Meat product drying device

A drying device and technology for meat products, applied in the direction of drying and preserving meat/fish, etc., can solve the problems of reducing the water loss rate, low drying efficiency, difficult industrial production, etc., to improve production efficiency and economic benefits, speed up drying, The effect of easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

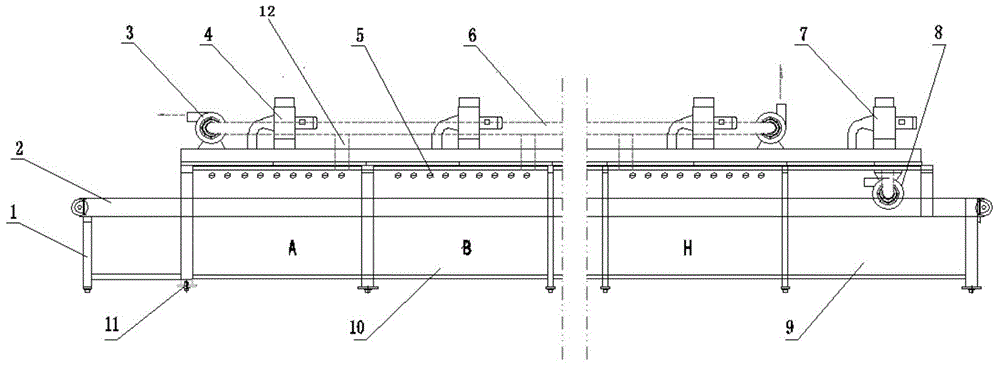

[0026] like figure 1 As shown, the present invention provides a meat product drying device, comprising:

[0027] The shell, its internal space is divided into two zones along the longitudinal axis, the drying zone 10 and the cooling zone 9, the drying zone 10 is divided into three zones along the longitudinal axis of the shell, the first drying zone is the Dehydration zone, the second drying zone is a dehydration zone, the third drying zone is a forced dehydration zone, the third drying zone is adjacent to the cooling zone 9, these three dehydration zones are set according to the dehydration and drying characteristics of materials , is conducive to rapid dehydration inside the material. Specifically, the drying zone 10 is preferably divided into 8 heating and drying stages....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com