Efficient revolving furnace gas rotational flow dewatering device and dewatering method thereof

A technology of dehydration device and coal cyclone, which is applied in the direction of swirl device and the device whose axial direction of swirl can be reversed, etc., can solve the problem of outer cylinder being corroded, shorten the separation time of gas and water, and evenly distribute the flow field , The effect of improving the dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

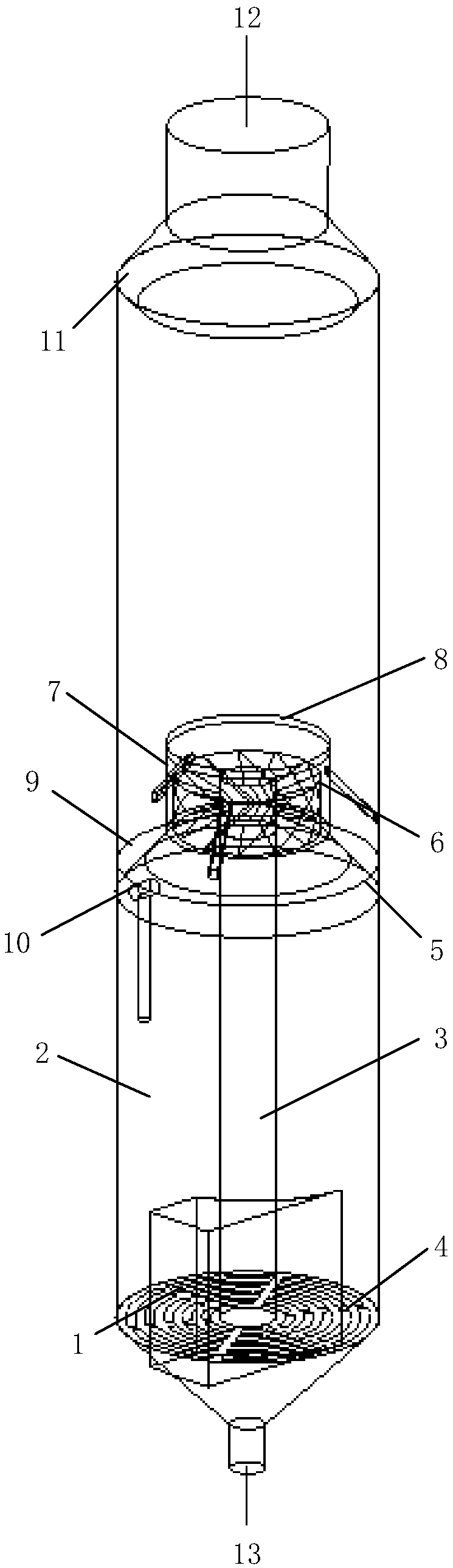

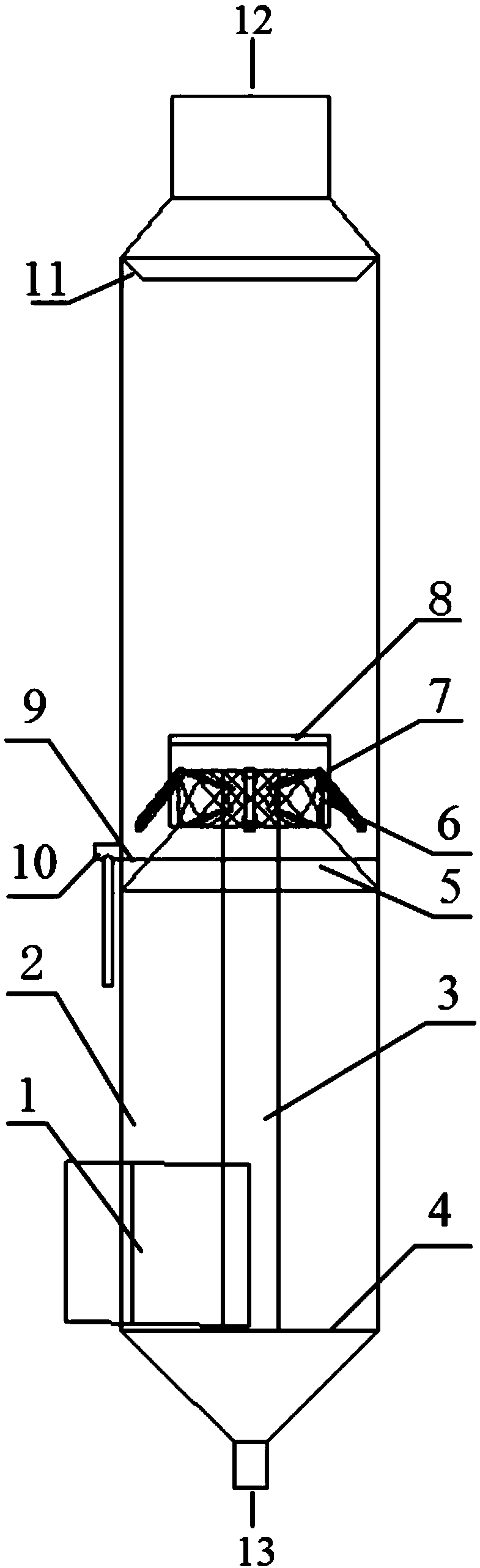

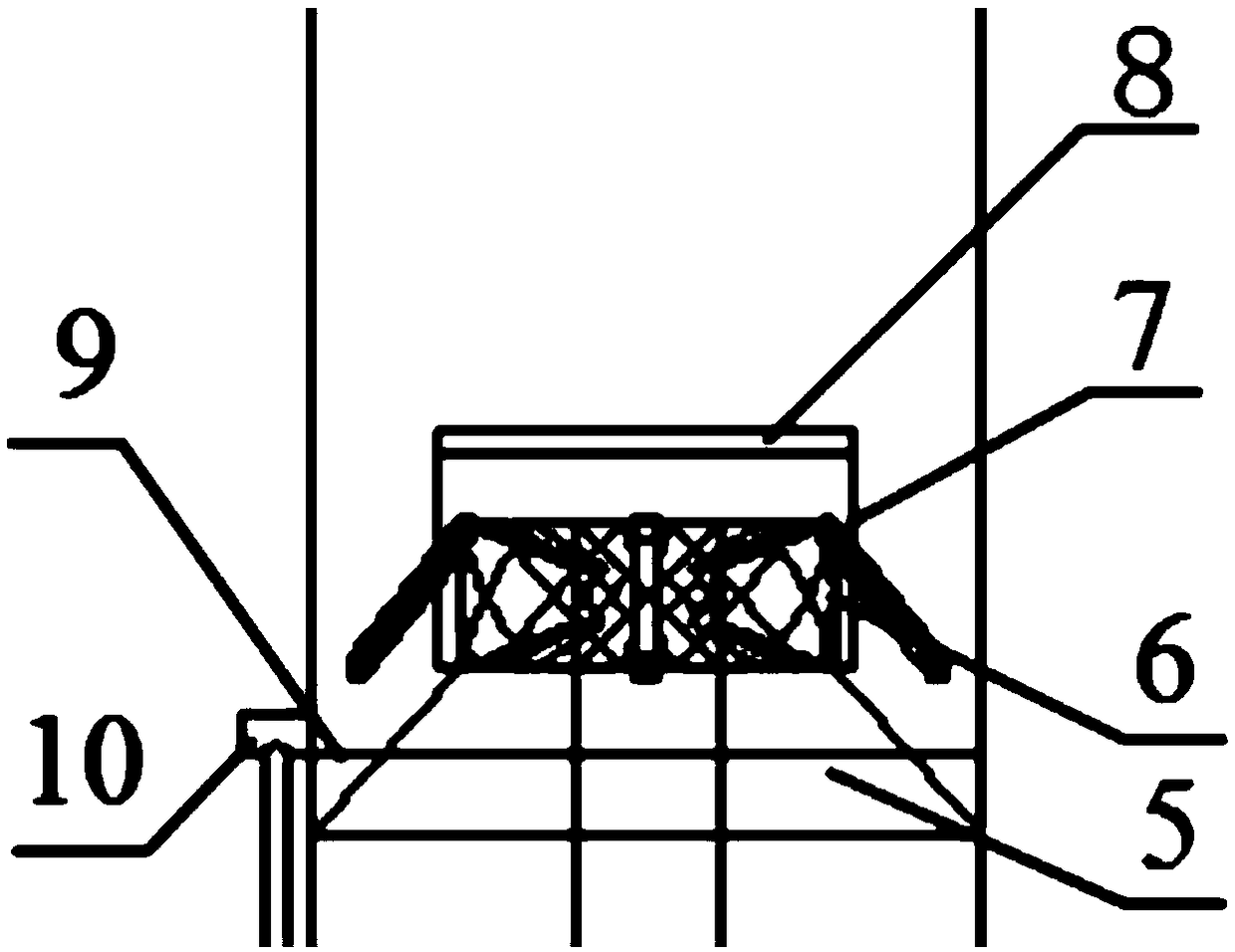

[0036] In conjunction with the accompanying drawings, this embodiment is suitable for a high-efficiency converter gas cyclone dehydration device for converter gas purification and recovery, including a flue gas inlet section 1, an outer cylinder wall 2, a gas guide column 3, an overflow plate 4, and a shrink tube 5. Cyclone 6, inner cylinder wall 7, water retaining ring 8, liquid sump 9, drain pipe 10 and water retaining ring 11. The flue gas inlet section 1 is arranged at the lower part of the outer cylinder wall 2, and the flue gas enters the dehydrator tangentially so as to generate swirl gas. see figure 2 , The flue gas inlet section 1 has a slightly inclined downward angle, so as to facilitate the separated water droplets before entering the dehydrator to flow into the drain bucket at the bottom of the dehydrator.

[0037] see figure 1 , The bottom of the outer cylinder wall 2 is provided with an overflow plate 4, and an annular overflow gap is opened on the overflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com