Patents

Literature

493 results about "Hazardous waste treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment – Using various processes, such as incineration or oxidation, to alter the character or composition of hazardous wastes. Some treatment processes enable waste to be recovered and reused in manufacturing settings, while other treatment processes dramatically reduce the amount of hazardous waste.

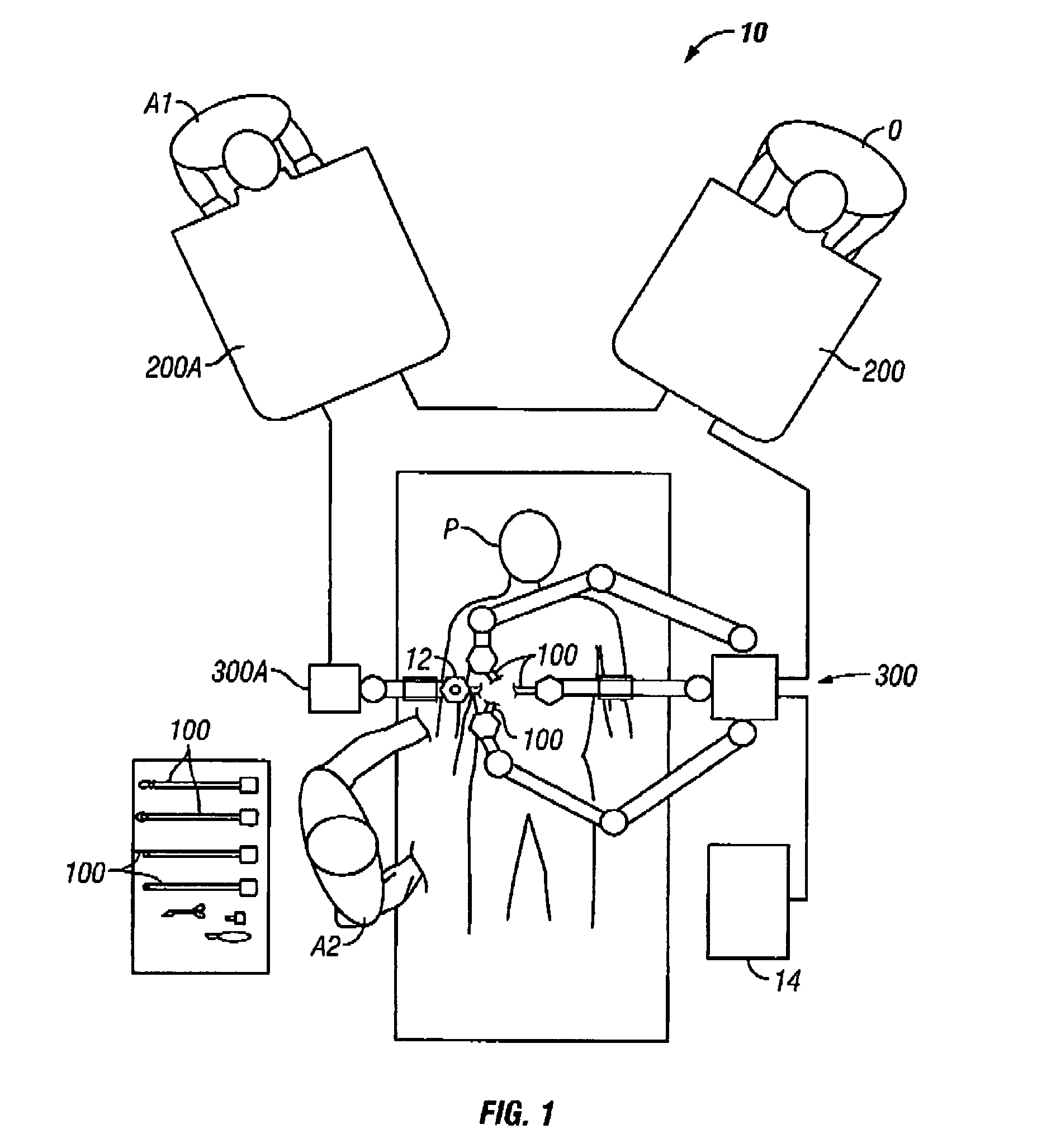

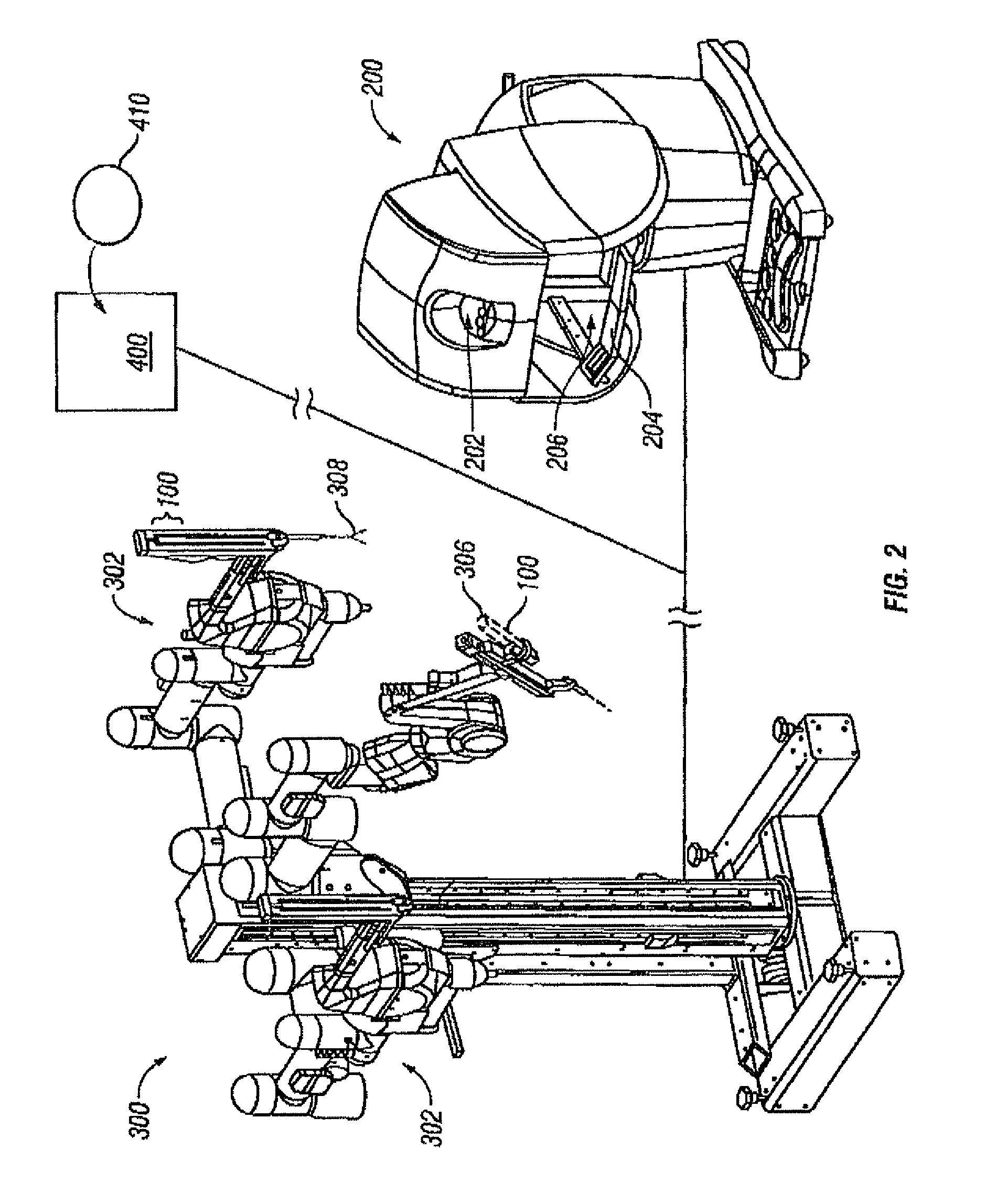

Methods and apparatus for surgical planning

ActiveUS7607440B2Easy to planPrecise positioningProgramme controlProgramme-controlled manipulatorSurgical siteEngineering

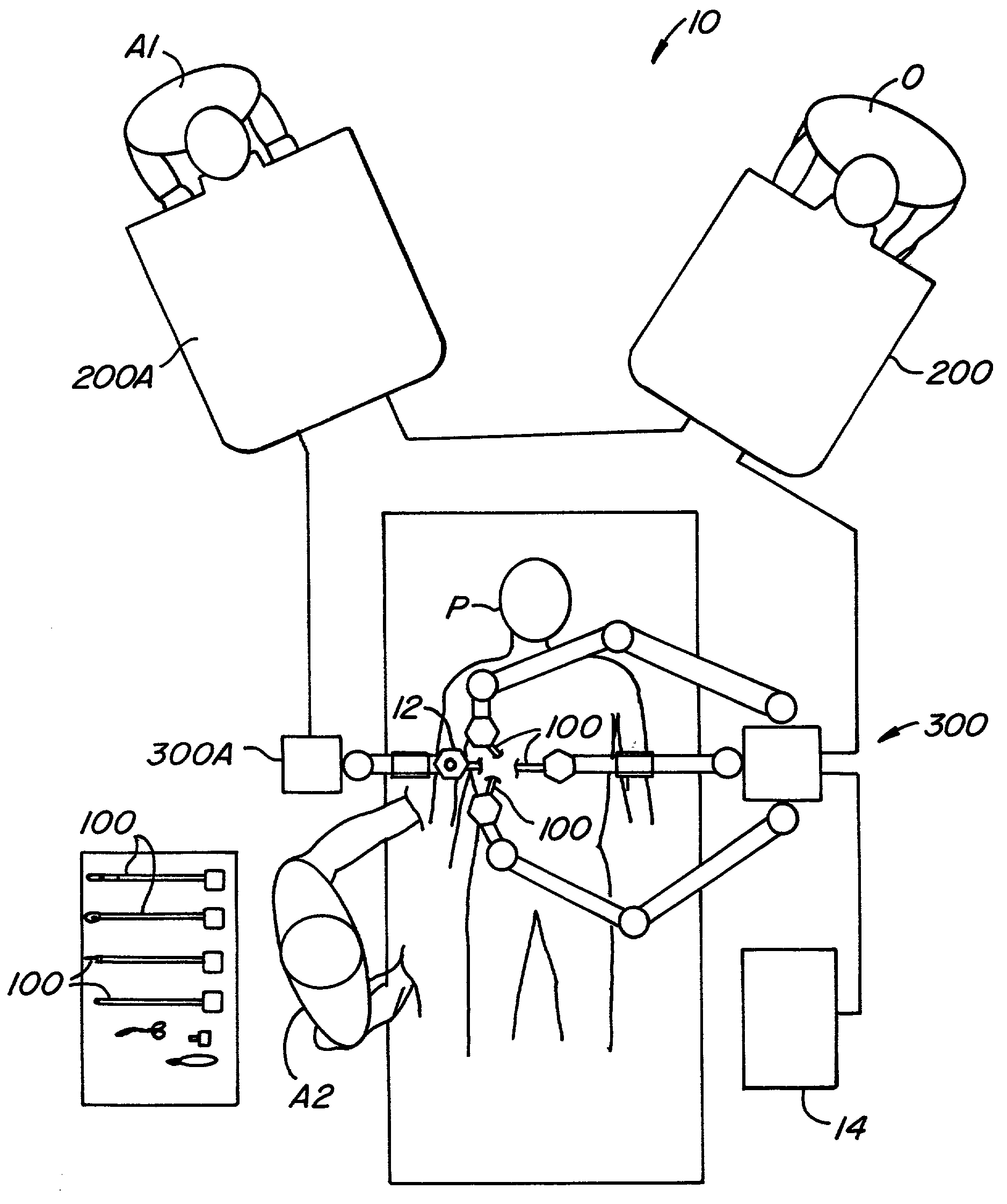

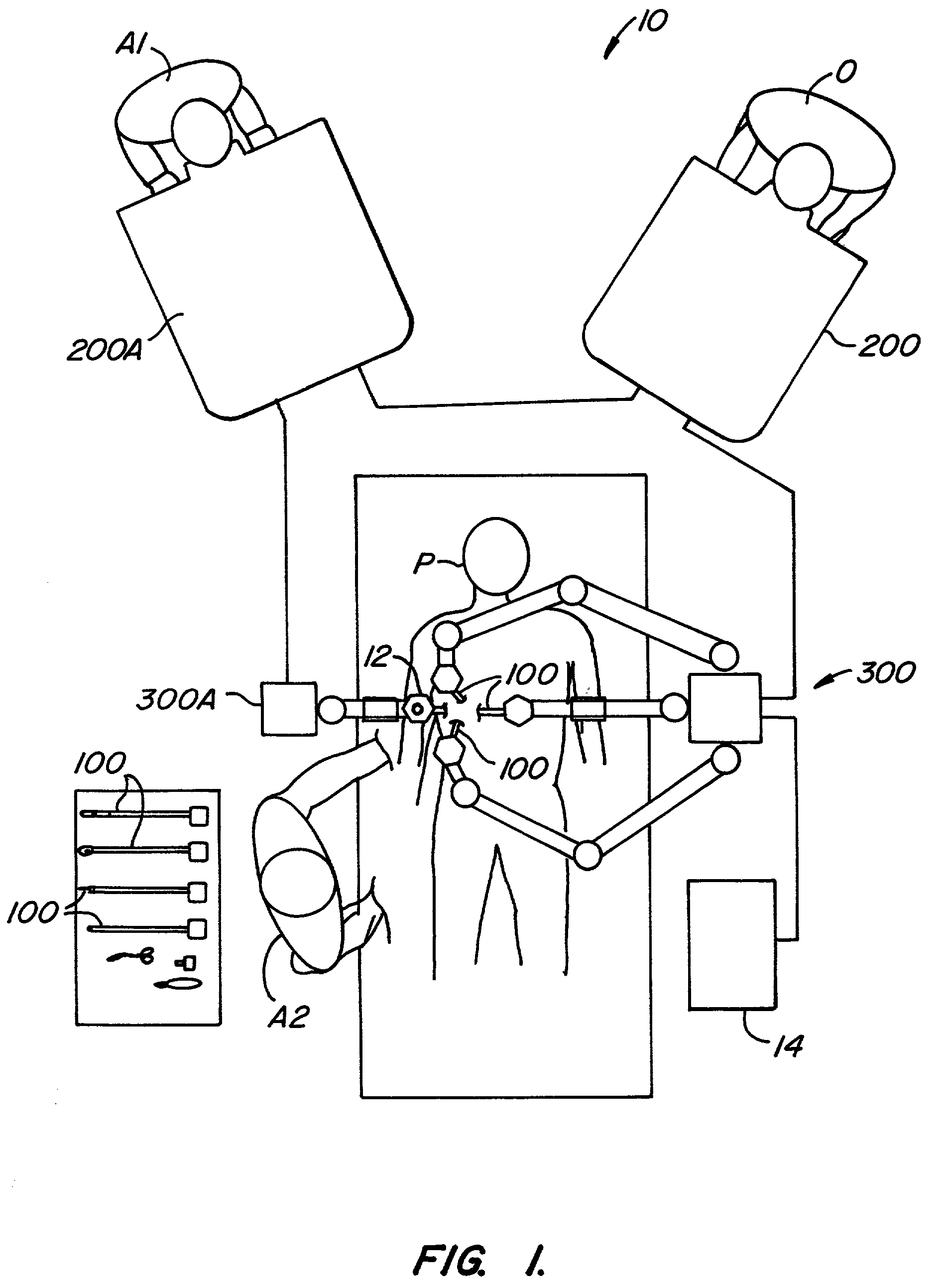

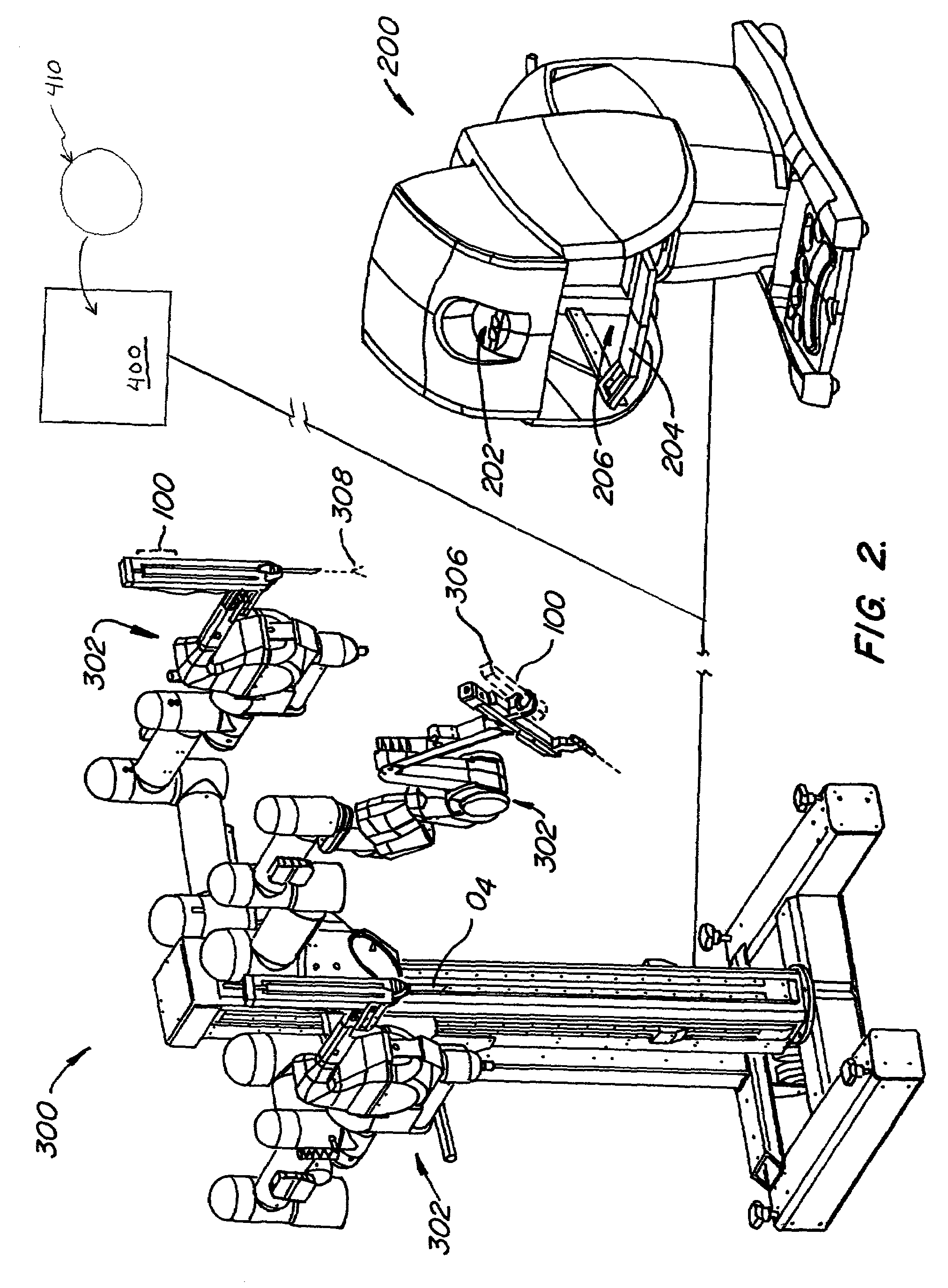

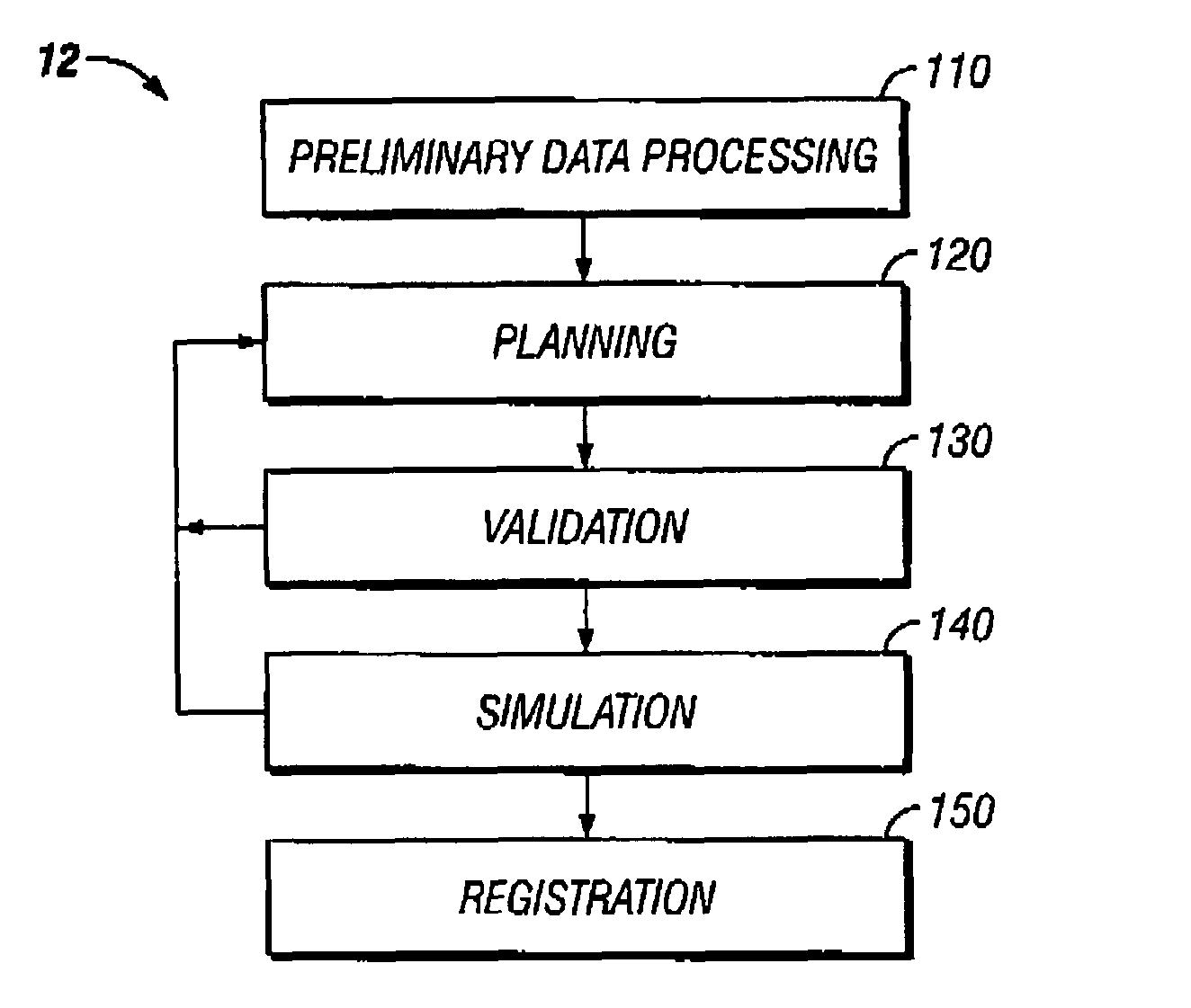

Methods and apparatus for enhancing surgical planning provide enhanced planning of entry port placement and / or robot position for laparoscopic, robotic, and other minimally invasive surgery. Various embodiments may be used in robotic surgery systems to identify advantageous entry ports for multiple robotic surgical tools into a patient to access a surgical site. Generally, data such as imaging data is processed and used to create a model of a surgical site, which can then be used to select advantageous entry port sites for two or more surgical tools based on multiple criteria. Advantageous robot positioning may also be determined, based on the entry port locations and other factors. Validation and simulation may then be provided to ensure feasibility of the selected port placements and / or robot positions. Such methods, apparatus, and systems may also be used in non-surgical contexts, such as for robotic port placement in munitions diffusion or hazardous waste handling.

Owner:INTUITIVE SURGICAL OPERATIONS INC +1

Methods and apparatus for surgical planning

ActiveUS8170716B2Easy to planPrecise positioningProgramme controlProgramme-controlled manipulatorSurgical siteEngineering

Methods and apparatus for enhancing surgical planning provide enhanced planning of entry port placement and / or robot position for laparoscopic, robotic, and other minimally invasive surgery. Various embodiments may be used in robotic surgery systems to identify advantageous entry ports for multiple robotic surgical tools into a patient to access a surgical site. Generally, data such as imaging data is processed and used to create a model of a surgical site, which can then be used to select advantageous entry port sites for two or more surgical tools based on multiple criteria. Advantageous robot positioning may also be determined, based on the entry port locations and other factors. Validation and simulation may then be provided to ensure feasibility of the selected port placements and / or robot positions. Such methods, apparatus and systems may also be used in non-surgical contexts, such as for robotic port placement in munitions diffusion or hazardous waste handling.

Owner:INTUITIVE SURGICAL OPERATIONS INC +1

Curing chelation method for waste incineration fly ash

The invention belongs to the technical field of hazardous waste treatment and environmental protection, and relates to a curing chelation method for waste incineration fly ash. The curing chelation method for the waste incineration fly ash comprises the following steps that (1) the waste incineration fly ash to be processed and a curing agent are mixed in a certain proportion and then stirred uniformly, and cured fly ash is obtained; (2) a certain amount of chelating agent is sprayed into the cured fly ash, uniform stirring is carried out, and cured and chelated fly ash is obtained; and (3) the cured and chelated fly ash is put into a compaction die for compaction molding, the maintenance is carried out for 3-7 days, and a waste incineration fly ash cured body is obtained. According to thecuring chelation method for the waste incineration fly ash, the fly ash and the curing agent are first mixed mode, then a stabilizer is sprayed for sprinkle wet stirring, and then the compaction molding is carried out under certain pressure, so that sufficient contact and reaction between the fly ash and the agents are realized to be beneficial to reducing the proportion of the agents used and improving the treatment effect of heavy metals in the fly ash.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

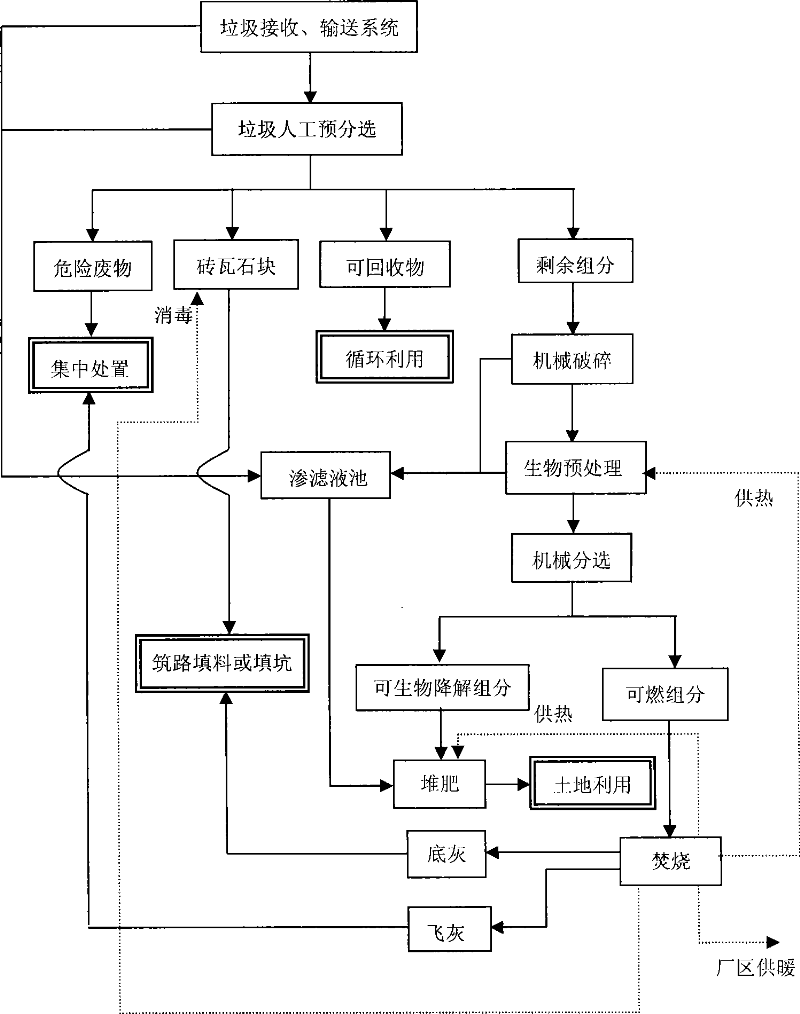

Domestic waste comprehensive treatment technology based on the pre-processing

InactiveCN101036916AReduce moisture contentChange mechanical propertiesSolid waste disposalClimate change adaptationLitterPre treatment

A technology based on the household garbage of the biology pretreatment, belongs to the environmental protection technical field, which is characterized by including a garbage manual presorting, the biology pretreatment, the garbage compost and the refuse burning technology. After the household garbage is sorted manually, the garbage is divided into four kinds: the tile stone component is used for roadbuilding or filling the pit, the recoverable component is reclaimed to use; the hazardous waste is sent to the hazardous waste disposal work for centralized disposition; after the residual garbage processes the biology pretreatment, and is sorted into the biodegradable component and the combustible constituent by the machine, while the biodegradable component processes the land use after composting, and the combustible constituent is fired for process. The effect and the benefit of the invention are to make the domestic garbage for a rational utilization after sorting, without processing the percolate and setting the sanitary landfill field. The invention realizes the 'innocuity, decrement, resource', reduces the cost of investment and the operating cost, which accords with the situation of China, and a reliable and effective household garbage comprehensive approach.

Owner:DALIAN UNIV OF TECH

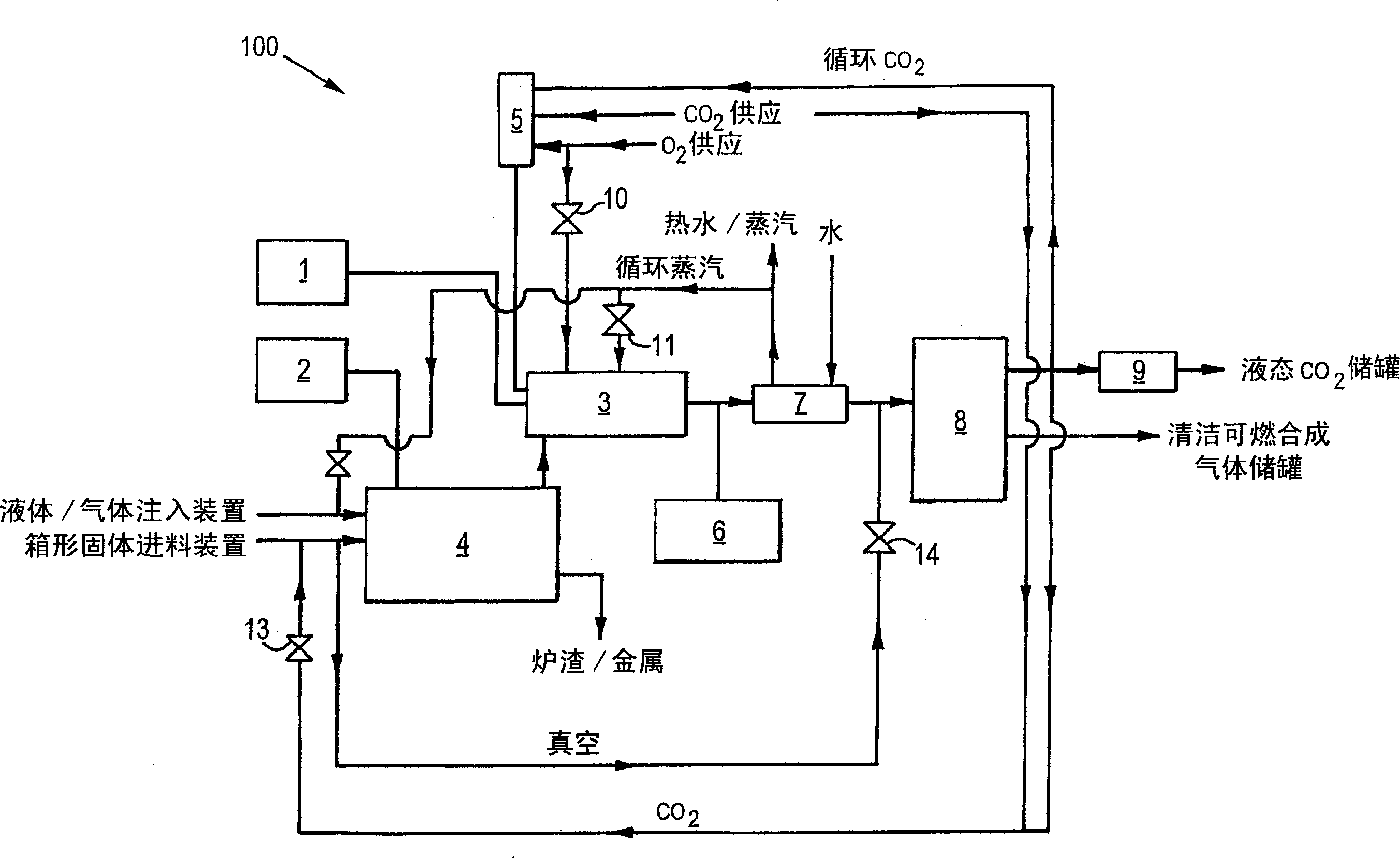

Hazardous waste treatment method and apparatus

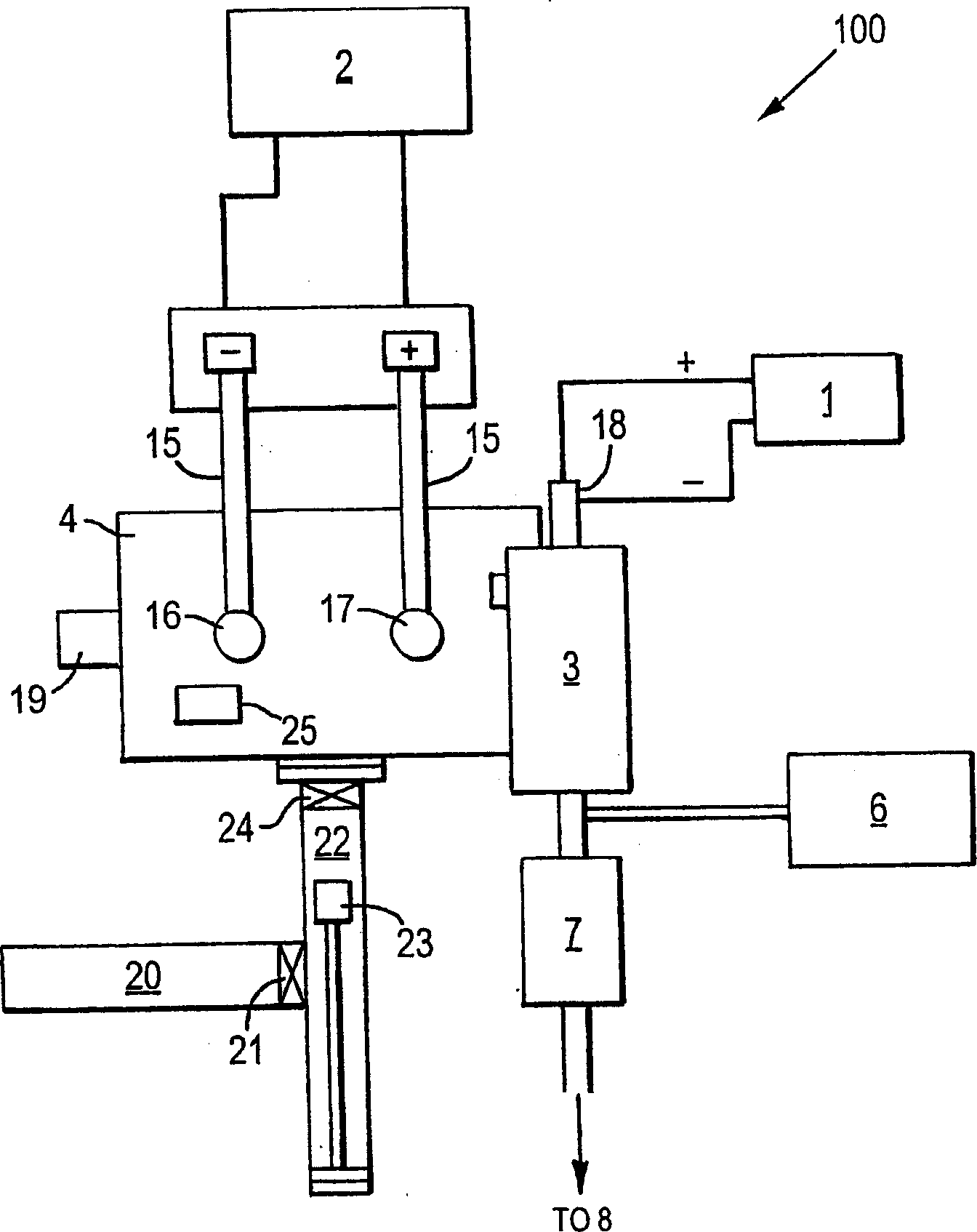

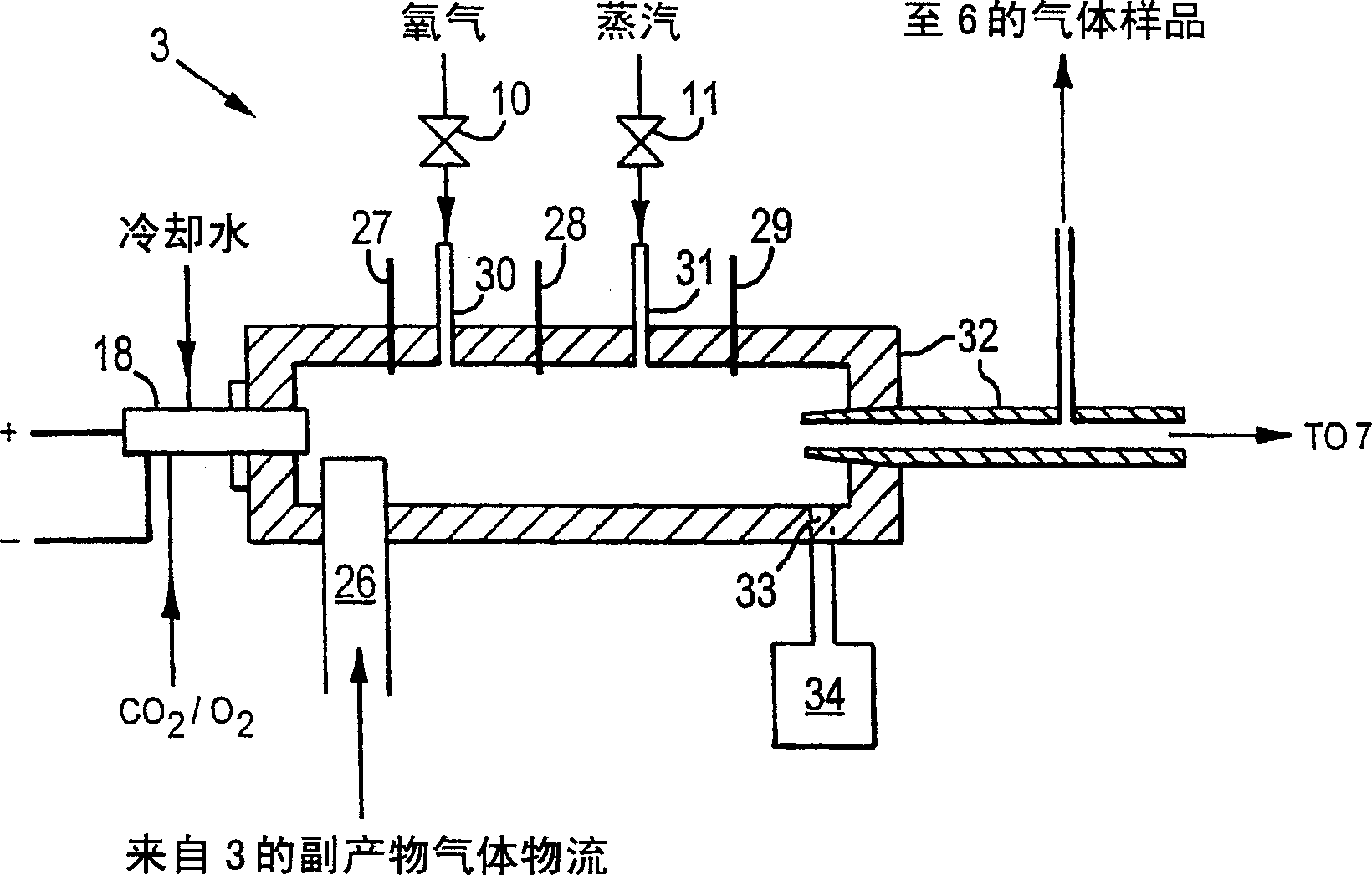

A synthetic gas production system from high heating value wastes is disclosed. The system comprises a primary waste treatment stage to receive the high heating value wastes and produce a by-product off-gas; and a secondary waste treatment stage coupled to said primary waste treatment stage to receive the by-product off-gas. The secondary waste treatment stage includes a refractory-lined cylindrical chamber having an input port for tangentially receiving said by-product off-gas and an output port. It also includes a DC powered plasma torch proximate the input port within the chamber, the torch receiving a nitrogen-free working as including a mixture of carbon dioxide and oxygen. The plasma torch heats the chamber and the by-product off-gas is converted a synthetic gas, which is ejected through the output port. An oxygen injector and a steam injector is in communication with said refractory-lined cylindrical chamber secondary treatment stage for atomized oxygen and atomized steam injections and a sensor is coupled to said output port of said refractory-lined cylindrical chamber for measuring temperature of said refractory-lined cylindrical chamber and analyzing the content of said synthetic gas. A process controller is coupled to said sensor for receiving data from said sensor and coupled to the injectors for controlling the injection of oxygen and steam.

Owner:刘健安 +1

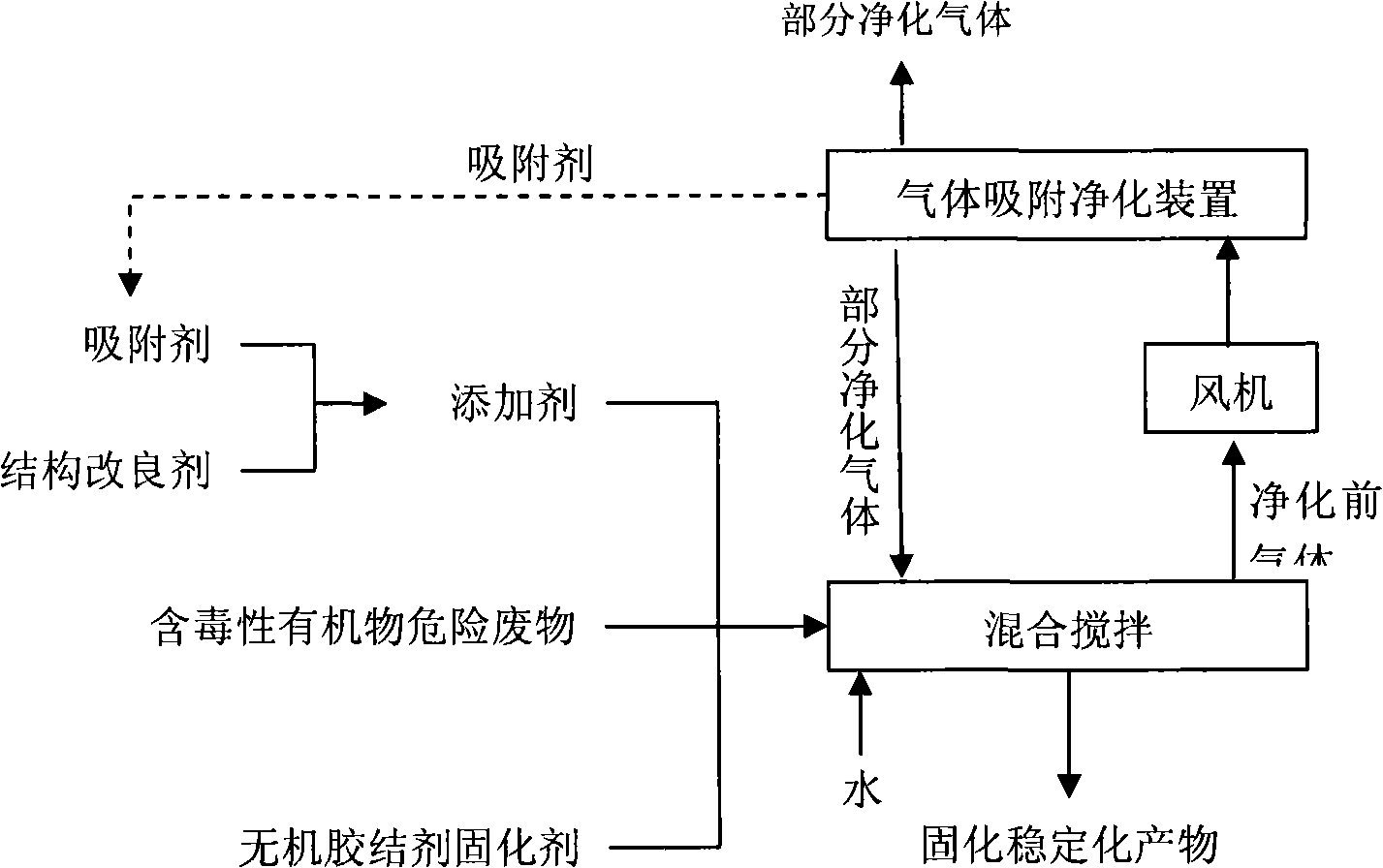

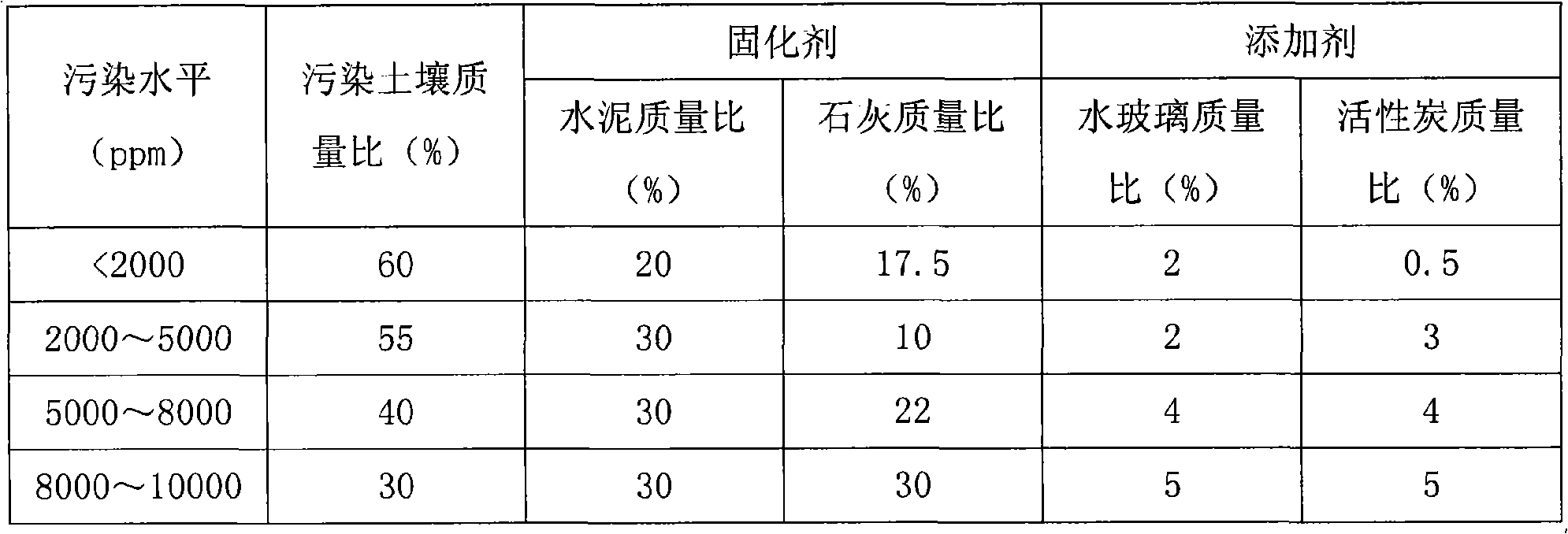

Solidifying and stabilizing method for toxicity containing organic matter dangerous waste matter

The invention discloses a solidification and stabilization method for a hazardous waste containing toxic organic compounds, which belongs to the hazardous waste treatment technical field of environment protection. According to a dry weight ratio, 30 to 60 percent of the hazardous waste containing toxic organic compounds, 0.5 to 10 percent of an additive, 30 to 60 percent of inorganic cementing agent and curing agent are added into an agitator and are stirred by adding water, meanwhile, a gas internal circulation device is started, the gas in the agitator is adsorbed and purified by a gas adsorbing and purifying device, and then part of the gas is fed back into the agitator; after being evenly mixed and stirred materials are discharged, solidified and fed into a maintenance house, and the solidification and stabilization of the hazardous waste containing toxic organic compounds is finished. The additive comprises an adsorbent with adsorbing effect and a structural modifier which can improve the structural performance of a product, such as activated carbon, water glass, calcium chloride, etc. The inorganic cementing agent and curing agent refers to hydraulicity cementing material. The solidification rate of the invention can reach more than 90 percent; and gas circulation can reduce polluted gas discharging, thus being capable of effectively reducing the occurrence of secondary pollution.

Owner:TSINGHUA UNIV

Method and system for completely recycling household garbage

PendingCN106001055AAchieving zero emissionsMeet environmental protection requirementsWaste processingSolid waste disposalGas releaseHazardous waste treatment

The invention discloses a method and a system for completely recycling household garbage. The method comprises a garbage unloading, temporary storage and feeding treatment process, a garbage sorting treatment process, an organic biomass hydrolysis and thorough decomposition treatment process, an organic fertilizer preparation treatment process, a reclaimed plastic raw material preparation treatment process, a combustible treatment, pyrolysis and gasification treatment process, an inorganic salt sintered ceramsite preparation treatment process, a pollution gas treatment process, a hydrolysis concentrated water and garbage leachate treatment process, and a hazardous waste treatment process, wherein the garbage sorting treatment process is used for classifying the garbage into organic biomass kitchen waste components, waste plastic components, combustible components, inorganic components and hazardous wastes; the pollution gas treatment process is used for recovering and treating pollution gases released in the other processes; the hydrolysis concentrated water and garbage leachate treatment process is used for recovering and treating waste water generated in the other processes; and the hazardous waste treatment process is used for treating the hazardous wastes. The method and the system, which are disclosed by the invention, are capable of realizing zero discharge of a garbage disposal process, meet environmental protection requirements, and also create a new means for the field of social renewable resources.

Owner:中科国发(深圳)技术有限公司

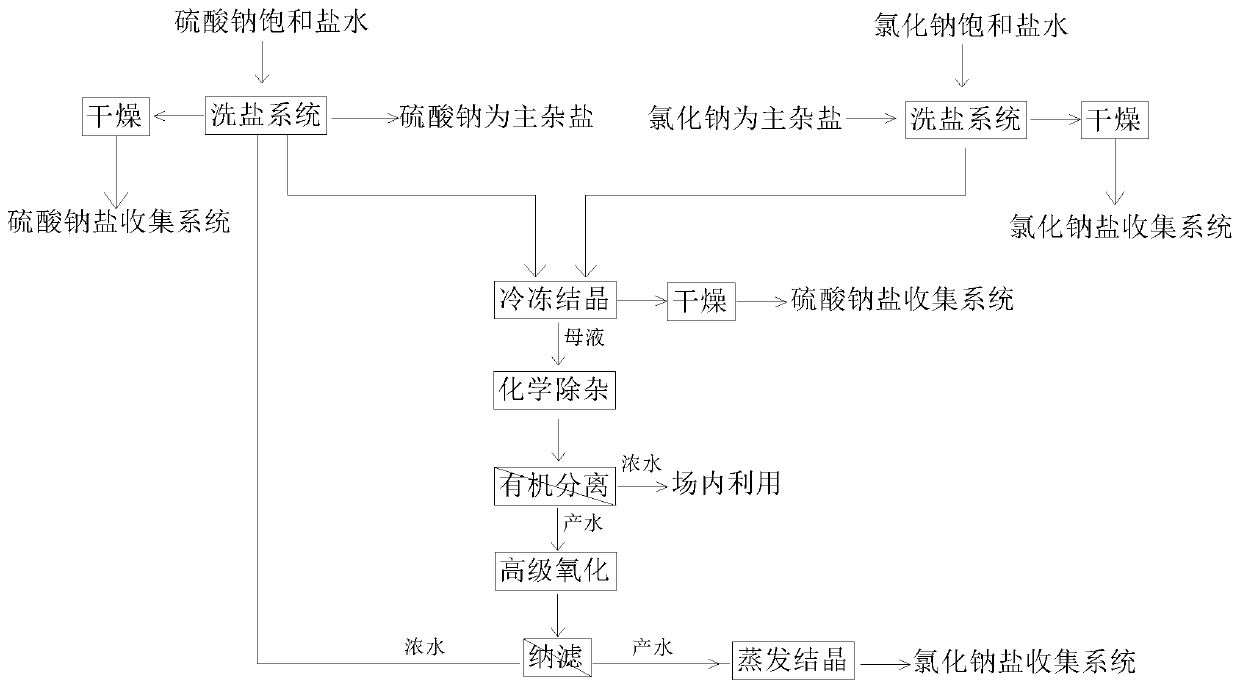

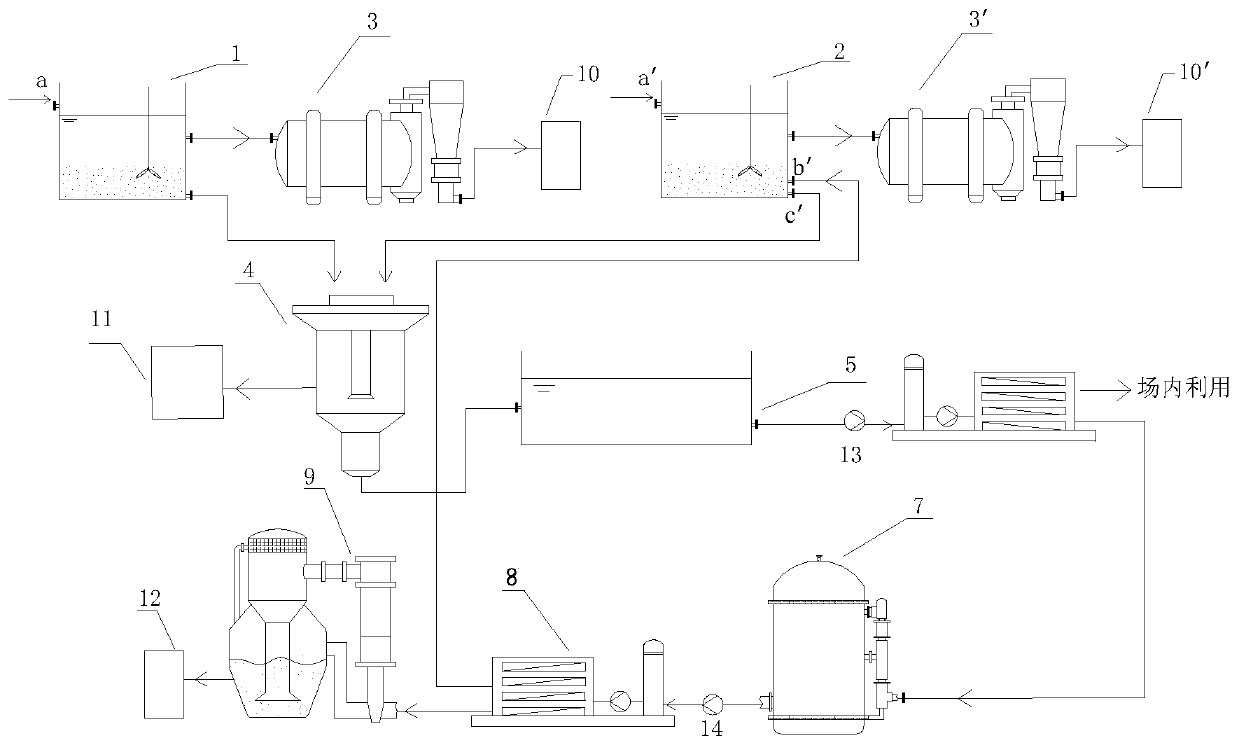

Waste salt resourceful treatment process and special equipment thereof

PendingCN110548750AEfficient separationEfficient removalSolid waste disposalTransportation and packagingFiltrationSulfate

The invention discloses a waste salt resourceful treatment process and special equipment thereof. The waste salt resourceful treatment process comprises the following steps: separately adding waste salt which mainly comprises sodium chloride and sodium sulfate into saturated salt water of sodium chloride and sodium sulfate to continuously stir, filtering to obtain mother liquor from salt wash, anddrying separated-out sodium chloride and sodium sulfate solids; freezing mother liquor from salt wash, evaporating and crystallizing crystals, chemically removing impurities of frozen mother liquor,removing organic and inorganic impurity ions, performing organic separation on impurity-removal outlet water, utilizing the mother liquor inside a field, oxidizing produced water, performing nano-filtration salt separation on oxidizing produced water, returning nano-filtration concentrated water into a salt washing system, evaporating and drying nano-filtration produced water to obtain sodium chloride solid. A series of processes such as salt washing, freezing, organic separating, oxidizing, nano-filtration salt separation, and evaporating are effectively combined, so that sodium chloride andsodium sulfate in the waste salt are separated and purified, and organic substances and other impurity irons in the waste salt are effectively separated or removed, and therefore, hazardous waste treatment cost is reduced, resourceful treatment of two waste salts is realized, and an economic value is created.

Owner:SHANGHAI JINGYU ENVIRONMENT ENG

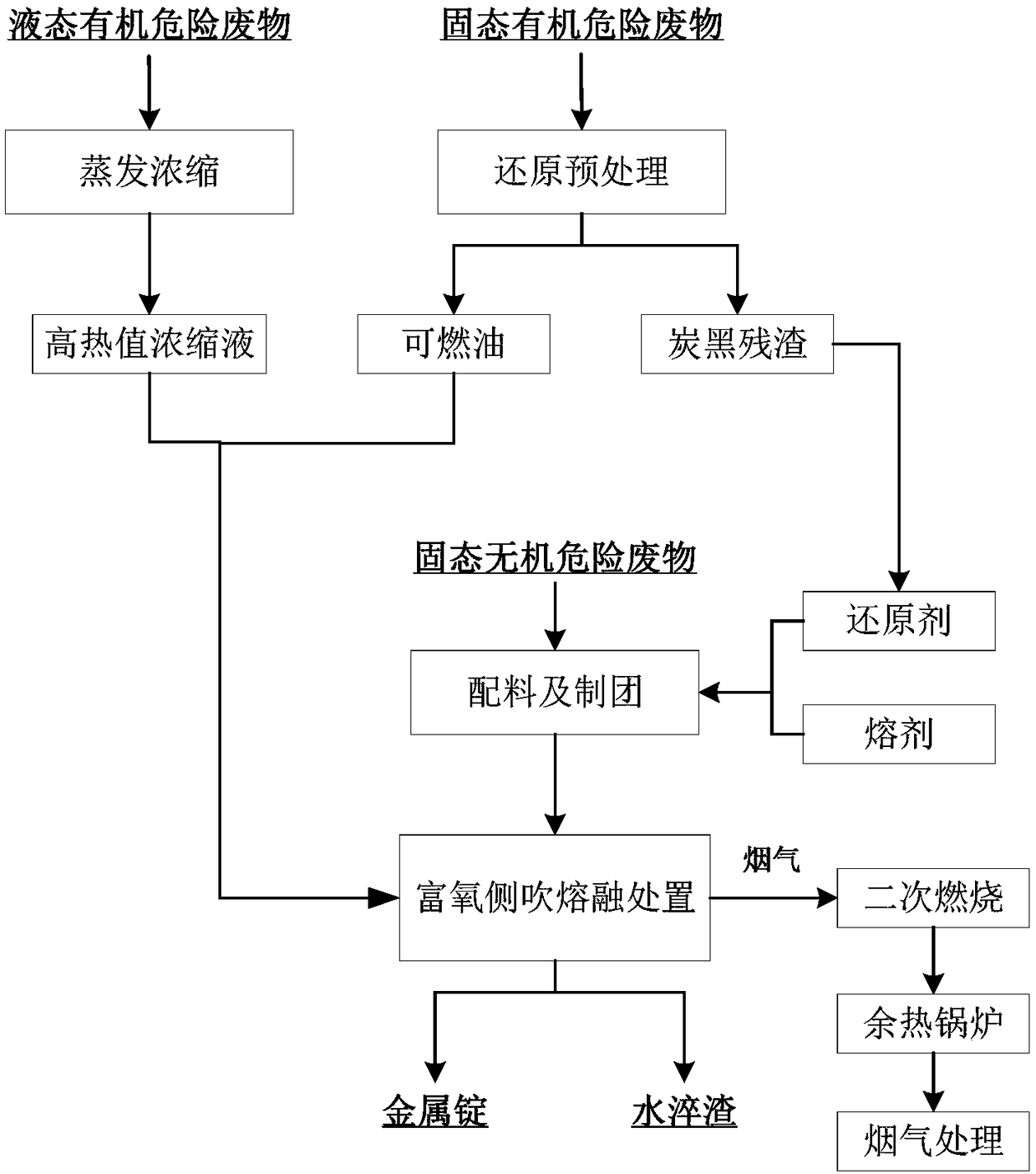

Hazardous waste melting disposal method

ActiveCN108380642AInhibitionEasy to handleWaste processingTransportation and packagingSlagResource recovery

The invention discloses a hazardous waste melting disposal method and belongs to the field of hazardous waste treatment. The hazardous waste melting disposal method can treat solid organic hazardous wastes, liquid organic hazardous waste and solid inorganic hazardous wastes at the same time. The hazardous waste melting disposal method mainly comprises the following steps of performing reduction pretreatment on the solid organic hazardous wastes, performing concentration pretreatment on the liquid organic hazardous wastes, performing burdening, mixing and briquetting on the solid inorganic hazardous wastes, a flux and a reducing agent to obtain a lump material, and transferring the lump material and an intermediate product obtained in the pretreatment step into an oxygen-enriched side blownmelting disposal furnace together for melting disposal to obtain a crude metal ingot and a vitreous water-quenched slag product; and performing secondary combustion, heat recovery and flue gas purification on flue gas produced with melting disposal, and performing standardized discharge on the treated flue gas. The hazardous waste melting disposal method provided by the invention has the advantages of wide application range of raw materials and capability of thoroughly realizing safety disposal and resource recovery of the hazardous wastes.

Owner:ZHEJIANG SHENLIAN ENVIRONMENTAL PROTECTION GRP CO LTD

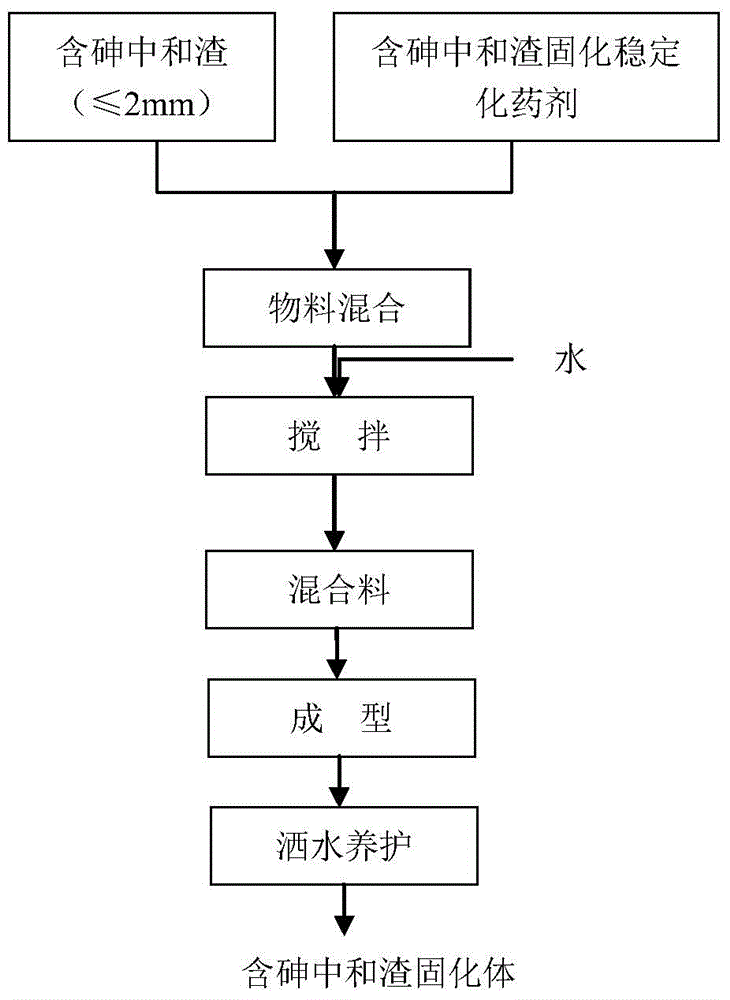

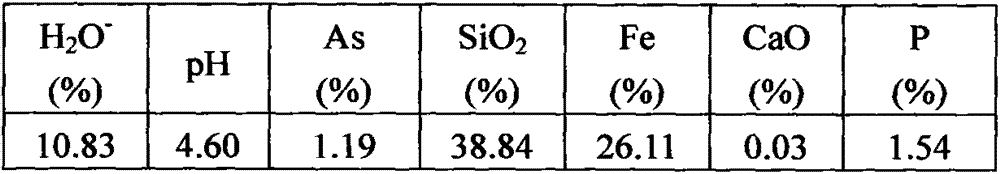

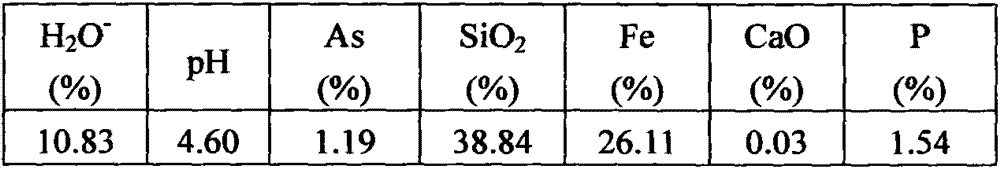

Arsenic-containing neutralization slag solidifying and stabilizing agent and method for solidifying and stabilizing arsenic-containing neutralization slag by using same

The invention relates to an arsenic-containing neutralization slag solidifying and stabilizing agent and a method for solidifying and stabilizing arsenic-containing neutralization slag by using the same, belonging to the technical field of hazardous waste treatment and disposition. The arsenic-containing neutralization slag solidifying and stabilizing agent is composed of a stabilizing agent A and a solidifying agent B, wherein the stabilizing agent A is composed of lime and ferrous sulfate, and the solidifying agent B is composed of cement and fly ash. The arsenic-containing neutralization slag solidifying and stabilizing agent is composed of the following components in percentage by weight: 40-60% of cement, 15-35% of fly ash, 5-10% of lime and 6-15% of ferrous sulfate. The arsenic-containing neutralization slag solidifying and stabilizing agent has favorable solidifying effect for the heavy metal arsenic in the neutralization slag, and the arsenic leaching rate after solidification can satisfy related requirements in GB5085.3-2007. All the raw materials are conventional raw materials and reagents which are cheap and accessible, so the agent cost is lower, thereby greatly lowering the disposition cost of the arsenic-containing neutralization slag.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

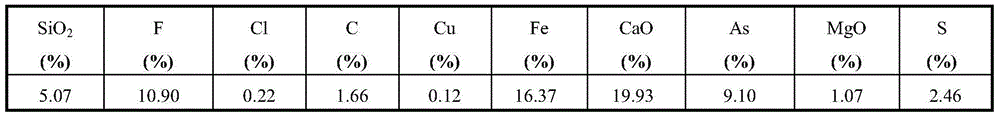

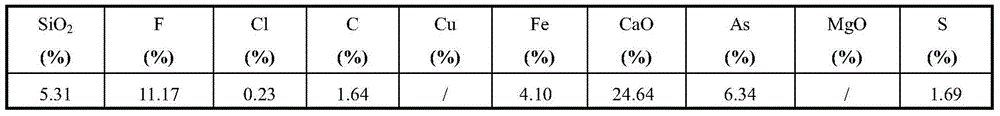

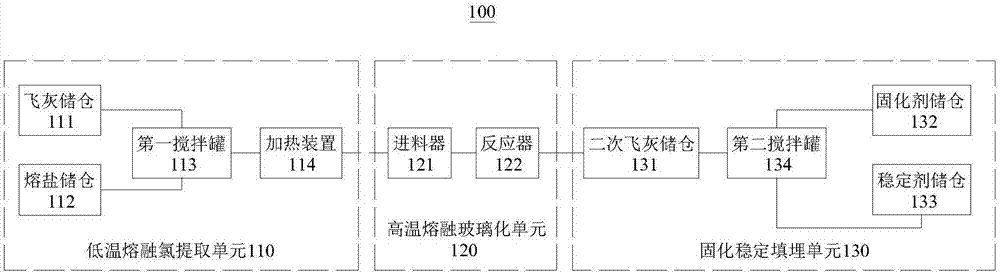

Waste incineration fly ash treatment and recycling method and device

InactiveCN107999520AAchieve permanent cureHigh degree of harmlessnessSolid waste disposalTransportation and packagingWaste treatmentHazardous waste treatment

The invention relates to the field of hazardous waste treatment and recycling, in particular to a waste incineration fly ash treatment and recycling method and device. According to the waste incineration fly ash treatment and recycling method, waste incineration fly ash is mixed with fused salt, and low-temperature fusing is conducted for 20-120 min in the environment at the temperature of 400-900DEG C; lower-layer solid products are mixed with a mineral auxiliary material, high-temperature fusing is conducted in the environment at the temperature of 1000-5000 DEG C, and then a vitrified formis obtained. By the adoption of the waste incineration fly ash treatment and recycling method, permanent solidification of heavy metal is achieved, recycling is also achieved, and good market prospect and application value are achieved. A low-temperature fusion chlorine extracting unit of the waste incineration fly ash treatment and recycling device comprises a flying ash storage bin, a fused salt storage bin, a first stirring tank, a heating device, a fused salt storage bin and a flying ash storage bin are connected with a first stirring tank. The first stirring tank is connected with a heating device. A high-temperature fusion vitrification unit comprises a feeding device and a reactor, wherein the feeding device is connected with the reactor. According to the waste incineration fly ashtreatment and recycling method and device, equipment is easy and convenient to use, and popularization is easy.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Harmless treatment method for cyanide-containing waste residues

InactiveCN106391674AReduce leaching concentrationTo achieve the purpose of harmless disposalTransportation and packagingSolid waste disposalAlkalinityCyanide

The invention relates to a harmless treatment method for cyanide-containing waste residues, and belongs to the technical field of hazardous waste treatment. The harmless treatment method for the cyanide-containing waste residues includes the steps of 1, adding water into the cyanide-containing waste residues and stirring to form slurry; 2, adding solid alkalis into the slurry and enabling the slurry to have strong alkalinity; 3, adding cyanide breaking agents in the stirring process; and 4, adding stabilizers and continuously adding curing agents after uniform stirring. According to the method, the operation is carried out at normal pressure and normal temperature, the technology is simple, the industrialized operation effect is stable, the cost of adopted chemicals is low, the removal rate of cyanides is high, and the hazardous waste landfill threshold standard is met after solidified bodies are leached.

Owner:云南大地绿坤环保科技有限公司

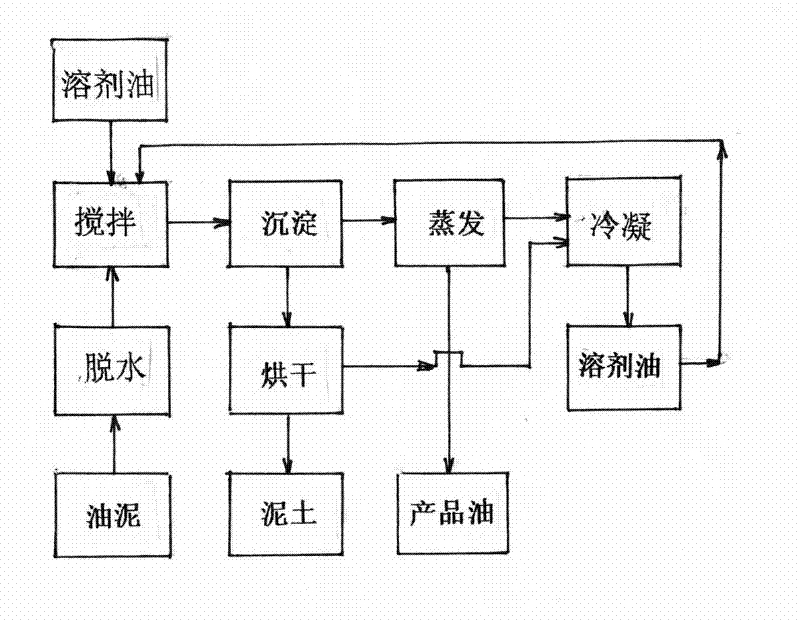

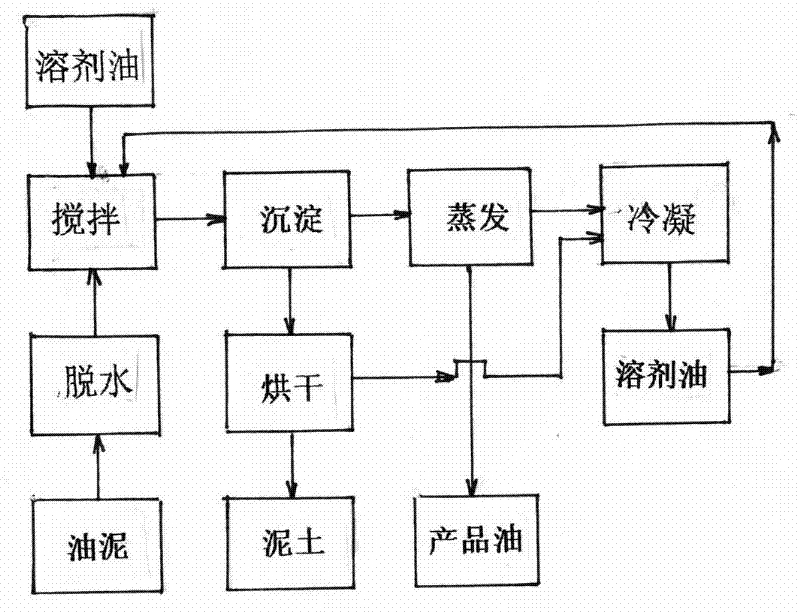

New technology for oil sludge processing

InactiveCN102381821AHigh recovery rateImprove qualityFatty oils/acids recovery from wasteSludge treatment by de-watering/drying/thickeningOil processingFiltration

The invention which belongs to the dangerous waste processing field relates to oil sludge processing and provides a new technology for the oil sludge processing. The technology is mainly characterized in that: after the oil sludge is processed with steps of dehydration, extraction, deposition, evaporation, extraction, pumping filtration, drying and the like, the content of oil in soil is 1% and accords with discharge standards, the total loss of solvent oil is about 1%, the recovery rate of product oil is more than 99%, and no waste gases and no wastewater are discharged. The technology whichhas the advantages of scientific method, mature process, simple equipment and large investment-output benefit and allows great technical problems, environmental protection problems and production safety problems which are difficult to solve for a long time in the dangerous waste processing field to be well solved deserves to be popularized and applied to broad petroleum enterprises, petroleum byproduct enterprises, and plant oil processing and oil product storage and transportation enterprises.

Owner:李廷安

System of innocent treatment for grease of oil

InactiveCN1872747AAchieve reductionHarmlessSludge treatment by oxidationWaste processingThermal energyOil sludge

This invention discloses a system for treating petroleum sludge produced during petroleum production and refinery. The system comprises a petroleum sludge pretreating system, a petroleum recovery system, a pyrolysis system, a off-gas treating system, a heat utilization system, and an automatic controlling system. The process comprises: pretreating the petroleum sludge, recovering crude oil, mixing, pyrolyzing, recovering the excess heat, treating the oss-gas, and discharging. The treated petroleum sludge does not contain petroleum or other harmful components, thus is environmentally friendly. The excess heat can be fully utilized, and the residue can be used as a pavement material.

Owner:张俊林

Low-temperature solidification of radioactive and hazardous wastes

Treatment of a radioactive waste stream is provided by adding sodium hydroxide (NaOH) and / or potassium hydroxide (KOH) together with a rapidly dissolving form of silica, e.g., fumed silica or fly ash. Alternatively, the fumed silica can be first dissolved in a NaOH / KOH solution, which is then combined with the waste solution. Adding a binder that can be a mixture of metakaolin (Al2O3.2SiO2), ground blast furnace slag, fly ash, or other additives. Adding an “enhancer” that can be composed of a group of additives that are used to further enhance the immobilization of heavy metals and key radionuclides such as 99Tc and 129I. An additional step can involve simple mixing of the binder with the activator and enhancer, which can occur in the final waste form container, or in a mixing vessel prior to pumping into the final waste form container, depending on the particular application.

Owner:P&T GLOBAL SOLUTIONS

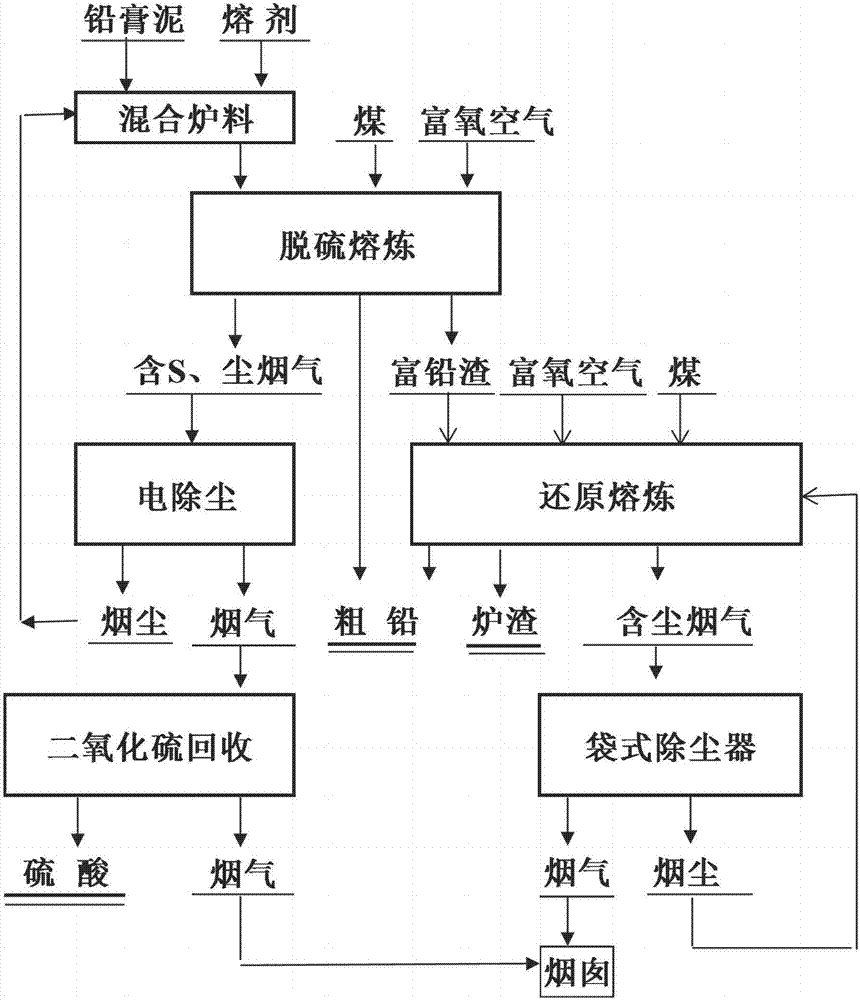

Waste lead-acid battery lead plaster molten bath smelting treatment method

ActiveCN107083488AAvoid pollutionLess investmentSulfur compoundsEnergy inputHigh concentrationElectrolysis

The invention discloses a waste lead-acid battery lead plaster molten bath smelting treatment method. Waste lead-acid battery lead plaster is treated by adopting an oxygen-enrichment molten bath smelting technology which replaces an existing production technology. The method is suitable for industrialized and large industrial production, and has the characteristics of being small in investment, high in efficiency and environmentally friendly and saving energy. Produced lead is returned to storage battery manufacturing after being subjected to pyrogenic or electrolytic refining, and circular economy is formed. Sulfuric acid can be prepared from produced high-concentration sulfur dioxide through a standard acid preparation process, the problem that environmental pollution is caused by low-concentration sulfur dioxide can be effectively solved, the lead content in produced slag does not exceed 2%, and the slag contains no ingredient which is dissolved in water and affects environment and does not need to be subjected to hazardous waste treatment.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD +1

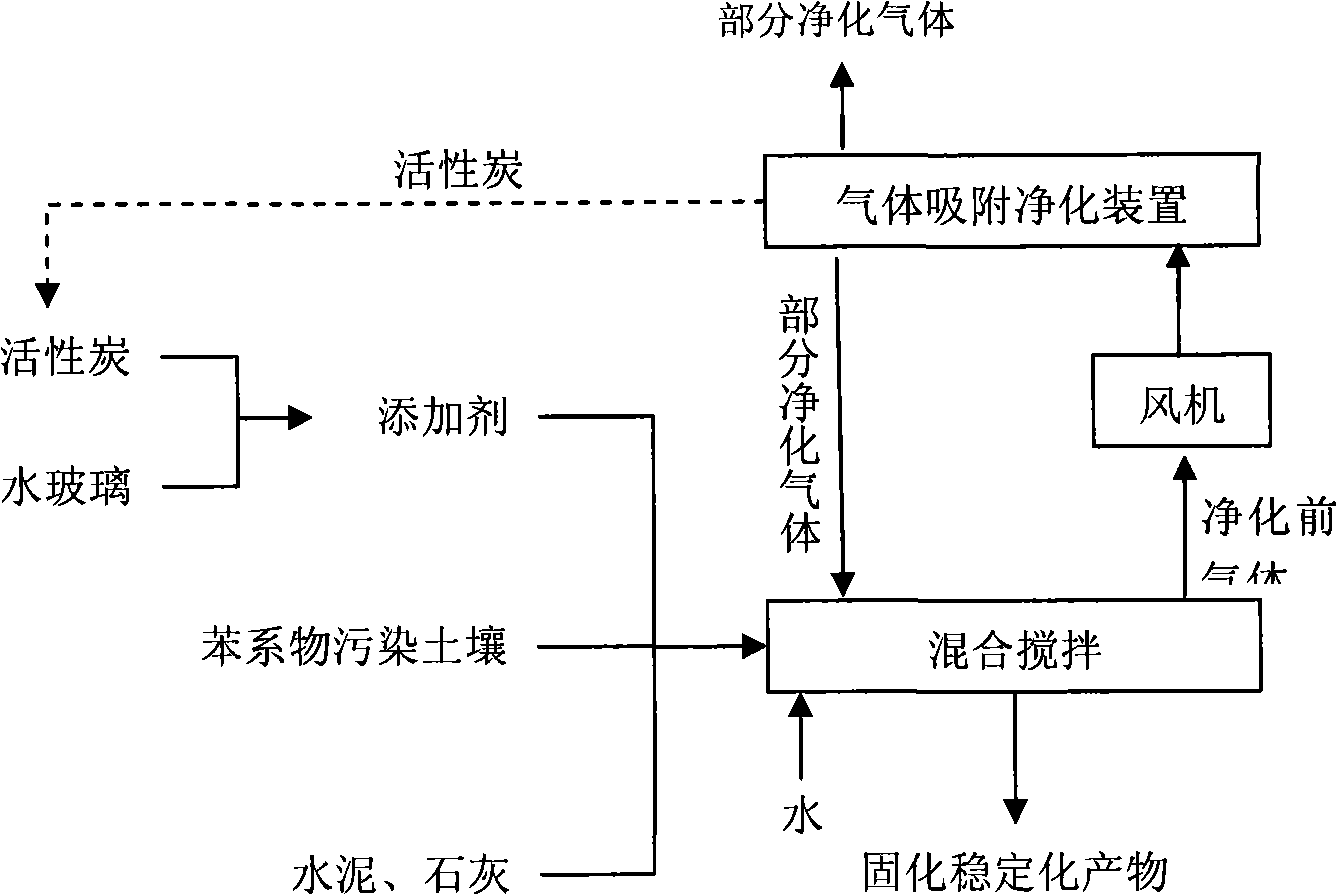

Reducibility solidification stabilization method of processing soil polluted by toxic organics

InactiveCN103143555AEasy to operateAdaptableContaminated soil reclamationMixed materialsHazardous waste treatment

The invention discloses a reducibility solidification stabilization method of processing soil polluted by toxic organics, and belongs to the technical fields of hazardous waste treatment and polluted field repair in environmental protection. The reducibility solidification stabilization method of the processing the soil polluted by the toxic organics comprises firstly, adding the soil which is polluted by the toxic organics, water, and a divalent molysite solution into a stirrer, stirring for 40 minutes-60 minutes; enabling the toxic organics to obtain degradation to the maximum extent; and adding inorganic grouting agent curing agents, continuously stirring until materials are evenly mixed, opening a discharge gate of the stirrer to discharge the evenly mixed materials; and at last, forming solidified body building blocks in a regular shape after carrying out a molding procedure on the mixed materials, conveying the building blocks into a maintenance workshop to carry out maintenance or directly placing the building blocks into packaging bags, and accomplishing reducibility solidification stabilization of the soil polluted by the toxic organics. The reducibility solidification stabilization method of the processing soil polluted by the toxic organics has the advantages of being high in a removal rate to the toxic organics, high in a solidification rate to residual pollutants, simple in operation, good in adaptability, and wide in use range.

Owner:TSINGHUA UNIV

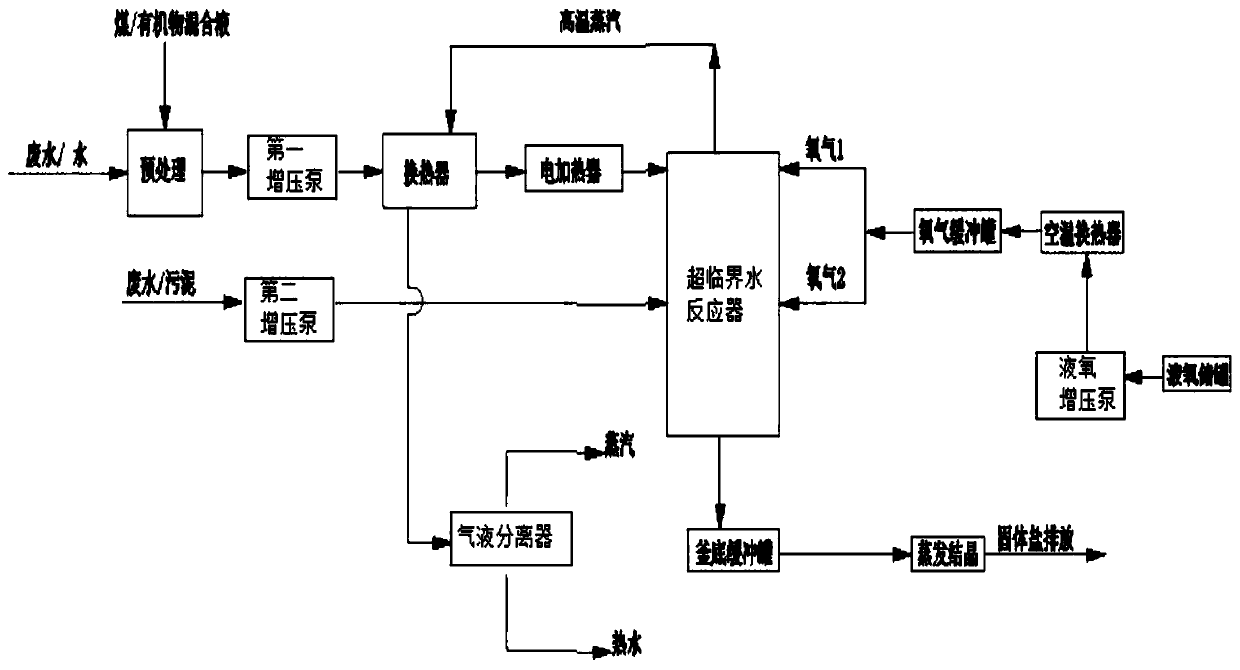

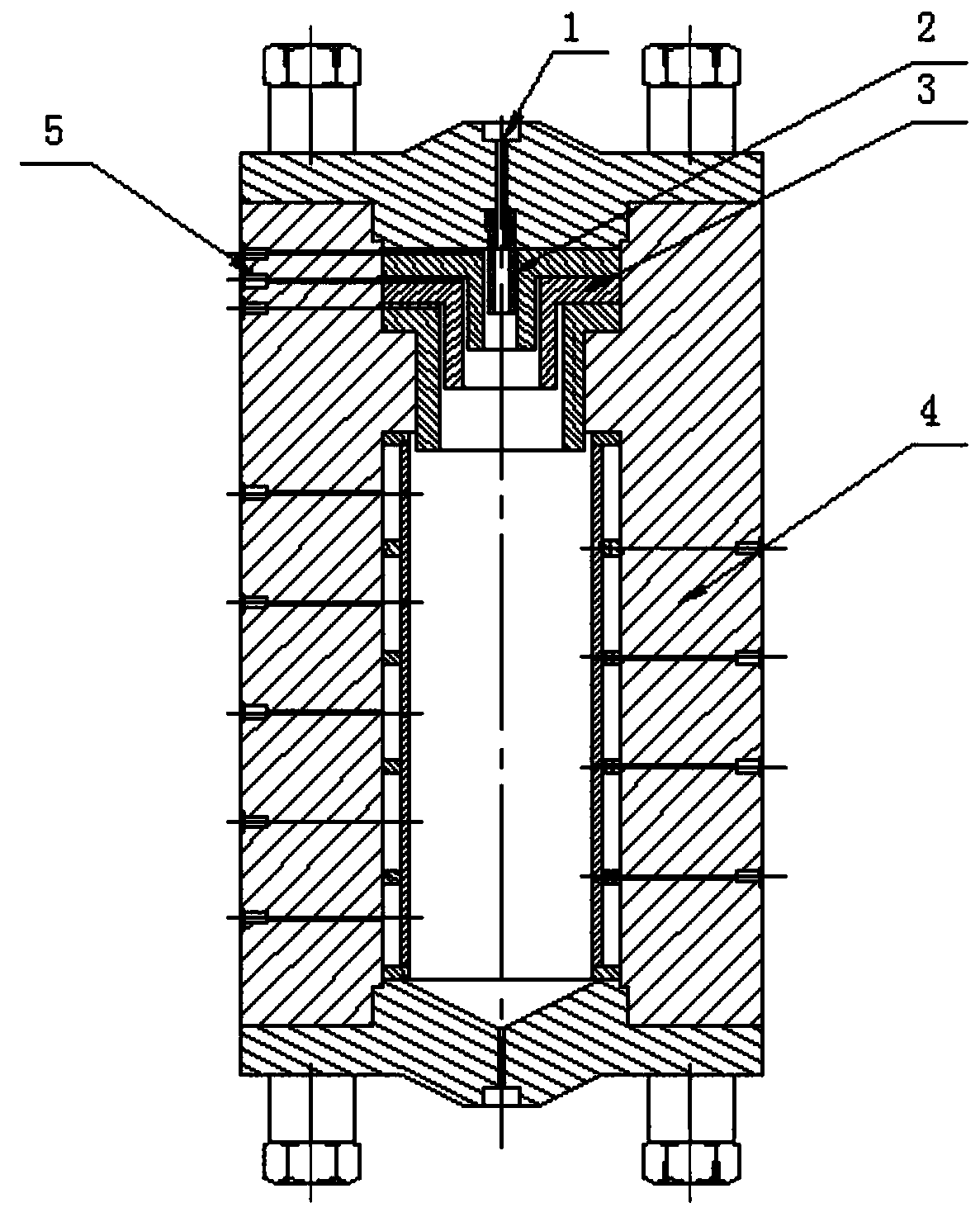

Wastewater and sludge treatment system and method using coal and organic matter as raw materials

PendingCN110510726ARealize clean utilizationNo secondary pollutionSludge treatment by oxidationSpecific water treatment objectivesHigh concentrationIndustrial waste water

The invention relates to a wastewater and sludge treatment system taking coal and organic matters as raw materials, the wastewater and sludge treatment system comprises a coal and organic matter mixedmaterial pretreatment unit; a liquid pressurizing unit; an oxygen supply unit; a supercritical water oxidation reaction unit; an evaporation crystallization unit; a heat recycling unit; a gas-liquidseparation unit and a waste heat utilization unit. The supercritical water oxidation reaction unit comprises a supercritical water oxidation reactor, wherein a liquid inlet of the supercritical wateroxidation reactor is connected with a coal and organic matter mixed liquid outlet of the coal and organic matter mixed material pretreatment unit, a first oxygen inlet is communicated into the supercritical water oxidation reactor after being merged with the liquid inlet, and a second oxygen inlet is communicated into the supercritical water oxidation reactor after being merged with a wastewater / sludge inlet. The waste water and sludge treatment system and process using coal and organic matters as raw materials have wide application range, high efficiency and zero pollution discharge, can realize energy and resource recovery at the same time, and are particularly suitable for industrial waste water, sludge, high-concentration organic waste water and hazardous waste treatment.

Owner:碧流天能(北京)科技股份有限公司

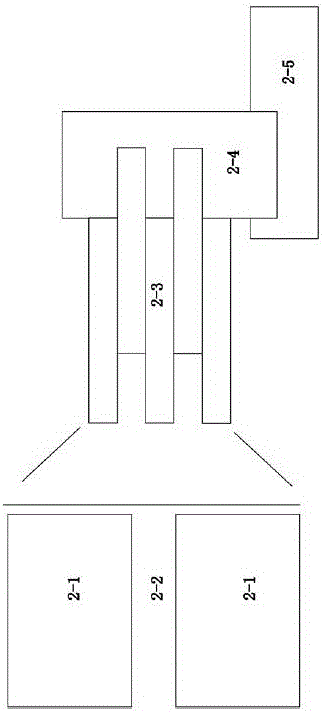

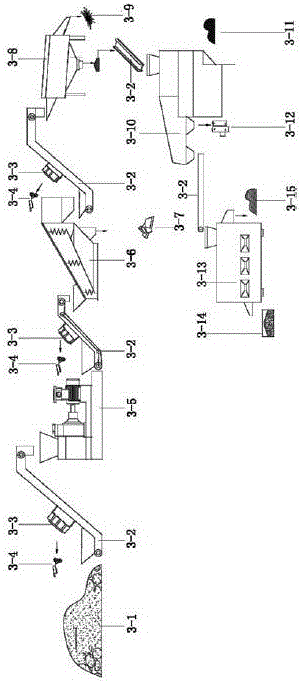

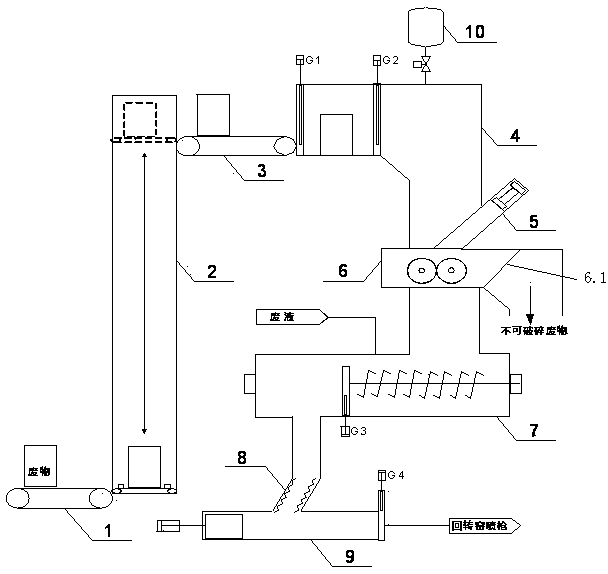

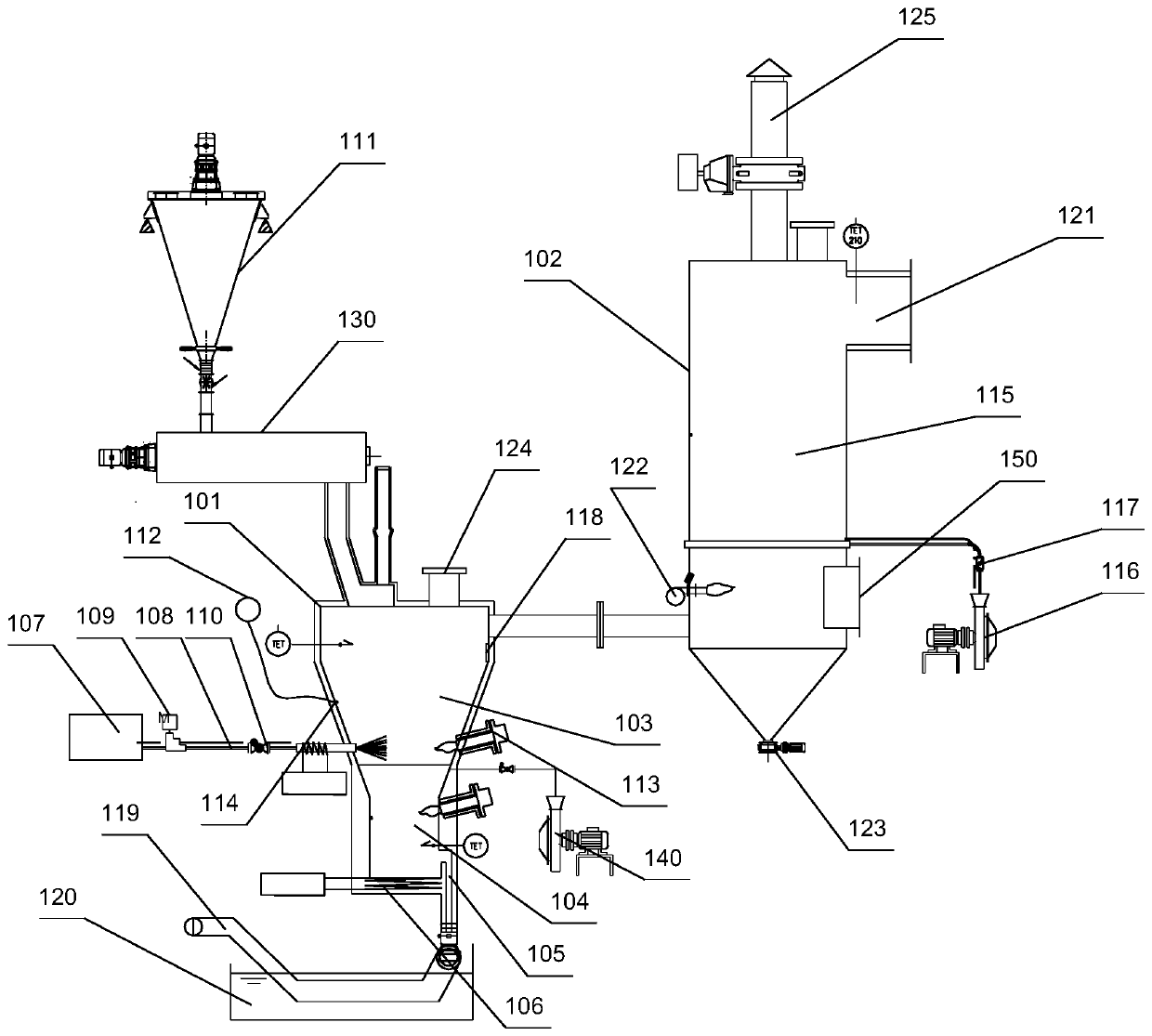

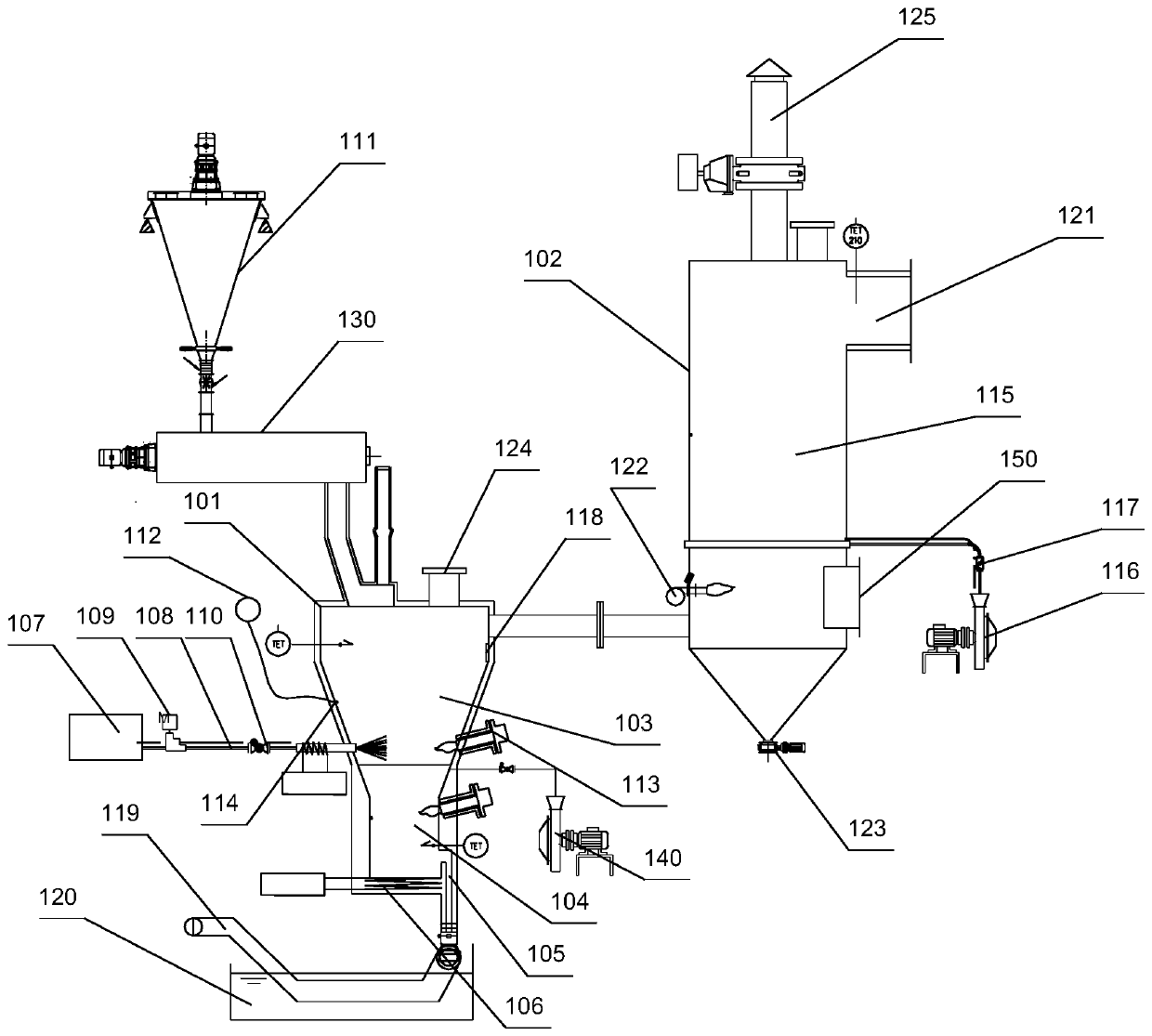

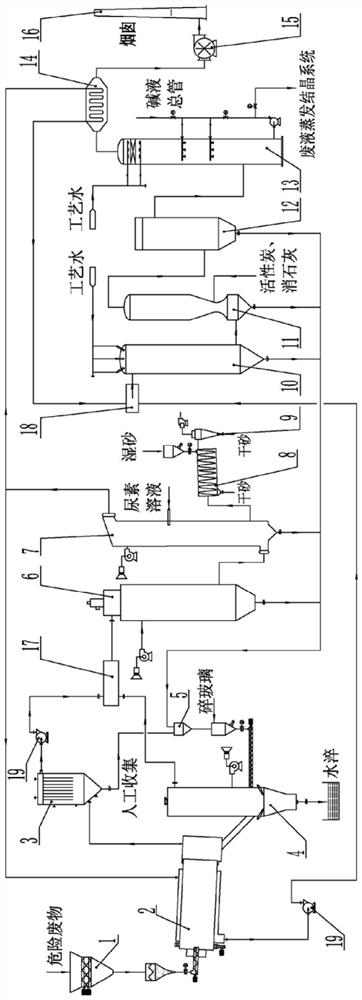

Crushing pretreatment system for hazardous wastes

InactiveCN104251490AIncrease real-time monitoringAdd nitrogen filling deviceIncinerator apparatusCrusherScrew conveyor

The invention discloses a crushing pretreatment system for hazardous wastes, which relates to the technical fields of environmental protection, waste crushing, hazardous waste treatment and the like. The crushing pretreatment system for hazardous wastes comprises a first roller conveyer, a vertically placed automatic elevator, a second roller conveyer, a chute, a feeder, a shear type crusher, a mixer, a screw conveyer and a plunger pump which are connected sequentially. A safe and explosion-proof tank is arranged over the chute. Compared with the prior art, the crushing pretreatment system for hazardous wastes is integrated with the functions of solid waste crushing, system sealing, powered conveying, system safety and explosion proofing and the like, and has the characteristics of safety, reliability, convenience and applicability.

Owner:TONGFANG ENVIRONMENT

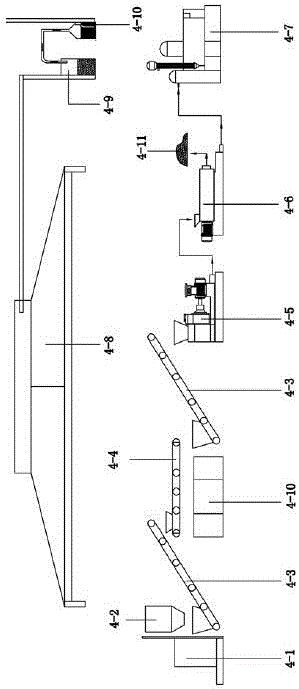

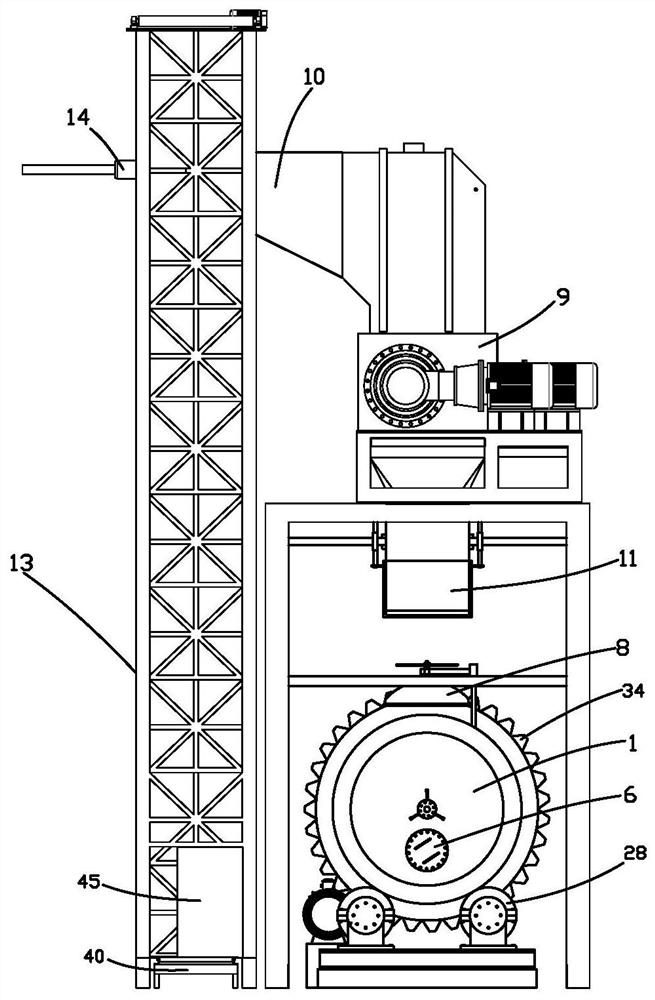

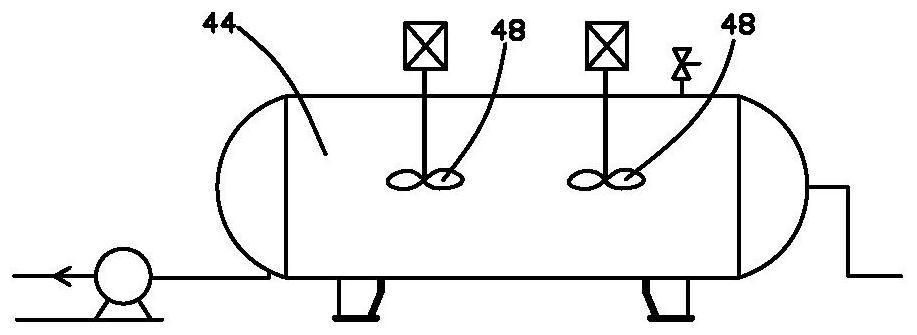

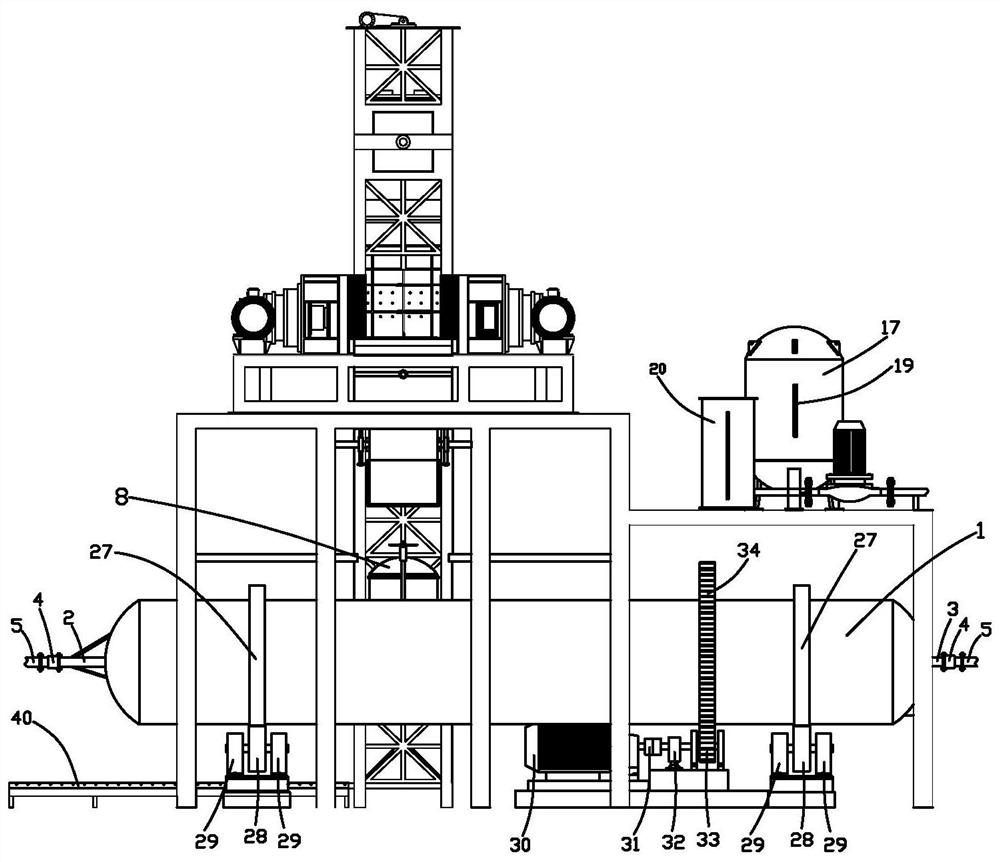

Barreled viscous colloidal hazardous waste treatment and recovery system device

ActiveCN113399426AHigh degree of automationImprove work efficiencySolid waste disposalCleaning using liquidsEngineeringEnvironmental engineering

The invention provides a barreled viscous colloidal hazardous waste treatment system device, which can be used for shredding and separating a material barrel and treating viscous colloidal hazardous waste into a flowable liquid chemical raw material, and comprises a cleaning roller, a roller supporting device and a roller driving device, and the cleaning roller is provided with a front-end central pipe and a rear-end central pipe and is respectively communicated with a water source and a steam source through a rotary joint and an external pipeline; the front end of the cleaning roller is provided with a solid roller sheet outlet and a sealing cover thereof, the rear end of the cleaning roller is provided with a liquid outlet, and a feeding hole and a sealing cover thereof are arranged on the wall of the cleaning roller; a shredding machine is arranged above the cleaning roller and comprises a barrel inlet; a detachable connecting pipe is arranged between the shredding machine and the feeding hole of the cleaning roller; an inner cavity of the shredding machine is communicated with a low-pressure nitrogen source, and a water mist spraying device is arranged above the inner cavity of the shredding machine; a material barrel lifting device is arranged from the ground to the barrel inlet of the shredding machine, and the material barrel lifting device is provided with a barrel pushing device at the barrel inlet of the shredding machine; and the viscous colloidal hazardous waste is thoroughly treated, and the operation efficiency is high.

Owner:绍兴凤登环保有限公司

Preparation and application method of heavy metal sludge stabilizer

The invention relates to a preparation and application method of a heavy metal sludge stabilizer. The preparation and application method of the heavy metal sludge stabilizer belongs to the technical field of dangerous waste treatment, and comprises the following steps of (1) a preparation method: according to the mass percent, preparing 10 to 50 percent of aggregate, 5 to 40 percent of precipitator, and 1 to 10 percent of additive; (2) an application method: stirring heavy metal sludge and water into slurry, meanwhile, using inorganic acid or inorganic base for adjusting pH of the slurry, adding 5 percent to 20 percent of stabilizer of the step (1), uniformly stirring, then adding a curing agent, and detecting after maintaining. According to the method provided by the invention, the preparation of the stabilizer and the treatment of the sludge are operated at normal temperature and normal pressure, the process is simple, a solidified body leaching agent meets a dangerous waste landfilling admission standard (GB 18598-2001), and an operation effect is stable; the aggregate of the stabilizer is industrial solid waste, the waste is used for treating the waste, the cost is low, and the aims of minimization, reclamation and harmlessness of the dangerous waste treatment are truly achieved.

Owner:云南大地绿坤环保科技有限公司

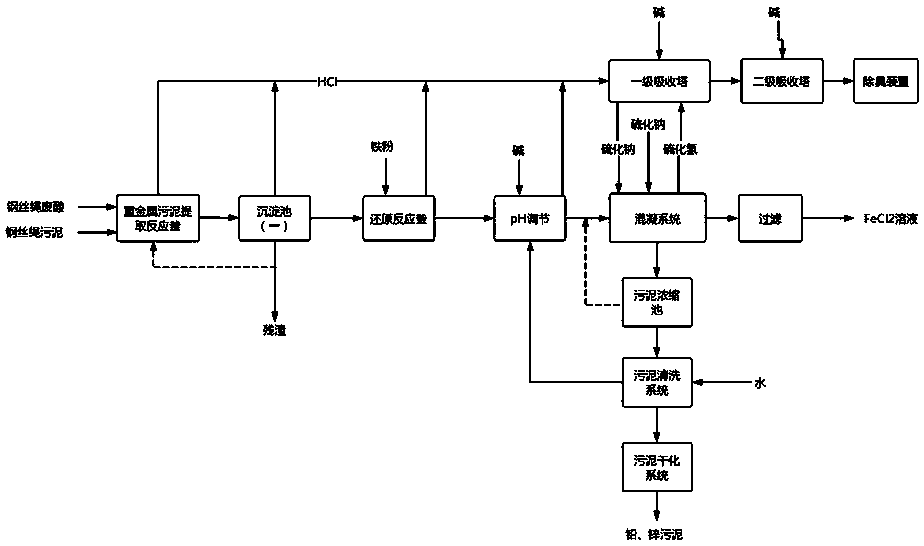

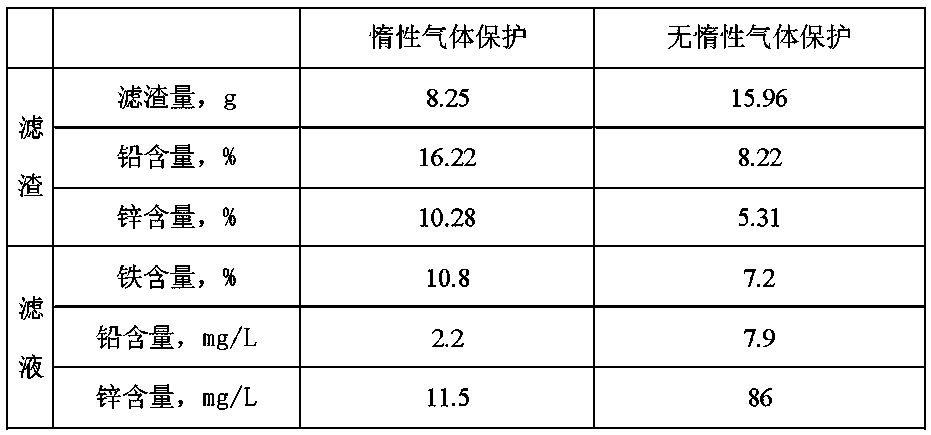

Waste acid recovery treatment method for sludge generated in steel wire rope plant

InactiveCN108383272AAchieve separationReduce usageSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeAcid washing

The invention discloses a waste acid recovery treatment method for sludge generated in a steel wire rope plant. Steel wire rope acid washing waste acid is used for leaching metal irons of iron, lead and zinc in the steel wire rope sludge; sludge residue is conveyed to a hazardous waste treatment center to be treated; iron powder is used for reducing ferric ions into ferrous ions; through sulfide precipitation, lead and zinc ions are precipitated; the generated lead and zinc precipitates are cleaned and dried; the material can be used as a lead and zinc melting raw material due to the lead andzinc abundance; the purified ferrous chloride solution can be sold as production raw materials of polymeric ferric chloride flocculant; hydrogen sulfide gas generated in the reaction process and unorganized emission hydrogen sulfide gas are treated by two-stages of filling material adsorption towers and an active carbon deodorization device, the discharge is performed after the contaminant discharge standard is met; the generated sulfide is reused in a coagulation precipitation system. The method provided by the invention solves the problems that the sludge and waste acid generated in the steel wire rope production process of high toxicity, great harm, high yield, difficult processing and secondary pollution generation and the like.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Vertical type hazardous waste treatment device

InactiveCN109915839ASimple structureEasy to operateIncinerator apparatusLiquid wasteCombustion chamber

The invention discloses a vertical type hazardous waste treatment device. The device mainly solves the problems that in the prior art, the existing incineration treatment temperature cannot reach thecombustion requirement, toxic and harmful substances are easily generated, such as dioxin, the occupied area is large, the size is large, and the installation is complex. The vertical type hazardous waste treatment device comprises a first furnace body and a second furnace body which are communicating with each other, a solid waste material inlet is formed in the top of the first furnace body, onecombustion chamber and a slag melting chamber which are communicating with each other are sequentially arranged in the first furnace body below the solid waste inlet, a heating device is arranged atthe outer bottom of the slag chamber, the vertical type hazardous waste treatment device further comprises a liquid waste storage pool and an electromagnetic induction heating pipe, the liquid waste storage pool is communicating with one combustion chamber through an electromagnetic induction heating pipe; and a pump and an electromagnetic switch valve are arranged on the electromagnetic inductionheating pipe. The invention has the advantages that the purposes of being small in occupied area, easy to install, efficient in treatment and free of harmful gas are achieved.

Owner:WUHAN HUALIN TECH

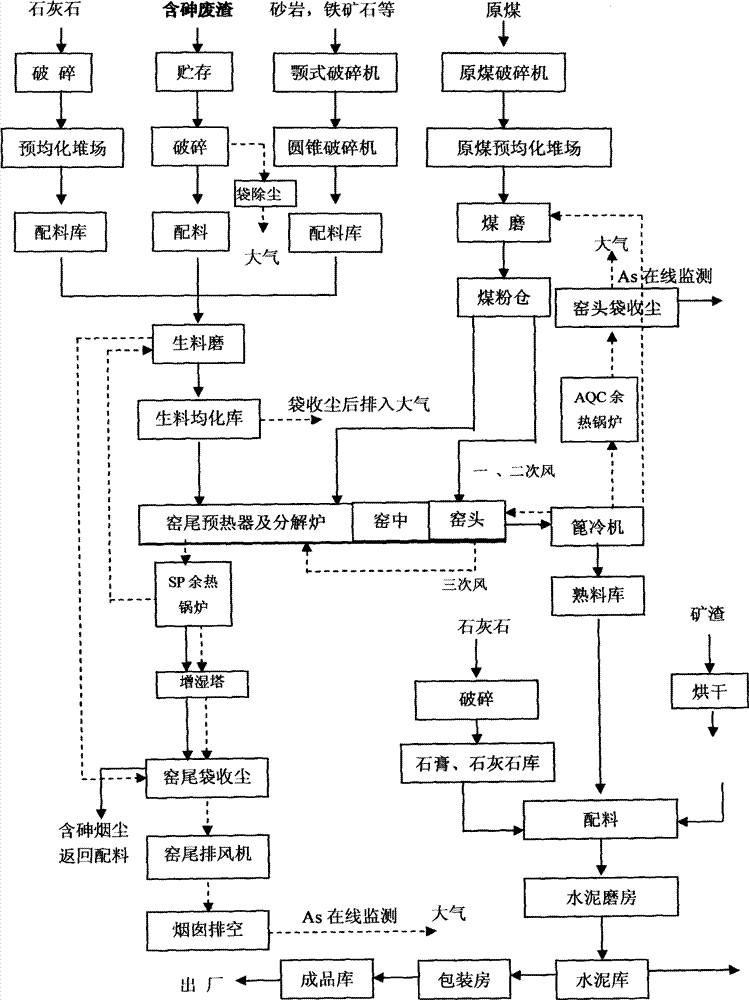

Method for treating arsenic-containing waste residues by using cement rotary kiln

ActiveCN103755169AReduced activityRealize harmless disposalCement productionResource utilizationEconomic benefits

The invention discloses a method for treating arsenic-containing waste residues by using a cement rotary kiln, belonging to the field of solid waste and hazardous waste treatment and disposal technologies. The method comprises the steps of (1) mixing the arsenic-containing waste residues with a cement raw material to obtain a raw material for preparing a cement clinker, wherein the arsenic-containing waste residues account for 0.6-4.0% of the weight of the raw material; and (2) putting the raw material obtained by mixing in the step (1) into the cement rotary kiln to prepare an arsenic-containing cement clinker. The method disclosed by the invention has the advantages that the arsenic-containing waste residues are treated through the existing dry method cement rotary kiln to facilitate harmless and resource utilization of the arsenic-containing waste residues, potential environmental pollution risks and secondary pollution during harmless treatment of the arsenic-containing waste residues are effectively controlled, and the environmental benefit and economic benefit are obvious.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

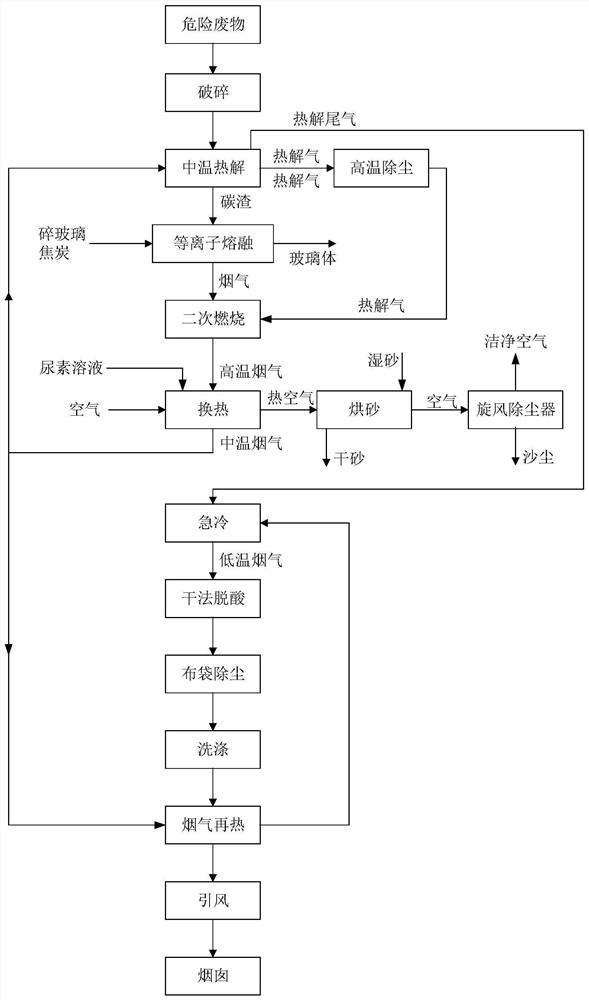

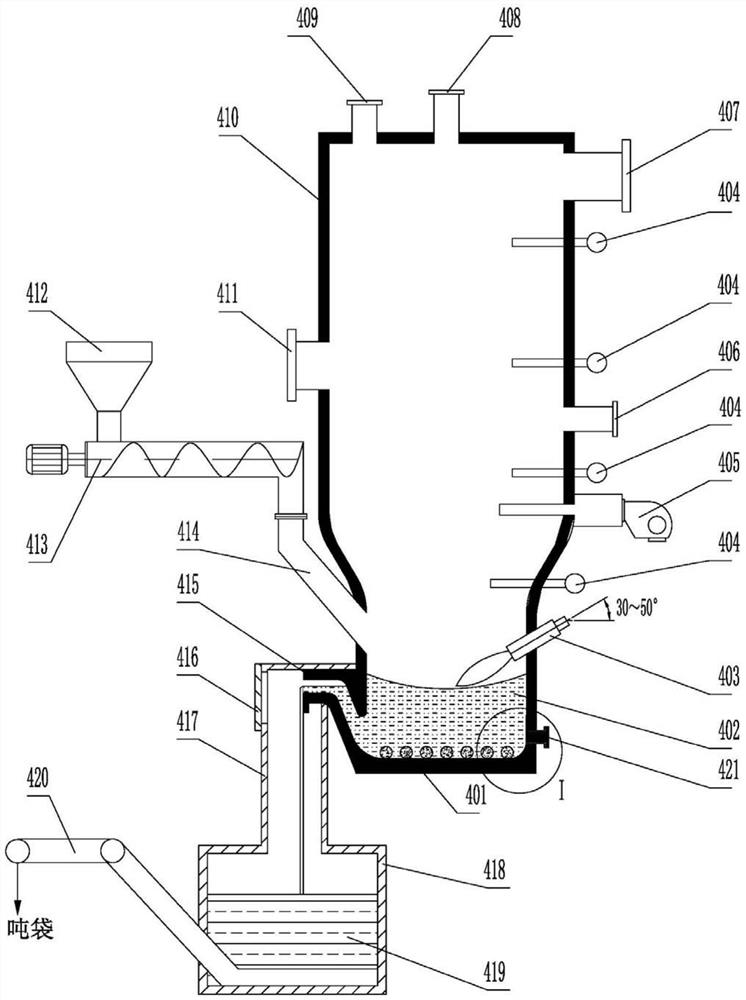

Hazardous waste treatment system and method based on medium-temperature pyrolysis and plasma high-temperature melting

ActiveCN113182311AHigh degree of harmlessnessHarmlessSolid waste disposalTransportation and packagingCombustion chamberDust control

The invention provides a hazardous waste treatment system and method based on medium-temperature pyrolysis and plasma high-temperature melting. The problems that existing hazardous waste incineration treatment is low in harmless degree, pyrolysis treatment is not thorough, and plasma melting treatment cost is high are solved. According to the system and method, hazardous waste is broken and then subjected to medium-temperature pyrolysis in an oxygen-deficient environment, pyrolytic carbon residues form harmless glass bodies through a plasma melting furnace, pyrolysis gas and smoke generated by plasma melting enter a combustion chamber to be subjected to secondary combustion, high-temperature smoke obtained after secondary combustion exchanges heat with air and then is cooled into medium-temperature smoke, the medium-temperature smoke is divided into two parts, one path enters a pyrolyzing furnace to heat materials, the other path enters a flue gas reheater to exchange heat, pyrolysis tail gas obtained after the materials in the pyrolyzing furnace are heated is mixed with flue gas obtained after heat exchange of the flue gas reheater, and after mixing, quenching cooling, dry-process deacidification, cloth bag dust removal, washing and reheating are conducted in sequence, and then a mixture is sent to a chimney to be discharged through an induced draft fan; and air is heated after heat exchange, is used as a heat source of a sand dryer, and is discharged after sand drying and cyclone dust removal.

Owner:ACADEMY OF AEROSPACE PROPULSION TECH +1

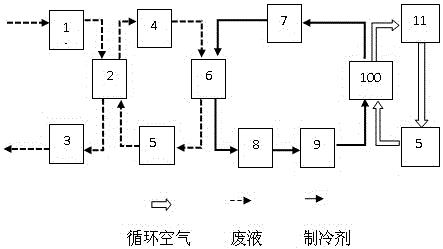

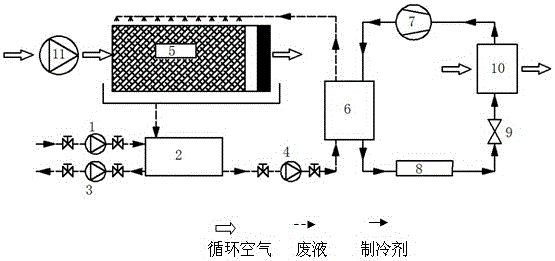

Industrial liquid hazardous waste treatment system

ActiveCN105776377AReduce processingReduce energy consumptionDispersed particle separationWater/sewage treatment by heatingAir cycleRefrigeration compressor

The invention provides an industrial liquid hazardous waste treatment system.The industrial liquid hazardous waste treatment system is composed of an air circulating treatment microsystem, a waste liquid concentrating treatment microsystem and a heat pump circulating microsystem, wherein the air circulating treatment microsystem is composed of a fan, an air and waste liquid concentrating treater and an air / refrigerant heat exchanger; the waste liquid concentrating treatment microsystem is composed of a waste liquid storage box, a waste liquid circulating pump, a waste liquid draining pump, a waste liquid inputting pump, a waste liquid / refrigerant heat exchanger and the air and waste liquid concentrating treater; the heat pump circulating microsystem is composed of a refrigeration compressor, a thermostatic expansion valve, the waste liquid / refrigerant heat exchanger, the air / refrigerant heat exchanger and a radiator.Industrial liquid hazardous waste high in water content is concentrated through a low-temperature evaporation technology, and the outsourcing handling capacity of the industrial liquid hazardous waste can be reduced by 70% or more.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

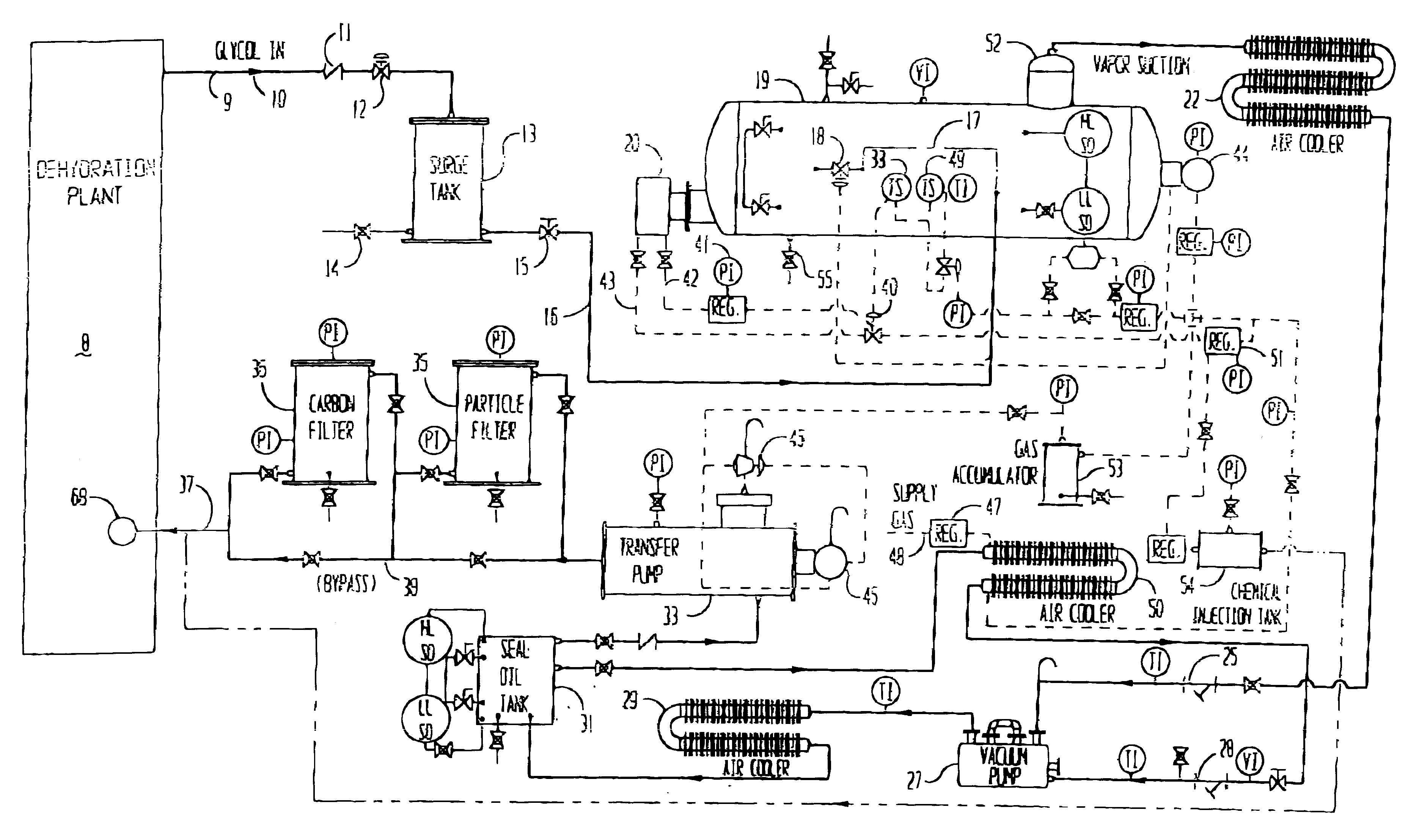

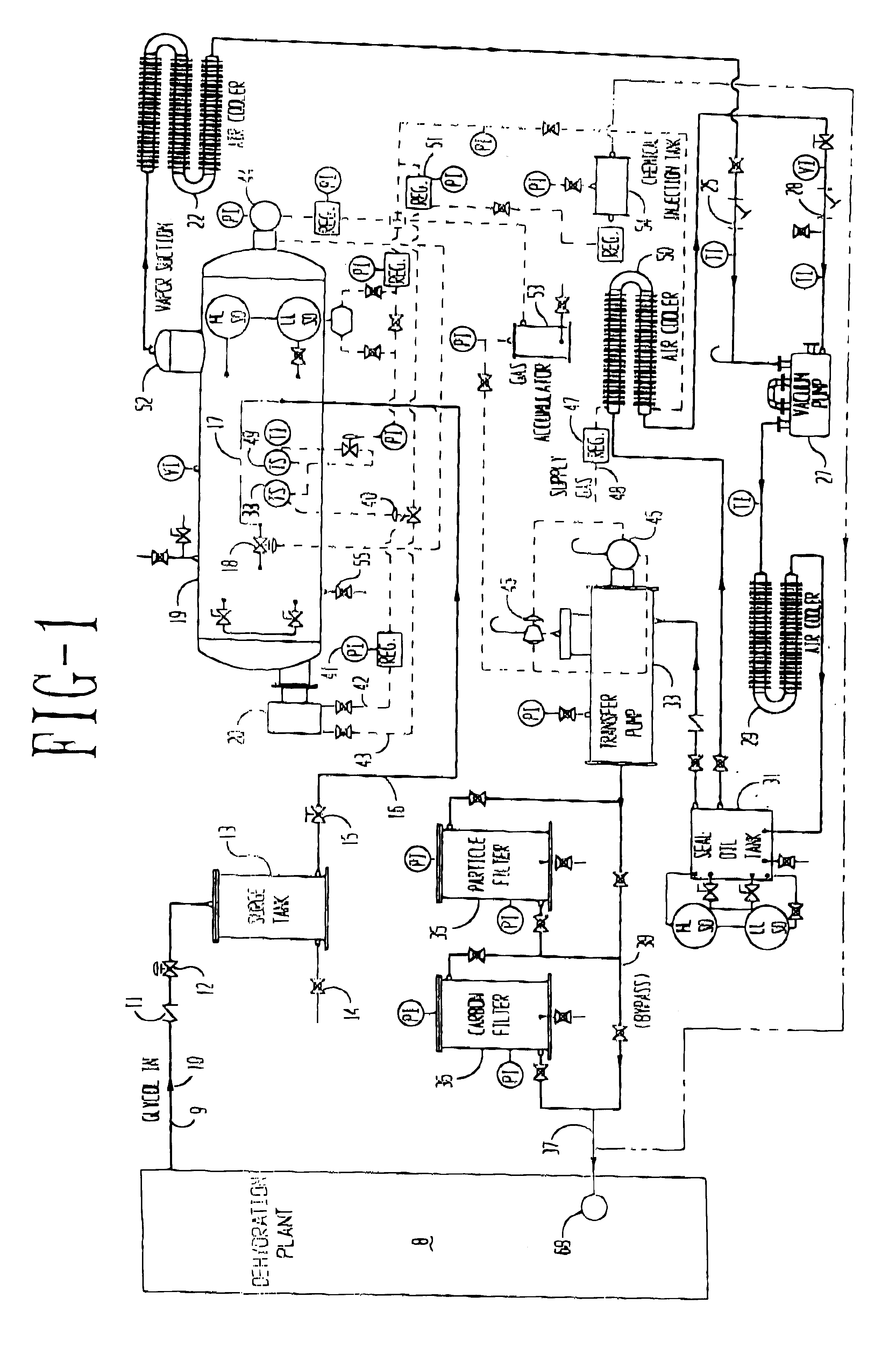

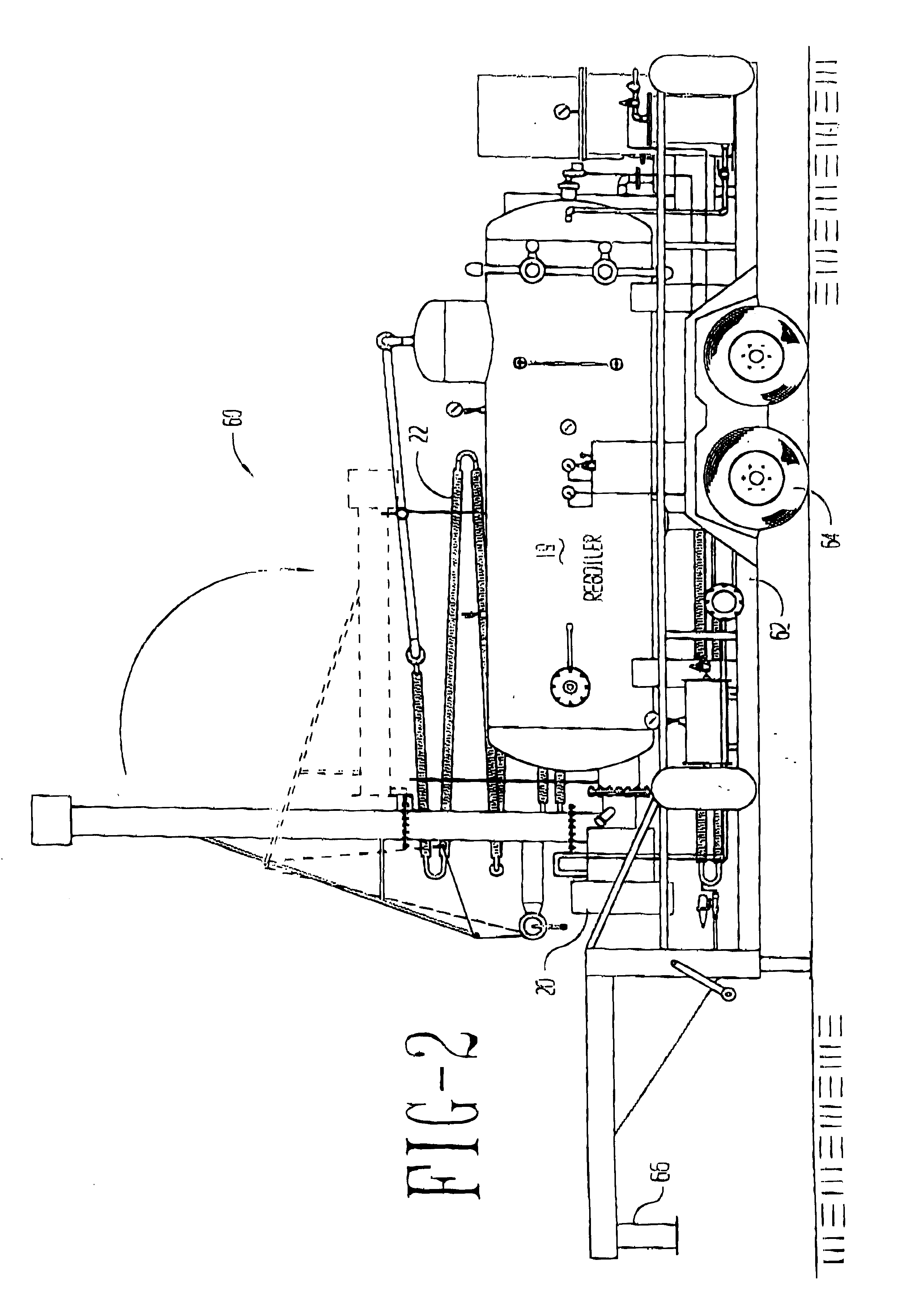

Hazardous waste disposal

InactiveUS6773554B1Reduce amountEliminate riskVapor condensationVacuum distillation separationGlycol degradationNatural gas dehydration

Contaminated glycol is refined by vacuum distillation. Specifically the evaporator is heated to a temperature below the degradation temperature of the glycol. The vacuum is used to bring the flashpoint down sufficiently so that glycol evaporates or flashes at that temperature. The glycol is condensed and filtered through activated granular carbon. The principal use of refining the glycol is to refine the triethylene glycol used in natural gas dehydration plants. For such purposes the equipment is mounted upon a trailer to be taken to the plant for cleaning glycol. In such instance, in addition to refining the glycol, a cleaning agent (which contains a degreaser) is added to the refined glycol. The glycol is refined while the natural gas dehydration plant is in normal operation and therefore it is not necessary to stop the natural gas dehydration plant for refining the glycol used therein. In addition, by the addition of the cleaning agent, the dehydrating plant equipment may be cleansed of hazardous waste. The hazardous waste will be separated and concentrated in the distillation. Therefore, the transportation of the hazardous waste to a disposal location is simplified.

Owner:MOORE JR JOHN W

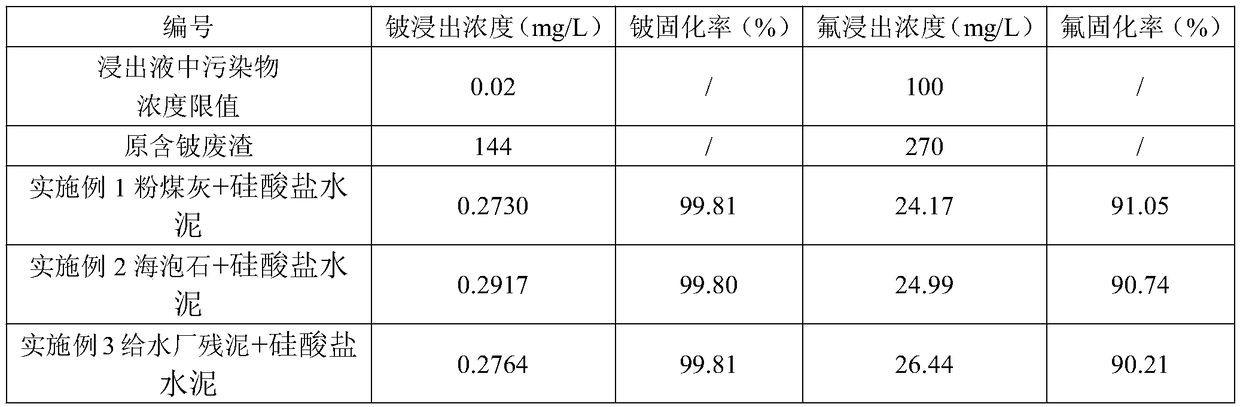

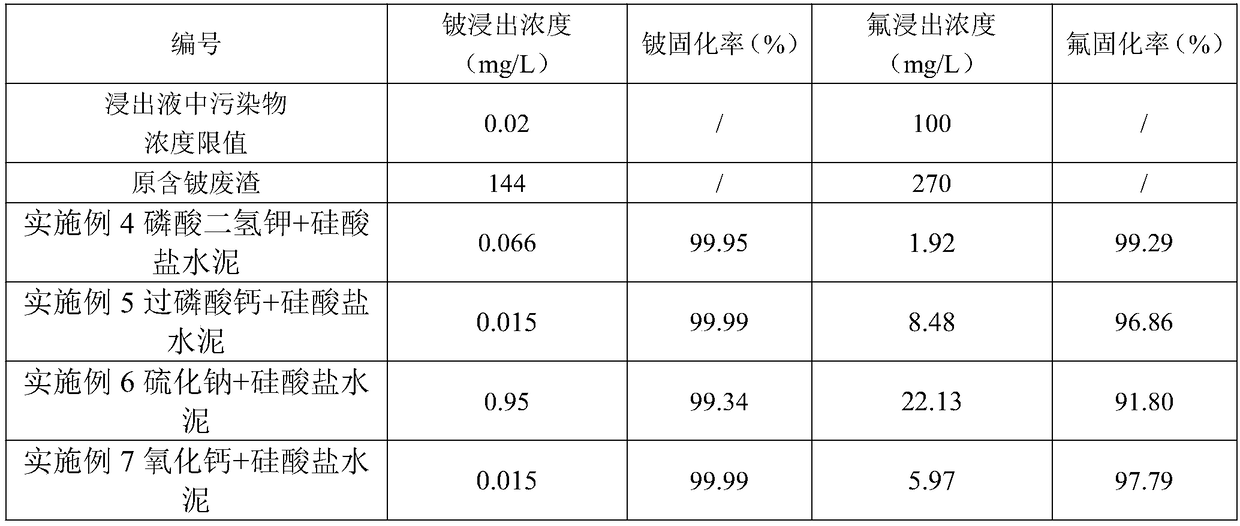

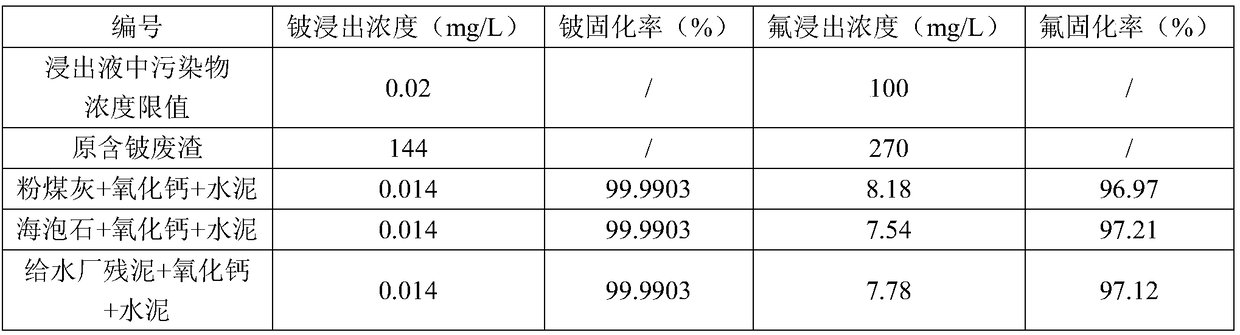

Stabilizing agentia used for treating waste residue containing beryllium and preparation method and application thereof

InactiveCN109453493AReduce leaching concentrationAchieve transformationTransportation and packagingSolid waste disposalMonopotassium phosphateHazardous waste treatment

The invention relates to a stabilizing agentia used for treating waste residue containing beryllium and a preparation method and application thereof and belongs to the technical field of hazardous waste treatment. The stabilizing agentia used for treating the waste residue containing beryllium comprises the following components including, by mass part, 15-25 parts of conditioning agent, 5-15 partsof additive and 60-80 parts of curing agent, wherein the conditioning agent is coal ash or sepiolite or remnant mud of a water supply factory, and the additive is monopotassium phosphate, or calciumsuperphosphate, or sodium sulfide or calcium oxide. The stabilizing agentia used for treating the waste residue containing beryllium can remarkably stabilize and cure beryllium and fluorine in the waste residue containing beryllium, the leaching-out concentration of beryllium and fluorine in the waste residue containing beryllium is reduced to the greatest extent, the curing rate reaches over 99%,the leaching-out concentration of beryllium is lower than the leaching-out toxicity identifying standard value, and the waste residue containing beryllium is converted from the hazardous waste into common solid waste. The stabilizing agentia is low in cost, the preparation method and the using method are simple, and the stabilizing agentia is beneficial for being applied and popularized.

Owner:湖南省环境保护科学研究院

Incinerating and proportioning method for hazardous waste

InactiveCN109708114AGuaranteed stabilityImprove incineration efficiencyIncinerator apparatusCorrelation coefficientDegree of association

The invention relates to the field of hazardous waste treatment and discloses an incinerating and proportioning method for hazardous wastes for guaranteeing the stability of an incinerating process and improving the incinerating efficiency and quality. The incinerating and proportioning method comprises the following steps: S1, constructing an index matrix based on indexes affecting incineration of hazardous wastes, wherein the indexes affecting incineration of hazardous waste comprise unit volume hazardous waste heat value, moisture content, corrosivity and toxicity; S2, standardizing the index matrix; S3, determining a reference sequence according to the standardized matrix; S4, calculating correlation coefficients between the indexes and the reference sequence in various hazardous wastes; S5, calculating the degree of association of various hazardous wastes based on the correlation coefficient; S6, calculating proportioning weights of various hazardous wastes based on the correlation coefficient obtained in the step 5; and S7, incinerating and proportioning the hazardous wastes based on the proportioning weights of the hazardous wastes. The incinerating and proportioning methodfor hazardous wastes provided by the invention is suitable for incinerating and proportioning the hazardous wastes.

Owner:SICHUAN UNIV +1

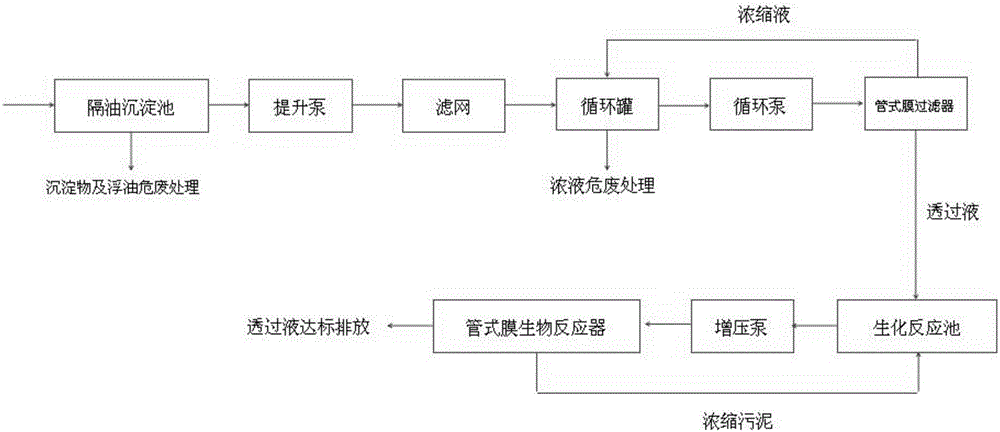

Waste cutting fluid treatment process

InactiveCN105906153AEasy to handleImprove effluent qualityTreatment involving filtrationTreatment with aerobic and anaerobic processesWater qualityMembrane bioreactor

The invention belongs to the technical field of cutting fluid, in particular to a waste cutting fluid treatment process. The process comprises the following steps that 1, waste cutting fluid enters a grease-separation sedimentation tank; 2, after being filtered through a filter screen, outlet water of the grease-separation sedimentation tank enters a circulation tank; 3, outlet water of the circulation tank enters a tubular membrane filter, permeation liquid enters a biochemical reaction tank, concentrated liquor flows back into the circulation tank, and after being concentrated, the concentrated liquor is drained for hazardous waste treatment; 4, outlet water of the biochemical reaction tank enters a tubular membrane bioreactor for mud-water separation, the permeation liquid is drained, and the concentrated liquor flows back into the biochemical reaction tank. The waste cutting fluid treatment process is simple in process, convenient to operate and high in quality of outlet water; according to the process, the tubular membrane technology is adopted, and the process is easy to operate, reliable in operation, high in treatment efficiency, stable in quality of outlet water and low in treatment cost.

Owner:TIANJIN HIPURE MEMBRANE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com