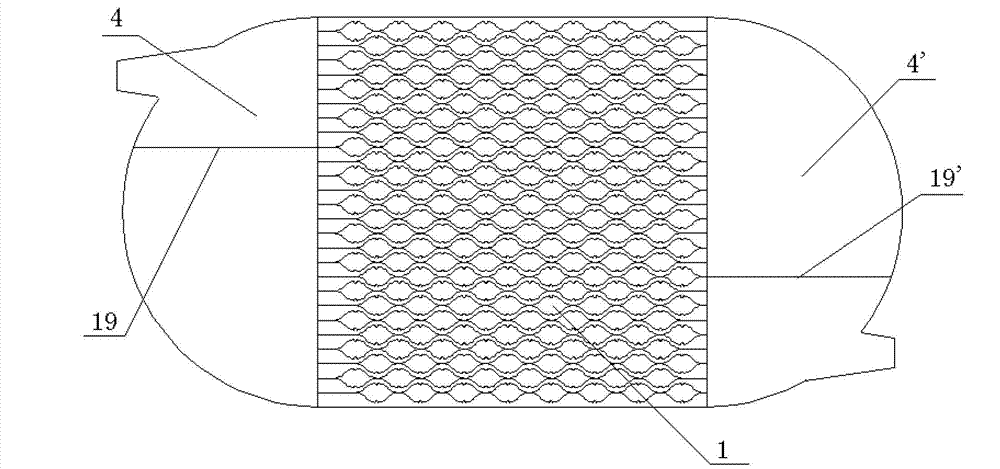

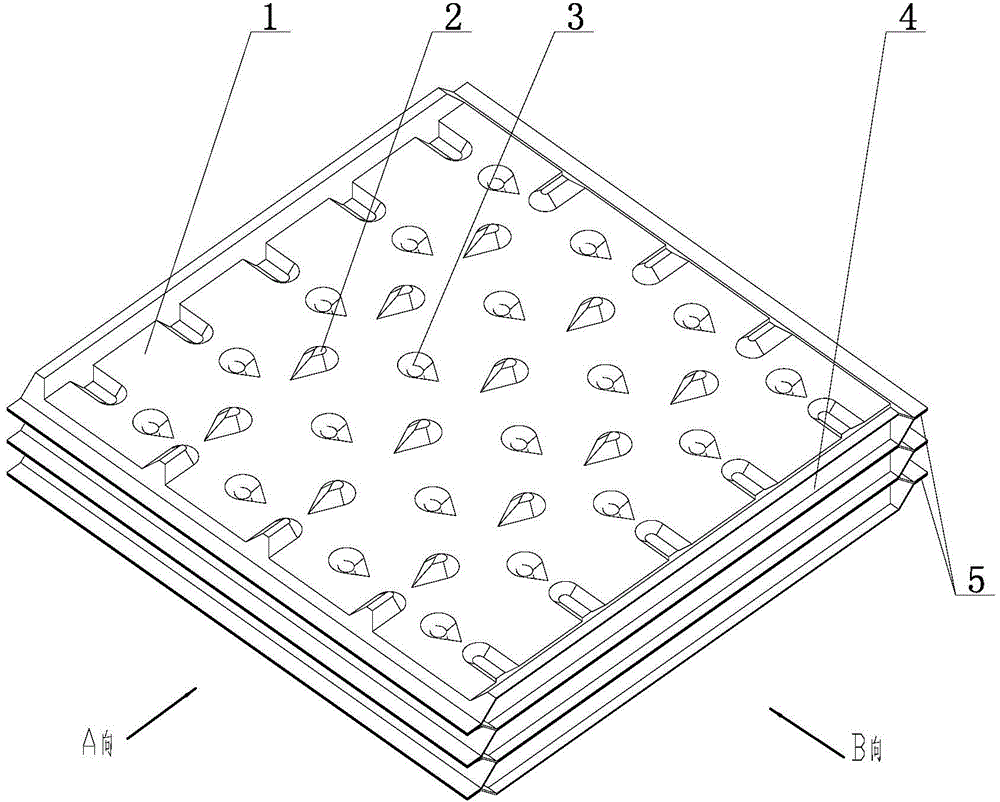

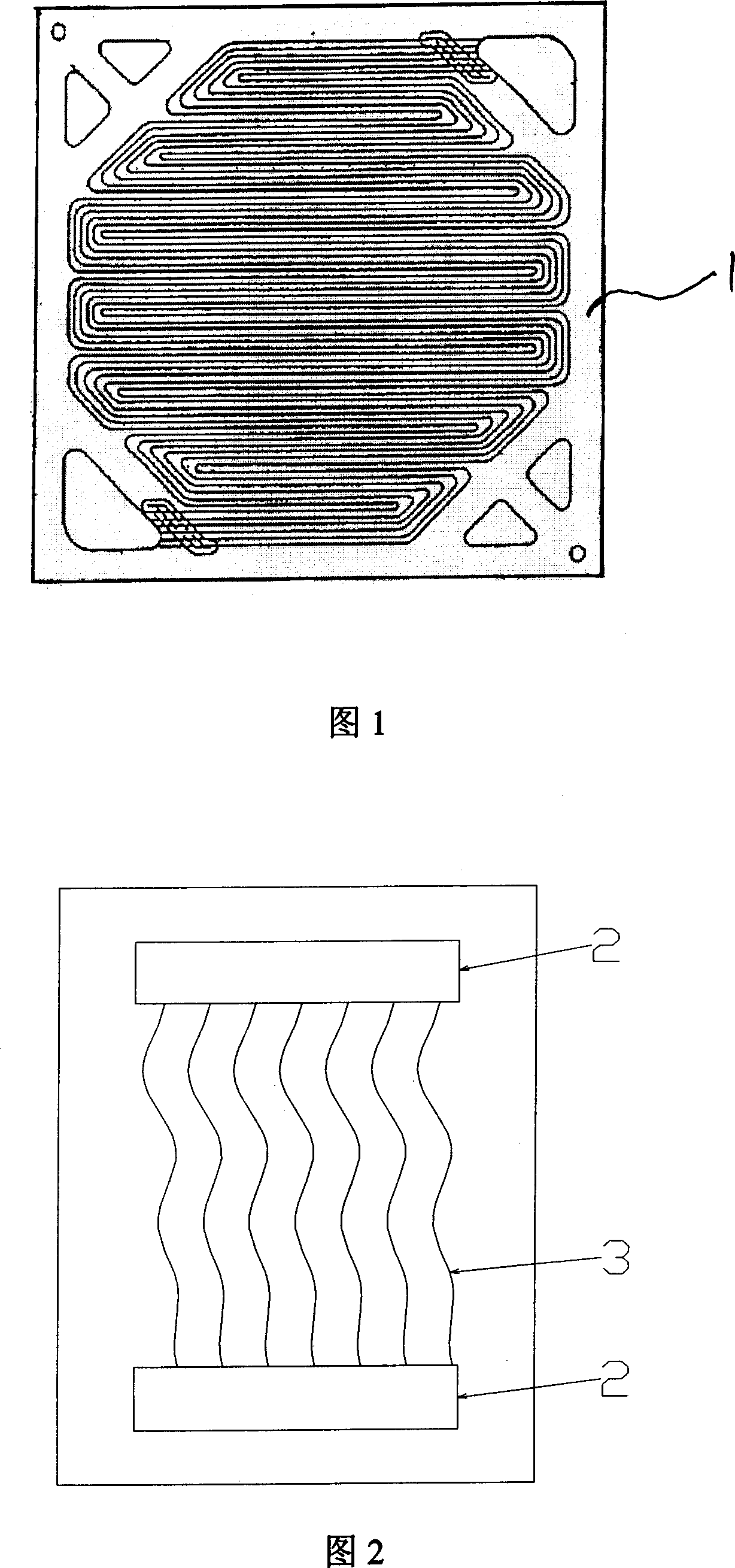

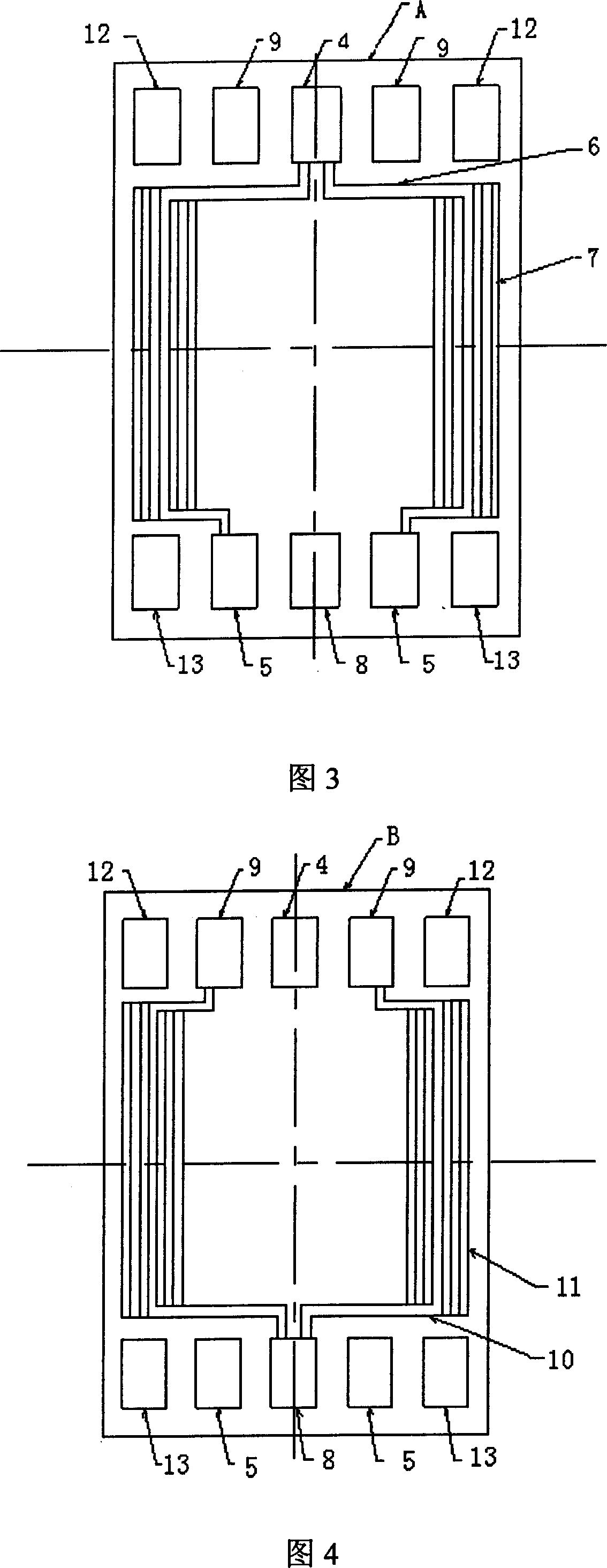

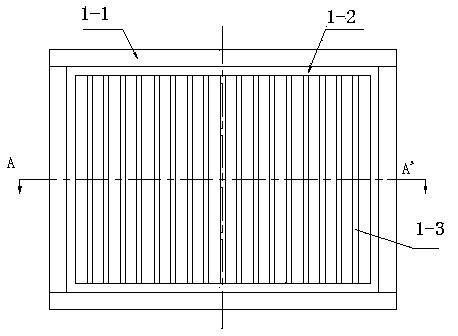

Novel plate type economizer

ActiveCN102954459AIncreased turbulenceSolve the problem of large differences in water and flue gas flowHeat exchanger casingsLaminated elementsPower stationHeat transfer efficiency

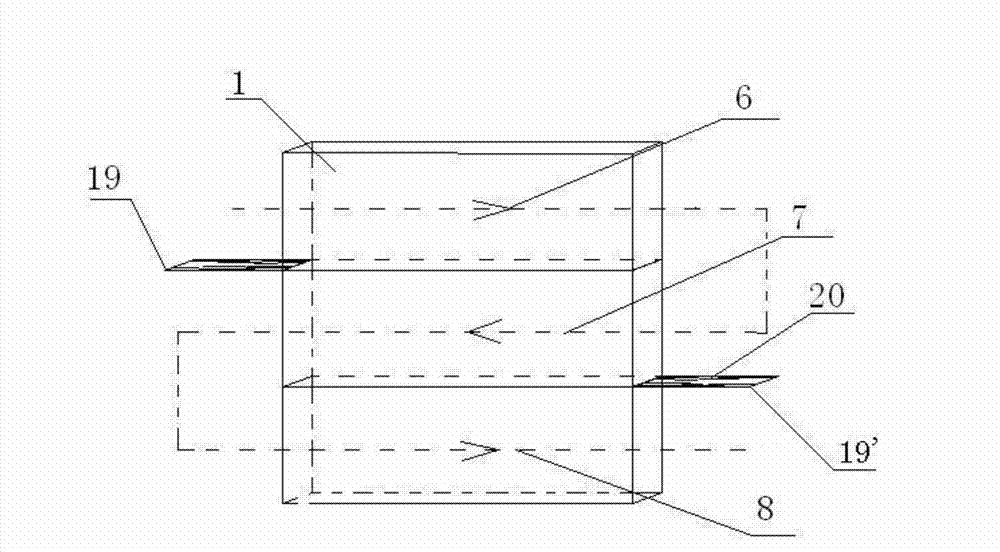

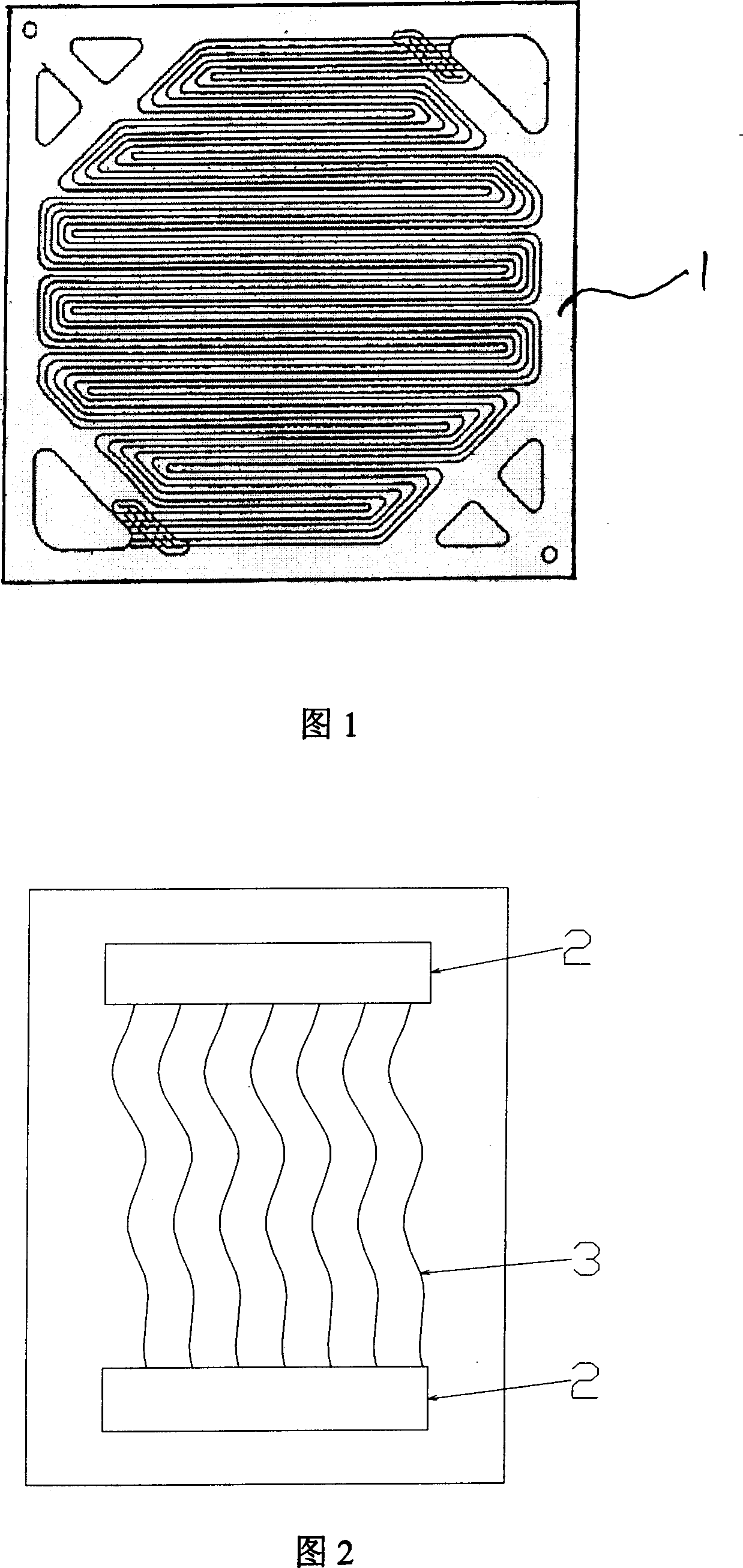

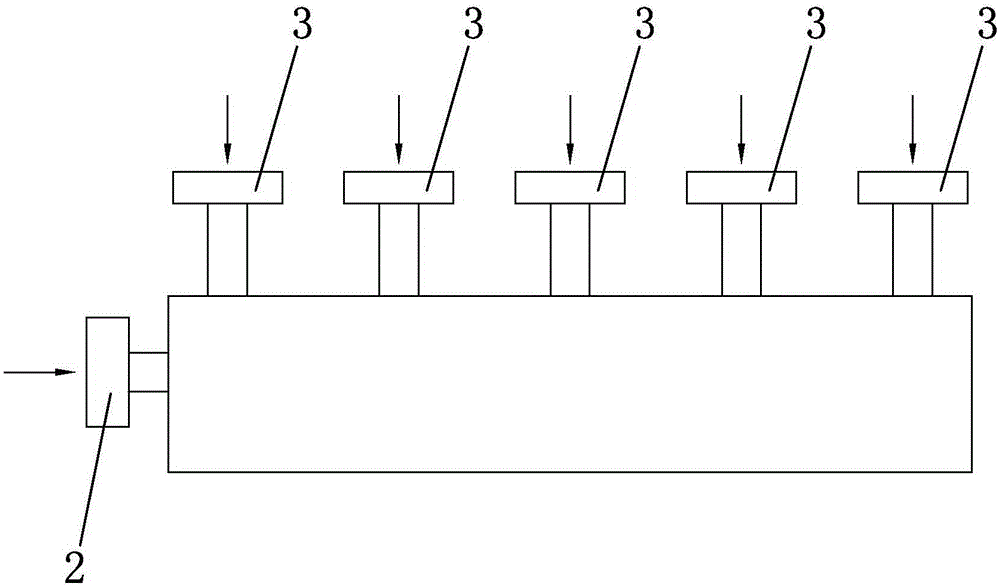

The invention belongs to the technical field of power station boiler afterheat recycling energy-saving devices and relates to a plate type economizer. The plate type economizer comprises a corrugated plate heat exchange core (1), a heat exchanger housing (2), smoke inlet-outlet pipelines (3, 3') and water inlet-outlet water tanks (4, 4'), wherein the front side and the back side of the heat exchanger housing (2) are respectively connected with the smoke inlet-outlet pipelines (3, 3'); the left side and the right side of the heat exchanger housing (2) are respectively connected with the water inlet-outlet water tanks (4, 4'); and clapboards (19, 19') are arranged inside the water inlet-outlet water tanks (4, 4'). With the adoption of the plate type economizer, the problem that the flow differences of water and smoke are large is solved, the turbulence intensity of smoke flow is increased, and the heat transfer efficiency is improved; and a smoke flow channel has the function of self-cleaning dusts, so dust accumulation to block does not easily happen.

Owner:NANJING TONGCHENG ENERGY SAVING & ENVIRONMENTAI PROTECTION EQUIP RES INST CO LTD

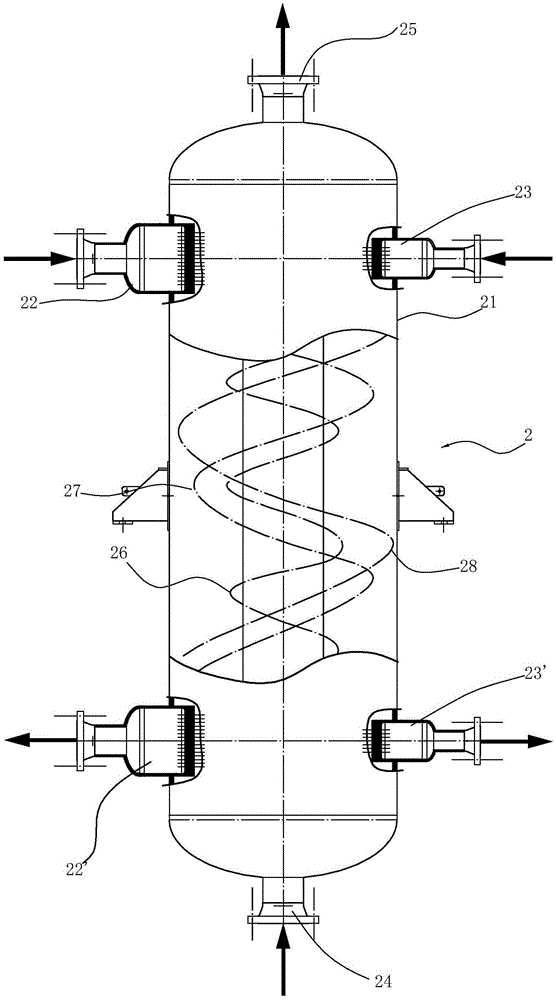

High-efficient gas-liquid mass transferring device

ActiveCN101108299AIncrease contact areaImprove the degree of purificationDispersed particle separationChemical reactionProduct gas

The invention discloses a high efficient gas and liquid mass transfer rig. A defoaming plate, a liquid distributor and a multilevel gas and liquid exchanging device is arranged in a tower body up and down, the bottom of the tower body is a liquid collecting chamber, the top of the tower body is an air gate; the invention uses the character of H2S and aqueous alkali which can proceed chemical reaction quickly and adopts gas and liquid direct contact, makes liquid and gas moving contact, turbulent motion mass transfer, the contact area between the liquid and the gas is increased greatly, makes the gas realize full mixing contact with the liquid and improves the purifying degree. The invention doesn't use filling, which solves the blocking problem in the filling desulfurizer and has simple structure, convenient installation, large operating flexibility, low tower resistance, low production cost and remarkable practical application effect.

Owner:CHANGCHUN DONGSHI TECH & TRADING INDAL

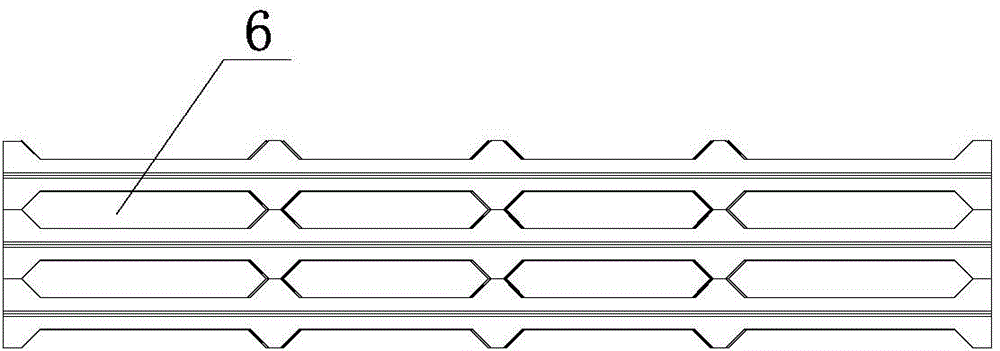

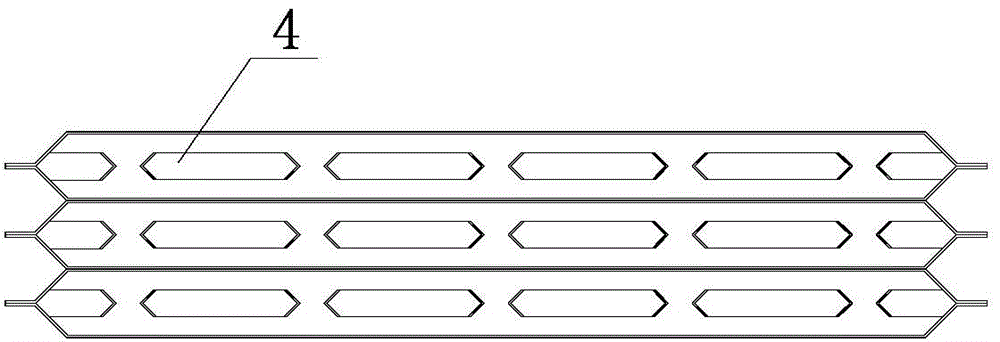

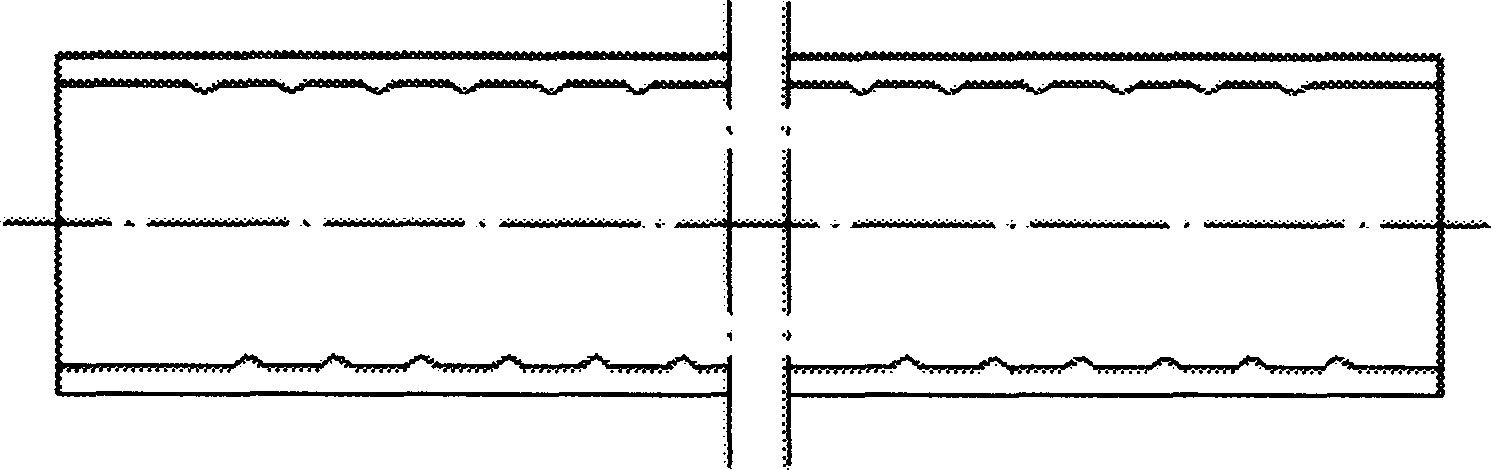

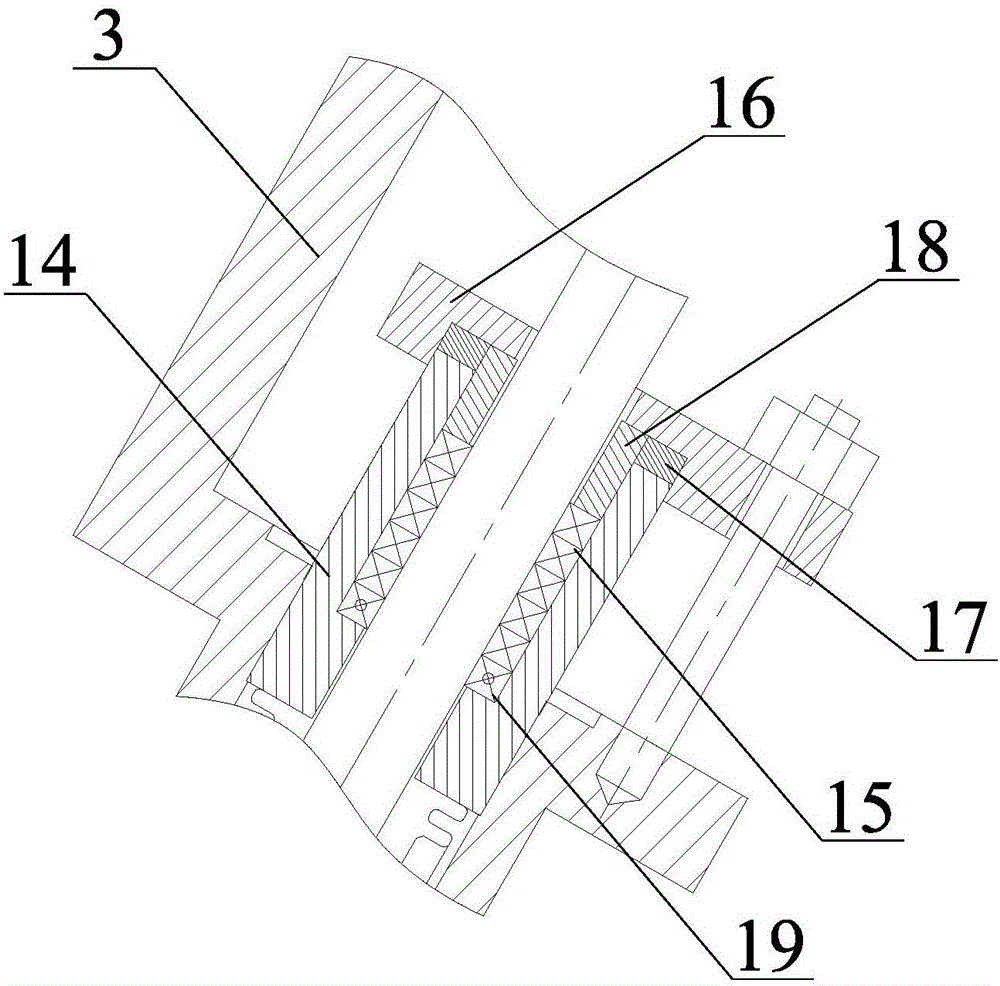

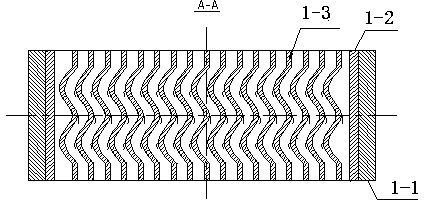

Self-supporting wide gap heat exchanging element

ActiveCN104696983ASelf-supportingReduce manufacturing costCombustion processIndirect carbon-dioxide mitigationFlue gasWide gap

The invention is applicable to the field of air cold medium pre-heating and particularly relates to a self-supporting wide gap heat exchanging element. The self-supporting wide gap heat exchanging element comprises a plurality of plate pairs which are overlapped layer by layer; each plat pair comprises upper and lower plate sheets which are arranged oppositely; a plurality of rows of convex ripples and concave ripples are distributed on the upper surfaces of the plate sheets along the same axis direction; the convex ripples and concave ripples are obtained by upwards and downwards pressing and molding the plate sheets; the convex ripples and concave ripples are distributed at intervals; the positions of the convex ripples and concave ripples on the upper plate sheets in the plate pairs correspond to the positions of the convex ripples and concave ripples on the lower plate sheets in the plate pairs; one group of opposite edges of the plate sheets are upwards folded and are transited into planes; the other group of opposite edges of the plate sheets are downwards folded and are transited into planes; the two adjacent folding edges in each plate pair are welded to form an air channel; the two adjacent plate pairs are symmetrical up and down, and the adjacent folding edges between the two adjacent plate pairs are welded to form a flue gas channel. The self-supporting wide gap heat exchanging element has the advantages that a wide gap channel can be combined, dirt and dust are not easy to deposit, the resistance fall also can be reduced and the heat exchanging efficiency is sufficiently improved.

Owner:SHANDONG WINTECH TECH CO LTD

High efficiency wet desulfuration and dust-removing device

InactiveCN1391978AWell mixedFull desulfurization and dust removalUsing liquid separation agentFlue gasEngineering

The efficient wet desulfurizing and dusting device especially for coal burning boiler in power plant has one vertical tower with inner tower in its center, tangent flue gas inlet pipe and flue gas outlet pipe, lime water and cinder output pipe, tangent chemical nozzle and water retaining ring. It features the inwards protruding ring set over the flue gas inlet pipe to make fluid passage turned first to tower center and then upwards, and one overflowing unit in the center of the tower to overflow downwards the showing chemical liquid. The present invention has high desulfurizing and dusing effect.

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

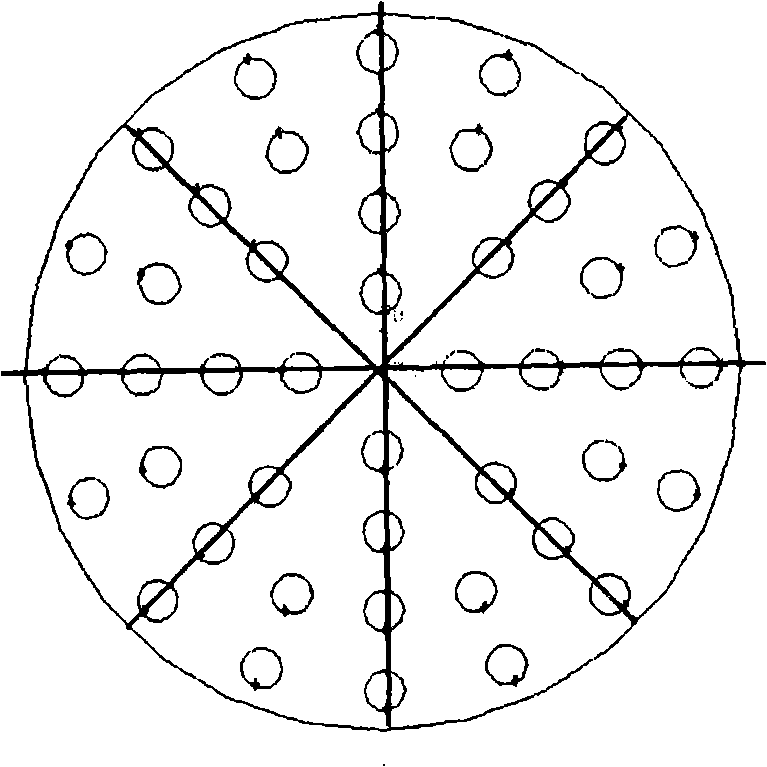

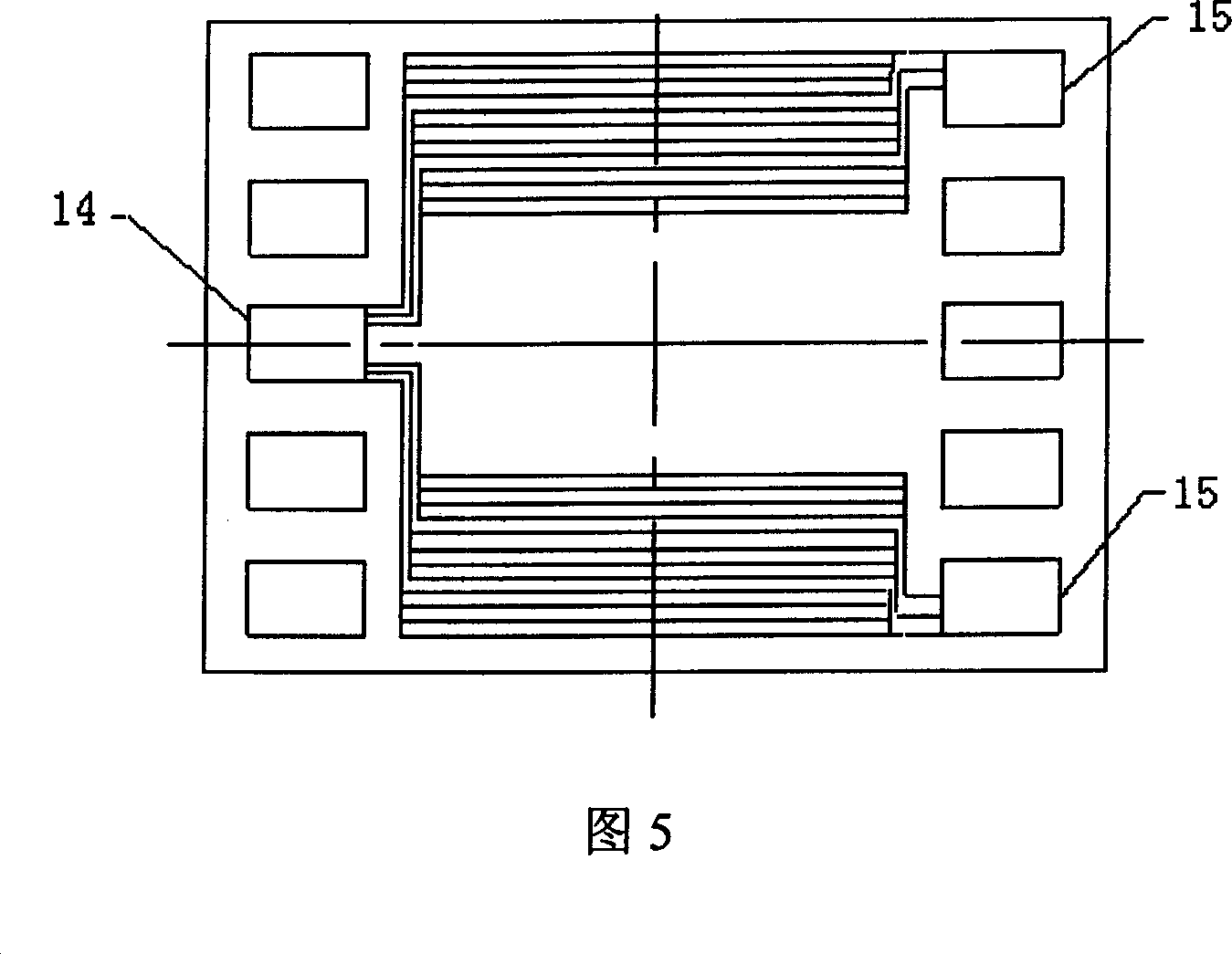

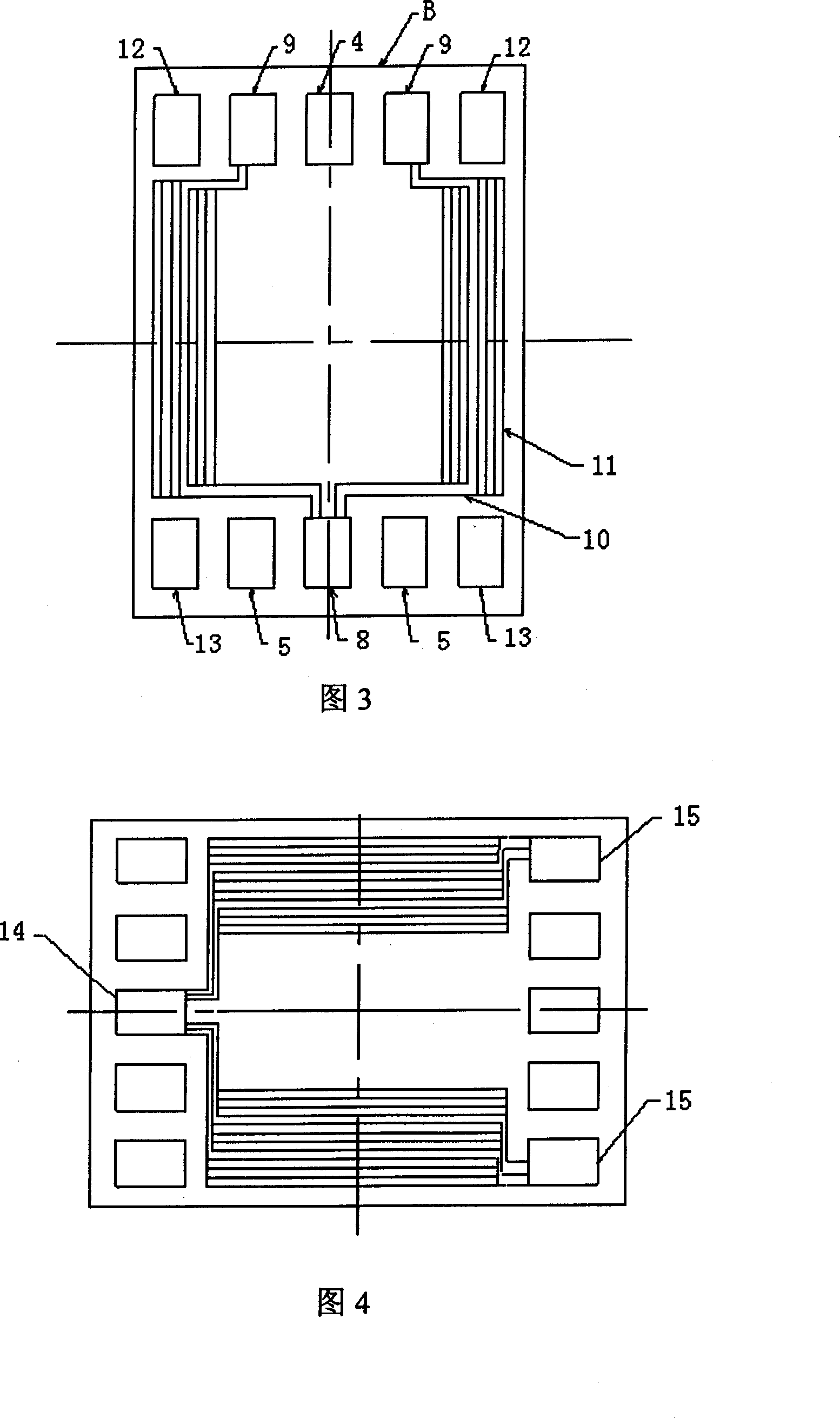

A flow guiding polarized plate of fuel battery

The invention relates to guiding board of fuel battery, said guiding board is guiding two-way board, said guiding two-way board comprises positive air guiding groove board; negative hydrogen guiding groove board and middle cooling flow interlayer, said guiding two-way board possesses flow hole for air, hydrogen, cooling liquid and guiding groove which is connected between flow holes; said flow hole which air or hydrogen in and out is single hole for in, two or more hole for out, the guiding groove which is designed between air or hydrogen holes is designed to direct flow groove or nearly direct flow groove; said flow hole for cooling liquid is single hole or double holes or more holes for in, two holes or more holes for out, guiding groove which is set between flow hole for cooling liquid is designed to direct flow groove or nearly direct flow groove. Comparing with current technique, the invention can decrease resistance and pressure reduction, liquid can flow on liquid field evenly, effective area can be increased; jam of guiding groove can be avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

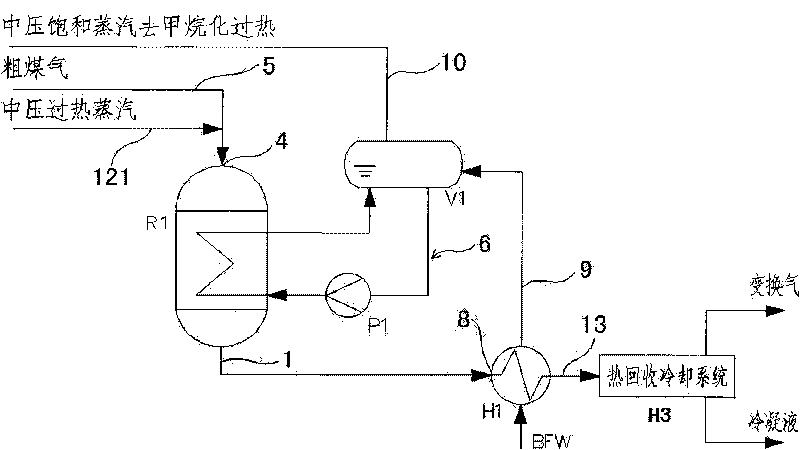

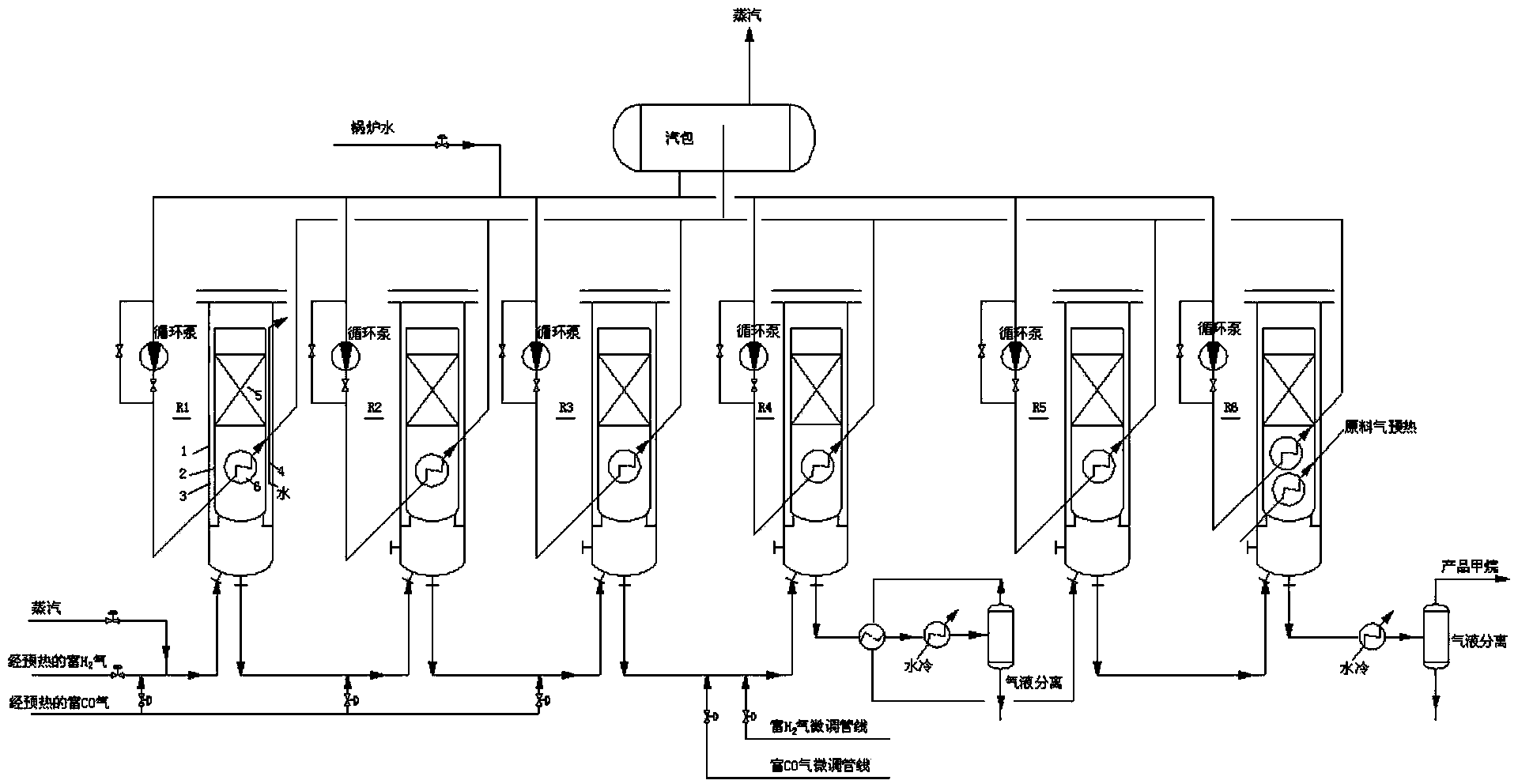

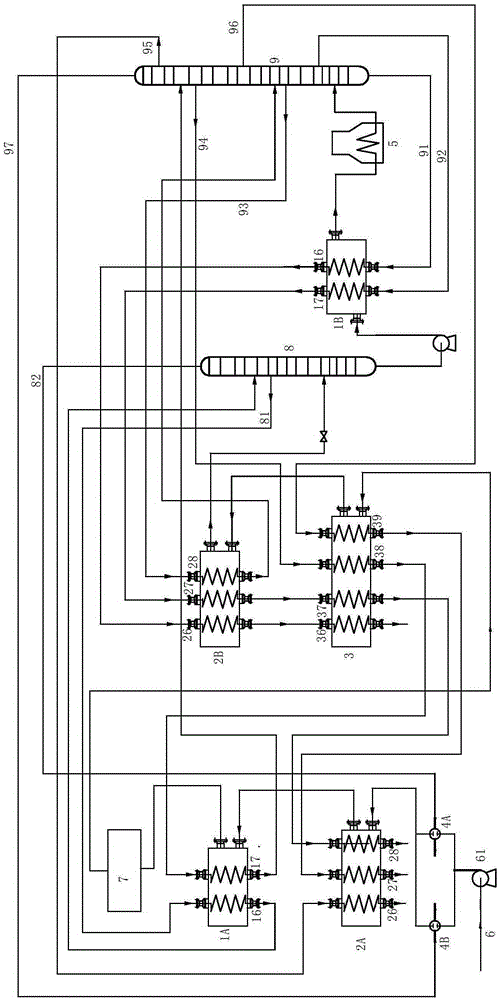

Circulation-free methanation system

The invention discloses a circulation-free methanation system which comprises a gas distribution methanation stage and a supplementation methanation stage, wherein in the gas distribution methanation stage, 1 to 3 stages of serially connected high-temperature reactors are adopted; in the supplementation methanation stage, 2 to 3 stages of serially connected low and medium-temperature reactors are adopted; the final-stage reactor in the gas distribution methanation stage is connected in series with the head-stage reactor in the supplementation methanation stage; technical gas discharged by the former stage of the reactor is used as part of or all the synthesized gas of the next stage of the reactor; technical gas discharged by the final-stage reactor is subjected to cooling separation to obtain a final methane product. The technical system is simple, and the reaction is steady, safe and reliable; the running cost and the manufacturing cost are low.

Owner:BEIJING HUAFU ENG +2

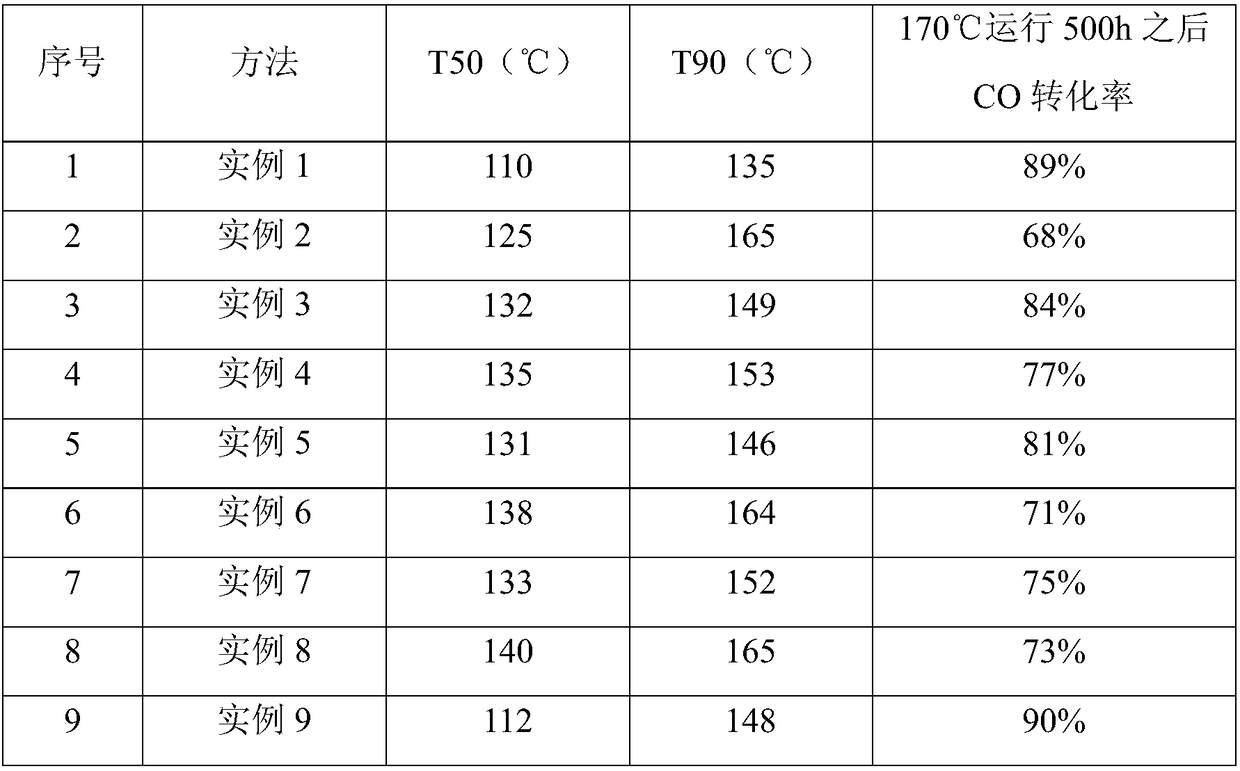

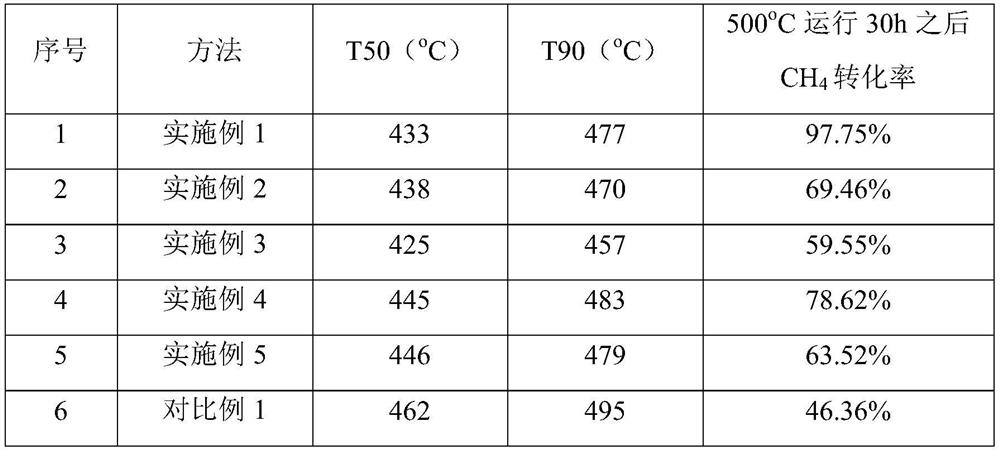

Ce-Zr-M integral structure combustion catalyst and preparation method thereof

InactiveCN108114718AHigh catalytic activityImprove catalytic stabilityHeterogenous catalyst chemical elementsIncinerator apparatusSulfur containingLiquid gas

The invention discloses a Ce-Zr-M integral structure combustion catalyst and a preparation method thereof. The matrix of the catalyst is an integral honeycomb, and the surface of the matrix is coatedwith oxides Ce, Zr and M, wherein the oxide M is prepared from one or several of oxides Ti, Si, Al, V, W, Co in a certain proportion; active components Pt and Pd are dipped into a carrier coated witha mixed oxide coating layer; and the proportion of Ce to Zr to M in the oxide coating layer is 1 to (0.1-4) to (1-50), the mass proportion of the oxides Ce, Zr and M in an integral honeycomb ceramic body is 0-30wt%, and the proportion of the active components Pt and Pd or Pt-Pd is 0.01wt%-0.2wt%. The integral structure combustion catalyst is high in activity and stability, low in ignition point and small in resistance drop, and a preparation process of the catalyst is simple and low in cost. The integral structure combustion catalyst is suitable for purifying combustion tail gas of a water heater or a gas-fired boiler utilizing natural gas, petroleum liquefied gas or coal gas as a fuel and effectively removing and purifying sulfur-containing VOCs gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

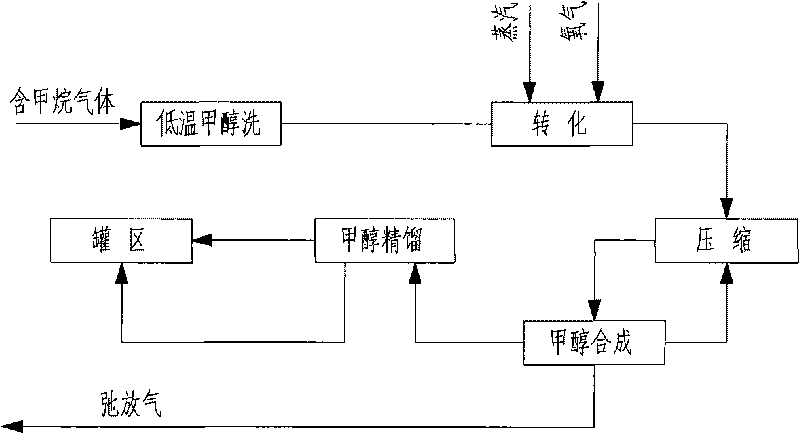

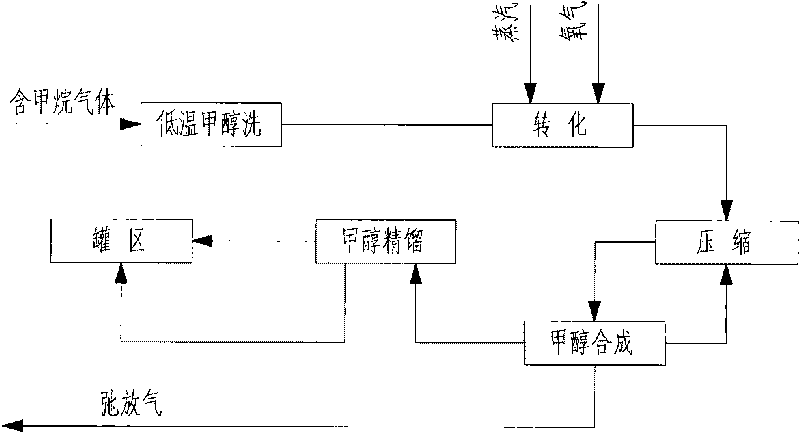

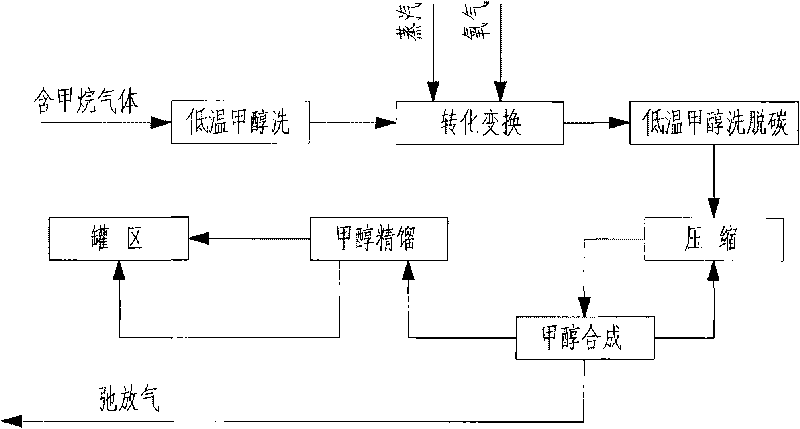

Method for preparing synthesis gas after pure oxygen catalytic partial oxidation of purge gas in methanol synthesis loop to increase yield of methanol and device

ActiveCN101704714APrevent oxidationAvoid burnsHydrogen separationOrganic compound preparationPartial oxidationHydrogen

The invention discloses a method for preparing synthesis gas after pure oxygen catalytic partial oxidation of purge gas in the methanol synthesis loop to increase yield of methanol, which is characterized in that methane-containing gas is compressed by a synthesis gas compressor, is mixed with recycle gas which exits the methanol synthesis loop and separates the methanol and is compressed and preheated by a recycle compressor, and then the mixed gas enters the methanol synthesis loop to synthesize methanol; the methane-containing gas which exits the methanol synthesis loop is condensed into crude methanol liquid, thus being separated; the purge gas separating the methanol enters a hydrogen recovery device after being washed; and hydrogen rich gas and tail gas are obtained after recovery of the hydrogen recovery device, wherein the hydrogen rich gas returns to be mixed with the methane-containing gas and then enters the synthesis gas compressor or is output as a hydrogen product, and the tail gas is sent to a pure oxygen catalytic partial oxidation device to undergo catalytic oxidation reaction, and the obtained converted gas returns to be mixed with the methane-containing gas and then enters the synthesis gas compressor or the recycle compressor, or is directly sent to the methanol synthesis loop. The invention also discloses a device used in the method.

Owner:SHANGHAI INT ENG CONSULTING

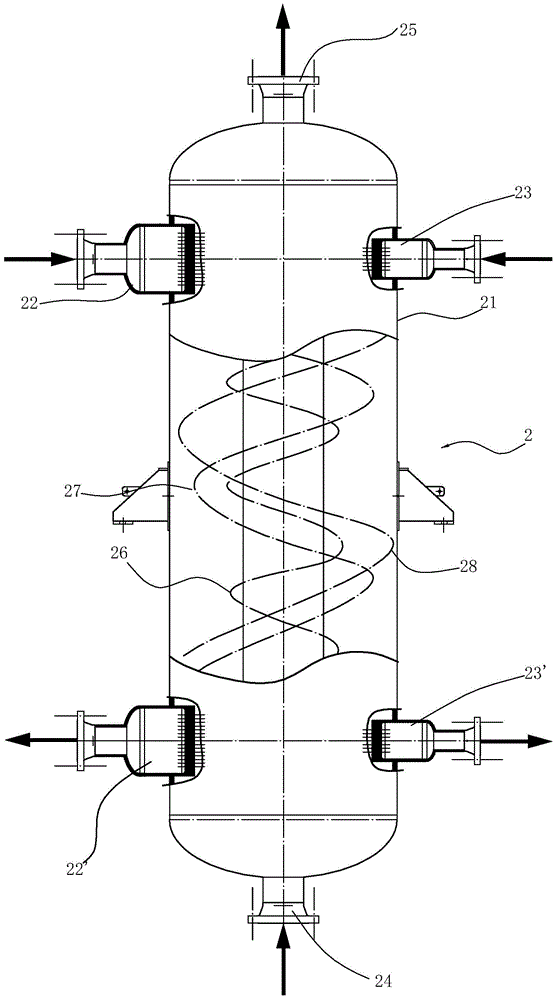

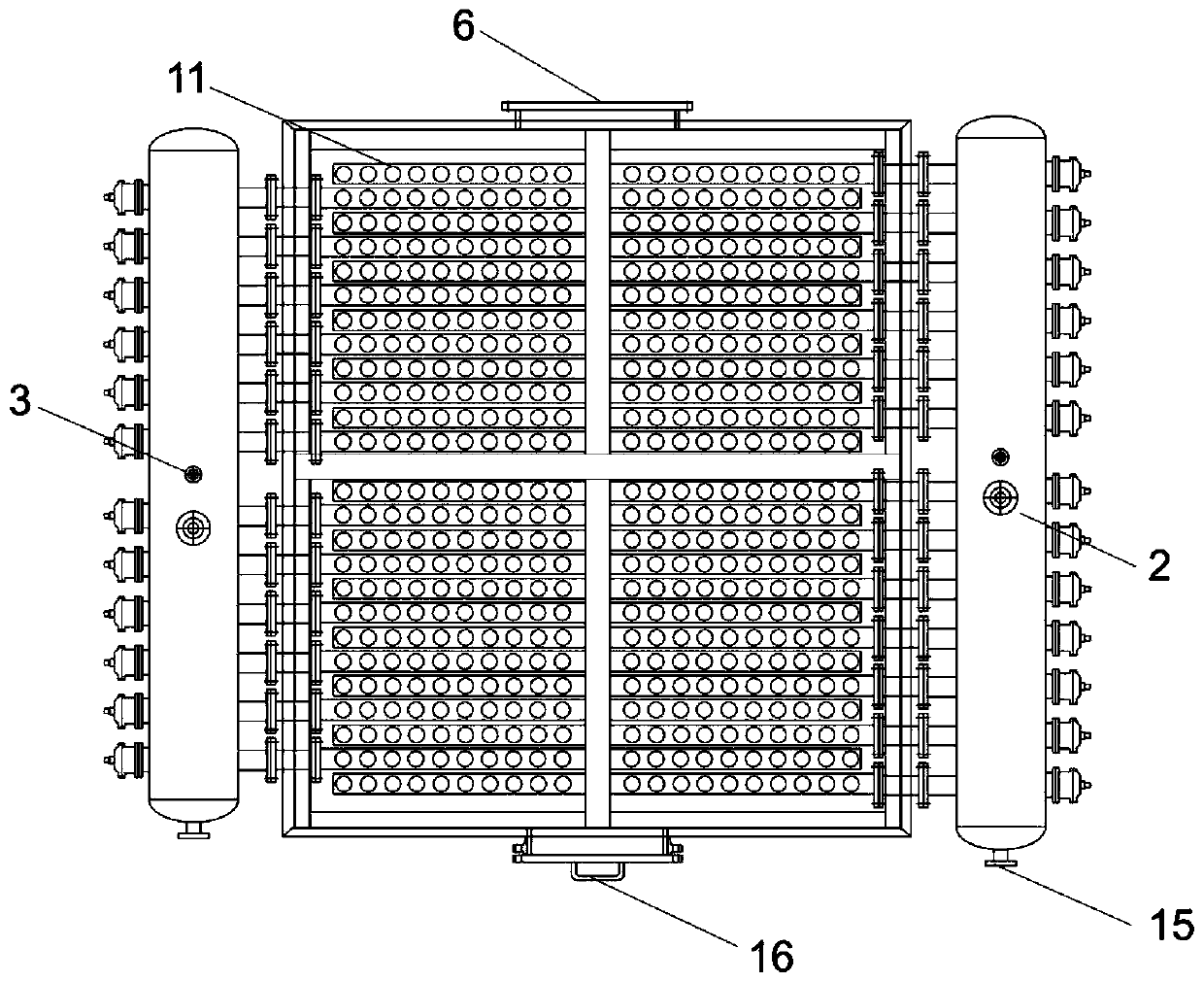

Heat exchange system and process of atmospheric and vacuum distillation unit

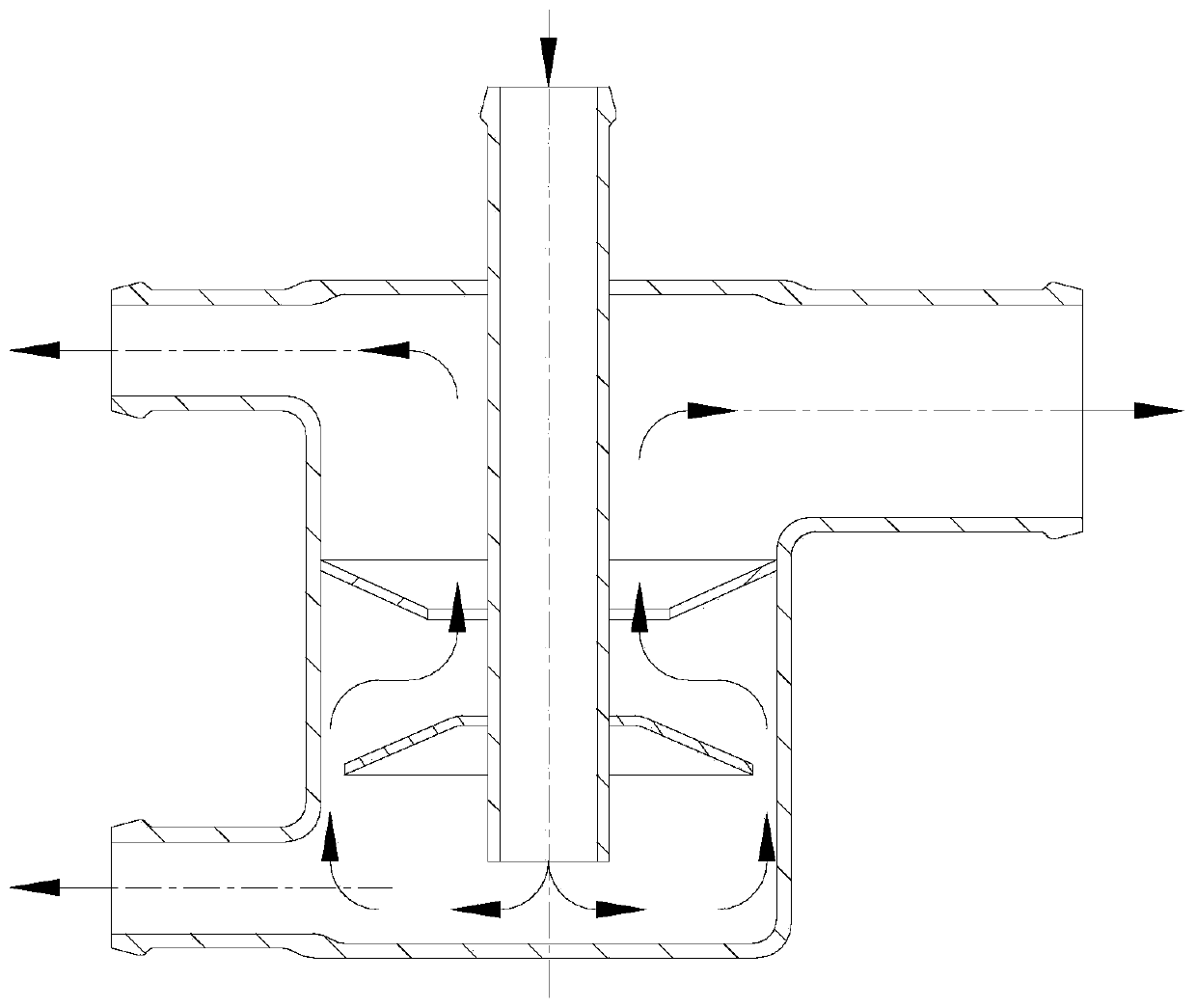

ActiveCN104479735AIncrease temperatureLess drag dropStationary tubular conduit assembliesHydrocarbon oils treatmentExchange networkEngineering

The invention relates to a heat exchange system and process of an atmospheric and vacuum distillation unit. Heat exchangers having special structures are adopted, multiple streams of material flow are simultaneously or sequentially subjected to heat exchange with material flow in shell pass, the resistance is reduced, the heat exchange efficiency is high, the temperature difference at a hot end is small, the operation is stable, the fouling resistance is good, the occupation area and investment of equipment are reduced, a heat exchange network is optimized, the temperature of a crude oil heat exchange terminal is increased, the crude oil heat exchange temperature can be increased by 4-5 DEG C under the condition that a heat exchange source is unchanged, and the energy saving and consumption reducing effects are very remarkable.

Owner:ZHENHAI PETROCHEM JIANAN ENG

Spinning flow high efficiency heat exchange pipe and its producing method

InactiveCN1821702AHigh surface finishNot easy to produce dressingStationary tubular conduit assembliesHeat transfer modificationShell and tube heat exchangerEngineering

The present invention relates to a kind of heat exchange pipe for shell-and-tube heat exchanger and its making process. The high efficiency heat exchange pipe has inward spherical lobes on the high smoothness inner wall. The making process of the high efficiency heat exchange pipe includes the following steps: molding steel plate with high smoothness surfaces to form spherical lobes, cutting into required sizes, and welding the steel stripe into pipe. The spherical lobes distributing in the inner surface of the pipe can produce strong flow swirling and spoiling effect on the heat exchange medium to strengthen heat exchange efficiency and avoid scaling.

Owner:张培洲

Diesel hydro-refining catalyst and preparation method thereof

ActiveCN104923244ALarge specific surface areaLow bulk densityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDecompositionSilicon dioxide

The invention relates to a diesel hydro-refining catalyst and a preparation method thereof. The catalyst is composed of an active component nickel-molybdenum metal oxide, a composite dispersion medium silicon dioxide and aluminum trioxide, and an organic salt mixture. The method is a deposition sedimentation method. According to the method, metal salts of nickel, molybdenum, silicon and aluminum are added into water according to a certain ratio, and a homogenous transparent SiO2-gamma-Al2O3 gel is formed through a sol-gel process; with the decomposition of urea, the pH value increases; a reaction of Ni and Mo is carried out under an alkaline condition, such that an Ni-Mo composition is produced and is deposited on the surface of SiO2-gamma-Al2O3; and steps such as filtering, drying, roasting are carried out, such that the bulk catalyst with relatively high dispersion activity is obtained. The catalyst has the advantages of high active component content, uniform active component dispersion, large specific surface area, and high catalytic activity. The catalyst can be used for producing clean diesel with ultralow sulfur content.

Owner:NORTH HUAJIN CHEM IND CO LTD

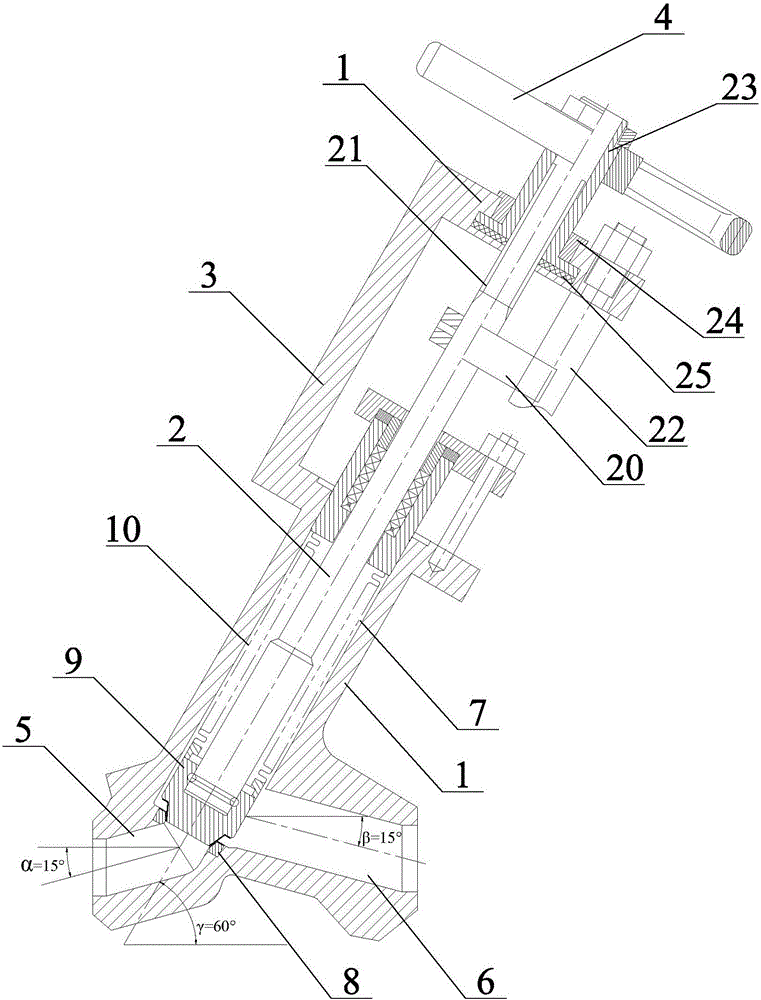

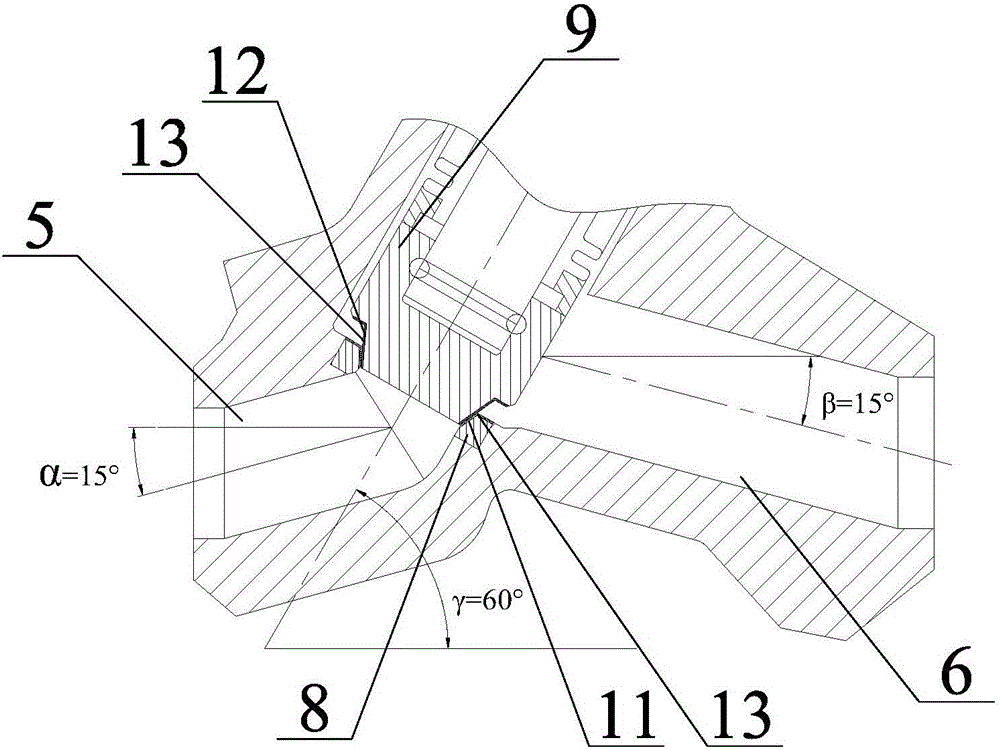

Novel photo-thermal power generation fused salt valve capable of avoiding residues

InactiveCN106051175AEasy maintenanceSimple structureSpindle sealingsLift valveInlet channelMolten salt

The invention discloses a novel photo-thermal power generation fused salt valve capable of avoiding residues. The novel photo-thermal power generation fused salt valve is a Y-shaped valve and comprises a valve body, a valve rod, a support, a hand wheel, a medium inlet channel and a medium outlet channel. The valve body and the support are integrally formed and integrally forged. A valve rod cavity is formed in the valve body, the valve rod extends into the valve rod cavity and is sleeved with a corrugated pipe in an embedded manner, and the corrugated pipe is located in the valve rod cavity. A packing box is arranged above the corrugated pipe, the valve rod is sleeved with the packing box in an embedded manner, a packing ring is placed in the packing box and is tightly pressed through a packing gland above the packing ring, and the packing gland is connected with the valve body through a bolt. The angle alpha formed between the medium inlet channel and the horizontal plane ranges from 10 degrees to 20 degrees, and the angle beta formed between the medium outlet channel and the horizontal plane ranges from 10 degrees to 20 degrees. The fused salt valve is simple in structure, good in sealing performance and convenient and rapid to operate; during work, no leakage happens, safety and reliability are achieved, and the service life is longer; and when a fused salt system stops operating, the situation that due to the fact that fused salt is left and solidified in the valve, the valve is blocked is avoided.

Owner:陈金环

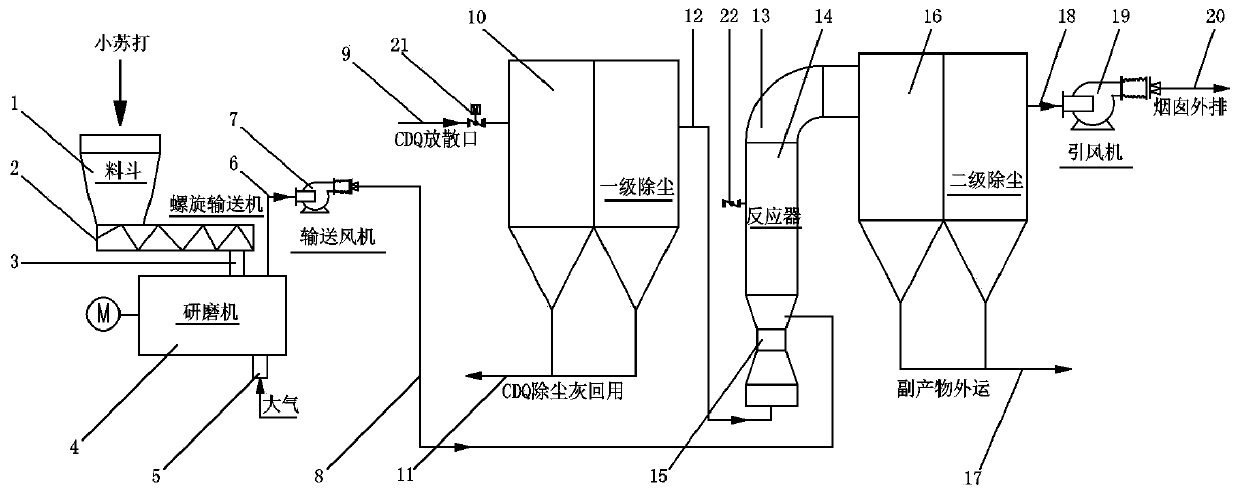

System for CDQ pressure control emitted gas desulfurization and dust removal

PendingCN110280124AEmission reductionNo corrosive effectsDispersed particle separationGrain treatmentsChemical reactionFlue gas

The invention discloses a system for CDQ pressure control emitted gas desulfurization and dust removal, comprising a baking soda hopper, a screw conveyor, a baking soda grinder, a conveying fan, a primary dust remover, a desulfurization reactor, a secondary dust remover and a draught fan. The emitted gas is taken out of an emission port through a pipeline and firstly enters the primary dust remover to remove dust, and the dust-removed emitted gas and the ground baking soda ultrafine powder enter the desulfurization reactor through a Venturi pipe to be uniformly mixed and undergo a chemical reaction in the reactor. The desulfurized flue gas passes through the secondary dust remover and the draught fan and then enters a chimney to be discharged. By the principle of baking soda dry desulfurization and two-stage high-efficiency dust removal, SO2 and dust in the flue gas can be effectively removed to ensure that the treated flue gas meets the latest national special emission limit standard.

Owner:JIANGSU WISDOM ENG TECH

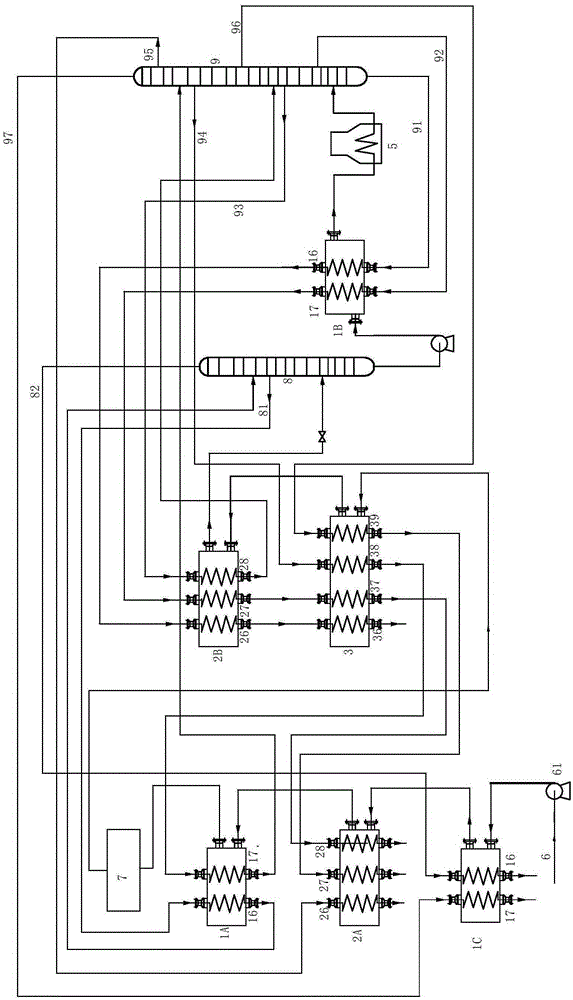

A heat exchange system and process for an atmospheric and vacuum device

ActiveCN104479735BIncrease temperatureLess drag dropStationary tubular conduit assembliesHydrocarbon oils treatmentExchange networkTemperature difference

The invention relates to a heat exchange system and process of an atmospheric and vacuum distillation unit. Heat exchangers having special structures are adopted, multiple streams of material flow are simultaneously or sequentially subjected to heat exchange with material flow in shell pass, the resistance is reduced, the heat exchange efficiency is high, the temperature difference at a hot end is small, the operation is stable, the fouling resistance is good, the occupation area and investment of equipment are reduced, a heat exchange network is optimized, the temperature of a crude oil heat exchange terminal is increased, the crude oil heat exchange temperature can be increased by 4-5 DEG C under the condition that a heat exchange source is unchanged, and the energy saving and consumption reducing effects are very remarkable.

Owner:ZHENHAI PETROCHEM JIANAN ENG

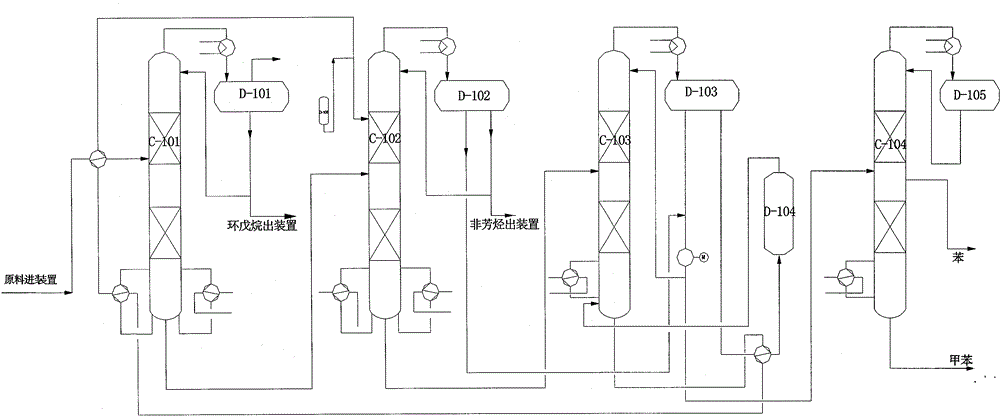

Novel extraction process for aromatic hydrocarbons

InactiveCN105085152AAvoid decompositionReduce decompositionDistillation purification/separationHydrocarbonsDecompositionReboiler

The invention relates to a novel extraction process for aromatic hydrocarbons. Key improvements in the novel extraction process are that a depentanizing tower, an extracting and rectifying tower, a solvent recovering tower and a benzene tower employ novel inward-bending arc fin flat-ring filling material and a unique liquid distribution apparatus and filling material support apparatus are cooperatively used, so resistance drop, a pressure drop ratio and loads of the towers are effectively reduced and production capacity is substantially improved. The depentanizing tower and the extracting and rectifying tower employ main and assistant reboilers for heat adjustment, so optimization of heat supply is realized and long-period stale operation of the towers is guaranteed. Meanwhile, since a sulfonic acid ionic liquid is used as a cosolvent, influence of decomposition and corrosion of the solvent is reduced, usage cost of equipment is lowered, the service life of the solvent is prolonged, the problems of high contents of aromatic hydrocarbons and napthene and easy azeotropy of aromatic hydrocarbons in the extracting process of aromatic hydrocarbons are effectively overcome, investment cost and operation cost of the facilities are substantially reduced, and substantial economic benefits are obtained.

Owner:BEIJING HUAHETUO TECH DEV CO LTD

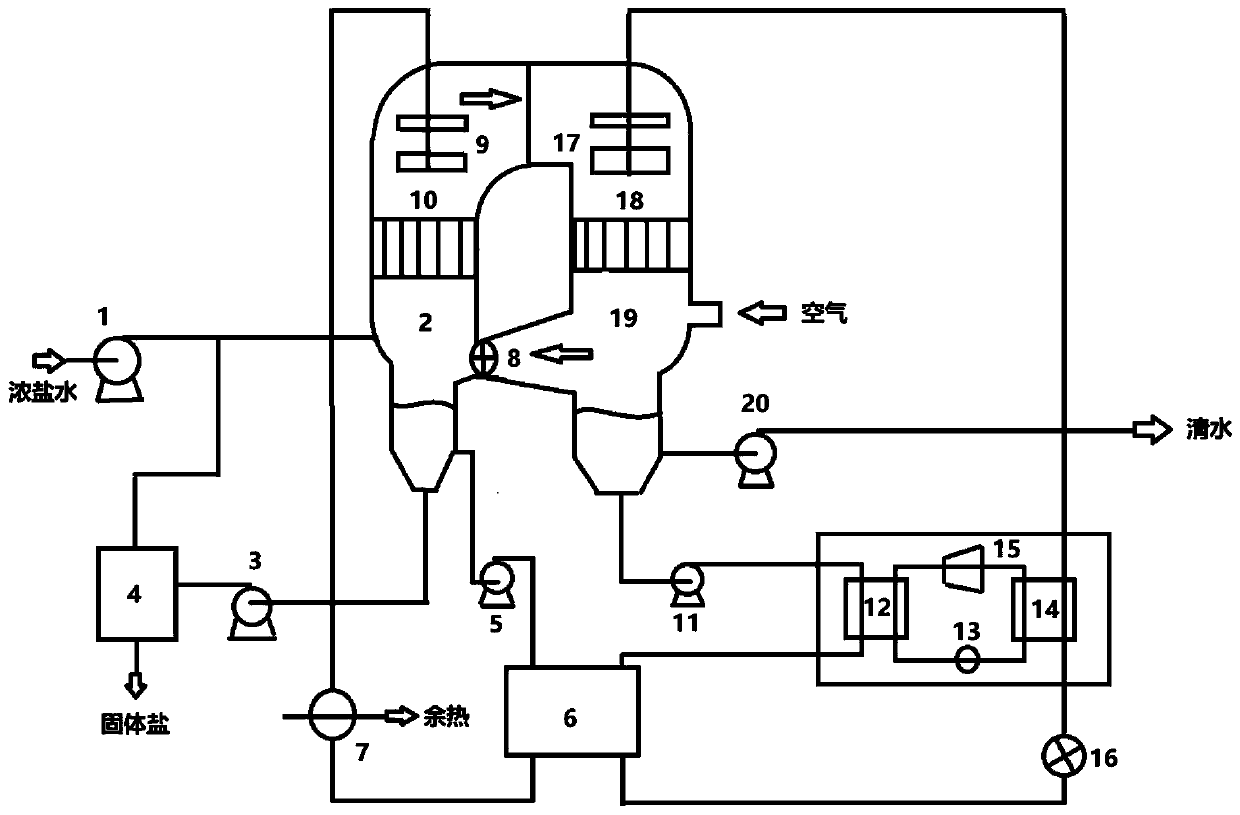

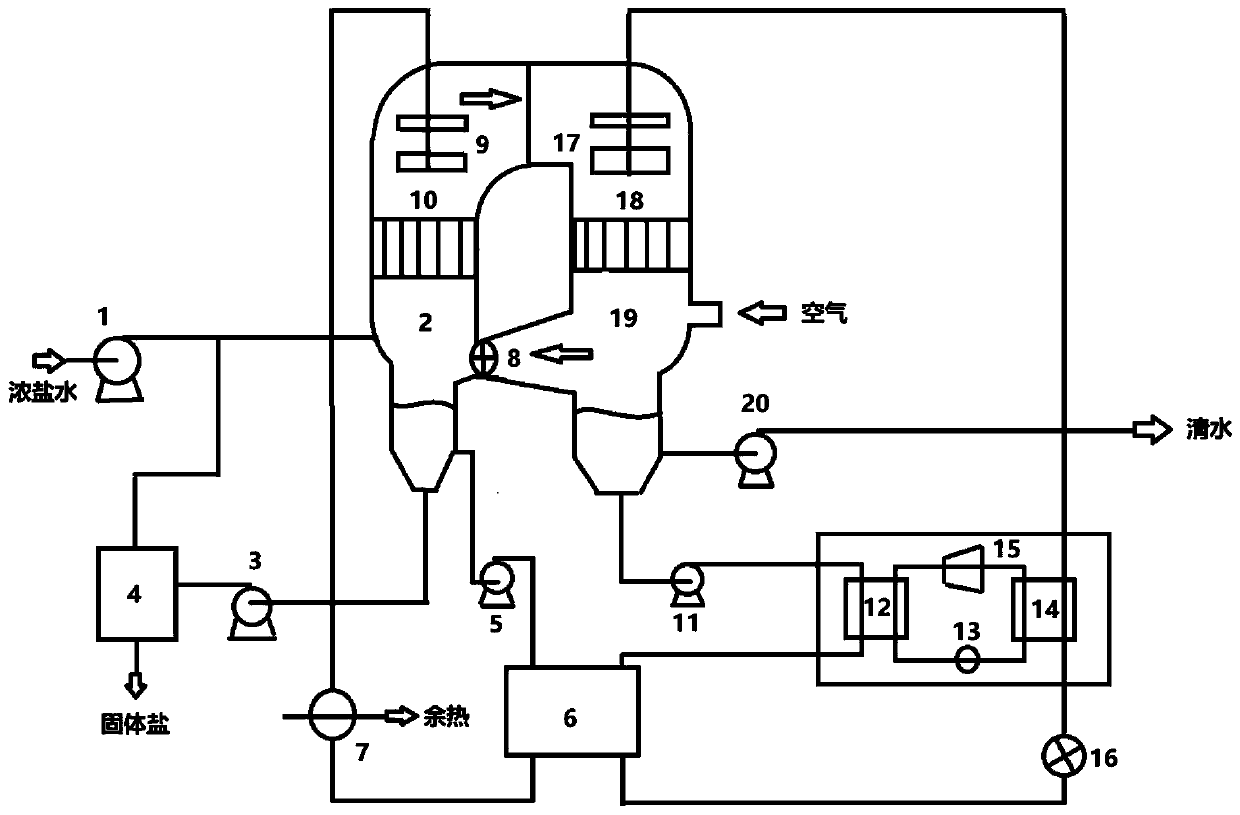

Energy-saving zero-emission low-temperature normal-pressure evaporation and crystallization system and working method thereof

PendingCN111153543ARealize energy saving and consumption reductionEasy to handleMultistage water/sewage treatmentWater/sewage treatment by heatingSaline waterZero emission

The invention discloses an energy-saving zero-emission low-temperature normal-pressure evaporation and crystallization system and a working method thereof, and belongs to the technical field of high-concentration brine zero emission. The system comprises an evaporation chamber, a crystallization kettle, an evaporation and condensation heat exchanger, a condensation chamber and a refrigeration chamber unit. Concentrated crystallization of strong brine and collection of condensate are achieved through circulation in the evaporation chamber and the condensation chamber according to the characteristic that the moisture carrying capacity of air at different temperatures is different, and high-concentration brine zero-discharge treatment at normal temperature and normal pressure is achieved. Thesystem is reasonable in design, high in automation degree, low in energy consumption, low in cost, zero in pollutant discharge, high in salinity and COD removal efficiency and remarkable in energy-saving effect, strong brine is treated into solid salt and clear water, and the system has good economic benefits, obvious environmental protection advantages and good application prospects.

Owner:HUANENG CLEAN ENERGY RES INST

Method for absorbing maleic-anhydride-containing gas by employing dynamic wave absorption tower

InactiveCN103157347ALess investmentReduce in quantityOrganic chemistryDispersed particle separationEconomic benefitsEngineering

The invention discloses an absorption technology in the field of production of maleic anhydride. In the traditional technology, by employing the absorption mode of a spraying board type absorption tower, a tower body is excessively huge along with the large scale of the device, the investment is obviously increased, and the equipment processing, transporting and mounting are relatively difficult; the absorption tower is complex in operation, and the strict control and the measurement means are required; and a large amount of cooling water and power are consumed in circulation fluid, so that the device is high in energy consumption, and the operation is not economic. By adoption of the absorption technology of the dynamic wave absorption tower, the mass transfer or the heat transfer is rapidly performed between the maleic anhydride and the absorption solvent or process water in a foam zone, so that the effects of absorbing the maleic anhydride and removing reaction heat are achieved. The equipment investment in the absorption system is effectively reduced, the absorption tower is easy to operate, low in energy consumption, free from tower internal and easy to clean and maintain and is suitable for new construction and technical transformation of a maleic anhydride device through a water absorption method and the solvent absorption method, and the economic benefits of maleic anhydride production are greatly improved.

Owner:PUHUI LIGHT HYDROCARBON TECH DEV

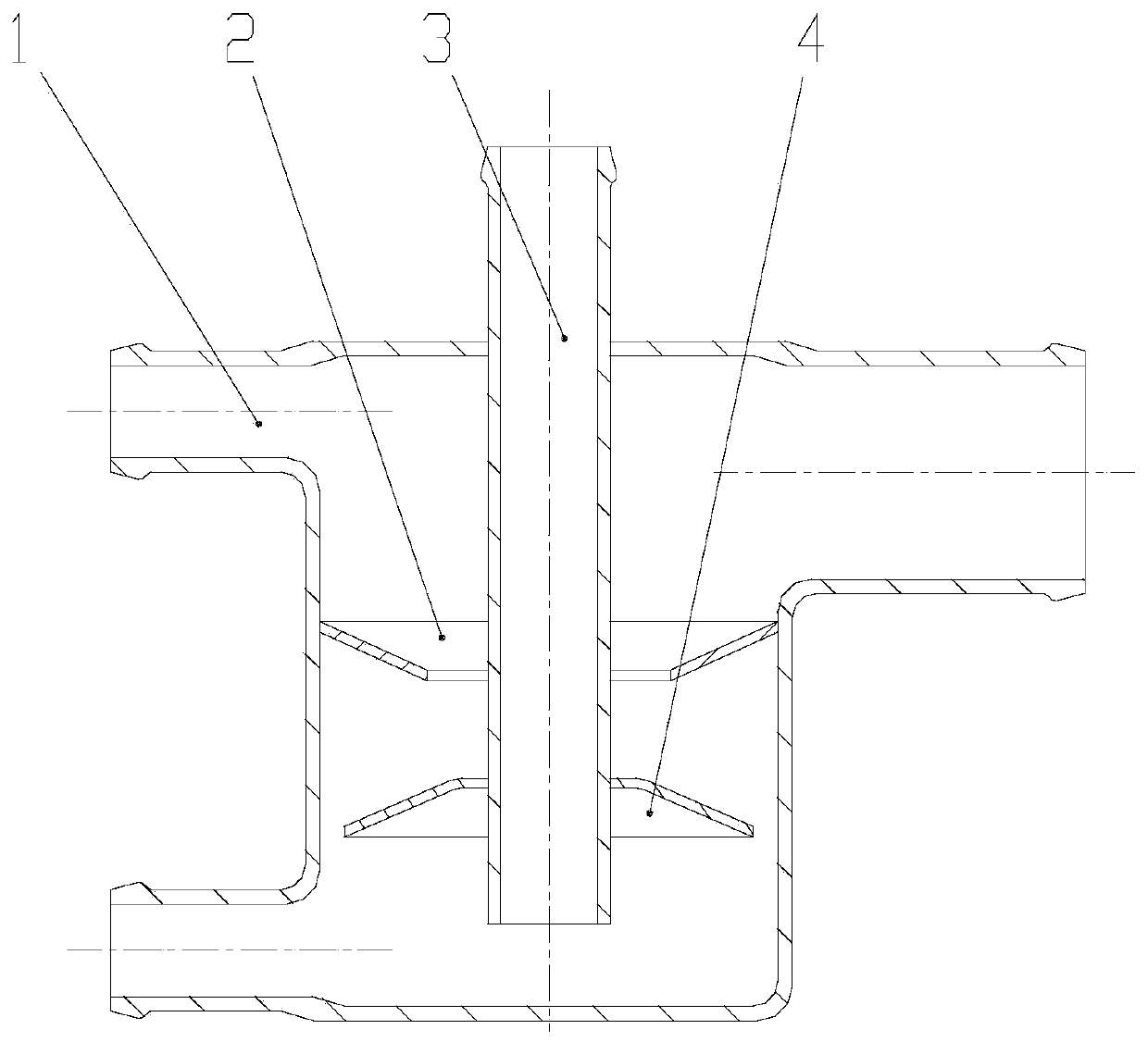

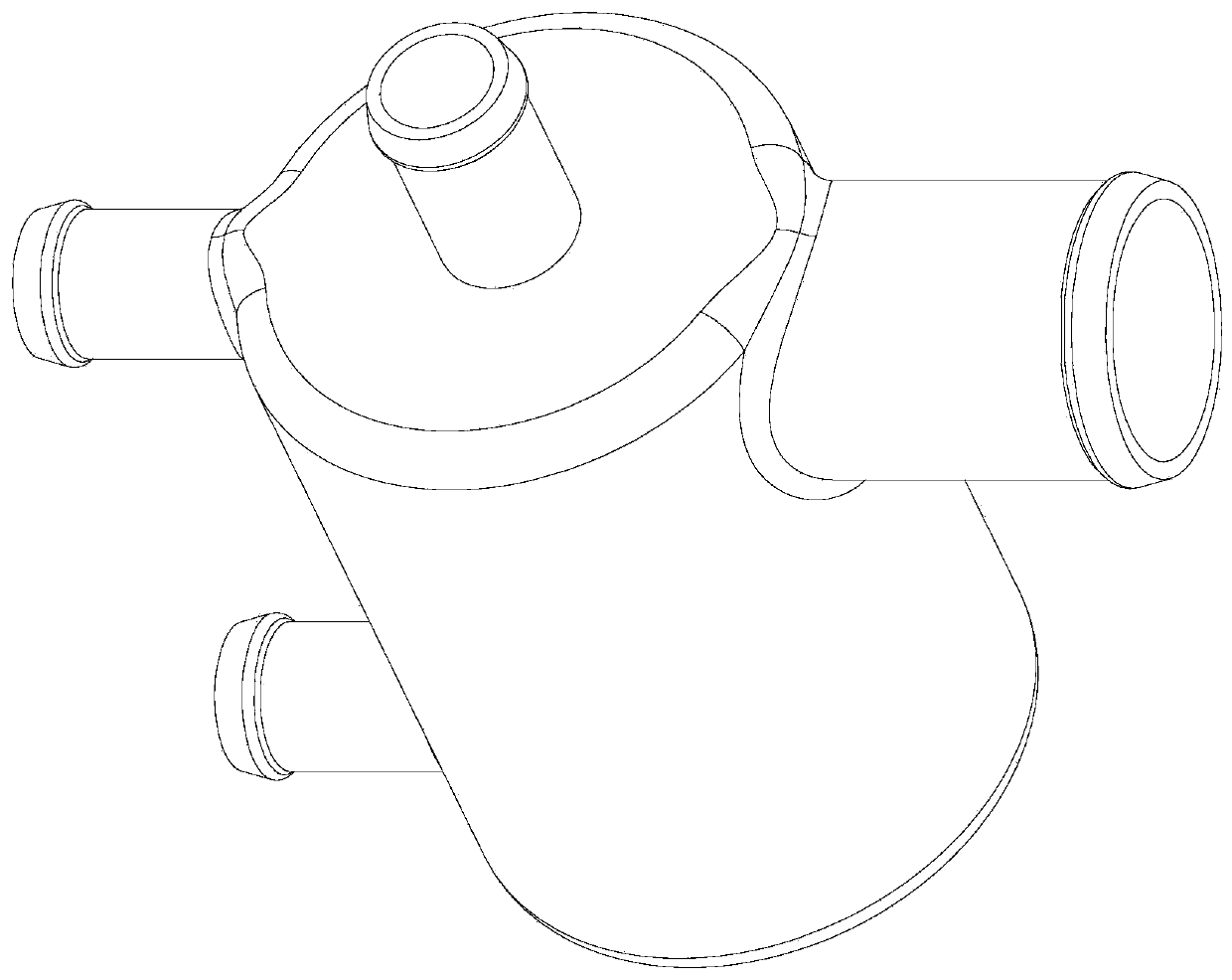

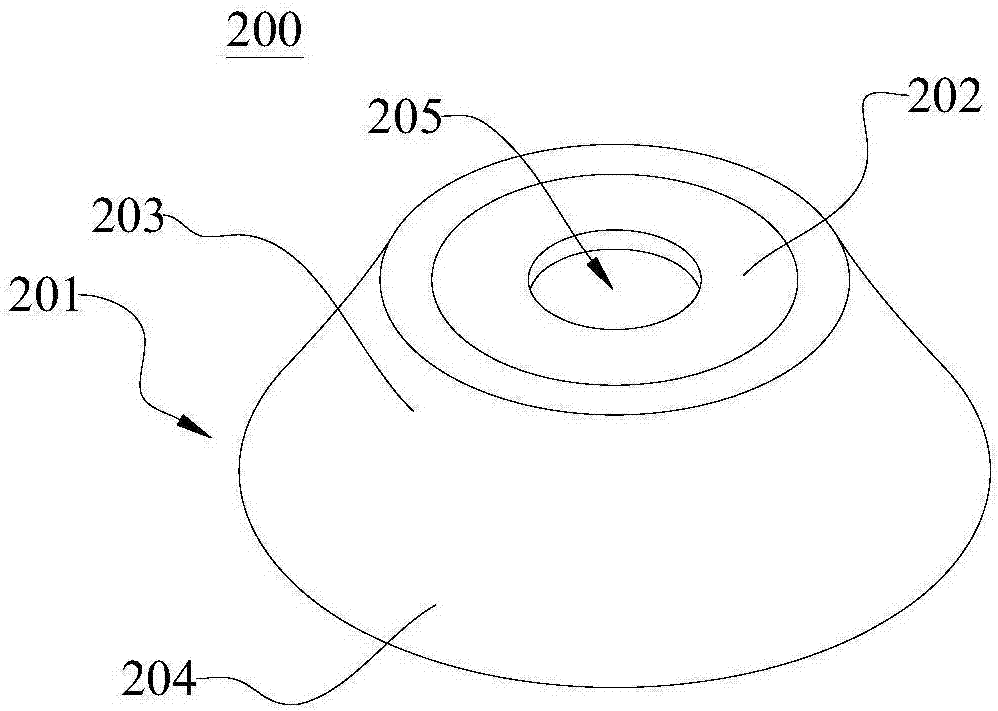

Steam-water separator for proton exchange membrane fuel cell engine hydrogen subsystem

PendingCN109772032AReduce volumeLess drag dropDispersed particle separationFuel cellsHydrogenEngineering

The invention provides a steam-water separator for a proton exchange membrane fuel cell engine hydrogen subsystem. The steam-water separator at least comprises a separator body, an inlet connection pipe, a lower baffle and an upper baffle; the inlet connection pipe is connected with the separator body and extends to the bottom of the separator body, and a gap is formed between the inlet connectionpipe and the bottom of the separator body; the upper baffle is connected with the separator body, and a gap is formed between the upper baffle and the inlet connection pipe; the lower baffle is connected with the inlet connection pipe, and a gap is formed between the lower baffle and the inlet connection pipe. The steam-water separator for the proton exchange membrane fuel cell engine hydrogen subsystem has the advantages of being small in size, low in resistance drop, simple in structure, high in water-dividing efficiency, free of maintenance and the like, and can assist in achieving low-temperature startup.

Owner:林奕辰

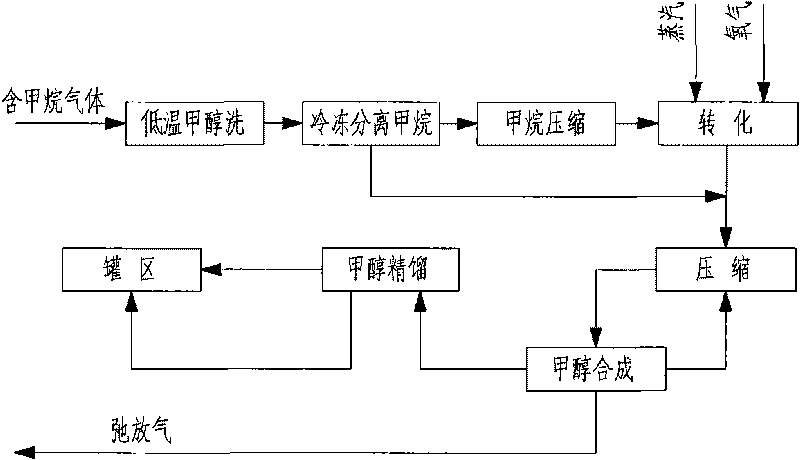

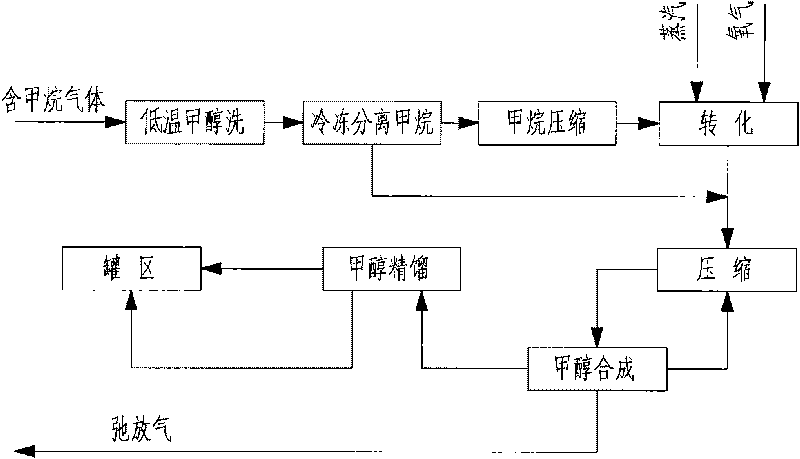

Method for preparing synthesis gas after pure oxygen non-catalytic partial oxidation of purge gas in methanol synthesis loop to increase yield of methanol and device

ActiveCN101704715APrevent oxidationAvoid burnsHydrogen separationOrganic compound preparationHydrogenPartial oxidation

The invention discloses a method for preparing synthesis gas after pure oxygen non-catalytic partial oxidation of purge gas in the methanol synthesis loop to increase yield of methanol, which is characterized in that methane-containing gas is compressed by a synthesis gas compressor, is mixed with recycle gas which exits the methanol synthesis loop and separates the methanol and is compressed and preheated by a recycle compressor, and then the mixed gas enters the methanol synthesis loop to synthesize methanol; the methane-containing gas which exits the methanol synthesis loop is condensed into crude methanol liquid, thus being separated; the purge gas separating the methanol enters a hydrogen recovery device after being washed; and hydrogen rich gas and tail gas are obtained after recovery of the hydrogen recovery device, wherein the hydrogen rich gas returns to be mixed with the methane-containing gas and then enters the synthesis gas compressor or is output as a hydrogen product, and the tail gas is sent to a pure oxygen non-catalytic partial oxidation device to undergo non-catalytic oxidation reaction, and the obtained converted gas returns to be mixed with the methane-containing gas and then enters the synthesis gas compressor or the recycle compressor, or is directly sent to the methanol synthesis loop. The invention also discloses a device used in the method.

Owner:SHANGHAI INT ENG CONSULTING

Heteroatom-resistant combustion catalyst as well as preparation method and application thereof

PendingCN112934219AHigh catalytic activityImprove catalytic stabilityHeterogenous catalyst chemical elementsIncinerator apparatusPtru catalystHeteroatom

The invention discloses a heteroatom-resistant combustion catalyst as well as a preparation method and application thereof. The heteroatom-resistant combustion catalyst comprises a composite matrix and an active component, wherein the composite matrix comprises a honeycomb carrier and a composite oxide; the composite oxide is coated on the surface of the honeycomb carrier; the composite oxide comprises Al2O3 and an L acid metal oxide; the active component is loaded on the composite matrix through impregnation, the active component comprises precious metal, and the precious metal is selected from at least one of Pt and Pd. The heteroatom-resistant combustion catalyst disclosed by the invention can purify the atmosphere of volatile organic compounds (VOCs) containing sulfur, chlorine and other heteroatoms, has higher activity and stability, and overcomes the defect that the traditional combustion catalyst is easy to inactivate in the atmosphere containing sulfur and chlorine. The catalyst is simple in preparation process, low in cost and suitable for efficient removal and purification of VOCs gas containing heteroatoms.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Defogging device for double-hook waved plate

InactiveCN103721480AReasonable structural designImprove separation efficiencyDispersed particle separationEngineeringDefogger

A defogging device for a double-hook waved plate comprises a waved plate defogger, an air inlet, a liquid discharge hole, a shell and an air outlet, wherein the air inlet is formed in one side of the shell; the liquid discharge hole is formed in the lower part of the shell; the air outlet is formed in the upper part of the shell; the waved plate defogger is arranged in the shell and between the air inlet and the air outlet; the waved plate defogger comprises a first housing, a second housing and a waved plate component; the second housing is embedded in the first housing, and forms a hollow separation space with the first housing; the waved plate component is arranged in the separation space, and formed by arranging not less than two waved plates.

Owner:JIANGSU MINSHENG SPECIAL EQUIP GRP

Gas cooling, desulfurization and pregnant solution regeneration integrated device and process

PendingCN110479075ASolve the low utilizationCompact structureCombination devicesTrickle coolersLiquid jetProcess engineering

The invention discloses gas cooling, desulfurization and rich liquid regeneration integrated device and process, wherein the device comprises an efficient washing cooler, a desulfurization tower, a base, a rich liquid pump and the like. The process comprises six process steps of efficient washing cooling, gas-liquid separation, spray cooling, absorption desulfurization, purified gas defoaming andrich liquid jet oxidation regeneration. The desulfurization device is additionally provided with the efficient washing cooler, so that by means of the special structure of the efficient washing cooler, high-temperature and high-dust-content sulfur-containing raw material gas can be efficiently cooled and dedusted, cooling and dedusting equipment does not need to be additionally arranged, and investment is saved. The rich solution oxidation regeneration tank section is integrally arranged on the desulfurizing tower, so that a barren solution pump does not need to be arranged, and the cost is effectively reduced. The rich liquor jet oxidation regeneration tank section is integrated on the desulfurization tower, the rich liquor jet oxidation regeneration tank is integrated on the top of the desulfurization tower, and barren liquor obtained by regeneration directly enters the absorption desulfurization section by using the high potential difference of the regeneration tank section, so thata barren liquor pump does not need to be arranged, and the desulfurization tower has the advantages of high desulfurization liquid sulfur capacity and high desulfurization efficiency.

Owner:四川省达科特能源科技股份有限公司

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513BChange temperatureChange Transform Response BalanceHydrogenChemical industryShunt typesSulfur

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

A hydrogen flow guiding slot plate of fuel battery

ActiveCN101087025AIncrease active areaImprove power densityCell electrodesCollectors/separatorsSingle holeFluid field

The invention relates to hydrogen guiding groove board of fuel battery, said hydrogen guiding groove board comprises positive hydrogen guiding groove board; negative surface is flat board or single board with cooling flow groove, said hydrogen guiding groove board possesses flow hole for air, hydrogen, cooling liquid and guiding groove which is connected between flow holes; said flow hole which air or hydrogen in and out is single hole for in, two or more hole for out, the guiding groove which is designed between hydrogen holes is designed to direct flow groove or nearly direct flow groove; said flow hole for cooling liquid is single hole or double holes or more holes for in, two holes or more holes for out, guiding groove which is set between flow hole for cooling liquid is designed to direct flow groove or nearly direct flow groove. Comparing with current technique, the invention can decrease resistance and pressure reduction, liquid can flow on liquid field evenly, effective area can be increased; jam of guiding groove can be avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Gas distribution structure and gas distributor

PendingCN107349898AEqual pressureUniform velocity distributionChemical/physical/physico-chemical processesEngineeringProduct gas

A gas distribution structure and a gas distributor belong to the field of chemical equipment. The gas distribution structure includes a plurality of splitter plates, and the splitter plates include annular plates and conical baffles that are matched and connected to each other, and the conical baffles define a conical cavity. The ring plate has a plate hole, the ring plate is connected to the starting end and the plate hole communicates with the starting opening, a plurality of splitter plates are arranged in the form of channels formed at intervals along the preset direction, and the plate holes of each ring plate are opposite and communicated . The arc-shaped baffle has an arc-shaped convex surface, and the arc-shaped convex surface of the arc-shaped baffle corresponds to the plate hole of the annular plate facing the adjacent splitter plate. The gas distribution structure plays a high-efficiency diversion role for the flow of gas. The pressure of the gas in each channel is equal, the flow velocity is evenly distributed, and the resistance drop is small. After the gas enters the equipment through the distributor, it can quickly reach a uniform distribution state, and can achieve uniformity at the inlet cross section of the bed, with low air flow turbulence and back mixing, good uniform distribution effect, and low energy loss.

Owner:BEIJING HUAFU ENG

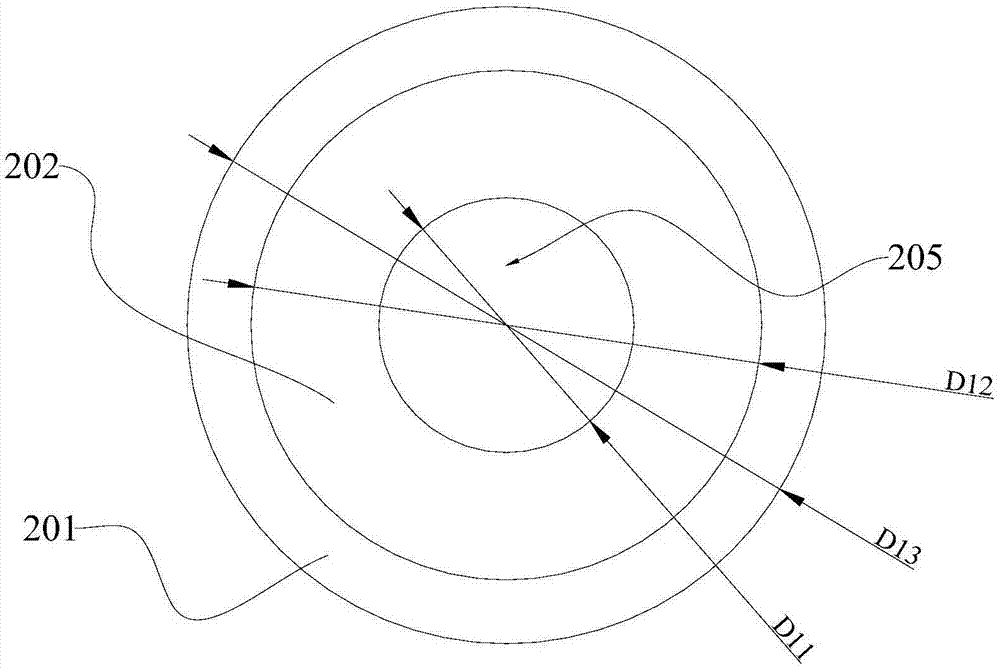

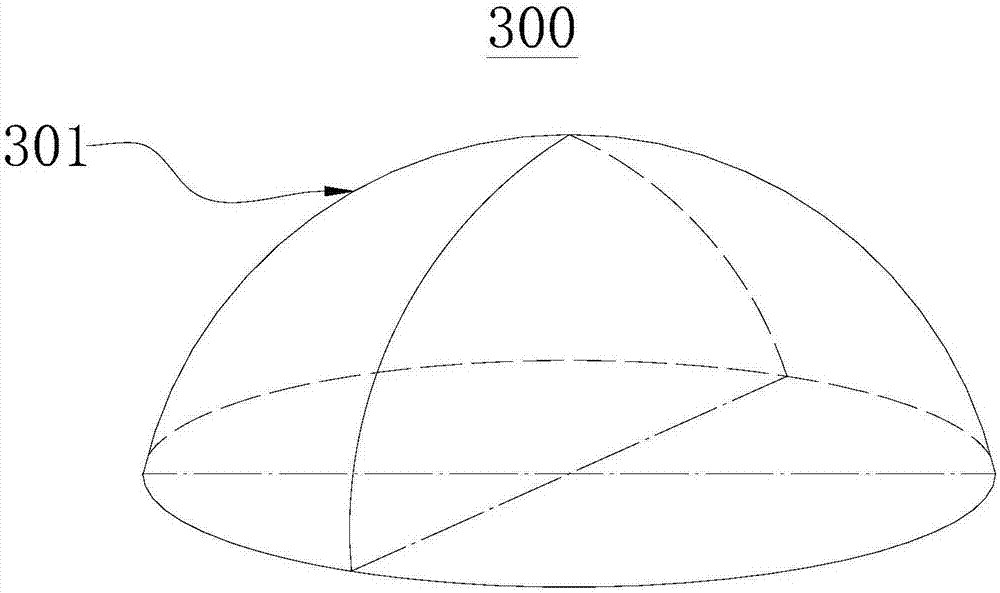

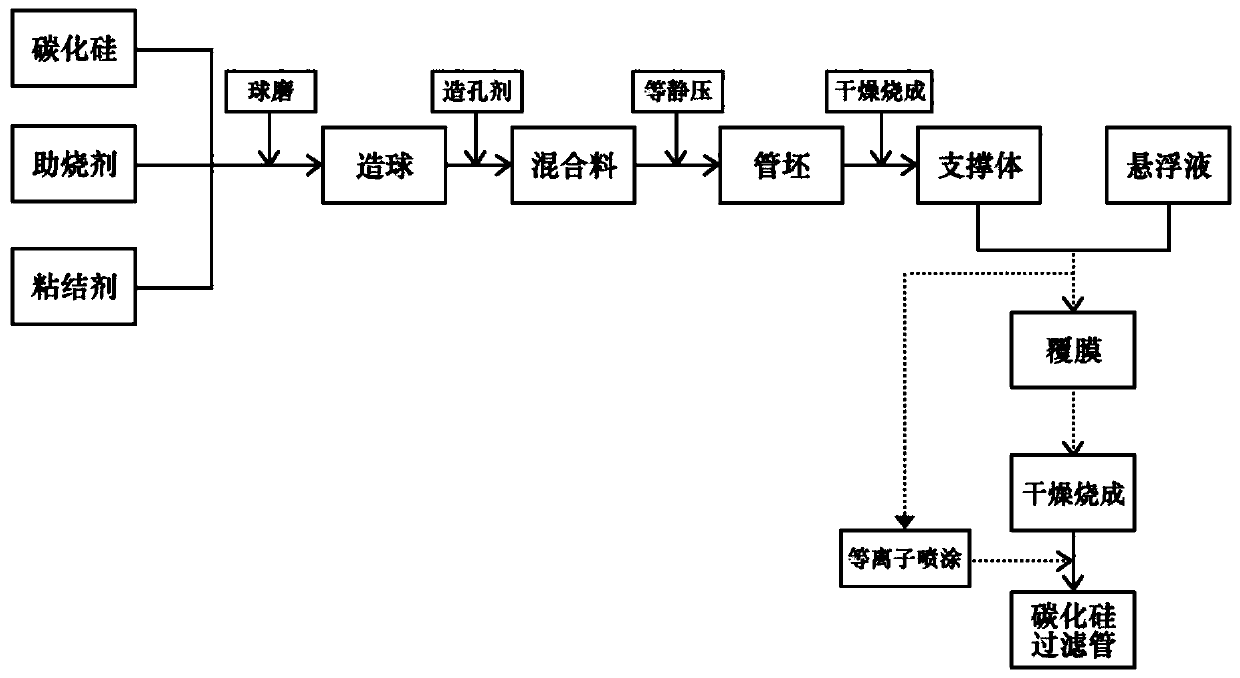

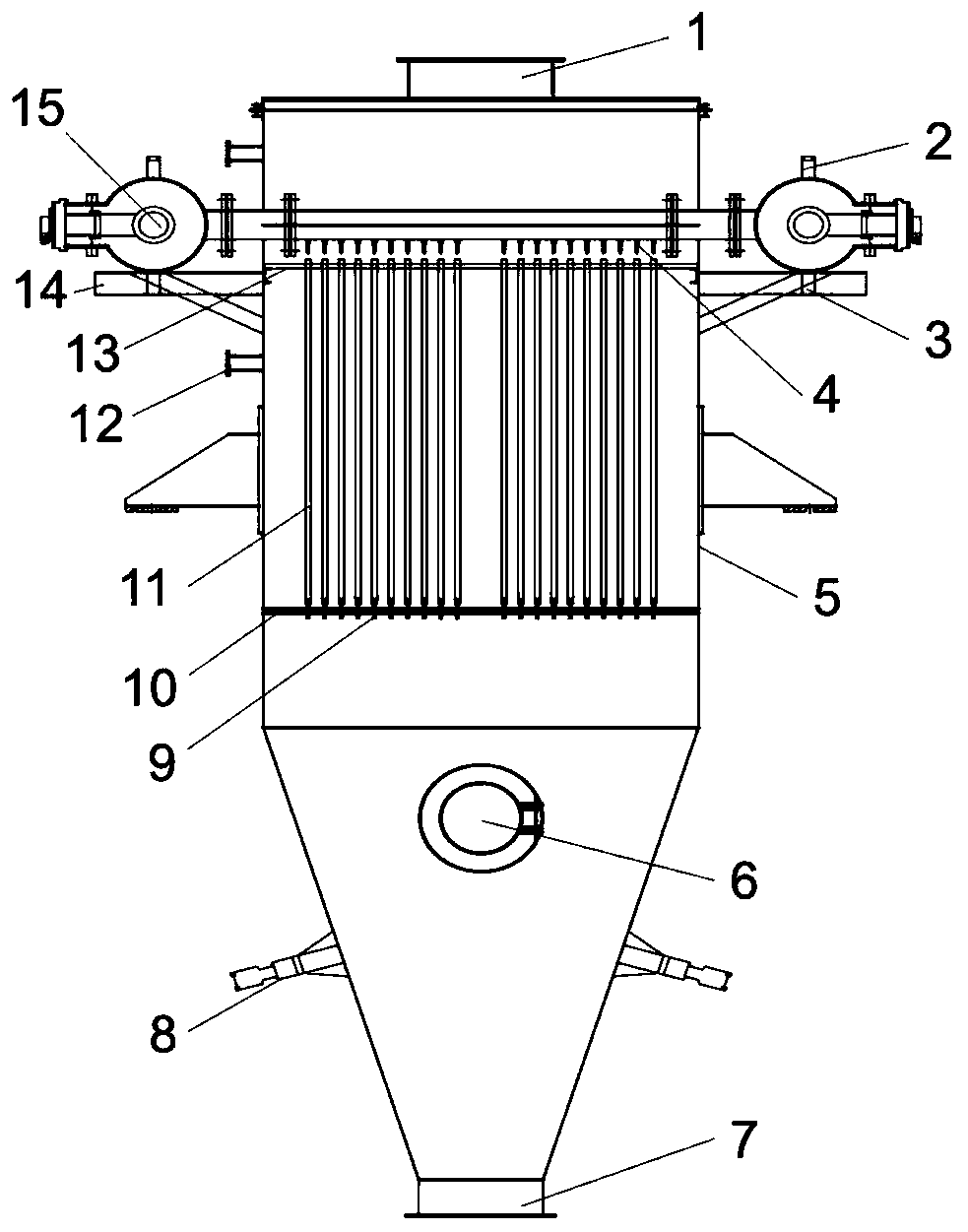

Preparation method of silicon carbide asymmetric composite filter tube membrane with controllable aperture, and device

PendingCN109867524ALess drag dropImprove filtering effectSemi-permeable membranesCeramicwareSlagFiltration

The invention provides a preparation method of a silicon carbide asymmetric composite filter tube membrane with controllable aperture, and a device, and belongs to the technical field of gas-solid separation. The method comprises the following steps: firstly, crushing and grinding raw materials, then carrying out mixing, carrying out pelletizing and mixing, carrying out isostatic pressing, carrying out drying, then carrying out firing, and carrying out plasma spraying, wherein the used raw materials are silicon carbide, kaolin, aluminum oxide, a pore-forming agent, a sintering aid and a binder. The device applying the prepared filter tube membrane comprises an air outlet, a pressure transmitter opening, an air bag slag discharging opening, a pulse nozzle, an air inlet, a sewage dischargingport, the silicon carbide asymmetric composite filter pipe membranes and a blowback opening. 20-960 silicon carbide filter tubes are installed in a filter chamber in the middle of the device; dust-containing flue gas enters the filter chamber from the air inlet; and clean gas filtered by the silicon carbide filter pipe enters an internal pipeline of the device from the pulse nozzle and is finallydischarged from the air outlet. The silicon carbide asymmetric composite filter tube membrane has the advantages of excellent high-temperature corrosion resistance and thermal shock resistance, goodfiltration performance, high filtration precision, long service life and the like.

Owner:UNIV OF SCI & TECH BEIJING

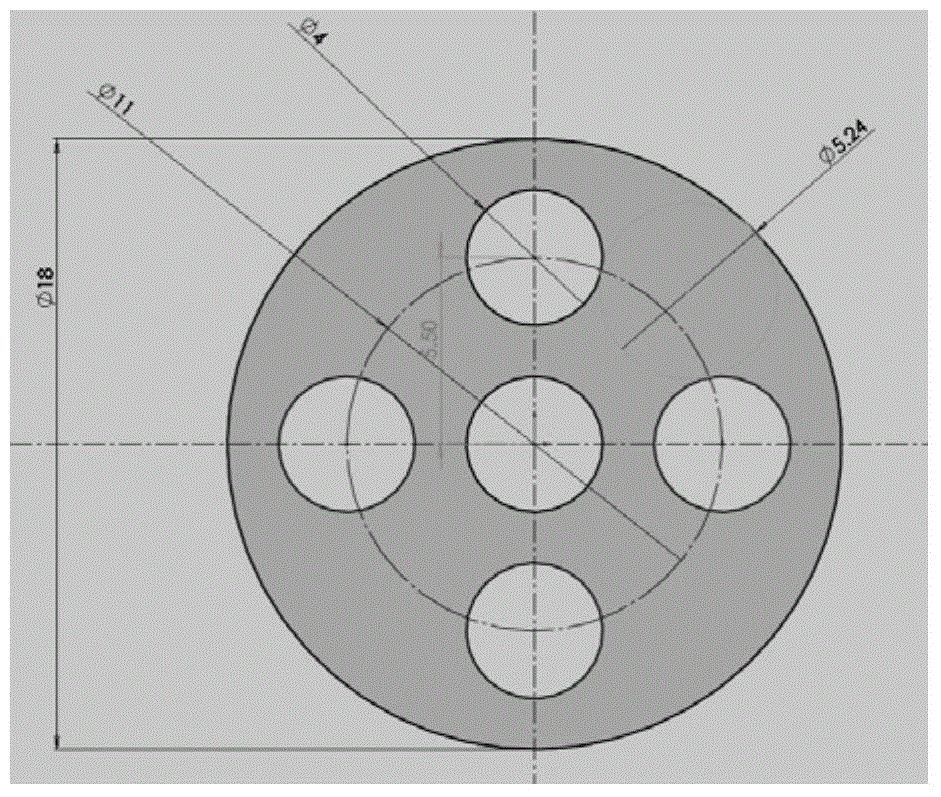

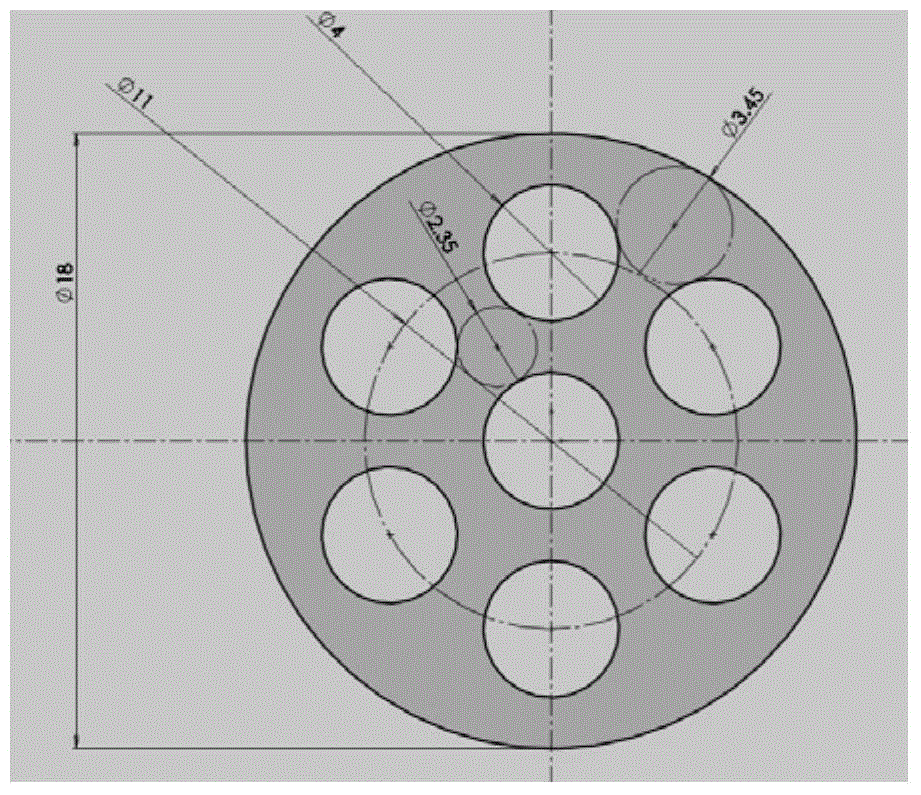

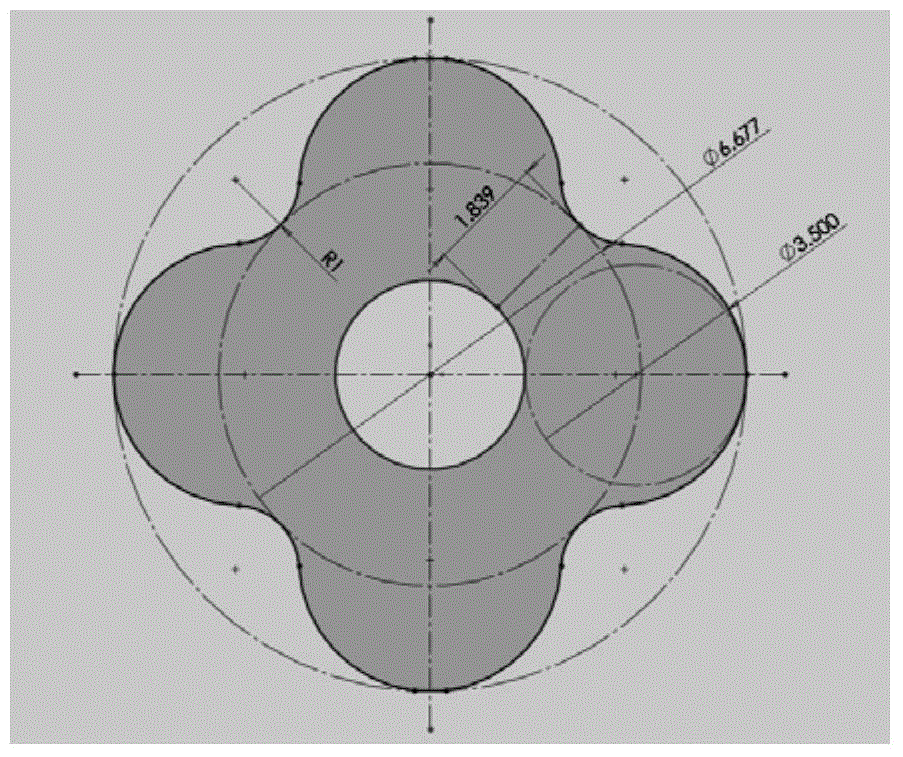

Hetero-type methanation catalyst and molding process and application thereof

ActiveCN105709794AHigh particle surface area/skeleton volume ratioSmall radial mass transfer distanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsActive componentMethanation

The present invention discloses a hetero-type methanation catalyst and a molding process and application thereof. The process is as follows: nickel-based synthesis gas methanation catalyst powder is prepared into porous cylinder particles by compression or squeezing, wherein diameter Phi of a profile circumscribed circle of the porous cylinder particles is 3-22mm, height is 3-12mm, ratio of surface area / grain skeleton volume is 0.8-1. 6mm<2> / mm<3>, the maximum radial mass transfer distance is 1.4-4.0mm, and the geometric shape of the porous cylinder particles is regular and symmetrical. The molding process of the hetero-type methanation catalyst aims at process characteristics and requirements of various stages of the synthesis gas methanation process, the utilization efficiency of catalyst active components can be improved, and the hetero-type methanation catalyst has an important role for reducing bed resistance drop and improving long-time operational stability of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

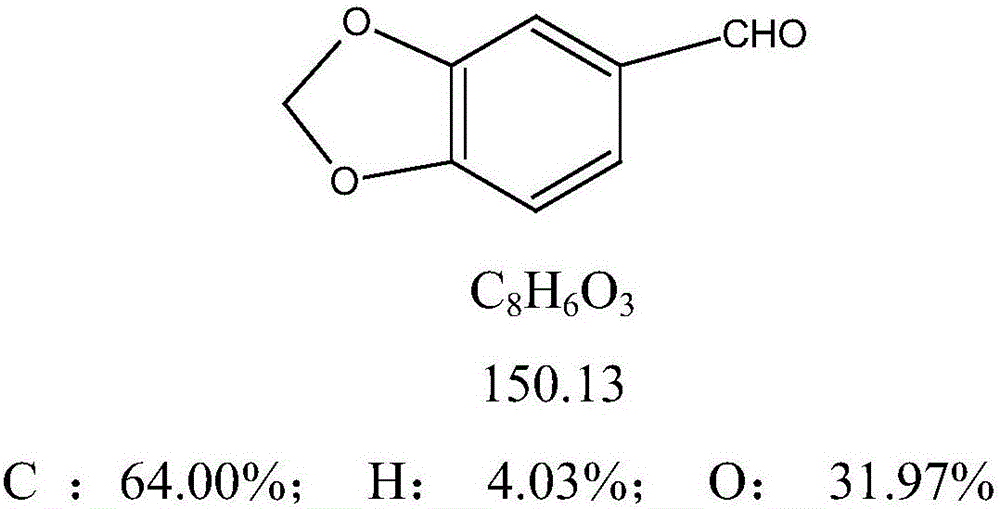

Double-tower continuous rectifying process of heliotropin

InactiveCN105777704AImprove product qualityImprove mass transfer efficiencyOrganic chemistryDecompression operationProcess engineering

The invention discloses a double-tower continuous rectifying process of heliotropin. The double-tower continuous rectifying process comprises the following steps: (a) enabling raw materials to fully react in a reactor; (b) arranging a first rectifying tower and a second rectifying tower at the top part of a reactor; (c) continuously heating the first rectifying tower and the second rectifying tower with heat-conducting oil; (d) distilling the materials; (e) extracting a light component in the material to a first product receiver, and extracting the heliotropin to a second product receiver; (f) carrying out pressure filtration on the heliotropin; and (g) packaging the heliotropin. The material feed composition and the feed quantity in the first rectifying tower are adjusted according to the material rectifying state in the first rectifying tower, so that the product quality is improved; meanwhile, the materials are continuously rectified in the first rectifying tower and the second rectifying tower, so that the required vacuum degree is easy to reach during decompression operation; and the double-tower continuous rectifying process has the beneficial effects that the rectifying efficiency is improved, the labor intensity is reduced and the uniformity and stability of the product quality are improved.

Owner:福建仁宏医药化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com