Patents

Literature

103results about How to "Solving Dehydration Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

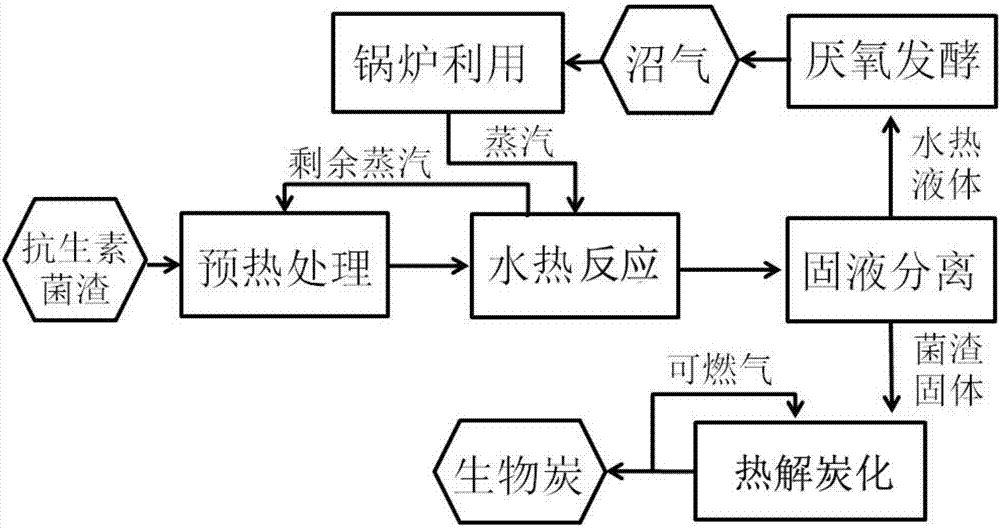

Method of preparing charcoal from antibiotic mushroom dregs

InactiveCN107365593APromote wall-breaking outflowImprove dehydration effectBiofuelsSpecial form destructive distillationCarbonizationCombustible gas

The invention discloses a method of preparing charcoal from antibiotic mushroom dregs. The method comprises the following steps: pre-heating treatment: feeding the antibiotic mushroom dregs into a pre-heating mixing tank for pre-heating treatment to obtain preheated mushroom dregs; hydrothermal reaction: feeding the pre-heated antibiotic mushroom dregs into a hydrothermal reaction kettle, introducing saturated steam into the hydrothermal reaction kettle to be directly contacted with the pre-heated antibiotic mushroom dregs to be heated for hydrothermal reaction, to obtain a hydrothermal mixture, and after discharging residual steam, feeding the mixture to the pre-heating mixing tank; solid-liquid separation: feeding the obtained hydrothermal mixture to mechanical dehydrating equipment for solid-liquid separation to obtain the mushroom dreg solids, the solid content rate of which is over 60% and a hydrothermal liquid; and pyrolysis carbonization: feeding the antibiotic mushroom dreg solids obtained by solid-liquid separation into a carbonization furnace for pyrolysis carbonization to obtain charcoal and combustible gas. According to the method disclosed by the invention, the high water content rate antibiotic mushroom dregs can be efficiently dehydrated, and meanwhile, byproducts in the mushroom dreg treatment process are utilized with high additional value, so that charcoal with high utilization value is output.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

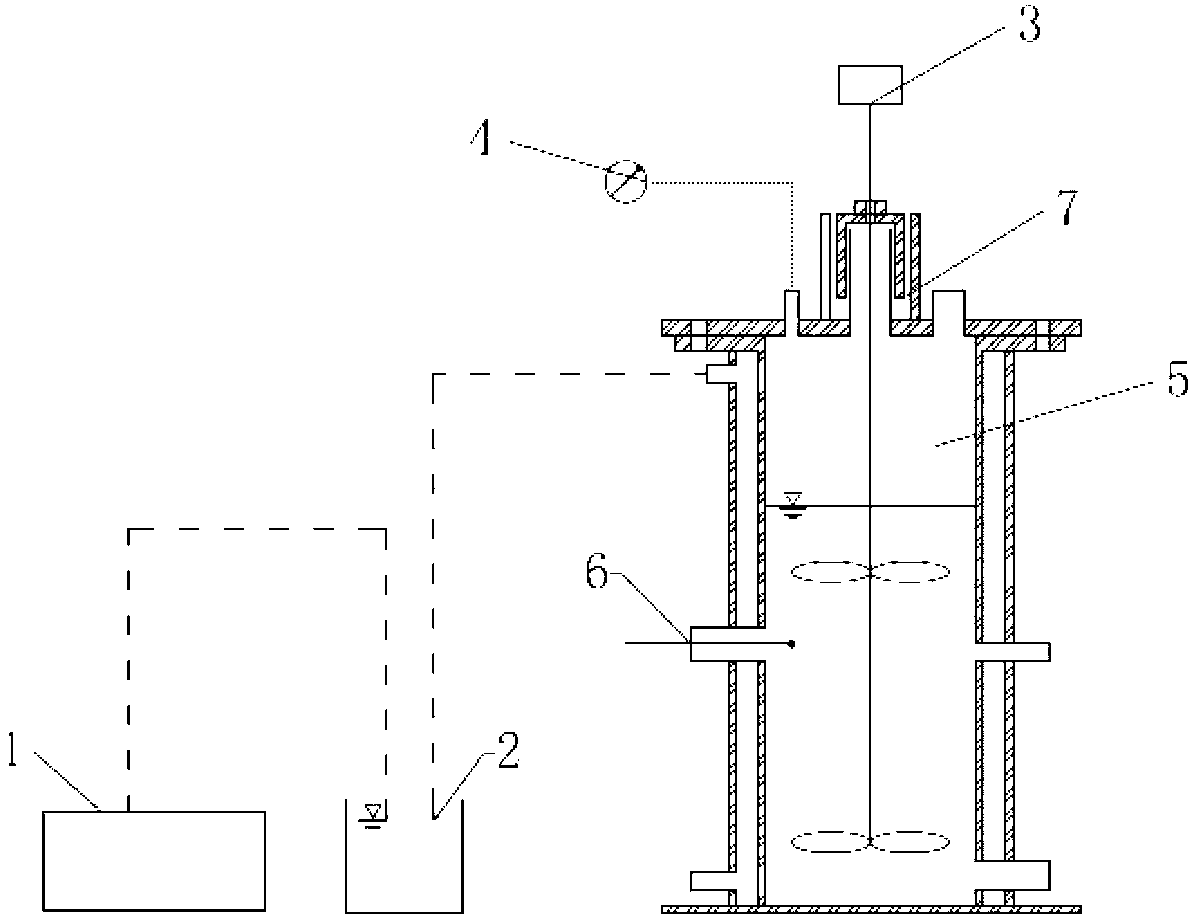

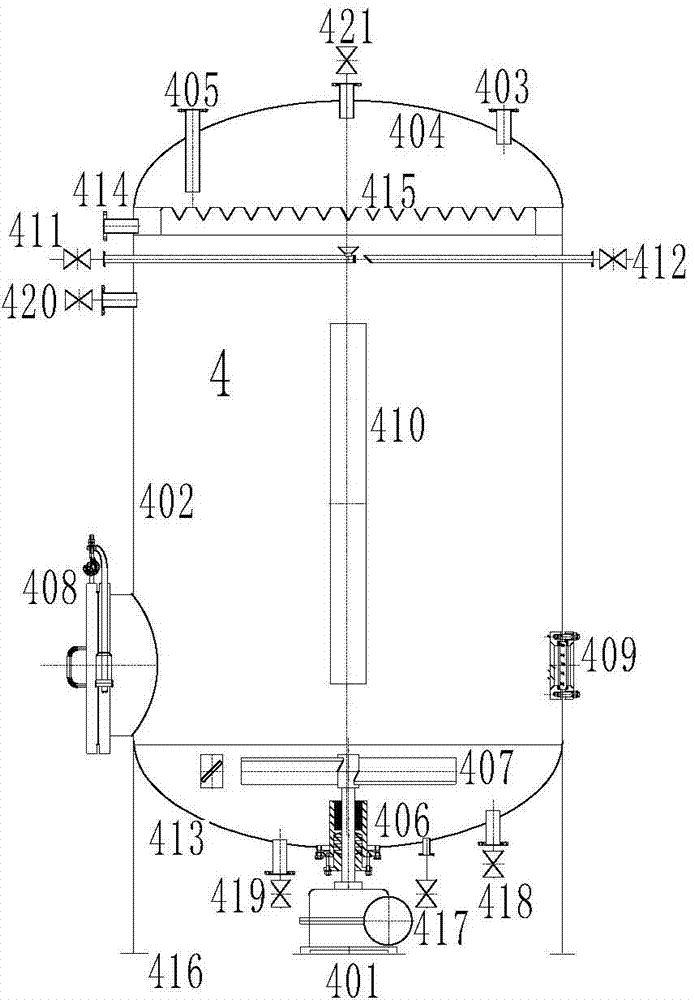

Anaerobic digestion device and process for pre-treating sludge with high solid content by heating method

InactiveCN103011542AIncreased rate of hydrolytic acidificationSolving Mass Transfer ProblemsSludge treatment by thermal conditioningBiological sludge treatmentPeristaltic pumpPhysical chemistry

The invention discloses an anaerobic digestion device and process for pre-treating sludge with high solid content by a heating method. The anaerobic digestion process comprises the following steps of: forming sludge with solid content of 10% in a sludge mixing unit; pumping the sludge to a heating tube of a heating tank by a peristaltic pump; heating and pre-heating the sludge for 30-60 minutes at the temperature of 70 DEG C; and adding the pre-treated sludge to an anaerobic digestion tank for carrying out stirring anaerobic digestion. According to the anaerobic digestion device and process provided by the invention, the problems that the sludge anaerobic digestion has larger traffic volume, the cost is high, and the sludge is difficult to hydrolyze and acidize are solved; and the reduction, reclamation and innoxious disposal of the sludge are realized.

Owner:TSINGHUA UNIV

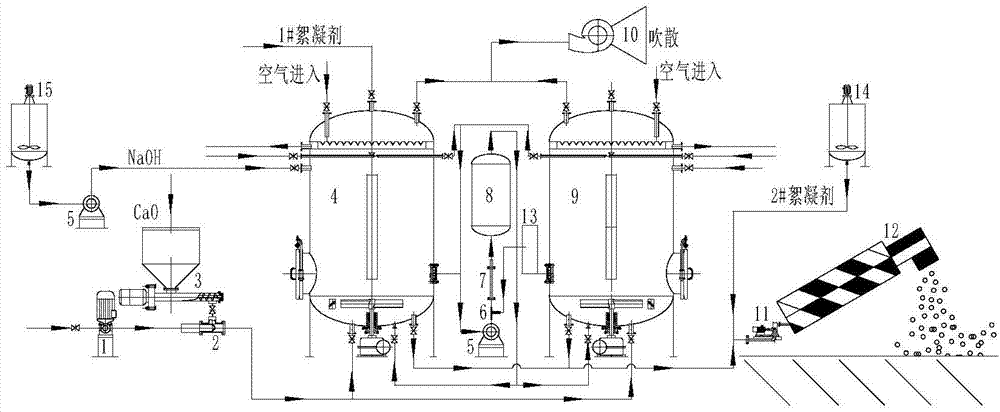

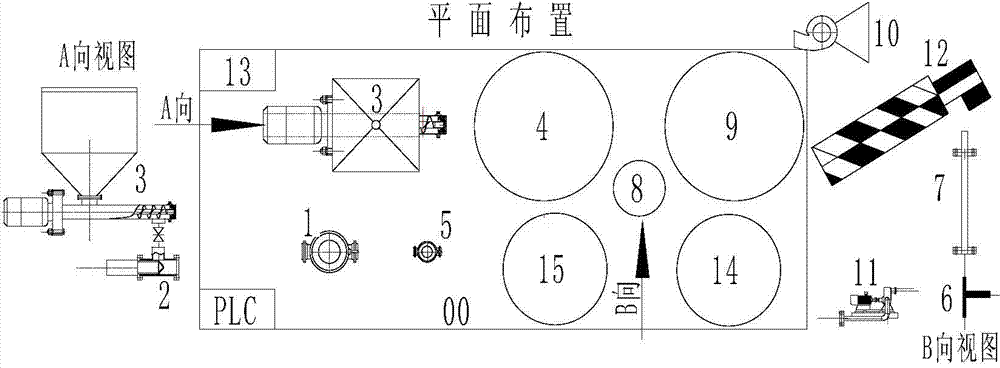

Oily sludge dehydration processing equipment and method thereof

ActiveCN103496837ASolving Dehydration ProblemsSimple processSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeStatic mixer

The invention discloses oily sludge dehydration processing equipment and a method thereof, and relates to the processing technology of oily sludge processing. The oily sludge dehydration processing equipment comprises a prying base, a conveying pump, a Venturi device, a feed screw, a first conditioning reaction tank, a circulation pump, an ozone ejector, a static state mixing device, an ozone strength control tank, a second conditioning reaction tank, a blower, a screw pump, a screw pressure dehydrator, an ozone device, a 2# flocculant adjusting tank and a NaOH adjusting tank. The oily sludge dehydration processing equipment is simple in technology and capable of well solving the dehydration problem of the oily sludge of an oil field, and innovatively adopts the ozone dehydration stabilization technology, medicament is not needed and no secondary pollution exists; the device adopted by the oily sludge dehydration processing equipment is a fully integrated automatic prying device, and the oily sludge dehydration processing equipment is small in ground-drilling area and high in automation degree, and the investment cost and operation cost of the oily sludge dehydration processing equipment are both lower than those of traditional processing equipment.

Owner:南京坤灿环境科技有限公司

Body paper of wettable tissues and production process of body paper

InactiveCN105568746AReduce churnHigh strengthPulp beating/refining methodsFiberUltimate tensile strength

The invention discloses body paper of wettable tissues. The body paper is prepared from the following raw materials: 240-250 parts by weight of long fiber wood pulp, 400-450 parts by weight of short fiber wood pulp, caustic soda, pulping enzyme and a softener. A production process of the body paper comprises the following steps: a, selecting and preparing the materials; b, crushing, namely separately crushing the long fiber wood pulp and the short fiber wood pulp; c, grinding, namely degritting the crushed long fiber wood pulp, sending the wood pulp to a mill grinder, and adding the caustic soda and the softener for pulping; and d, papermaking from pulp, namely mixing the crushed short fiber wood pulp with the ground long fiber wood pulp for papremaking, thereby obtaining the finished body paper. According to the invention, long and short fibers in the raw materials are mixed for pulping in a reasonable ratio, and the short fibers are separately ground, so that the advantages of existing mixed grinding is kept while the problem of dehydration caused by overhigh beating degree is solved, the thickness of paper is increased, loss of fibers is lowered, and the tissues manufactured from the body paper are high in strength and good in softness and can be taken as wet tissues after wetted.

Owner:CHONGQING LONGJING PAPER CO LTD

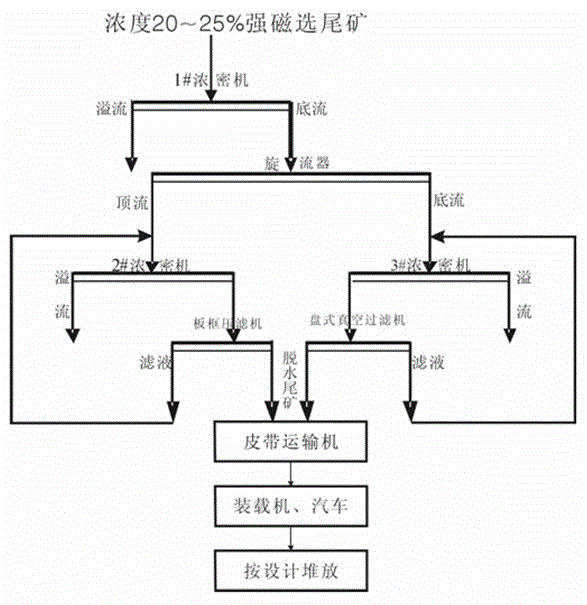

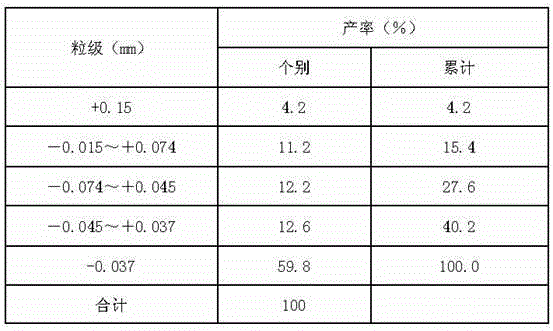

Method for treating high-mud-content fine-graded iron tailings

InactiveCN102974452ASolving Dehydration ProblemsAddressing high safety risks of dam failuresWet separationCycloneEngineering

The invention provides a method for treating high-mud-content fine-graded iron tailings. The method is characterized by comprising the following steps of: feeding high-mud-content fine-graded iron tailings into a first-stage thickener for precipitating to separate overflow water and bottom current out; feeding the bottom current into a cyclone for grading into high-mud-content top current and fine-graded tailing bottom current out; feeding high-mud-content top current into a second thickener for precipitating to separate overflow water and bottom current out, feeding the bottom current to a plate and frame filter press for treating to obtain filtrate and a filter cake, returning the filtrate to the second thickener for precipitating, and feeding the filter cake to a storage yard for piling; and feeding the high-mud-content top current into the second thickener for precipitating, separating overflow water and bottom current out, feeding the bottom current to the plate and frame filter press for treating to obtain filtrate and a filter cake, returning the filtrate to the second thickener for precipitating, and feeding the filter cake to the storage yard for piling. Due to the adoption of the method, the problem of dehydration of the high-mud-content fine-graded iron tailings is solved, 0.3-0.6 ton of overflow water can be recovered additionally from every ton of tailings, dry piling of high-mud-content fine-graded iron tailings is realized, and the high potential safety hazard of dam-break is eliminated.

Owner:KUNMING IRON & STEEL HLDG CO LTD

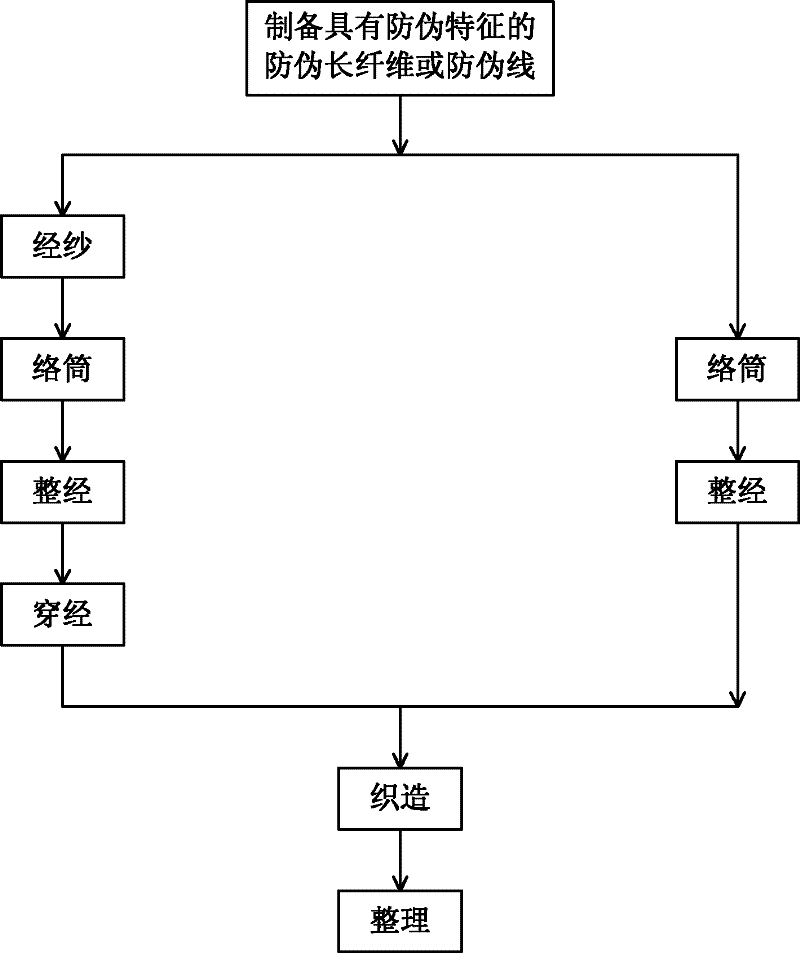

Anti-counterfeiting seat belt and anti-counterfeiting paper applied to the anti-counterfeiting seat belt

ActiveCN102296486AImplement machine readable detectionImprove anti-counterfeitingNon-fibrous pulp additionYarnSeat beltPhotoluminescence

The invention relates to an anti-counterfeiting safety belt and anti-counterfeiting paper applied to the anti-counterfeiting safety belt. An anti-counterfeiting safety belt, which is a belt-shaped fabric with anti-counterfeiting information in at least a part of the area, wherein the anti-counterfeiting information is formed by anti-counterfeiting materials, and the anti-counterfeiting materials include photoluminescent materials, magnetic materials, pressure-sensitive materials and bio-anti-counterfeiting materials; preferably, the photoluminescent material includes a combination of one or more of quantum dot materials, fluorescent materials, temperature-changing materials and infrared materials, the Biological anti-counterfeiting materials include antigens, antibodies and / or DNA. The present invention also provides an anti-counterfeit paper with the above-mentioned anti-counterfeit safety belt. The invention solves the problem of dehydration of the polymer security thread in the process of spreading the wide thread by adopting the water-permeable and air-permeable properties of the webbing and the non-woven fabric, and at the same time, it can bring multiple anti-counterfeiting effects to the paper through compounding with the anti-counterfeiting material.

Owner:BAODING BANKNOTE PAPER CO LTD +1

Natural water shield drink

The invention provides a natural water shield drink. A preparation process of the natural water shield drink comprises the following steps of: (1) blanching and deactivating the collected water shield at 90 to 100 DEG C, then smashing and beating the deactivated water shield, and filtering to obtain water shield juice; (2) crushing astragalus root into powder and mixing the astragalus root powderwith water based on the mass ratio of 1:15 to 1:25 and then boiling and filtering the mixture to obtain astragalus root juice; and (3) mixing the water shield juice obtained in the step (1) with the astragalus root juice in the step (2) based on the mass ratio of 1:1 to 1:2, and sterilizing and then filling the mixed juice to obtain the water shield drink. The water shield drink disclosed by the invention contains no additive, is longer in shelf life, can maintain and replenish water in human body, has the efficacies of clearing away heat and toxic materials, sterilizing and diminishing inflammation and tonifying middle-Jiao and qi, and can also be used for preventing and treating anaemia, hepatitis and other diseases and intensifying the immunologic function of body.

Owner:CHONGQING WANJIANG FOOD

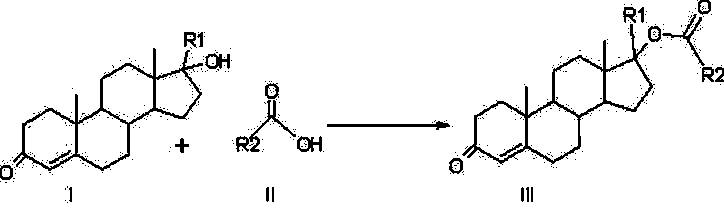

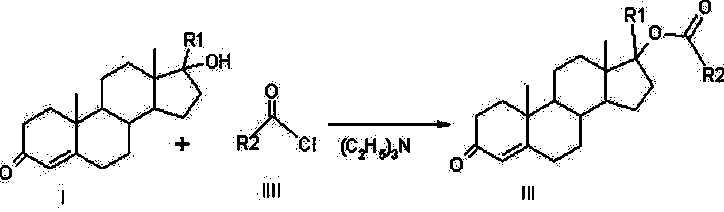

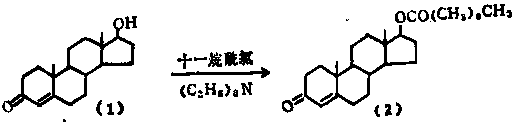

Steroid ester preparation method

The invention discloses a steroid ester preparation method. According to the preparation method, an alcoholic hydroxyl steroid compound (I) as a starting material generates an esterification reaction with an alkyl acid compound (II) by using a dehydrant after being subjected to the catalysis of a catalyst, so that a steroid ester (III) is obtained, and the process route is as shown in the specification, wherein the R1 in the alcoholic hydroxyl steroid compound (I) contains hydrogen, alkanes, ene-alkyne and ketone; the R2 in the alkyl acid compound (II) contains C2-C18 alkyl acids. By the combination of the novel dehydrant and the specific catalyst, the dehydrating problem in the esterification reaction can be solved, the reaction is moderate and complete, the operation is simple, the yield and the quality are enhanced greatly, and products have no dehydrant residue.

Owner:ZHEJIANG XIANJU PHARMA

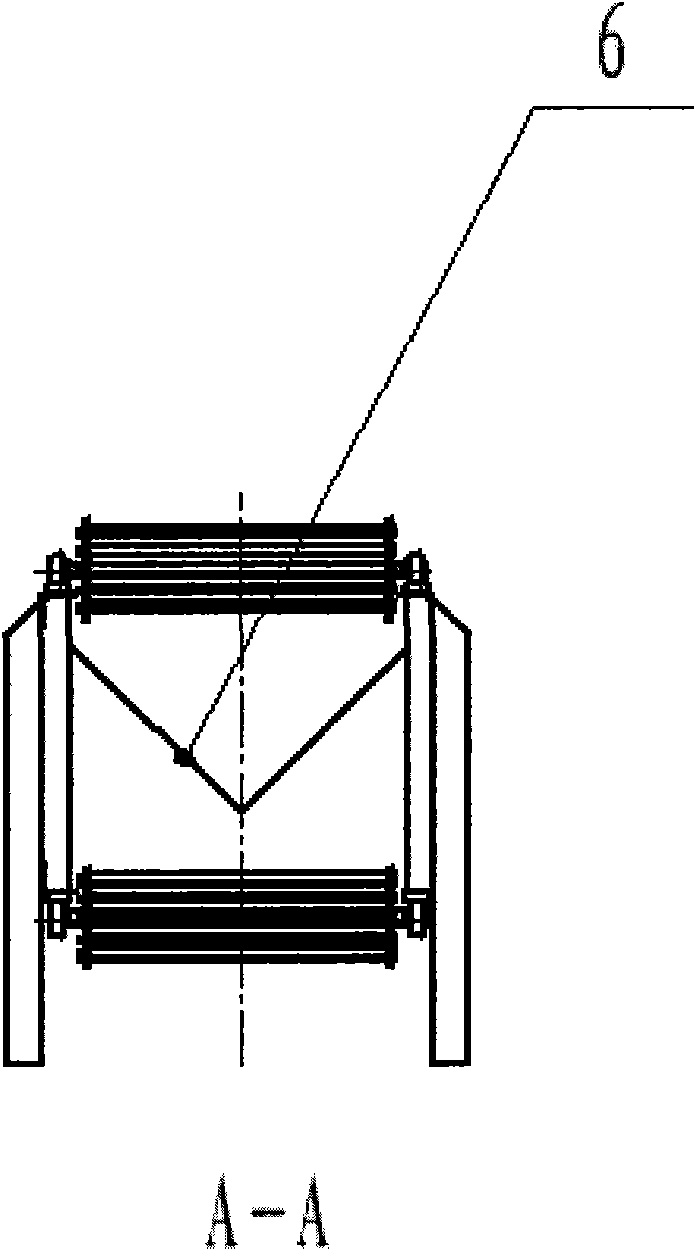

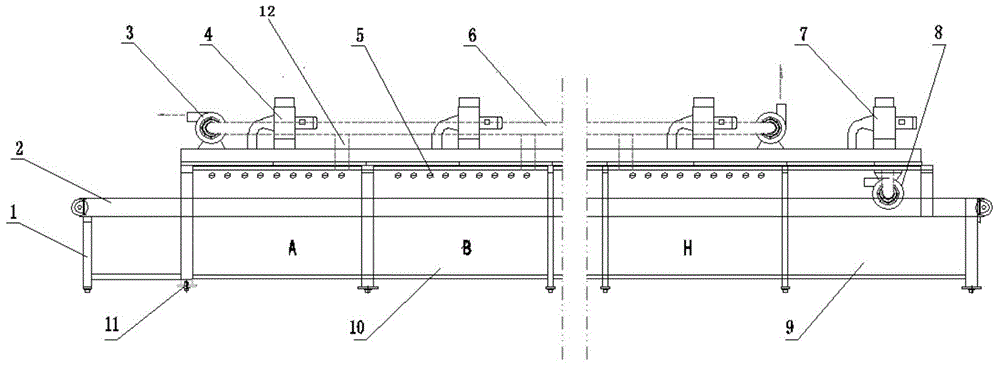

Autonomous vibration online primary dewatering method and device

ActiveCN101804269ASolving Dehydration ProblemsImprove stabilityMoving filtering element filtersEngineeringHigh water content

The invention provides an autonomous vibration online primary dewatering method and a device, wherein the online primary dewatering device comprises a conveyor belt, a transmission drum, a turnabout drum, a conveyor carrier roller, a deflector and a vibration mechanism, materials containing water are conveyed by the conveyor belt, the conveyor belt is driven by the transmission drum to generate horizontal conveying movement, the conveyor carrier roller supports a conveyor to keep the conveyor approximately balance, and the deflector is used for guiding the water dewatered from the materials containing water and collecting the water in a waste water disposal basin; the vibration mechanism makes the conveyor belt generate irregular movement while conveying the materials containing water so as to make the conveyor belt generate autonomous vibration, and thereby accelerating the dewatering of the water in the materials containing water. The invention effectively solves the dewatering problem of the materials containing high water content, realizes the purpose of conveying the materials like other conveying equipment, such as conveyors, is simple and reliable, and has good stability and low energy consumption.

Owner:李功民

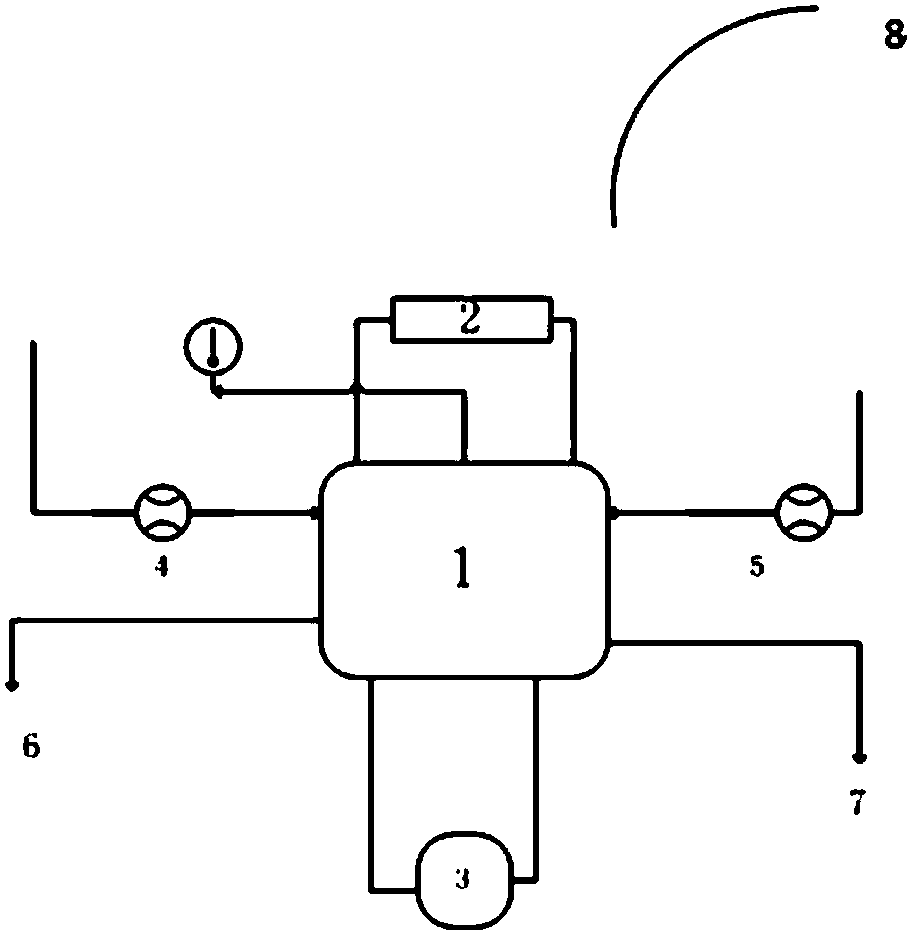

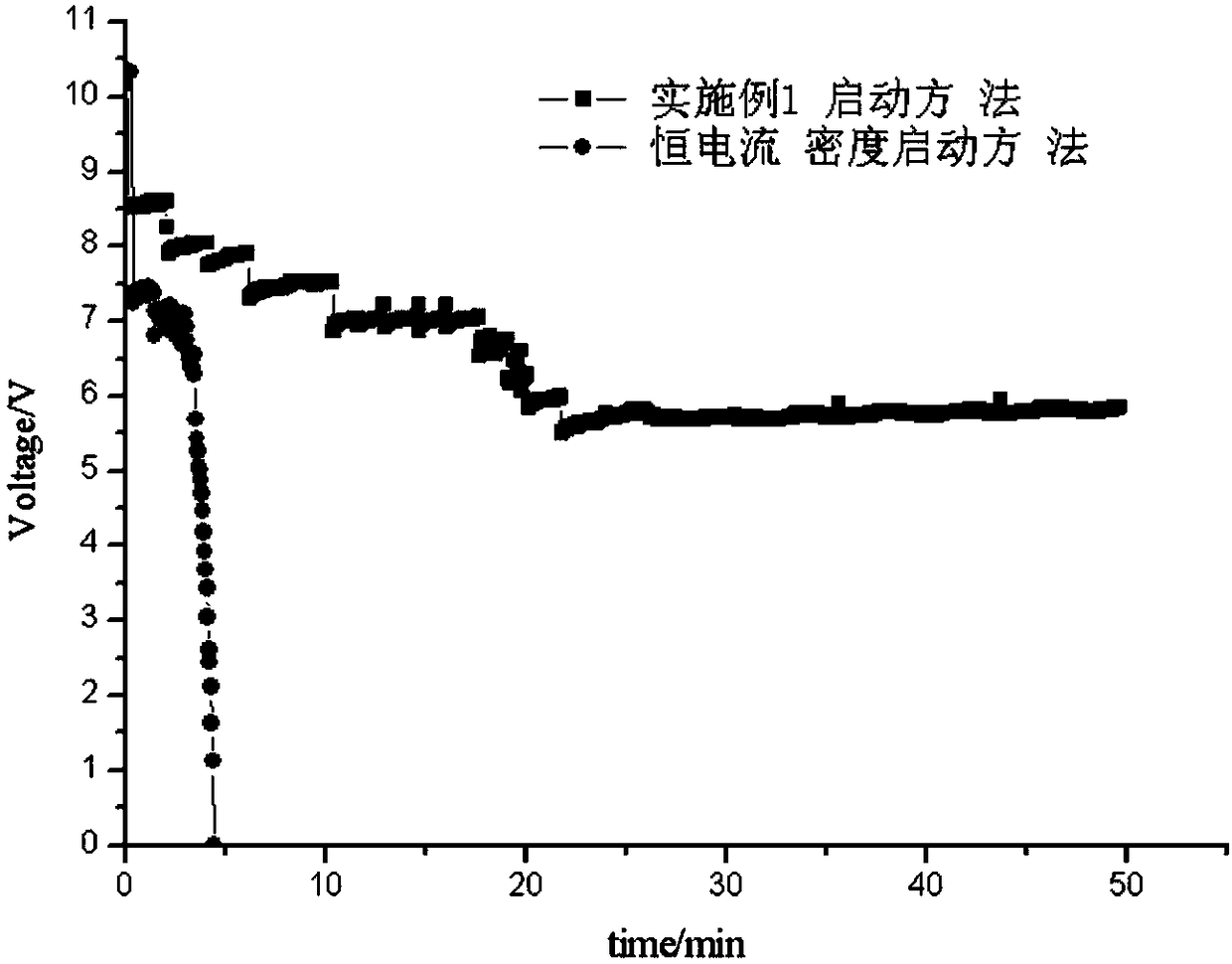

Method for starting and operating fuel cell of hydrogen-air proton exchange membrane under non-humidifying condition

ActiveCN108075154AGuaranteed startup and stable operationSolving Dehydration ProblemsFuel cell controlLiquid waterAutomotive engineering

The invention relates to a method for starting and operating a fuel cell of a hydrogen-air proton exchange membrane under a non-humidifying condition. Under the dry gas intake condition of the fuel cell, a fuel and oxidant counter-flow gas intake mode is adopted to set the current loading mode, loading time and gas intake flow of the fuel cell; the fuel cell operates for a period of time under lowcurrent density; during operating of the fuel cell, water generated at the cathode side of the fuel cell enables the cathode side of the proton exchange membrane to be in a wetting state; furthermore, part of liquid water is inversely diffused to the anode side from the cathode side under the action of water concentration gradients of two sides of the membrane, so that the anode side of the membrane is also in the wetting state, and the problem of dehydration of the membrane in a dry gas state is avoided; and after the fuel cell operates stably under the low current density, the starting of the fuel cell is completed, and then, the current density is gradually loaded to the working current density, thereby keeping the stable operation of the fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

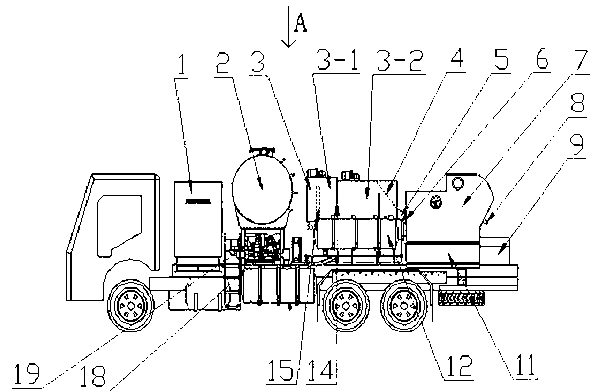

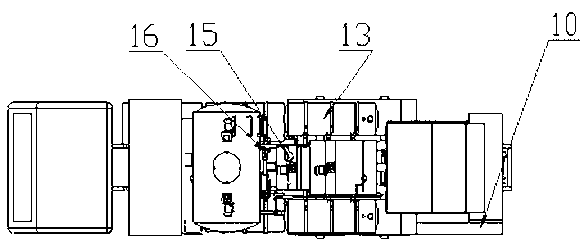

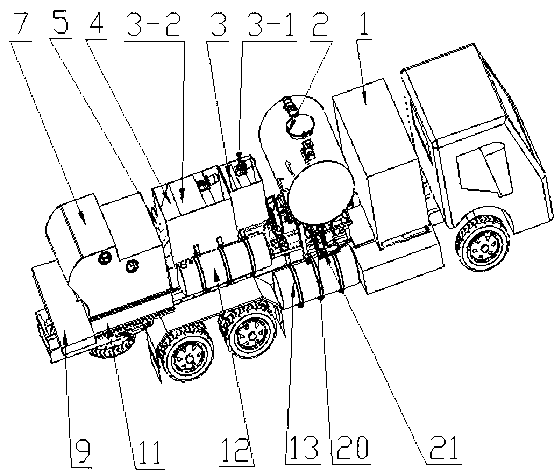

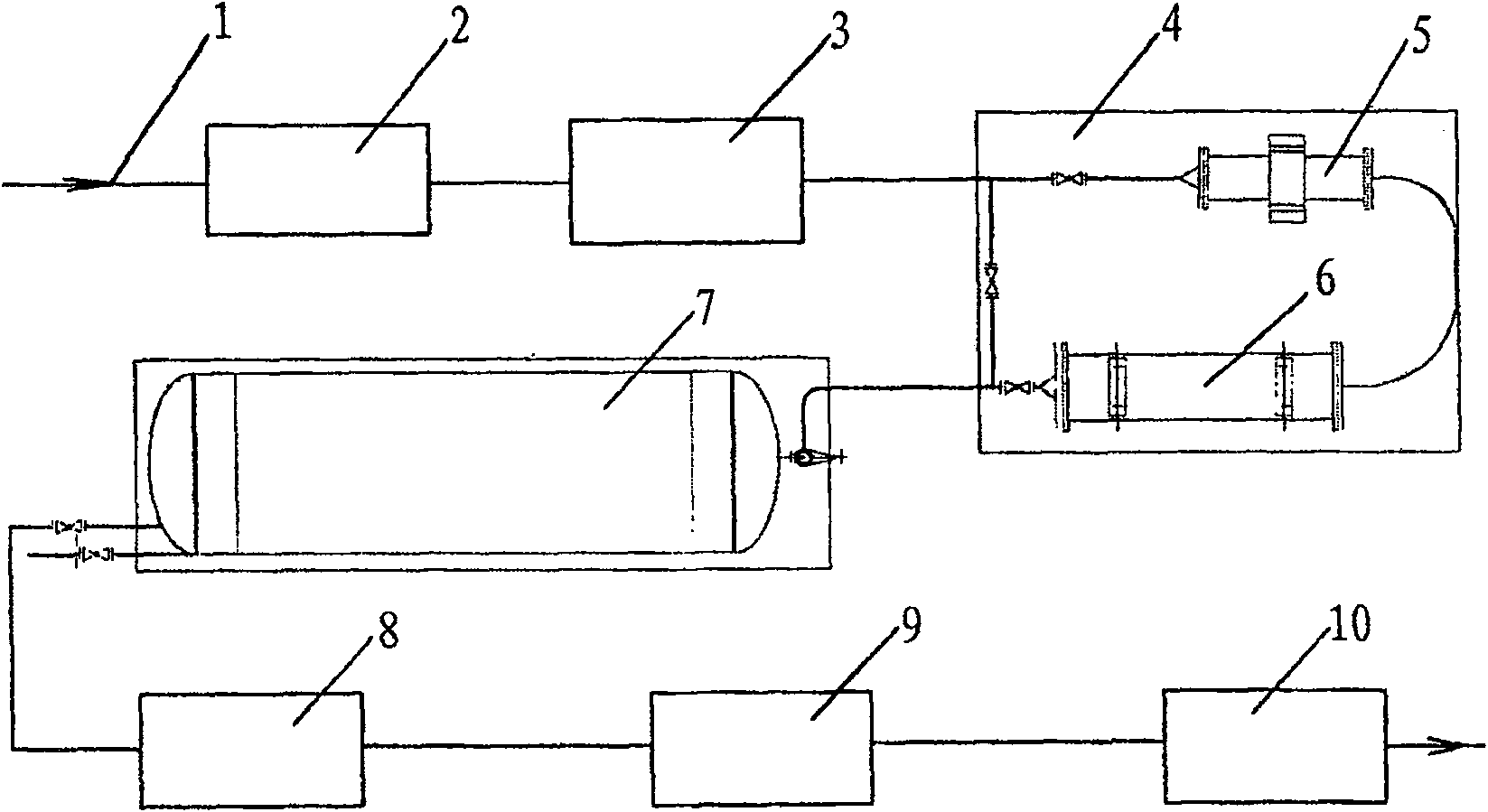

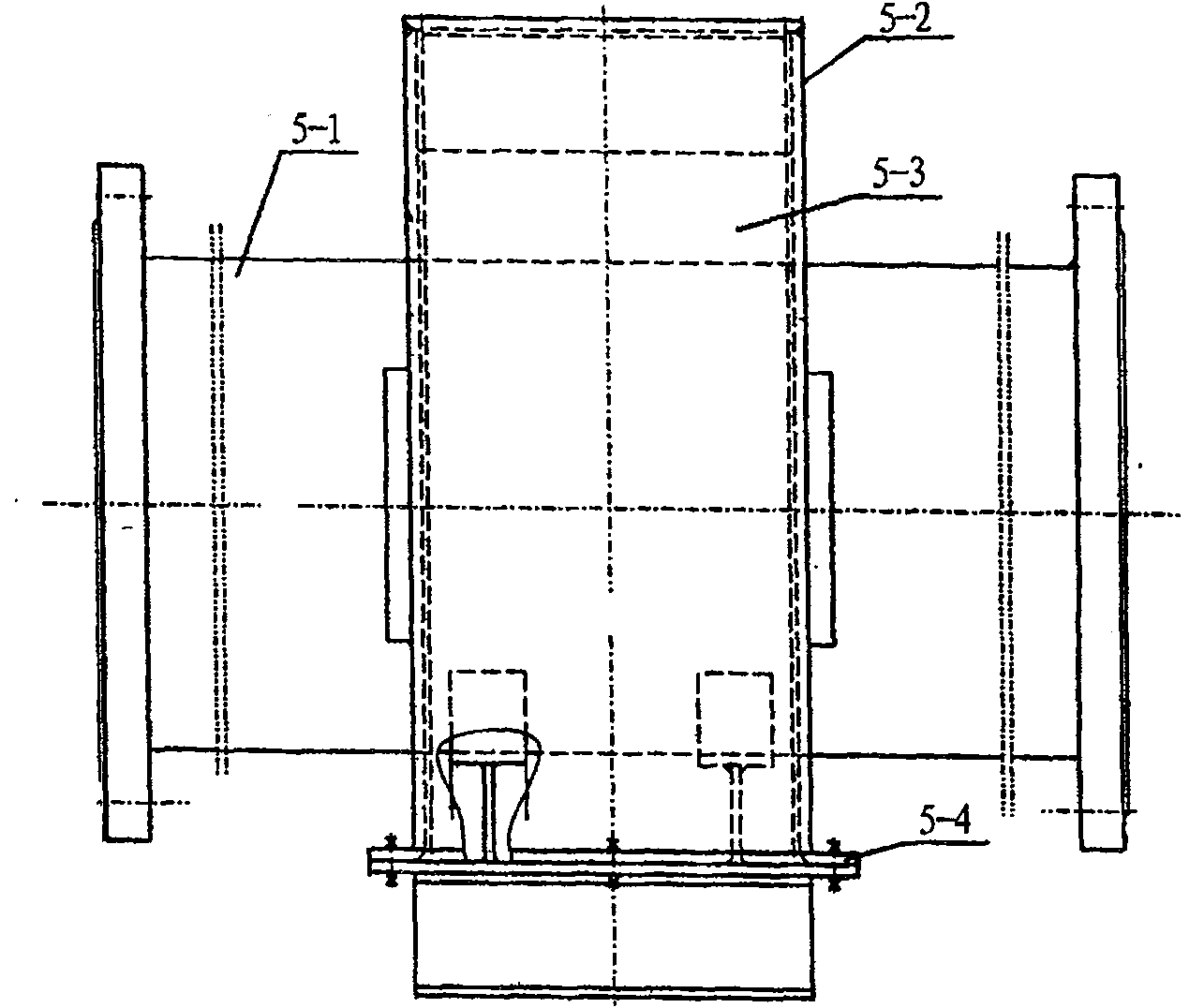

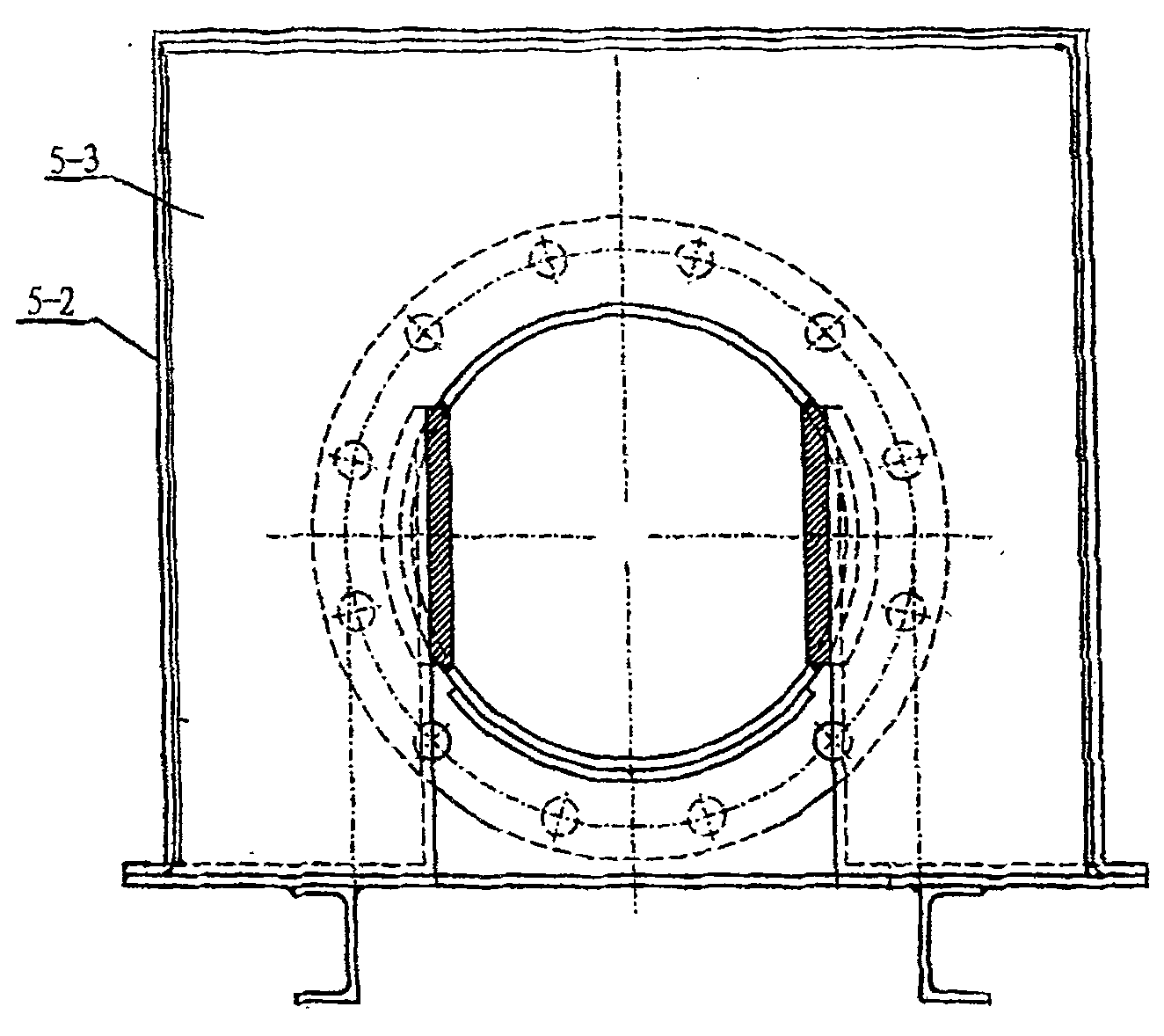

All-digital intelligent mobile septic tank sewage disposal device

InactiveCN103183461AStir wellFully integratedSludge treatment by de-watering/drying/thickeningItem transportation vehiclesElectrical controlSewage treatment

The invention discloses an all-digital intelligent mobile septic tank sewage disposal device. The all-digital intelligent mobile septic tank sewage disposal device comprises an electrical control system, a stirring box, a flocculant tank, a sewage suction pipe and the like, and is characterized in that a cam pump is arranged on the sewage suction pipe, an outlet of the cam pump is communicated with the stirring box through a pipeline, the sewage suction pipe communicated with an inlet of the cam pump is communicated with the flocculant tank through the pipeline, the all-digital intelligent mobile septic tank sewage disposal device is provided with a squeezer and a conveyor, which are sequentially connected with the stirring box, a sewage discharge port of the stirring box is connected with a feed port of the squeezer through the pipeline, and a discharge port of the squeezer is connected with the conveyor. The all-digital intelligent mobile septic tank sewage disposal device disclosed by the invention can realize full-automatic operation and management through the electrical control system, has a plurality of advantages of simple structure, convenience in movement, low energy consumption, no pollution during the disposal process, short disposal time, great disposal capacity and the like, can solve the technical difficult problems of dehydration, deodorization and sterilization of sewage in a septic tank, as well as incapability of utilizing the sewage and further has very extensive practicality.

Owner:杨渊博

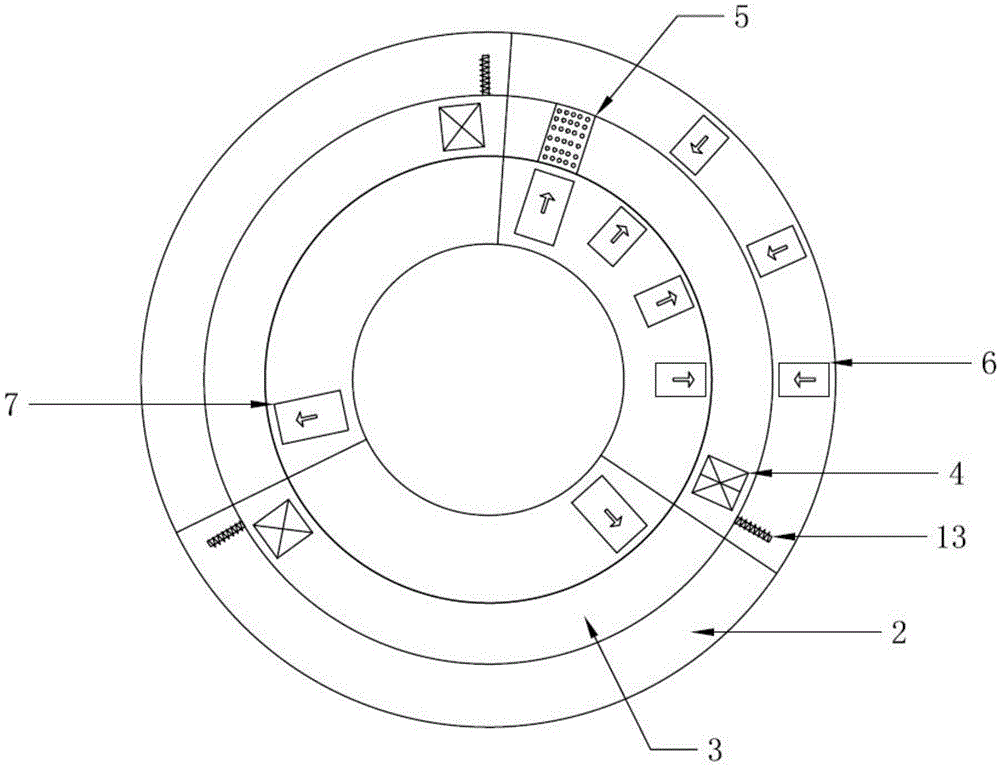

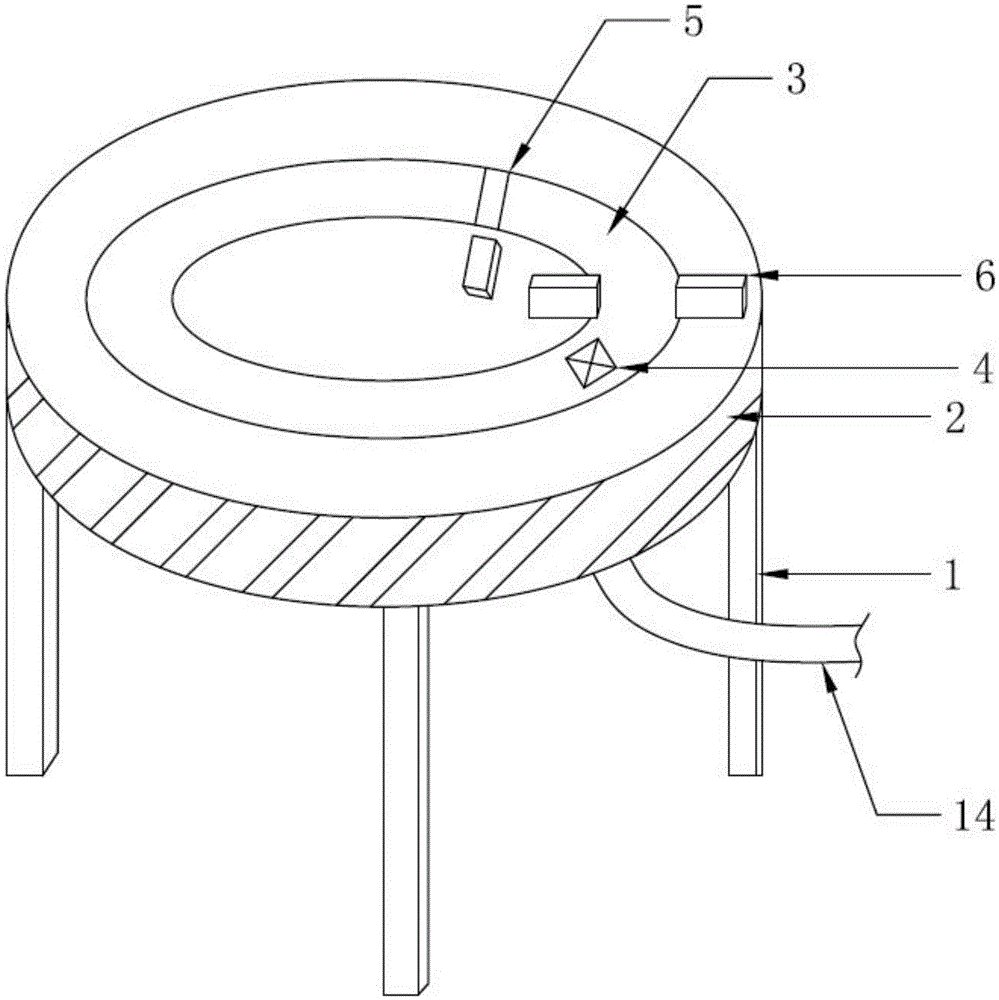

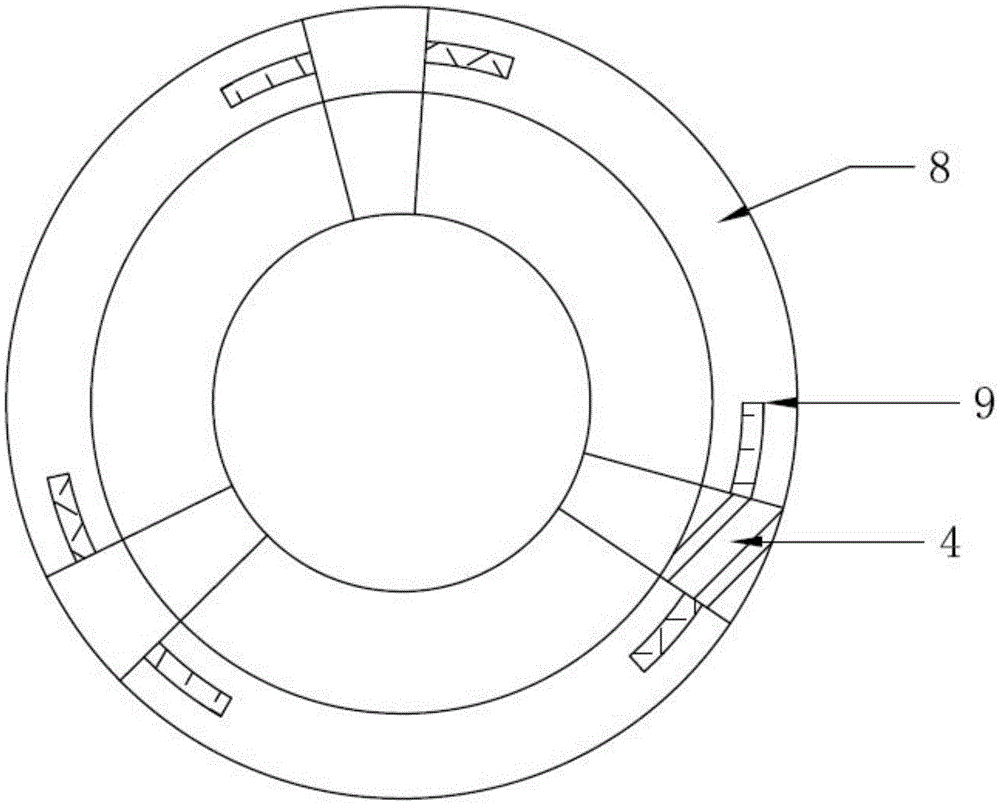

Novel plant waste residue squeezing and dewatering equipment

The invention relates to the field of agricultural squeezing and filtering, and provides novel plant waste residue squeezing and dewatering equipment which comprises a rack. A fixed disk is arranged on the rack and provided with an annular groove. An annular rotary table is arranged on the annular groove. A plurality of sets of feeding openings and discharging openings are evenly distributed in the rotary table. A plurality of sets of squeezing modules are evenly distributed between each set of feeding opening and discharging opening. An annular gear rack is annularly arranged outside the bottom of the rotary table, anti-skid grain is annularly arranged in the bottom of the rotary table, and the annular gear rack is connected with a clearance gear. An ejection mechanism is arranged at one side of the discharging openings. A traditional screw mechanical squeezing manner is changed, at least 30%-45% of water in waste residues is squeezed out and drained through the three-time opposite squeezing modules, and therefore the time and cost for material drying are greatly reduced. Meanwhile, a grinding disk type squeezing structure is adopted, automatic feeding, triple squeezing and discharging are achieved in the whole process, and the problem about dewatering of a large amount of matter waste in factories is greatly solved.

Owner:何莞婷

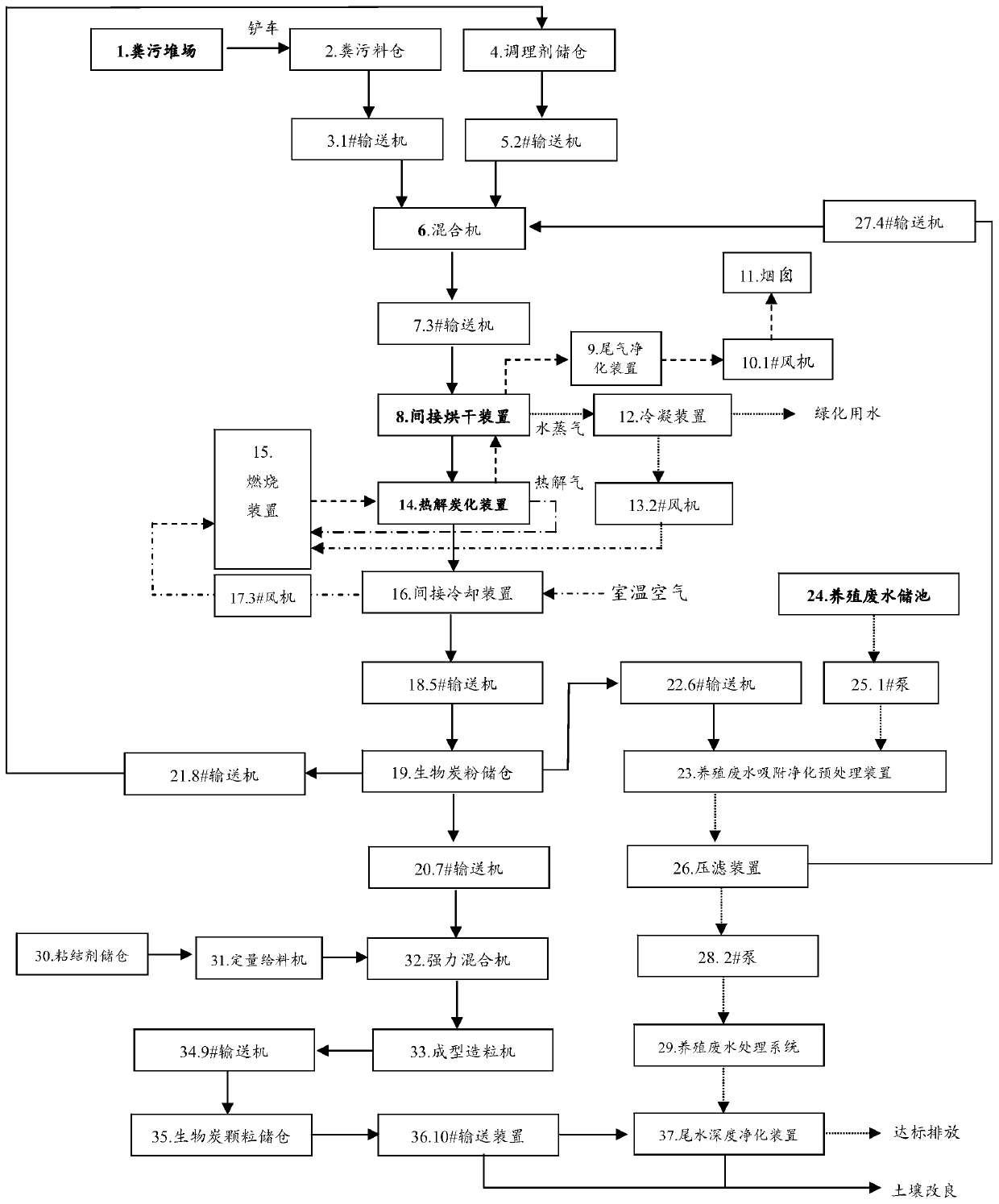

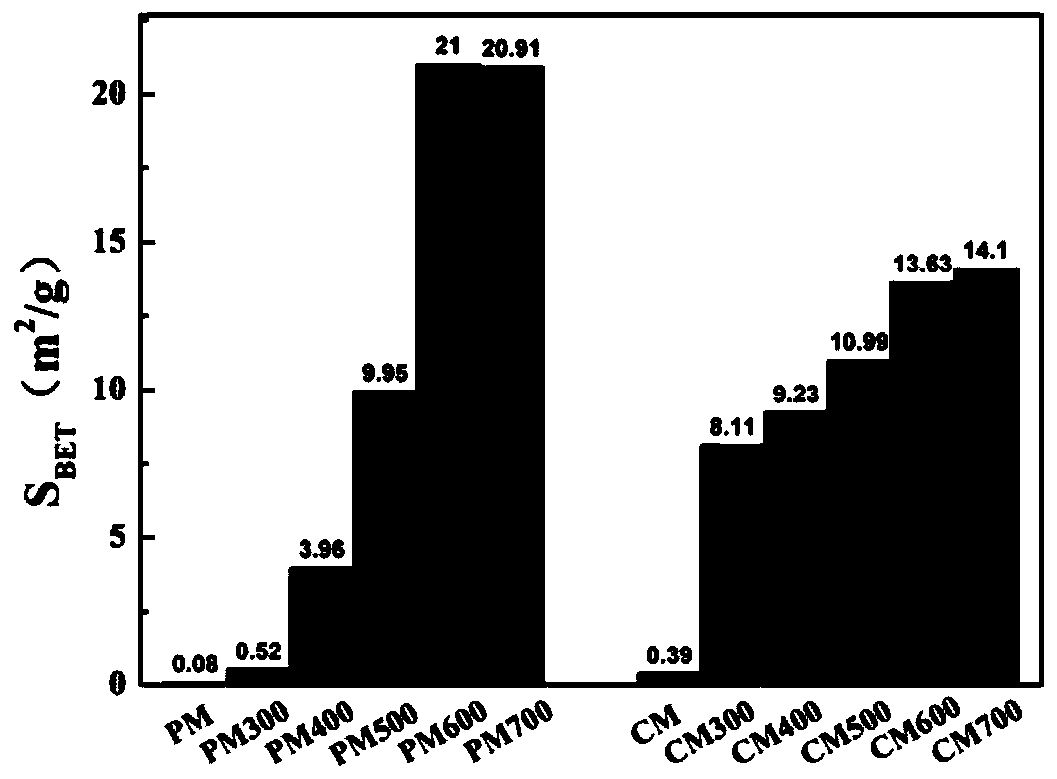

Method and device for cyclically treating breeding wastewater and/or improving soil by utilizing livestock and poultry manure

PendingCN111423096ASolving Dehydration ProblemsLow viscositySludge treatment by de-watering/drying/thickeningOther chemical processesAmmoniacal nitrogenCarbonization

The invention discloses a method and a device for cyclically treating breeding wastewater and / or improving soil by utilizing livestock and poultry manure. The method comprises the following steps: adding a conditioner into livestock and poultry manure for mixing and conditioning; then pre-drying and dehydrating at low temperature to reduce the moisture content to be less than 10% to obtain dried livestock and poultry manure, indirectly heating the livestock and poultry manure in a pyrolysis and carbonization device, indirectly cooling the obtained charcoal powder, and adding the obtained cooled charcoal into breeding wastewater; and forming charcoal particles; the invention can be directly used for soil improvement; part of COD, ammonia nitrogen, phosphorus and other effective elements andantibiotics and other micropollutants can be pre-removed, and the biochemical treatment load of the aquaculture wastewater is reduced; or the invention is used for deep adsorption and purification ofaquaculture wastewater before tail water is discharged. According to the method and device, pollution caused by simple composting of livestock and poultry manure is avoided, comprehensive treatment of breeding waste is fully achieved, and good social benefits, economic benefits and environmental benefits are achieved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Seedling root-dipping humectant as well as preparation method and application thereof

ActiveCN105494471ASimple production processRaw materials are easy to getBiocidePlant growth regulatorsDiseaseSide effect

The invention discloses a seedling root-dipping humectant as well as a preparation method and an application thereof and relates to the technical field of seedling cultivation. The seedling root-dipping humectant comprises components in parts by mass as follows: 3-26 parts of one or more of carboxymethylcellulose, polyacrylamide and polyvinyl alcohol, 2-15 parts of humic acid, 0.1-1.875 parts of copper sulfate, 0.1-4 parts of compound sodium nitrophenolate, 1-10 parts of plant tobacco powder, 0.5-6 parts of one or more of composted crop straw and weed powder and 37-94 parts of water. With the adoption of the seedling root-dipping humectant, the problem of water loss in a seedling transportation process is effectively solved, the survival rate of seedlings in the transportation process is greatly increased, furthermore, root development of the seedlings can be promoted during planting, more capillary roots grow up, the surface area of absorbing roots is increased, and the problem of insufficient nutrition supply at a seedling recovering stage of the seedlings is solved; the seedling root-dipping humectant has the advantages of high disease and pest resistant capacity, avoidance of toxicity, pollution and side effects, degradability, outstanding effect and high safety.

Owner:李开森

Dewatering process for domestic sludge

InactiveCN101337759ASolving Dehydration ProblemsSludge treatment by de-watering/drying/thickeningSludgeSewage

A dehydration method of domestic sludge relates to a dehydration method of sludge. The dehydration method solves the problem in the prior dehydration method that a system formed by a sludge flock and sewage causes the dehydration of the sludge and demulsification to be mutually restrained. The dehydration method comprises the following steps: standing for 1 to 2 minutes after a cationic surfactant with 5 percent of quality concentration and a cationic nucleating agent with 1 to 4 percent quality concentration are added to the sludge; then adding a starch type bridging agent with 0.4 to 0.6 percent of quality concentration or a hydrotalcite type bridging agent with 0.4 to 0.6 percent of quality concentration under the agitating condition; and finally filtering after ageing for 8 to 15 minutes, namely the dehydration of the domestic sludge is finished. The method had the advantages that the demulsification is realized; the formed flock after being aged is more compact than the flock formed by applying flopamem 235 under the same condition; and the dehydration capacity is strong.

Owner:HARBIN INST OF TECH

Umbrella dewatering machine

InactiveCN107401887ASolving Dehydration ProblemsConvenient lifeDrying solid materials without heatDrying gas arrangementsPulp and paper industryAir blower

The invention relates to an umbrella dewatering machine and belongs to the technical field of dewatering. A power source is switched on, the front end of an umbrella is inserted into a round hole, rotation of an umbrella rod is pressed by a hand, the umbrella is fixed, a switch is turned on to enable a motor to drive a gear shaft through a gear set so as to enable a dewatering barrel fixed to the gear shaft to rotate, and dewatering of the umbrella is realized through centrifugal motion; at the same time, an electric-heating air blower blows air to assist in drying the umbrella, so that dewatering efficiency of the umbrella is improved. Through detection, the umbrella dewatering machine is high in dewatering speed, dewatering can be completed within 2min, the dewatering problem of the umbrella can be solved effectively, and separation of water drops on the umbrella and treatment of the water drops can be completed, so that convenience is brought to ours life; secondary utilization of stored water can be realized, and the umbrella dewatering machine is pollution-free, environment-friendly, attractive in appearance, novel in design, compact and portable and has wide application prospect.

Owner:常州蓝森环保设备有限公司

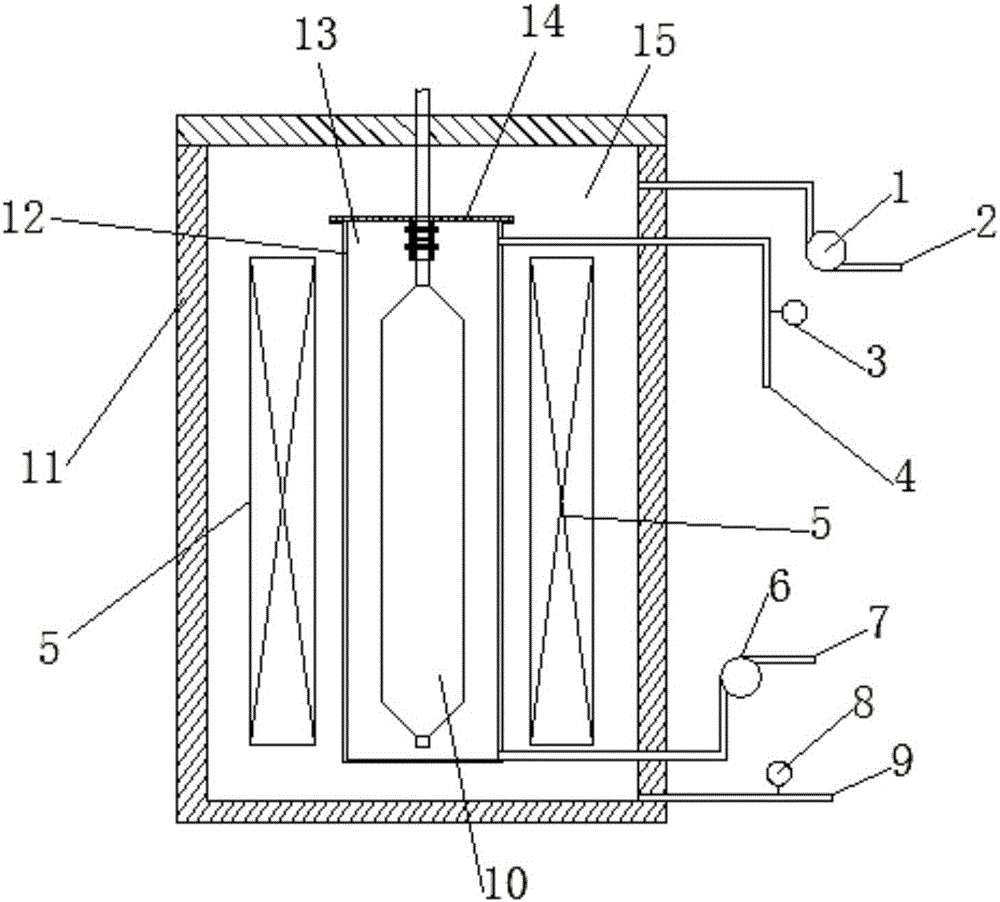

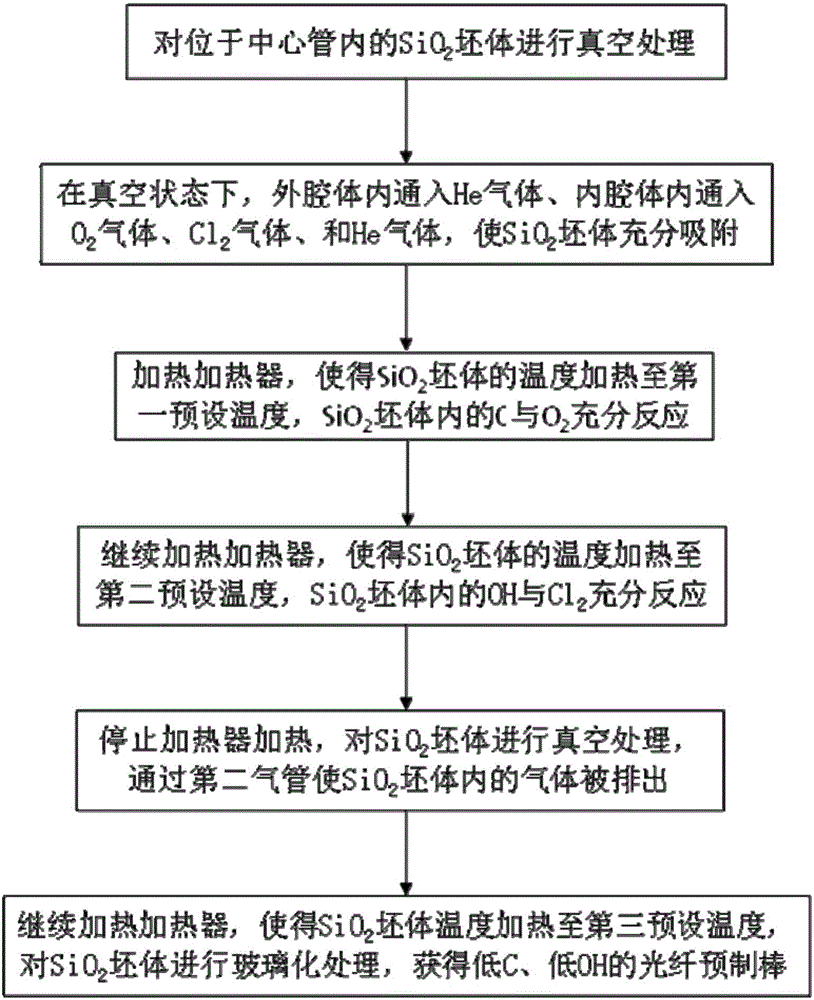

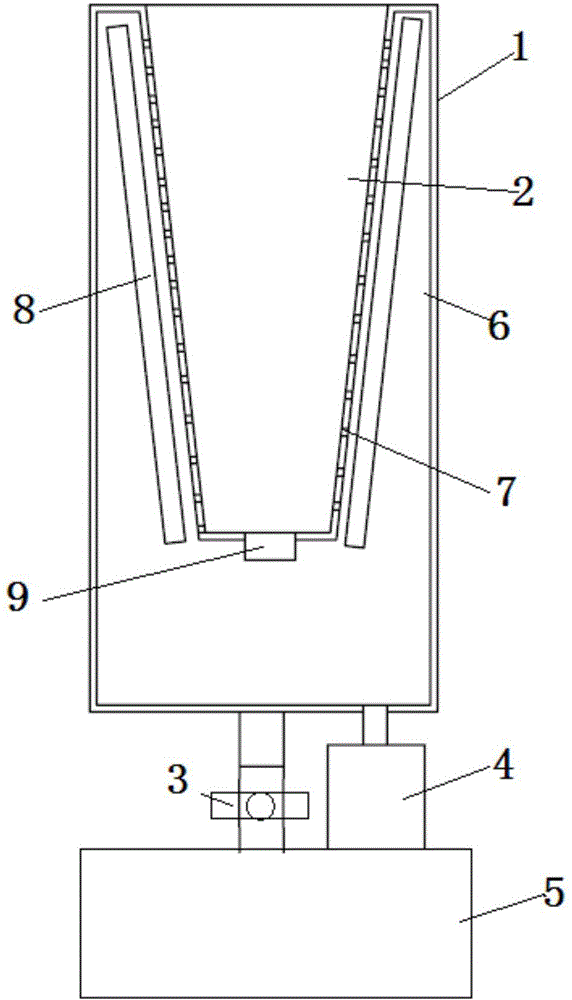

Manufacturing device and manufacturing method of optical fiber preform rod

ActiveCN105669019ASolve carbon removal and dehydration problemsSimple structureGlass making apparatusDecarburizationMetallurgy

The invention provides a manufacturing device and manufacturing method of an optical fiber preform rod. The manufacturing device of the optical fiber perform rod comprises an oxidizing dehydration sintering furnace, a central pipe located in the sintering furnace, at least one heating body which is located in the sintering furnace and located outside the central pipe, a SiO2 blank located in the central pipe, a sealing cover used for sealing the central pipe, an inner cavity located in the central pipe, an outer cavity which is located outside the central pipe and located in the sintering furnace, a first vacuum exhaust pipe, a first air pipe, a second vacuum exhaust pipe and a second air pipe, wherein the first vacuum exhaust pipe and the first air pipe are connected to the outer cavity, the second vacuum exhaust pipe and the second air pipe are connected to the sintering furnace, and the heating bodies, the SiO2 blank and the sealing cover are all located in the sintering furnace. According to the method, through an OH removal and decarburization method of the SiO2 blank and the oxidizing dehydration sintering furnace, the decarburization and dehydration problems are solved to obtain the low-C and low-OH optical fiber preform rod. The manufacturing device is simple and reliable in structure.

Owner:HENGTONG OPTICAL MATERIAL CO LTD +1

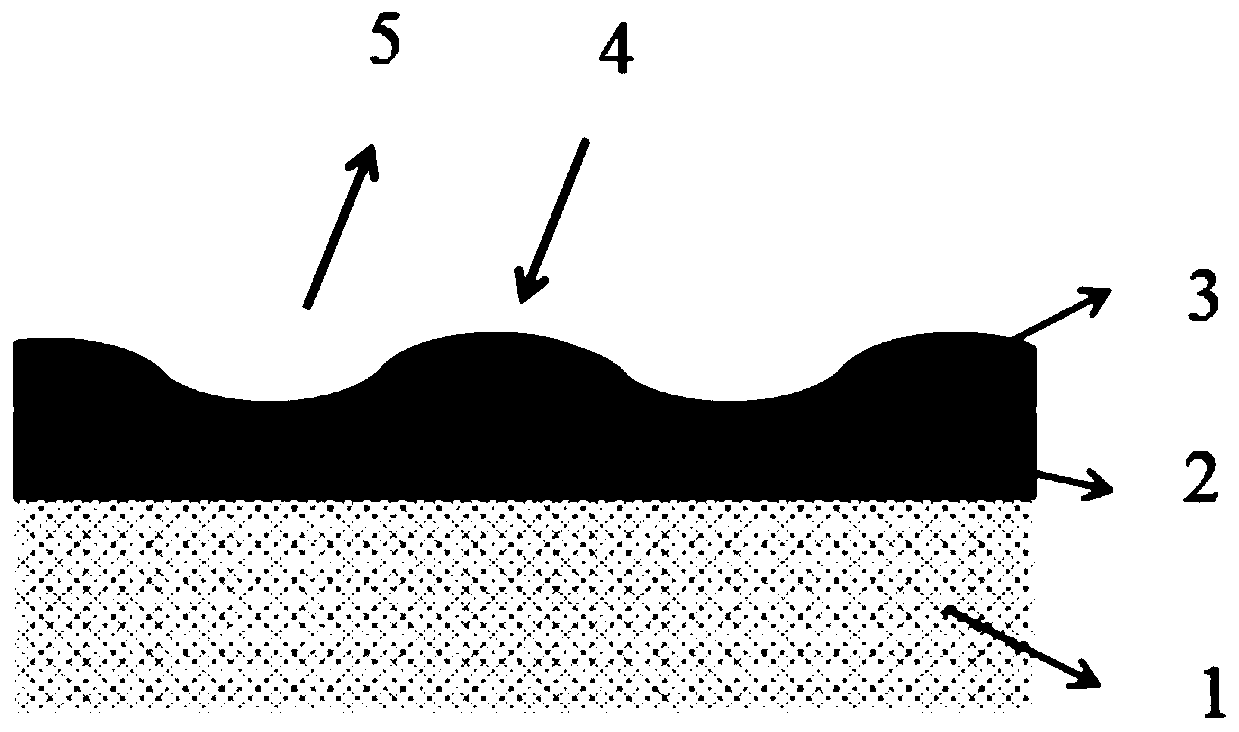

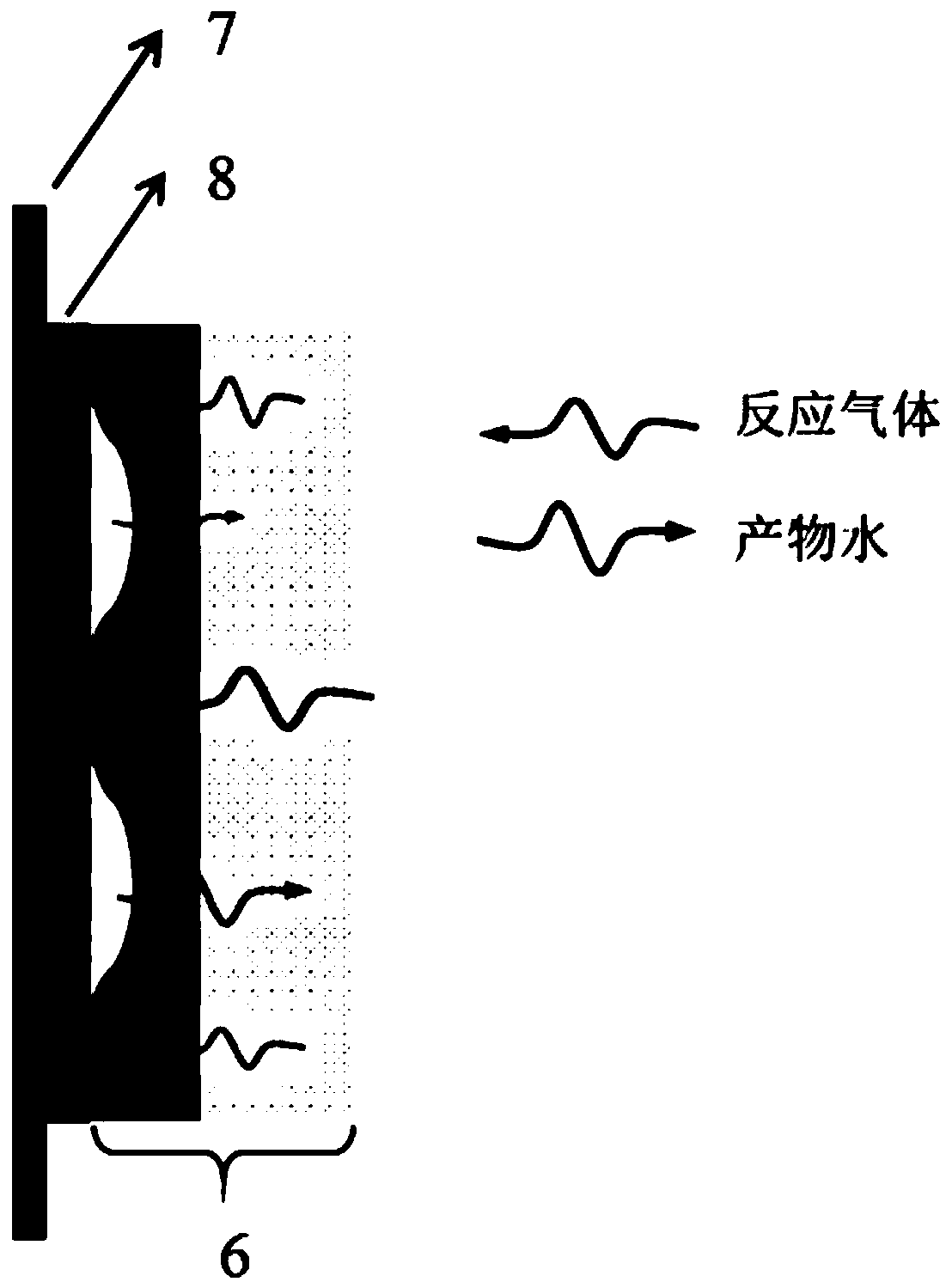

Wide-width humidity self-adaptive fuel cell gas diffusion layer

The invention relates to a wide-width humidity self-adaptive fuel cell gas diffusion layer which comprises a carbonaceous porous base material (1), a leveling layer (2) and a corrugated layer (3) which are sequentially stacked; the leveling layer (2) is made of carbon powder dispersion liquid in a self-made mode, and the corrugated layer (3) is made of carbon powder gel in a self-made mode. Compared with the prior art, self-adaption of a fuel cell under the wide-width humidity working condition can be achieved, and the preparation method is simple and environmentally friendly.

Owner:TONGJI UNIV

Umbrella dehydrating and drying device

InactiveCN104654746ASolving Dehydration ProblemsTroubleshoot drying technical issuesDrying solid materials without heatEngineering

The invention relates to an umbrella dehydrating and drying device, comprising a dehydrating barrel; an empty cavity and an umbrella insert tube are arranged in the dehydrating barrel; a water outlet and a drain valve are arranged below the empty cavity; the umbrella insert tube is communicated with the empty cavity which is connected with a vacuumizing device; heating tubes are uniformly distributed in the empty cavity close to the external wall of the umbrella insert tube; and a temperature sensor is arranged at the bottom of the umbrella insert tube. When the umbrella inserts an umbrella insert opening, the vacuumizing device is started to dry water on the umbrella cover by means of the empty cavity and the heating tubes are heated to dry water on the internal structure of the umbrella; the umbrella dehydrating and drying device solves technical problems of dehydrating and drying the umbrella cover and the internal structure of the umbrella after use and is simple in structure and convenient in use.

Owner:张建华

Coal slime argillization inhibition method based on adjustment and control of solution chemical properties

InactiveCN105903547AImprove settlement performanceImprove filtering effectSolid separationCyclic processMagnesium salt

The invention discloses a coal slime argillization inhibition method based on adjustment and control of solution chemical properties. Inorganic salt is utilized to change the chemical properties of water body solution during the coal washing process so as to inhibit clay argillization and coal slime argillization in coal. The coal slime argillization inhibition method comprises the following step: adding an argillization inhibitor, along with supplementary water, in a coal washing system, wherein the adding site of the argillization inhibitor is a water tank of supplementary water of a coal preparation plant; the argillization inhibitor is one selected from natural gypsum, halogen piece or halogen powder of magnesium salt, or industrial high-salt waste water; the adding amount of the argillization inhibitor ensures that the conductivity of coal slime water is greater than or equal to 1.5*10<3> [mu]s / cm during the entire cyclic process. The argillization inhibitor added during the coal washing process can effectively prevent clay particles in coal from hydration swelling and dispersion and has the effects that the argillization process of coal slime is blocked, and the settling property of coal slime water and the dehydration property of coal slime are improved. The coal slime argillization inhibition method has the following advantages: clay and coal slime in coal are prevented from argillization from source; the method is simple and practicable, remarkable in effect, and suitable for washing of coal containing expansive clay.

Owner:CHINA UNIV OF MINING & TECH

Meat product drying device

ActiveCN104054798AImprove the heating effectEasy temperature controlMeat/fish preservation by dryingDried meatEngineering

The invention discloses a meat product drying device which comprises a shell and a conveying device, wherein an internal space of the shell is longitudinally divided into two regions, namely a drying region and a cooling region; the drying region is longitudinally divided into three regions along the shell, the first drying region is a pre-dewatering region, the second drying region is a dewatering region, and the third drying region is a forced dewatering region; the third drying region is adjacently connected with the cooling region; a plurality of infrared generators are longitudinally arranged in each of the first, second and third drying regions to heat meat products to be dried in the shell; a cooling device is arranged in the cooling region; the conveying device is used for conveying the meat products to be dried and longitudinally runs through the internal space of the shell along the shell, so that the meat products to be dried enter the shell from one end of the shell, pass through the drying regions and the cooling region in sequence and penetrate out of the other end of the shell. The device can be used for continuously producing dry meat products on a large scale, and both the drying efficiency and the product quality are improved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

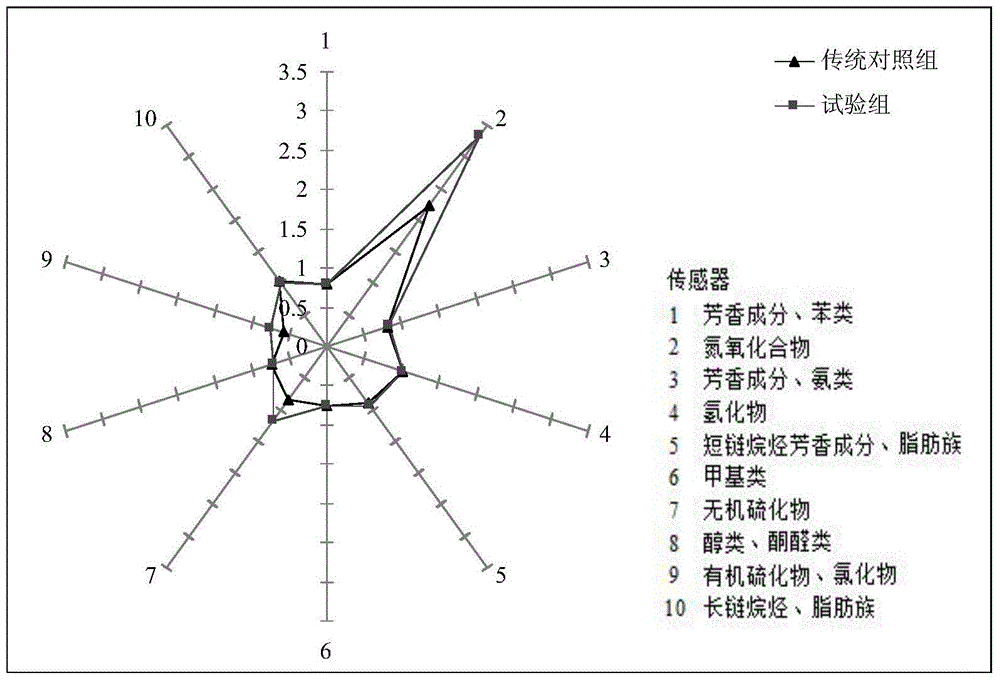

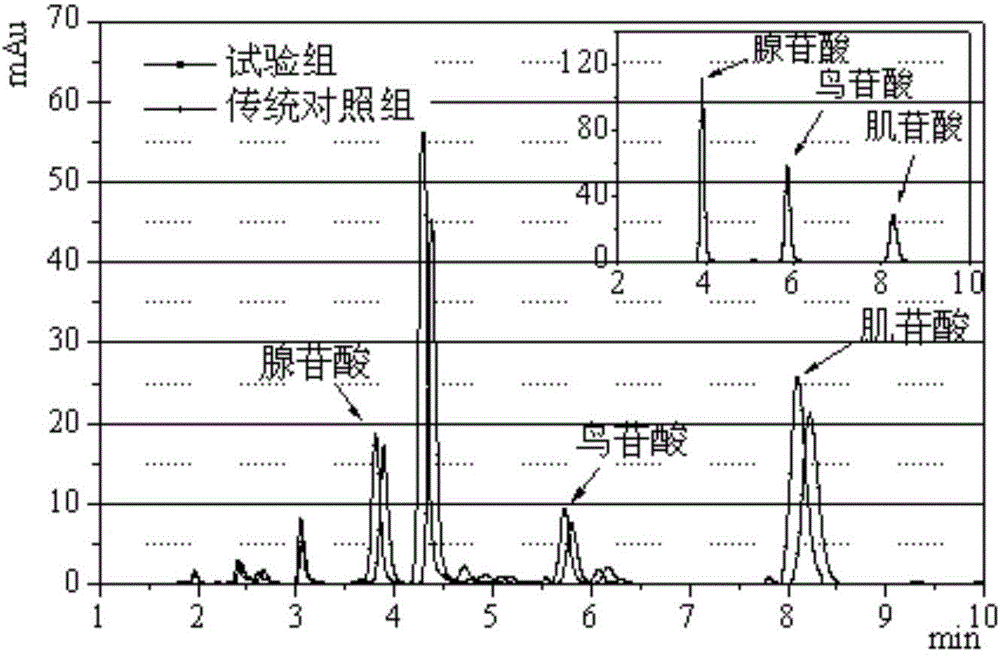

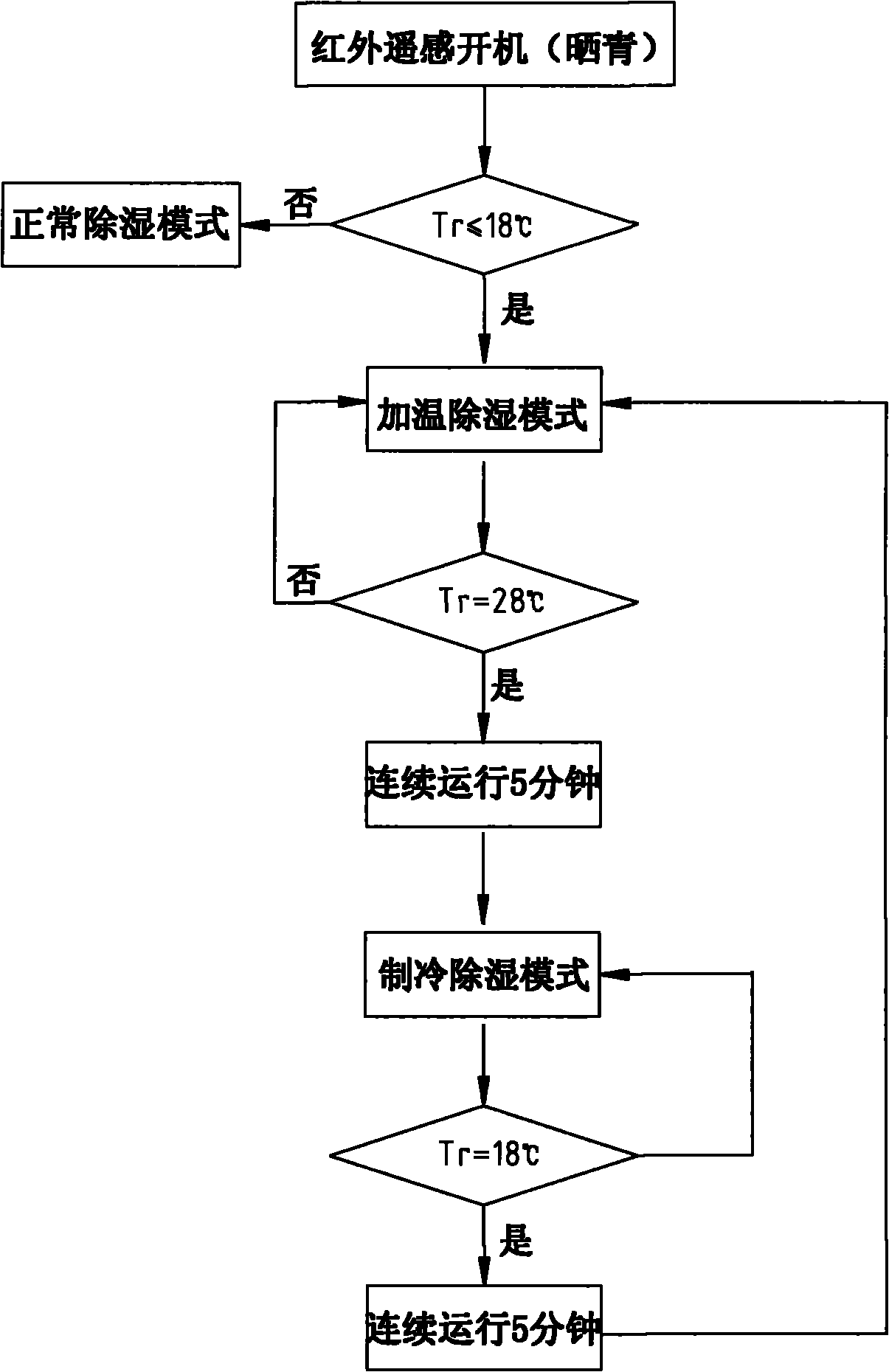

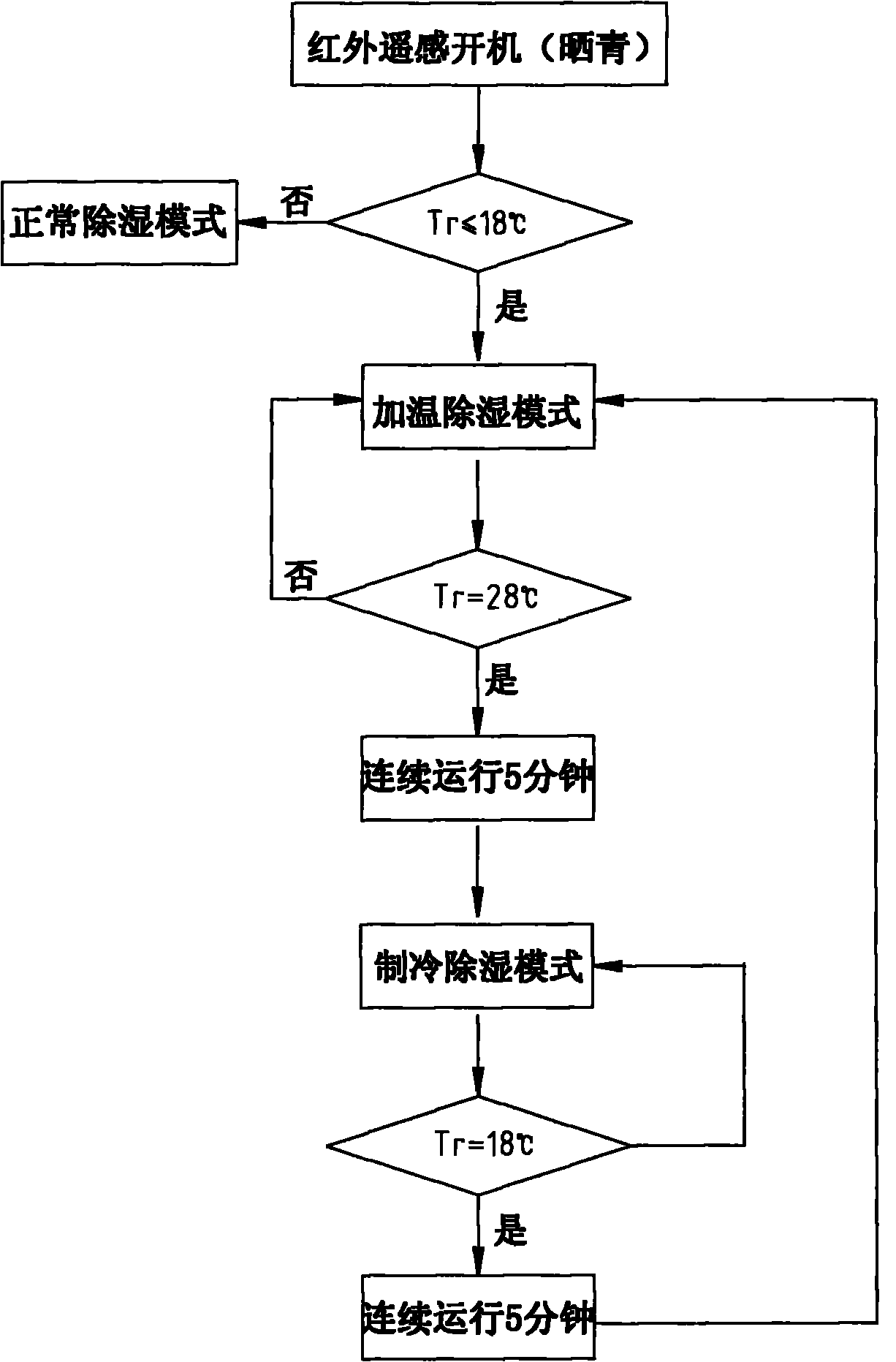

Tea leaf dehumidifier and dehumidification control method

InactiveCN101963444AImprove the effectGuaranteed freshnessPre-extraction tea treatmentDrying solid materialsElectric heatingElectricity

The invention discloses a tea leaf dehumidifier and a dehumidification control method. The method comprises a heating and dehumidification step and when the current environmental temperature is less than or equal to a first set temperature, the dehumidifier is started. The heating and dehumidification step comprises the following steps of: A10, starting an electric heating device and a dehumidification device and continuously detecting the current environmental temperature; A20, when the current environmental temperature is raised to a second set temperature, keeping the current working state for 3 to 5 minutes and then closing the electric heating device; and A30, when the current environmental temperature is reduced to the first set temperature, keeping the current working state for 3 to 5 minutes, and then starting the electric heating device, and returning to the step A20. In the method, the heating and dehumidification step is started when the environmental temperature is very low, and the heating and dehumidification step and a refrigeration and dehumidification step are converted alternately, so that on the one hand, freshness of an object to be dehumidified can be kept, on the other hand, the object to be dehumidified can be quickly dehumidified; and thus the dehumidification effect is improved.

Owner:NINGBO AOKESI ELECTRIC EQUIP FACTORY

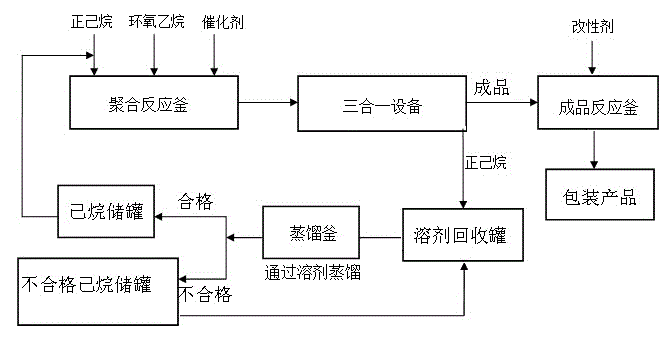

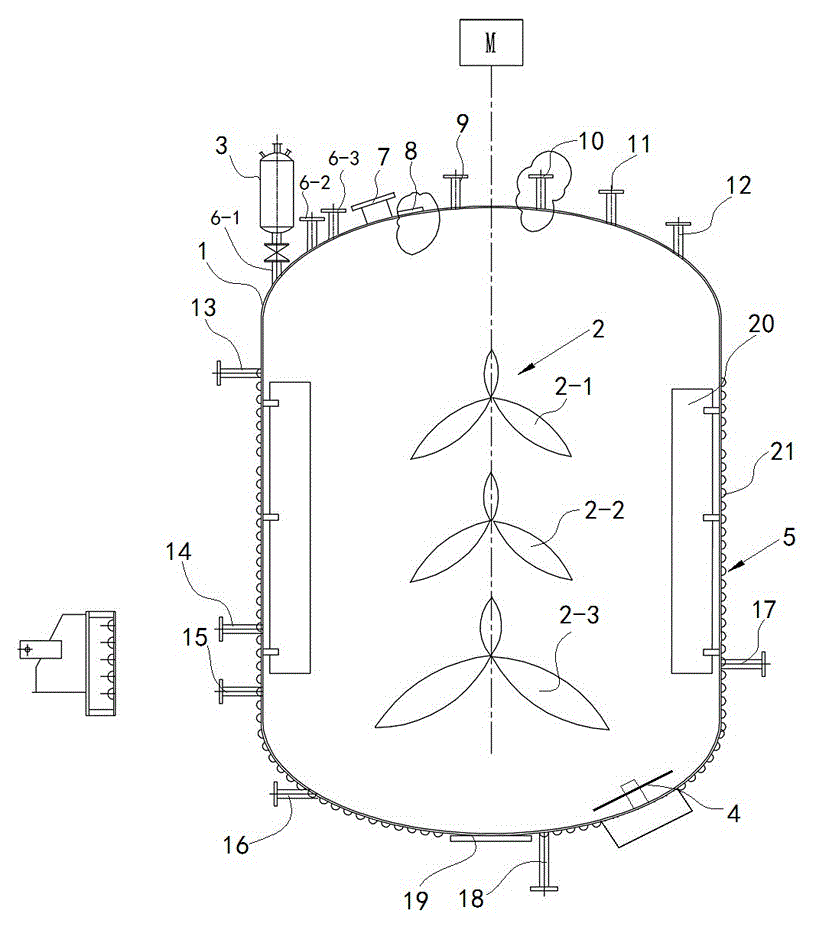

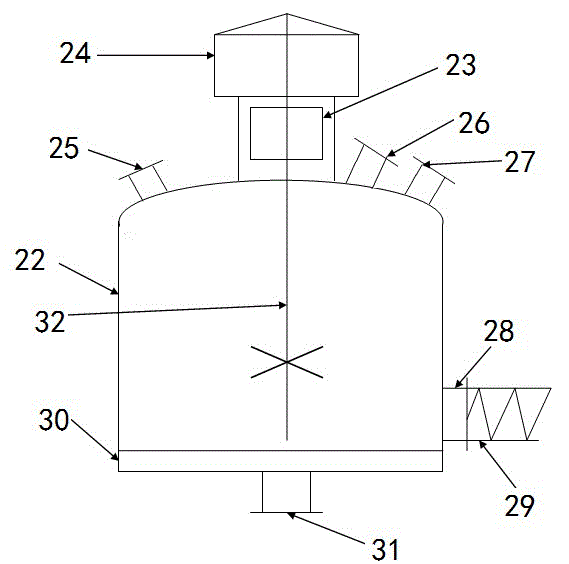

Production equipment for polyoxyethylene products and preparation method thereof

The invention relates to production equipment for polyoxyethylene products and a preparation method thereof. The equipment comprises a polymerization reaction kettle, integrated equipment, a finished product mixing kettle, a solvent recycling tank, a distillation kettle, a hexane storage tank and an unqualified hexane storage tank. The production process of the polyoxyethylene products comprises the steps that ring opening polymerization is performed on ethylene oxidein C6 or C7 solvent through the action of a catalyst, exothermic reaction is performed at a certain temperature and under certain pressure, and the requirements of product specifications are achieved through the growth of polymeric chains; after the reaction is finished, the products are processed through the integrated equipment with the functions of filtering, drying and washing, and then packaging is performed. According to the production equipment for the polyoxyethylene products and the preparation method thereof, the partial implosion phenomenon caused by the reaction is avoided, the volume of the reaction kettle is successfully enlarged to 6000 litres, the production scale of a PEO device is enlarged, and the stability of the product quality is improved; the method solves the problems of solvent dehydrating and solvent recycling and reusing.

Owner:吉化集团吉林市星云化工有限公司

Preparation method of vinyl silicone oil with low hydroxyl content

The invention discloses a preparation method of vinyl silicone oil with low hydroxyl content, which comprises the following steps: (1) adding a dimethyl siloxane ring body and an end capping agent into a reaction kettle with stirring and heating functions; (2) adding a catalyst, and reacting for 25 hours at the temperature of 80-110 DEG C; (3) adding a silicon hydroxyl eliminating agent, and reacting for 0.5-1.5 h; (4) breaking enzyme for 30-60 minutes; and (5) at the temperature of 160-180 DEG C and the vacuum degree of greater than 0.095, removing the solvent for 3-5 hours, cooling and filtering to obtain a finished product. Silicon hydroxyl in the vinyl silicone oil is eliminated by adopting the silicon hydroxyl eliminating agent, so that the process is simplified, the energy is saved, the efficiency is improved, the content of silicon hydroxyl in the vinyl silicone oil is reduced, and the quality of the vinyl silicone oil is improved.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

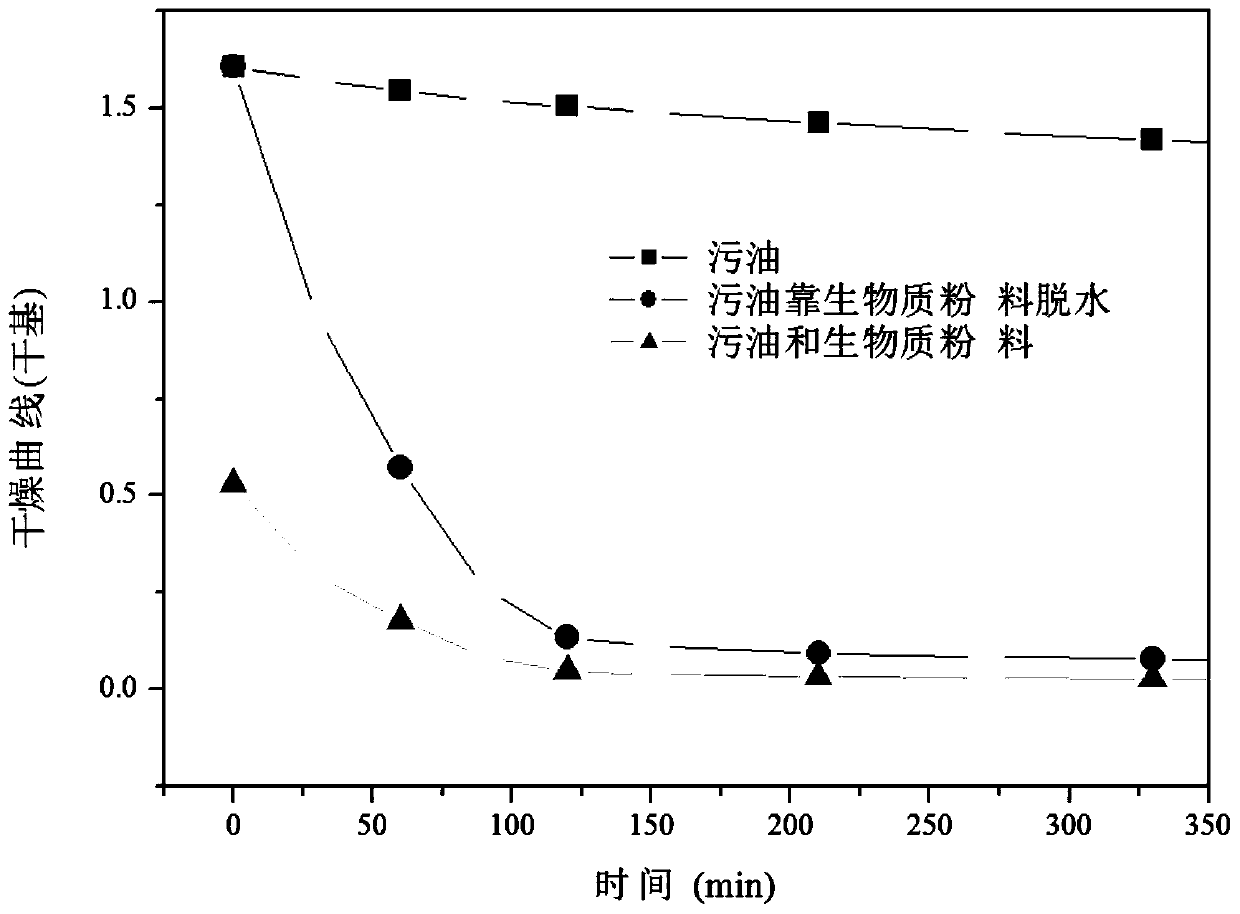

Preparation method of hazardous waste granular fuel

InactiveCN110331019AReduce moisture contentHigh calorific valueBiofuelsSolid fuelsWater contentNatural gas

The invention relates to a preparation method of hazardous waste granular fuel. The preparation method comprises: (1) mixing, stirring and dehydrating biomass powder and hazardous waste according to amass ratio of 1:(0.2-9) until the moisture content of the mixture is less than or equal to 30%; and (2) pressing the material dehydrated in the step (1) into granular fuel. After the hazardous wasteis treated by the method, the obtained hazardous waste granular fuel is homogenized in physical and chemical properties, low in water content and high in heat value. When the hazardous waste granularfuel is incinerated, high-price fuel such as natural gas does not need to be supplemented, so that the hazardous waste treatment cost is greatly reduced; by means of the method, hazardous waste treatment is more environment-friendly, and the application range is wider.

Owner:张家港百赫科技有限公司

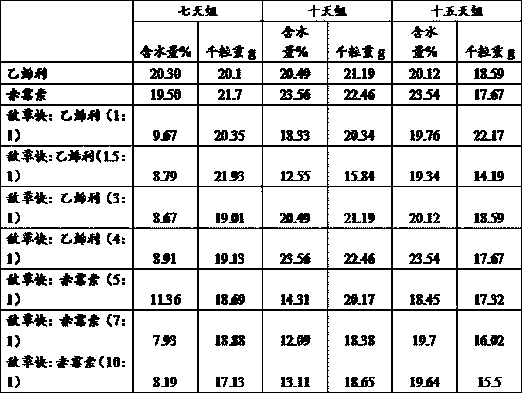

Composition for rice withering acceleration

InactiveCN105494375ASolving Dehydration ProblemsSolve the problem of production reduction after witheringBiocidePlant growth regulatorsEconomic benefitsGrowth regulator

The invention discloses a composition for rice withering acceleration. The composition comprises diquat and a growth regulator; the diquat and the growth regulator are prepared according to a weight ratio of (1:1) to (10:1). According to the composition for rice withering acceleration, the diquat and the growth regulator are blended, therefore not only is the problem that production reduction after withering acceleration is caused by the diquat solved but also the problem of rice dewatering caused by withering acceleration can be solved; airing labor cost is reduced, and economic benefit is effectively increased.

Owner:INST OF PLANT PROTECTION GUANGXI ACADEMY OF AGRI SCI

A kind of sludge dehydration method

InactiveCN102267793ASolving Dehydration ProblemsEffective dehydration methodSludge treatment by de-watering/drying/thickeningRebarReinforced concrete

The invention relates to treatment of sludge, in particular to a dehydrating method for sludge, belonging to the technical field of environmental protection. The method comprises the following steps of: excavating a chuck hole, setting a dewatering well, arranging an electrode in the middle of the chuck groove, draining water in the sludge into a water well pipe for dehydrating by using an electrophoresis method; and forming a reinforced concrete chuck hole, draining moisture in the sludge by using a vacuum dewatering method, and extracting moisture from the sludge by using a gravity method or a vacuum method. The method is a most effective, cheapest and most complete sludge dehydrating method; and according to the method, waste is utilized, and harmful substances are changed into valuable.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Oil field extraction liquid electromagnetic agglomerating pretreatment device

The invention relates to a pretreatment device for electromagnetic coalescence of oilfield produced water, mainly comprising magnetic-field coalescer structure and electrostatic coalescer structure, characterized in that magnetic-field coalescer structure and electrostatic coalescer structure are designed into online pipe structure; they are designed on the module and are connected in the dehydration process of oil produced water in series; the inlet of magnetic-field coalescer is connected with heating furnace or buffer tank at the upstream of liquid and the outlet is connected with the inlet of electrostatic coalescer structure; the outlet of electrostatic coalescer is connected with the inlet of three-phase separator, or settling tank, or external transportation tank at the downstream of liquid. The invention improves the coalescence effect of produced water and solves the dehydration difficulty for produced water with much water.

Owner:中石化石油工程技术服务有限公司 +1

Processing method of dried persimmons

InactiveCN107897640ASolving Dehydration ProblemsTransparent fleshFood scienceRoom temperatureYounger people

The invention discloses a processing method of dried persimmons, and relates to the technical field of processing of agriculture products. The processing method comprises six steps of performing sorting and cleaning; performing deastringent treatment: putting thoroughly-cleaned persimmons in a deastringent agent, performing soaking, loading the soaked persimmons in a closed container, performing deastringent treatment at room temperature for 10-15h, and during the deastringent treatment period, opening the closed container every 3-4h to perform ventilation once, wherein a preparation method ofthe deastringent agent comprises the steps of uniformly mixing and stirring 10-20 parts of corn peptide with 8-15 parts of glutathione and 70-100 parts of a 20-30% alcoholic solution and adjusting the pH to be 7-10; performing peeling; performing drying and shaping; performing frost appearance; and performing packaging. According to the processing method disclosed by the invention, a method of firstly performing low-temperature quick deastringent treatment and then performing high-temperature dehydration and baking is adopted, so that the deastringent problem of the dried persimmons is solved, and the made dried persimmons are transparent in meat quality, and sweet, delicious and pure in taste, and are superior foods suitable for both old and young people.

Owner:桂林国农生态农业科技有限公司

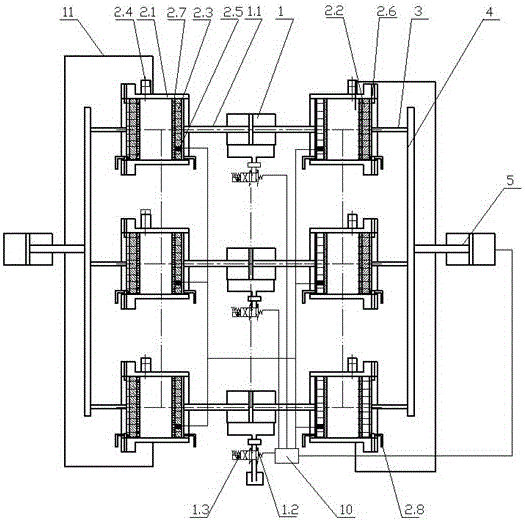

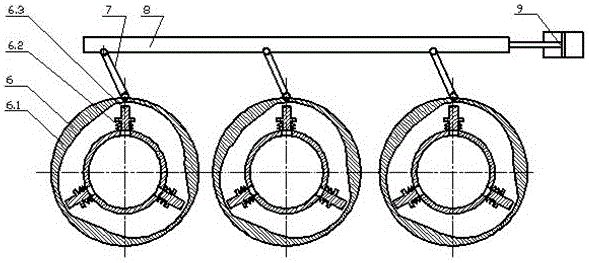

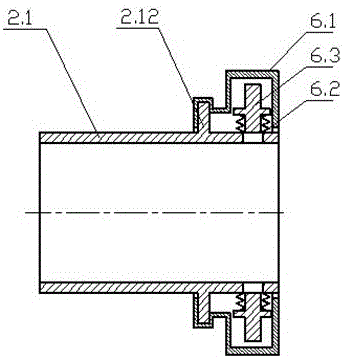

Reduction dehydration device for sewage sludge

InactiveCN105800901ARealize unloadingAchieving deep reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeEngineering

The invention discloses a reduction dehydration device for sewage sludge. The reduction dehydration device comprises at least one dehydration module. Each dehydration module comprises a bidirectional oil cylinder (1) and two symmetric dehydration units (2). Each dehydration unit (2) comprises a dehydration barrel (2.1), a supporting plate (2.2) and an extruding plate (2.3). The supporting plates (2.2) are located on the outer sides of the dehydration barrels (2.1), and the extruding plates (2.3) are located on the inner sides of the dehydration barrels (2.1). Feeding ports (2.4) are formed in the dehydration barrels (2.1). Each bidirectional oil cylinder (1) is provided with two piston rods (1.1) which are connected with the extruding plates (3) of the two corresponding dehydration units (2) respectively. According to the reduction dehydration device, feeding dehydration and squeezing dehydration are carried out at the same time, so that work efficiency is improved; meanwhile, the pressure of fed materials is ingeniously utilized for dehydration in the squeezing dehydration process, so that the power use effect is improved, and product energy consumption is reduced.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com