Preparation method of hazardous waste granular fuel

A technology for pellet fuel and hazardous waste, which is applied in the field of preparation of hazardous waste pellet fuel, can solve the problem of inapplicability of similar liquid hazardous waste, etc., and achieve the effects of reducing treatment cost, environmental protection of hazardous waste treatment, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a preparation method of hazardous waste particulate fuel. The hazardous waste of the preparation method adopts waste emulsion. See Table 1 for its physical and chemical properties. The preparation method specifically includes the following steps:

[0032] (1) The biomass powder and waste emulsion are added to the jacketed stirring mixing dehydrator at a mass ratio of 1:0.2, the jacket heating temperature is 110°C during the stirring process, and the material is discharged when the moisture content is about 20% .

[0033] (2) Compress the dehydrated material in step (1) into pellet fuel.

[0034] The biomass powder in this example was prepared by the following method:

[0035] (1) Pre-treatment: remove stones, iron, ash and other impurities in waste wood chips;

[0036] (2) Drying: Put the pretreated wood chips into the dryer, the drying temperature is 110℃, the residence time is 20min, and the material is discharged after drying;

[0037] (3) Mixing and c...

Embodiment 2

[0041] This embodiment provides a method for preparing hazardous waste particulate fuel, except that the mass ratio of biomass powder to waste emulsion is 1:0.4, the others are the same as in embodiment 1.

Embodiment 3

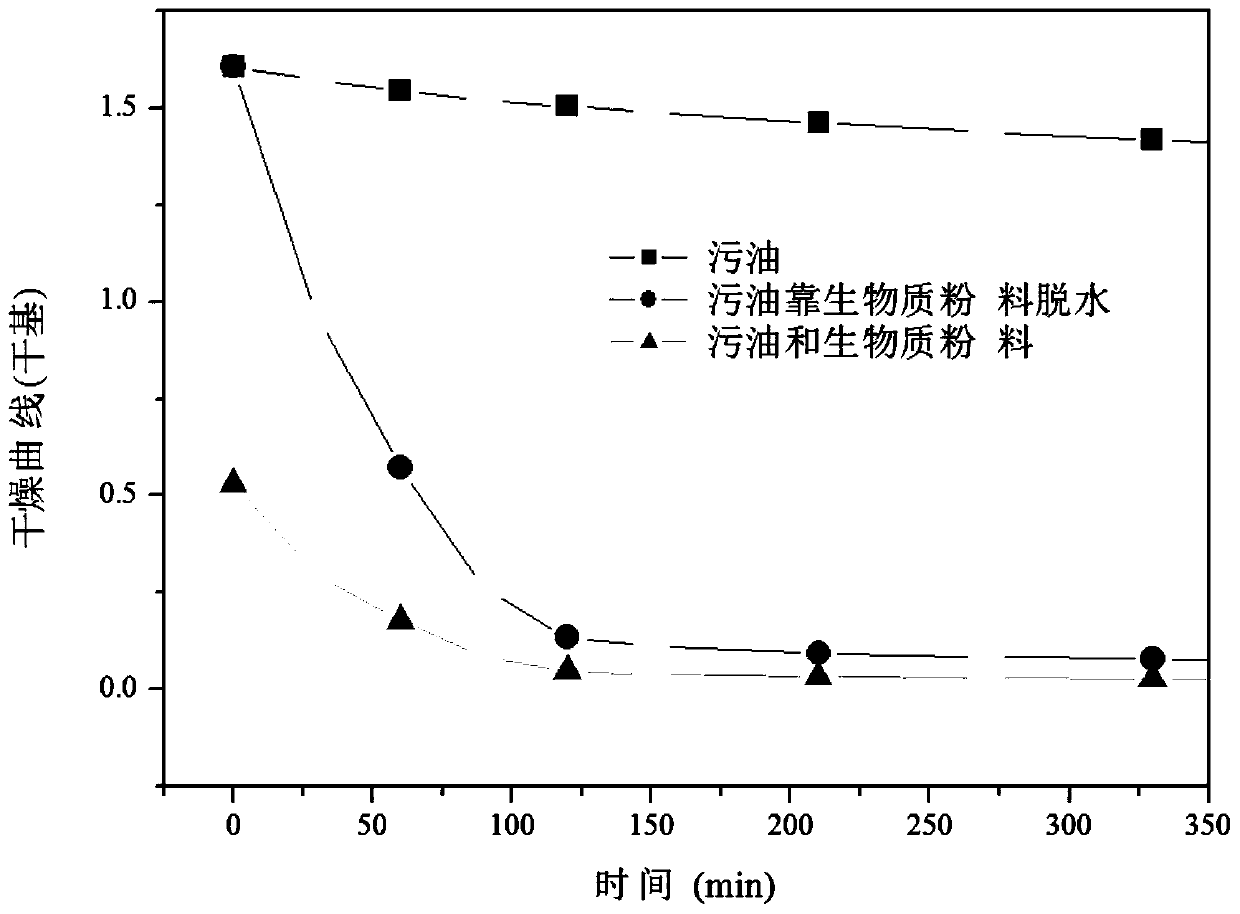

[0043] Take the hazardous waste produced by refining and chemical enterprises as an example. The sludge hazardous waste is mainly slop oil with high water content, low heating value, and difficult combustion. The physical and chemical parameters of sludge oil are shown in Table 1.

[0044] This embodiment provides a method for preparing hazardous waste particulate fuel, including the following steps:

[0045] (1) The biomass powder and slop oil are added to the jacketed stirring mixing dehydrator according to the mass ratio of 1:2.3. The jacket heating temperature is 110°C during the stirring process, and the material is discharged when the water content is about 20%.

[0046] (2) Compress the dehydrated material in step (1) into pellet fuel.

[0047] The biomass powder in this example is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com