Method for treating arsenic-containing waste residues by using cement rotary kiln

A cement rotary kiln and waste slag technology is applied in the fields of harmless arsenic-containing waste slag, disposal of arsenic-containing waste slag, and resource utilization. Secondary pollution, health protection, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

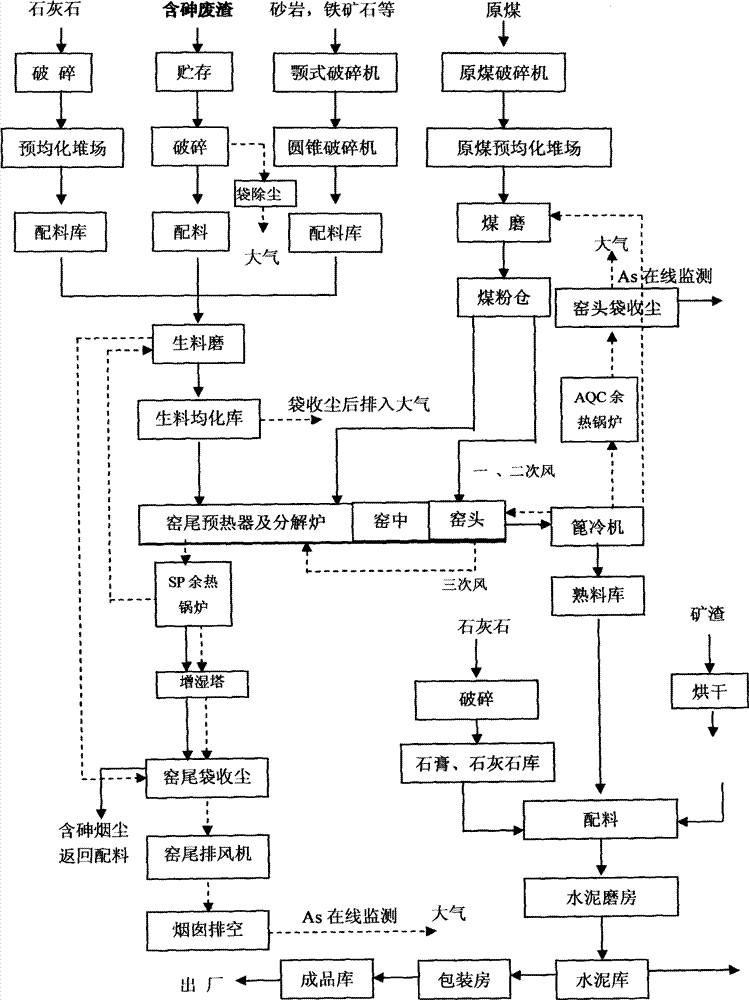

Image

Examples

Embodiment 1

[0030] Example 1: The method of treating arsenic waste residue by cement rotary kiln:

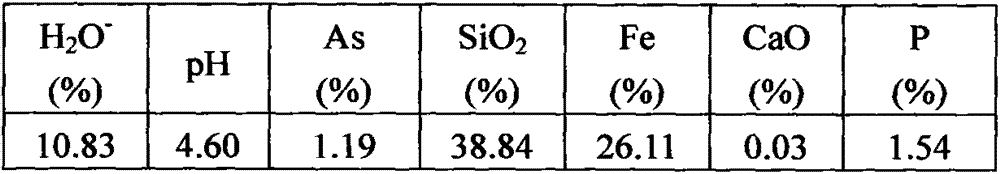

[0031] Raw material 1: arsenic-containing waste residue

[0032] The main components of arsenic-containing waste residue are shown in the table below:

[0033]

[0034] Raw material 2: limestone 81.92%, sandstone 8.65%, pyrite slag 2.23%, laterite 3.60%, phosphorus slag 3.0%.

Embodiment 2

[0037] Example 2: The method of treating arsenic waste residue by cement rotary kiln:

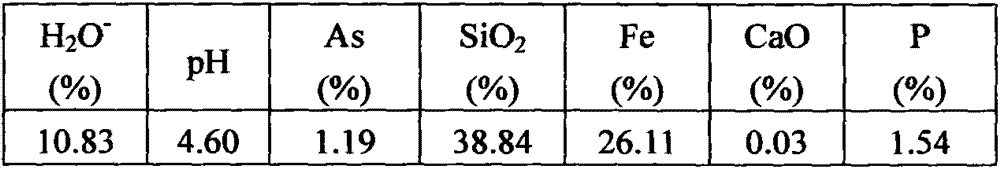

[0038] Raw material 1: arsenic-containing waste residue

[0039] The main components of arsenic-containing waste residue are shown in the table below

[0040]

[0041] Raw material 2: limestone 81.12%, sandstone 8.25%, pyrite slag 2.03%, laterite 3.60%, phosphorus slag 3.0%.

[0042] Method of implementation:

[0043] Under the operating conditions of maintaining the cement kiln as kiln tail temperature: 1050°C, kiln head temperature: 900-1100°C, speed: 4.1r / min, the weight of the arsenic-containing waste residue in the raw material (the sum of raw material 1 and raw material 2) The percentage is 2.0%. The arsenic-containing waste residue is evenly transported to the raw material mill through the feeder, and then sent to the rotary kiln to produce fired cement clinker. The treated cement clinker is analyzed by X-ray diffractometer. Quantitative determination by diffraction showed that...

Embodiment 3

[0044] Example 3: The method of treating arsenic waste residue by cement rotary kiln:

[0045] Raw material 1: arsenic-containing waste residue

[0046] The main components of arsenic-containing waste residue are shown in the table below

[0047]

[0048] Raw material 2: limestone 80.12%, sandstone 7.26%, pyrite slag 1.93%, laterite 3.60%, phosphorus slag 3.0%.

[0049] Method of implementation:

[0050] Under the operating conditions of maintaining the cement kiln as kiln tail temperature: 1050°C, kiln head temperature: 900-1100°C, speed: 4.1r / min, the weight of the arsenic-containing waste residue in the raw material (the sum of raw material 1 and raw material 2) If the percentage is 4.0%, X-ray diffractometer will be used to carry out diffraction quantitative determination on the treated cement clinker, and the content of arsenic in the clinker is between 196.57 mg / kg and 218.70 mg / kg. Using "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com