Patents

Literature

104results about How to "Uniform distribution of flow field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

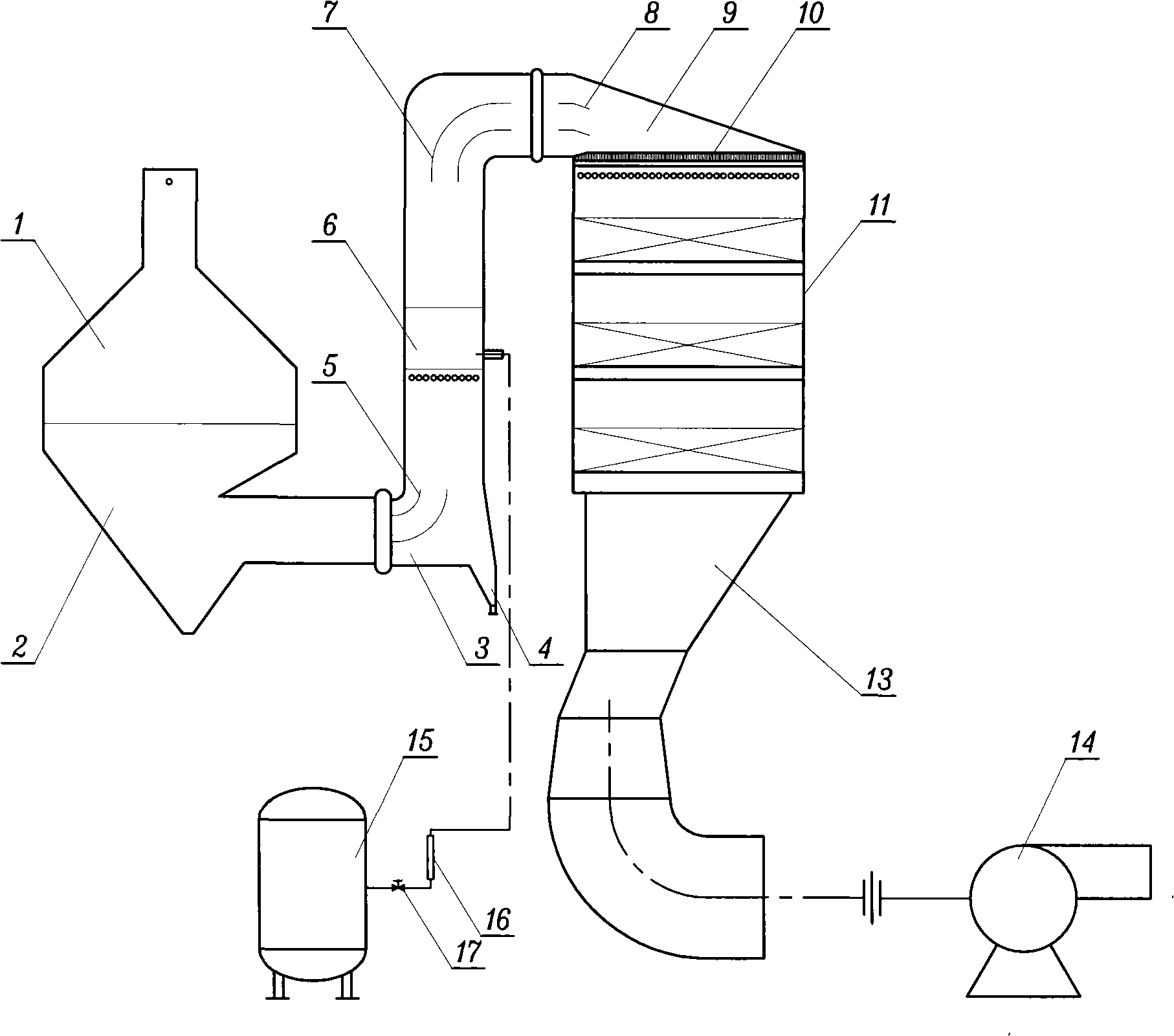

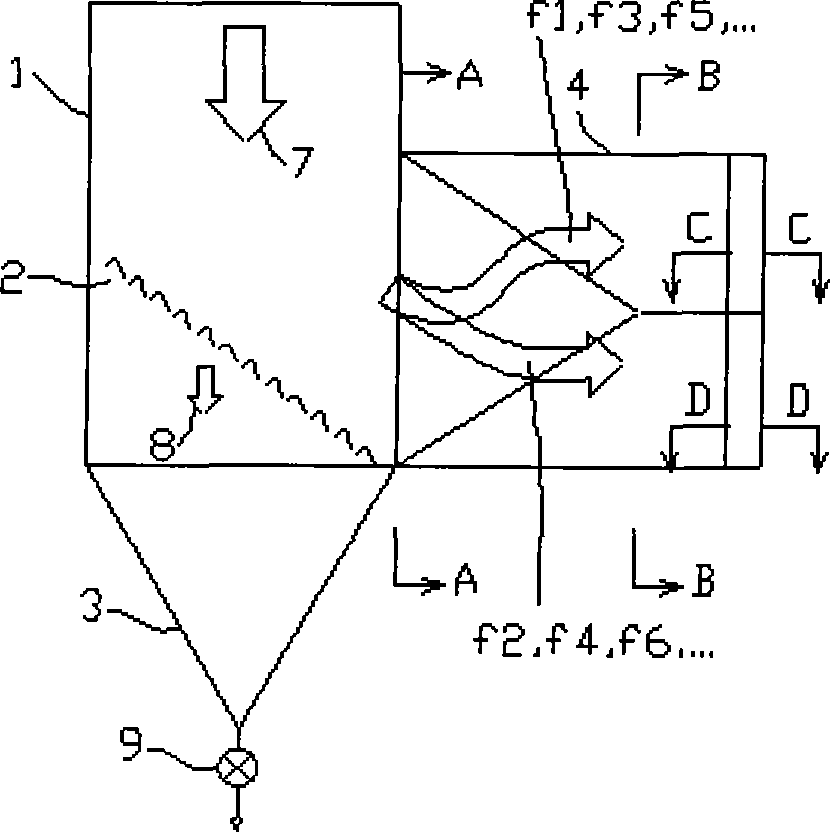

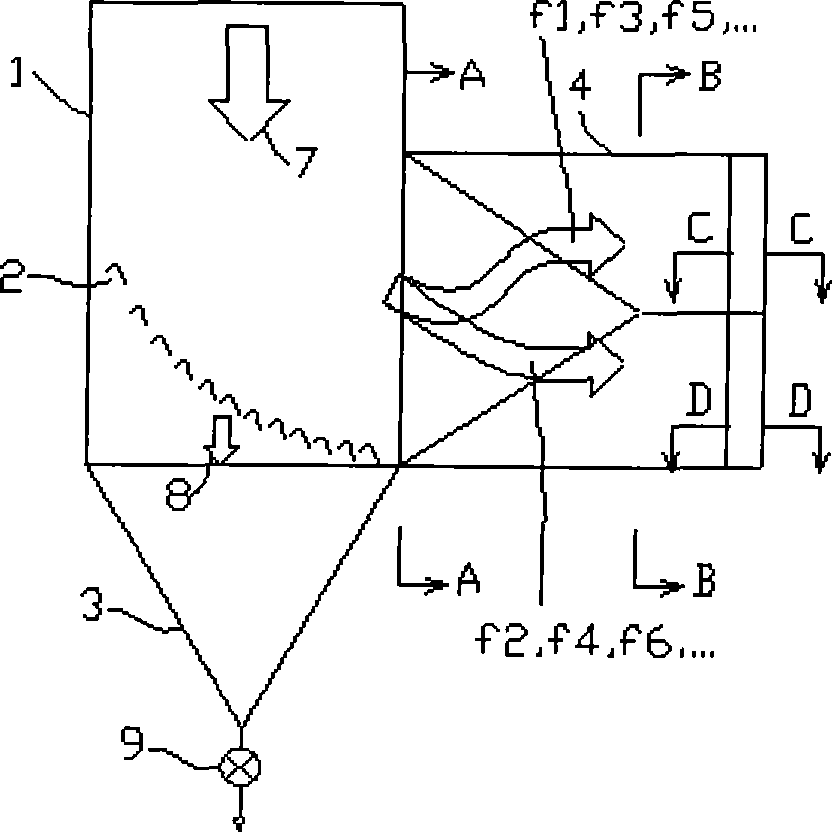

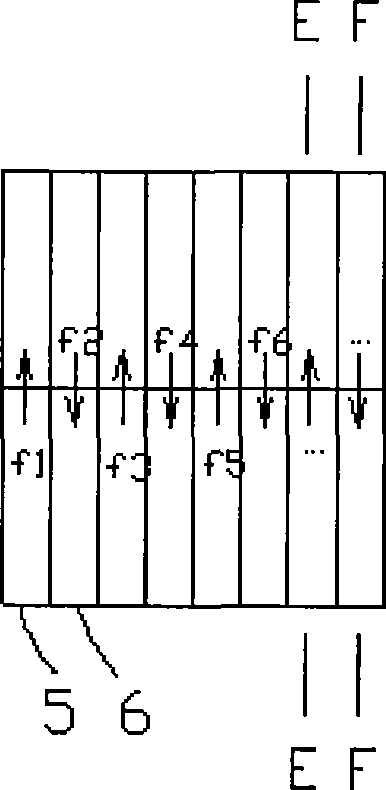

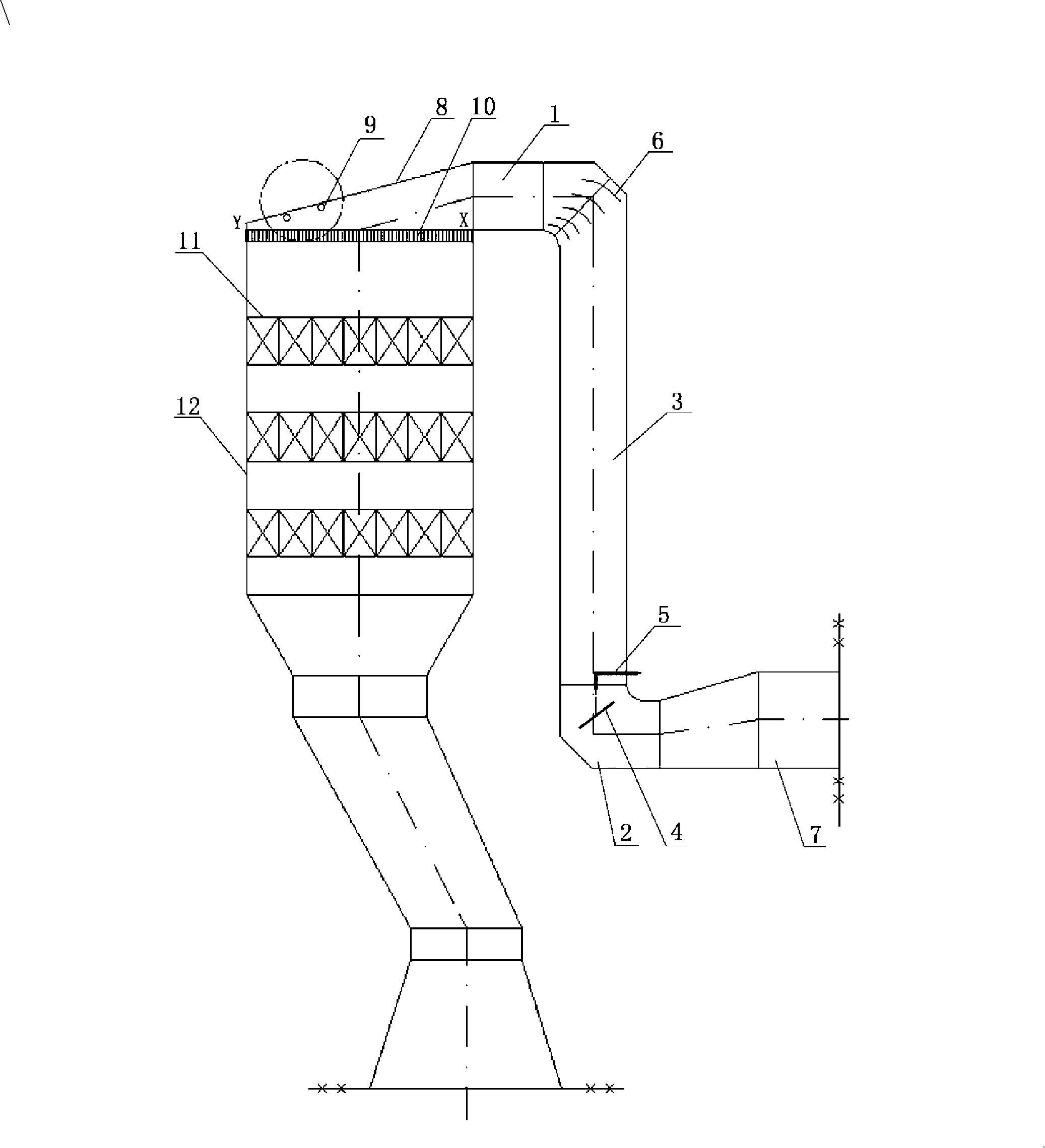

Simulation platform and test method for flow field arrangement structure of flue gas denitration apparatus

The invention discloses a simulating platform of the fume denitration device flow field distributing structure and a testing method. At present the denitration efficiency of the fume denitration device is greatly affected by the fume velocity distributing uniformity and the reducer ammonia gas / nitrogen oxide mixing uniformity. The invention includes an inlet pipe, a coal economizer, an inlet flue, a current stabilizing plate, a reactor, an outlet flue and a blower connected in turn, wherein an ash bucket is arranged at the round of the bottom of the inlet flue, and an air jetting device is arranged on the vertical section of the inlet flue. Guide plates located on the bottom of the top flue are arranged on the round of each flues. A plurality of layers of catalyzer are provided in the reactor, and a plurality of speed measuring holes are arranged at the entrance of the air jetting device and under the current stabilizing plate. The invention builds the simulating platform of the denitration device flow field structure, performs the experiment through the simulating platform, obtains the flow field distributing status of the denitration device, provides reasonable engineering measurement to improve the flow field distributing structure in the denitration system.

Owner:浙江融智能源科技有限公司

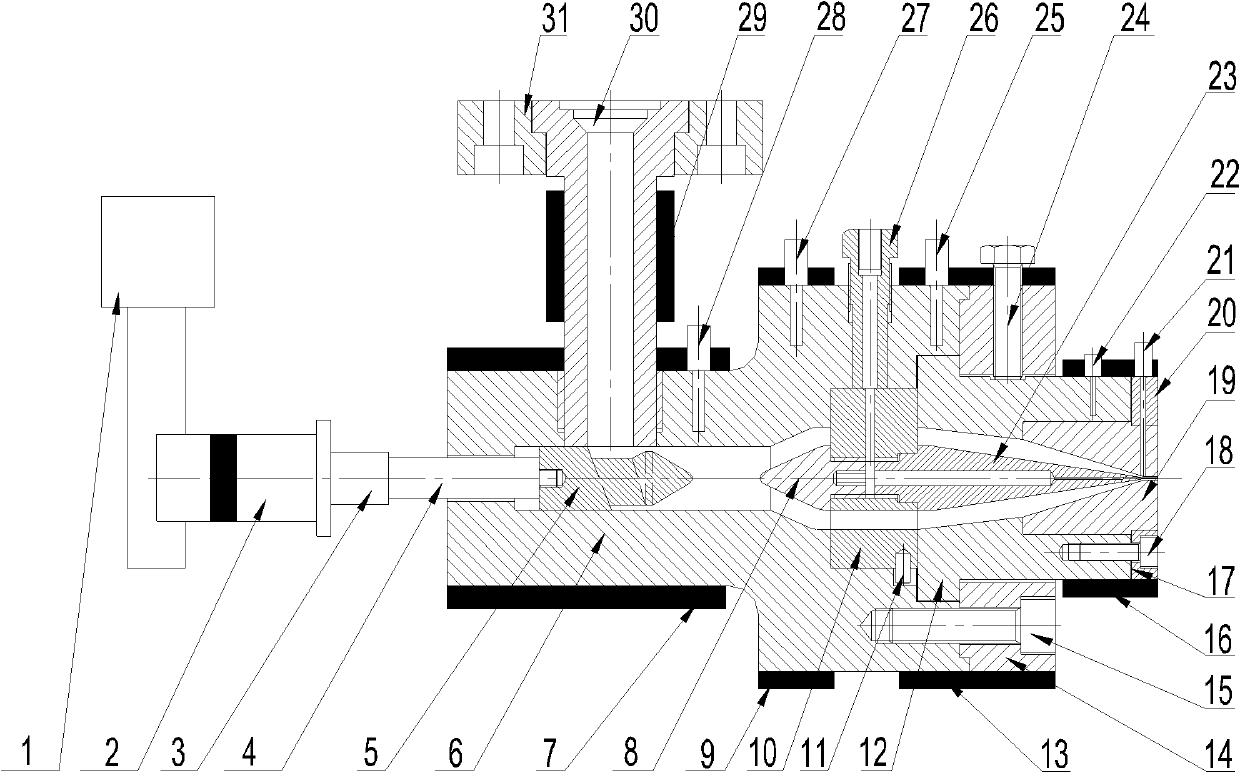

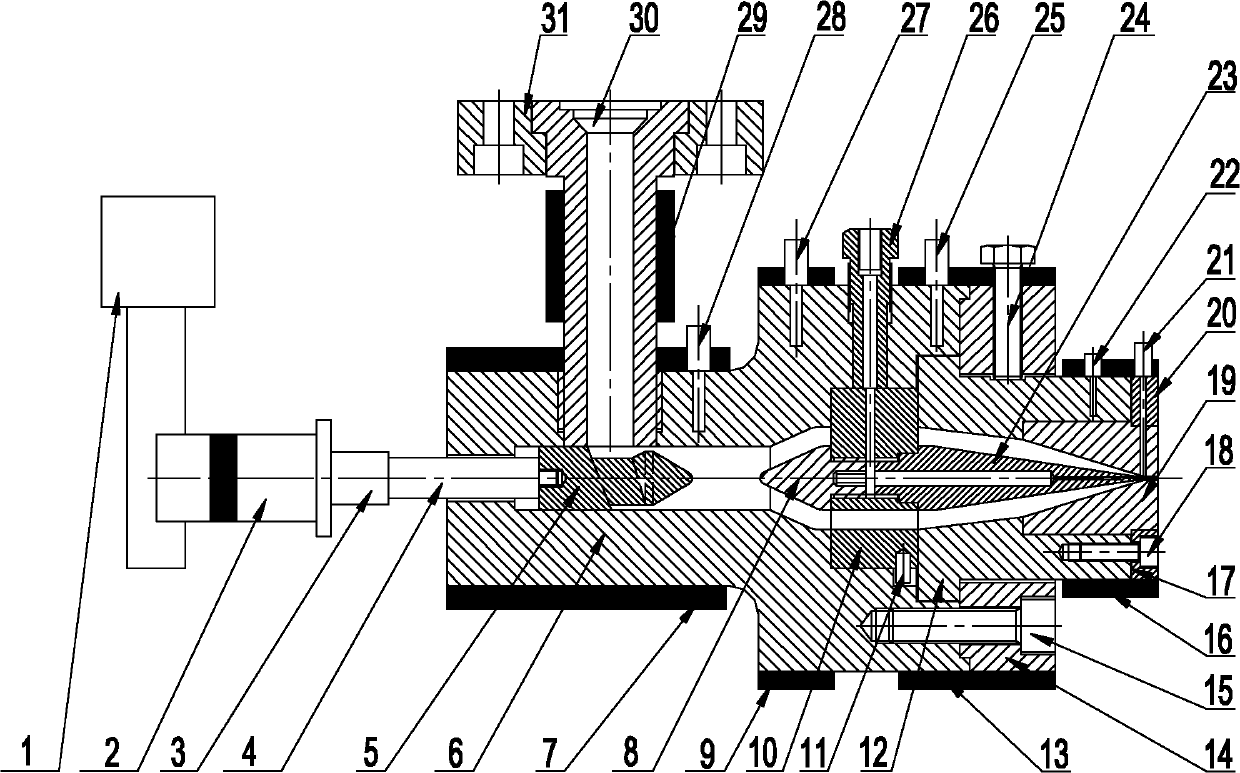

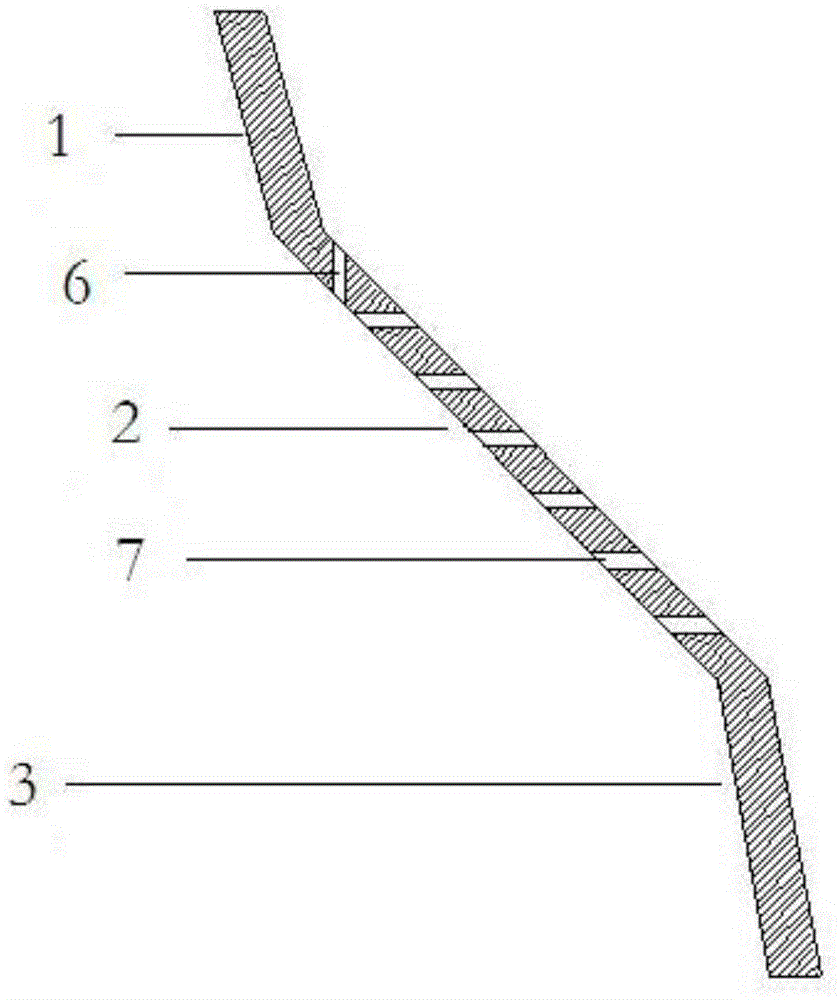

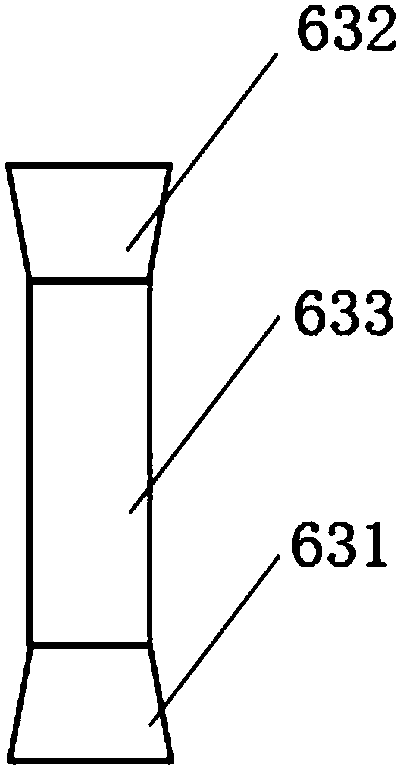

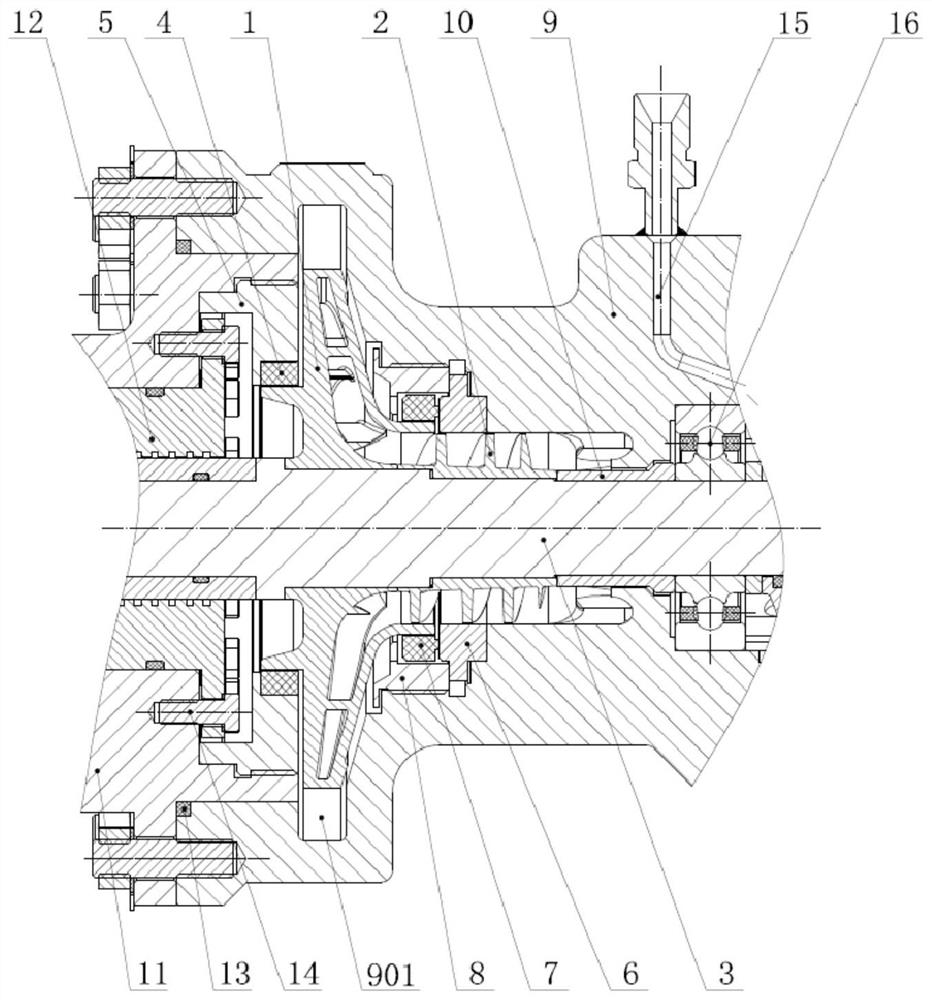

Ultrasonic vibration microtube extrusion mould

InactiveCN101947846AUniform distribution of melt flow fieldUniform distribution of flow fieldTubular articlesTransformerEngineering

The invention discloses an ultrasonic vibration microtube extrusion mould, belonging to the technical field of polymer extrusion moulding. The invention is characterized in that the mould comprises an ultrasonic-frequency power supply, an energy converter, a vibration rod, an amplitude transformer, a vibration head, a die head body, a spure sperader, a support plate, a positioning pin, a die supporting plate, a baffle plate, a fastening bolt, a washer, a die, a check ring, an integrated pressure / temperature sensor, a mandrel, an adjusting bolt, an air vent bolt, a heating ring, a temperature sensor, a connecting pipe and a flange plate. The mould adopts a feeding mode of which feeding direction is perpendicular to the extrusion direction; the vibration head adopts a spiral groove type structure and vibrates along the microtube extrusion direction; different spure speraders, mandrels and dies with different structural parameters can be changed according to demands; and the integrated pressure / temperature sensor is used to measure the changes of the pressure / temperature in the runner of the mould. By designing the ultrasonic vibration microtube extrusion mould capable of realizing vertical feeding, ultrasonic vibration is combined with the plastic microtube extrusion moulding, thus reducing flow resistance, increasing the production efficiency and obtaining the plastic microtube with high quality.

Owner:DALIAN UNIV OF TECH

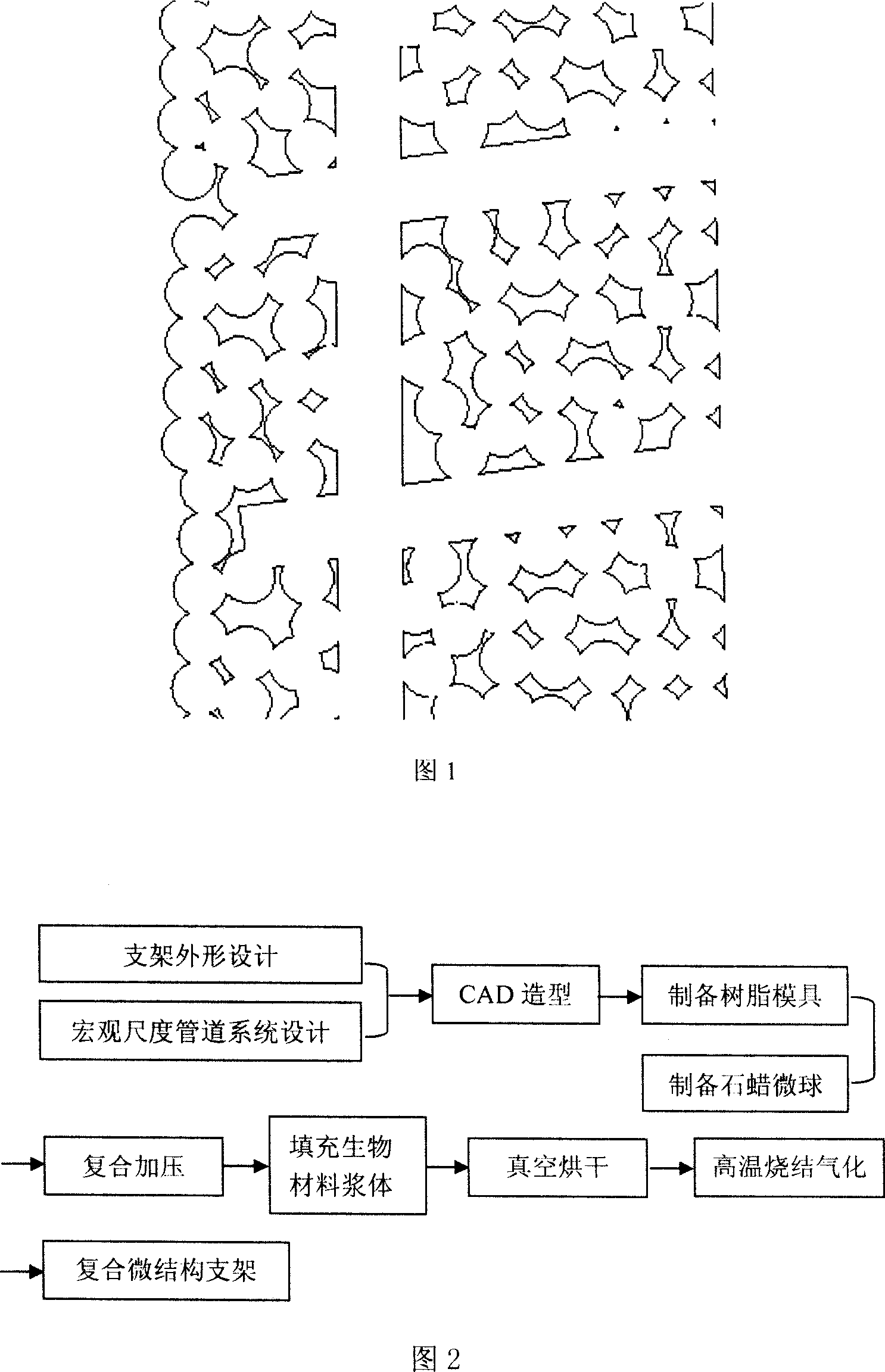

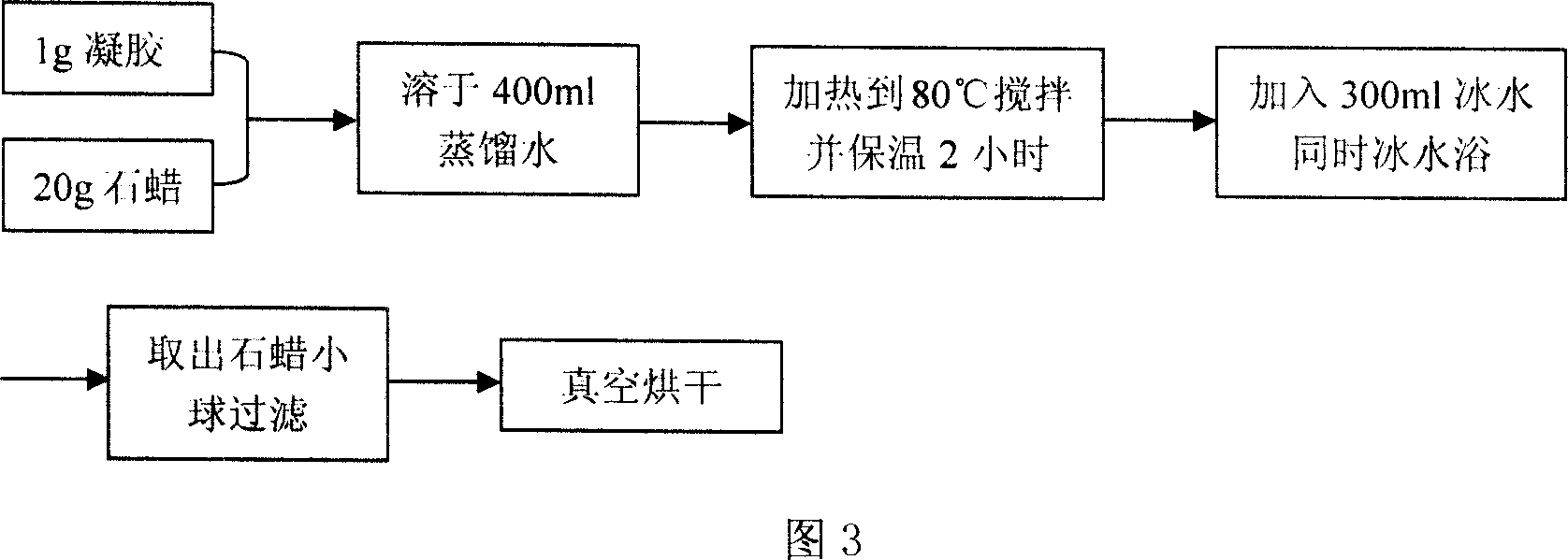

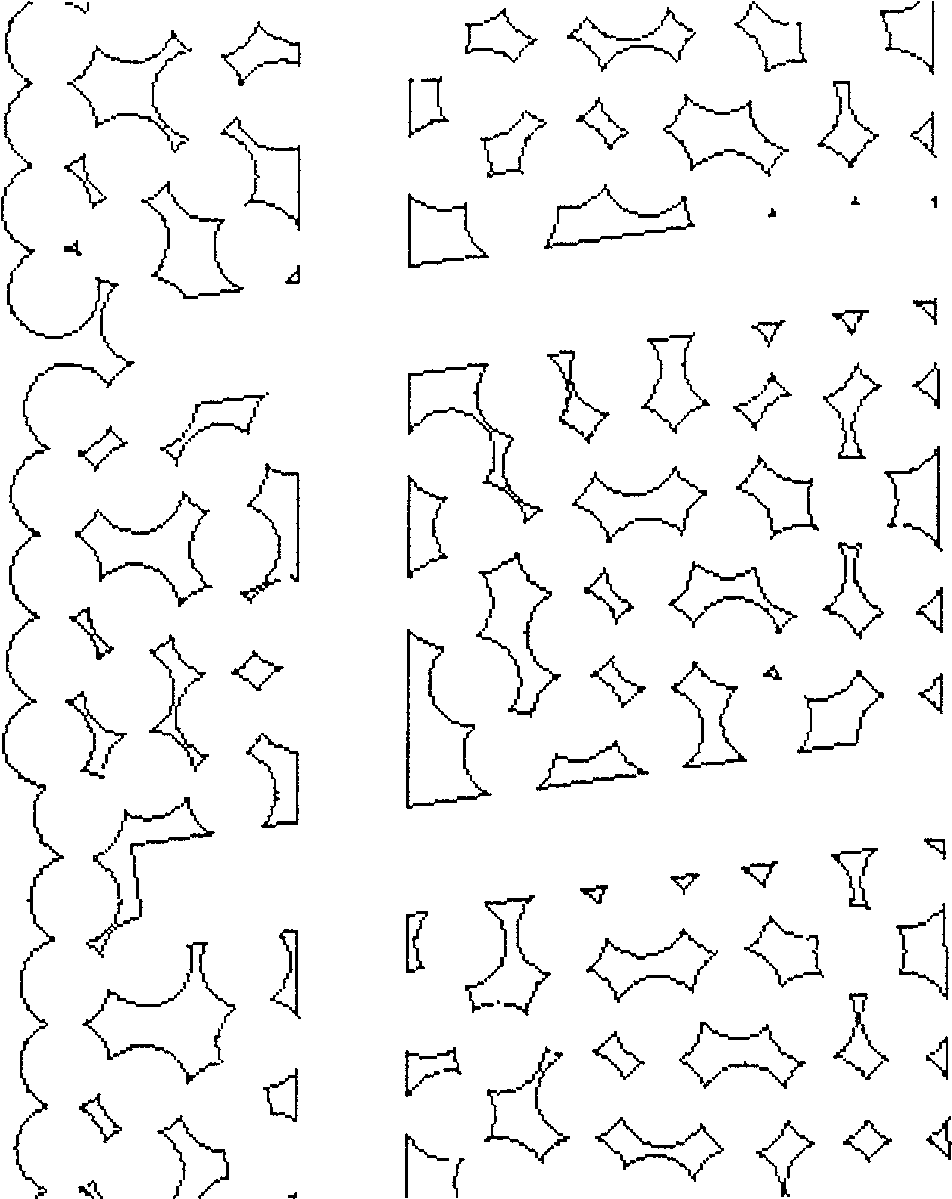

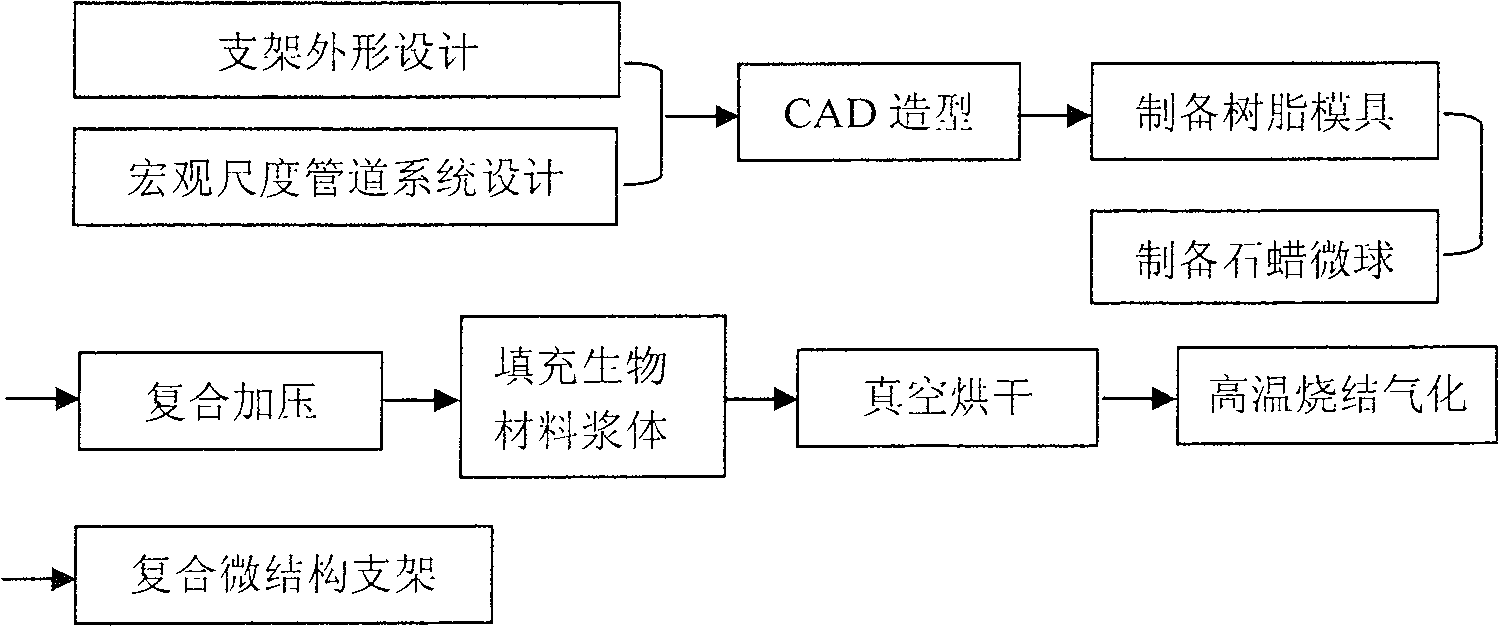

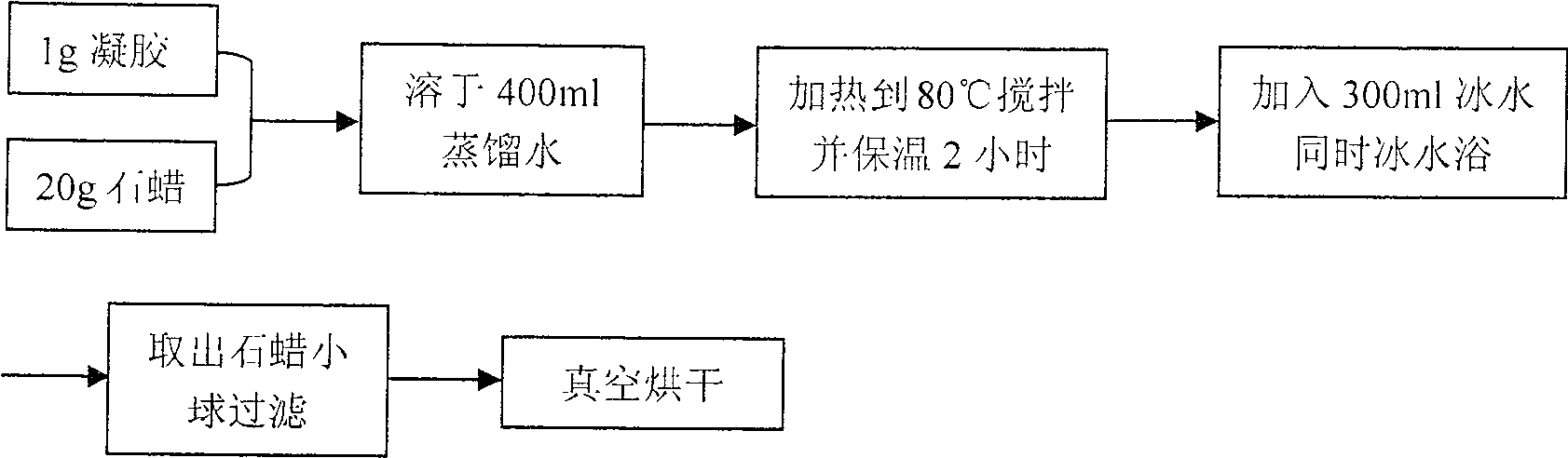

Dual-scale micro-structure artificial bone scaffold and preparation method thereof

InactiveCN1994243ASolve the blockageSolve for uniformityStentsBone implantMicro structureMINERAL WAX

The invention relates to a dual-size micro bone support and relative production, wherein said support comprises micro ball connecting hole and macro tube; the micro tube is formed by connected ball holes; the macro tube is formed by connected straight tubes; the ball hole is through to the tube; the ball holes are randomly arranged; the tube structure can be controlled. And production comprises that: first using CAD and light solidifying shaping technique to design and control the tube structure; preparing the resin mould of bone structure; filling mineral wax balls into mould; filling biological slurry; when it is solidified and dried, thermally decomposing the resin mould and mineral wax, to obtain the bone support.

Owner:XI AN JIAOTONG UNIV

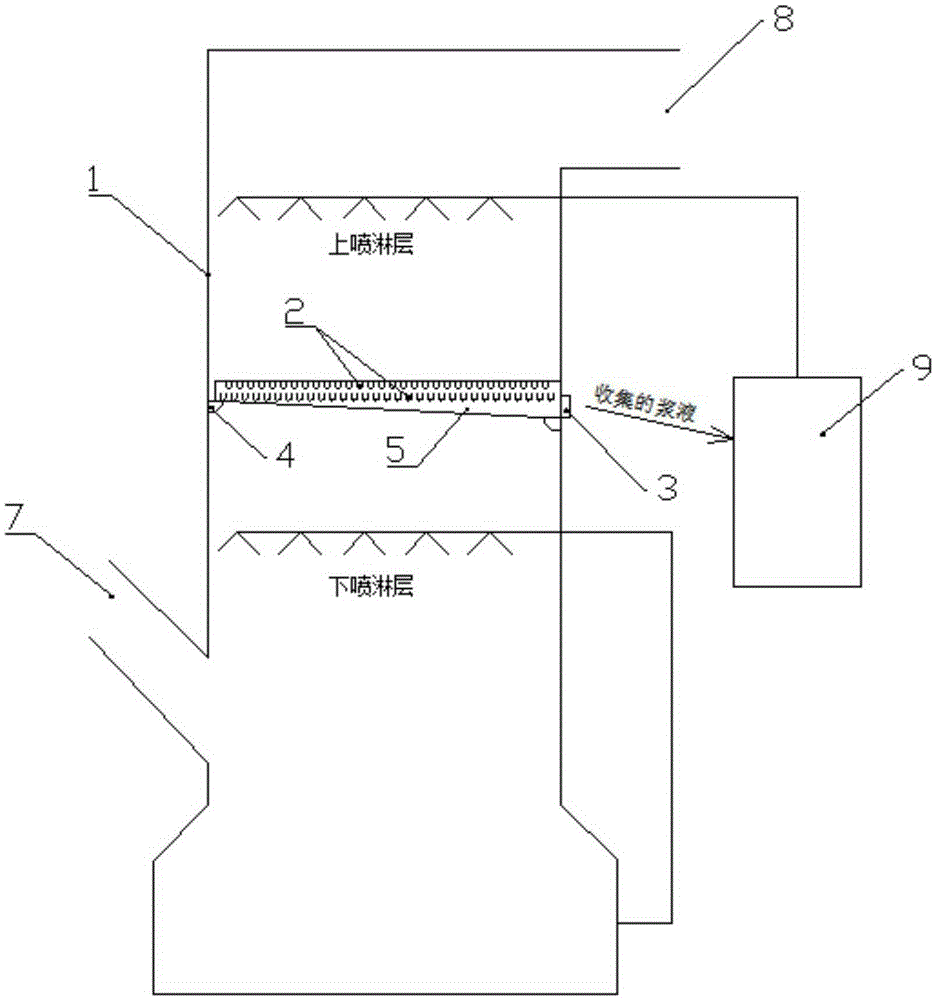

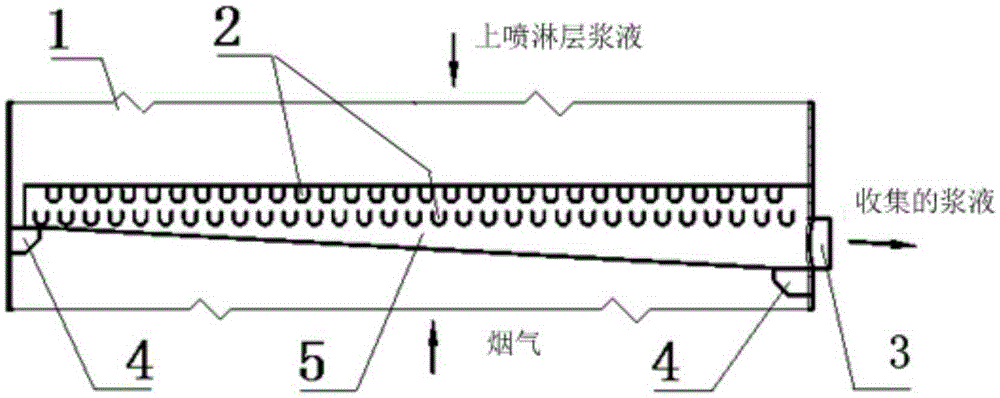

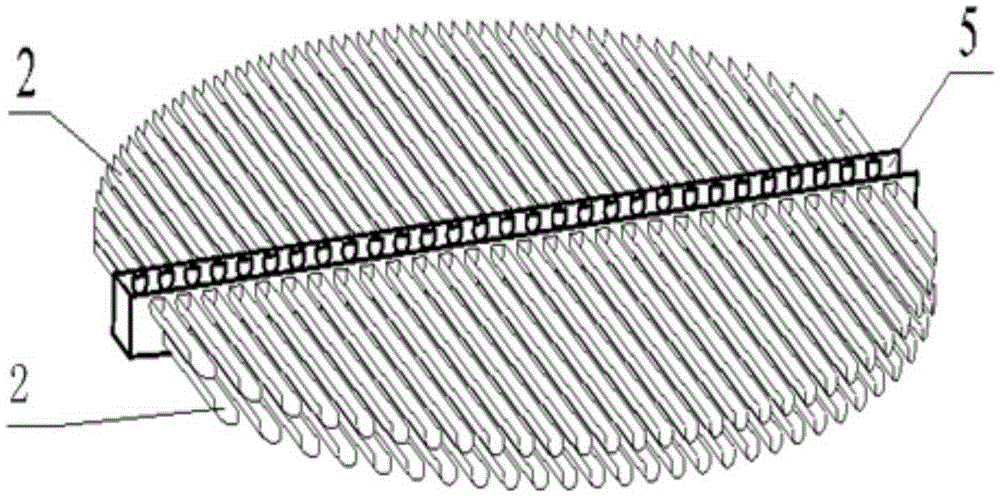

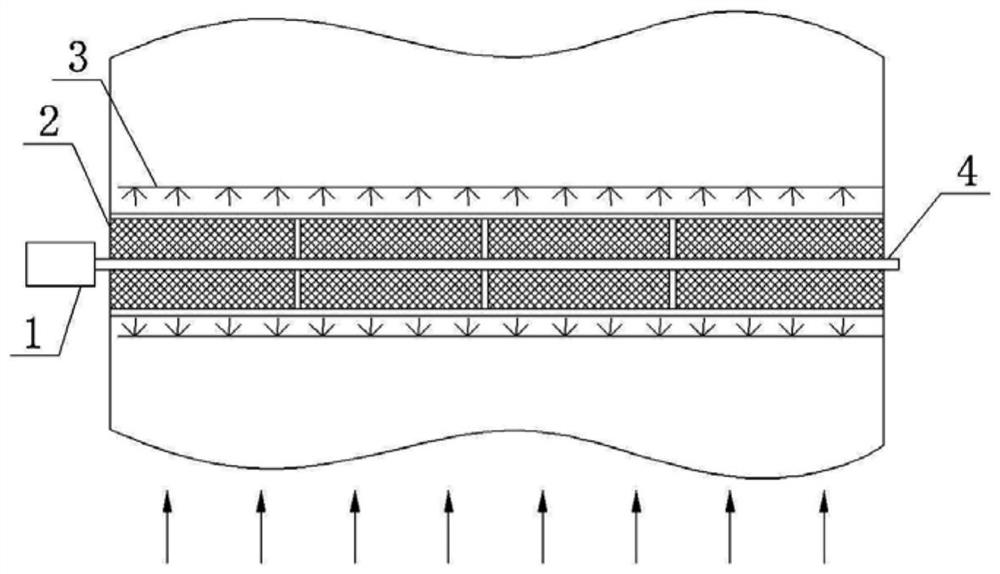

Single-tower dual-cycle wet flue gas desulfurization tower and tube groove type liquid collection device

ActiveCN105413444ALittle resistance lossReduce resistanceGas treatmentDispersed particle separationFlue gasFriction loss

The invention provides a single-tower dual-cycle wet flue gas desulfurization tower and a tube groove type liquid collection device, and belongs to the technical field of flue gas desulfurization. The desulfurization tower comprises a tower body, the bottom of the tower body is provided with a flue gas inlet, the top of the tower body is provided with a flue gas outlet, an upper spray layer and a lower spray layer are arranged on the portion, between the flue gas inlet and the flue gas outlet, inside the tower body, and the tube groove type liquid collection device is installed between the upper spray layer and the lower spray layer and separates slurry of the upper spray layer from slurry of the lower spray layer; the tube groove type liquid collection device comprises multiple liquid collection tube grooves which are formed for multiple layers in the longitudinal direction, the two adjacent layers of the liquid collection tube grooves are arranged in a staggered mode, the liquid collection tube grooves are arranged in an inclined mode, and the lower ends of the liquid collection tube grooves are communicated with a diversion groove. According to the single-tower dual-cycle wet flue gas desulfurization tower and the tube groove type liquid collection device, the flow field is uniformly distributed, the resistance loss of the structural design is small, and the contact effect between the gas and liquid is good. Therefore, the slurry of the upper spray layer can be collected, the system resistance can be reduced, and the desulphurization efficiency is improved.

Owner:SHANDONG UNIV

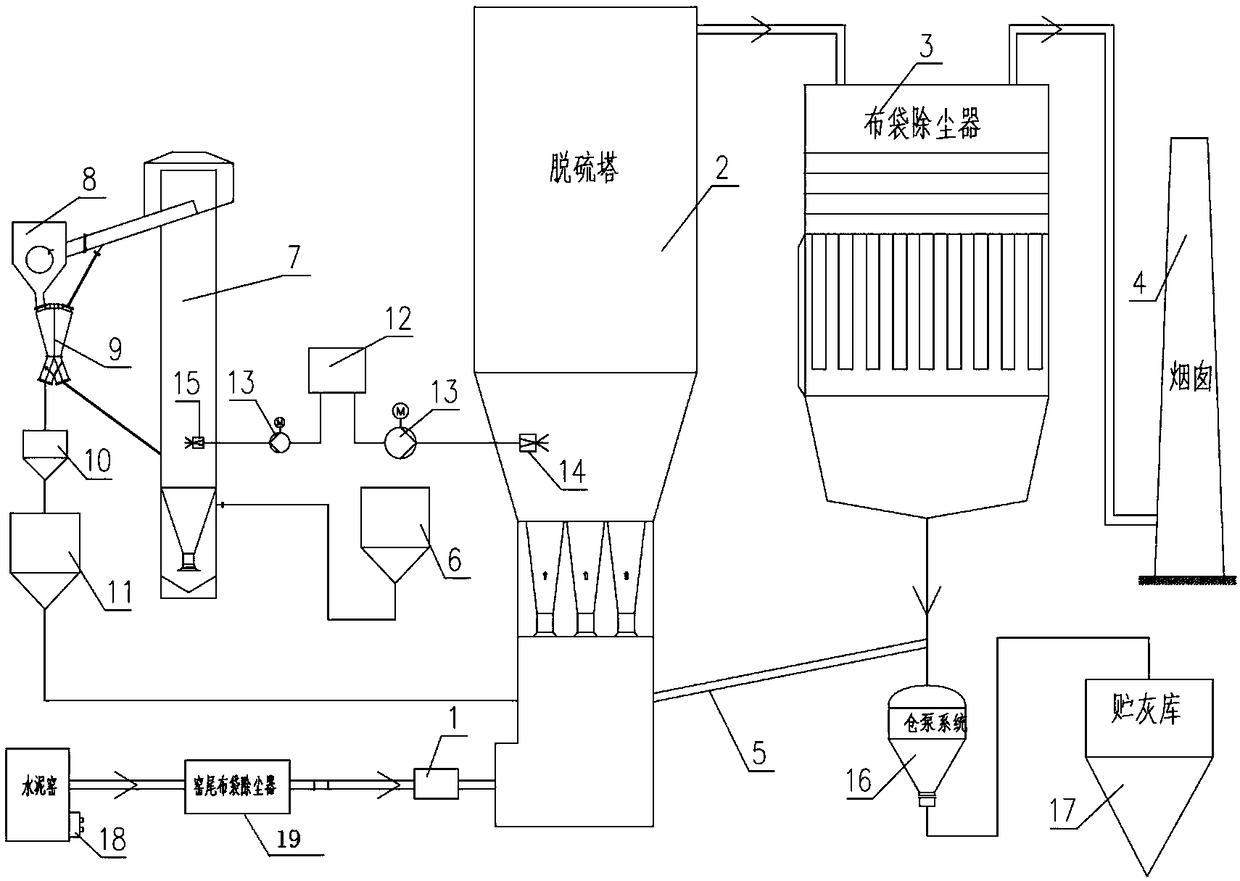

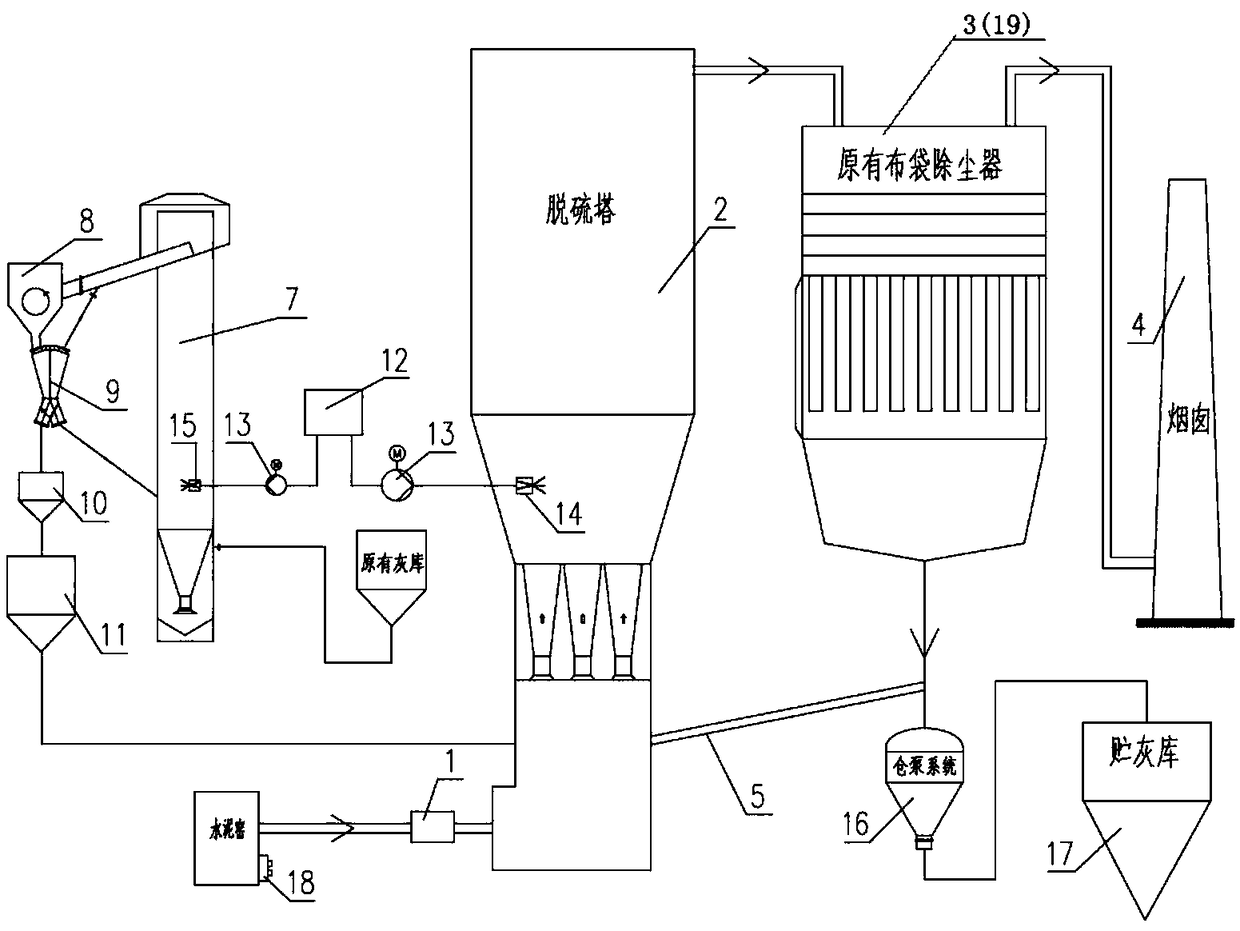

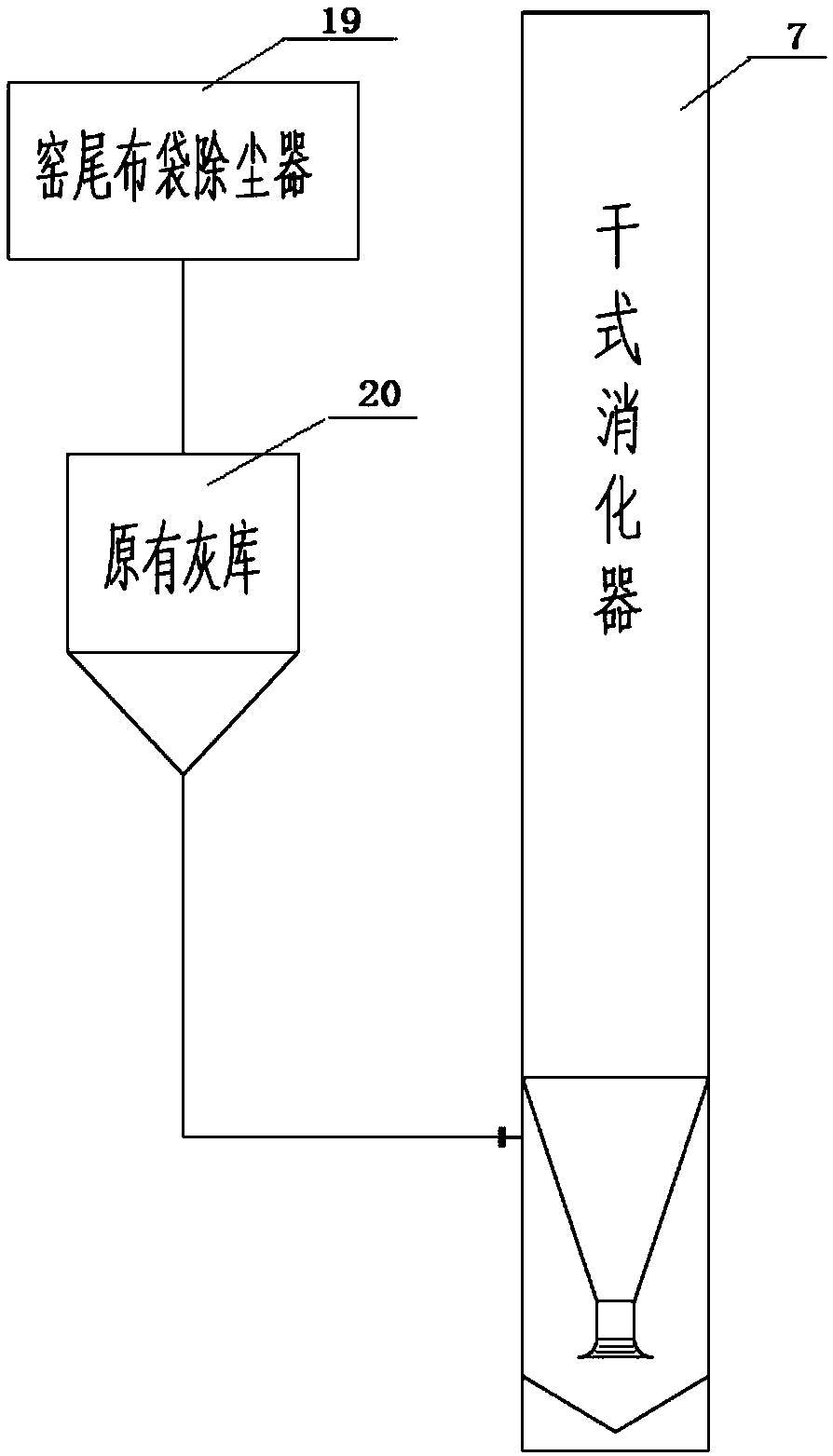

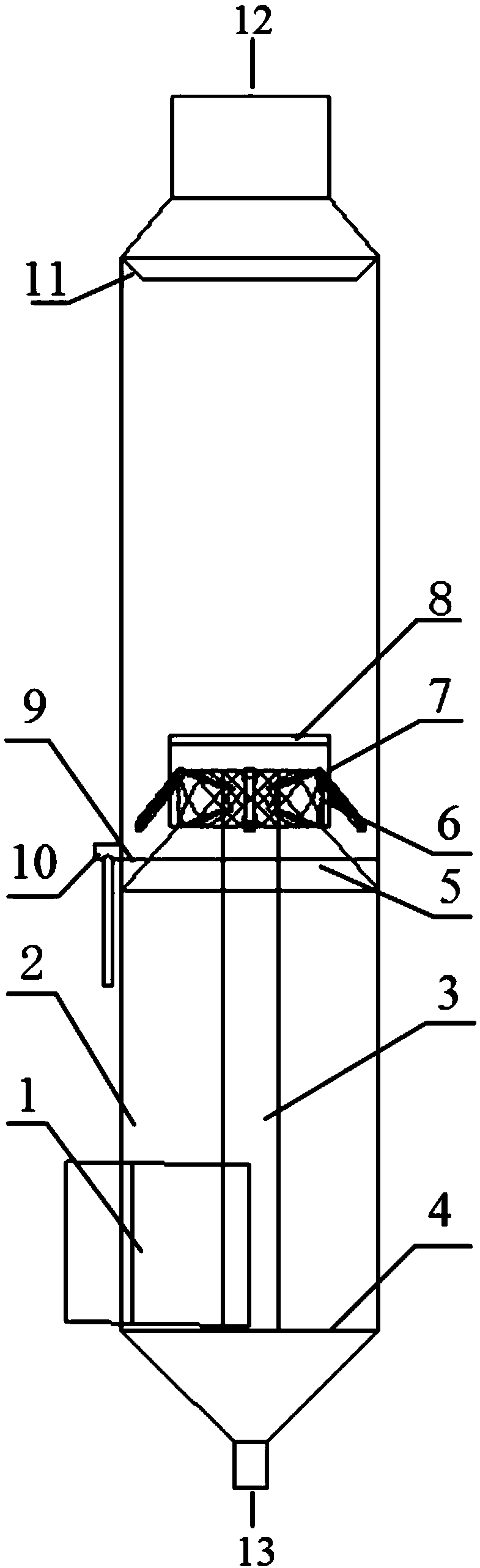

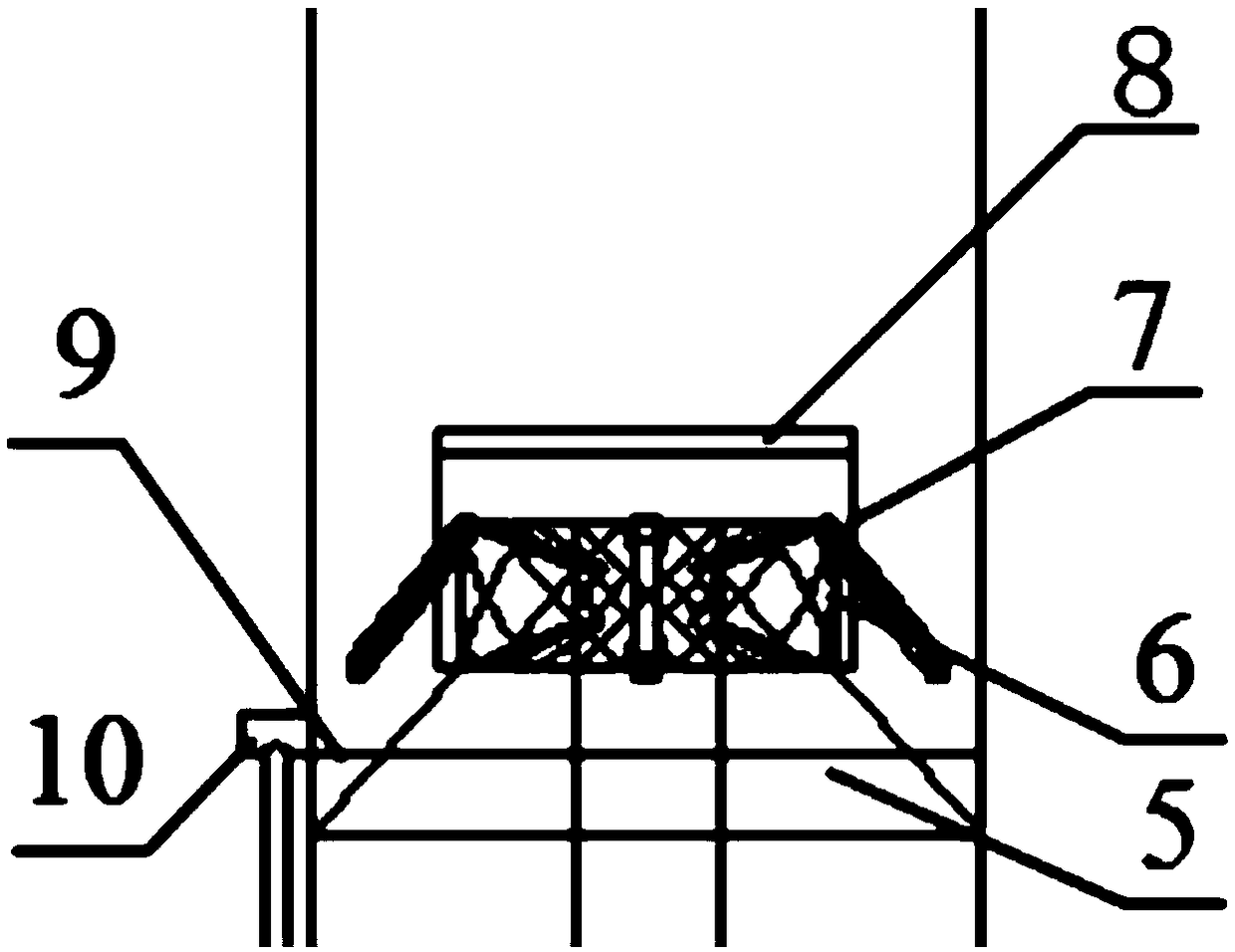

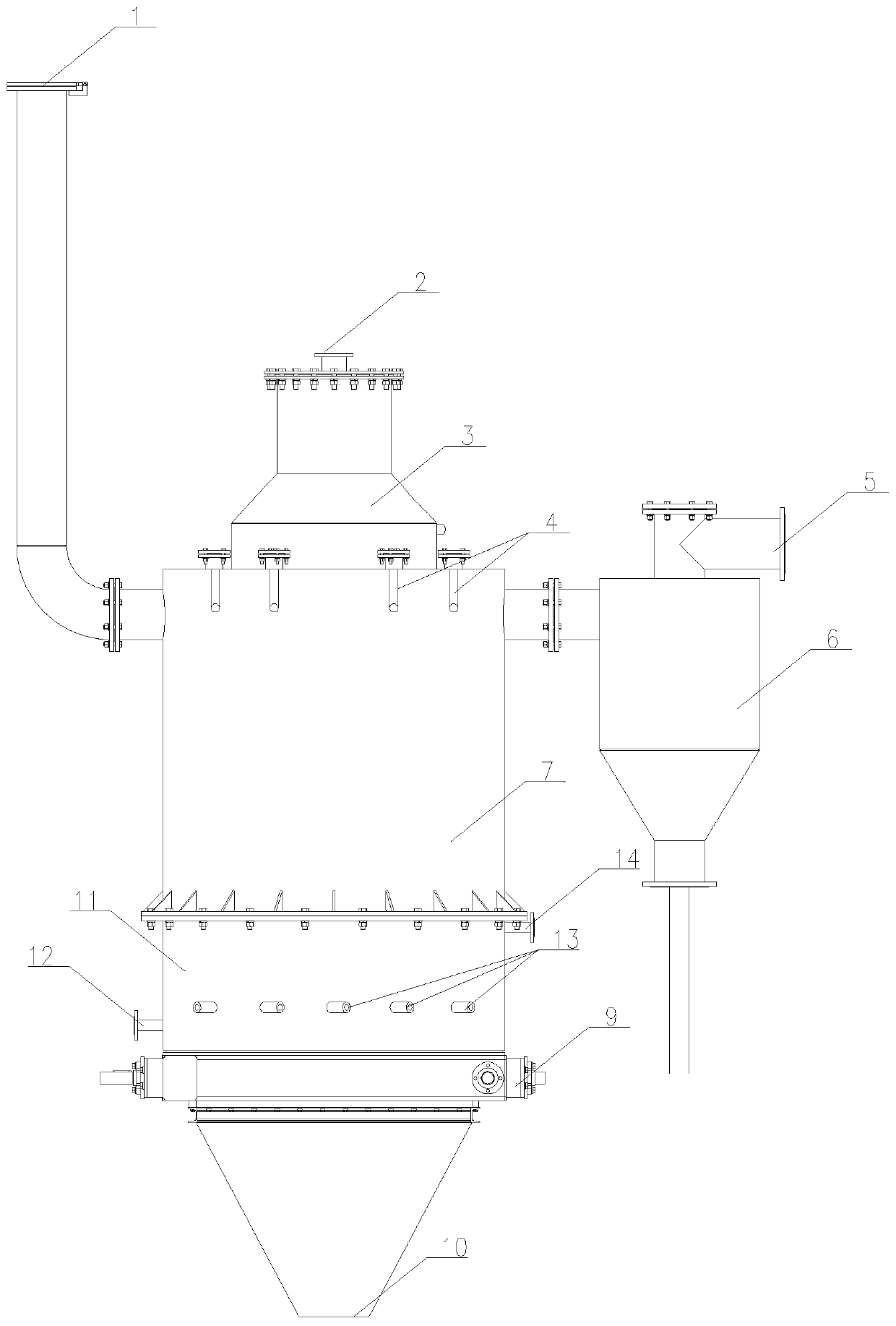

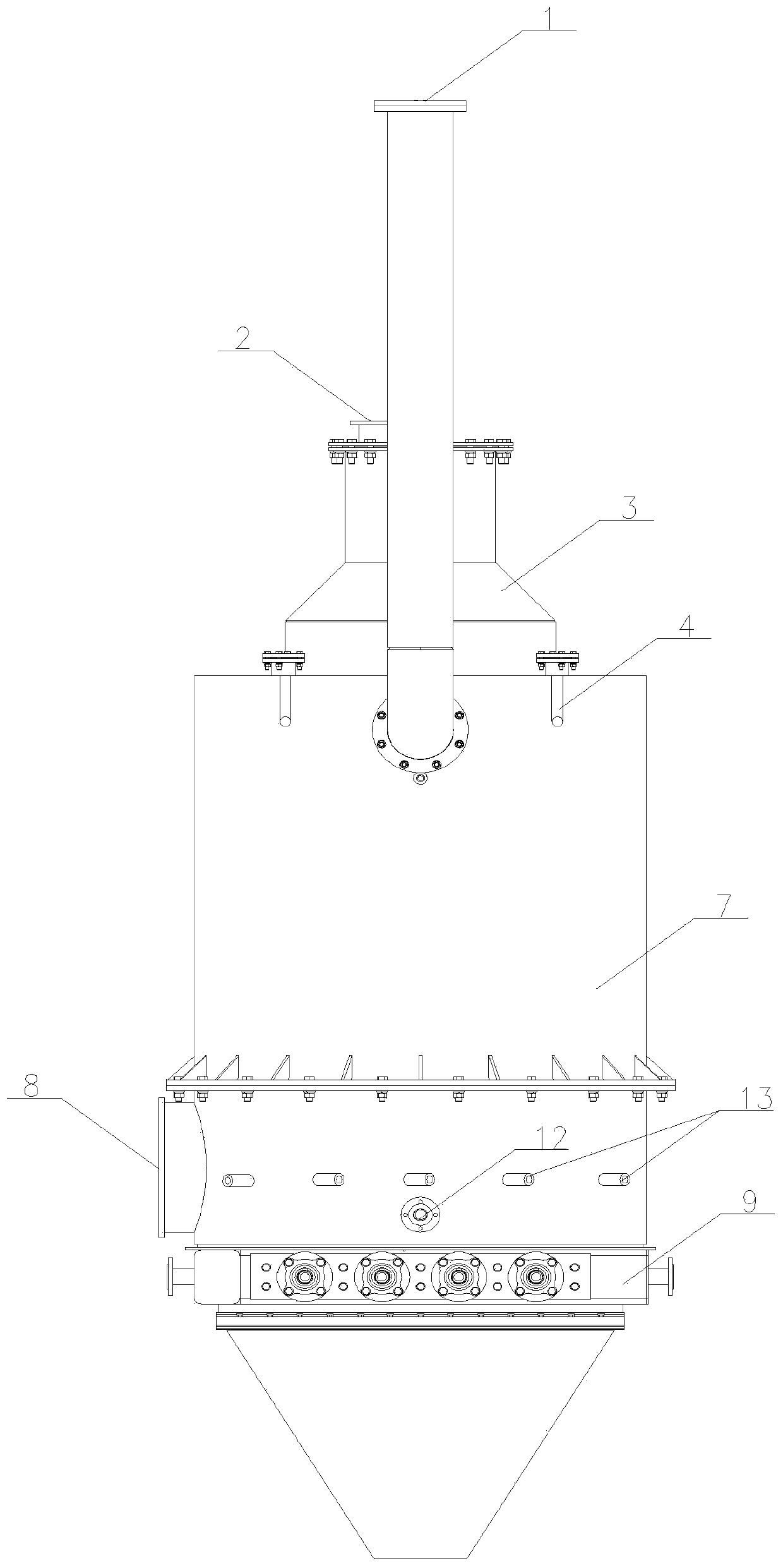

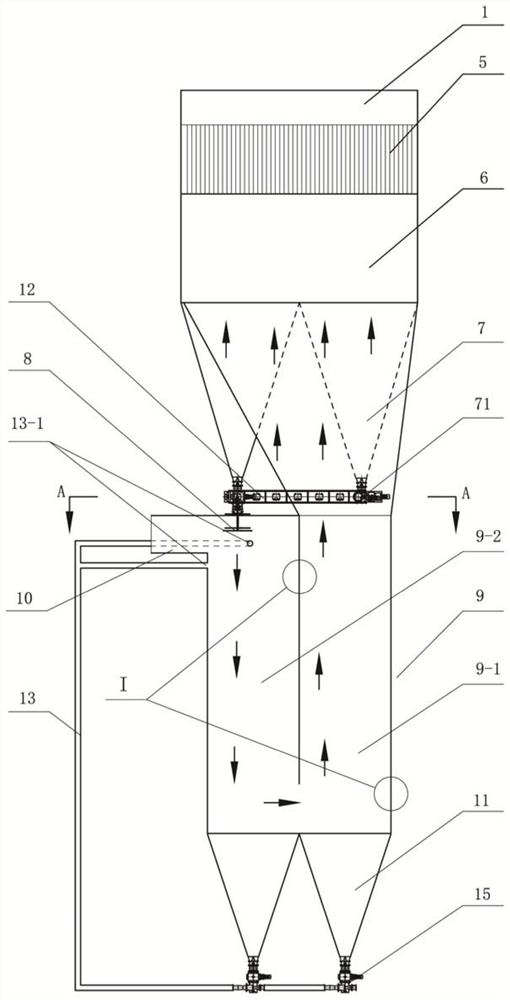

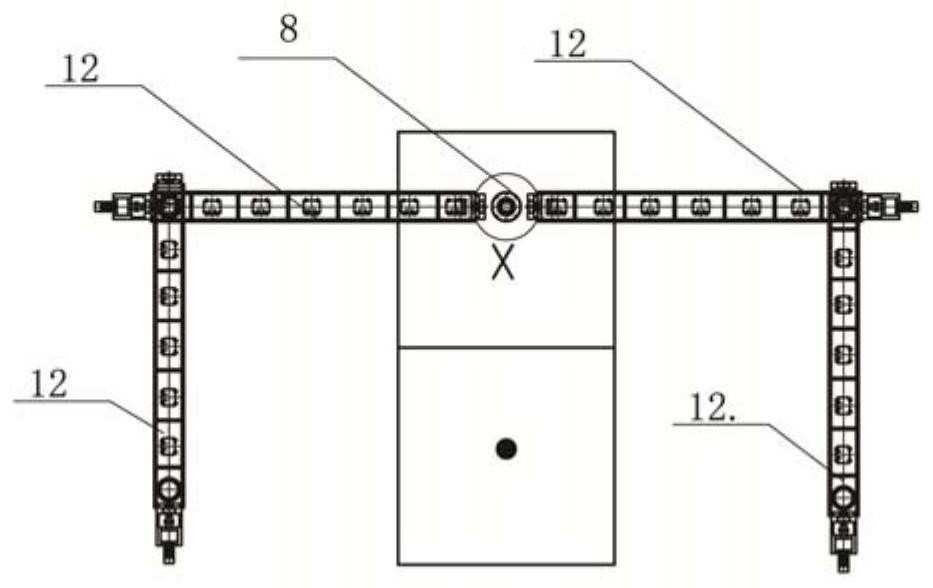

Flue gas system for ultra-clean treatment of cement kiln exhaust gas

PendingCN109364711ALow running costSmall footprintGas treatmentDispersed particle filtrationEngineeringCement kiln

The invention provides a flue gas system for ultra-clean treatment of cement kiln exhaust gas. The flue gas system includes an oxidative denitration reactor, a CFB absorption tower, a bag filter, a process water system, an absorbent preparation and supply system, a desulfurization ash circulation and conveying system and a chimney. The process water system includes a process water tank, a water pump, a desulfurization spray gun and a digestion spray gun. An absorbent preparation system includes a quick lime bin, a dry digester, a cyclone separator, a buffer bin and a slaked lime bin. The desulfurization ash circulation and conveying system includes an air chute and a bin pump. A dry type coupling desulfurization and denitrification technology is adopted, nitrogen oxides and sulfur oxides in flue gas can be effectively removed, to meet national regulations on ultra-low emission of flue gas pollutants, the flue gas system is free of waste water or secondary pollution, and a by-product can be utilized.

Owner:NANJING CEEP TECH

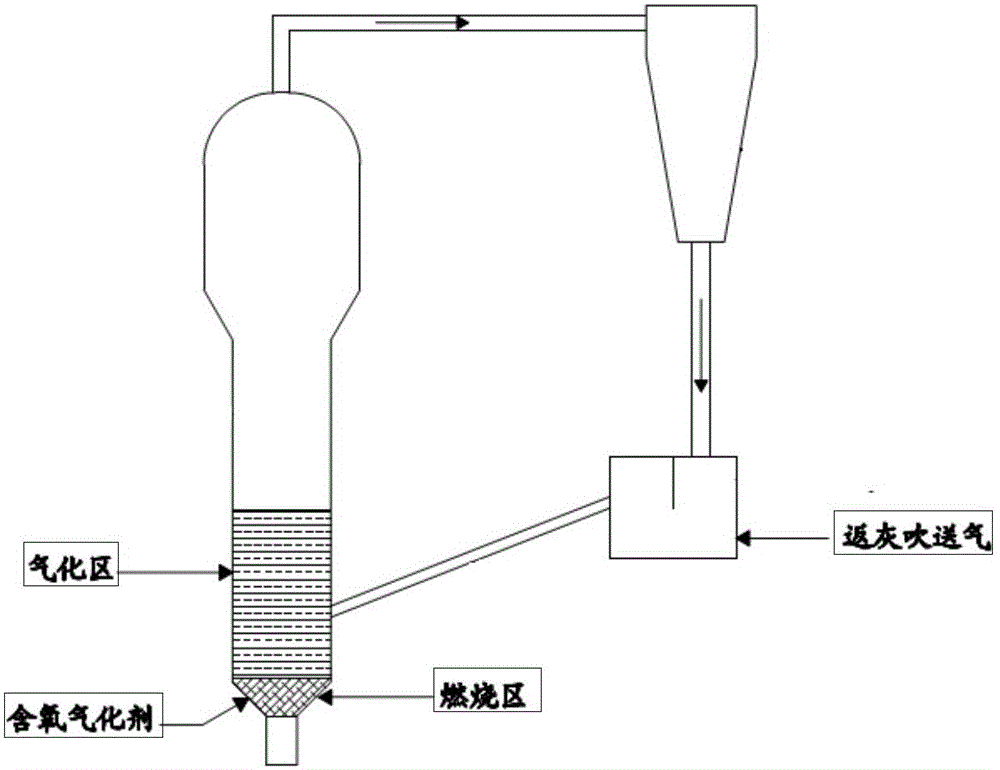

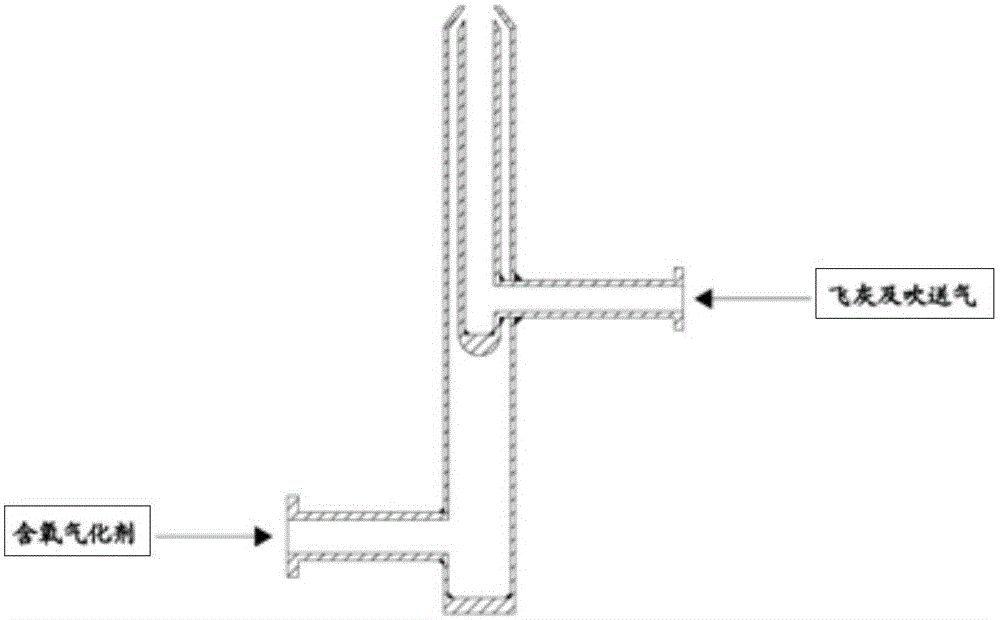

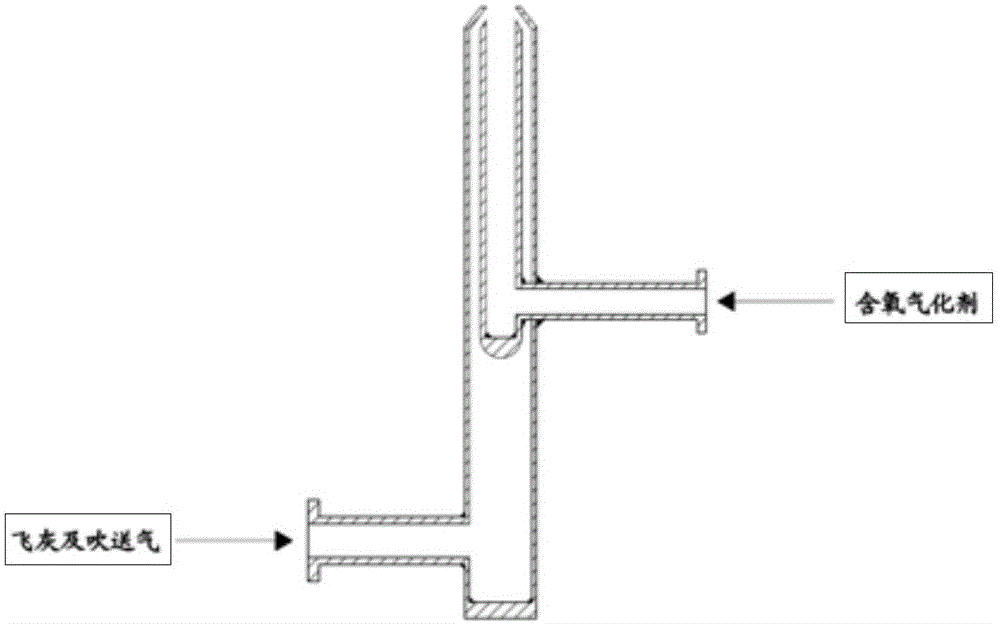

Fluidized-bed fly ash back-to- furnace gasification apparatus and method

ActiveCN105132039AEffective impactEffective disturbanceGranular/pulverulent flues gasificationCombustionFluidized bed

The present invention provides a fluidized-bed fly ash back-to- furnace gasification apparatus and method, and belongs to the technical field of coal gasification, fly ash back-to- furnace can be efficiently converted, at the same time, and distribution of the flow field inside a gasifier is more uniform. The fly ash back-to- furnace gasification apparatus includes a fly ash injection device, the fly ash injection device includes an inner layer channel and an outer layer channel, the inner layer channel is used for introducing an oxygen-containing gasification agent, the outer layer channel is used for introducing a backing fly ash blowing gas and fly ash mixture, or the inner layer channel is used for introducing the backing fly ash blowing gas and fly ash mixture, and the outer layer channel is used for introducing the oxygen-containing gasification agent, so that fly ash and the oxygen-containing gasification agent can be fully mixed at an outlet and injected into the gasifier for combustion reaction. The fluidized-bed fly ash back-to- furnace gasification apparatus can be used for fly ash handling in coal gasification process.

Owner:ENN SCI & TECH DEV

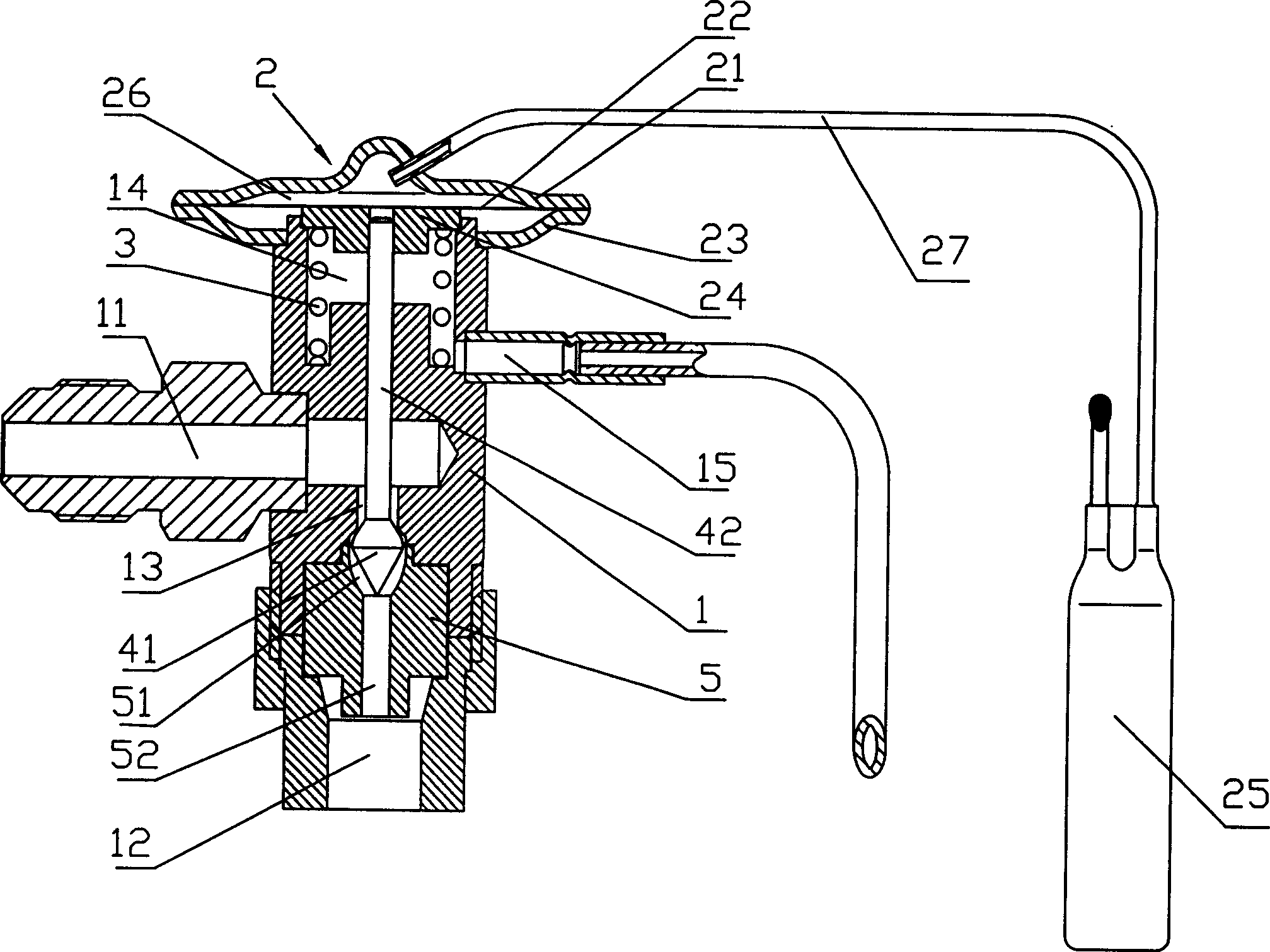

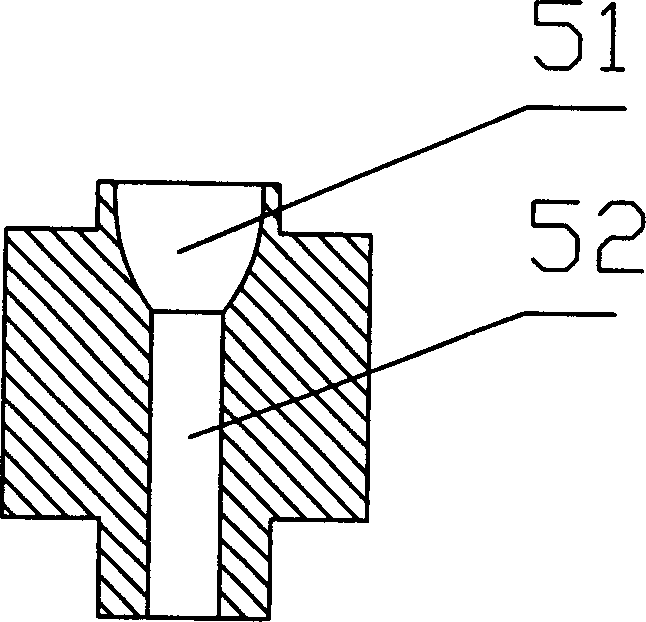

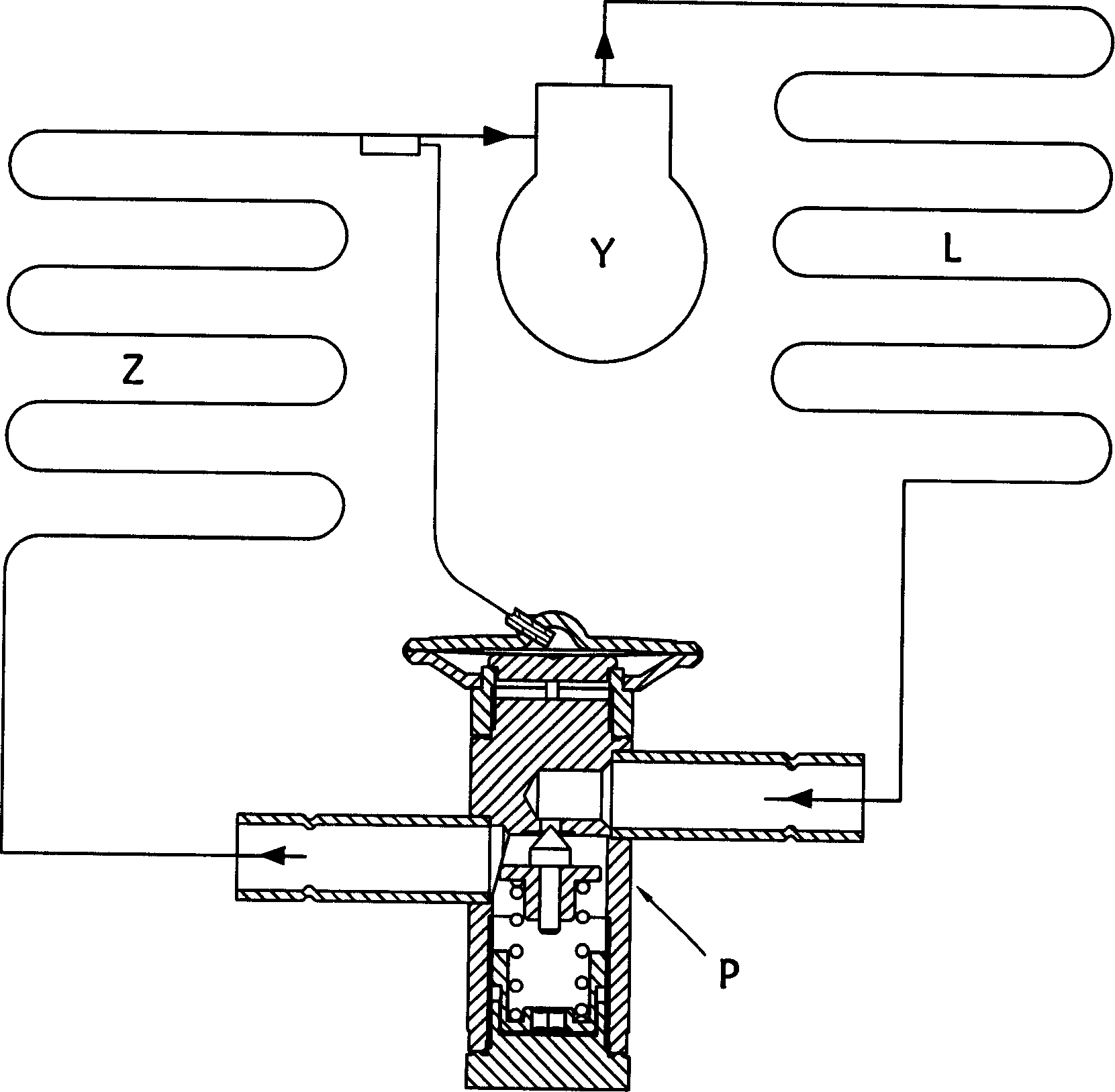

Thermal expansion valve having diversion function

The present invention relates to a thermal expansion valve with the function of guiding flow. It is characterized by that in the end portion of valve port faced with outlet a flow-guiding channel is set, after having been passed through valve port and flow-guiding element the refrigerant is expanded, in the flow-guiding channel the refrigerant is flowed through curved expansion portion (streamlined portion) firstly so as to make working medium flow field be stable and uniform, then the refrigerant is passed through isometric hole portion, mixed and flow-guided to outlet so as to make the working medium in the outlet of expansion valve be stable and uniform. In particular, when the outlet of expansion valve is connected with distributor element, the distributor can be used for uniformly distributing expanded refrigerant medium, so that it can reduce vibration and noise, and can raise control performance of valve.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

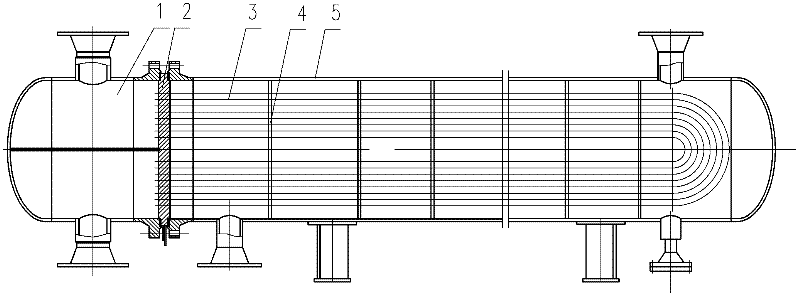

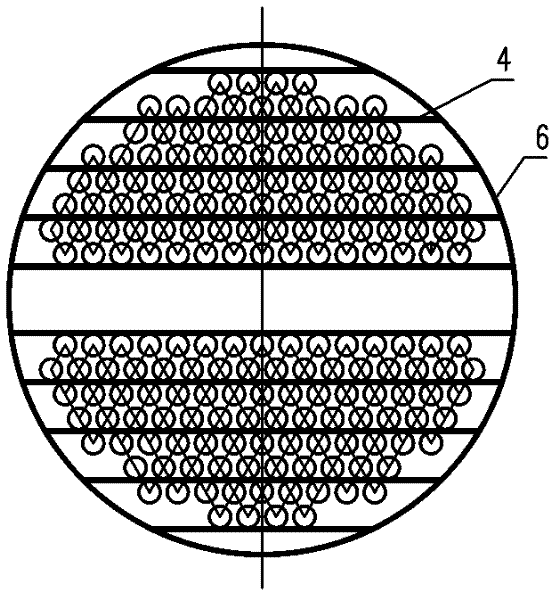

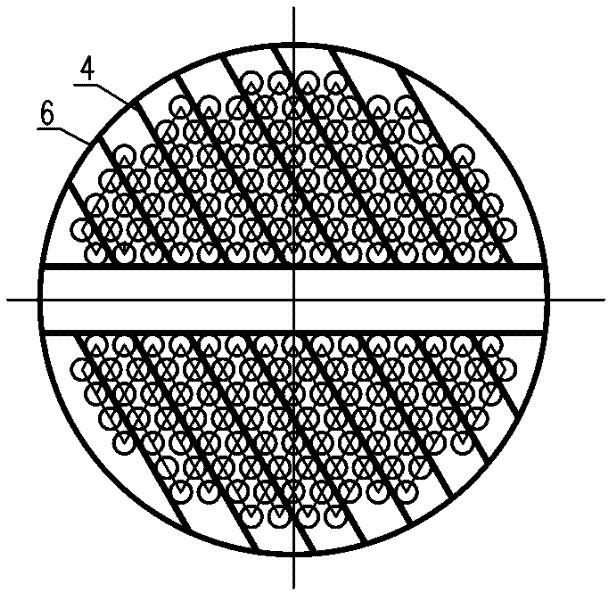

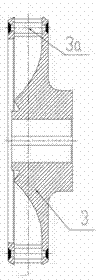

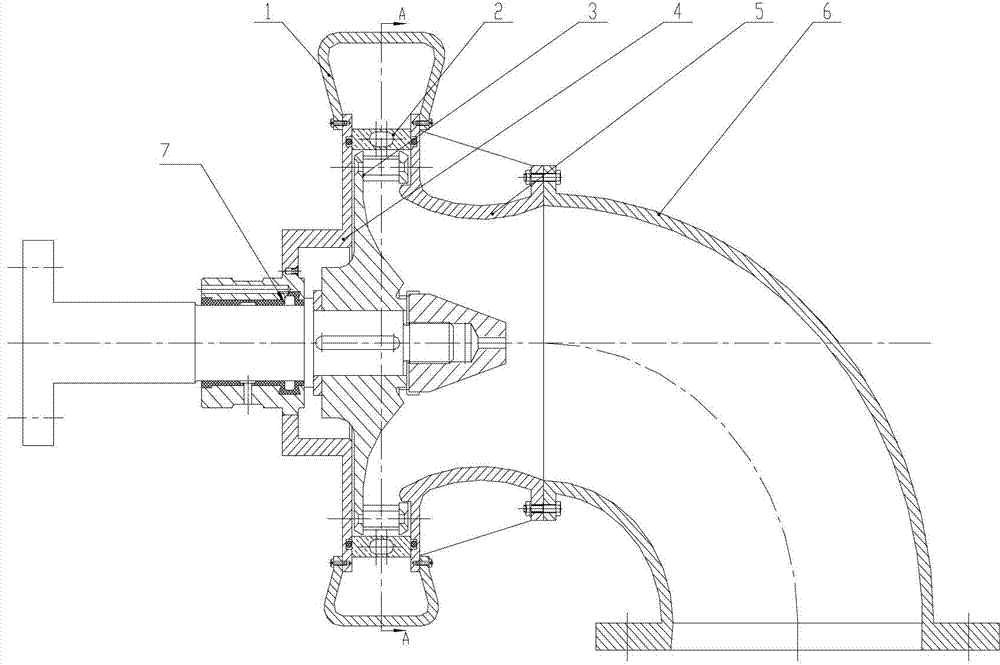

Rod baffle heat exchanger

InactiveCN102419130AElimination of Induced VibrationReduce shear stressHeat exchanger casingsShear stressEngineering

The invention relates to a rod baffle heat exchanger for a benzene hydrogenation refining process. The rod baffle heat exchanger comprises a tube box, a tube plate, a shell and heat exchange tubes. A plurality of blast fences are arranged at intervals in a direction vertical to the axial direction of the shell in the shell. The blast fence is formed by welding parallel rod baffles onto a baffle ring. A heat exchange tube bundle passes through the rod baffles. The extension directions of the rod baffles in adjacent blast fences are different, so that a turbulent flow is produced once every time when a shell-side fluid passes through a blast fence. The section of the rod baffle may be circular, rectangular or prismatic. By the heat exchanger, the shell-side fluid forms a longitudinal flow along the axial direction of the shell, so that transversal scouring to the heat exchange tube bundle is avoided, the shearing stress of the tube bundle and a support structure is effectively weakened, and the vibration and abrasion of the tube bundle are reduced; moreover, the structure also has a turbulent flow self-cleaning function, and fouling is difficult to deposit.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

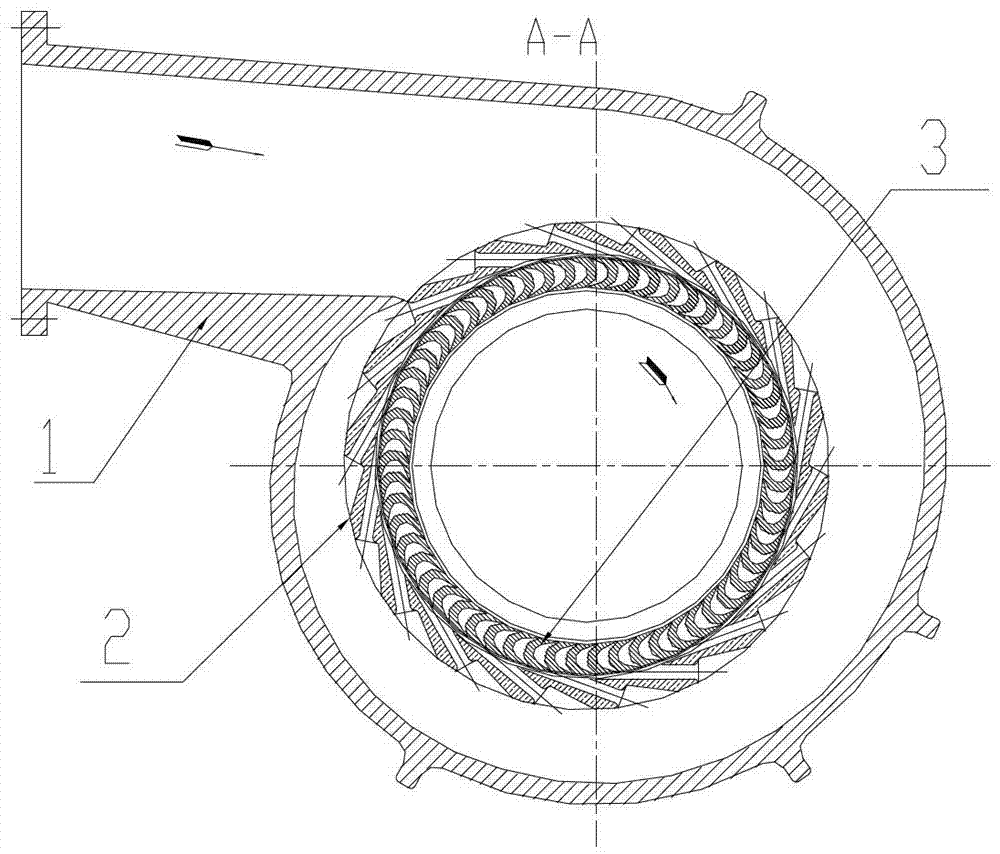

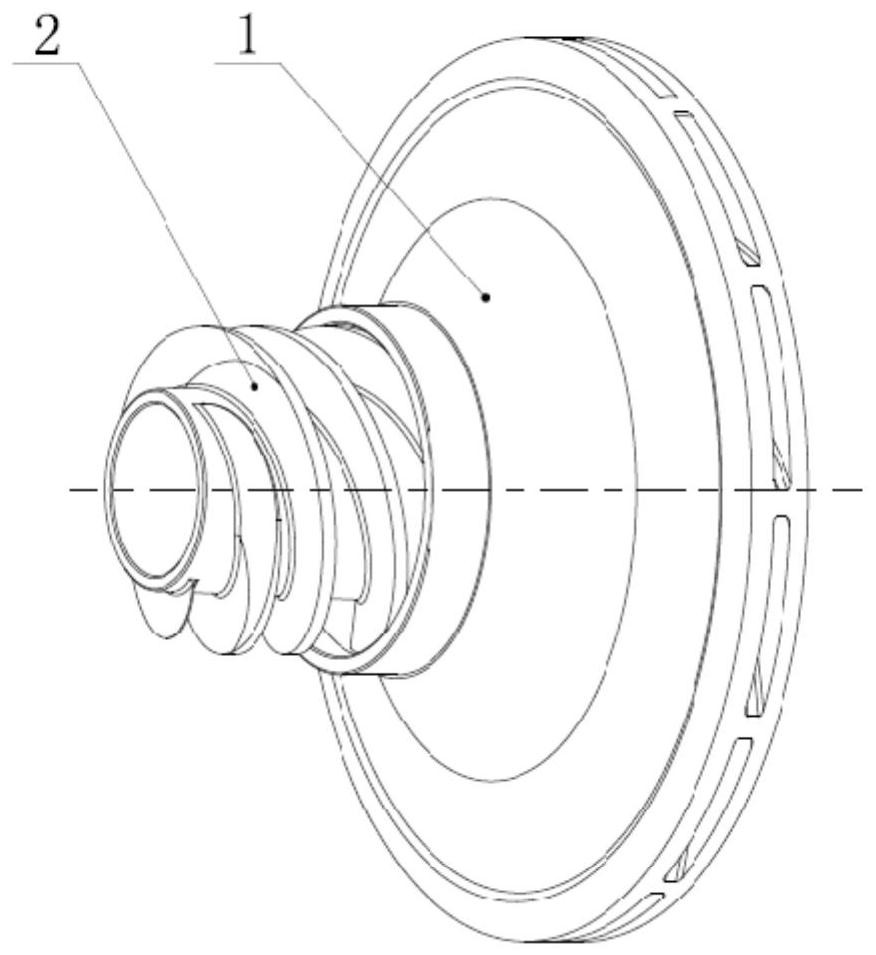

Water turbine with multiple vanes

ActiveCN103244335ASimple structureSimple design and manufactureFinal product manufactureHydro energy generationLiquid dynamicsControl system

The invention discloses a water turbine with multiple vanes. The water turbine comprises volutes, rotating wheels, a support cover, a bearing, a bottom ring and a drainage pipe. Nozzle rings are arranged in volute spiral runners and on the radial peripheries of the rotating wheels, orifices for jetting liquid flow to drive the rotating wheels are arranged on the nozzle rings at equal intervals, vanes are evenly arranged on the circumferences of the rotating wheels at equal intervals, and arc-shaped runners matched with the liquid flow jetted by the orifices are formed between the vanes. The runners of the water turbine with multiple vanes can convert not only kinetic energy of the liquid flow but also part of potential energy of the liquid flow; within a certain range of revolving speed, output power and flow are basically in a linear relationship, so that a complex adjustment and control system is not needed; and the structure of the water turbine is greatly simplified, the production process is simple and the cost is reduced. The water turbine is compact in structure, applicable to purposes such as small-size (miniature) hydroelectric generation and conversion from liquid dynamic energy to rotary mechanical energy in pipelines.

Owner:XIHUA UNIV

Dual-scale micro-structure artificial bone scaffold and preparation method thereof

InactiveCN100536802CSolve the blockageSolve for uniformityStentsBone implantMicro structureMINERAL WAX

The invention relates to a dual-size micro bone support and relative production, wherein said support comprises micro ball connecting hole and macro tube; the micro tube is formed by connected ball holes; the macro tube is formed by connected straight tubes; the ball hole is through to the tube; the ball holes are randomly arranged; the tube structure can be controlled. And production comprises that: first using CAD and light solidifying shaping technique to design and control the tube structure; preparing the resin mould of bone structure; filling mineral wax balls into mould; filling biological slurry; when it is solidified and dried, thermally decomposing the resin mould and mineral wax, to obtain the bone support.

Owner:XI AN JIAOTONG UNIV

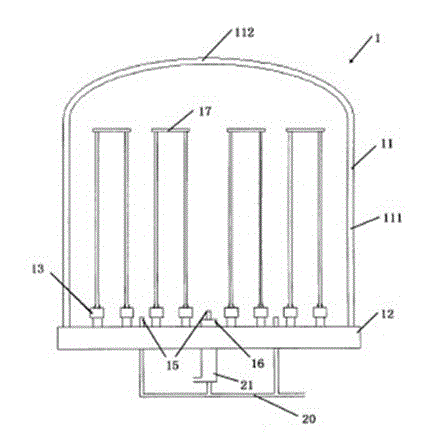

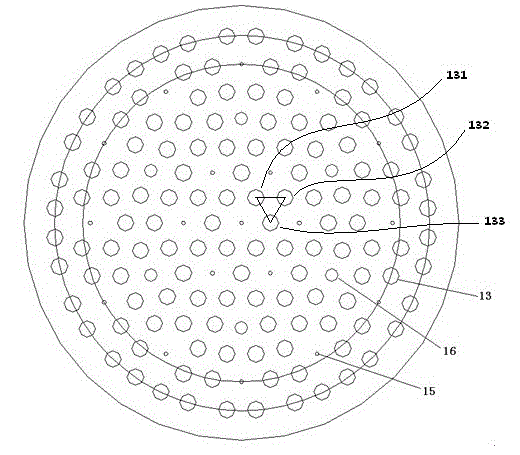

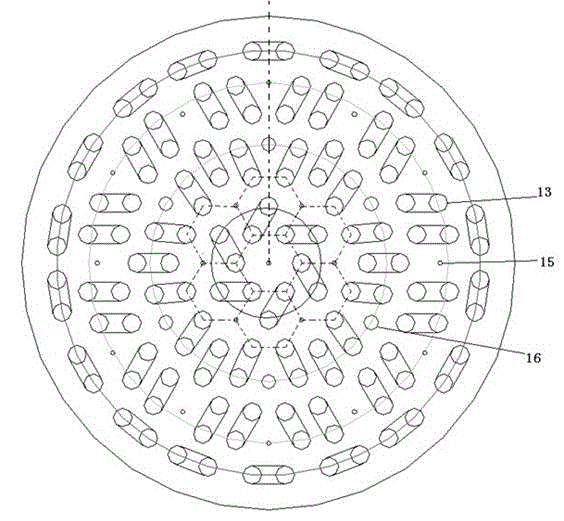

Reactor used for producing polycrystalline silicon

The invention discloses a reactor used for producing polycrystalline silicon. The reactor comprises a furnace tube with a cooling device, a chassis, and electrodes, raw material gas inlets and gas outlets positioned on the chassis. The reactor is characterized in that except the outermost electrodes close to the furnace tube, each electrode has 4 or 5 other adjacent electrodes and one or two adjacent gas inlets and / or outlets at distances of 150mm-300mm. A matrix formed by the electrodes, gas inlets and gas outlets is arranged as equilateral triangle and / or approximate equilateral triangle matrix. With the reactor, denser silicon core arrangement can be realized, thermal energy utilization rate in a reduction furnace can be improved, and more uniform flow field distribution is realized, such that polycrystalline silicon yield in each bath is improved, product surface quality is improved, and energy consumption is reduced.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

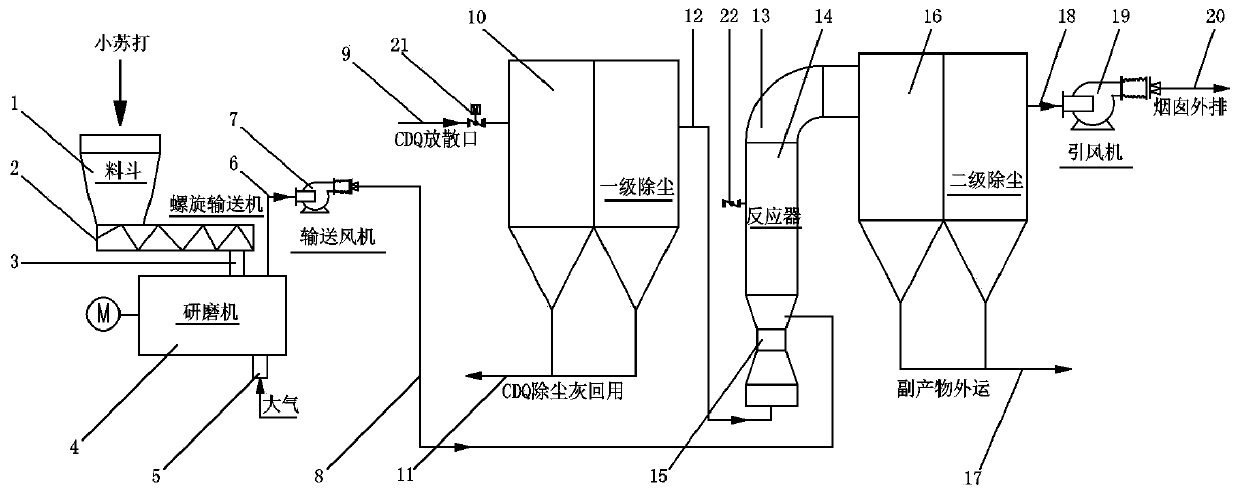

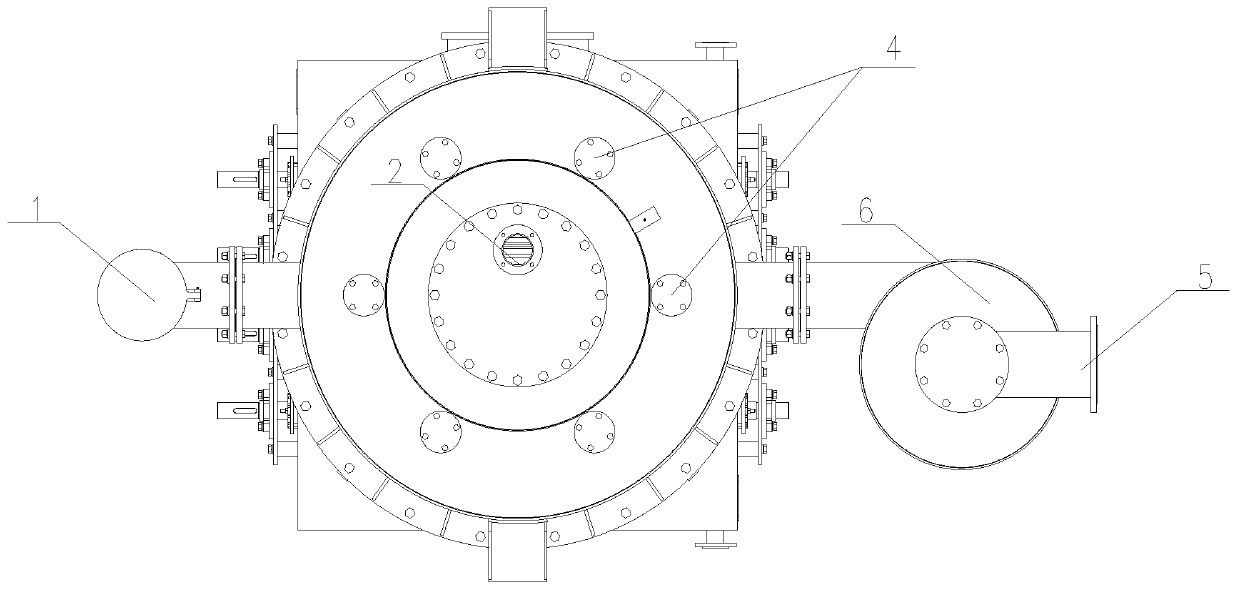

System for CDQ pressure control emitted gas desulfurization and dust removal

PendingCN110280124AEmission reductionNo corrosive effectsDispersed particle separationGrain treatmentsChemical reactionFlue gas

The invention discloses a system for CDQ pressure control emitted gas desulfurization and dust removal, comprising a baking soda hopper, a screw conveyor, a baking soda grinder, a conveying fan, a primary dust remover, a desulfurization reactor, a secondary dust remover and a draught fan. The emitted gas is taken out of an emission port through a pipeline and firstly enters the primary dust remover to remove dust, and the dust-removed emitted gas and the ground baking soda ultrafine powder enter the desulfurization reactor through a Venturi pipe to be uniformly mixed and undergo a chemical reaction in the reactor. The desulfurized flue gas passes through the secondary dust remover and the draught fan and then enters a chimney to be discharged. By the principle of baking soda dry desulfurization and two-stage high-efficiency dust removal, SO2 and dust in the flue gas can be effectively removed to ensure that the treated flue gas meets the latest national special emission limit standard.

Owner:JIANGSU WISDOM ENG TECH

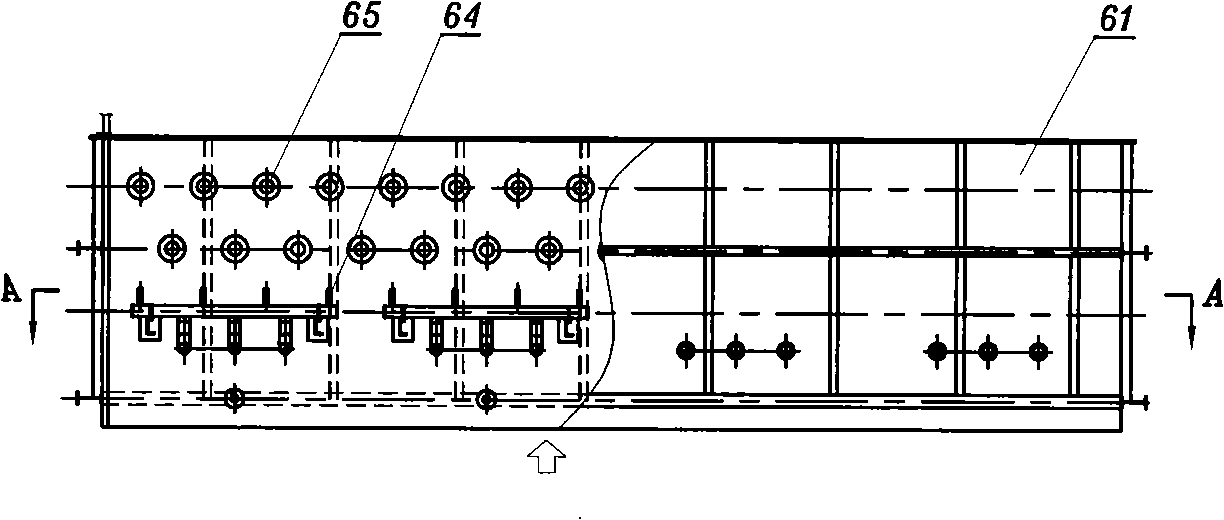

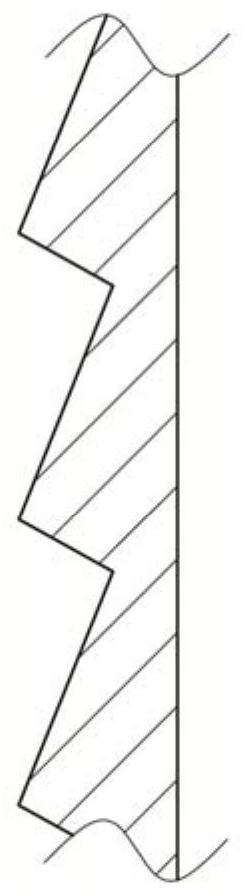

Zig air flue K-shaped flow equalizing apparatus with flyash separation

A K-type flow equalizing device with flying ash separated flashback air flue comprises a vertical air flue and a horizontal air flue, the lower end of the vertical air flue is provided with a flue-dust retainer and ash discharge device, the position of the vertical air flue turning to the horizontal air flue is provided with a flue gas turning external coating surface composed of delta wing grilles, the adjacent clearance between two delta wing grilles is communicated with the flue-dust retainer, the entrance of the horizontal air flue is distributed transversely with ascending and descending small air flues, the sum of the entrance cross sections of the ascending and the descending small air flues is equal to section area of the horizontal air flue, the ascending and the descending small air flues are alternately arranged inside the horizontal air flue and respectively introduces 50 0.000000lue gas to the upper semi-cross section of the horizontal air flue and 50 0.000000lue gas to the lower semi-cross section of the horizontal air flue. The flying ash described by the present invention is separated into the flue-dust retainer by delta wing grilles, which avoids the flue gas master stream from entering the flue-dust retainer and the flying ash from entering the flue gas by secondary entrainment, the ascending and descending small air flue alternate settings is alternately arranged in the horizontal air flue, the present invention realizes to make the severe oblique flow field distribution after acute steering in ultrashort distance evenly distribute in the whole air flue cross section rapidly.

Owner:XIAN THERMAL POWER RES INST CO LTD

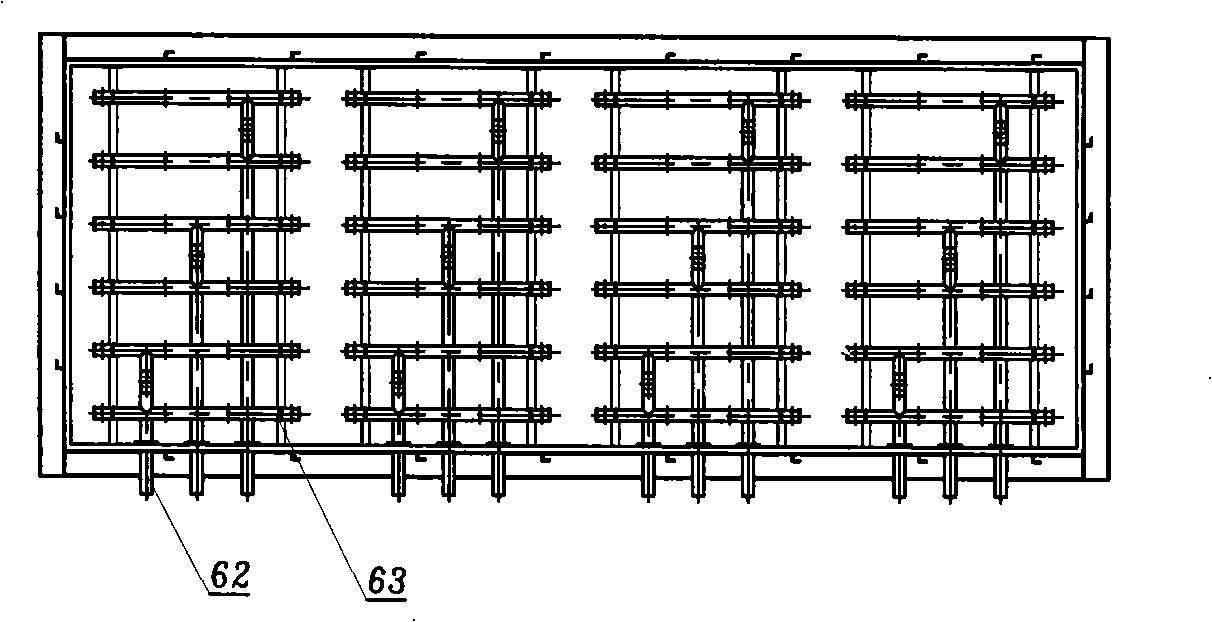

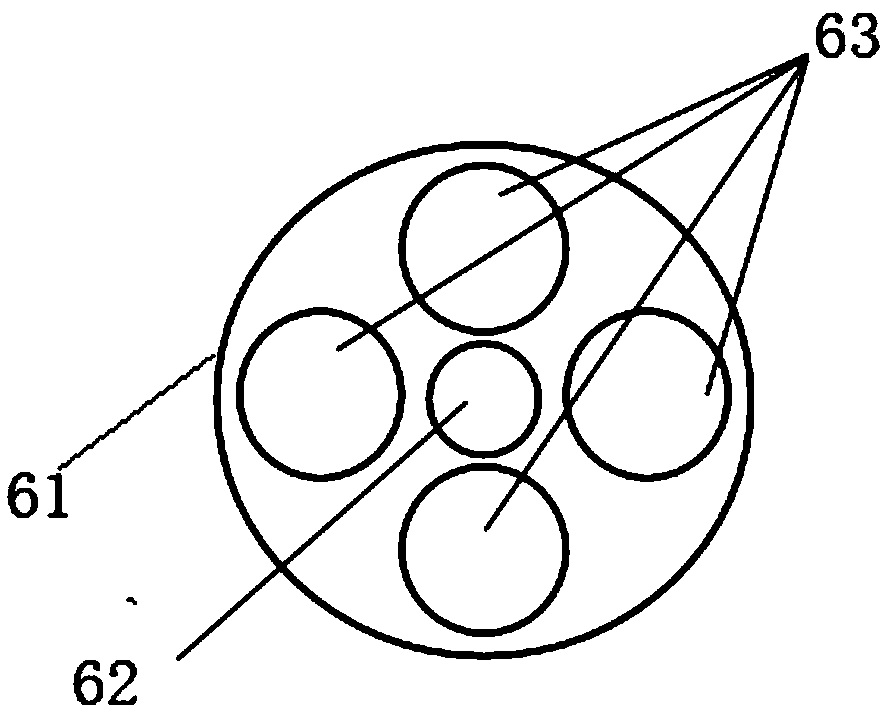

Fluidized bed gas distributor and gasifier

ActiveCN104673397AUniform distribution of flow fieldPrevent slaggingGranular/pulverulent flues gasificationProcess engineeringFluidized bed

Owner:ENN SCI & TECH DEV

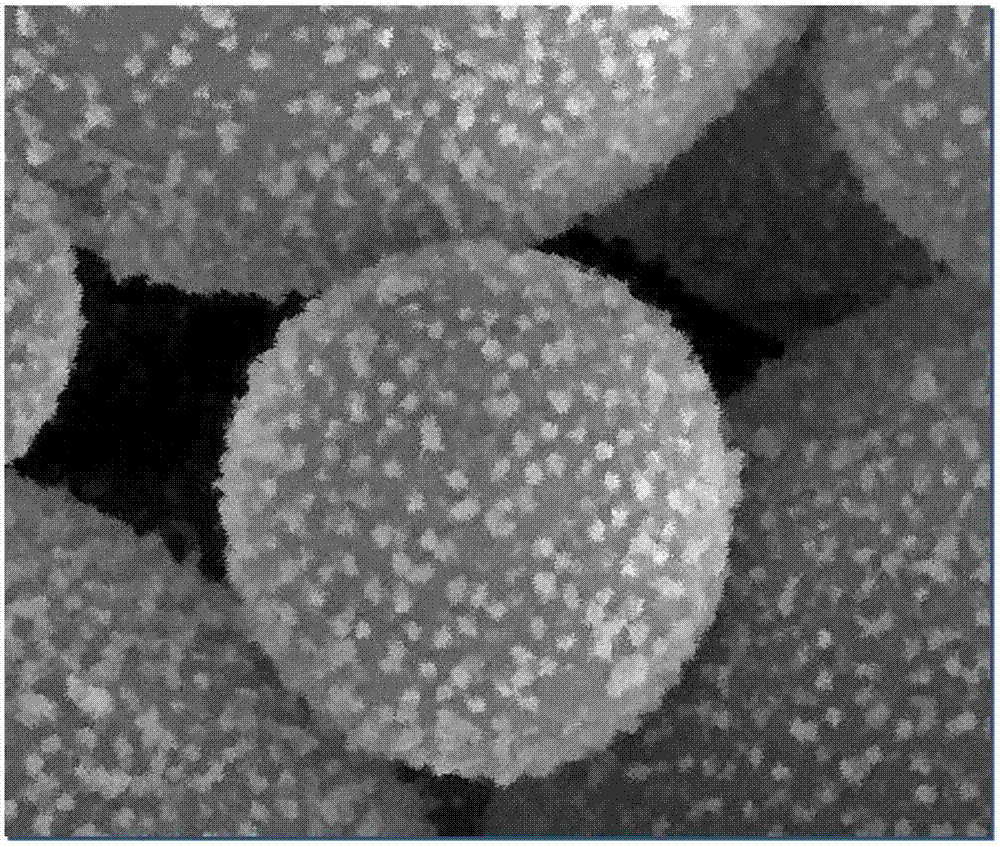

Polystyrene sulfonic acid resin catalyst as well as preparation method and application of polystyrene sulfonic acid resin catalyst

ActiveCN107457001AUniform distribution of flow fieldFast heat conductionOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPolystyreneSustained-Release Preparations

The invention relates to a polystyrene sulfonic acid resin catalyst as well as a preparation method and application of the polystyrene sulfonic acid resin catalyst to respective tertiary butanol dehydration and isobutylene oligomerization to co-produce isobutylene and diisobutylene. The catalyst comprises polystyrene sulfonic acid resin, metal and metal sulfate; the metal comprises two parts, namely metal coated with the polystyrene sulfonic acid resin and metal not coated with the polystyrene sulfonic acid resin; and the metal sulfate is converted from an exposed surface of the metal not coated with the polystyrene sulfonic acid resin in the catalyst. When the catalyst is respectively used for tertiary butanol dehydration and isobutylene oligomerization, due to the high heat conductivity of the catalyst, the energy required by tertiary butanol dehydration is compensated after the two reactions are coupled, and the hot spot temperature of a bed layer for isobutylene oligomerization is greatly reduced; during reaction, the per-pass conversion rate of TBA dehydration can reach up to 40% or above, and the selectivity of isobutylene can reach up to 99% or above; and meanwhile, no sustained release preparations are needed to be added when isobutylene oligomerization is catalyzed, and even if isobutylene with the concentration being larger than 80wt% is used as a raw material, the selectivity of DIB is still 80% or above, and the per-pass conversion rate is 90% or above.

Owner:WANHUA CHEM GRP CO LTD

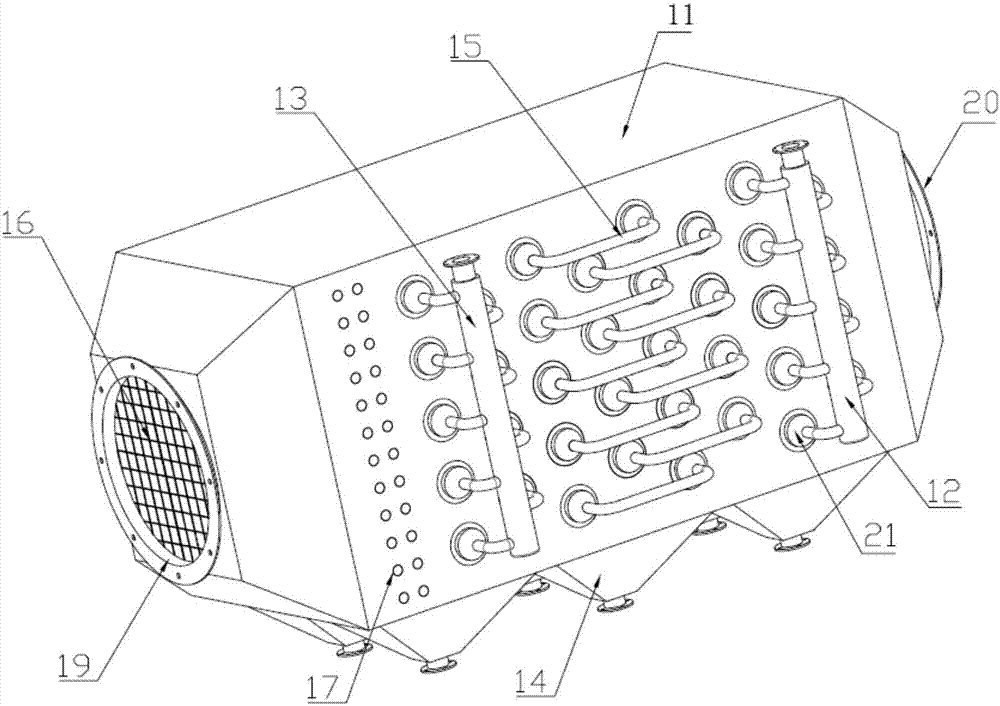

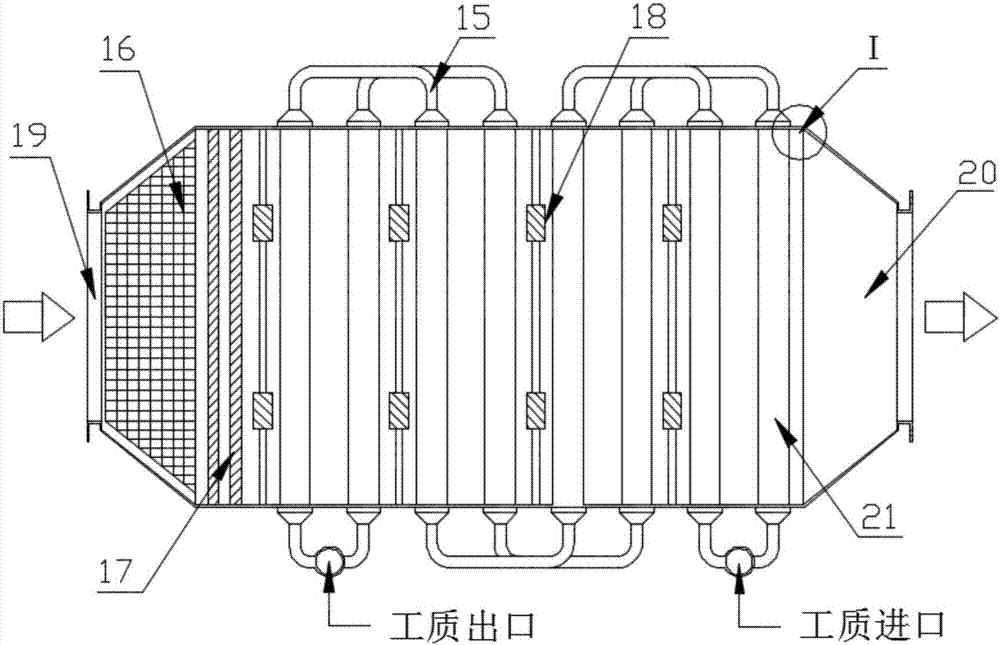

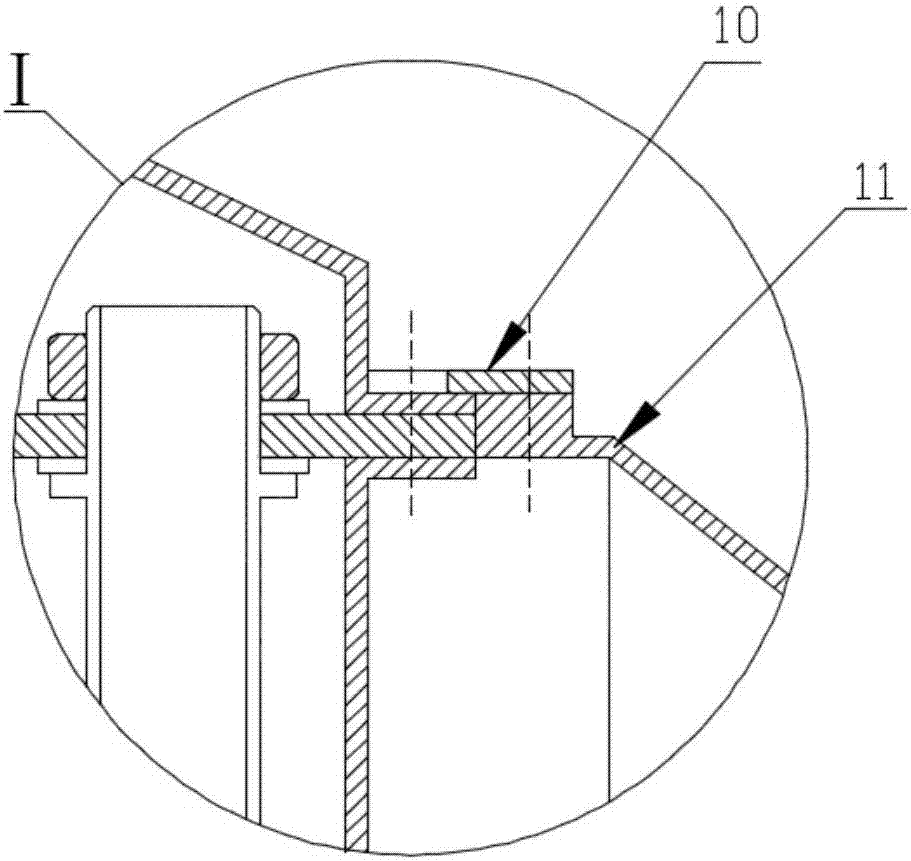

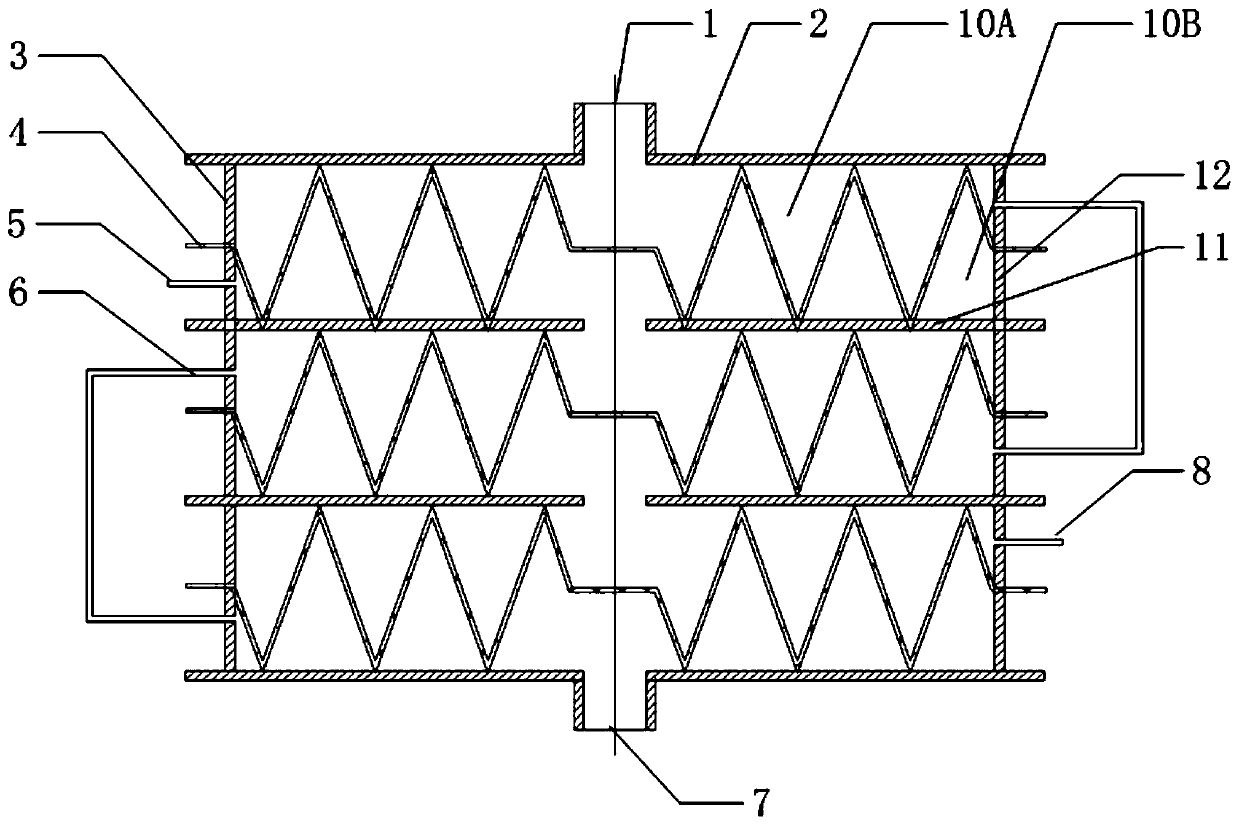

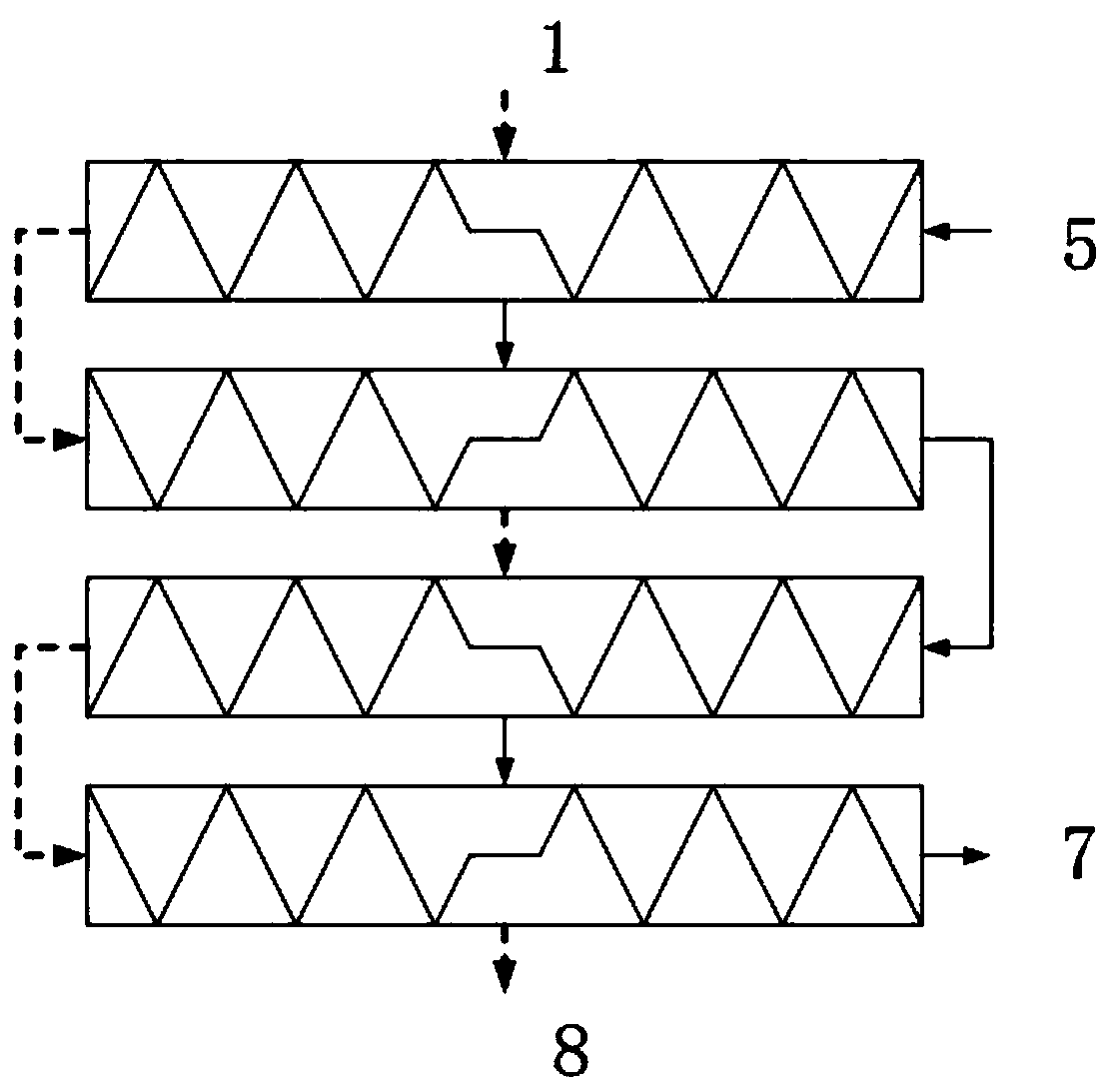

Detachable modular wear-resistant ash-removal three-dimension finned tube type heat exchanger

ActiveCN107543434APromote exchangeAvoid disassemblyCorrosion preventionHeat exchanger casingsWear resistantAcoustic wave

The invention discloses a detachable modular wear-resistant ash-removal three-dimension finned tube type heat exchanger. The detachable modular wear-resistant ash-removal three-dimension finned tube type heat exchanger comprises a heat exchanger shell connected with a flue; an air inlet is formed in a front end plate of the heat exchanger shell, and an air outlet is formed in a rear end plate of the heat exchanger shell; and a cold working medium inlet header pipe and a cold working medium outlet header pipe are arranged on the outer portion of the heat exchanger shell. The detachable modularwear-resistant ash-removal three-dimension finned tube type heat exchanger is characterized in that a damping screen is disposed in the heat exchanger shell and at the air inlet end; a plurality of wear-resistant false tubes stacked in the height direction are arranged on the rear side of the damping screen; the two ends of the wear-resistant false tubes are fixed to the left end plate and the rear end plate of the heat exchanger shell in a threaded or press-jointed mode; a plurality of acoustic wave dust removers overlapped in the height direction are arranged on the rear side of the wear-resistant false tubes; a plurality of three-dimension finned tube type heat exchange units are arranged on the rear side of the acoustic wave dust removers; and the three-dimension finned tube type heatexchange units are overlapped in the height direction as well as in the horizontal direction. The detachable modular wear-resistant ash-removal three-dimension finned tube type heat exchanger can be widely applied to the field of waste heat recovery of different types of industrial exhaust gas.

Owner:CHONGQING UNIV

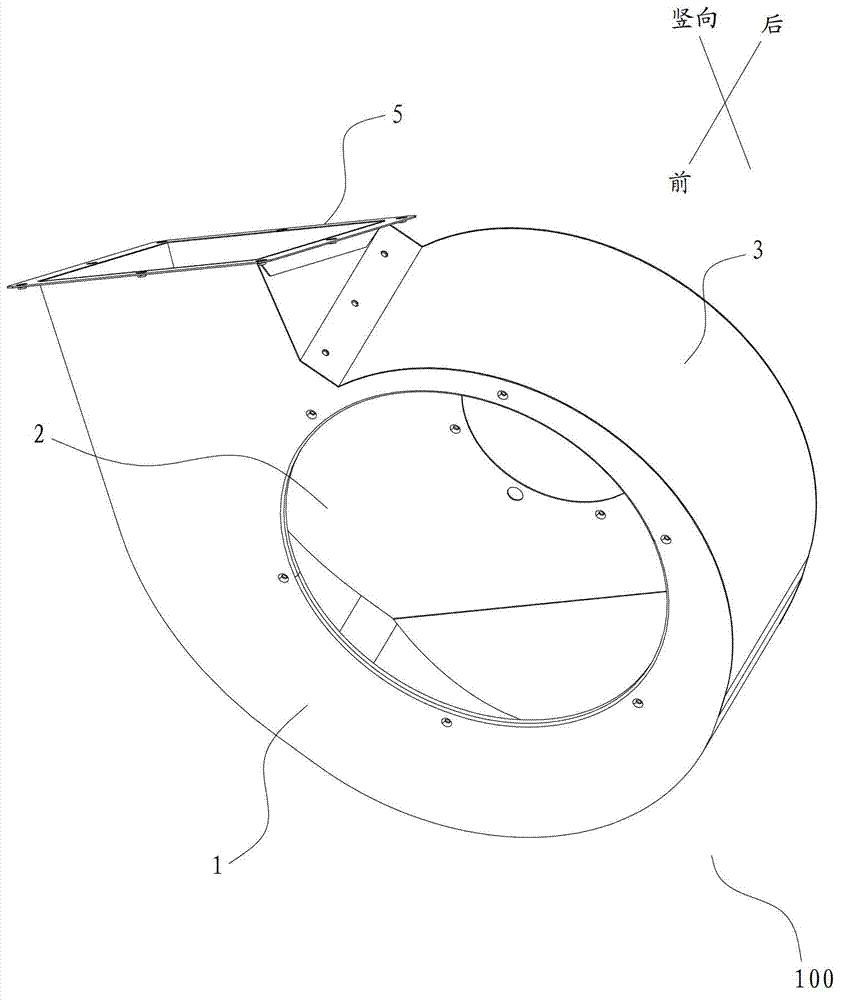

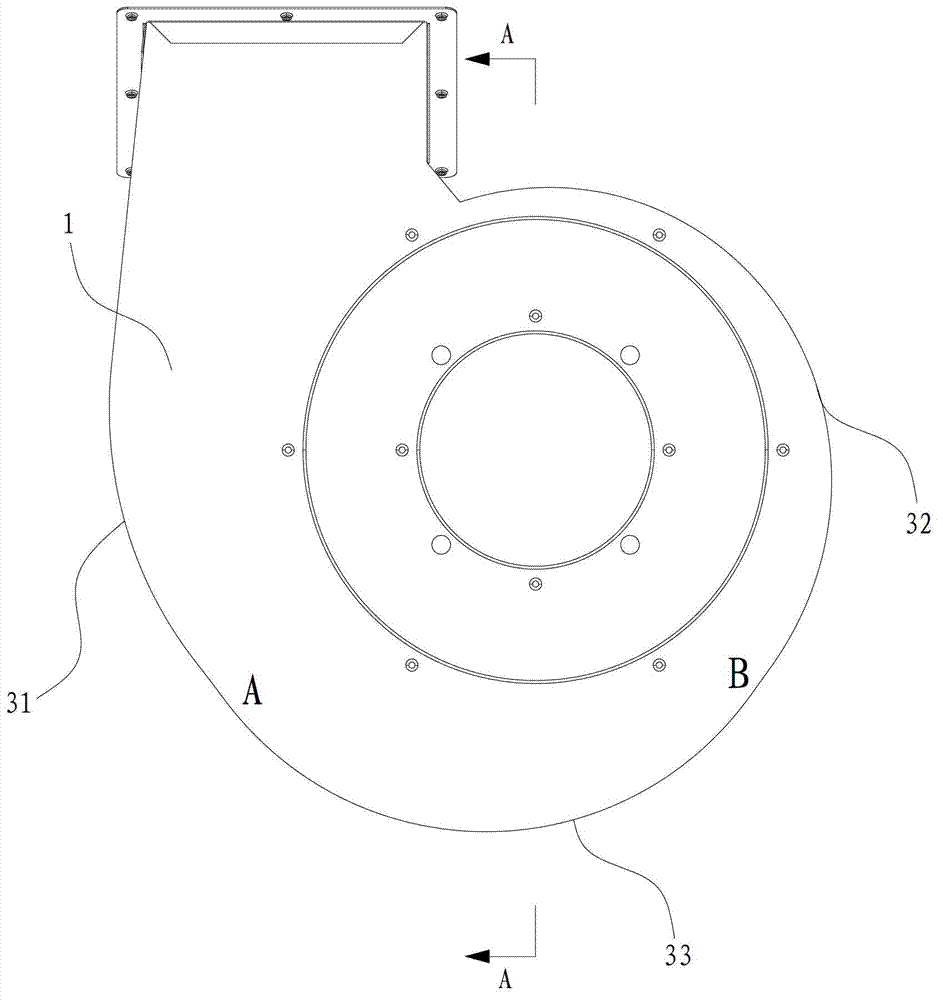

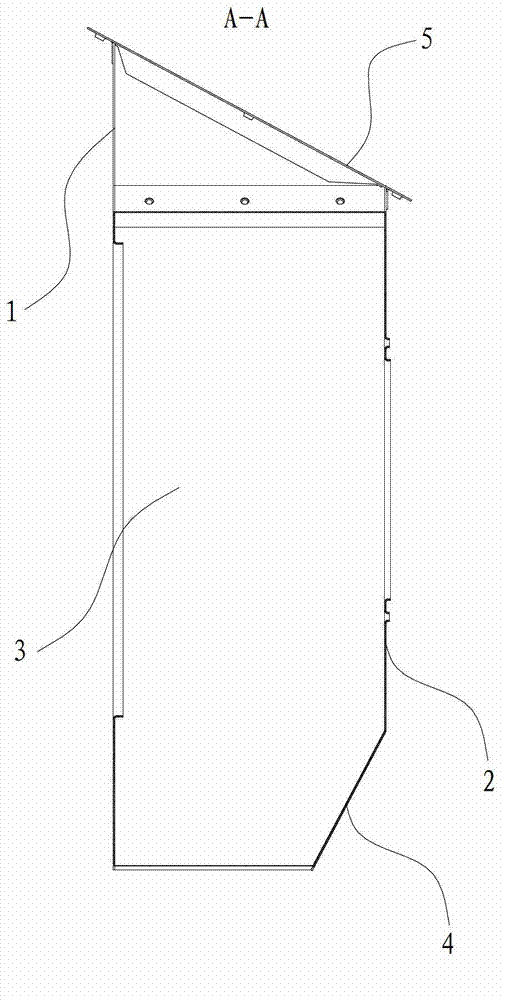

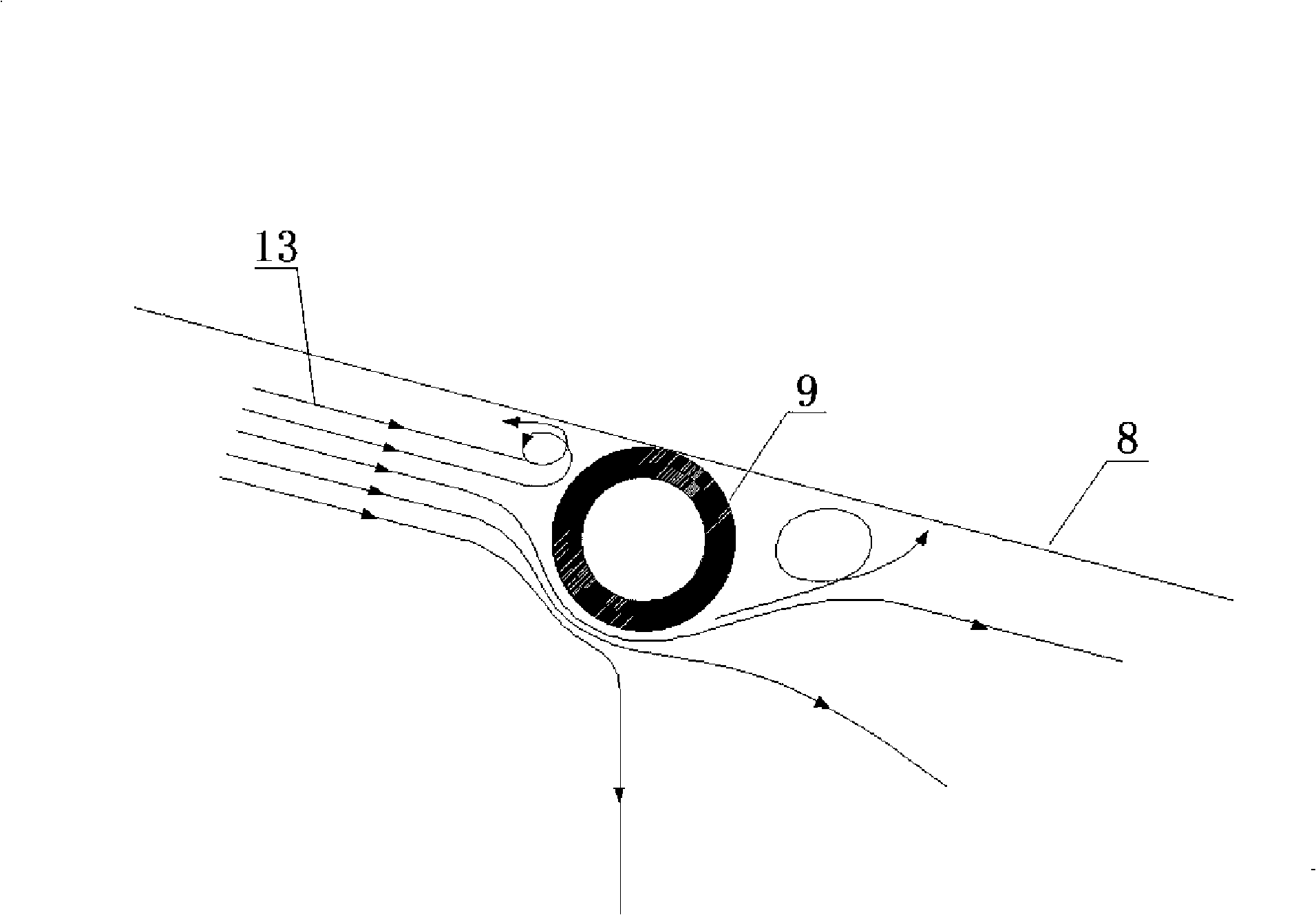

Volute, fan with same and exhaust hood

ActiveCN103711730AEnsure consistencySpeed up the flowDomestic stoves or rangesPump componentsAir volumeEngineering

The invention discloses a volute which comprises a front plate, a rear plate and a surrounding plate. The front plate and the rear plate are parallel to each other in the front-back direction, and an inclined face plate which is inclined towards a space between the front plate and the rear plate is formed on the lower portion of one of the front plate and the rear plate at least; the surrounding plate is connected between the front plate and the rear plate and comprises a first helical surface section, a second helical surface section and a curved surface section, the second helical surface section corresponds to the first helical surface section, the curved surface section is connected between the first helical surface section and the second helical surface section, corresponds to the inclined face plates, and is deviated from helical surfaces to be outwardly protruded, and the first helical surface section and the second helical surface section are located on the helical surfaces. The volute has the advantages that the outwardly protruded curved surface section is reasonably arranged on the surrounding plate, so that a flowing space of airflow inside a fan can be enlarged, flow fields in the volute can be uniformly distributed, the air volume and the air pressure of an exhaust hood can be increased, and noise can be effectively lowered. The invention further discloses the fan with the volute and the exhaust hood.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

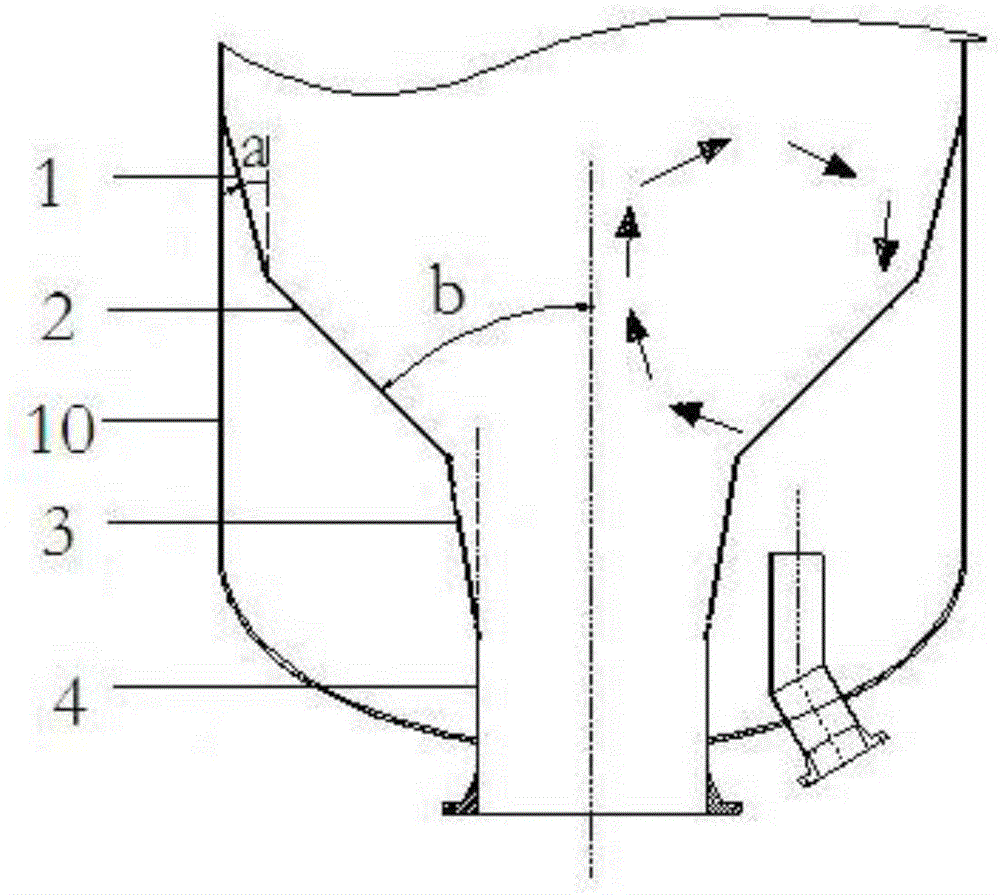

Flue gas denitrating method and flue gas denitrating apparatus with special rectifier cell

ActiveCN101342463AReduce debugging workloadSimple structureDispersed particle separationFlue gasProcess engineering

The invention relates to a smoke gas denitration method and a device provided a special rectifying element; the flue of a tapered section and the horizontal flue of an entrance section on the top of a reactor are communicated successively; at least one catalyzator layer is arranged inside the reactor; the invention is characterized in that at least one rectifying steel tube perpendicular to a smoke gas flow direction is fixed on the head plate of the flue of the tapered section; space between the adjacent two rectifying steel tubes is larger the diameter of the rectifying steel tube. The special rectifying element of the invention has the advantages of simple structure and fixation, and convenient installation and adjustment. The invention adopts a smoke gas rectifying device with simple structure, high efficiency and easy adjustment to distribute evenly the flow field of the smoke gas in a SCR system and make the smoke gas and the catalyzator contacted fully and evenly so as to improve denitration efficiency. The smoke gas denitration method and the device provided the special rectifying element can be applied broadly to a selective catalytic reduction smoke gas denitration system in a heat power plant to adjust the flow field of the smoke gas and guarantee uniform distribution of the flow field in a SCR reactor under various working conditions.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

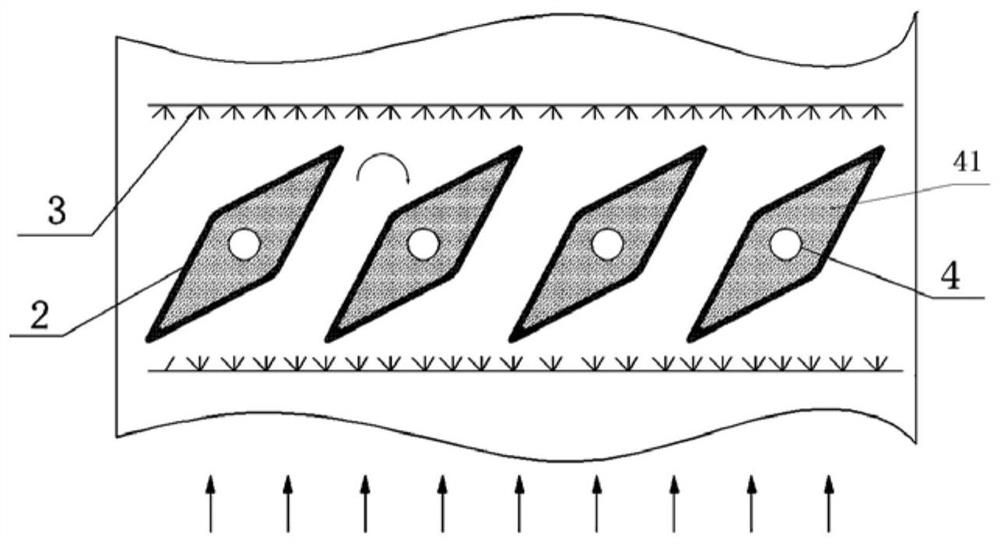

Rotary rhombic wire mesh demisting method and device

PendingCN112717615AImprove the ability of dust removal and fog removalAdd spoilersCombination devicesAuxillary pretreatmentPhysicsDemister

The invention discloses a rotary rhombic wire mesh demisting method and a rotary rhombic wire mesh demisting device. The rotary rhombic wire mesh demisting device comprises a rhombic wire mesh demisting system arranged at the top of a desulfurizing tower and an automatic rotary control system. When flue gas flows into the lower layer of the rhombus-shaped wire mesh demister, droplets and other fine particles carried in the flue gas are intercepted by a wire mesh in the rhombus-shaped wire mesh demister, the droplets and the large particles are subjected to inertial separation, the small particles are subjected to coagulation, sedimentation and separation, and the flue gas subjected to preliminary demisting of the lower layer of wire mesh enters the upper layer of wire mesh again and then is demisted and dedusted. According to the device, the wire mesh demister is rotationally combined with the connecting rod, so that the device has the characteristics of efficient demisting and dedusting, uniform flue gas distribution, energy conservation, adaptability to different working condition changes and the like, can effectively solve the problems of poor working condition applicability, large resistance, easiness in scaling and easiness in blockage of the traditional demister, and can effectively reduce the formation of gypsum rain and the secondary carrying of flue gas.

Owner:SOUTH CHINA UNIV OF TECH +1

Efficient revolving furnace gas rotational flow dewatering device and dewatering method thereof

PendingCN108772213AImprove dehydration effectPrevent the situation of being easily entrained by the flue gasReversed direction vortexIncreasing energy efficiencyCycloneEngineering

The invention discloses an efficient revolving furnace gas rotational flow dewatering device and a dewatering method thereof and belongs to the technical field of steel dust removal. The efficient revolving furnace gas rotational flow dewatering device comprises an outer barrel wall, a gas guiding pillar, an overflow plate, a contracting pipe and a cyclone. The overflow plate is arranged at the bottom of the outer barrel wall. The gas guiding pillar is arranged on the upper portion of the overflow plate and located at the central axis of the outer barrel wall. The gas guiding pillar extends toan inlet of the cyclone in the height direction. The bottom end of the cyclone is connected with the contracting pipe. An inner barrel wall is arranged outside the cyclone in a sleeving manner and fixed to the outer barrel wall. The overflow plate is provided with an annular overflow gap. By means of the efficient revolving furnace gas rotational flow dewatering device and the dewatering method thereof, under the conditions that the structure of an outer barrel body is not changed and the resistance is not increased obviously, structural optimization is conducted on a rotational flow dewaterer; dewatering efficiency can be improved, thus, the gas recycling quality is improved, and the gas recycling rate is increased; the application effect of a fan is improved, and the cleaning cycle of the fan is prolonged; and the problem that the inner side of the outer barrel body is corroded can be solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

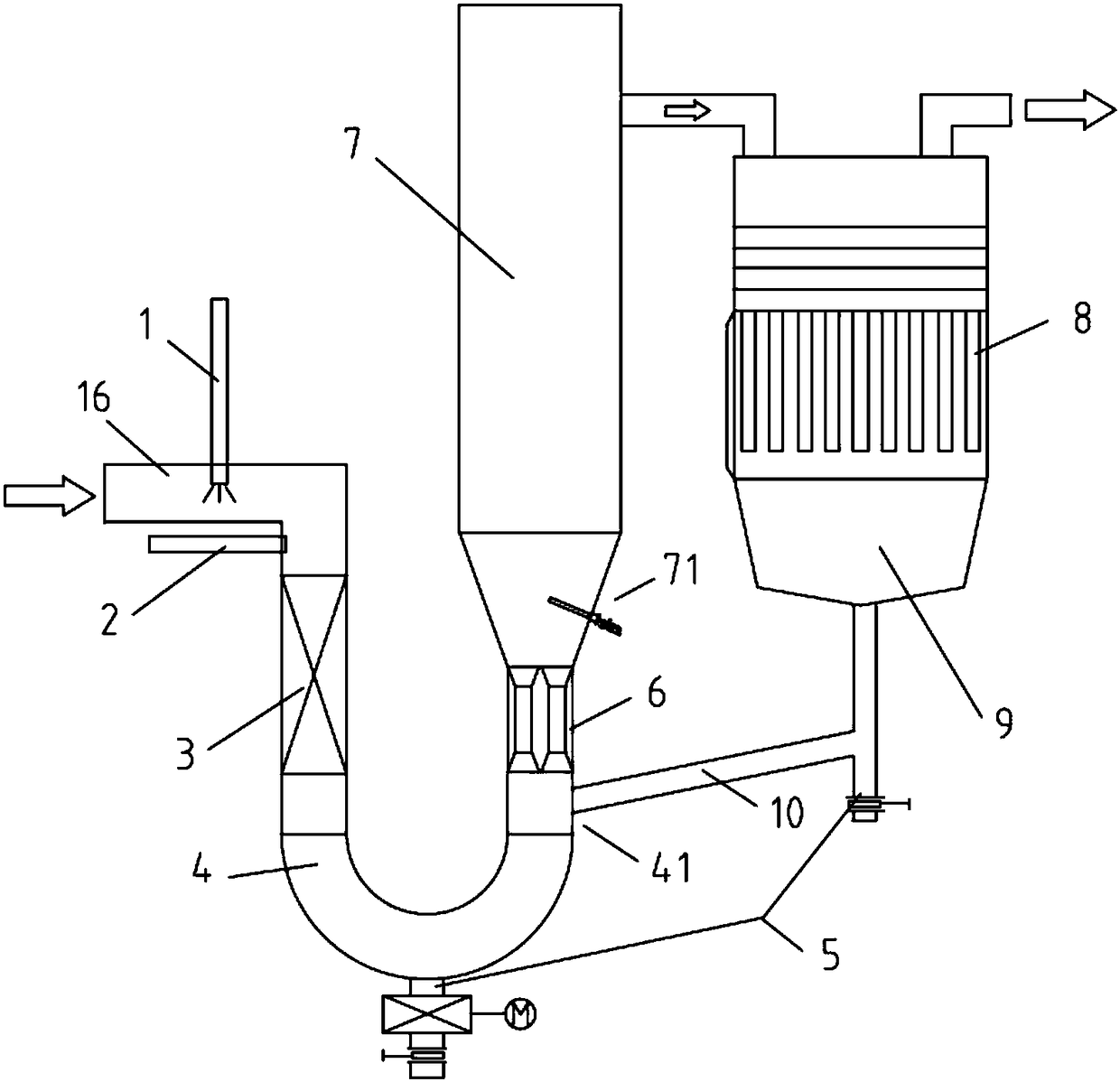

Integrated device and method for removing sulfur oxide and heavy metal in non-ferrous metal smelting and acid-making flue gas

InactiveCN108499315AFlexible temperature controlQuality assuranceCombination devicesGas treatmentResource utilizationNon-ferrous extractive metallurgy

The invention discloses an integrated device and method for removing sulfur oxide and heavy metal in non-ferrous metal smelting and acid-making flue gas. The integrated device comprises a gas inlet flue, a heat exchanger, a U-shaped flue, a venturi tube bundle, a circulating fluidized bed reactor and a dust remover, which are connected in sequence; the acid-making flue gas enters the heat exchanger from the gas inlet flue and enters a U-shaped pipeline through the heat exchanger from top to bottom; then the acid-making flue gas enters the venturi tube bundle through the U-shaped pipeline frombottom to top and enters the fluidized bed reactor from the venturi tube bundle; finally, the acid-making flue gas is subjected to dust removal through the dust remover and then is exhausted. According to the device disclosed by the invention, the temperature of the flue gas can be flexibly controlled according to the acid dew point of the flue gas and SO3 is selectively absorbed; meanwhile, impurities including dust, arsenic, fluorine, mercury and the like are captured and the purification efficiency is high; the quality of the acid-making flue gas can be ensured; a system has a simple structure and a small occupied area; resource utilization of byproducts can be directly realized and no secondary pollution is caused.

Owner:CEEP CO LTD

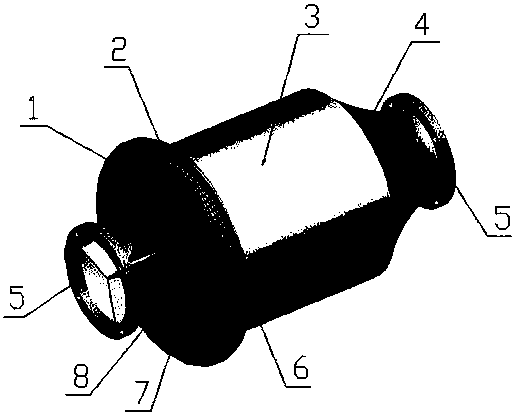

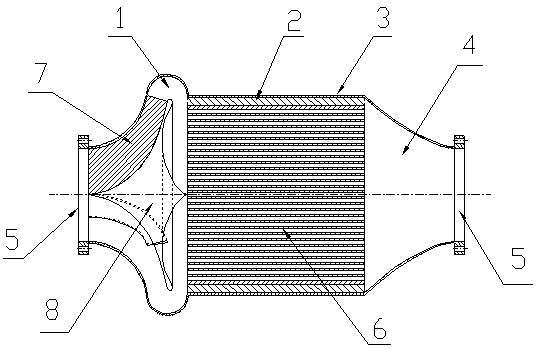

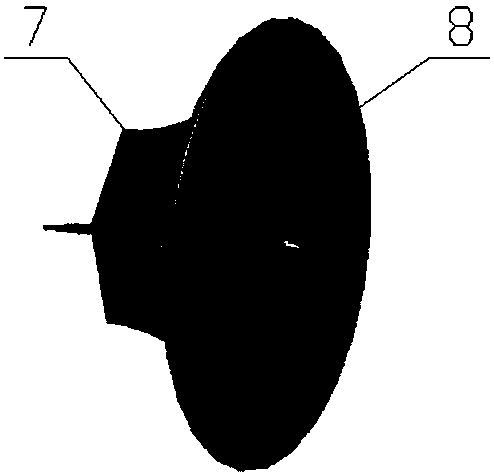

Engine catalytic converter with novel expansion pipe flow guiding device and sepiolite carrier

ActiveCN108590825AEliminate localized flow lossesLow flow resistanceExhaust apparatusSilencing apparatusGasolineEngineering

The invention relates to an engine catalytic converter with a novel expansion pipe flow guiding device and a sepiolite carrier. The engine catalytic converter is composed of a flange, an expansion pipe, the flow guiding device, a fixing rib plate, a shell, a vibration reduction layer, the sepiolite carrier and a shrinkage pipe. The expansion pipe is of a smooth streamline curved surface structure,local flow losses generated inside the expansion pipe are eliminated, and a curved surface bent segment at the tail of the expansion pipe is used for changing the flow direction of tail gas. The expansion pipe is internally provided with the flow guiding device; and the inner wall of the expansion pipe cooperates with the outer wall of the flow guiding device to guide flow of the tail gas, so that gas flow are more uniform in flow distribution when passing through the sepiolite carrier. The fixing rib plate is added, and the flow guiding device is fixed to the inner wall of the expansion pipe. The engine catalytic converter is applicable to purification, conducted under different working conditions, of the tail gas of a gasoline engine or a diesel engine and also applicable to ceramic honeycomb carriers and metal carriers of different hole densities and in different hole shapes; sepiolite is added to a carrier catalyst coating material, and compound conversion efficiency of the tail gas is improved; the streamline curved surface is adopted for the shrinkage pipe, and the flow resistance inside the shrinkage pipe is reduced; and the engine catalytic converter is simple in structure.

Owner:XIANGTAN UNIV

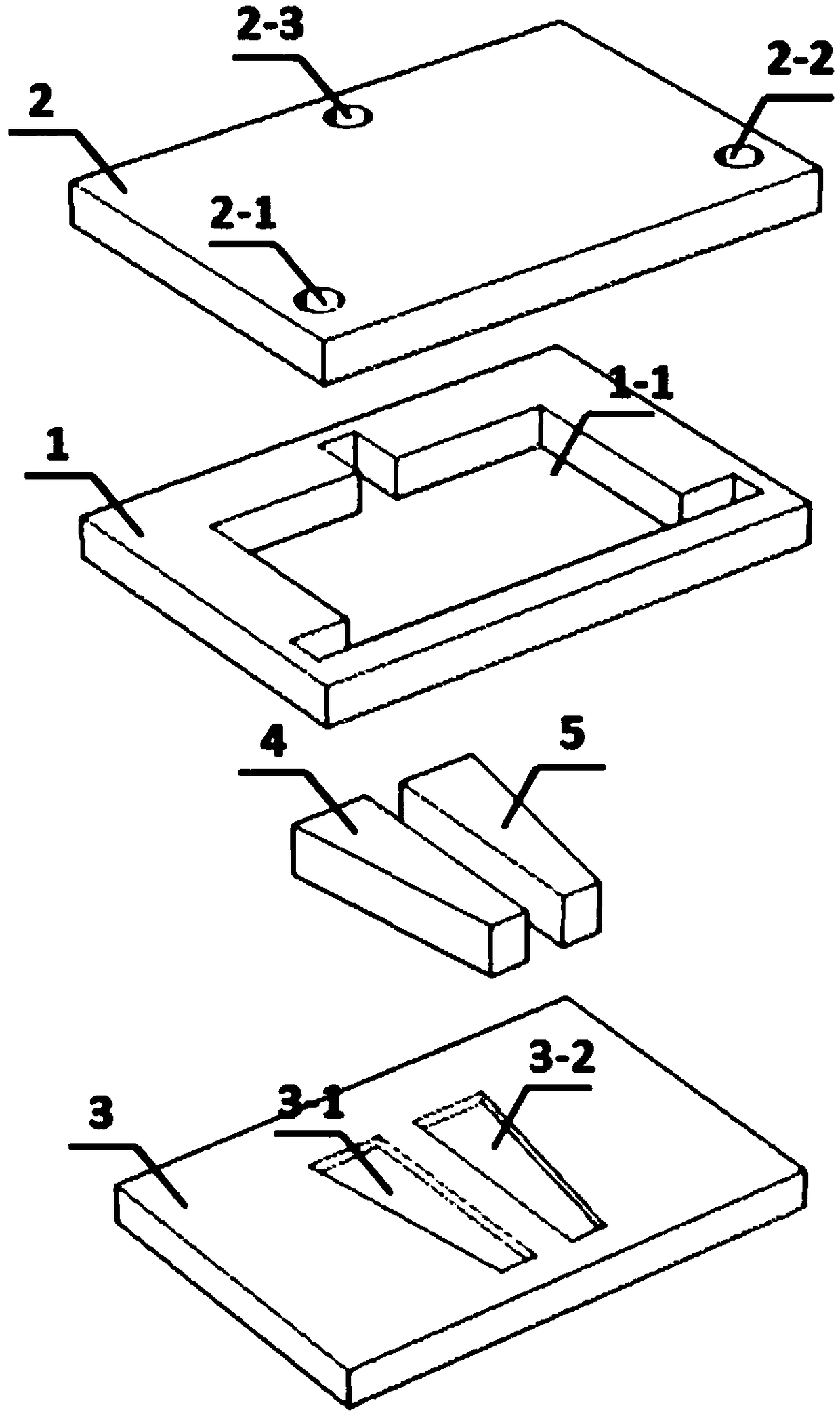

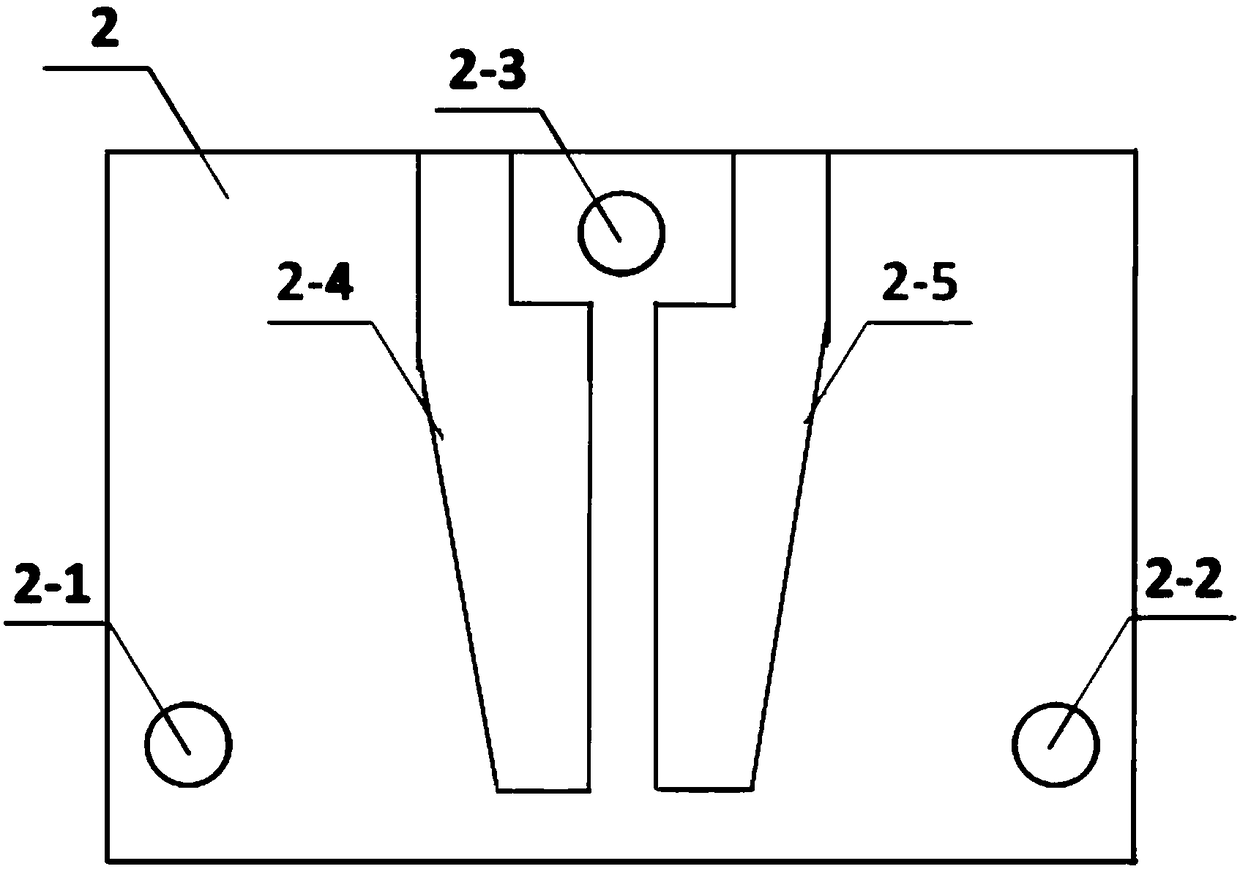

Microfluid fuel cell with right trapezoid-shaped porous electrodes

The invention discloses a microfluid fuel cell with right trapezoid-shaped porous electrodes, which belongs to the technical field of fuel cells. The microfluid fuel cell is made of a diaphragm and anupper cover board and a lower cover board covering the top and bottom of the diaphragm by hot-pressing packaging, the interior of the diaphragm is provided with a fluid flow passage, the upper coverboard is provided with an anolyte inlet, a catholyte inlet, and a reaction fluid outlet, an anode current collector and a cathode current collector which are metal layers are deposited on the internalsurface of the upper cover board, the anode current collector and the cathode current collector are respectively connected to external wires in order to output electric energy generated in the fuel cell to an external circuit load, the bottom of the lower cover board is provided with grooves, and the right trapezoid-shaped porous electrodes are arranged in the grooves. The lower cover board groove design adopted by the invention can prevent the enlargement of cell size while effectively fixing the porous electrodes, and the adopted right trapezoid-shaped electrode design can balance the distribution of flow fields in the porous electrodes.

Owner:JIANGSU UNIV OF TECH

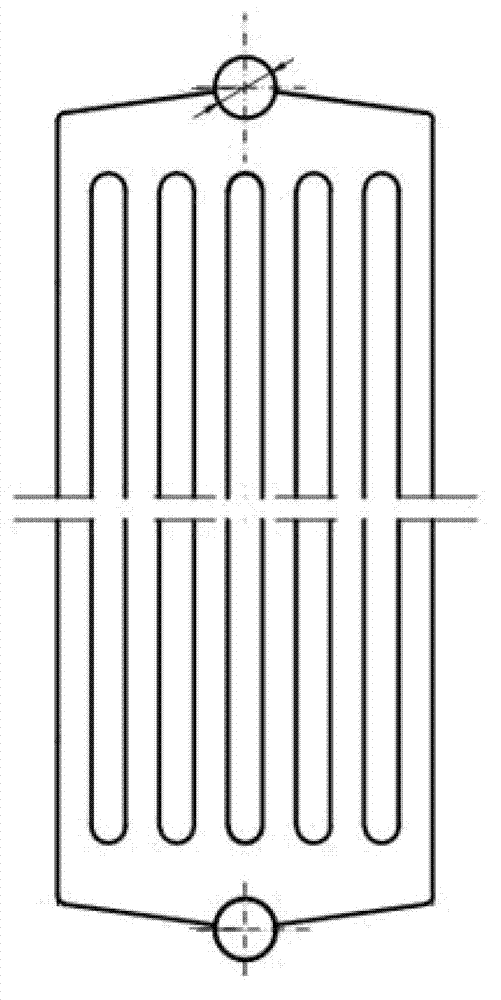

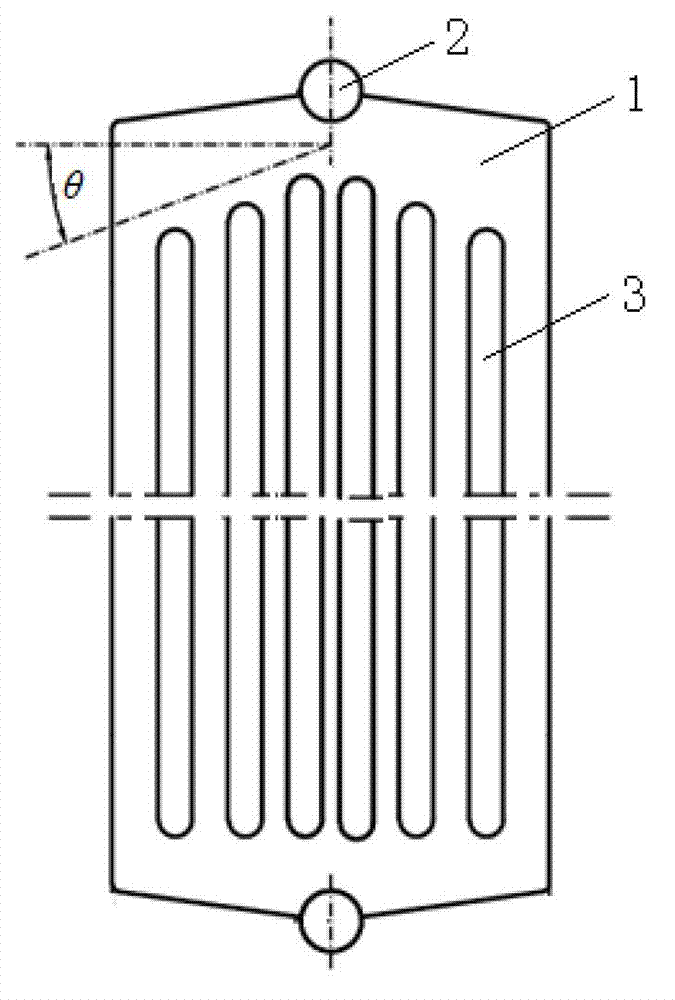

Plate radiator unit box for double-sloping-shoulder transformer

InactiveCN102760556ANovel structureUniform distribution of flow fieldTransformers/inductances coolingEngineeringSimulation testing

The invention relates to a plate radiator unit box for a double-sloping-shoulder transformer, which belongs to the field of transformer radiators. An oil collecting pipe inlet and an oil collecting pipe outlet are formed above and below a main body respectively; an oil channel is formed inside the main body; a high point is formed on the middle part of the oil channel; and the inclination angles theta of the oil channel inclining towards both sides are 13-20 degrees. The plate radiator unit box has the advantages: the structure is novel; and in the refitting process of a plate radiator of an ordinary transformer, a shoulder is cut on a horizontal oil flow channel on the middle upper part of a sheet fan at a certain angle, an upper oil flow channel is widened gradually, pressure distribution in the sheet fan tends to be consistent, and the flow field distribution inside the sheet fan tends to be uniform, so that heat of transformer oil is exchanged completely in a single sheet fan. Theoretical analysis and simulation testing analysis are performed on the flowing and heat transferring properties of transformer cooling oil before and after refitting respectively, so that an optimal angle theta is obtained.

Owner:JILIN ELECTRIC POWER RES INST +1

A novel pyrolysis gasification furnace for organic solid waste

PendingCN110437880AUniform distribution of flow fieldUniform concentration distributionWaste processingTransportation and packagingSlagMetallurgy

The invention discloses a novel pyrolysis gasification furnace for organic solid waste. The furnace includes, in order from top to bottom, a furnace top, an upper furnace body, a lower furnace body, amulti-rotating water-cooled grate, and a slag discharge port, wherein the furnace top is provided with a feeding port and an atomizing spray structure; an upper side wall of the upper furnace body isprovided with an explosion-proof door, and the other side is provided with a gas outlet; the gas outlet is communicated with a cyclone separator; purified combustible gas is discharged from a purified gas outlet at the upper end of the cyclone separator; water separated by the cyclone separator is circulated to the atomizing spray structure and sprayed into the gasification furnace; and the sidewall of the lower furnace body is provided with a gas inlet, a multi-point multi-angle gas feeding structure and a gas outlet. The furnace has a simple structure, solves the problem that organic solidwaste gasification processes in the prior art are uneven in gasification, low in gasification efficiency, and high in tar content of combustible gas, and solves the problem that a water washing method which is adopted to remove tar oil at the rear end of a gas flue causes water pollution and waste of energy.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

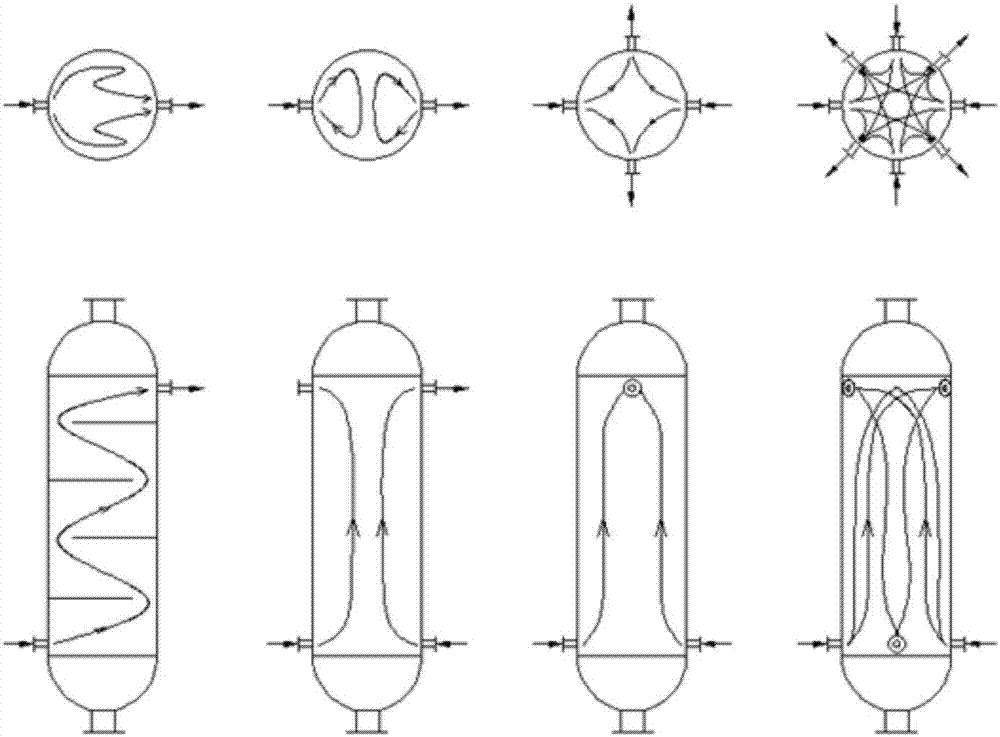

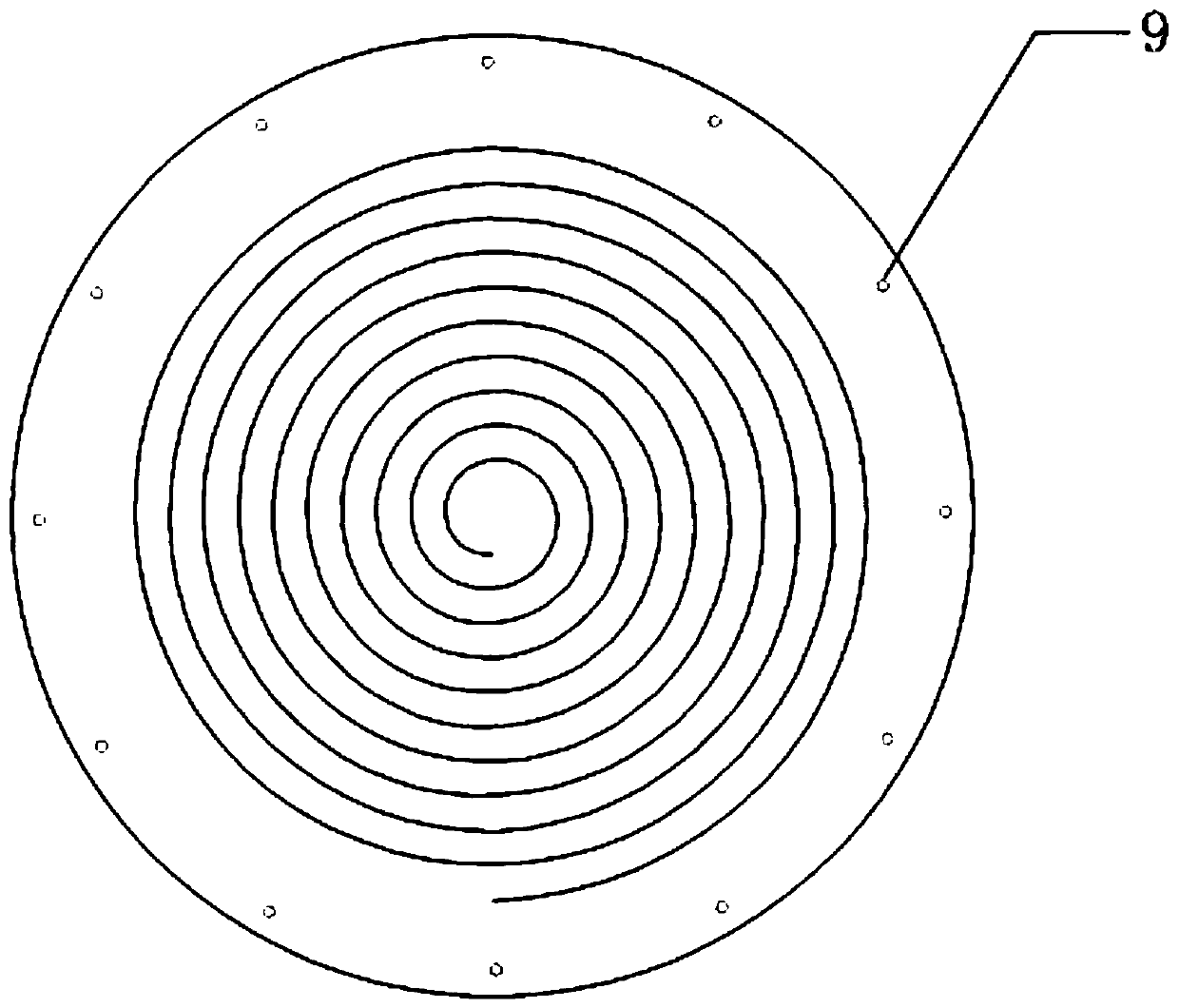

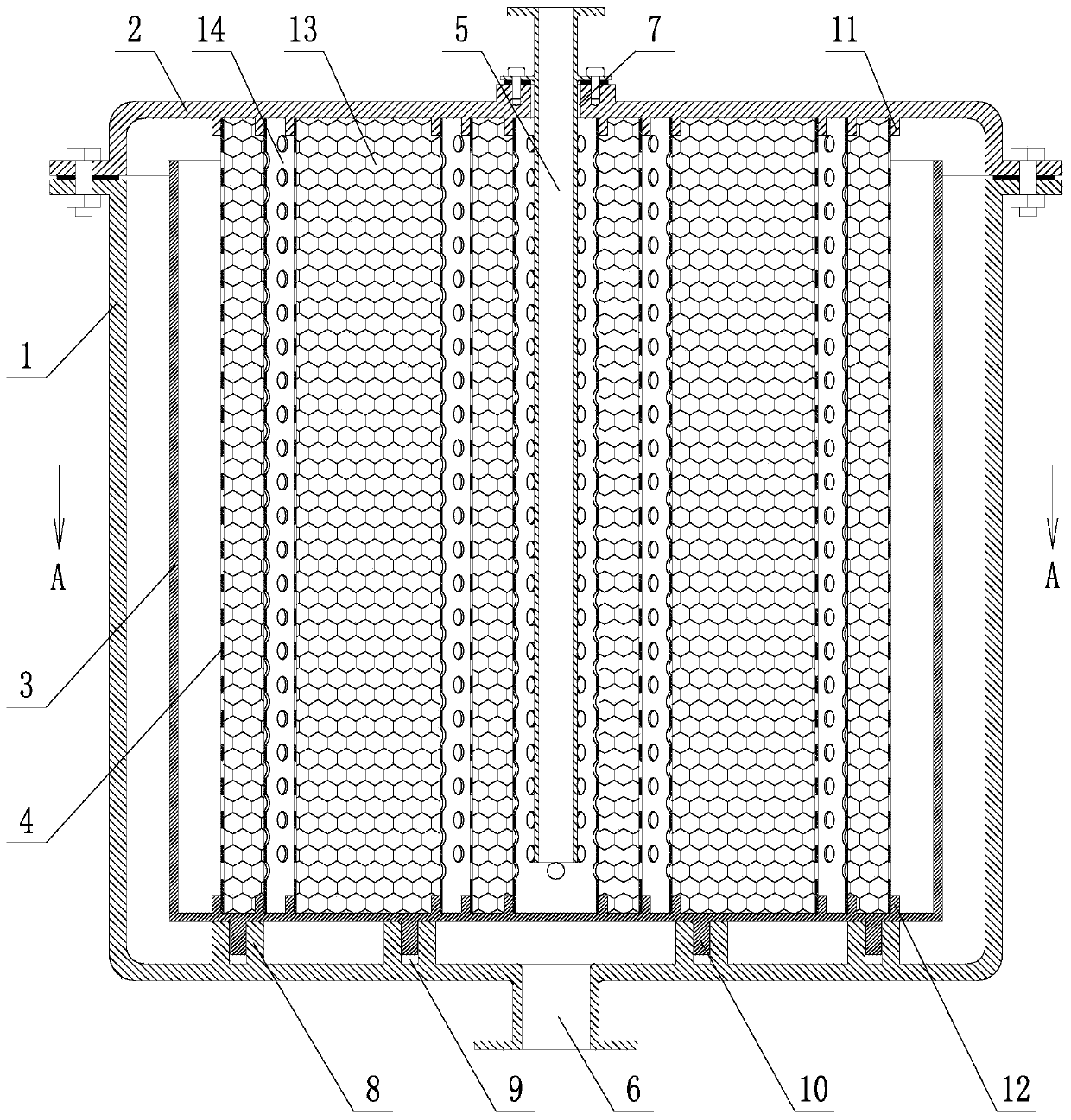

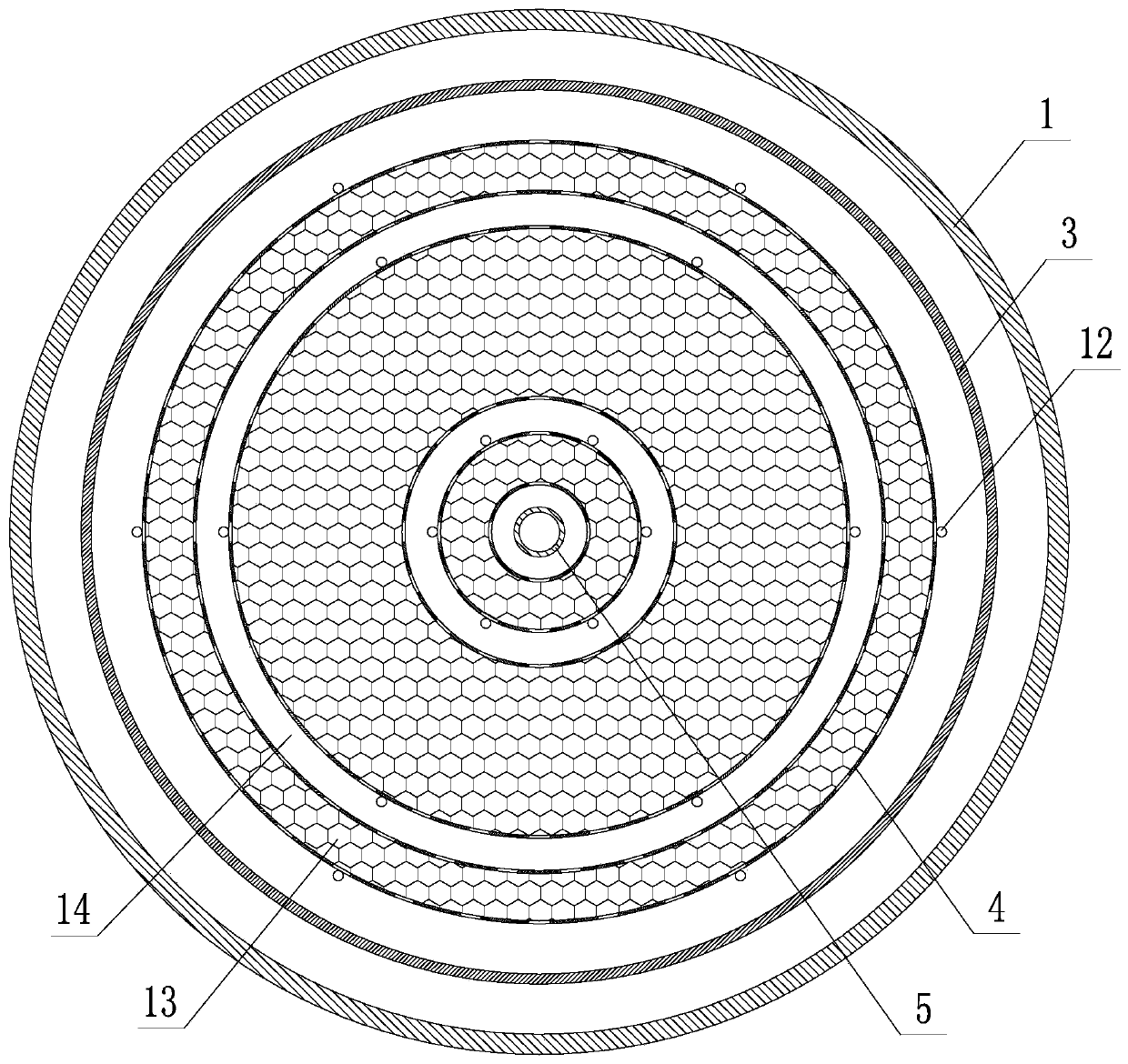

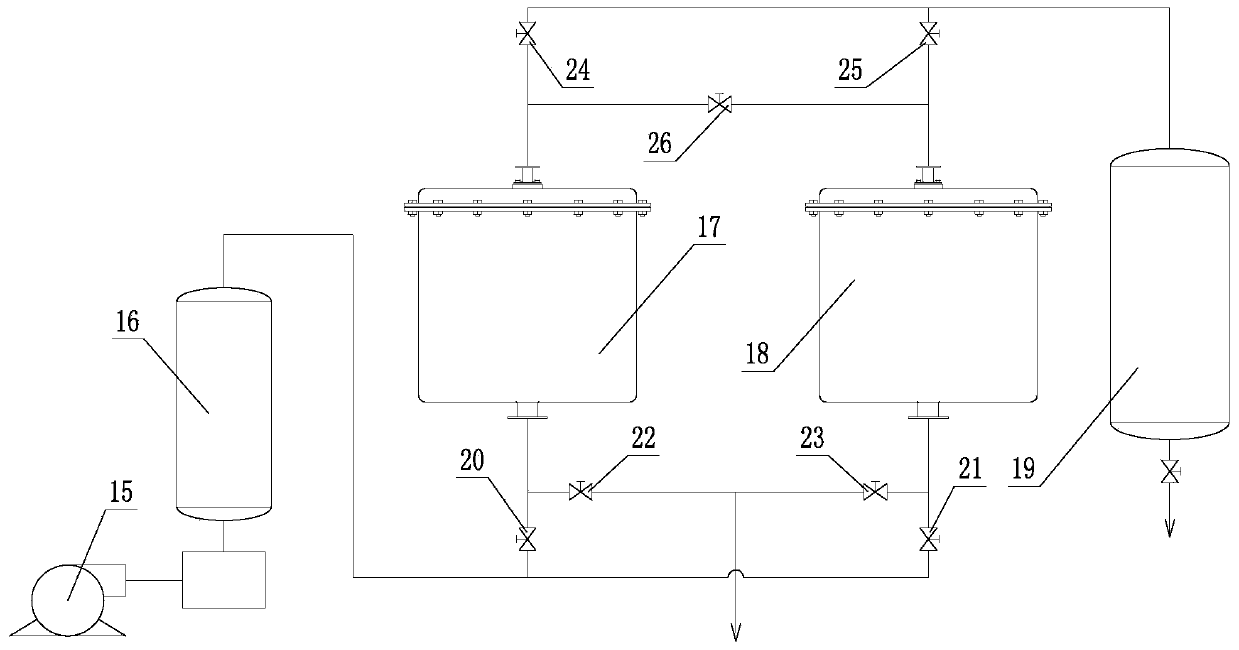

A multi-unit composite spiral plate heat exchanger

ActiveCN108061471BUniform distribution of flow fieldCompact structureLaminated elementsStationary plate conduit assembliesMulti unitPlate heat exchanger

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

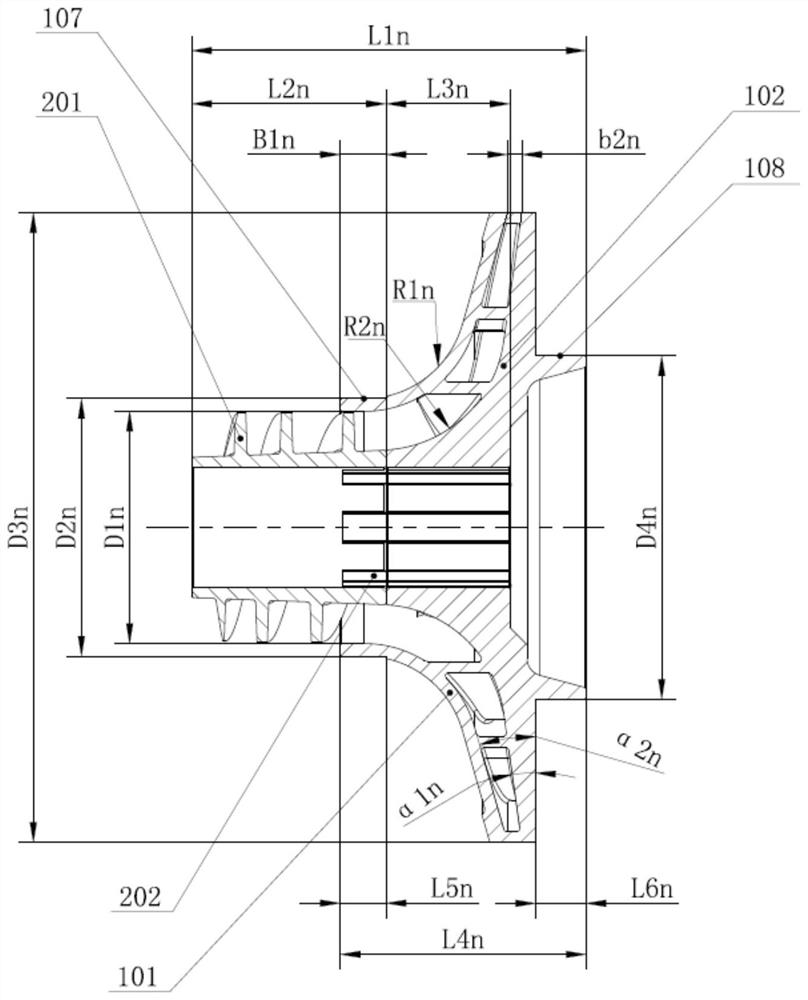

Efficient long-runner impeller low-specific-speed centrifugal pump

PendingCN113586513AImprove work efficiencyUniform change in flow areaPump componentsPumpsCircular discDrive shaft

The invention discloses an efficient long-runner impeller low-specific-speed centrifugal pump. The efficient long-runner impeller low-specific-speed centrifugal pump comprises a centrifugal impeller, an inducer, a transmission shaft, a centrifugal pump shell and sealing structures; the centrifugal impeller and the inducer are in rigid connection; the centrifugal impeller and the inducer are coaxial with the transmission shaft; the centrifugal impeller comprises a front cover plate and a rear cover plate which are in single-arc transition; and the sealing structures are arranged on the outer side of the front cover plate and the outer side of the rear cover plate correspondingly. According to the efficient long-runner impeller low-specific-speed centrifugal pump, the axial length is properly increased, the blade angle distribution of the centrifugal impeller is smoother, the inlet impact loss of the centrifugal impeller is reduced, the work efficiency of the low-specific-speed centrifugal pump is obviously improved, and the problem that due to the long and narrow runner characteristic of the low-specific-speed centrifugal pump, the impeller disc friction loss and the inlet impact loss of the low-specific-speed centrifugal pump are large, and consequently the efficiency of the low-specific-speed centrifugal pump is low is solved.

Owner:XI AN JIAOTONG UNIV

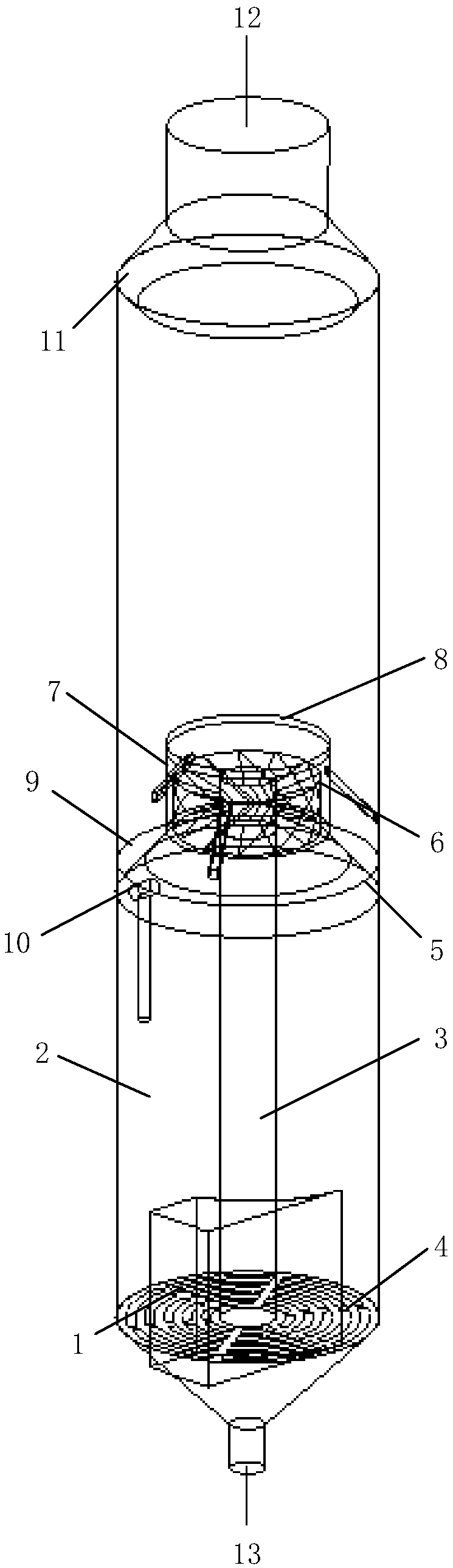

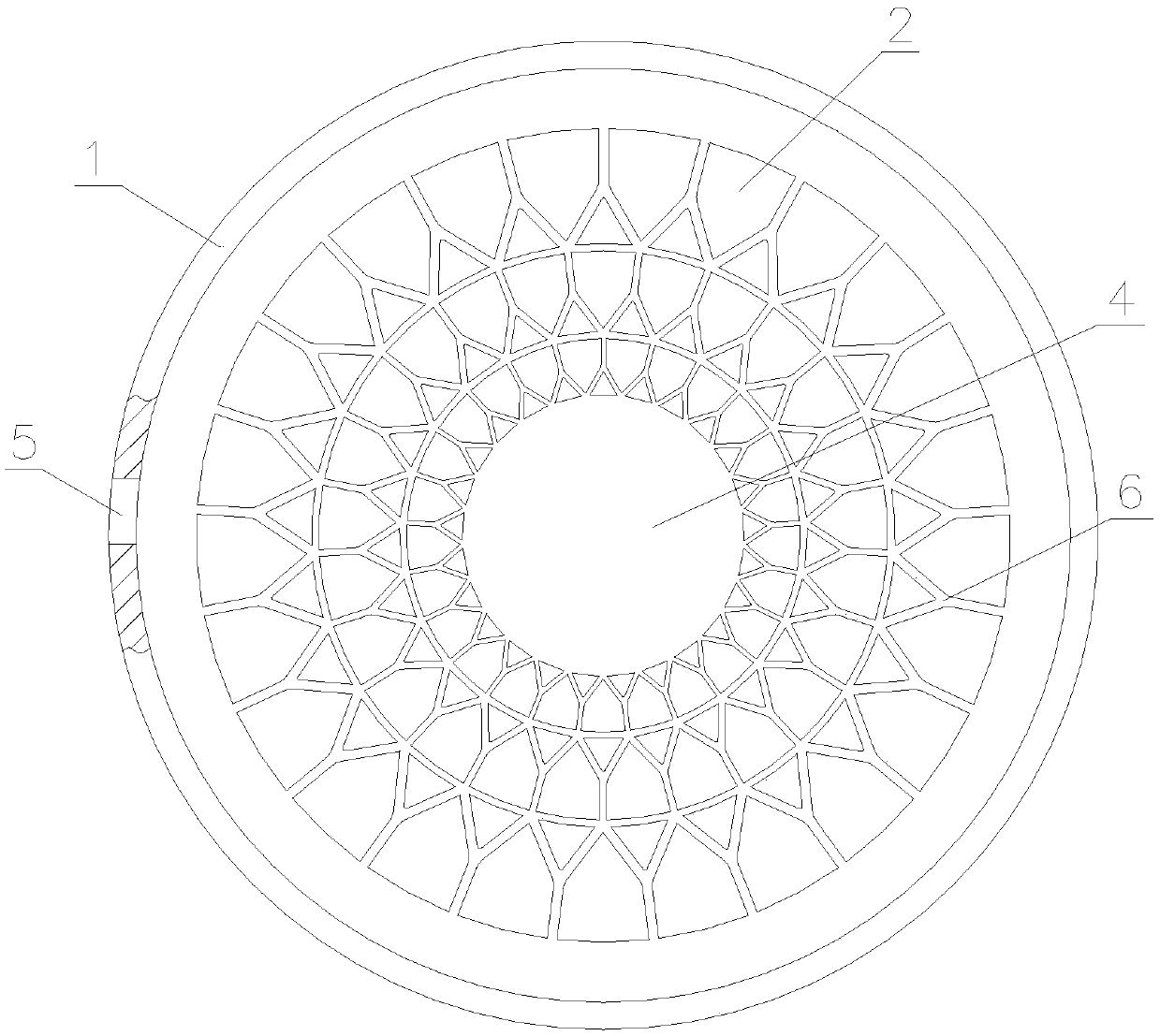

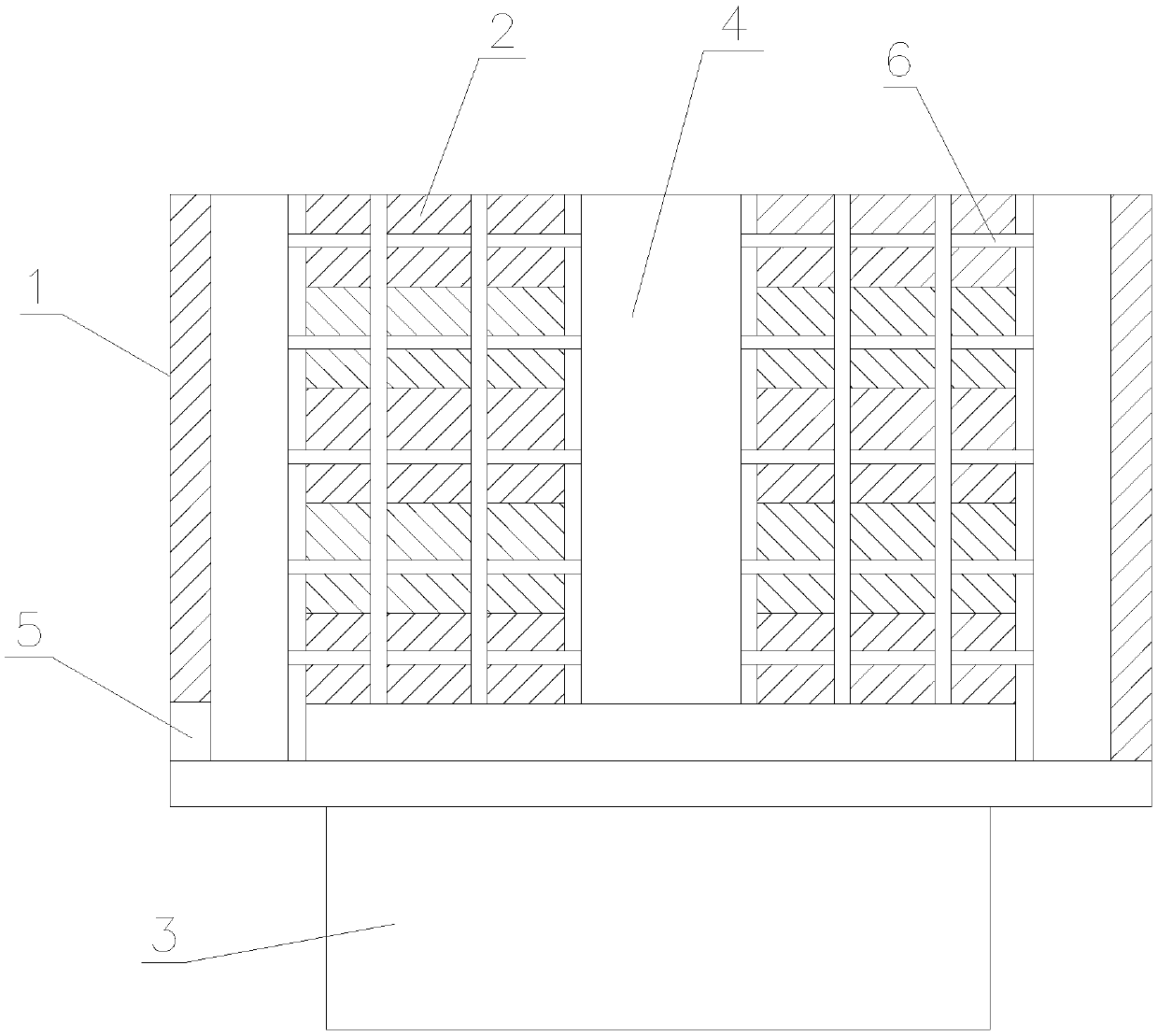

Supergravity-fractal impact bed reactor

ActiveCN109603702AAchieve impingement mixingAchieve decentralizationChemical/physical/physico-chemical microreactorsEngineeringCentrifugal force

The invention discloses a supergravity-fractal impact bed reactor. The supergravity-fractal impact bed reactor mainly comprises a cylindrical outer shell and a rotary cylinder assembled by a pluralityof fractal circular ring pieces; a tray is arranged under the rotating cylinder; and the tray is connected with an external centrifugal machine. The supergravity-fractal impact bed reactor is characterized in that a feeding hole is formed in the center of the rotary cylinder; the cylindrical shell is provided with a fluid outlet pipe; the fractal circular ring pieces are internally provided withfractal channels which are through stage by stage in the radial direction; the fractal stage n of the fractal channels inside the fractal circular ring pieces is smaller than or equal to 15 and largerthan or equal to 3, and the diameters of the fractal channels are in a range from 1 micron to 0.5 meter; the diameter of the fractal channel of n-1 stage is 1.2-2 times of the diameter of the fractalchannel of n stage, so that the distribution force of the inner side channels is prevented from being insufficient; and the flow of a fluid in the channels can be adjusted by adjusting the rotating speed of the cylinder. A centrifugal force is adopted as power to drive the reactor, ordered and repeated instant impact mixing and dispersion among fluids in a supergravity field are realized, and disorder mixing among the fluids in filler of a supergravity device is greatly improved.

Owner:ANHUI SCI & TECH UNIV

Deacidification-dust removal integrated device for flue gas based on dense phase dry tower

PendingCN113144771AEmission reductionReduce pollutionGas treatmentDispersed particle filtrationFlue gasDust control

The invention provides a deacidification-dust removal integrated device for flue gas based on a dense phase dry tower. The device comprises a dense phase dry tower deacidification device and a special deacidification dust remover, wherein the dense phase dry tower deacidification device comprises a flue gas inlet, a deacidification device body, ash hoppers of the deacidification device body, ash hopper feeders of the deacidification device body, an ash conveying device, a humidifier and a stirrer; the deacidification device body is divided into a gas inlet side and a gas outlet side by a partition plate, the lower ends of the gas inlet side and the gas outlet side communicate with each other, and the ash hoppers of the deacidification device body and the ash hopper feeders of the deacidification device body are arranged at the lower ends of the gas inlet side and the gas outlet side; the ash hopper feeders of the deacidification device body are connected with the ash conveying device; and the flue gas inlet is formed in the upper part of the gas inlet side, the top of the gas inlet side is also connected with a discharge hole of the humidifier, and the stirrer is arranged at the top of the gas inlet side. The deacidification-dust removal integrated device of the invention has the following beneficial effects: flow field distribution is more uniform and reasonable; land occupation and investment can be reduced; and deacidification efficiency is very high, and operation cost is remarkably reduced.

Owner:UNIV OF SCI & TECH BEIJING

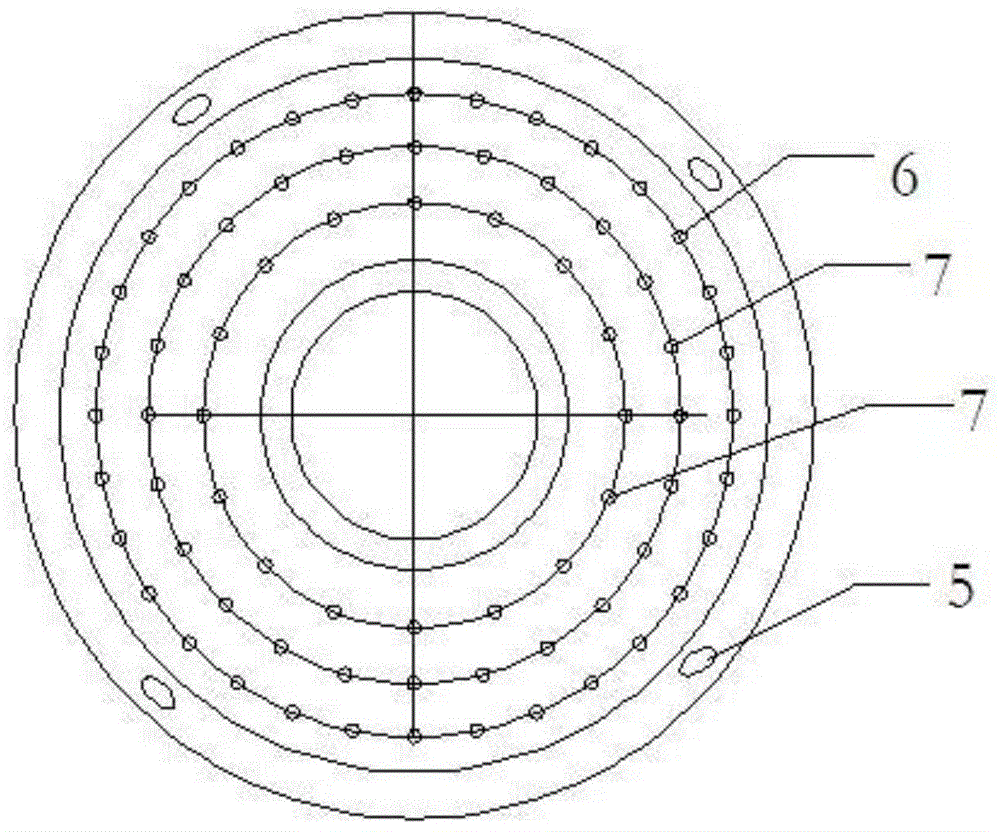

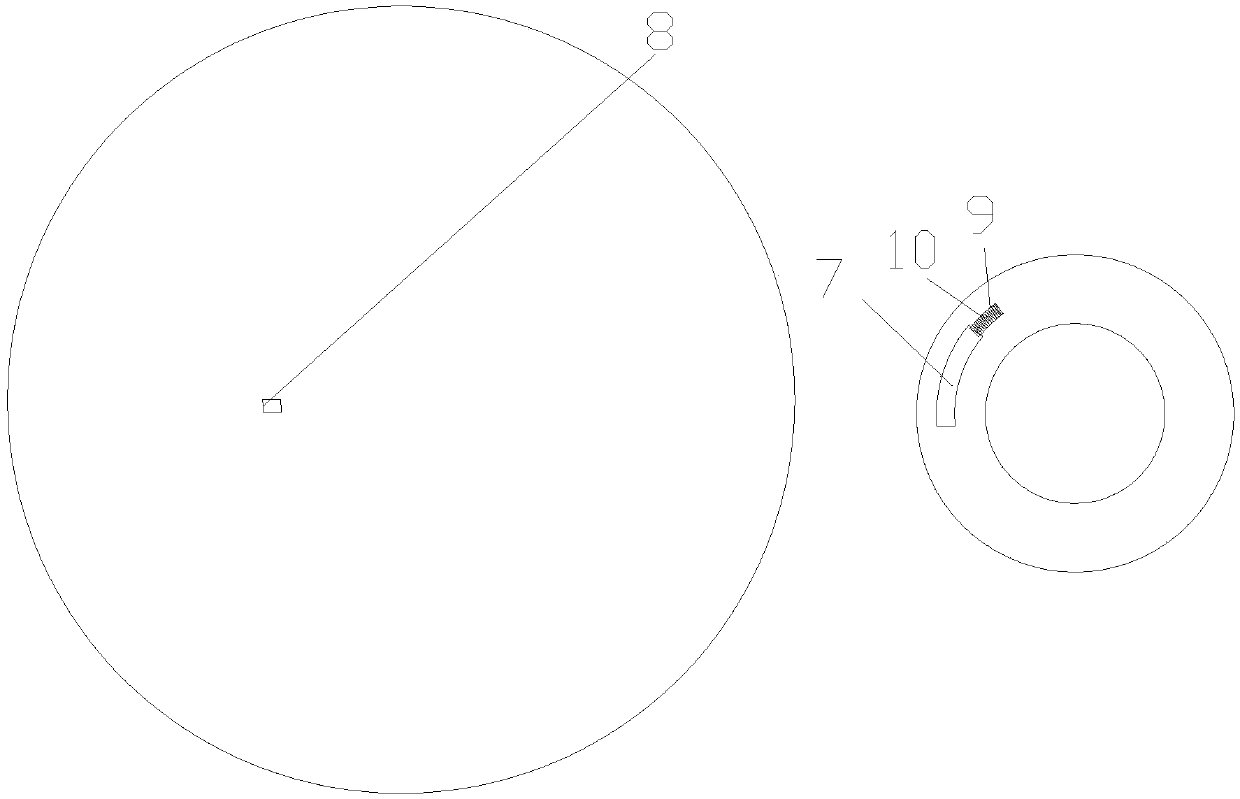

Radial flow equalization pressure swing adsorption tower

InactiveCN110201488APurge thoroughlyUniform distribution of flow fieldDispersed particle separationEngineeringEqualization

The invention relates to a radial flow equalization pressure swing adsorption tower, which comprises an outer shell, a sealing cover, a flow guiding cylinder, wind distribution cylinders and a ventingpipe, wherein a venting port is arranged on the bottom portion of the outer shell, the venting pipe is inserted in the center of the sealing cover, and extends into the outer shell, the flow guidingcylinder is concentrically arranged in the outer shell, support blocks are arranged in front of the bottom plates of the flow guiding cylinder and the outer shell, the support blocks and the flow guiding cylinder are positioned by positioning pins and positioning holes, the wind distribution cylinders are concentrically arranged inside the flow guiding cylinder, and are fixedly arranged between the sealing cover and the bottom plate of the flow guiding cylinder through positioning snapping blocks, the surface of the wind distribution cylinder is uniformly provided with gas-permeable holes, a plurality of the wind distribution cylinders are arranged and have different diameters, the plurality of the wind distribution cylinders are arranged concentrically, the circumferential gaps between the wind distribution cylinders are respectively arranged as adsorption chambers and gas chambers, the adsorption chambers and the gas chambers are alternately distributed in the radial direction, and the adsorption chamber is filled with an adsorbent. According to the present invention, at the adsorption phase and the backflush stage, the flow field inside the adsorption tower is uniformly distributed, the gas flow distribution is reasonable during the gas producing, and the purging is clean and complete during the backflushing, such that the gas production efficiency and the gas production quality can be effectively improved.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com