Method for absorbing maleic-anhydride-containing gas by employing dynamic wave absorption tower

An absorption tower and dynamic wave technology, applied in the field of maleic anhydride production, can solve the problems of difficult to guarantee product quality and yield, large consumption of cooling water and electricity, high investment cost of instruments, large gas-liquid contact surface area, and reduced resistance drop. , the effect of fast solvent renewal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

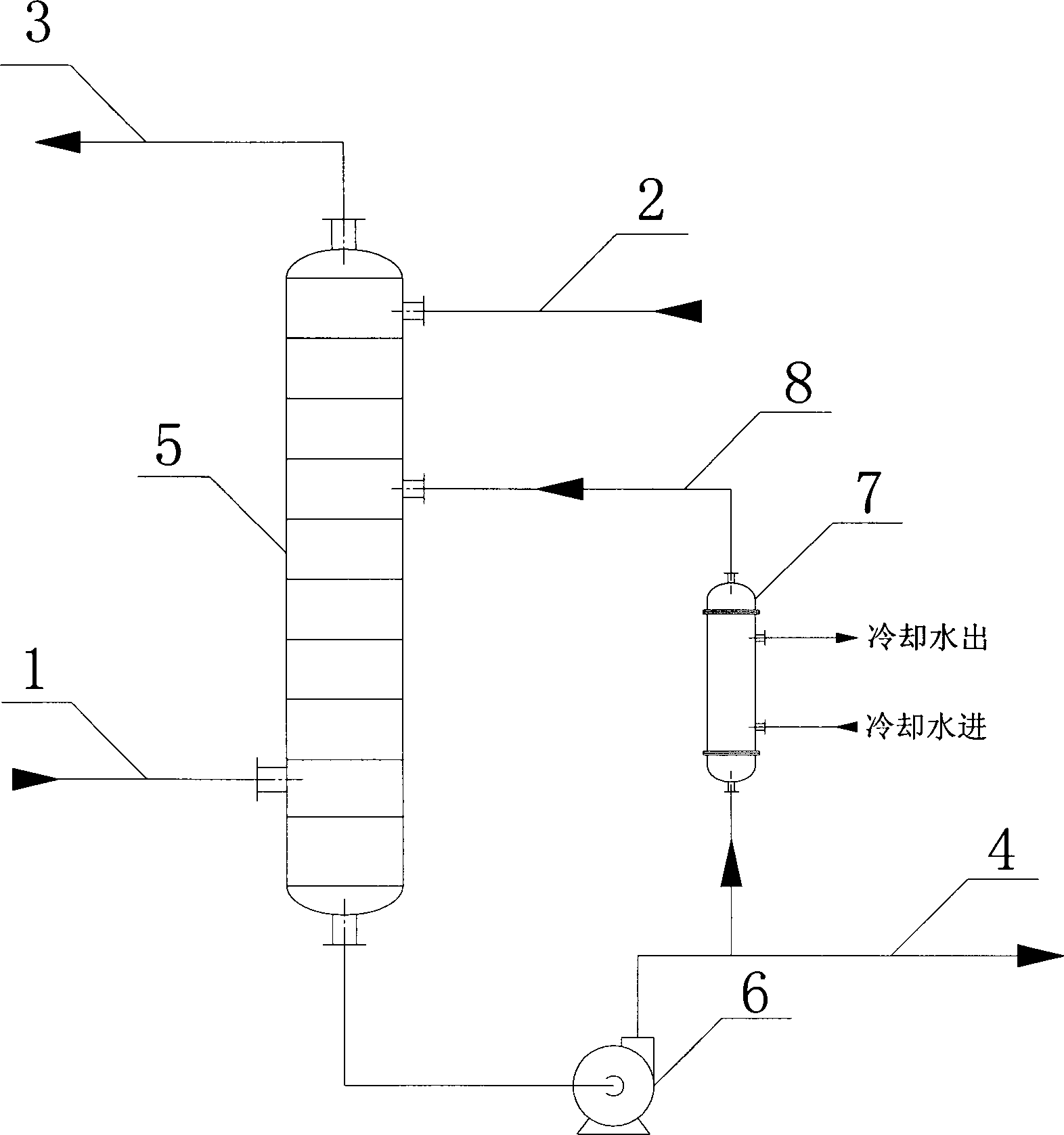

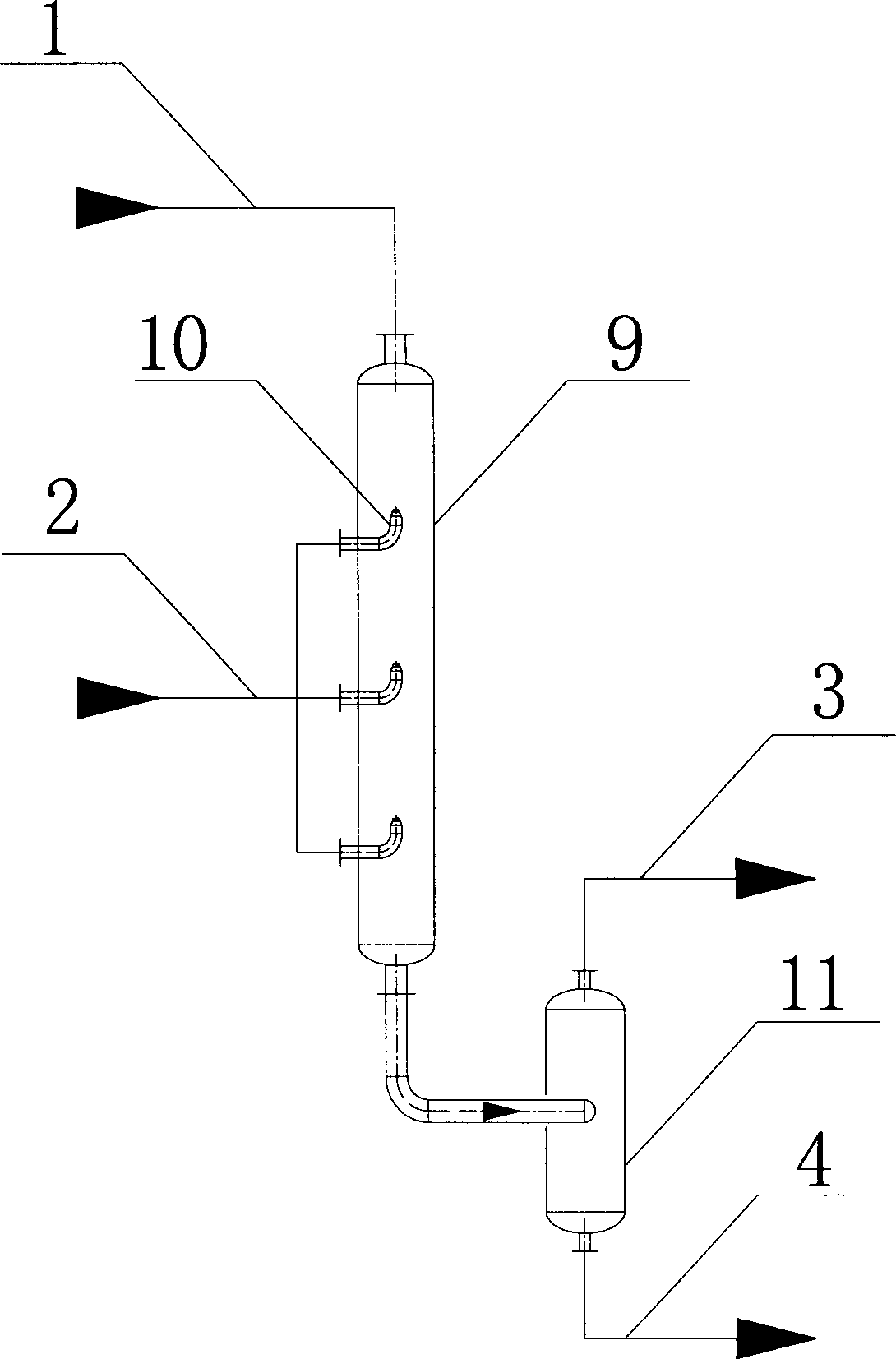

[0038] according to the invention figure 2 The device can implement the following two working conditions:

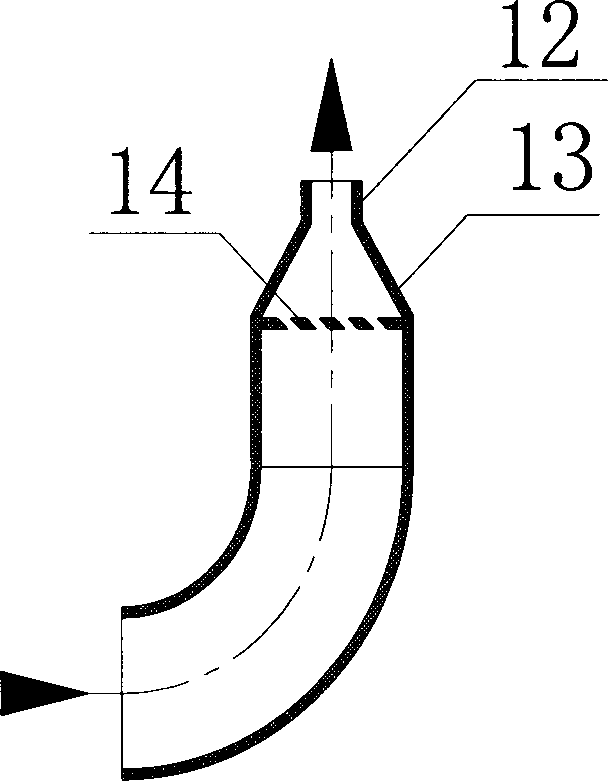

[0039] The first working condition is to send the gas 1 containing maleic anhydride into the dynamic wave absorption tower 9 from the top of the tower, and the absorption solvent DBP is sprayed upward into the tower from the nozzle 10 against the air flow, and the gas-liquid mixture after absorption enters the separator 11 for further processing. Gas-liquid separation, the separated gas phase and liquid phase are sent out separately.

[0040] The second implementation scenario is similar to the first implementation scenario, except that process water is used instead of DBP solvent as the absorbent.

[0041] The size of the dynamic wave absorption tower used in the implementation of working conditions 1 and 2 is: 0.1 meters in diameter and 2 meters in height; the size of the separator is 0.5 meters in diameter and 1.2 meters in height.

[0042] Implementation Case 1: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com