Method of preparing charcoal from antibiotic mushroom dregs

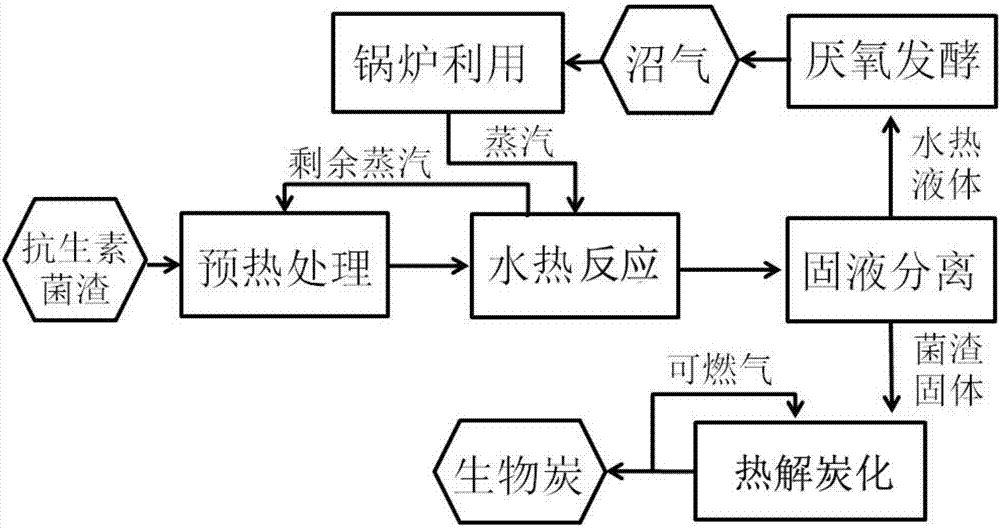

A technology of antibiotic bacteria residue and biochar, which is applied in the field of resource utilization of solid waste, can solve problems such as low resource utilization rate, incomplete removal of residual pollutants, and difficult dehydration, so as to achieve resource utilization and good environmental benefits , Solve the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The antibiotic bacteria residue with a water content of 80% is injected into the preheating mixing tank, and the remaining steam after the subsequent hydrothermal reaction is completed is used to preheat the antibiotic bacteria residue. Send the preheated slag into the hydrothermal reaction kettle, and pass the saturated steam generated by the steam boiler at 180°C through the steam pipe into the reaction kettle to directly contact the preheated slag for heating, so that the reaction temperature of the hydrothermal reaction kettle is 160 ℃, the pressure is 1.5MPa, and the hydrothermal reaction time is 0.5h. Under the environment of high temperature and high pressure, the structure of the colloid and cells in the antibiotic residue is destroyed, and the precipitation of the liquid in the antibiotic residue is promoted. After the completion of the hydrothermal reaction, the temperature of the remaining steam is 150°C, and it is sent to the preheating mixing tank for prehe...

Embodiment 2

[0041] The antibiotic bacteria residue with a water content of 85% is injected into the preheating mixing tank, and the remaining steam after the subsequent hydrothermal reaction is completed is used to preheat the antibiotic bacteria residue. Then feed the preheated slag into the hydrothermal reaction kettle, and pass the saturated steam generated by the steam boiler at 200°C through the steam pipe into the reaction kettle to directly contact the preheated slag for heating, so that the reaction temperature of the hydrothermal reaction kettle is 180°C, pressure 1.8MPa, hydrothermal reaction time 1.5h. Under the environment of high temperature and high pressure, the structure of the colloid and cells in the antibiotic residue is destroyed, and the precipitation of the liquid in the antibiotic residue is promoted. After the completion of the hydrothermal reaction, the temperature of the remaining steam is 160°C, which is sent to the preheating mixing tank for preheating the anti...

Embodiment 3

[0044] The antibiotic bacteria residue with a water content of 90% is injected into the preheating mixing tank, and the remaining steam after the subsequent hydrothermal reaction is completed is used to preheat the antibiotic bacteria residue. Then feed the preheated slag into the hydrothermal reaction kettle, and pass the saturated steam generated by the steam boiler at 220°C through the steam pipe into the reaction kettle to directly contact the preheated slag for heating, so that the reaction temperature of the hydrothermal reaction kettle is 200°C, pressure 2MPa, hydrothermal reaction time 1h. Under the environment of high temperature and high pressure, the structure of the colloid and cells in the antibiotic residue is destroyed, and the precipitation of the liquid in the antibiotic residue is promoted. After the completion of the hydrothermal reaction, the temperature of the remaining steam is 180°C, and it is sent to the preheating mixing tank for preheating the antibio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com