System for CDQ pressure control emitted gas desulfurization and dust removal

A technology for desulfurization, dust removal, and pressure regulation. It is used in the separation of dispersed particles, grain treatment, chemical instruments and methods, etc. It can solve the problem of less control work, reduce SO2 and dust emissions, and achieve a simple system and uniform flow field distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

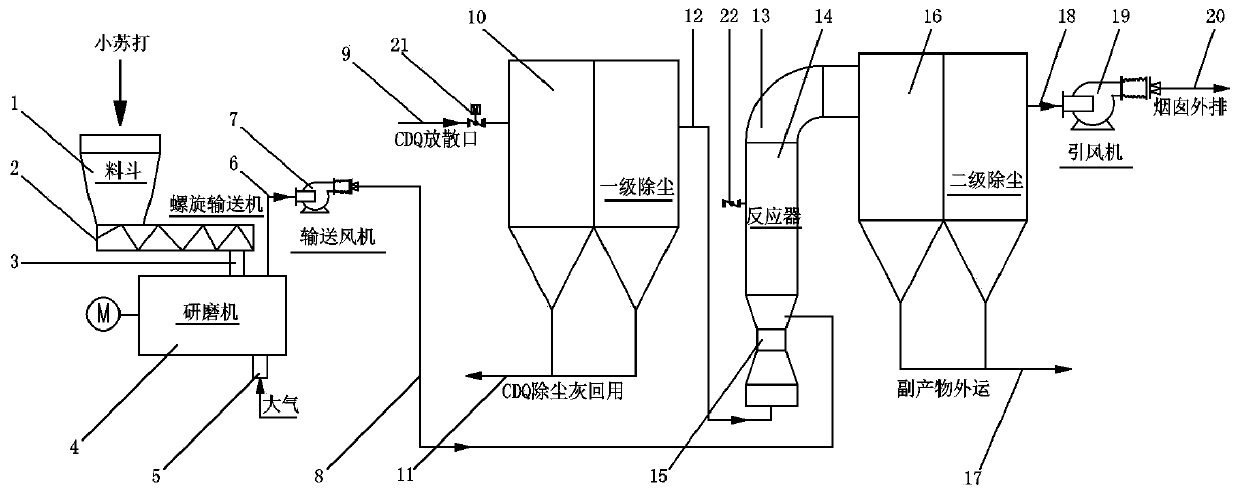

[0016] In order to enable those skilled in the art to better understand the technical solution of this patent, the patent will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0017] Such as figure 1 As shown, a system for desulfurization and dust removal of CDQ pressure-adjusted vent gas mainly includes a hopper 1, a screw conveyor 2, a baking soda grinder 4, a conveying fan 7, a first-stage dust collector 10, a venturi 15, and a desulfurization reactor 14. Secondary dust collector 16 and induced draft fan 19. After the baking soda raw material (feeding particle size2 CO 3 SO in the vented gas 2 A chemical reaction occurred. The desulfurized diffused gas entrains powdery granular products into the secondary dust collector 16, and the clean diffused gas enters the chimney through the induced draft fan 19 for discharge.

[0018] The whole system can be divided into three parts: baking soda grinding system, desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com