Patents

Literature

154results about How to "Realize harmless disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive recovery method for waste lithium ion battery

ActiveCN109449523ASolve the problem of high concentration enrichment recoveryRealize harmless disposalWaste accumulators reclaimingProcess efficiency improvementRecovery methodLithium-ion battery

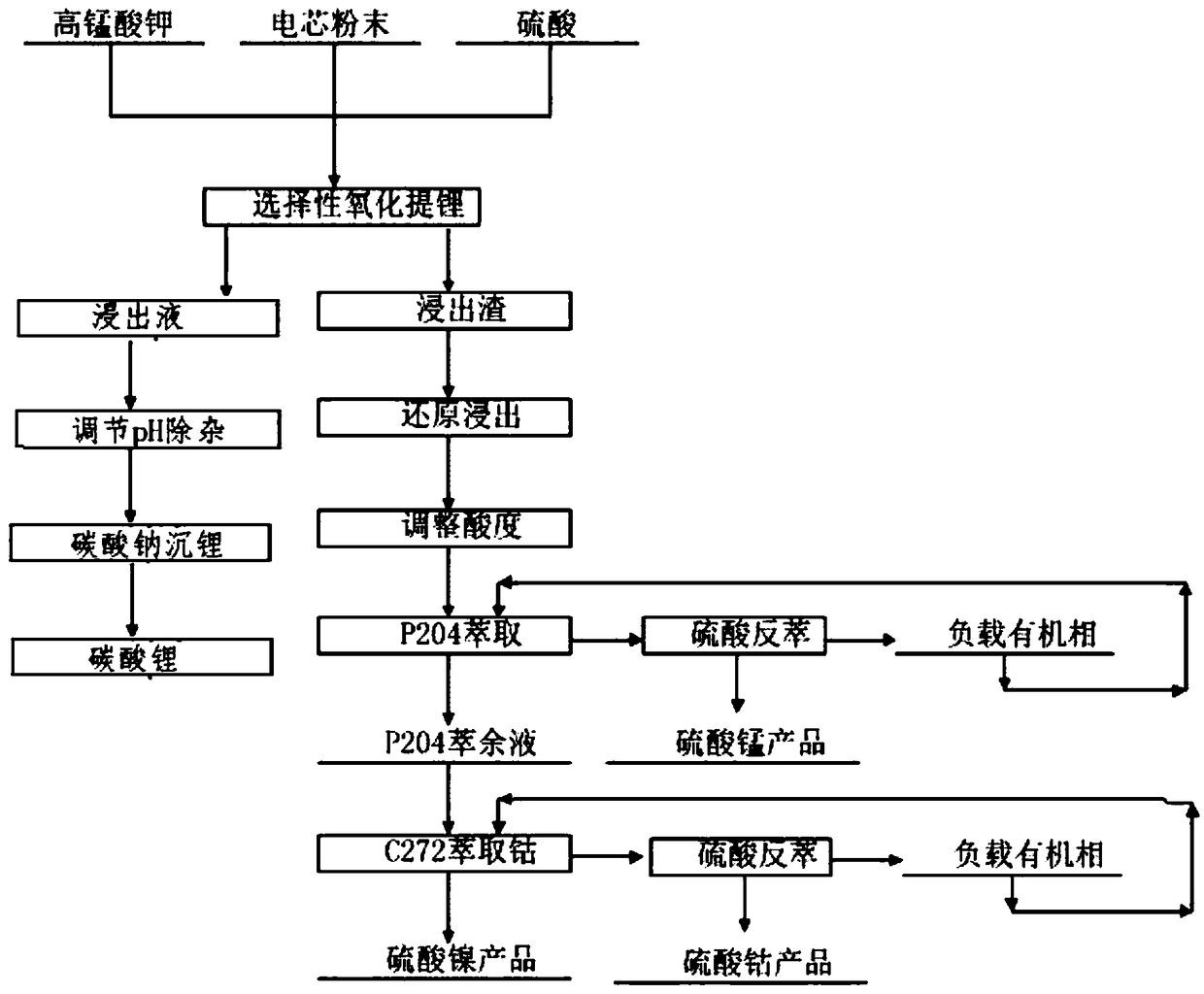

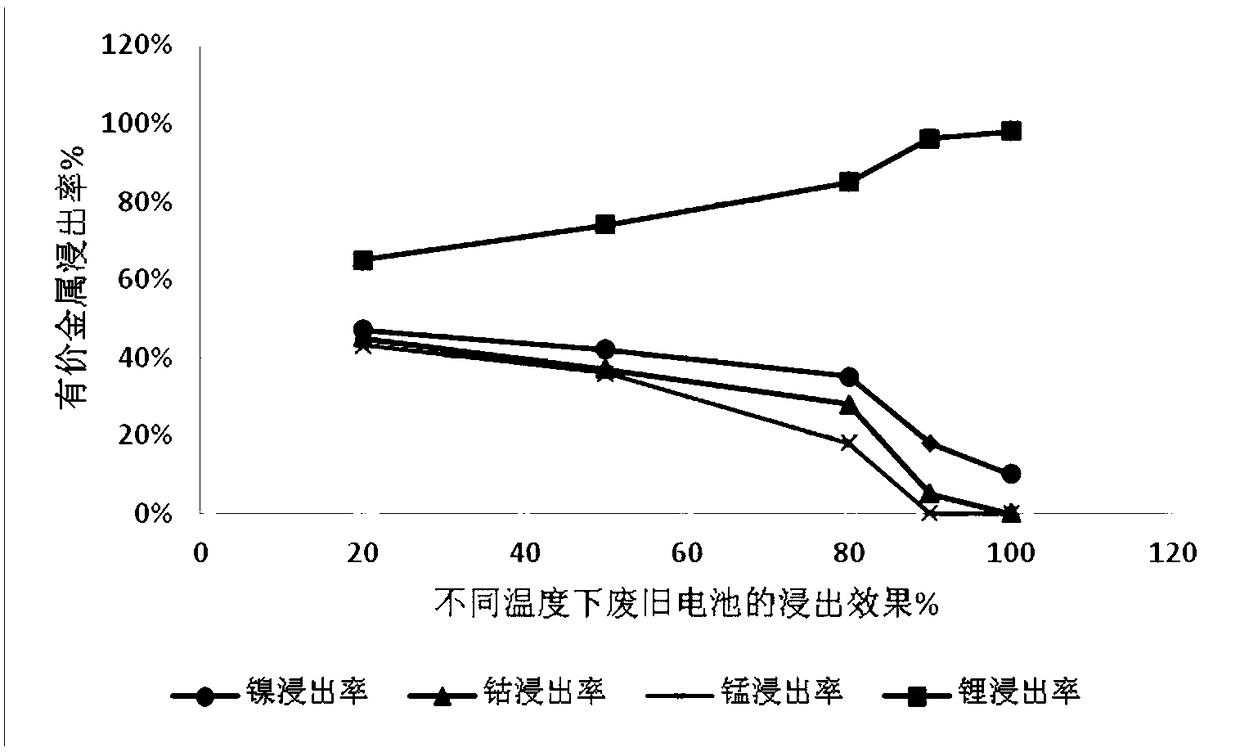

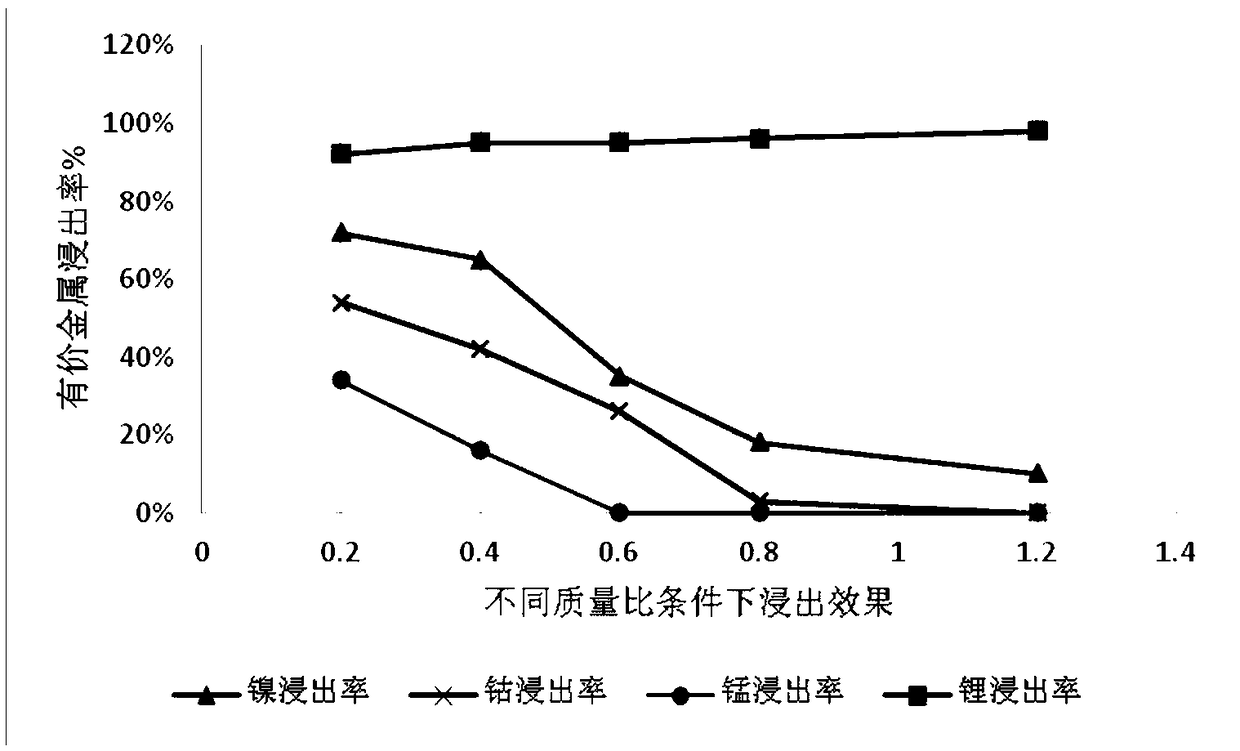

The invention provides a comprehensive recovery method for a waste lithium ion battery. The method comprises the following steps: three-element waste lithium battery cell powder is leached by sulfuricacid and potassium permanganate for the first time so as to obtain a first leaching solution and a first leaching residue; sodium carbonate is used for carrying out lithium precipitation on the firstleaching solution to obtain lithium carbonate; selective reduction leaching is carried out on the first leaching residue by using hydrogen peroxide and sulfuric acid so as to obtain a second leachingsolution and a second leaching residue; the pH value of the second leaching solution is adjusted to be 4.2-4.5, and P204 is used for extracting the second leaching solution so as to obtain a P204 raffinate and a P204 loaded organic phase; reverse extraction is carried out on the P204 loaded organic phase by using sulfuric acid, and evaporating and crystallizing are carried out to prepare manganese sulfate; the pH value of the P204 raffinate is adjusted to be 4.5-5, and the P204 raffinate is extracted by using C272 so as to obtain a C272 extracting solution and a C272 loaded organic phase; reverse extraction is carried out on a C727 loaded organic phase by sulfuric acid to obtain a cobalt sulfate solution, and evaporating and crystallizing are carried out to prepare battery-grade cobalt sulfate; and the pH value of a C272 raffinate is adjusted to be 5-5.5, the C272 extracting solution is extracted by using P507 to obtain a P507 loaded organic phase, sulfuric acid back-extraction is carried out on the P507 loaded organic phase to obtain a nickel sulfate solution, and evaporating and crystallizing are carried out to obtain nickel sulfate.

Owner:天齐锂业资源循环技术研发(江苏)有限公司

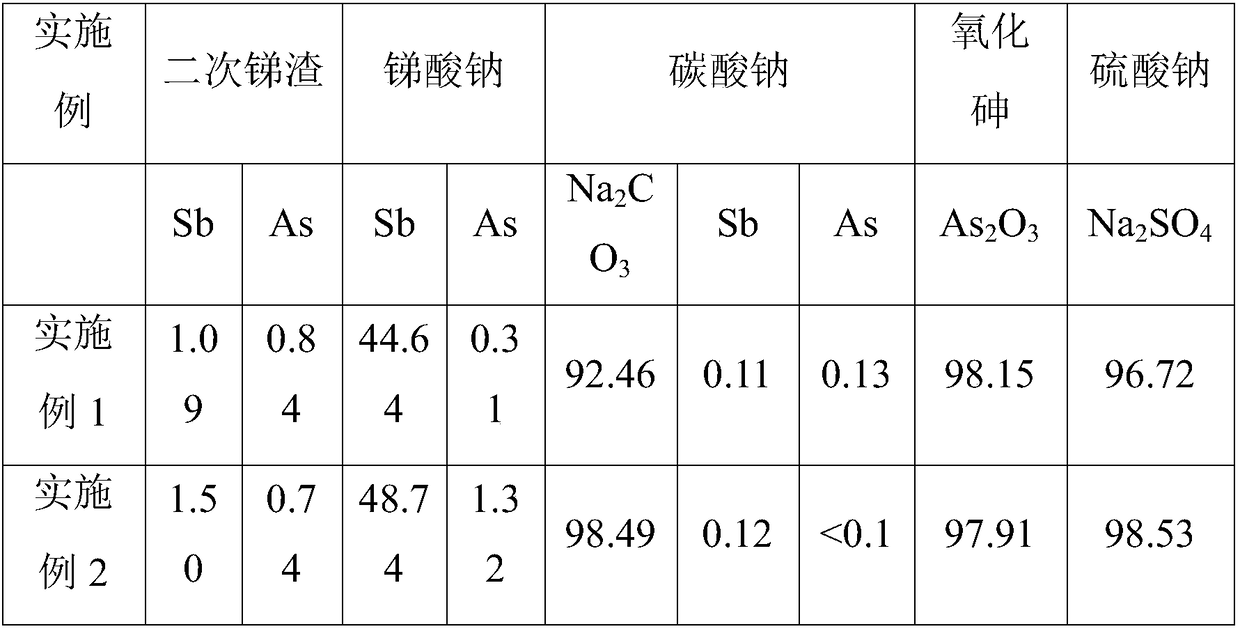

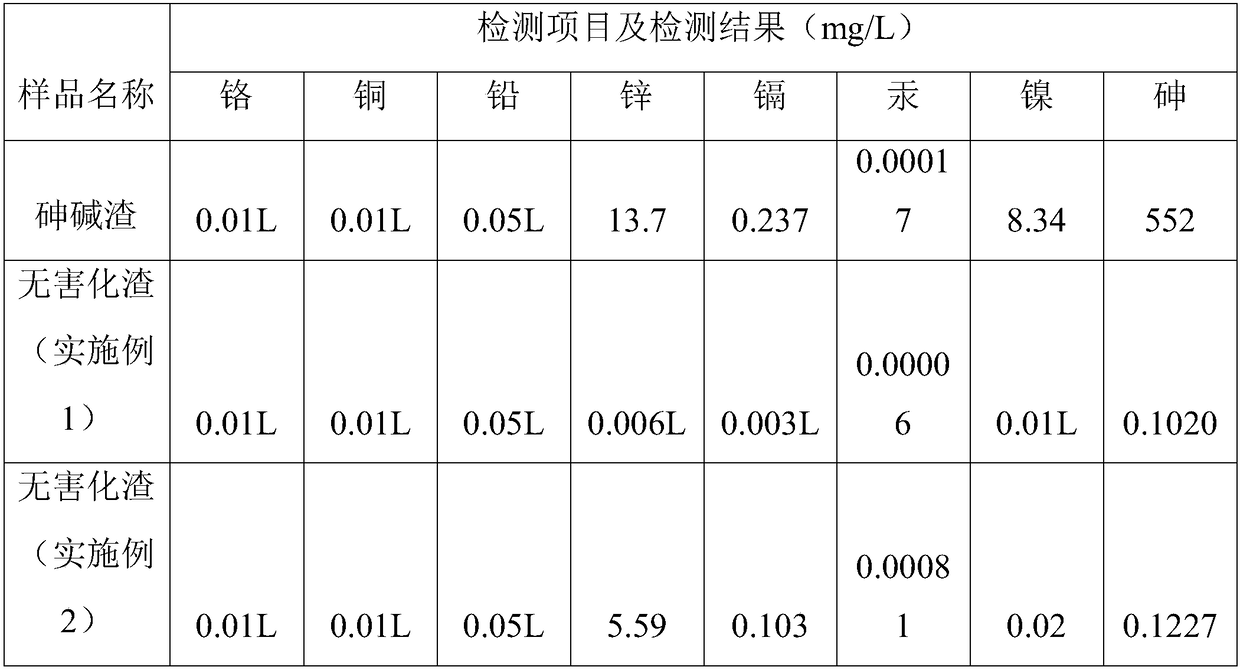

Wet-method recycling and harmless treatment process for antimony smelting arsenic alkali residue

PendingCN108441642ARealize green and clean cycle productionHigh recovery rateSolid waste disposalAlkali metal sulfite/sulfate purificationWastewaterImpurity

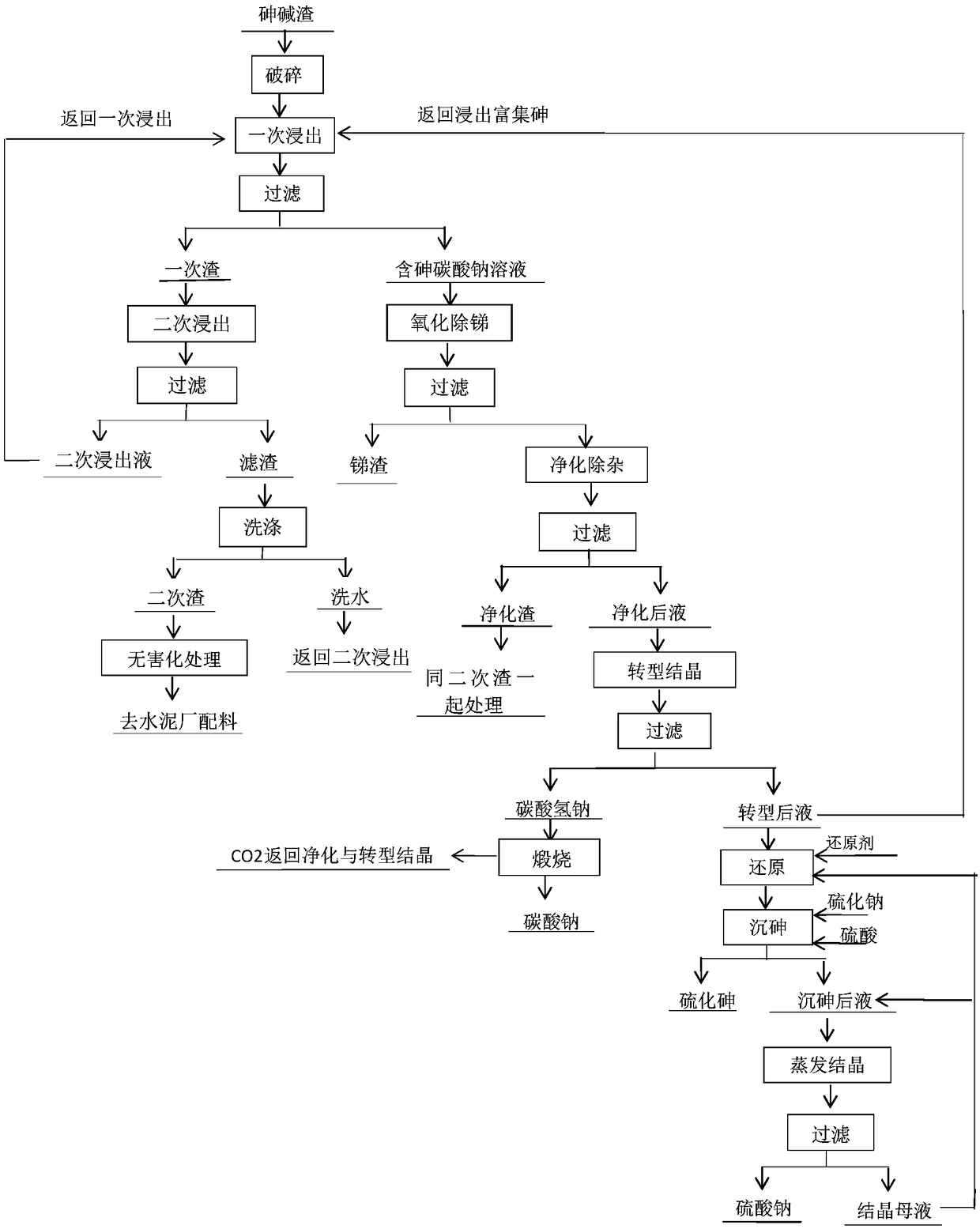

The invention belongs to the field of antimony smelting arsenic alkali residue treatment and particularly discloses a wet-method recycling and harmless treatment process for antimony smelting arsenicalkali residue. The process adopts a whole-wet-method treatment process and mainly comprises the eight working procedures of breaking, dissolving for leaching, oxidation for antimony outlet, purification for impurity removing, transition for crystallizing, reduction for arsenic sinking, evaporative crystallization and secondary residue harmless treatment. Recycling and harmless treatment of the arsenic alkali residue, zero emission of waste residue and waste water and up-to-standard discharge of exhaust gas are thoroughly achieved, the long-term plagued arsenic alkali residue environmental pollution problem in the antimony smelting industry in China is thoroughly solved, and the environmental risk caused by stacking the arsenic alkali residue is eliminated; and meanwhile, separation, enrichment and effective recovering of valuable elements are achieved.

Owner:CHENZHOU YANGTAO CHEM

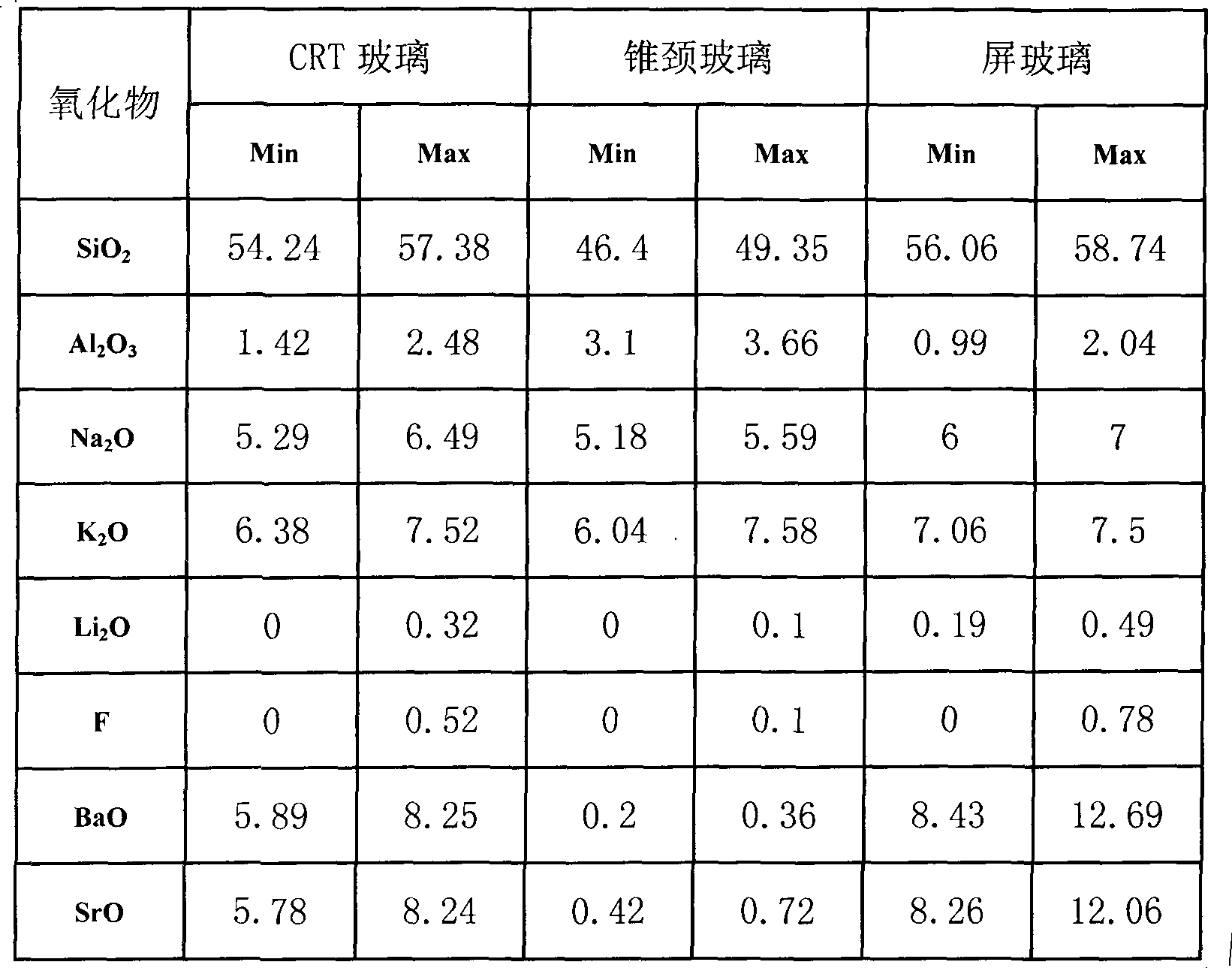

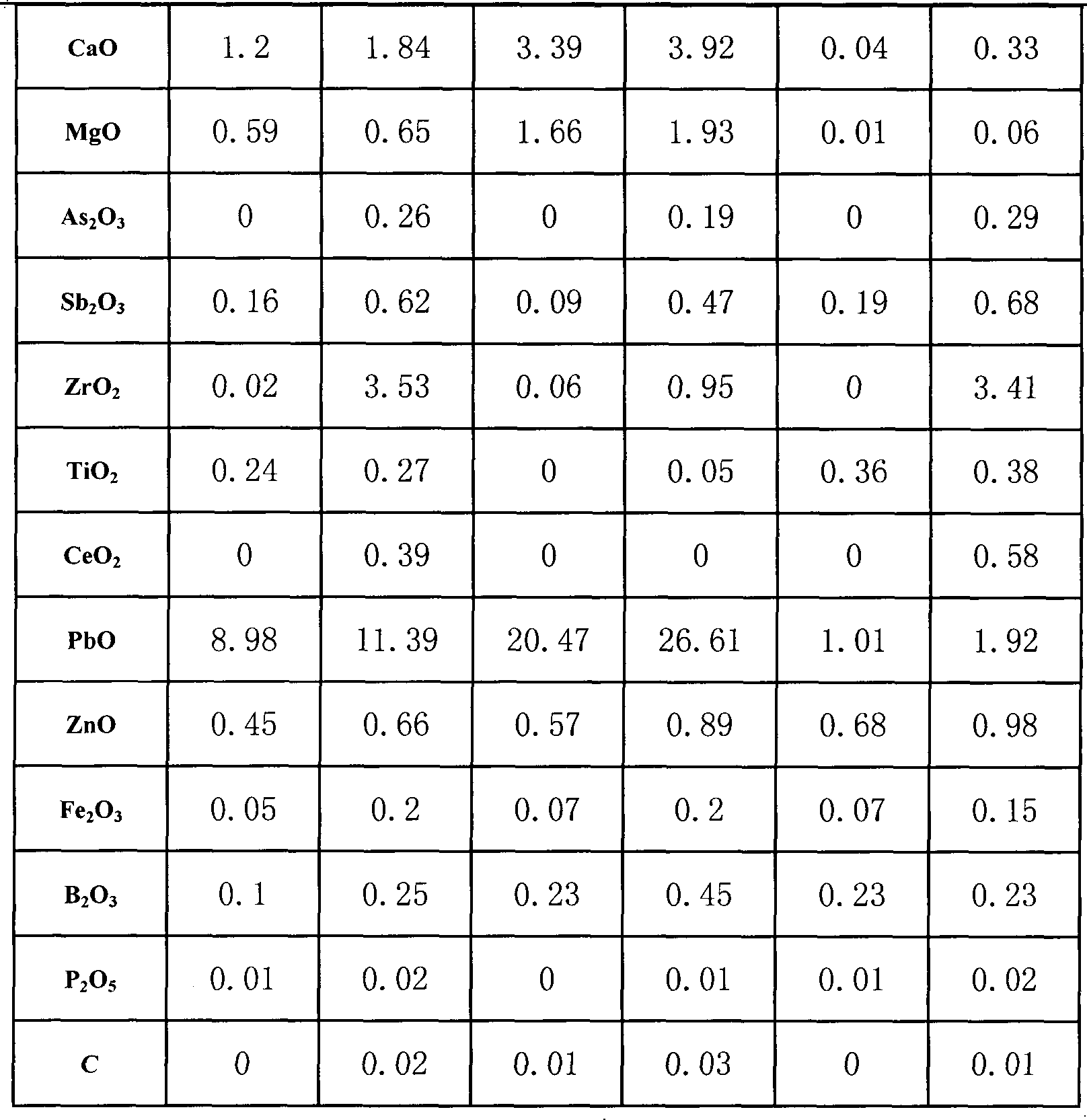

Anti-radiation building putty powder and preparation method thereof

The invention provides anti-radiation building putty powder and a preparation method thereof. Color picture tube glass and reinforced ingredients are mixed in proportion and ground till the particle size is 60 to 100 meshes to obtain ground powder; the ground powder is further mixed with cement in proportion to obtain ground anti-radiation building putty powder; the ground powder can be further calcined and mineralized and then mixed with the cement in proportion to obtain sintered anti-radiation building putty powder, so that the anti-radiation building putty powder can obtain higher chemical stability and use safety. By the method, the waste color picture tube glass is turned into resources, and the harmless disposal, recycling and high-value utilization of the waste color picture tube glass are implemented. The anti-radiation building putty powder can be widely applied to the surface treatment of a radiation protection body and a radioactive building material (building).

Owner:YANCHENG INST OF TECH +2

Novel chromium slag innocent treatment method

The invention discloses a novel chromium slag innocent treatment method. In the method, quartz sand and an alkaline medicament are taken as melting agents, and chromium slag, the quartz sand and the alkaline medicament are uniformly mixed in a weight ratio of 25-45:35-75:5-22; the mixture is added into an electric glass melting furnace and is fully melted at a high temperature of between 1,350 and 1,500 DEG C to form molten glass; and the molten glass is subjected to water quenching by cold water, and cooled at room temperature to form glass slag. Through high-temperature electric melting treatment, hexavalent chromium in the chromium slag is reduced into trivalent chromium and is cured and stabilized after entering glass lattices, and the chromium slag is converted into glass state inert waste, and the leaching concentration of heavy metals is far lower than a standard limit value in Identification Standard for Hazardous Wastes-Identification for Extraction Procedure Toxicity (GB5085.3-2007) of the nation.

Owner:刘阳生 +1

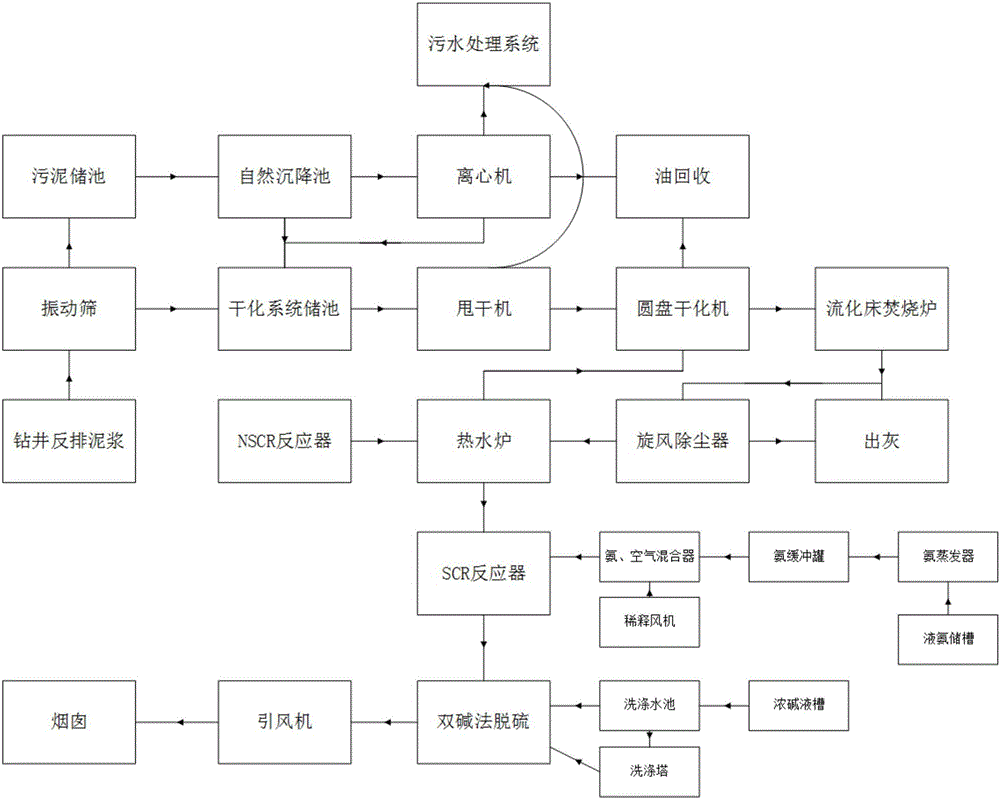

A waste oil-based drilling fluid solid residue treating method

ActiveCN106630504AClean up thoroughlyAchieve efflux indicatorsWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningLiquid wasteAbsorption column

A waste oil-based drilling fluid solid residue treating method is disclosed. The main objective is to overcome the problem that oil, inorganic salts and metal ions in discharged drilling fluid solid waste exceed standards. The method is characterized in that mud waste liquid is treated through a vibrating screen, drilling scraps are fed into a drying system storage tank, mud is fed into a settling tank and separated, then dehydration separation is performed, materials in the drying system storage tank are fed into a system spin dryer, subjected to spin drying, fed into a disc type dryer after dehydration, and dried, residues after drying are fed into a fluidized bed incinerator, the incineration temperature is controlled, gas after incineration is dedusted by a deduster and then fed into a water heater, nitrate in exhaust gas that is finally generated is treated through an SCR+NSCR process, then desulphurization is performed by a two-alkali process, the exhaust gas is fed into an absorption column and brought into reverse contact with a cyclic liquid that is mist formed by injection through an atomizing nozzle, and dust in the exhaust gas is adsorbed by the cyclic liquid to achieve thorough dust removing. The treating method can achieve thorough harmless treatment for waste oil-based drilling fluid solid residues.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for preparing inorganic mixture by using waste concrete recycled aggregate

InactiveCN102838306ALow costRealize harmless disposalSolid waste managementConstruction aggregateMaterials science

The invention provides a method for preparing inorganic mixture by using waste concrete recycled aggregate. The method comprises mixing, by mass percentage, 65-75% of the recycled aggregate with the grain diameter of 0-5 millimeters, 5-15% of the recycled aggregate with the grain diameter of 5-10 millimeters, and 20-30% of the recycled aggregate with the grain diameter of 10-31.5 millimeters, wherein the recycled aggregate is prepared by crushing waste concrete; and then adding cement to obtain the inorganic mixture, wherein the mass percentage of the mixed aggregate is 95.5-97%, and the mass percentage of the cement is 3-4.5%. The method for preparing the inorganic mixture by using the waste concrete recycled aggregate achieves grading design of the inorganic mixture by combination of the characteristics of the waste concrete aggregate and proportioning design, effectively utilizes part of activity of the waste concrete aggregate, reduces the proportion of the added cement, utilizes a large proportion of fine aggregate raw materials of the waste concrete recycled aggregate, and reduces cost.

Owner:SHOUGANG CORPORATION

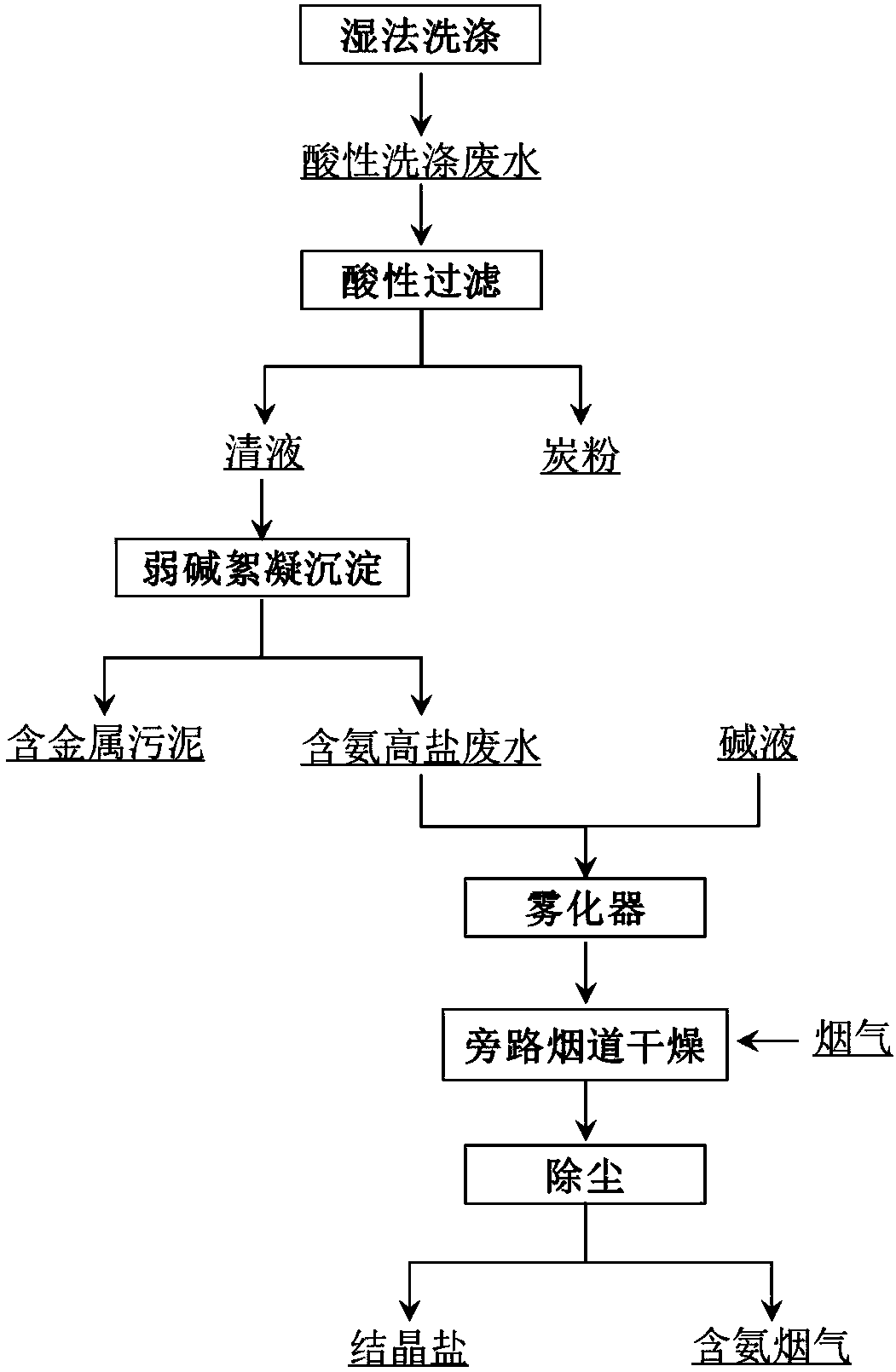

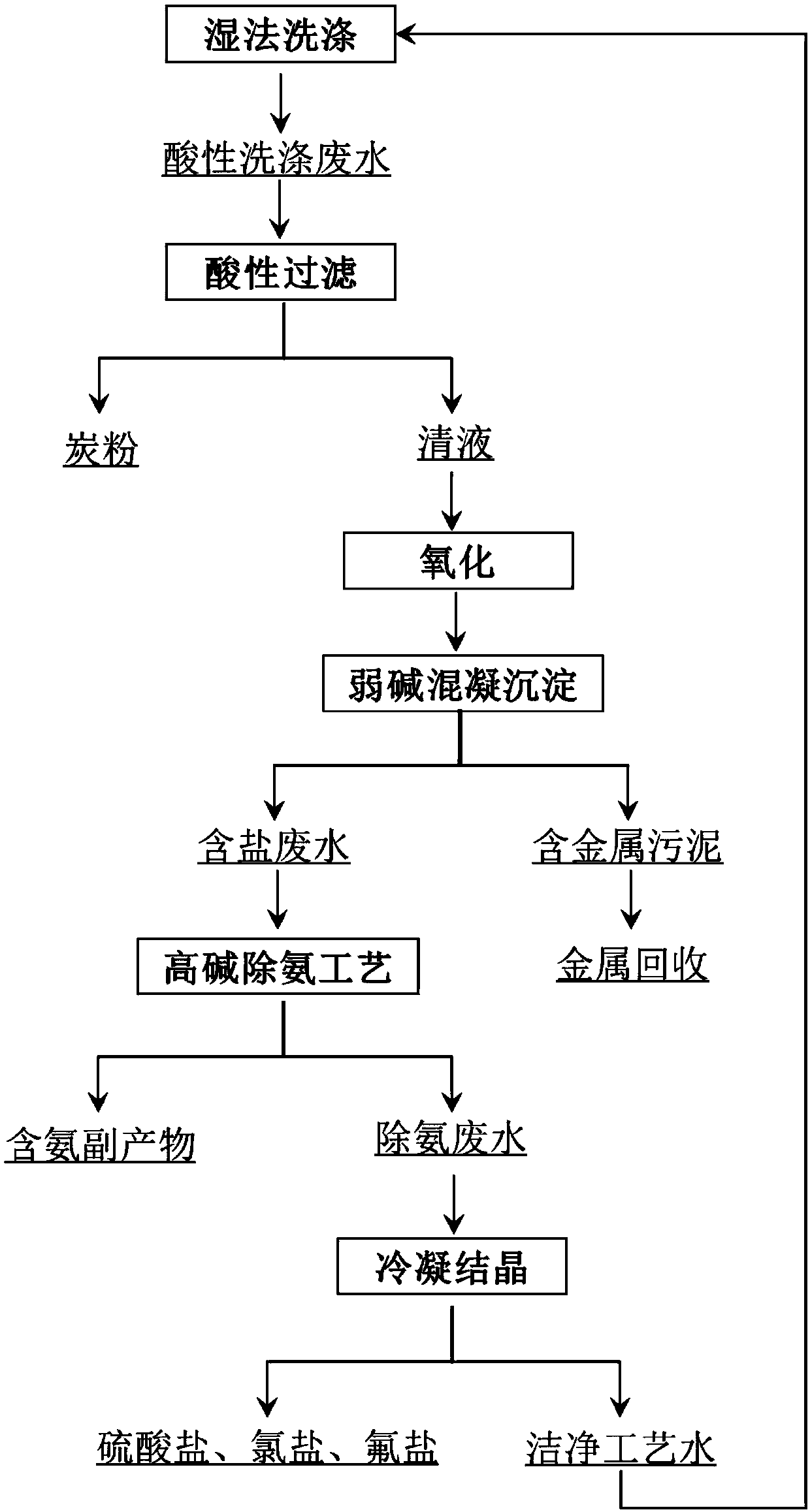

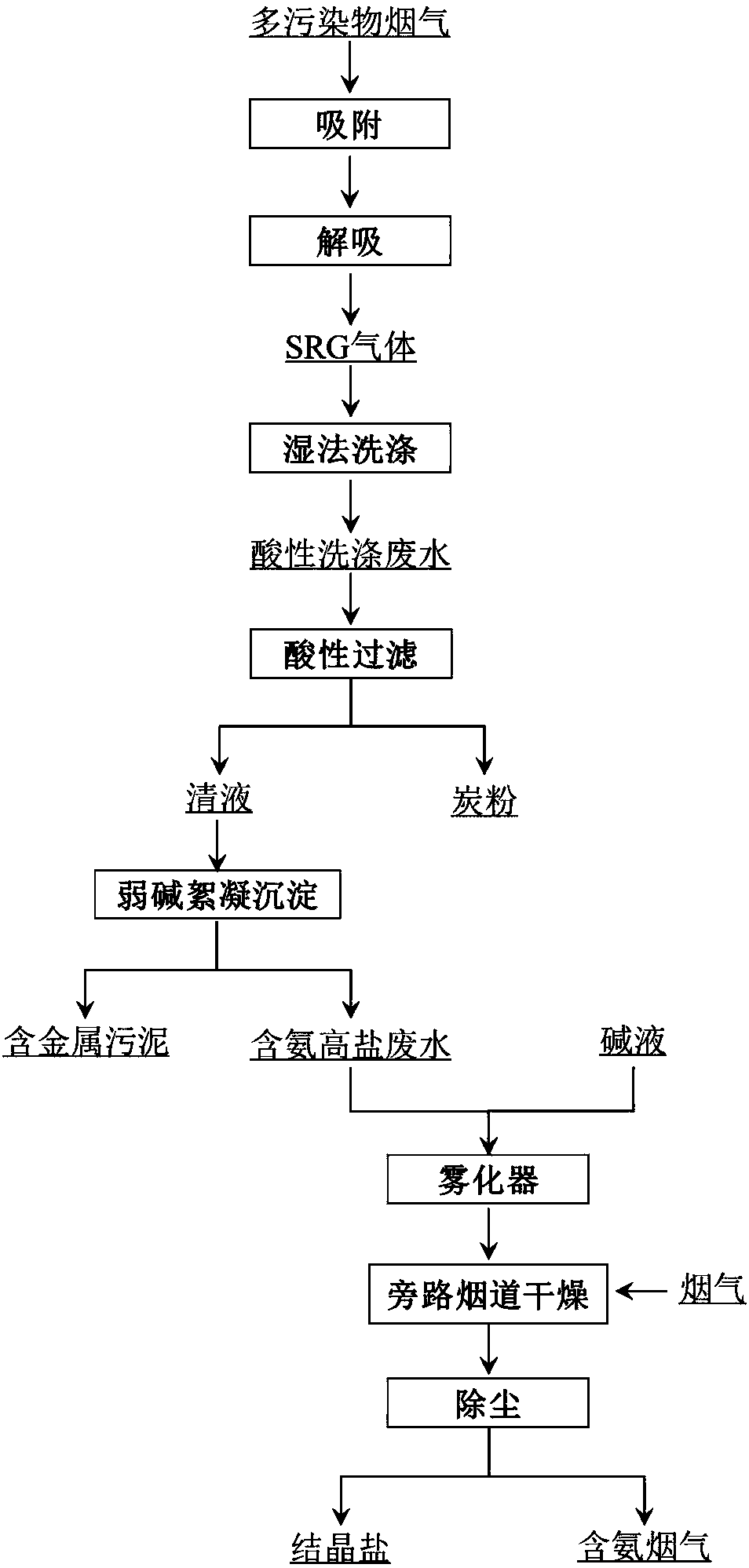

Acidic flue gas washing wastewater zero-discharge treatment method and apparatus thereof

ActiveCN110127918AClean thoroughlyAchieve reuseGas treatmentWater/sewage treatment by irradiationFiltrationPrecipitation

The invention provides an acidic flue gas washing wastewater zero-discharge treatment method, which comprises: removing suspended matters from wastewater through acid filtration; removing metal ions through flocculation precipitation; recovering fluorine, chlorine and other substances and removing organic substances through drying; or recovering ammonia-containing by-products through a high alkaliammonia removing process, and recovering fluorine, chlorine and other substances through condensation crystallization. According to the present invention, the method can effectively treat acidic washing wastewater, achieve the reduction of heavy metal hazardous waste and the cleaning treatment and reuse of ammonia nitrogen, avoid the equipment blockage caused by elemental sulfur, and achieve thezero discharge of wastewater and the low viscosity of dust, and cannot produce bag pasting phenomenon; and resources are recovered and reused, and the environment is protected.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Treatment method and device for oil sludge

InactiveCN107937003AThe processing method is simpleGood economic benefitsSpecial form destructive distillationTarCircular economy

The invention discloses a treatment method and device for oil sludge. The method comprises the following steps: mixing and pressing oil sludge, charred coal, coking flash ash and tar residue into a ball, mixing coking coal into the coal ball to perform coking, treating the oil sludge through a coking oven, and ensuring that oil in the oil sludge is converted into coal gas for utilization, components, such as iron and calcium, are cured into coke, enter a blast furnace with the coke and are reduced in the blast furnace and fused into molten iron to be utilized, so as to realize completely harmless disposal. The treatment method is simple, and harmless disposal of oil sludge is realized; the problem that oil sludge water treatment is difficult to dispose and high in disposal cost is solved;the method meets the national policies on environmental protection and cyclic economy, and has good social benefit and environmental protection and energy saving benefit.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

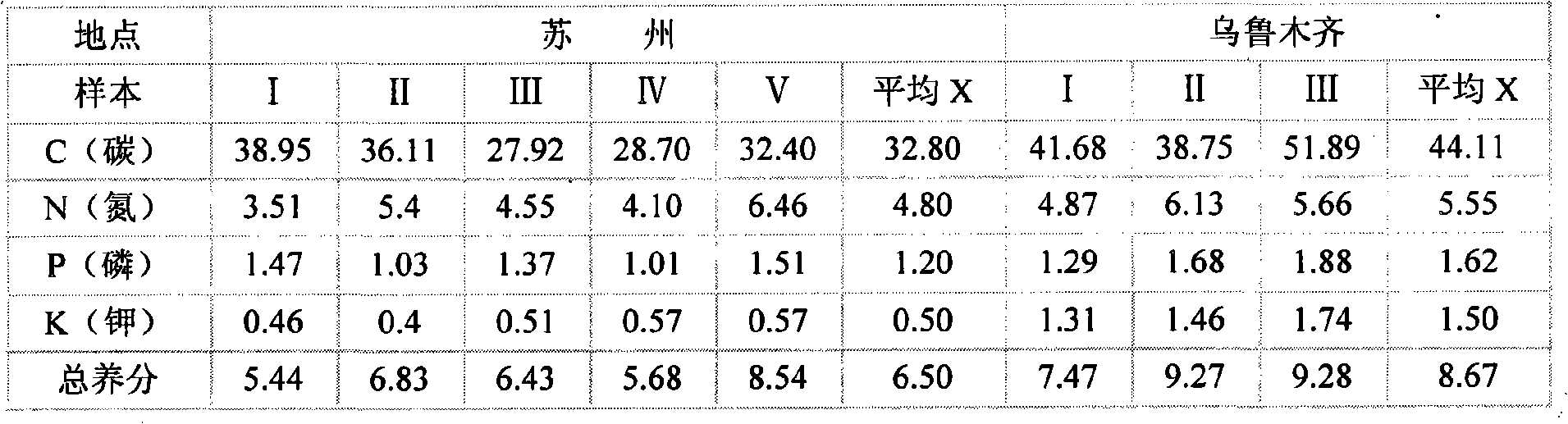

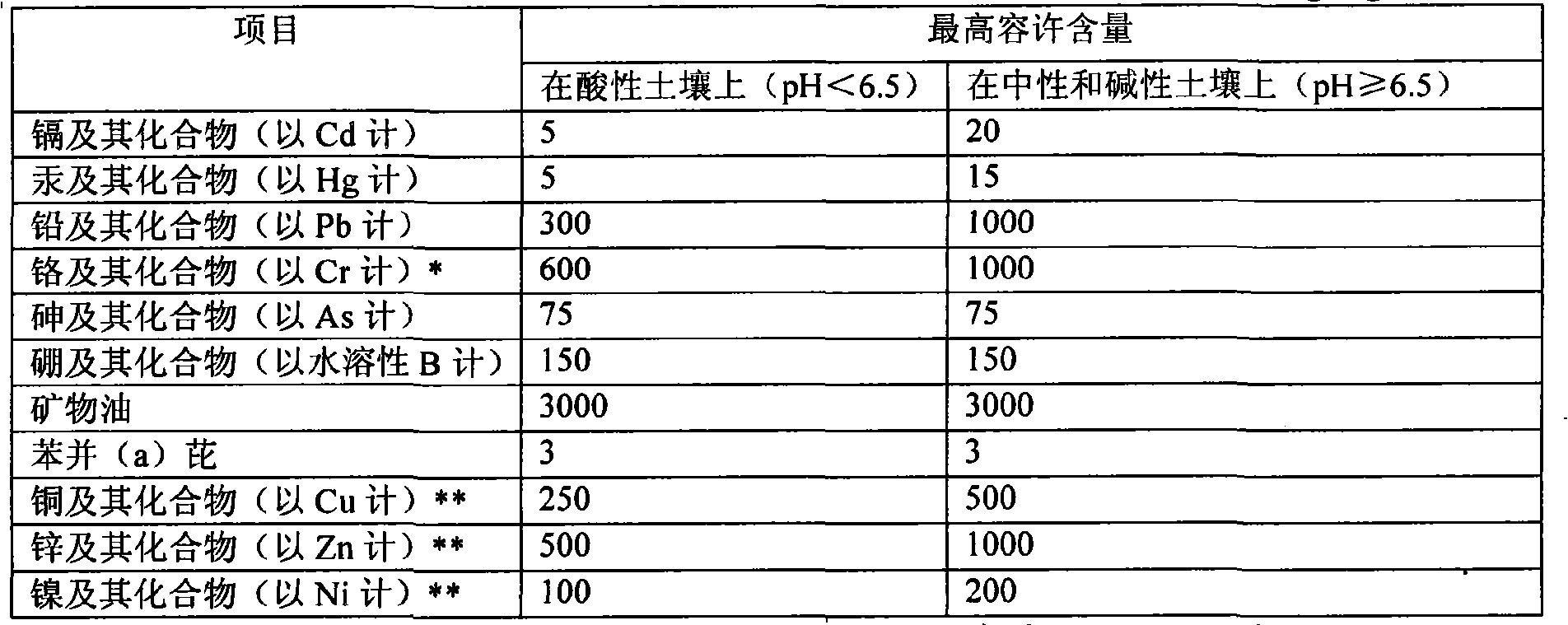

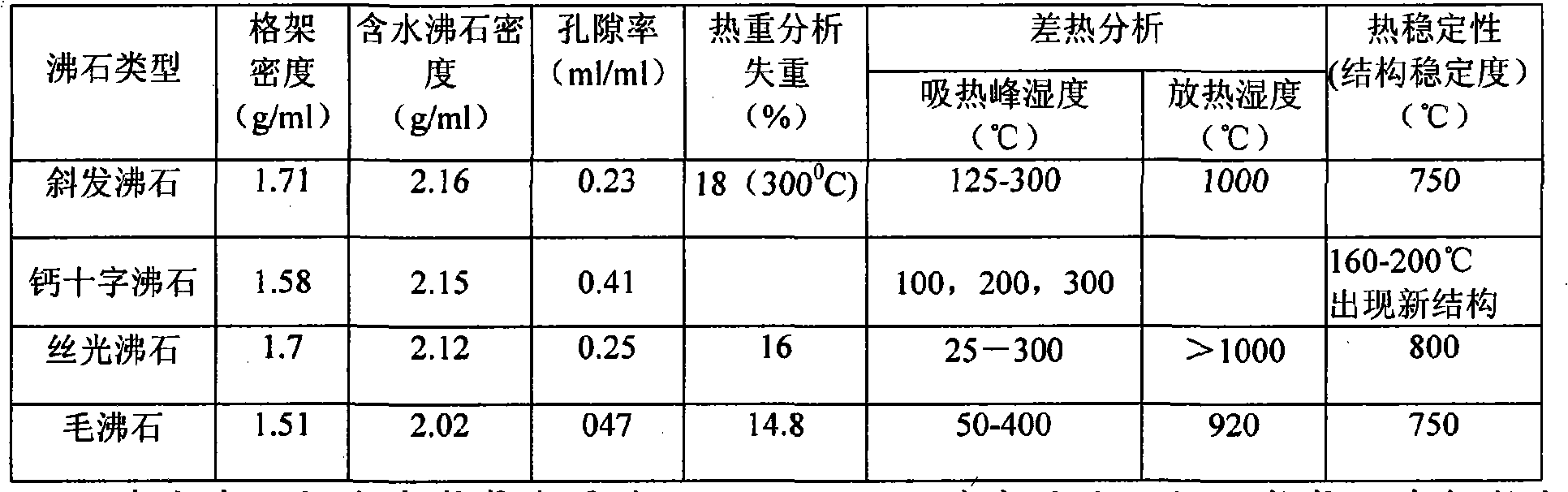

Long active organic compounded fertilizer and production method

InactiveCN101289348ASolve land occupationSolve secondary pollutionAlkali orthophosphate fertiliserClimate change adaptationResource utilizationPhosphate

The invention relates to a long-acting organic compound fertilizer and a manufacturing method thereof, which belongs to the manure field. By taking sludge in a municipal sewage treatment plant as main raw material, adding zeolite, urea, ammonium diacid phosphate, potassium chloride and sodium silicate, then being stirred and mixed with the urea, the ammonium diacid phosphate and the potassium chloride after sludge compression, zeolite drying, stirring and mixing, natural air drying or kiln drying and grinding, and spraying the sodium silicate so as to granulate, dry, disinfect and sterilize the mixture, a product is then produced. The long-acting organic compound fertilizer and the manufacturing method solve the problem of land occupation of the sludge in the sewage treatment plant and secondary pollution, and realize the harmless disposal and resource utilization of the sludge. The fertilizer ensures that crops has good growth power, high plants, more grains, stronger lodging resistance and obvious stimulation effect and ensures that the quality of agricultural products is improved. Furthermore, the fertilizer can increase the ability of reserving nutrients in soil, can modify acid or saline alkali sandy soil, can improve soil aggregate structure, can keep fertilizer efficiency and resist crop diseases.

Owner:屈智和 +1

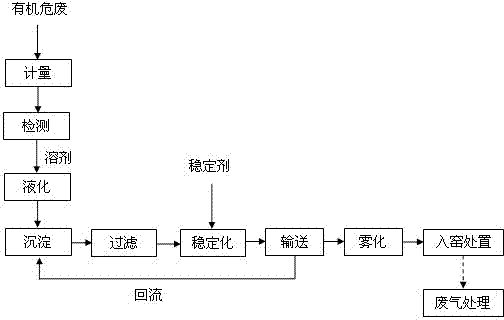

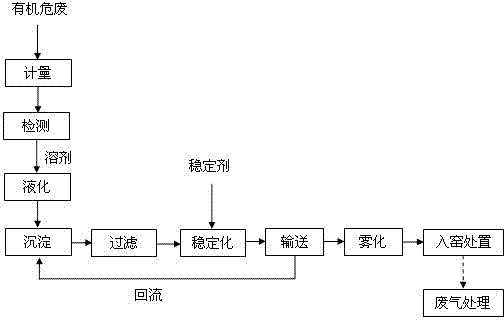

Co-processing technology of organic hazardous wastes in cement kiln

InactiveCN102519048AHarmlessRealize resource utilizationIncinerator apparatusEmission standardSolvent

The invention provides a co-processing technology of organic hazardous wastes in a cement kiln. The co-processing technology comprises the following steps of: (a) liquefying the organic hazardous wastes with a solvent for reducing the viscosity of the organic hazardous wastes; (b) filtering the organic hazardous wastes after precipitation; (c) adding a stabilizer into the organic hazardous wastes after filtering for stabilization; and (d) spraying the organic hazardous wastes after pretreatment into the cement kiln via a kiln entry system for replacing part of fuel. Waste gas produced in the step (d) can achieve the emission standard after treatment. The co-processing technology disclosed by the invention is low in energy consumption, the organic hazardous wastes can be effectively disposed, the production of clinker during the incineration process is avoided, the coal consumption during the cement production process is saved, and the organic hazardous wastes can truly realize reduction, harmlessness and resource disposal.

Owner:郑慧

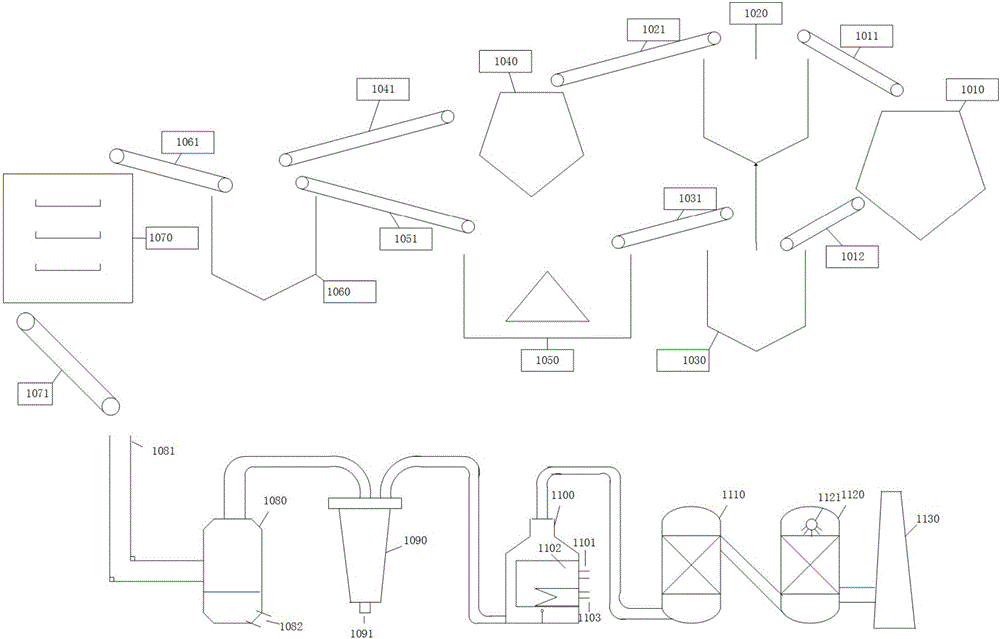

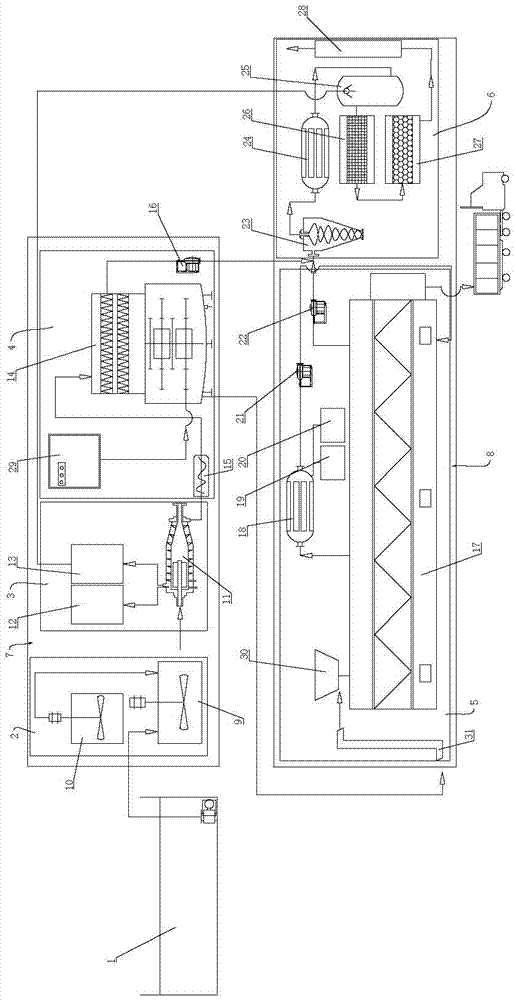

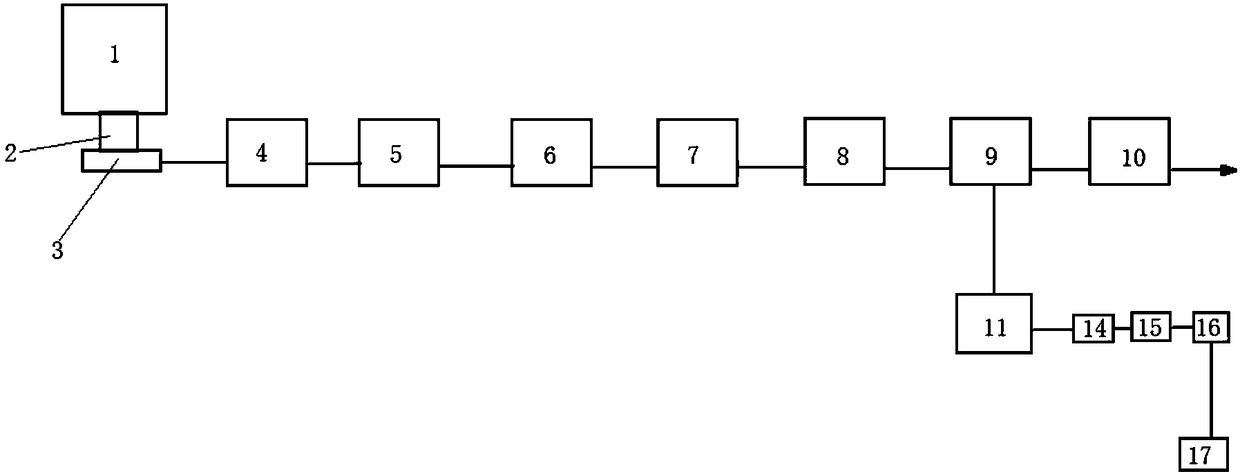

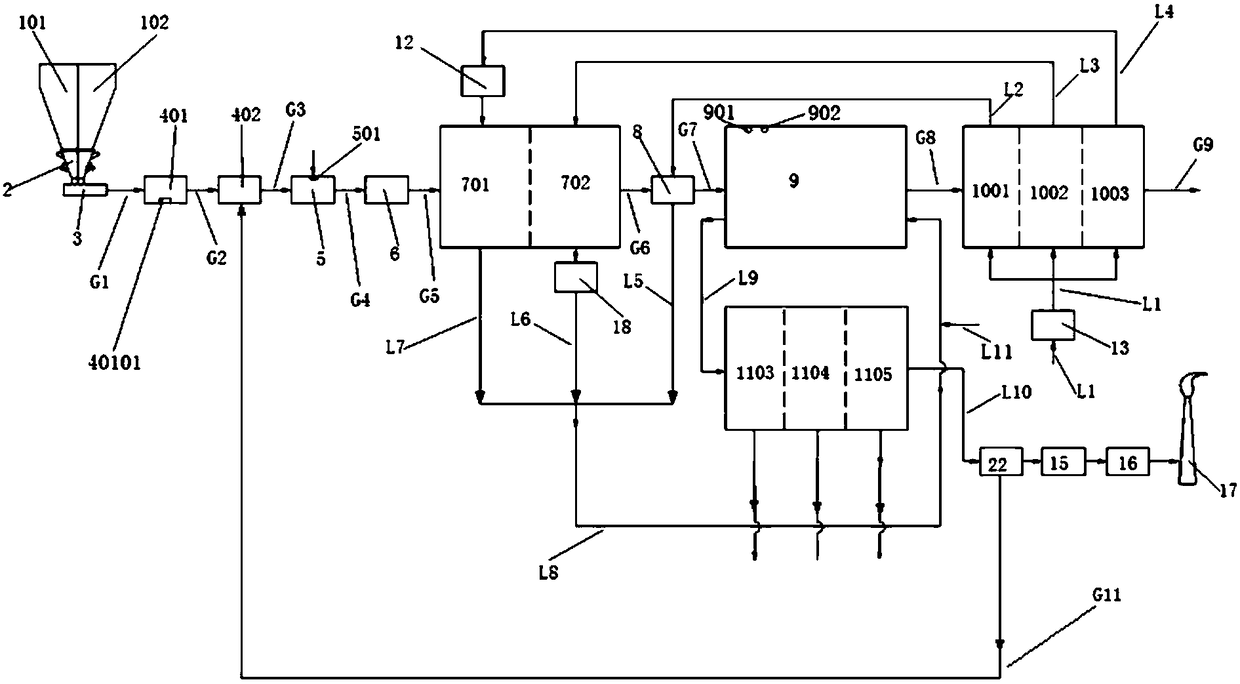

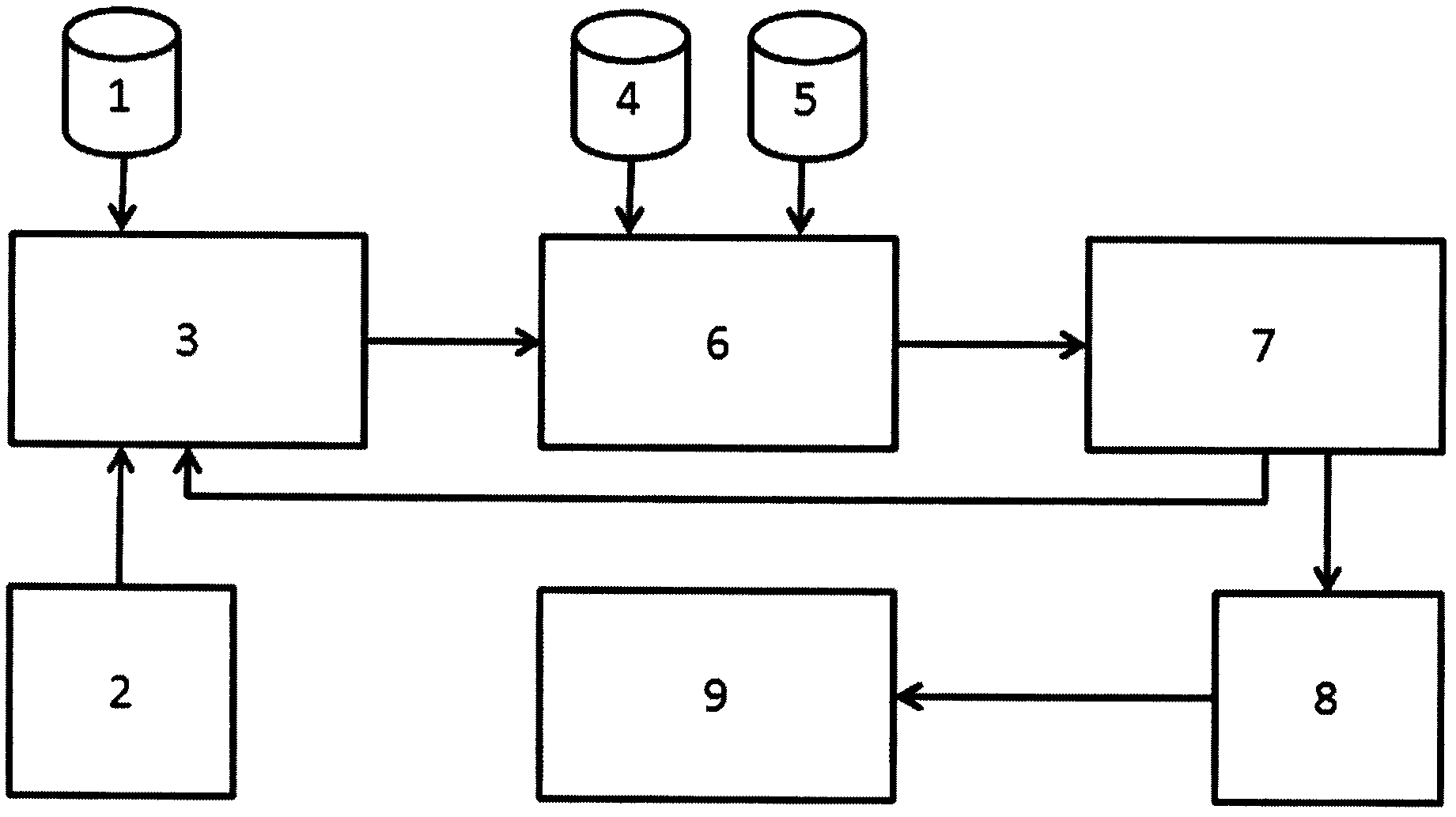

Refinery oily sludge disposal system and method

PendingCN107500501ARealize harmless disposalEliminate hazardsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCentrifugationSludge

The present invention provides a refinery oily sludge disposal system which realizes non-hazardous treatment of oily sludge and effectively solves the problem of resource treatment and utilization of the oily sludge, the refinery oily sludge disposal system has the advantages of skid-mounted design, compact structure and small floor area, the refinery oily sludge disposal system includes an oily sludge reservoir, a quenching and tempering unit, a centrifugal processing unit, a pelletizing and drying unit, a thermal cracking unit and an exhaust gas treatment unit, the quenching and tempering unit, the centrifugal processing unit and the pelletizing and drying unit are respectively arranged on a quenching and tempering centrifugation drying integrated skid body, the exhaust gas treatment unit and the thermal cracking unit are respectively arranged on a thermal cracking exhaust gas integrated skid body, and the invention also provides a refinery oily sludge disposal method.

Owner:无锡雪浪康威环保科技有限公司

Recycling hazardous waste treatment system and treatment method by synergizing rotary kiln and plasma gasification

PendingCN106642159AImprove operational reliabilityEconomicalIncinerator apparatusHigh energyRotary kiln

The invention relates to a recycling hazardous waste treatment system and treatment method by synergizing a rotary kiln and plasma gasification. The system comprises a hazardous waste storage device, a hazardous waste sorting device, a rotary kiln incinerator, a plasma gasification furnace, a first crushing feeder and a second crushing feeder. The hazardous waste sorting device sorts hazardous wastes in the hazardous waste storage device, and easily handled hazardous wastes are fed into the first crushing feeder and hardly handled hazardous wastes are fed into the second crushing feeder; the first crushing feeder is connected to a feed inlet of the rotary kiln incinerator, and the second crushing feeder is connected to a feed inlet of the plasma gasification furnace. Through a reasonable design, hazardous waste harmless treatment is realized by virtue of technological advantages of the rotary kiln and the plasma gasification, so that the problem of dioxin and heavy metal pollution is avoided. Synthesized gas generated by gasification by the plasma gasification furnace supplements energy required by the rotary kiln, and meanwhile, a high energy utilization ratio of the system is achieved through recovered heat of a waste heat boiler.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

In-situ stabilized solidification construction process for sludge

InactiveCN108929004AReduce secondary pollutionSludge disturbance is smallSpecific water treatment objectivesFixation/solidifcation sludge treatmentSelf checkingSludge

The invention relates to an in-situ stabilized solidification construction process for sludge. The process comprises the steps: primary-stage preparation of stabilized solidification construction; grid-to-be-treated partition before construction and physicochemical property analysis of sampled sludge; in-situ stabilized sludge solidification construction method determining; in-situ stabilized sludge solidification stirring construction; sludge curing after stabilized solidification; and sludge effect self-check after stabilized solidification and secondary dosed stabilized solidification, thereby completing the construction process. Through the in-situ stabilized solidification construction process for the sludge, in-situ solidification stirring equipment and sludge stabilized solidification agents are used in a matched manner, and thus, the secondary pollution to surrounding environments can be effectively lowered while the harmless treatment of the sludge is achieved; and the processhas many advantages that the disturbance to the sludge is low, the secondary pollution is light, the equipment process is simple and convenient, the site condition requirements are low, the efficiency of construction is high, the coefficient of safety is big, the practicability of engineering is high, and the like, thereby facilitating large-scale popularization and application.

Owner:BEIJING GEOENVIRON ENG & TECH

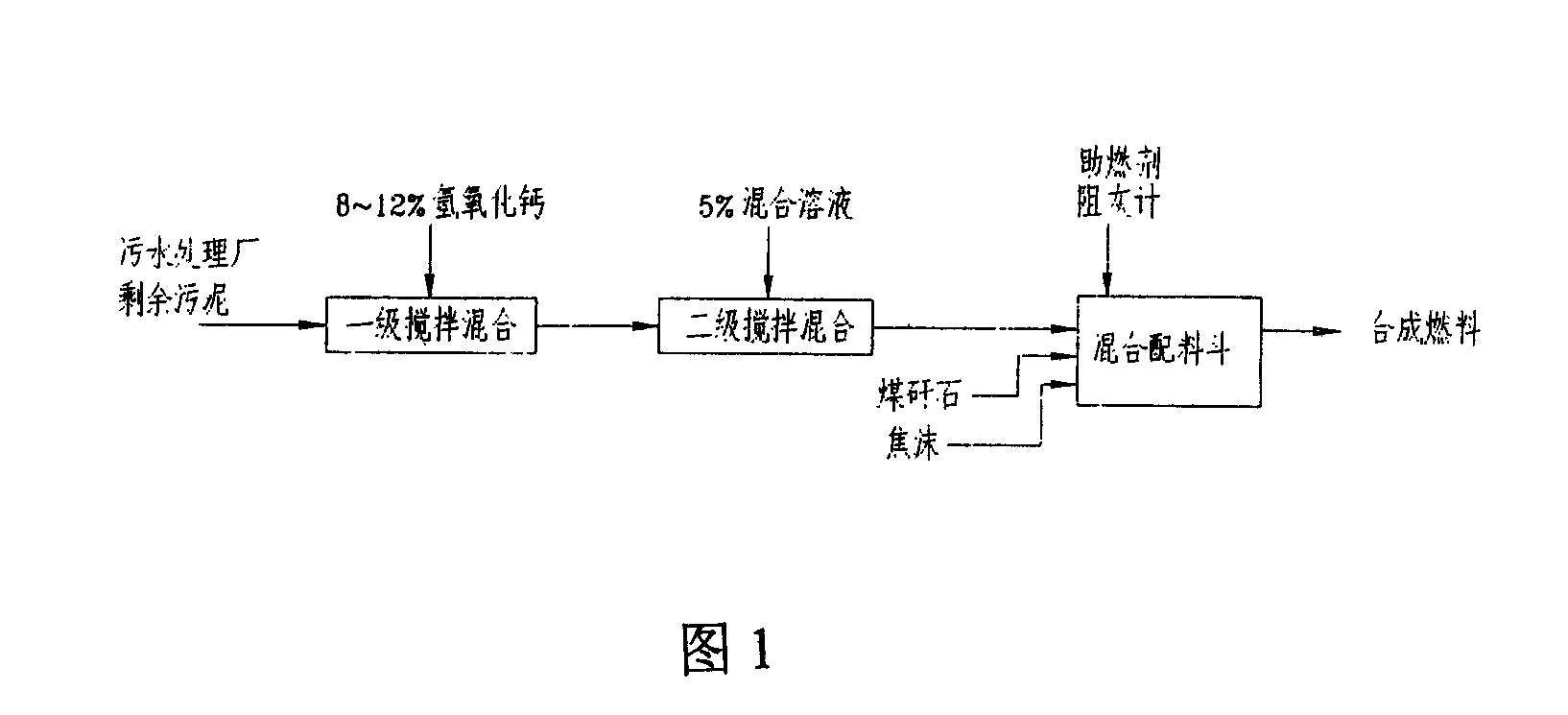

Technique for producing synthetic fuel by sludge of municipal sewage plant

InactiveCN101250456ARealize harmless disposalRealize resourcesBiofuelsSolid fuelsDeodorantWastewater

The invention relates to a technological method which utilizes sludge from wastewater treatment plant to prepare synthetic fuel, which comprises the following steps: firstly, feeding sludge whose water content is 80% after being dewatered by a municipal wastewater treatment plant into a stable stirring tank, adding CaO which is 8-12% of the amount of sludge, stirring for 10 minutes, lowering water content to 65%, feeding sludge whose water content is lowered to 65% into a deodorant stirring tank, adding Fe2(SO4), FeSO4(NH4)SO4.6H2O, CuSO4, CO(NH2)2 and water to prepare mixed solution which is 5%, stirring and mixing for 5 minutes, leading sludge to be totally loosed and stable to be end product sludge, feeding 30-40% end product sludge, 40-50% coke foam and 20% coal gangue into an automatic batch hopper, simultaneously adding 0.05-0.1g Fe2O3, stirring, mixing for 5 minutes, and preparing synthetic fuel. The invention achieves innocent treatment and resource treatment of sludge, and achieves comprehensive utilization of coal making industry.

Owner:刘志刚 +1

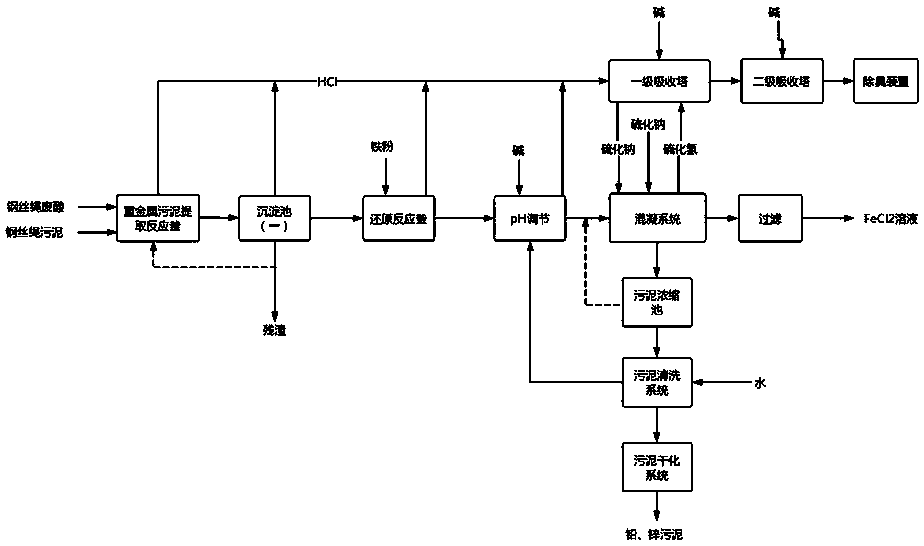

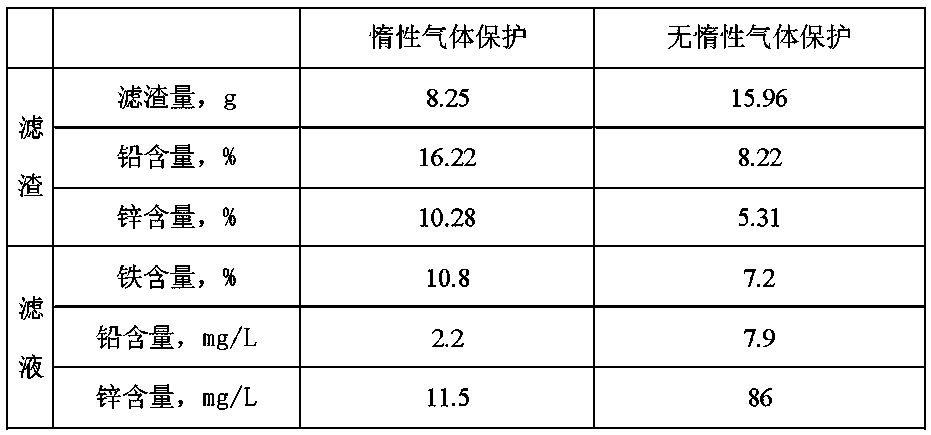

Waste acid recovery treatment method for sludge generated in steel wire rope plant

InactiveCN108383272AAchieve separationReduce usageSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeAcid washing

The invention discloses a waste acid recovery treatment method for sludge generated in a steel wire rope plant. Steel wire rope acid washing waste acid is used for leaching metal irons of iron, lead and zinc in the steel wire rope sludge; sludge residue is conveyed to a hazardous waste treatment center to be treated; iron powder is used for reducing ferric ions into ferrous ions; through sulfide precipitation, lead and zinc ions are precipitated; the generated lead and zinc precipitates are cleaned and dried; the material can be used as a lead and zinc melting raw material due to the lead andzinc abundance; the purified ferrous chloride solution can be sold as production raw materials of polymeric ferric chloride flocculant; hydrogen sulfide gas generated in the reaction process and unorganized emission hydrogen sulfide gas are treated by two-stages of filling material adsorption towers and an active carbon deodorization device, the discharge is performed after the contaminant discharge standard is met; the generated sulfide is reused in a coagulation precipitation system. The method provided by the invention solves the problems that the sludge and waste acid generated in the steel wire rope production process of high toxicity, great harm, high yield, difficult processing and secondary pollution generation and the like.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

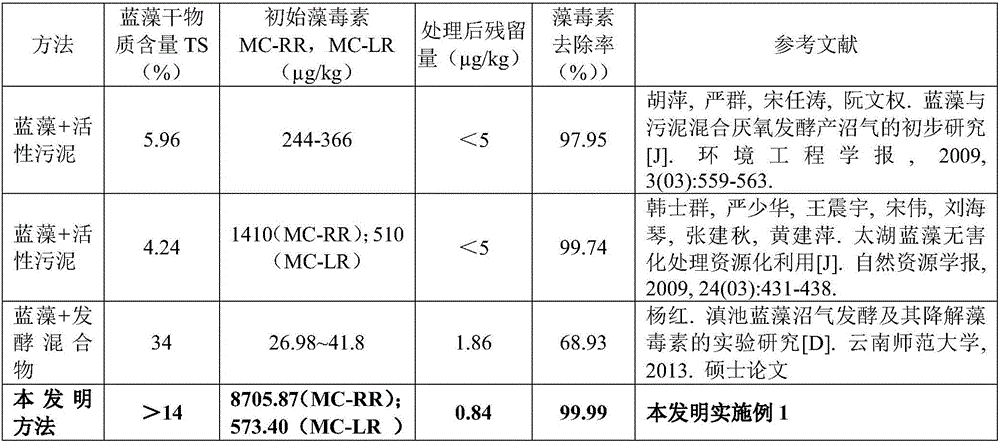

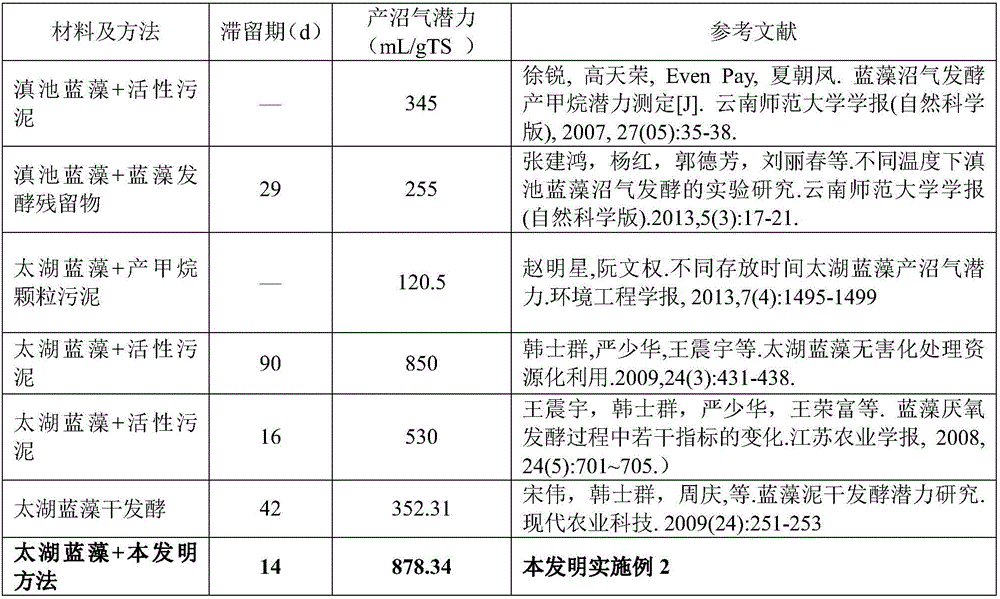

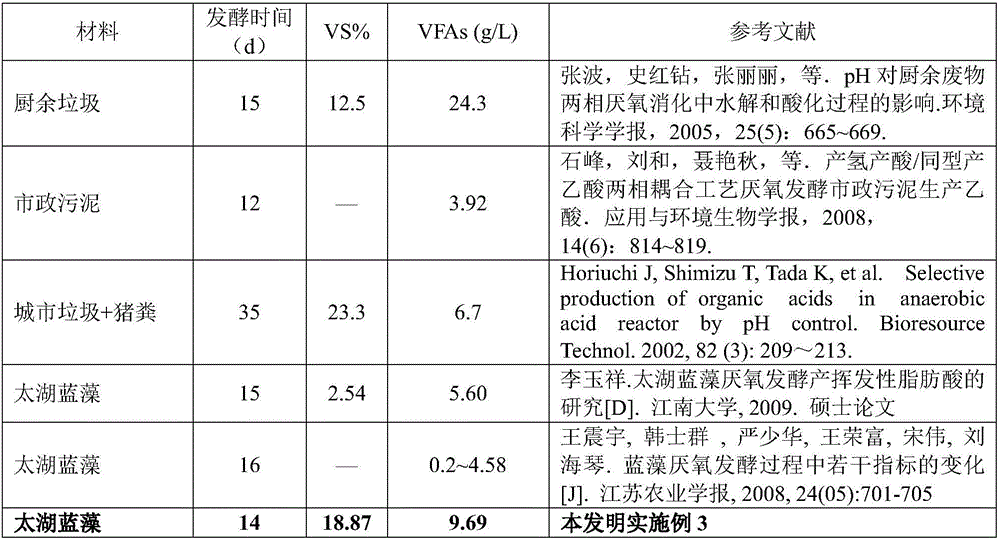

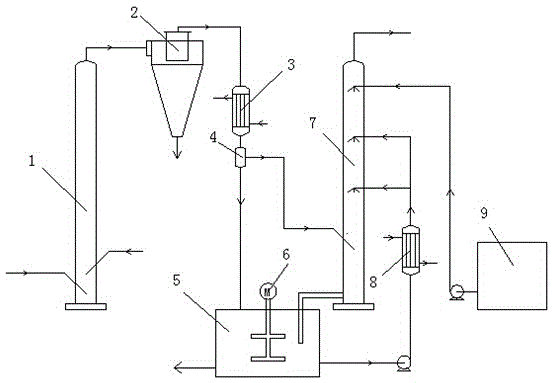

Blue-green algae harmless disposal and recycling treatment method

PendingCN106222206ARealize harmless disposalImplement resourcesWaste based fuelFermentationThree levelDecomposition

The invention relates to a blue-green algae harmless disposal and recycling treatment method. The method includes: step 1, performing wall breaking and decomposition on blue-green algae; step 2, degrading algal toxin on three levels; step 3, strongly acidizing; step 4, performing dry fermentation to generate biogas. The method realizes harmless disposal and recycling of blue-green algae and is high in treatment rate, low in algal toxin residue and high in biogas generating potential.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Method for producing nanosilicon dioxide and by-product hydrochloric acid through chlorosilane waste gas

ActiveCN105036141AFine particleReduce moisture contentChlorine/hydrogen-chlorideMaterial nanotechnologyHigh concentrationWater vapor

The invention discloses a method for producing nanosilicon dioxide and by-product hydrochloric acid through chlorosilane waste gas, and belongs to the field of chlorosilane waste gas recycling in the polycrystalline silicon industry. The method includes the steps that chlorosilane waste gas and water vapor react, gas-liquid separation is conducted on the reaction product to obtain the nanosilicon dioxide, gas obtained through gas-solid separation is cooled, most of the water vapor is condensed, part of hydrogen chloride is absorbed, the rest of the gas where gas-liquid separation is conducted is washed through hydrochloric acid and industrial water, and high-concentration hydrochloric acid is obtained. According to the method, the water vapor and the chlorosilane waste gas perform a gas-vapor hydrolysis reaction so that the nanosilicon dioxide can be obtained, and gas-solid separation is conducted on tail gas through the industrial water and the hydrochloric acid so that the concentrated hydrochloric acid can be obtained. The water vapor is mainly used as the hydrolysis reagent of the mixed chlorosilane waste gas, the high-concentration hydrochloric acid is used as absorbent, less impurity elements are brought in, and the quality of silicon dioxide and the concentrated hydrochloric acid is ensured. Harmless processing of the chlorosilane waste gas is achieved, and silicon elements and chlorine elements in the waste gas are recycled.

Owner:KUNMING UNIV OF SCI & TECH +1

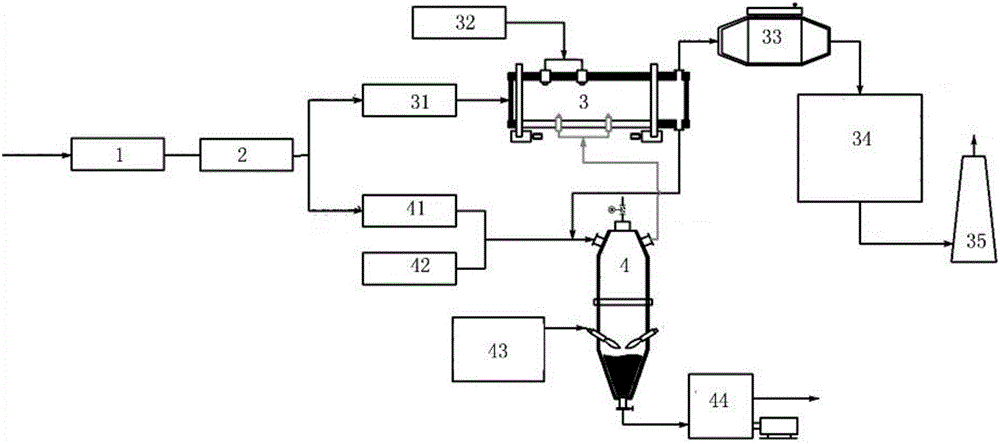

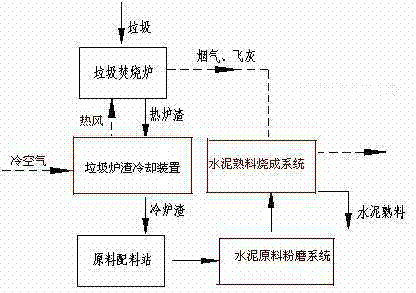

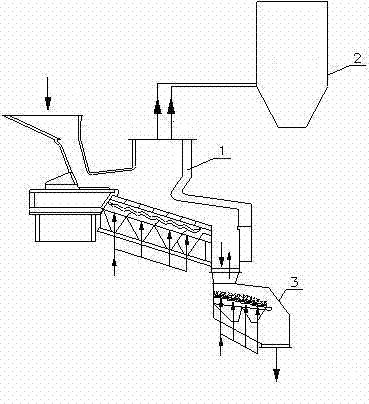

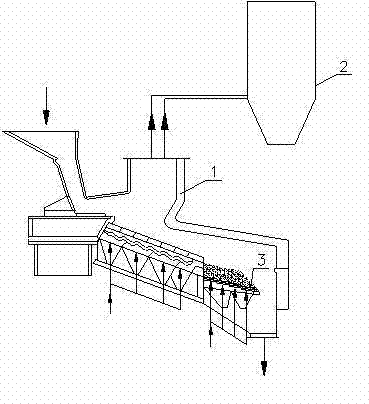

Treatment method and implementation system for refuse incineration ash

InactiveCN102730993ARealize capacity reductionImplement resourcesCement productionThermodynamicsSlag

The invention relates to a treatment method and system for refuse incineration ash. The treatment method for the refuse incineration ash comprises the steps that: the refuse is incinerated in an refuse incinerator (1) and the generated fly ash as well as the incineration smoke enters a decomposition furnace (2) of a cement clinker sintering system and then enters a cement kiln together with cement raw meal to be sintered to the cement clinker; hot slag is discharged out of the refuse incinerator after incineration, and is cooled in a refuse slag cooling device (3) by cooling air; the cool air exchanges heat with the hot slag to form hot air, and the hot air enters the refuse incinerator for drying and incinerating the refuse; cool slag formed by air cooling of the hot slag enters a raw material batching station to be used as the raw material of the cement and to enter a cement raw material milling system to be subjected to cement raw meal milling; and the cool slag and the other raw materials are milled to obtain the powdery cement raw meal, and the powdery cement raw meal enters the cement clinker sintering system to sinter to obtain the cement clinker. According to the system for the refuse incineration ash, the refuse slag cooling device is connected with the refuse incinerator and is arranged below the refuse incinerator.

Owner:NANJING KISEN INT ENG

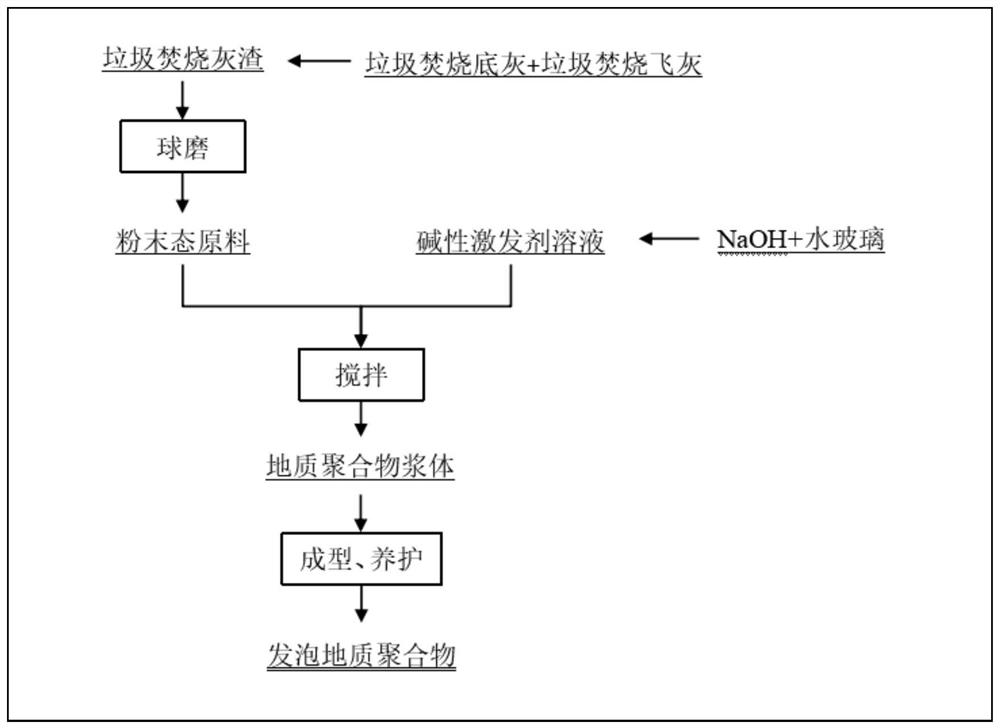

Method for preparing foam geopolymer from waste incineration ash

The invention belongs to the field of comprehensive utilization of solid wastes, and particularly relates to a method for preparing a foam geopolymer from waste incineration ash. The method comprises the following steps: carrying out ball milling on waste incineration bottom ash and fly ash, conducting mixing with an alkaline activator, and conducting stirring, pouring, maintaining and demolding to obtain the porous geopolymer. The waste incineration ash is used as a raw material for preparing the porous geopolymer, so that the economic benefit is high, the environmental pollution is reduced, and harmless treatment and high-value utilization of the waste incineration ash are realized.

Owner:UNIV OF SCI & TECH BEIJING

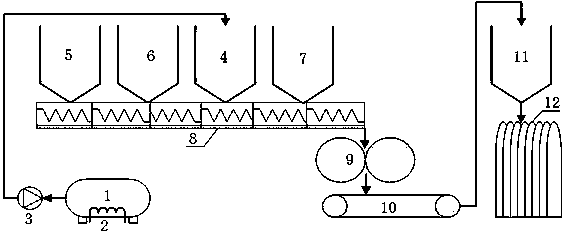

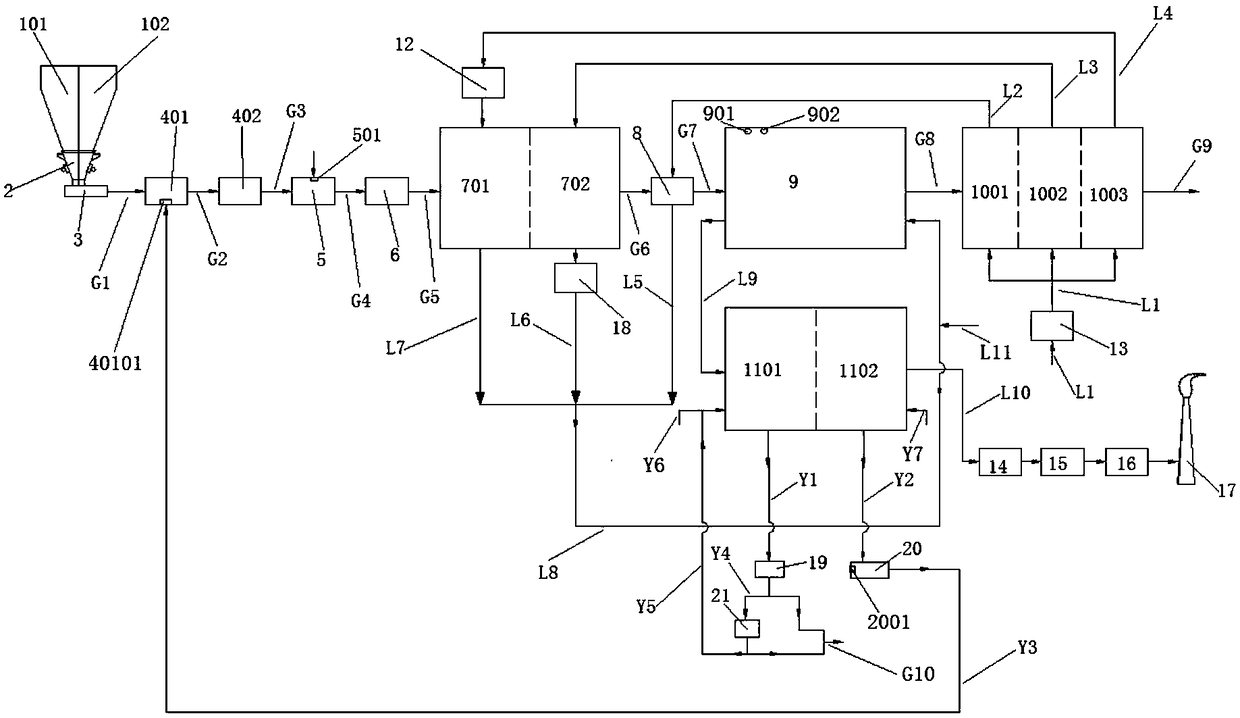

Process for municipal and metallurgical refractory solid waste synergic resource utilization

InactiveCN109423558ASolve environmental problemsSolve social problemsProcess efficiency improvementResource utilizationFlue gas

The invention discloses a process for municipal and metallurgical refractory solid waste synergic resource utilization. The process comprises the following steps that 1) distribution is performed, wherein garbage incineration fly ash in a garbage incineration fly ash bin and metallurgical dust in a metallurgical dust bin pass through a vibration hopper and a feeding machine, and then are conveyedto a mixing device; 2) mixing is performed, wherein mixing is performed by the mixing device, and then mixed powder is obtained; 3) damp grinding is performed, wherein damp grinding is performed on the mixed powder, and the mixed powder subjected to damp grinding is obtained; and 4) pelletizing is performed, wherein pelletizing is performed on the mixed powder subjected to damp grinding, and powder pellets are obtained; 5) drying is performed, wherein drying is performed on the powder pellets, and the dried powder pellets are obtained; 6) preheating is performed, wherein preheating is performed on the dried powder pellets, and the preheated powder pellets are obtained; and 7) roasting is performed, wherein high-temperature chlorination roasting is performed on the preheated powder pellets.According to the process, the garbage incineration fly ash is used as a chlorinating agent, the heavy metal metallurgy dust containing lead, zinc and the like is treated by adopting the high-temperature chlorination roasting process, a flue gas treatment process, a valuable metal recovery process and other processes are adopted.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

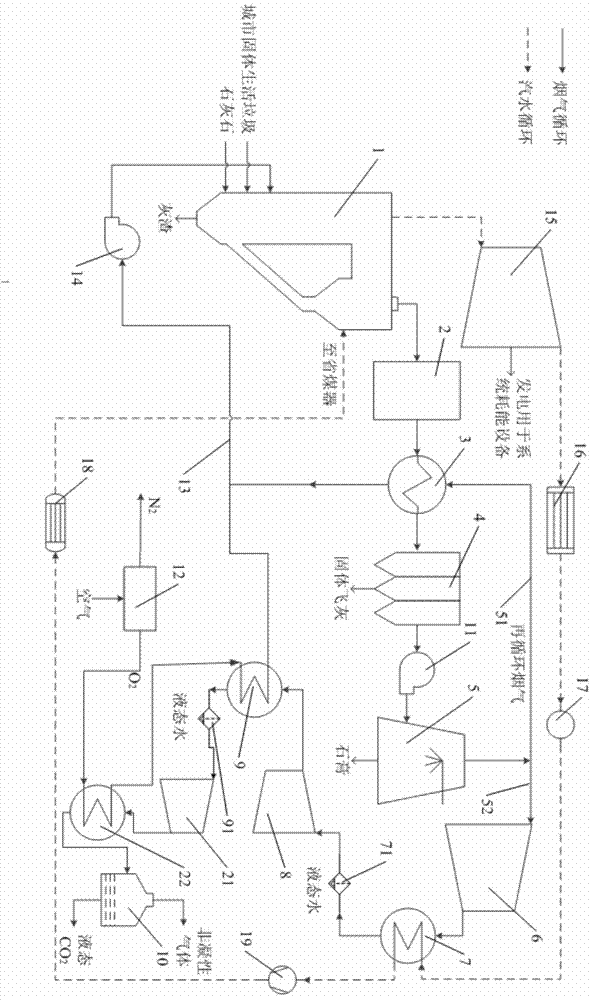

Harmless disposal system for refuse and method for refuse disposal by harmless disposal system

InactiveCN104501176AAvoid corrosionLow costSolidificationLiquefactionHigh concentrationChemical products

The invention relates to a harmless disposal system for refuse and a method for refuse disposal by the harmless disposal system. The refuse is subjected to combustion disposal by a circulating fluidized bed combustion technology, and O2 / CO2 mixed gas formed by mixing of high-concentration oxygen with recycled flue gas is adopted to substitute for air to participate in solid refuse combustion during refuse combustion. A relatively high-temperature combustion condition can be achieved in oxygen-enriched and oxygen-enriched combustion environments, and generation of dioxin and dioxin precursors is inhibited. After flue gas is subjected to denitration, dust removal and desulfurization, one part of the flue gas forms the recycled flue gas after being preheated by a gas-to-gas heat exchanger; after the other part of the flue gas is subjected to multi-stage compression and multi-stage cooling and water therein is recycled, high-purity liquid-state CO2 is formed to serves as chemical products or be used for oil well oil displacing or geological storage. The harmless disposal system adopting refuse combustion does not discharge gaseous pollutants any longer, so that the problem of secondary pollution caused by refuse combustion is solved thoroughly, and harmless disposal with near-zero emission of gaseous pollutants caused by refuse combustion is realized truly.

Owner:BEIJING JIAOTONG UNIV

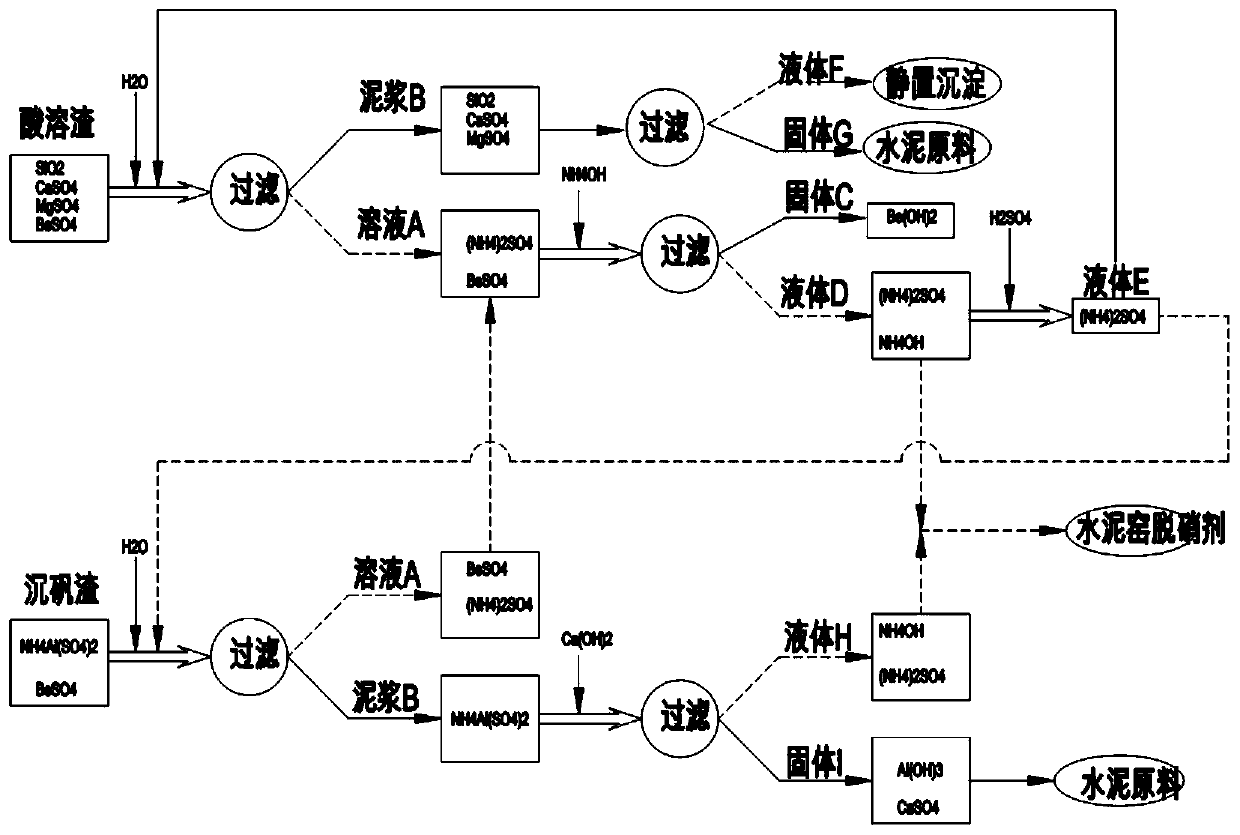

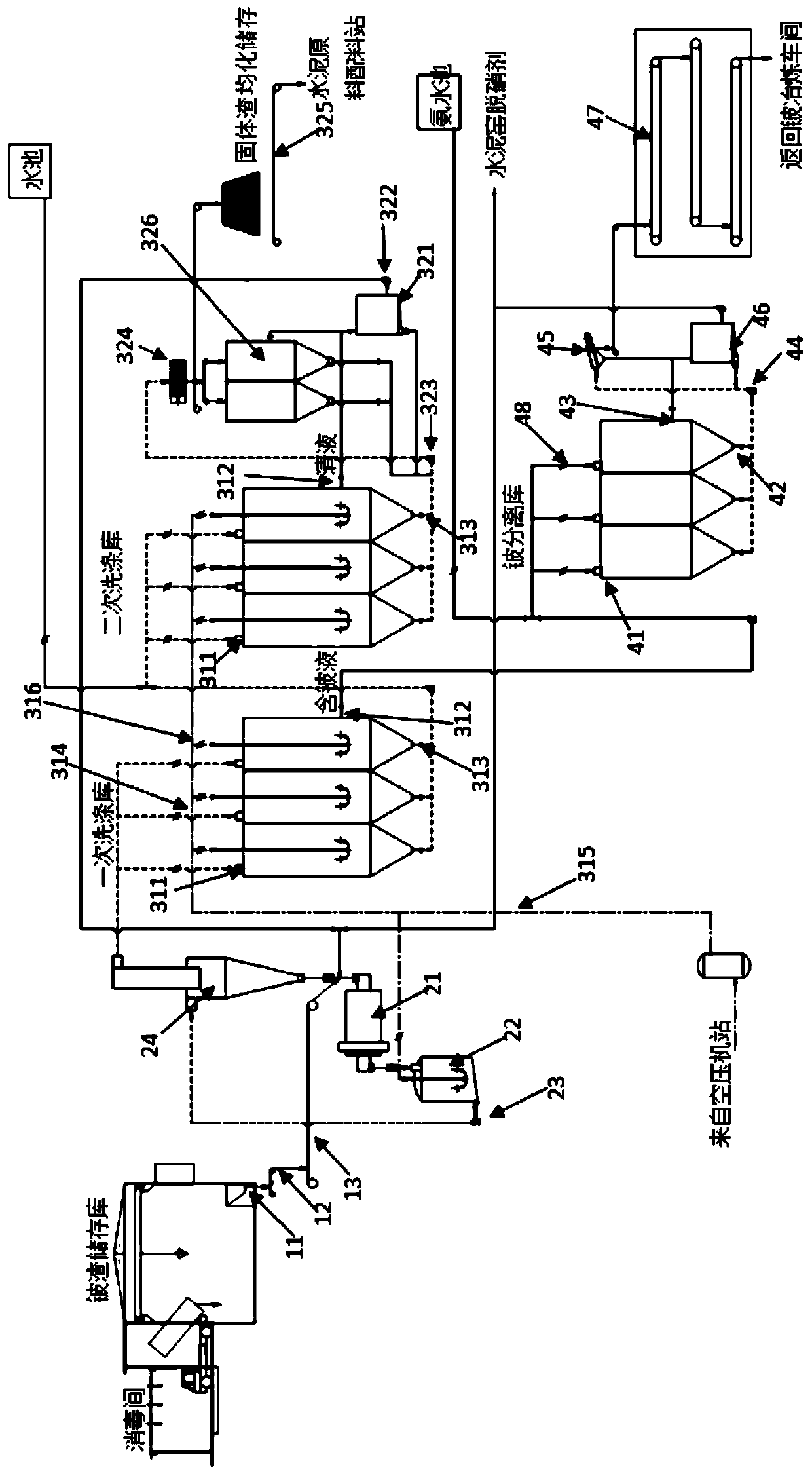

Detoxification and cement kiln cooperated resource-converting treatment system for beryllium slag and process

ActiveCN109761514ARealize harmless disposalMeet protection requirementsDispersed particle separationCement productionSolubilityTreatment system

The invention discloses a detoxification and cement kiln cooperated resource-converting treatment system for beryllium slag and a process. A beryllium sulfate solution and solid residues can be formedthrough subjecting the beryllium slag to water washing under acidic conditions, beryllium hydroxide precipitates are produced after subjecting the beryllium sulfate solution to a reaction with ammonia water, the precipitates are separated, and then, beryllium hydroxide is recovered; the solid residues are treated and then are fed to a system cement kiln for high temperature calcination, berylliumsolids contained in the solid residues are melted into cement clinker lattices to form minerals such as ferrum calcium beryllate, aluminum calcium beryllate and calcium beryllate; the content of beryllium in cement reaches trace, and the leaching solubility is lower than 0.1microgram / l, so that the requirements of the cement on raw materials are met; an ammonia nitrogen compound produced during reaction is converted into ammonia water or ammonium salts, which can serve as a cement kiln denitration agent or return to a beryllium smelting plant as auxiliaries, residual can be eliminated completely, the toxic hazard characteristic is eliminated thoroughly, and the resource-converting and innocent treatment of the beryllium slag is achieved.

Owner:长沙中硅环保科技有限公司

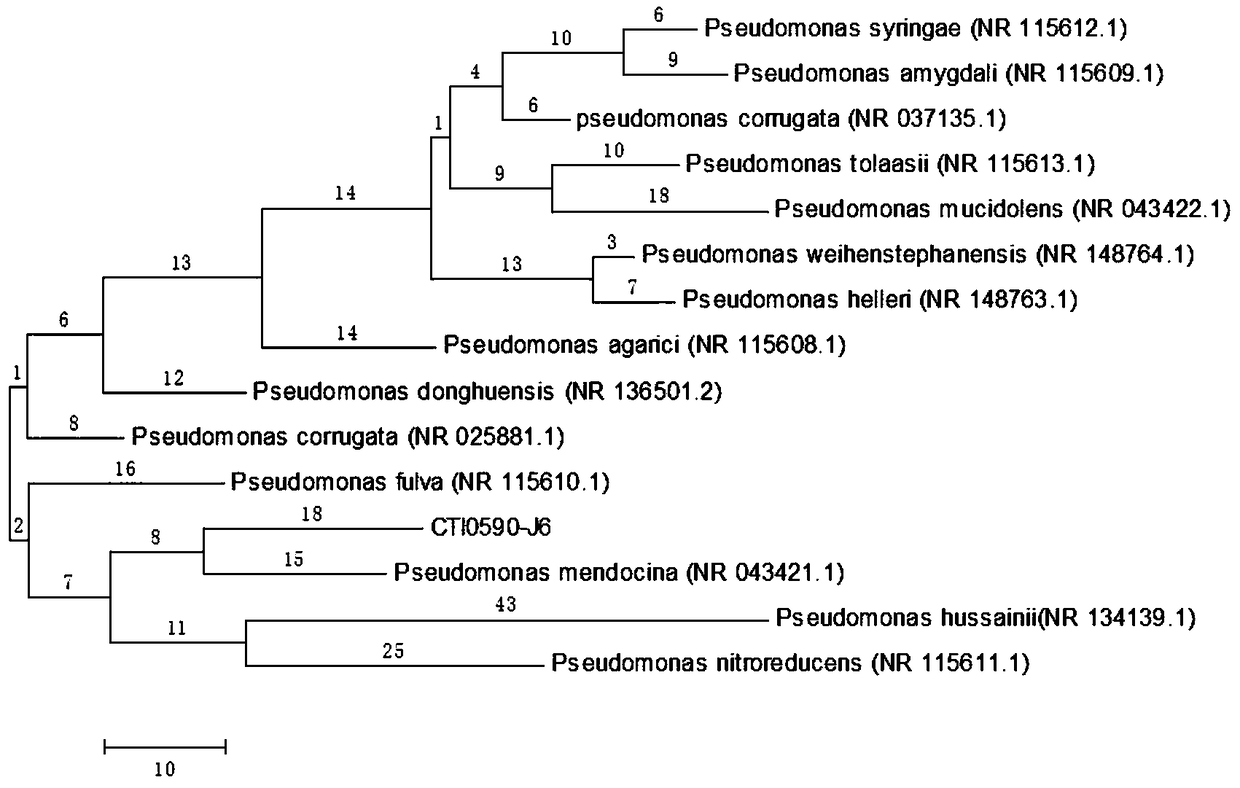

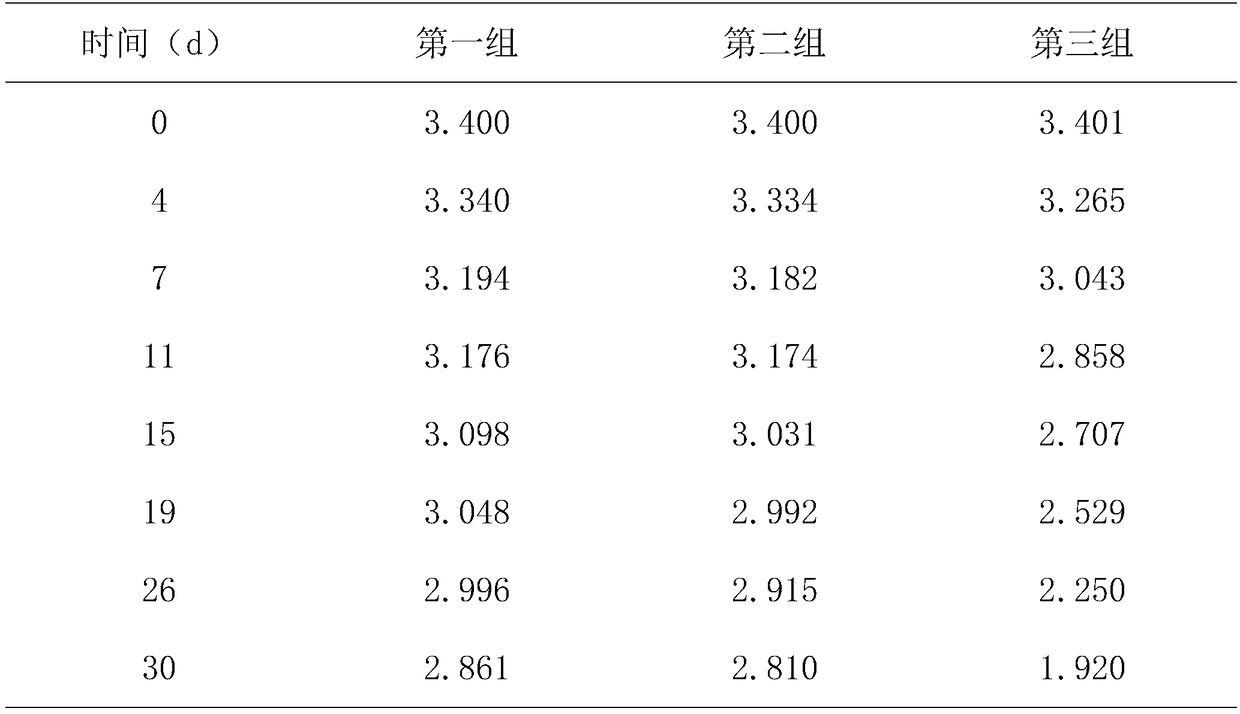

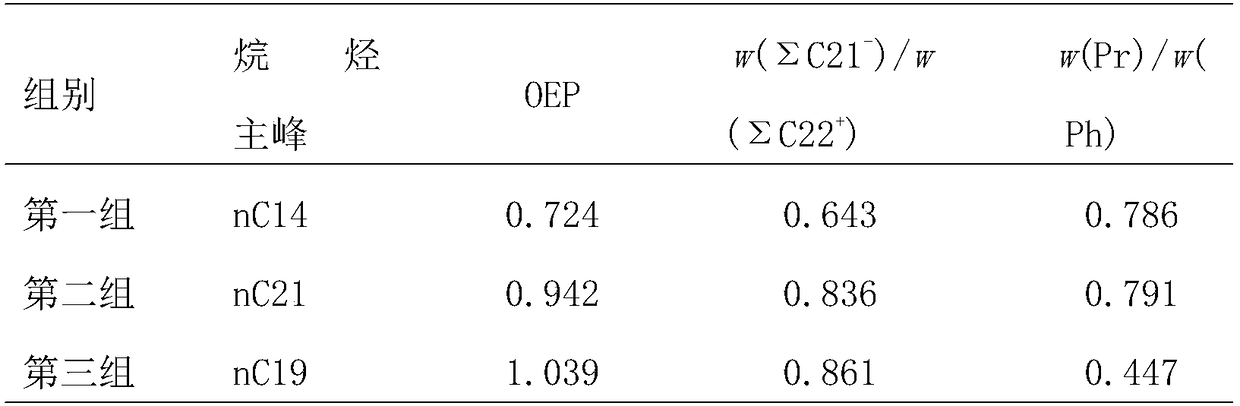

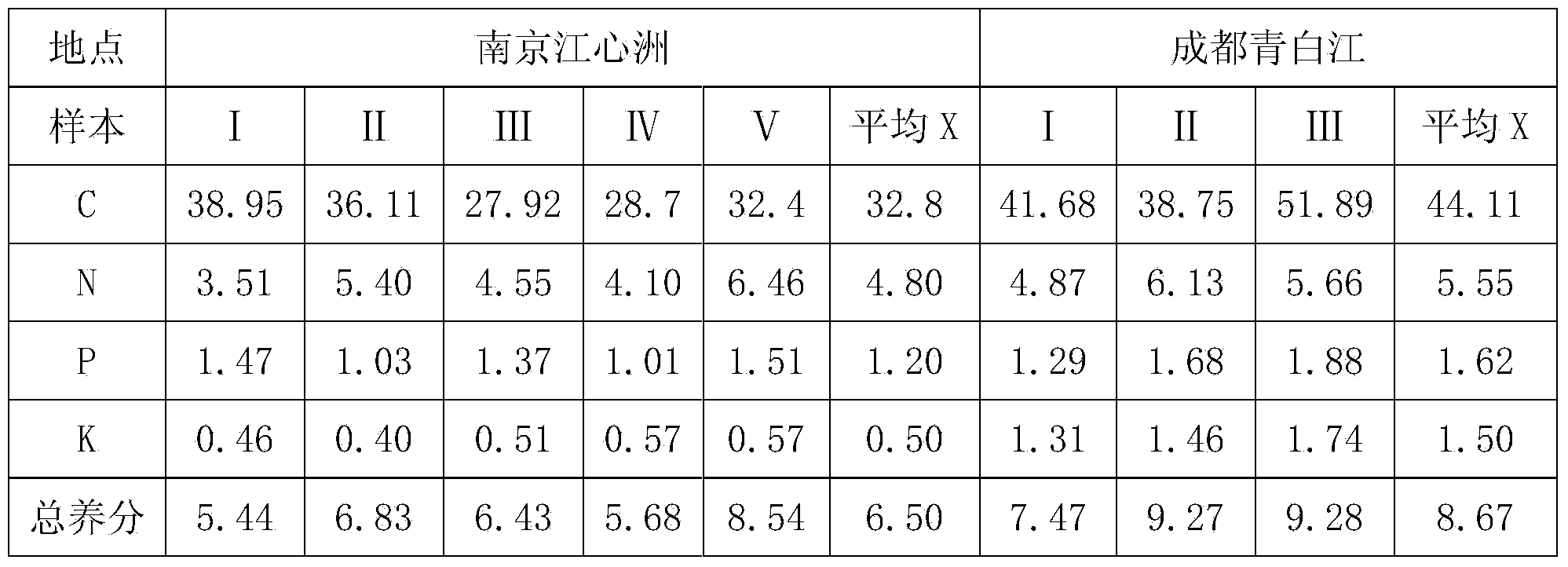

Pseudomonadaceae petroleum degrading bacterium L-1, microbial mixed agent of Pseudomonadaceae petroleum degrading bacterium L-1 and in-situ remediation method of petroleum-contaminated soil

InactiveCN109482638AReduce contentRealize harmless disposalContaminated soil reclamationContaminated soilsPseudomonadaceae

The invention provides a Pseudomonadaceae petroleum degrading bacterium L-1, a microbial mixed agent of the Pseudomonadaceae petroleum degrading bacterium L-1 and an in-situ remediation method of petroleum-contaminated soil. The preservation number of the Pseudomonadaceae petroleum degrading bacterium is CGMCC NO.16557. The microbial mixed agent contains the Pseudomonadaceae petroleum degrading bacteria in the preservation number being CGMCC NO.16557 and indigenous bacteria. By the aid of the method, the content of petroleum hydrocarbon and polycyclic aromatic hydrocarbon in petroleum-containing sludge can be reduced effectively, harmless treatment of the petroleum-containing sludge can be realized, harms caused by the contaminated soil to human bodies can be eliminated, and ecological functions of the soil can be restored. Thus, degradation of the petroleum hydrocarbon is used as a starting point, microbes having the obvious degrading effect on soil petroleum are separated and cultivated, and the specific implementation measure of an on-site petroleum-contaminated soil microbial in-situ remediation technology is further provided. The petroleum-contaminated soil with the concentration being 3% can be degraded by 77% after 30 days.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Organic-inorganic compound fertilizer and production method thereof

The invention discloses an organic-inorganic compound fertilizer and a production method thereof. The production method comprises the following steps: squeezing sludge until the water content is 60-70%; drying and dehydrating montmorillonite and zeolite, mixing with the squeezed sludge while hot; aerobically treating the mixture and drying to obtain powder, mixing the powder with urea, MAP (monoammonium phosphate) and potassium chloride, spraying sodium silicate to pelletize, drying, sterilizing and packing. The organic-inorganic compound fertilizer has the benefits that the problems of land occupation and secondary pollution caused by a great amount of sludge from an urban sewage treatment plant are solved, the fertilizer efficiency is obvious, better than that of various fertilizers on current market, and achieves the national compound fertilizer standard; the montmorillonite and the zeolite are capable of promoting the ion exchange of soil, improving the capacity of conserving nitrogen, phosphorus and potassium and other nutrients of the soil and improving the granular structure of the soil and has a remarkable effect of improving acid soil and saline alkali soil; since the sodium silicate contains about 65% effective silicon, the rice blast can be effectively resisted, and the product quality of crops can be improved.

Owner:李泓坤

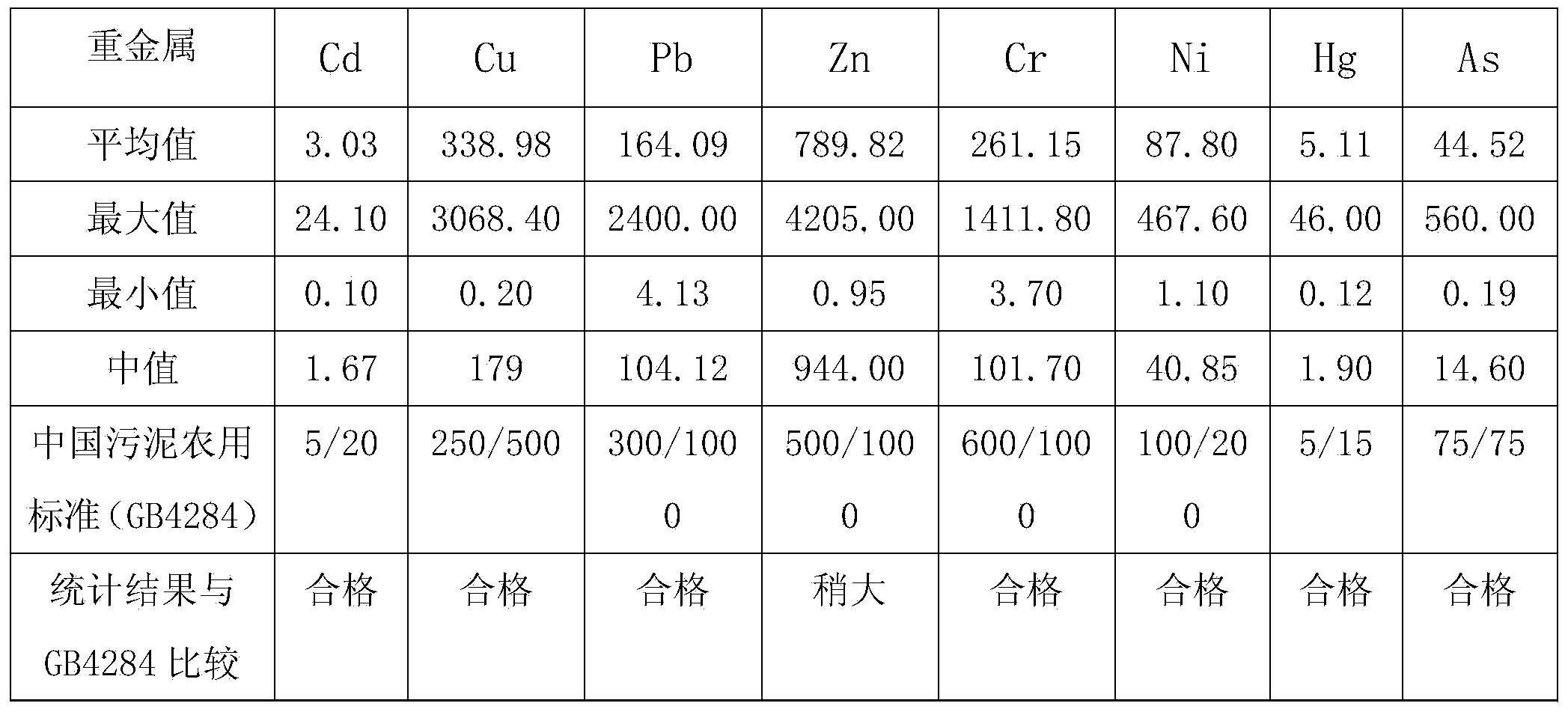

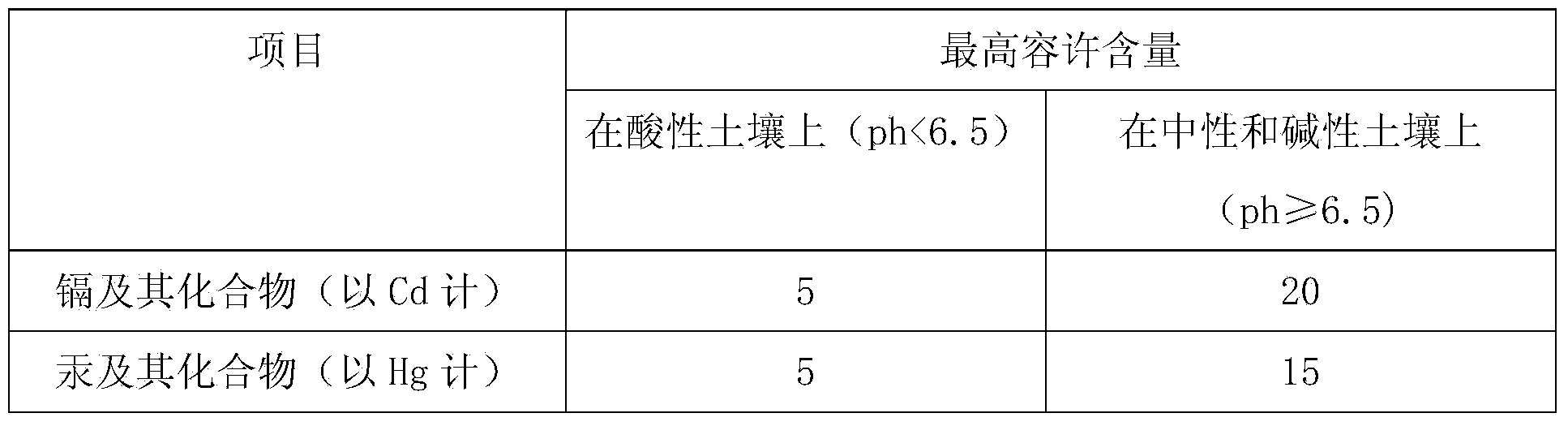

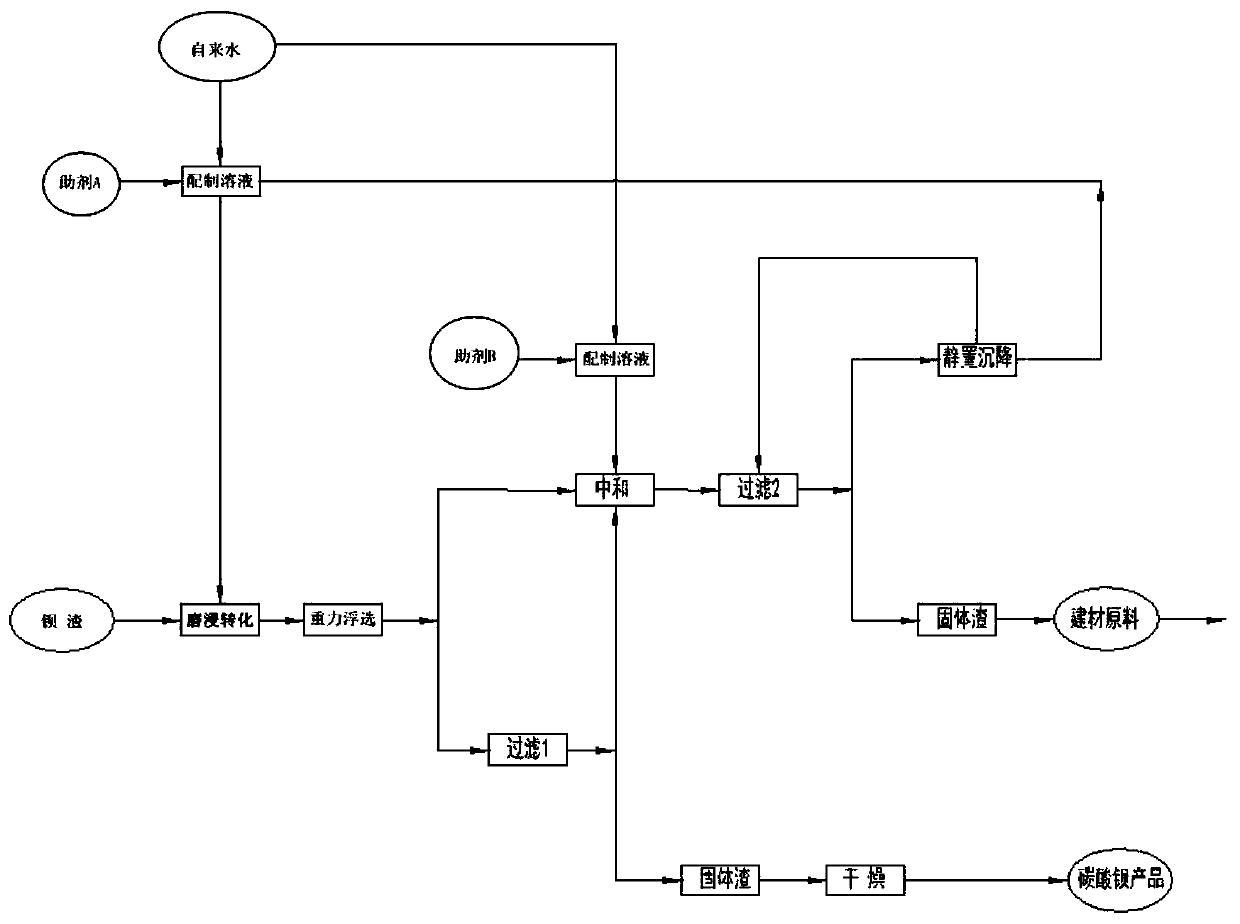

Combined treatment method for acid sludge and desulfurization ash

InactiveCN104415963ARealize harmless disposalSimple processSolid waste disposalActivated sludgeEconomic benefits

The invention relates to the field of comprehensive utilization of industrial wastes and particularly relates to a combined treatment method of waste acid sludge in the lubricating oil recycling industry and desulfurization ash in the dry-process / semidry process flue gas desulfurization industry. The combined treatment method of the acid sludge and the desulfurization ash comprises the following steps: after pulping the desulfurization ash, mixing and aerating with the acid sludge, and performing phase separation by virtue of emulsion-breaking and neutralizing effects, wherein an oil phase is utilized as fuels, a water phase is returned to a desulfurization ash pulping system for recycling, and a solid phase is utilized as a building material. The combined treatment method disclosed by the invention is simple in process, environmentally friendly, and capable of realizing innocent treatment of harmful wastes and developing a new way for recycling the harmful wastes, and has good economic benefits and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD +1

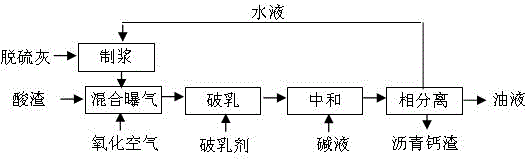

Waste organic solvent recycling method

ActiveCN108410526AResource utilization is efficient and safeAvoid contamination riskWaste based fuelLiquid carbonaceous fuelsHydrogenOrganic solvent

The invention provides a waste organic solvent recycling method which includes the steps: (1) mixing waste organic solvents, water and auxiliaries and adjusting pH (potential of hydrogen) values to prepare pretreating solution; (2) mixing the pretreating solution with carbon source substances to obtain water-coal-slurry; (3) performing gasification reaction on the water-coal-slurry in oxygen-bearing atmosphere at the temperature of 1100-1700 DEG C under 0.5-4MPa to obtain gaseous products and liquid slag; (4) separating the gaseous products and the liquid slag by chilling to obtain mixed gas and glassy slag. Waste is cooperatively disposed by water-coal-slurry gasification and high-temperature melting, so that the waste organic solvents are decomposed at high temperature in a short time, all elements C, H, O and N in the waste organic solvents are transferred into the gaseous products, the gaseous products are purified and transformed to obtain the mixed gas with high CO2 and H2 content, the mixed gas is used for producing ammonium bicarbonate, and the waste organic solvents are efficiently and safely treated and recycled.

Owner:ZHEJIANG FENGDENG CHEM

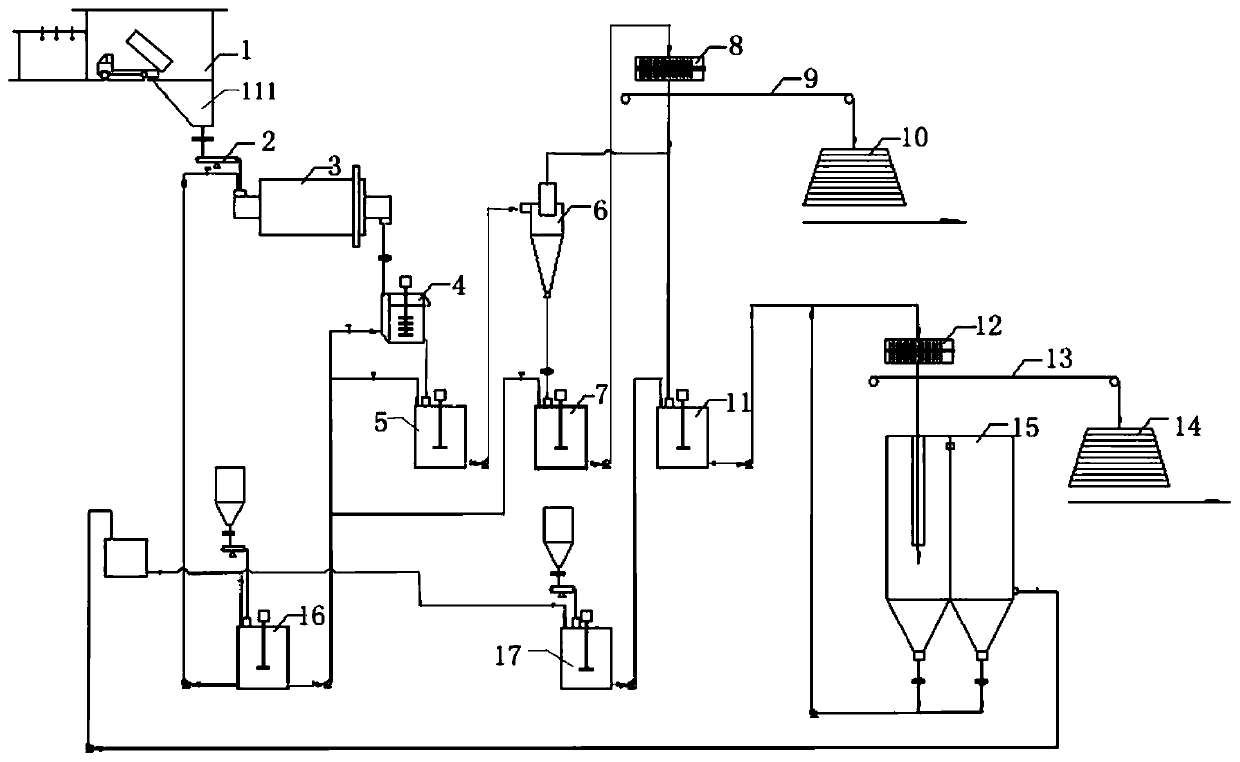

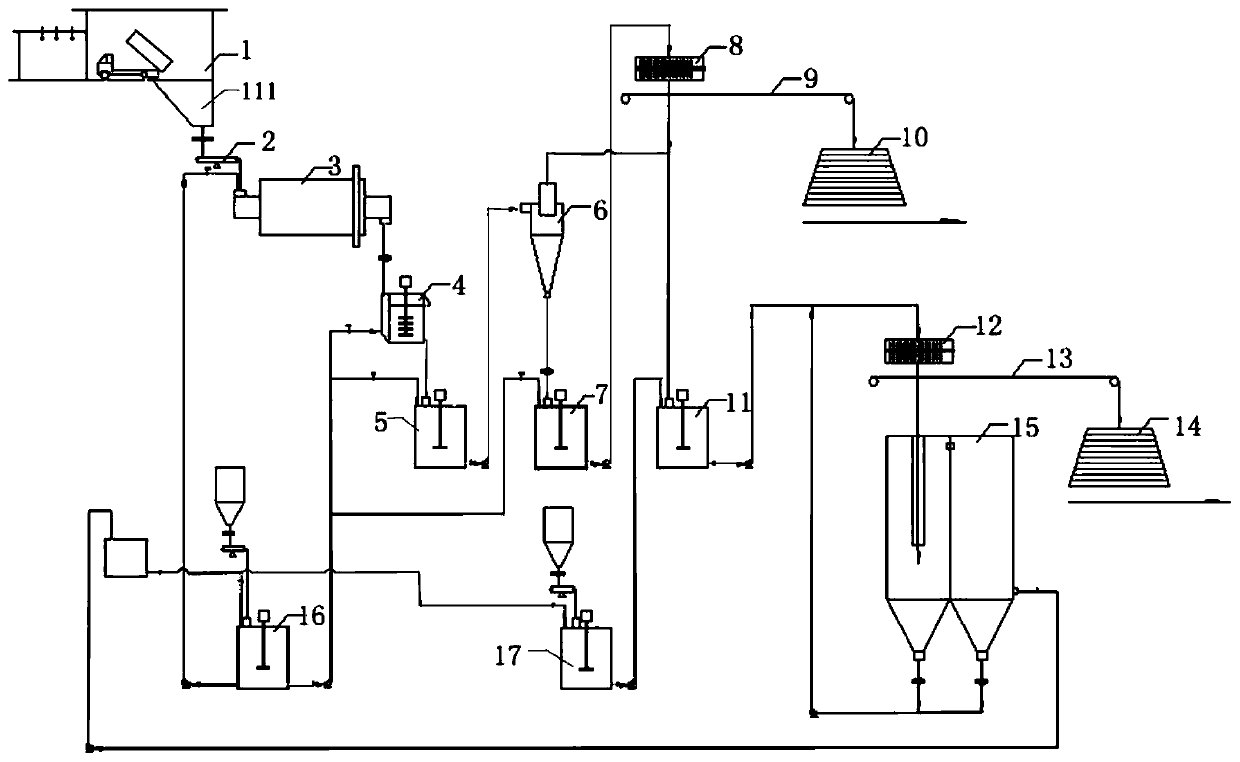

Method and system for preparing barium sulfate by using barium slag

PendingCN109970089AReduced chemical contentAchieve recyclingCalcium/strontium/barium sulfatesSlagBarium sulfate

The invention discloses a method and system for preparing barium sulfate by using barium slag. The method includes a step of grinding, soaking and conversion, a step of gravity flotation, a step of solution impurity removal and recycling, and the like. The system comprises a barium slag feeding system, a grinding, soaking and conversion system, a gravity flotation system, a solution impurity removal and recycling system and a building raw material application system. A cheap converting agent is adopted for grinding, soaking and conversion to convert soluble barium in the barium slag into an insoluble matter so that toxicity of the barium slag is removed, the barium slag becomes a nontoxic building raw material, and a high amount of a BaSO4 product can be recovered. The method and the system have advantages of a short process, simple operation, and capability of being economical, environmentally friendly, clean and efficient, are suitable for industrial production of barium slag detoxification, and accord with resource recycling.

Owner:长沙中硅环保科技有限公司 +1

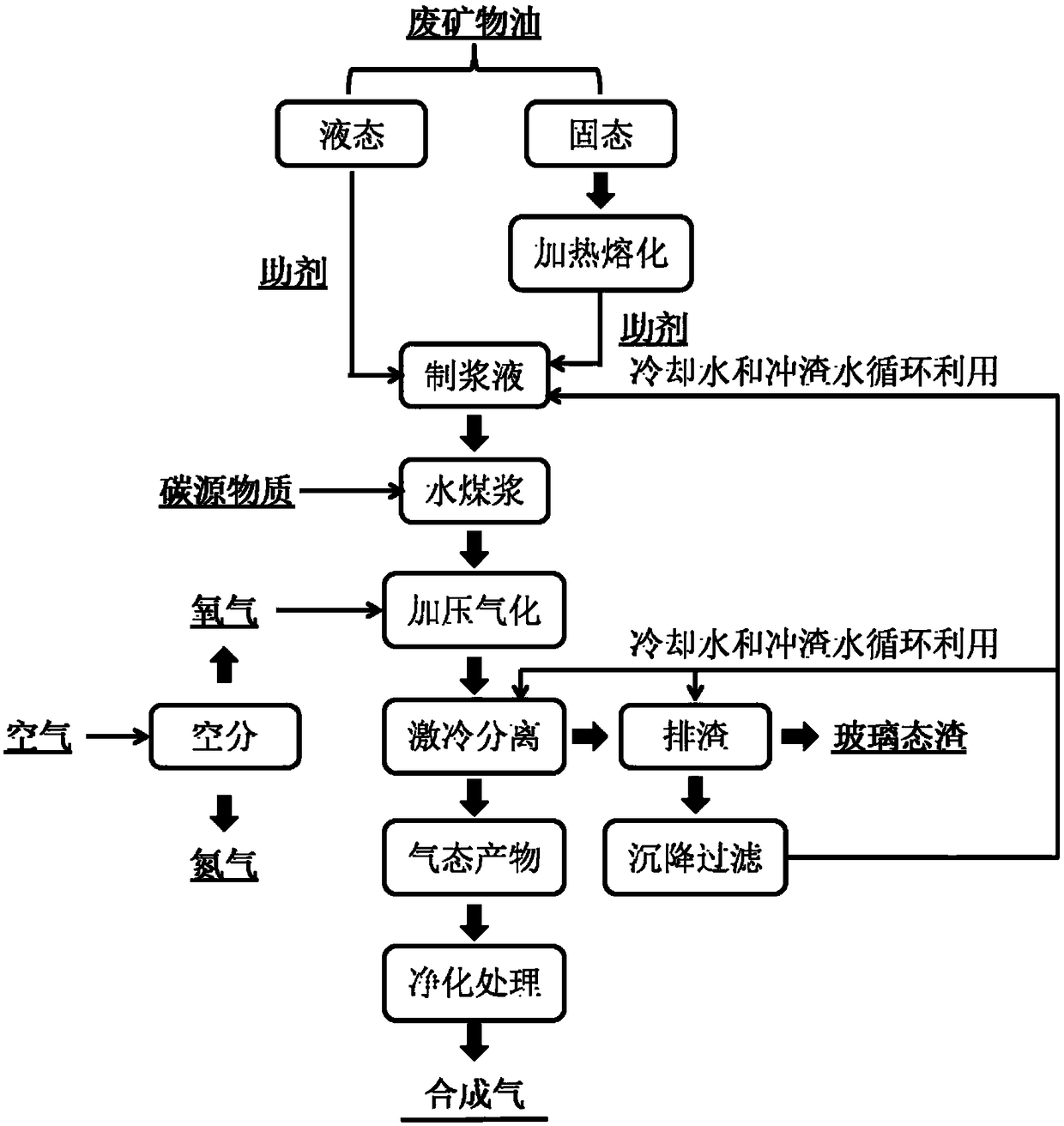

Harmless disposal and utilization method of waste mineral oil

ActiveCN108264946ARealize harmless disposalNo secondary pollutionGasification processes detailsLiquid carbonaceous fuelsDecompositionResource utilization

The invention provides a harmless disposal and utilization method of waste mineral oil. The method comprises the following steps of mixing the waste mineral oil and auxiliary agents to obtain slurry;mixing the prepared slurry with carbon source substances for preparing water-coal slurry; performing gasification reaction on the water-coal slurry in an oxygen-containing atmosphere at 1100 to 1700 DEG C and 0.5 to 4 MPa to obtain a gaseous product and a liquid-state molten slag; performing quenching separation on the gaseous product and the liquid-state molten slag to obtain mixed gas and glass-state slag. By aiming at the characteristics of the waste mineral oil, the water-coal slurry gasification and high-temperature melting cooperated waste treatment technology is used, so that the wastemineral oil realizes the high-temperature decomposition in a short time; the contained C, H, O, N and Cl are totally converted into the gaseous product; after the purification treatment, synthesis gasusing CO and H2 as major ingredients is obtained; the method can be used for producing basic chemical engineering raw materials or fuel gas of various high-added-value products; the harmless treatment and resource utilization f the waste mineral oil can be realized.

Owner:ZHEJIANG FENGDENG CHEM

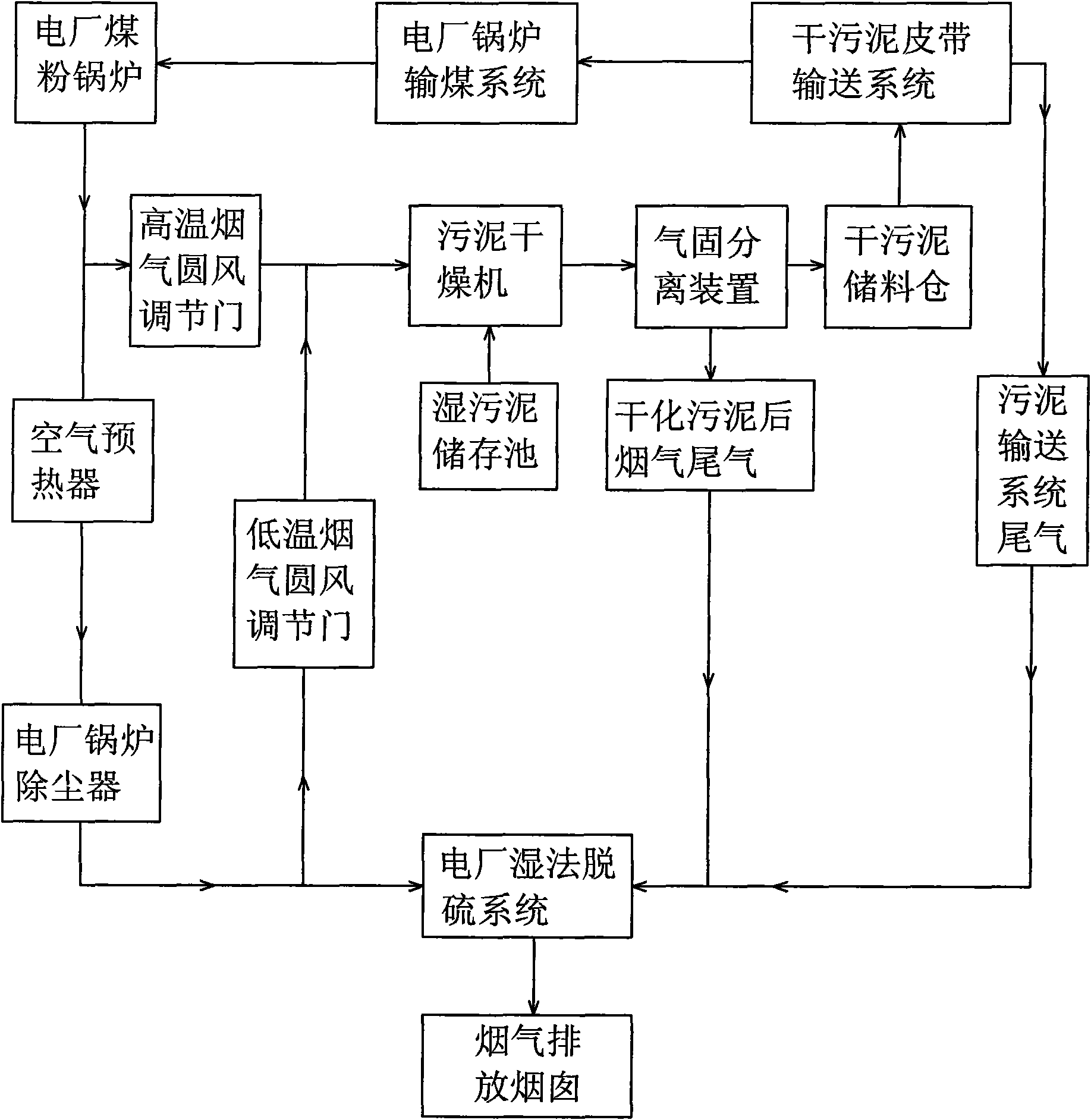

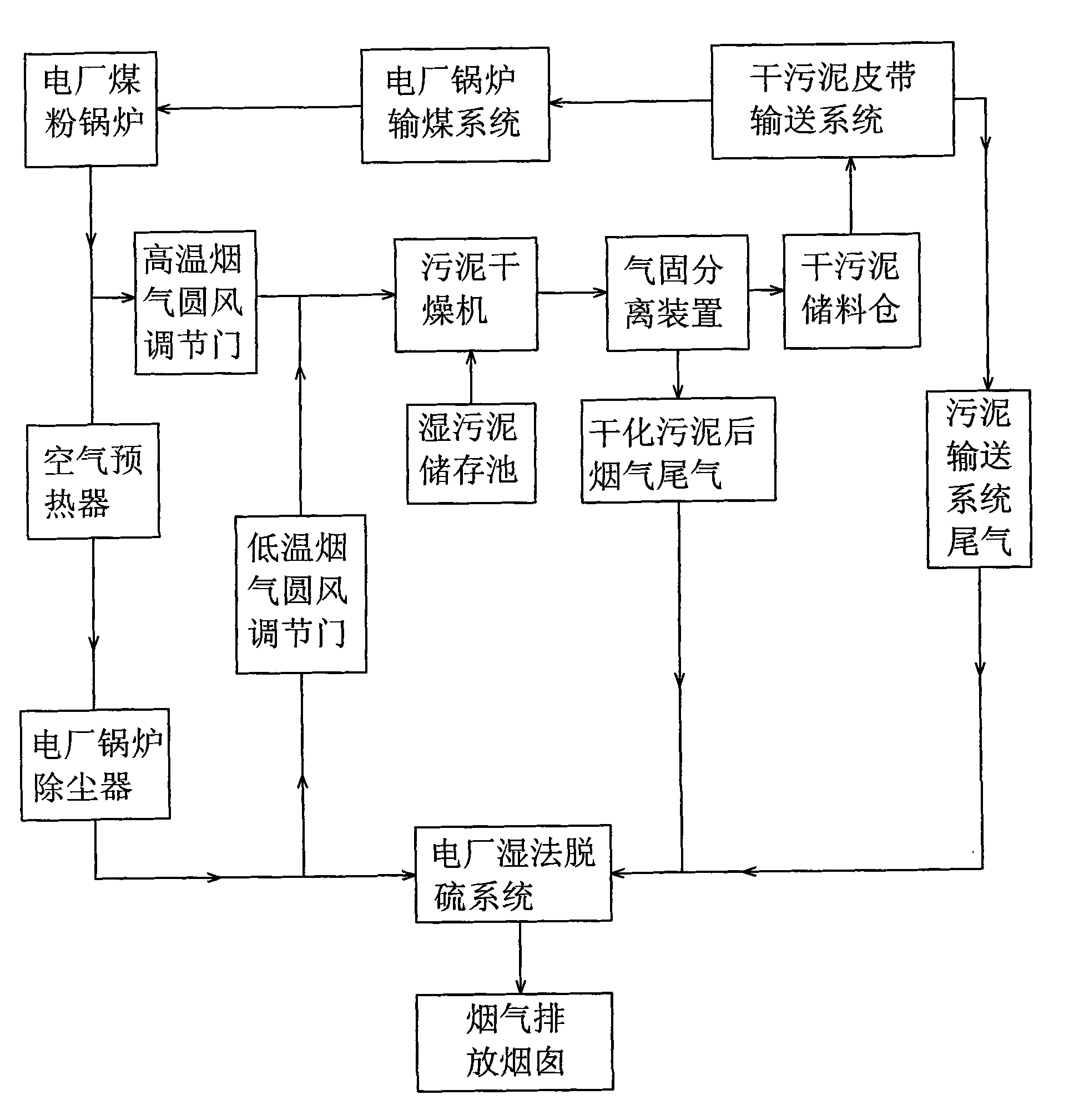

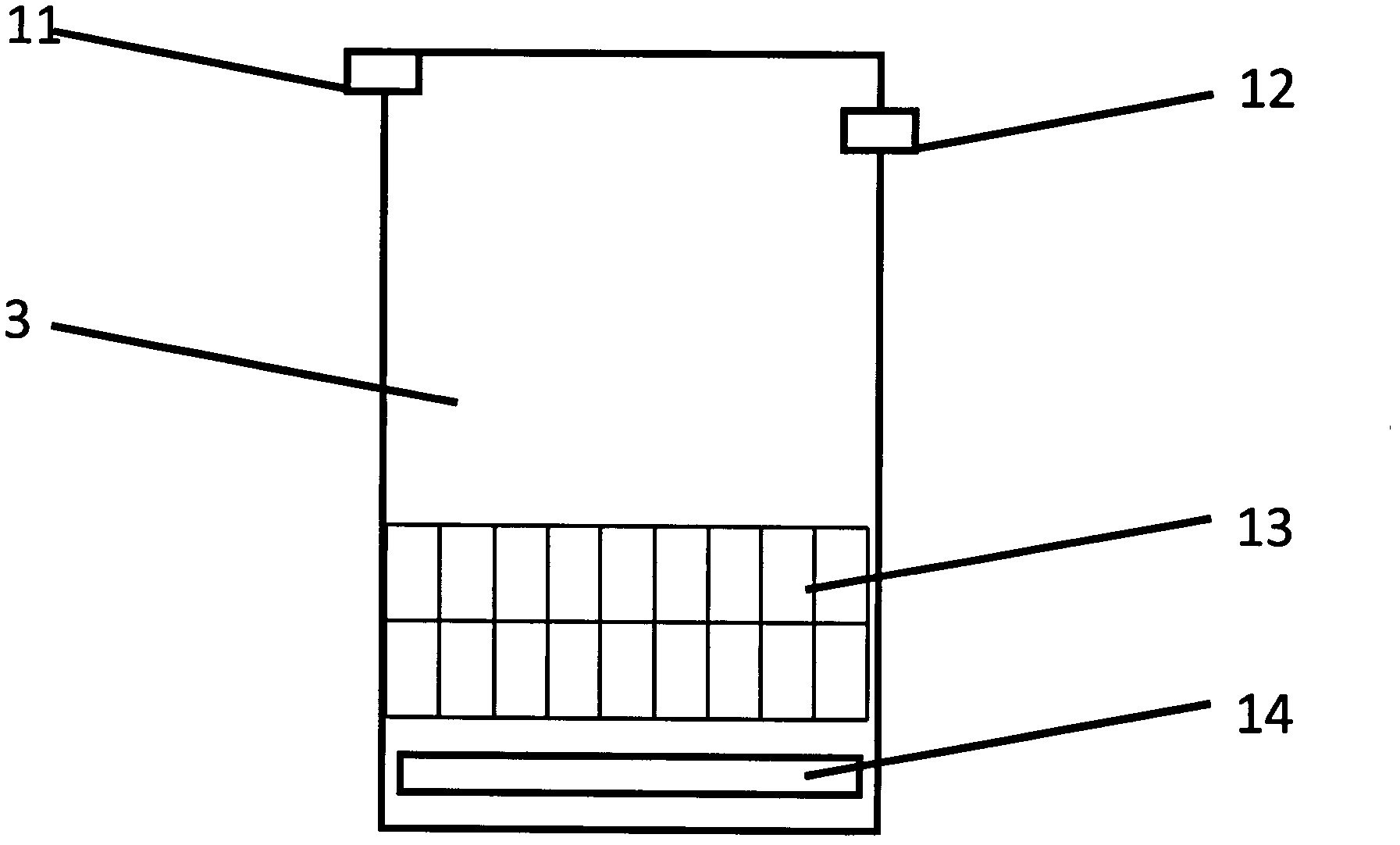

Harmless recycling treatment process for urban sludge

ActiveCN101570388BSimple processLess investmentSludge treatment by de-watering/drying/thickeningDispersed particle separationAir preheaterFlue gas

A harmless recycling treatment process for urban sludge carries out urban sludge treatment through the prior pulverized coal boiler and coal conveying and tail exhaust treatment systems in a power plant. In the treatment process, flue gas extracted from the front part of an air preheater of a power plant pulverized coal boiler is mixed with flue gas extracted from the back part of a power plant boiler dust remover into flue gas with the temperature ranging between 140 and 180 DEG C; the flue gas is conveyed to a sludge drier to carry out sludge drying; and the dried sludge is fed into a powerplant coal conveying system, mixed with coal, and then fed into a furnace to carry out incineration for power generation so as to realize the recycling utilization of the sludge. The coal and dry sludge are burnt in a boiler and discharged flue gas is fed into the power plant boiler dust remover and a wet desulphurization system for treatment; and the flue gas after the drying and tail gas generated by storing and conveying the dry sludge are discharged into a power plant desulphurization system for treatment, so that the standard discharge of pollutants is realized and secondary environmentalpollution is eliminated. The harmless recycling treatment process makes effective use of the prior power plant boiler and coal conveying, burning, dust removal and desulphurization facilities, and has the advantages of simple equipment, less investment, short construction cycle and low operating cost.

Owner:华电滕州新源热电有限公司

Treatment process suitable for rapidly oxidizing magnesium sulfite to magnesium sulfate

InactiveCN103387246ALow costReduce power consumptionMagnesium sulfatesChemical recyclingEvaporationMagnesium sulfite

The invention relates to a treatment process suitable for rapidly oxidizing magnesium sulfite to magnesium sulfate. The process is characterized by comprising the steps of pumping a magnesium sulfite slurry with a certain concentration into an efficient oxidizer; adding a catalyst (copper-cobalt-aluminum composite salt) with a concentration of 0.001-0.003 mol / L in the efficient oxidizer; oxidizing for one hour, and thus magnesium sulfite solid in a desulfurated slurry is almost oxidized completely; transferring the oxidized magnesium sulfite into a condensation reactor; adding a coagulant and coagulant aid so that solid impurities in the slurry are condensed into easily settled large particles; introducing the slurry into a purifier to carry out two-phase separation so as to remove the solid impurities from the solution; overflowing a supernatant liquid to a buffer tank for use by an evaporation and concentration system; and crystallizing the solution in the buffer tank by evaporation and concentration to produce magnesium sulfate heptahydrate. The treatment process has the beneficial effects that by adding the catalyst, oxidation rate is shortened to one hour and power consumption and operation cost are reduced; reuse rate of the catalyst reaches 75%; catalyst cost is reduced; and environmental waste can be treated harmlessly and recycled efficiently.

Owner:CECEP L&T ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com