Novel plate type economizer

A kind of economizer, plate type technology, applied in the direction of feed water heater, heat exchanger type, heat exchanger shell, etc., can solve the problem of increasing flue gas resistance, low heat transfer coefficient of flue gas side, and no enhanced heat transfer at flue gas side Thermal measures and other issues, to achieve the effect of increasing turbulence, improving heat transfer efficiency, and not easy to be blocked by dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

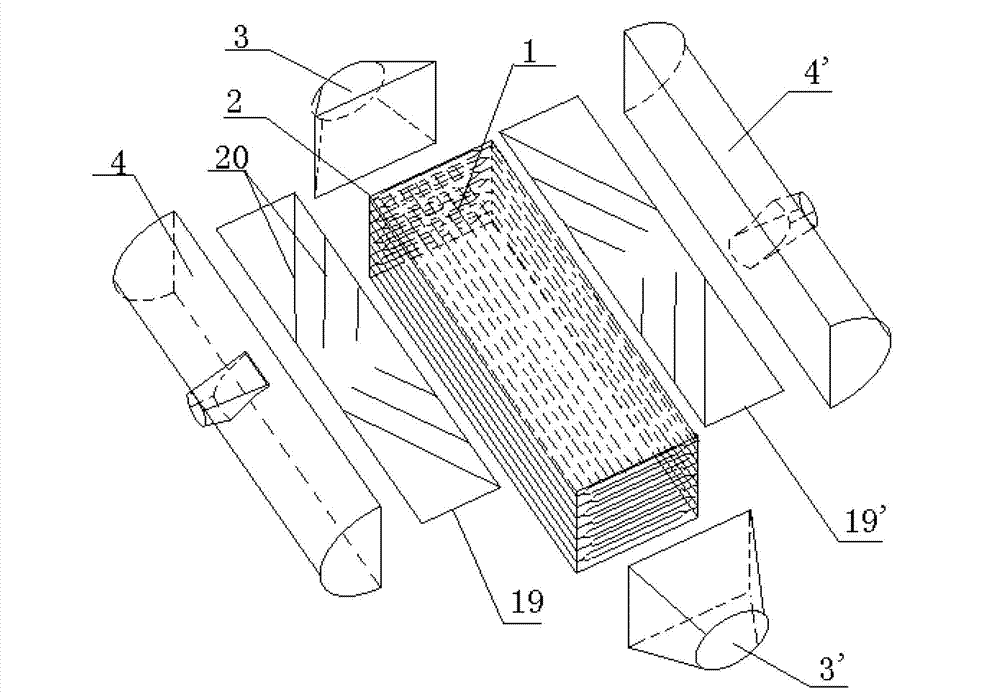

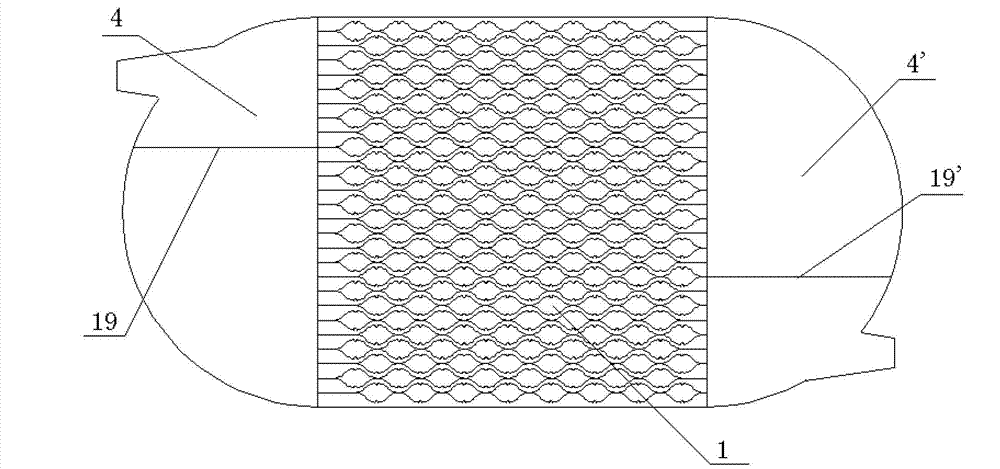

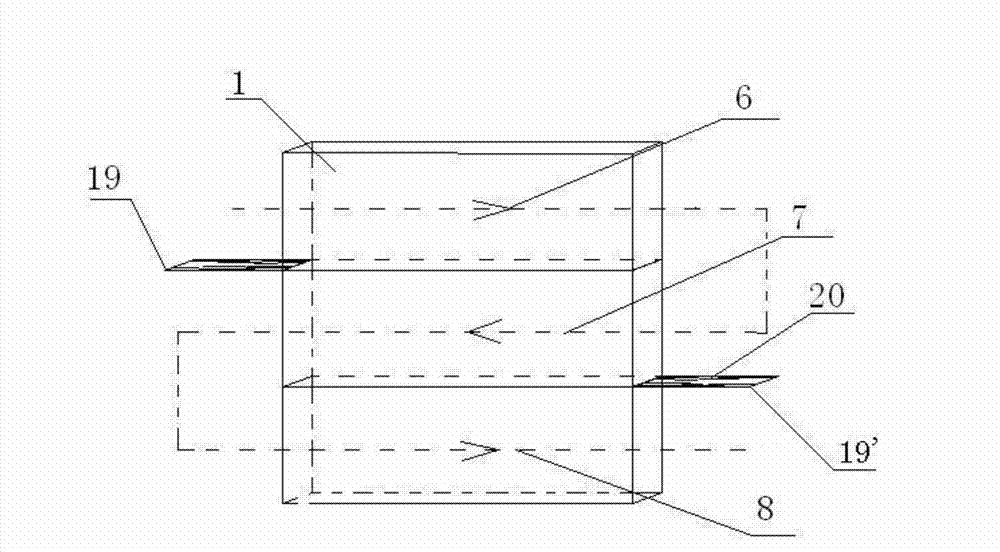

[0040] A plate economizer (such as Figure 1-2 shown), including corrugated plate heat exchange core 1, heat exchanger shell 2, flue gas inlet and outlet pipelines 3, 3' and water inlet and outlet tanks 4, 4', front and rear sides of heat exchanger shell 2 The flue gas inlet and outlet pipelines 3, 3' are respectively connected, the water inlet and outlet tanks 4, 4' are respectively connected to the left and right sides, and the water inlet and outlet tanks 4, 4' are provided with partitions 19, 19'.

[0041] The corrugated plate heat exchange core 1 is formed by stacking more than two heat exchange corrugated plates 5 (such as figure 2 shown), wherein the heat exchange corrugated plate 5 is a thin plate with planar areas 11, 12, 13, 13' around, wherein the planar areas 11, 12 are upturned (such as Figure 4 shown); the surface of the corru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com