Treatment method for strengthening dewatering performance of excess activated sludge

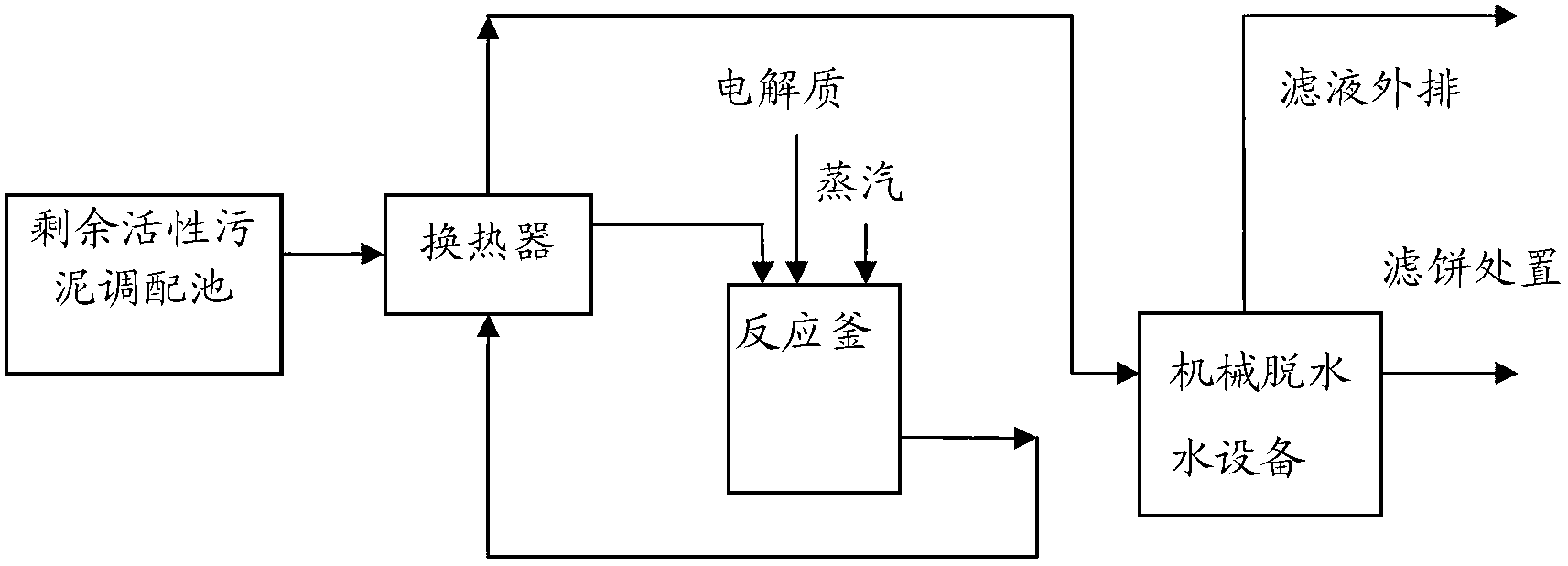

A residual activity and sludge dehydration technology, applied in the field of resources and environment, can solve the problems of heavy metal and phosphorus dissolution, acid or alkali exceeding the standard, equipment corrosion, etc., and achieve the effect of simple equipment, short process and improved dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

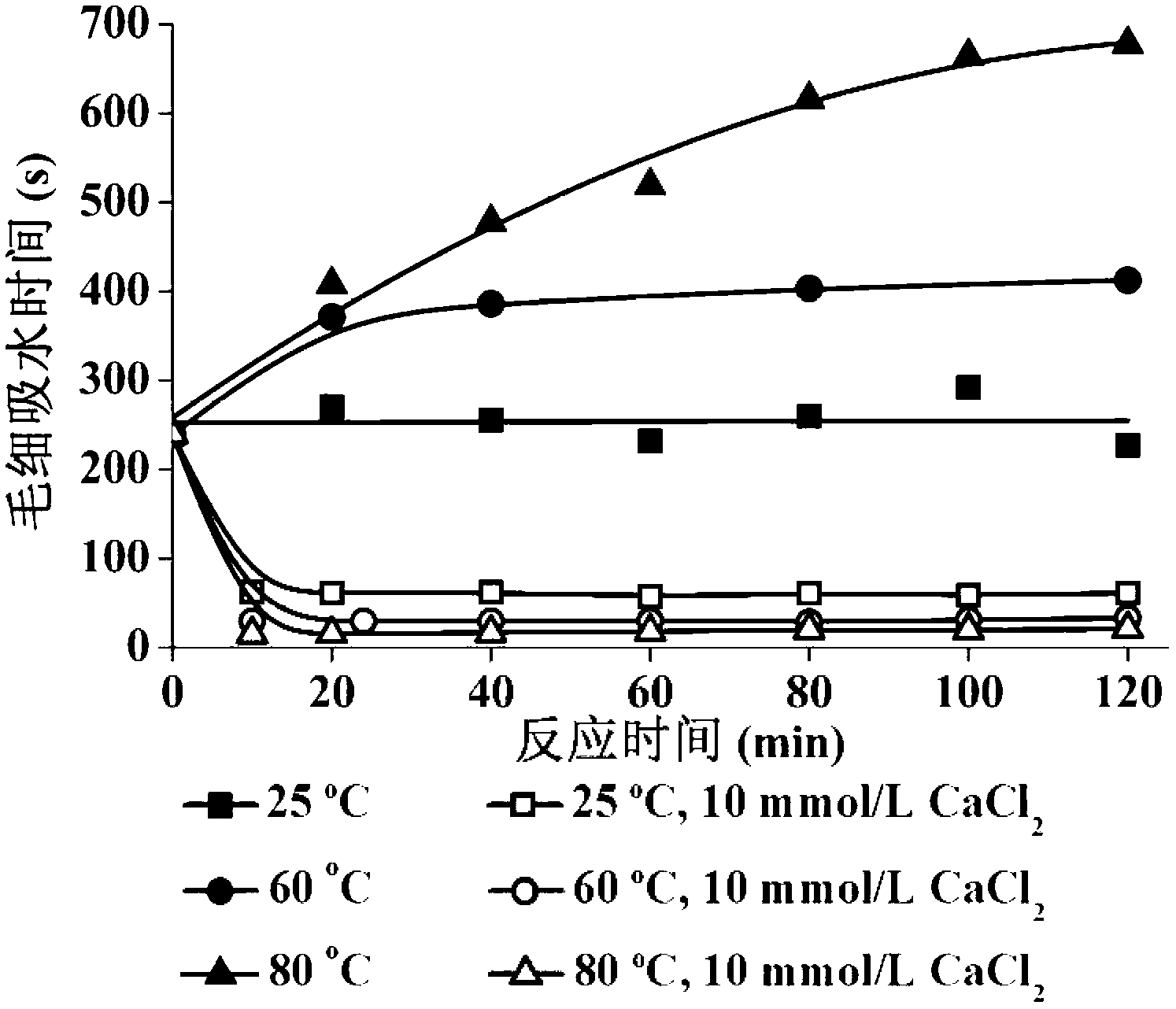

[0023] The remaining activated sludge with a moisture content of 95.6% is transported to the jacketed enamel reaction kettle after heat exchange by a heat exchanger, and electrolyte calcium chloride is added to make the concentration of calcium chloride 9mmol / L, and the hydrothermal temperature is controlled at 85°C. Stir evenly, after 1 hour of reaction, the activated sludge is discharged from the reactor, and after heat exchange in the heat exchanger, it is input into a plate and frame filter press (BAMS 0.6 / 315-UBK type) for pressure filtration, and the moisture content of the obtained mud cake is 54.7%. .

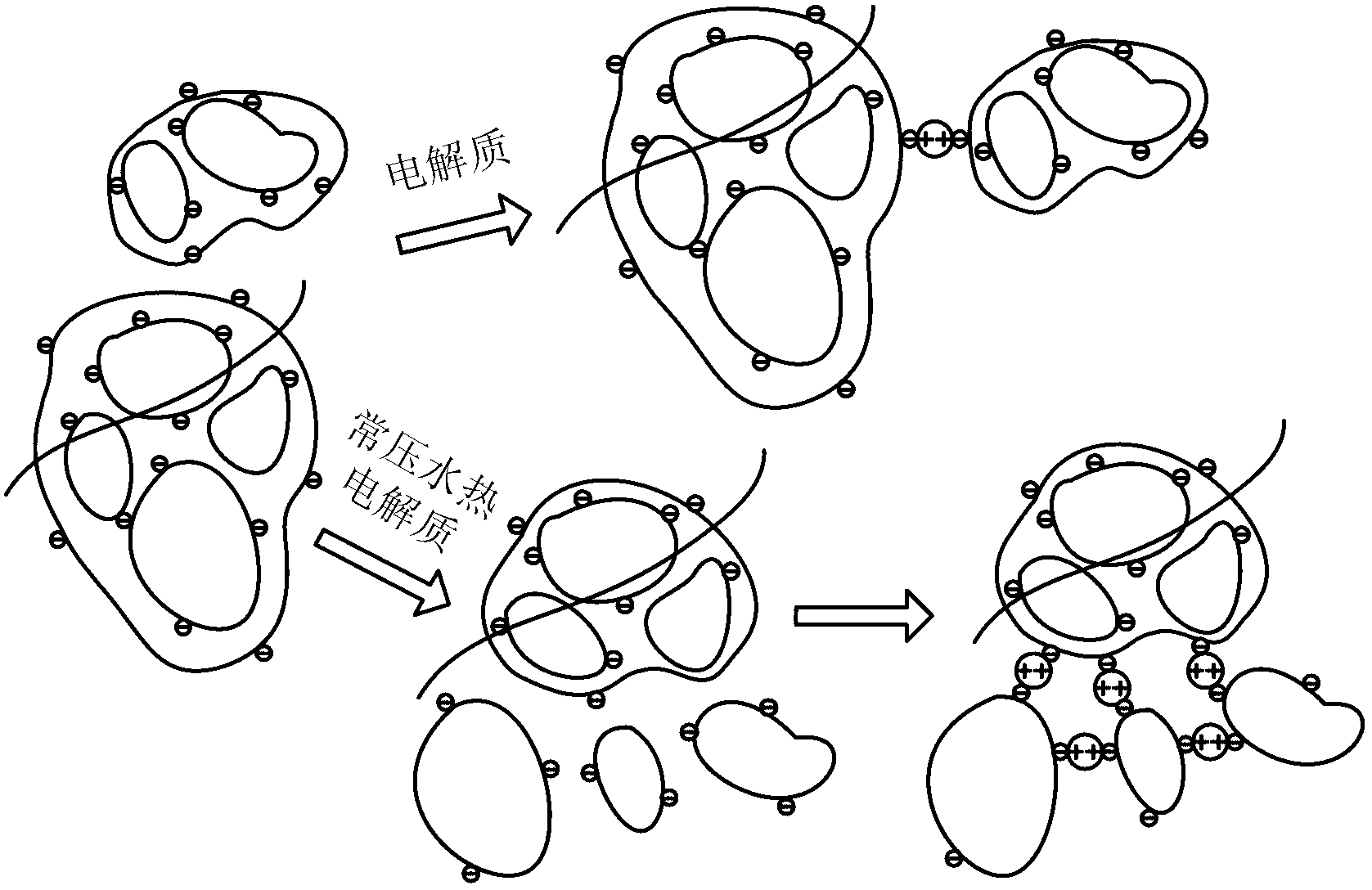

[0024] principle such as figure 2 Shown: Under heating conditions, the flocs of the remaining activated sludge are broken, the internal negatively charged groups are exposed, and the intracellular substances are released, providing more bridging binding sites for cations. At this time, chlorine The calcium ions ionized by calcium chloride can reduce the surface charge...

Embodiment 2

[0026] The remaining activated sludge with a moisture content of 97.1% is transferred to the jacketed enamel reaction kettle after heat exchange by a heat exchanger, and electrolyte sodium chloride is added so that the concentration of sodium chloride is 72mmol / L, and the hydrothermal temperature is controlled at 60°C. Stir evenly, after 3 hours of reaction, the activated sludge is discharged from the reactor, and after heat exchange in the heat exchanger, it is input into a plate and frame filter press (BAMS 0.6 / 315-UBK type) for pressure filtration, and the moisture content of the obtained mud cake is 52.4%. .

Embodiment 3

[0028] The remaining activated sludge with a moisture content of 90.3% is transferred to the jacketed enamel reaction kettle after heat exchange by a heat exchanger, and the electrolyte magnesium chloride is added so that the concentration of magnesium chloride is 205mmol / L, and the hydrothermal temperature is controlled at 70°C. After 7 hours, the activated sludge was discharged from the reactor, and after being exchanged in the heat exchanger, it was input into a chamber filter press (XBAMQ2-6-420UBK type) for pressure filtration, and the moisture content of the obtained mud cake was 48.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com