High efficiency wet desulfuration and dust-removing device

A technology of wet desulfurization and dust removal device, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problems of short contact time, large drop of fluid resistance in the tower, and low contact probability, and achieve contact reaction. The effect of complete, sufficient desulfurization and dust removal, and sufficient gas-liquid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

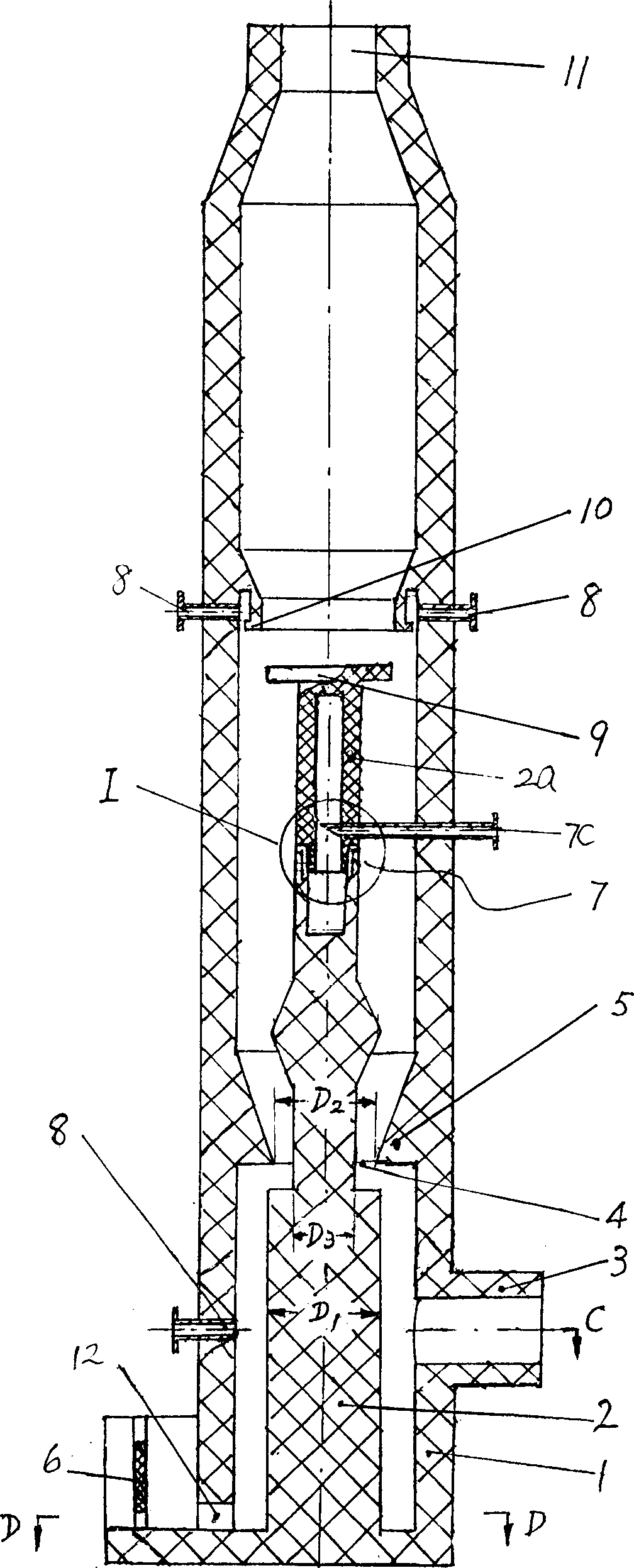

[0017] Embodiment 1. The high-efficiency wet desulfurization and dust removal device of this embodiment can be obtained from figure 1 and figure 2 As can be seen in the figure, it includes an upright main tower 1 with an inner tower 2 in its center, a flue gas outlet pipe 11 is arranged at the top of the main tower, and a tangential flue gas inlet pipe 3 and gray water and desulfurization pipes are arranged at the bottom. The outlet pipe 12 of the slag, the upper and lower parts of the tower wall are respectively provided with a group of tangential liquid spray pipes 8, and the inner wall of the main tower 1 above the top of the inner tower 2 has a water retaining ring 10, and the main tower is located at the flue gas inlet. The inner wall of the tower above the tube 3 is provided with a circle of inner convex ring 5 which can make the channel of the fluid fold to the center of the tower first and then expand gradually upwards.

[0018] The above-mentioned inner convex ring ...

Embodiment 2

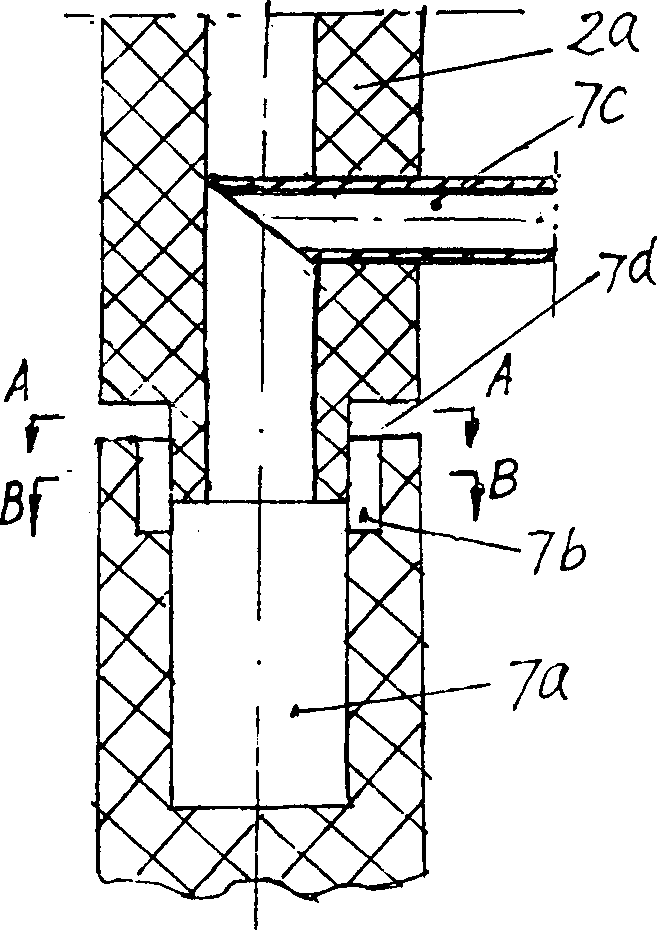

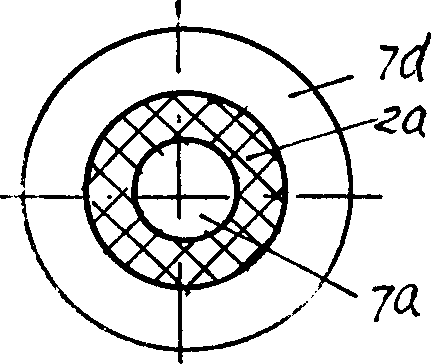

[0020] Embodiment 2. This embodiment can be obtained from figure 1 and figure 2 Seen in, it differs from embodiment 1 in that: the overflow device 7 with liquid medicine in the center of the main tower, this overflow device can be obtained from figure 2 , image 3 and Figure 4As can be seen in the figure, it includes a liquid medicine inlet pipe 7c connected to the wall of the main tower, a liquid medicine pool 7a connected to the liquid medicine inlet pipe and arranged on the inner tower, and an overflow channel 7b opened at the top of the pool, an annular overflow Orifice 7d. For the convenience of manufacturing and installation, the overflow device 7 can be installed through an upper cover 2a that is fitted with the inner tower, and the annular overflow port 7d is directly arranged at the bottom of the upper cover, and the overflow channel 7b is provided On the top end of the tower where the inner tower and the upper cover are fitted, the overflow channel 7b communic...

Embodiment 3

[0021] Embodiment 3. This embodiment can be obtained from figure 1 Seen in, it differs from embodiment 1 or 2 in that: the top of inner tower 2 can also be provided with dehydrator 9, and this dehydrator is a disc that is fixed on the top of inner tower and its diameter is greater than inner tower diameter. In this example, the dehydrator is installed on the top of the inner tower loam cake 2a. Together with the water retaining ring 10, it intercepts liquid droplets and solids from different radial positions in the main tower, and drops down by their own weight. The slag is discharged from the outlet pipe 12, while the flue gas is discharged from the flue gas outlet pipe 11 upwards by inertia.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com