Double-tower continuous rectifying process of heliotropin

A kind of jasmine aldehyde and process technology, applied in the field of rectification, can solve the problems of low yield, frequent operation, low efficiency and the like, achieve the effect of high mass transfer efficiency and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

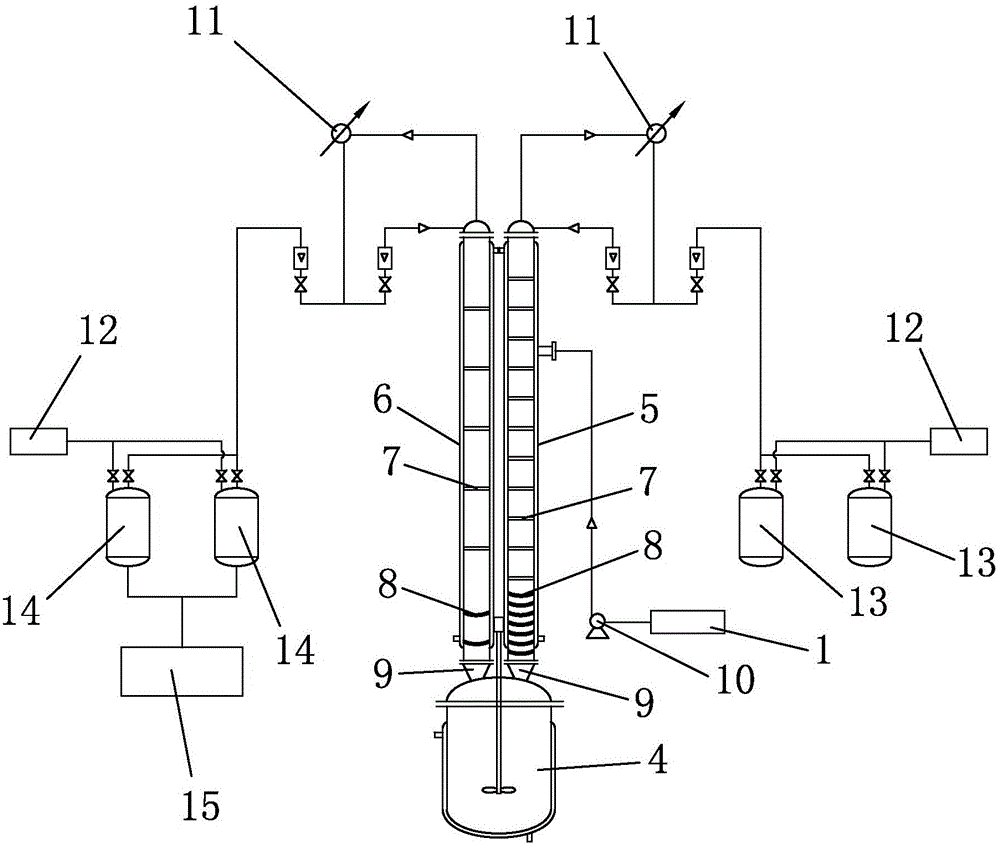

[0028] Such as figure 1 and figure 2 Shown, be the two-tower continuous rectification process of a kind of jasmonal of the present invention, comprise the steps:

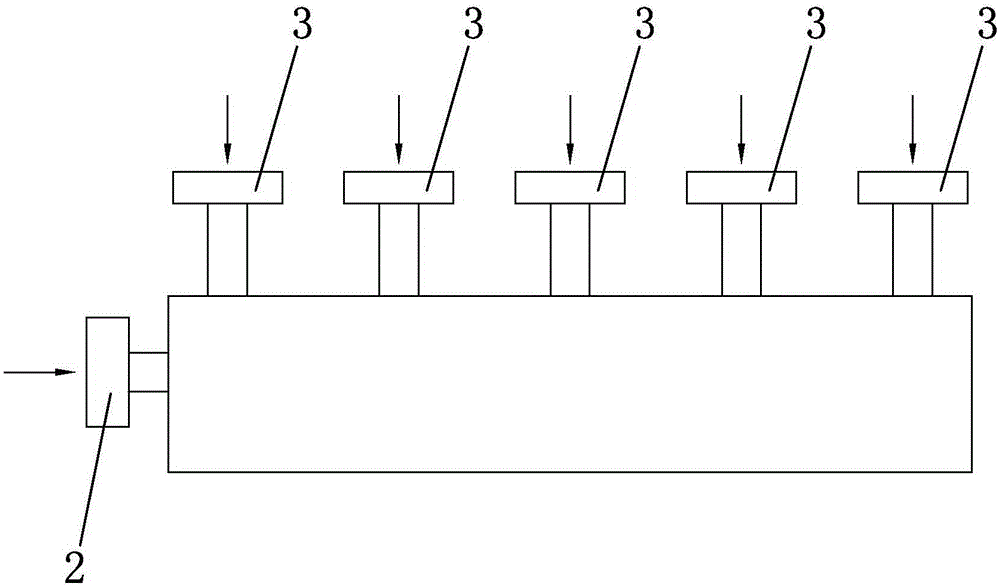

[0029](a) adopt piperonine and glyoxylic acid as raw material, select the reactor 1 of bar shape for use, on reactor 1, main feeding inlet 2 is arranged horizontally, on reactor 1, at least three auxiliary feeding inlets 3 are vertically arranged, The auxiliary feed ports 3 are uniformly distributed on the reactor 1 in a straight line. Glyoxylic acid is continuously fed into the reactor 1 through the main feed port 2. When the glyoxylic acid is at 1 / 5 of the total volume of the reactor 1, the piperonyl ring is divided into the first batch, the second batch, and the third batch. Batch, etc., the specific batch is determined according to the quantity of the auxiliary feed port 3, the batch of pepper rings closest to the main feed port 2 has the heaviest weight, and then the pepper ring weight decreases in turn, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com