Production equipment for polyoxyethylene products and preparation method thereof

A polyethylene oxide, production equipment technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of non-recycling of solvents, uneven product mixing, affecting product quality, etc., to solve the problem of recycling The effect of reuse, improving economic efficiency and expanding production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

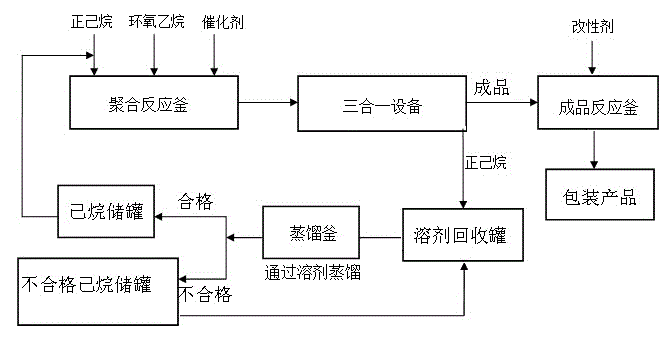

[0049] attached by figure 1 Shown: The production equipment of this polyethylene oxide product includes:

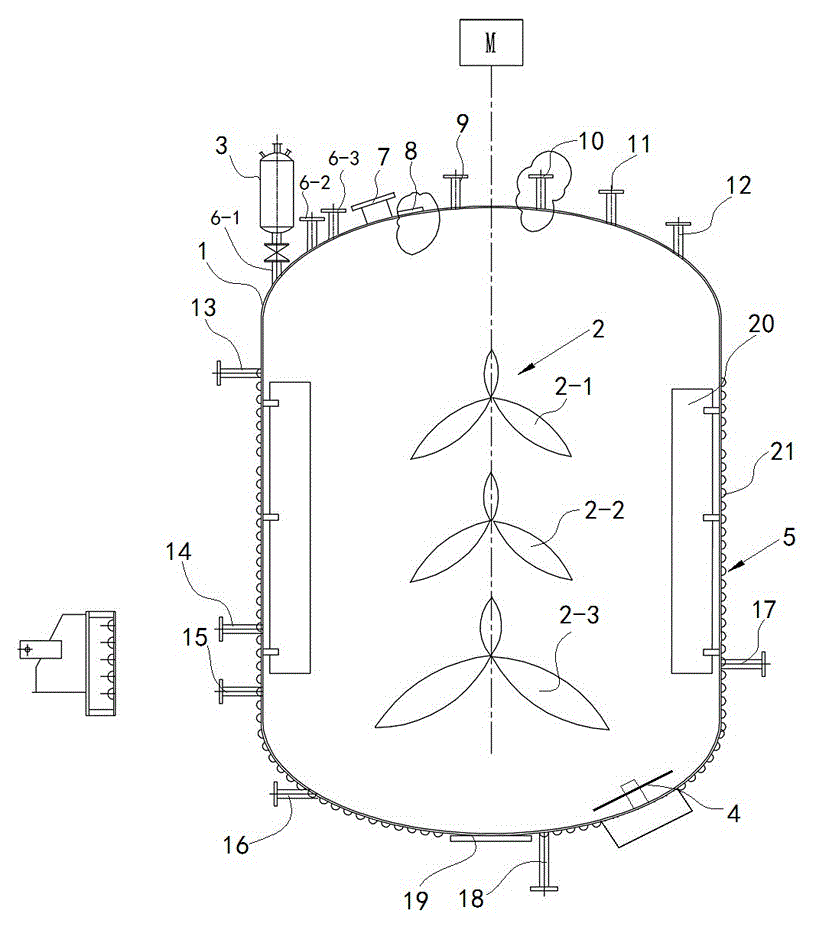

[0050] A polymerization reactor, by adding solvent, catalyst and ethylene oxide for polymerization reaction to generate a polymer; avoiding the phenomenon of partial detonation in the reaction, so that the volume of the reactor is enlarged to 6000 liters;

[0051] An integrated equipment, which integrates filtration, drying and washing, is used to solve the problems of fire prevention, explosion prevention, dust prevention and nitrogen loss in this production step;

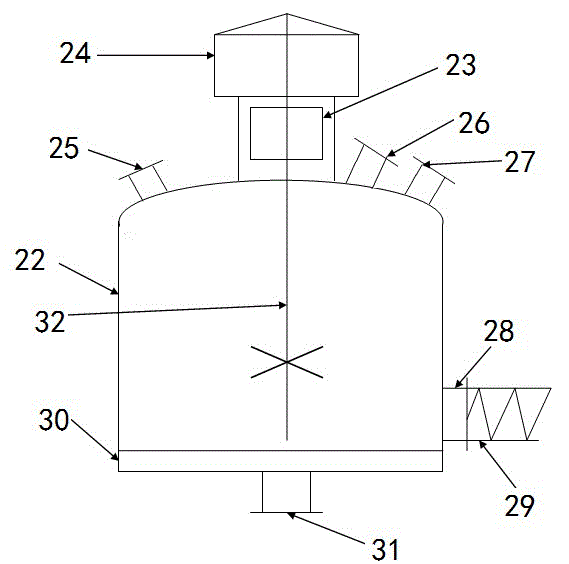

[0052] A finished product mixing tank, so that the material can achieve a very uniform mixing degree after adding modifiers in the finished product mixing tank, ensuring the stability of product quality;

[0053] A solvent recovery tank, a still, a hexane storage tank and an unqualified hexane storage tank are used to recover and reuse the reaction solvent.

[0054] The production process of the polyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com