Acidic flue gas washing wastewater zero-discharge treatment method and apparatus thereof

A zero-emission, flue gas technology, applied in gaseous effluent wastewater treatment, degassed water/sewage treatment, gas treatment, etc., can solve the problems of increasing dry ash viscosity, sticking bags in dust collectors, inability to volatilize ammonia nitrogen, etc. The effect of blocking equipment, low dust viscosity and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

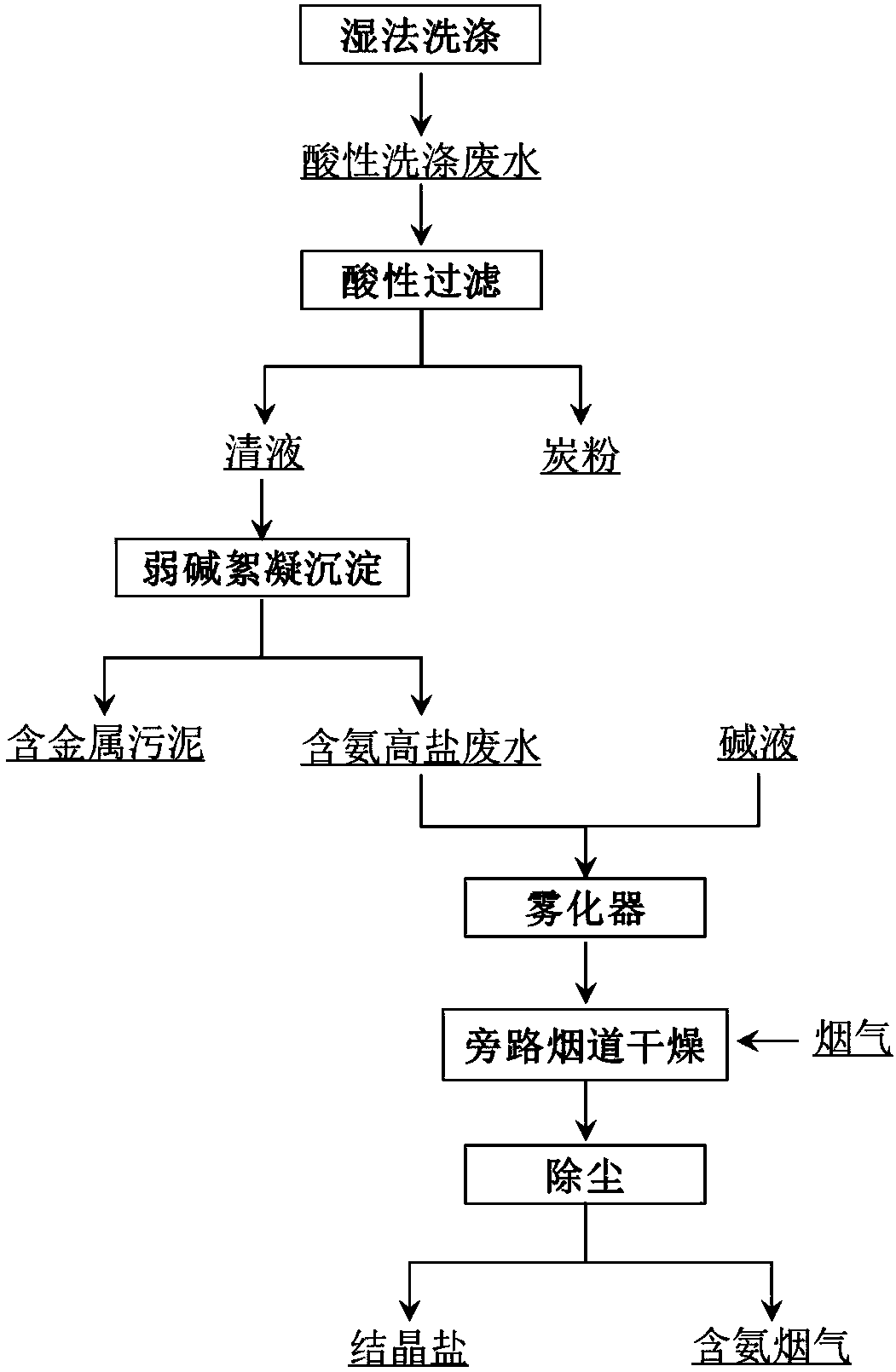

[0147] Such as Figure 4 As shown, a zero-discharge treatment device for acidic flue gas washing wastewater or a device for the method described in the first or second embodiment, the device includes a wet scrubbing device 1, an acidic filtration device 2, and a flocculation and sedimentation device 3 , atomizer 4, flue gas pipeline L1 and dust collector 5. The acid flue gas is transported to the feed port of the wet scrubbing device 1 . The liquid outlet of the wet scrubbing device 1 is connected to the acid filter device 2 . The liquid outlet of the acid filter device 2 is connected to the flocculation sedimentation device 3 . The liquid outlet of the flocculation and sedimentation device 3 is connected to the atomizer 4 . The atomizer 4 is connected to the flue gas duct L1. The flue gas pipe L1 is connected to the dust collector 5 .

Embodiment 2

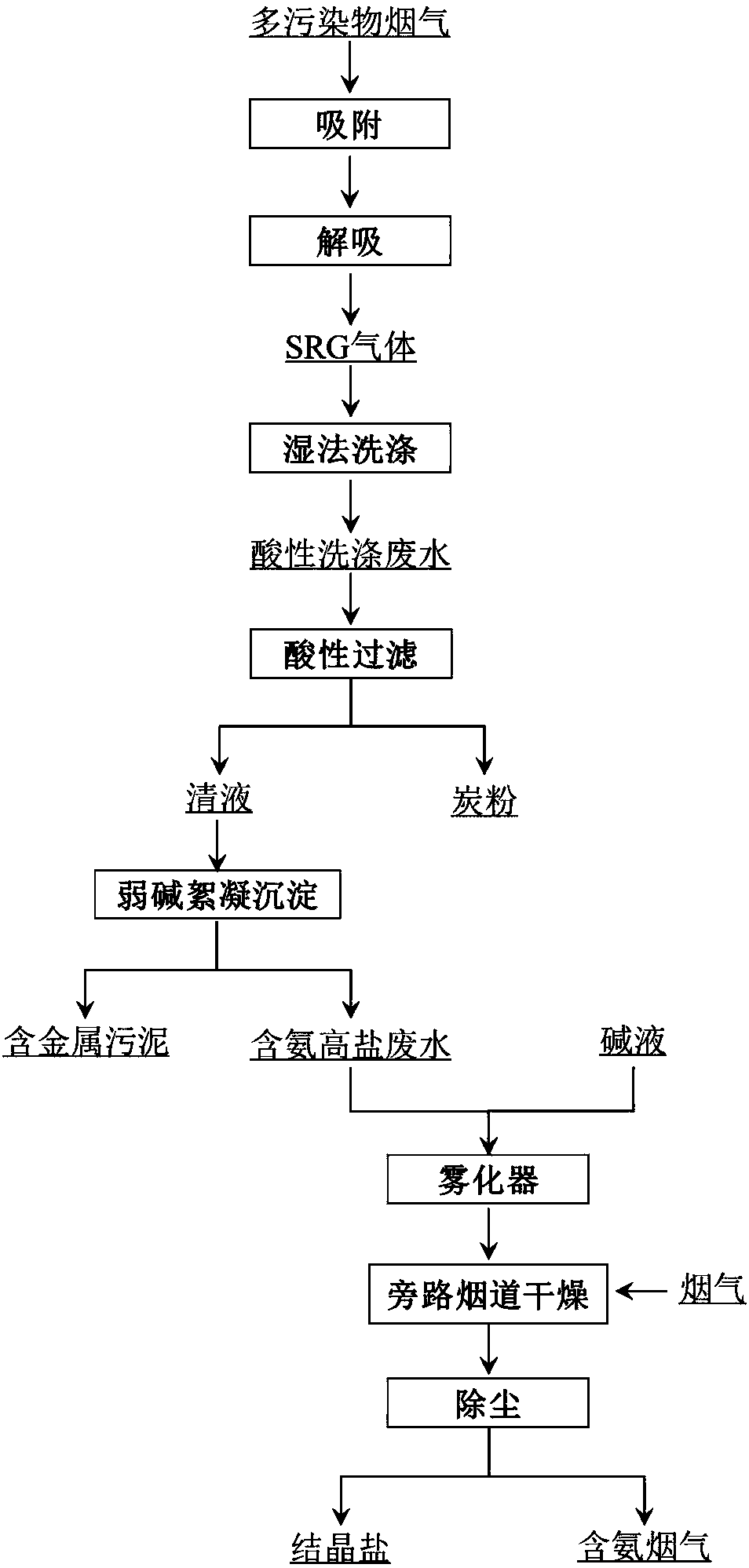

[0149] Repeat embodiment 1, just this device comprises oxidation device 9, adsorption tower 10 and desorption tower 11. The multi-pollutant flue gas is transported to the adsorption tower 10 through the flue gas delivery pipeline L1. The adsorbent outlet of the adsorption tower 10 is connected to the desorption tower 11 . The SRG gas outlet of the analysis tower 11 is connected to the feed port of the wet scrubbing device 1 through a pipeline. The liquid outlet of the wet scrubbing device 1 is connected to the acid filter device 2 . The liquid outlet of the acid filter unit 2 is connected to an oxidation unit 9 . The outlet of the oxidation device 9 is connected to the flocculation and sedimentation device 3 . The plant includes a metal recovery unit 8 . The solid outlet of the flocculation and sedimentation device 3 is connected to a metal recovery device 8 . The solid outlet of the acid filter device 2 is connected to the adsorbent inlet of the adsorption tower 10 . Th...

Embodiment 3

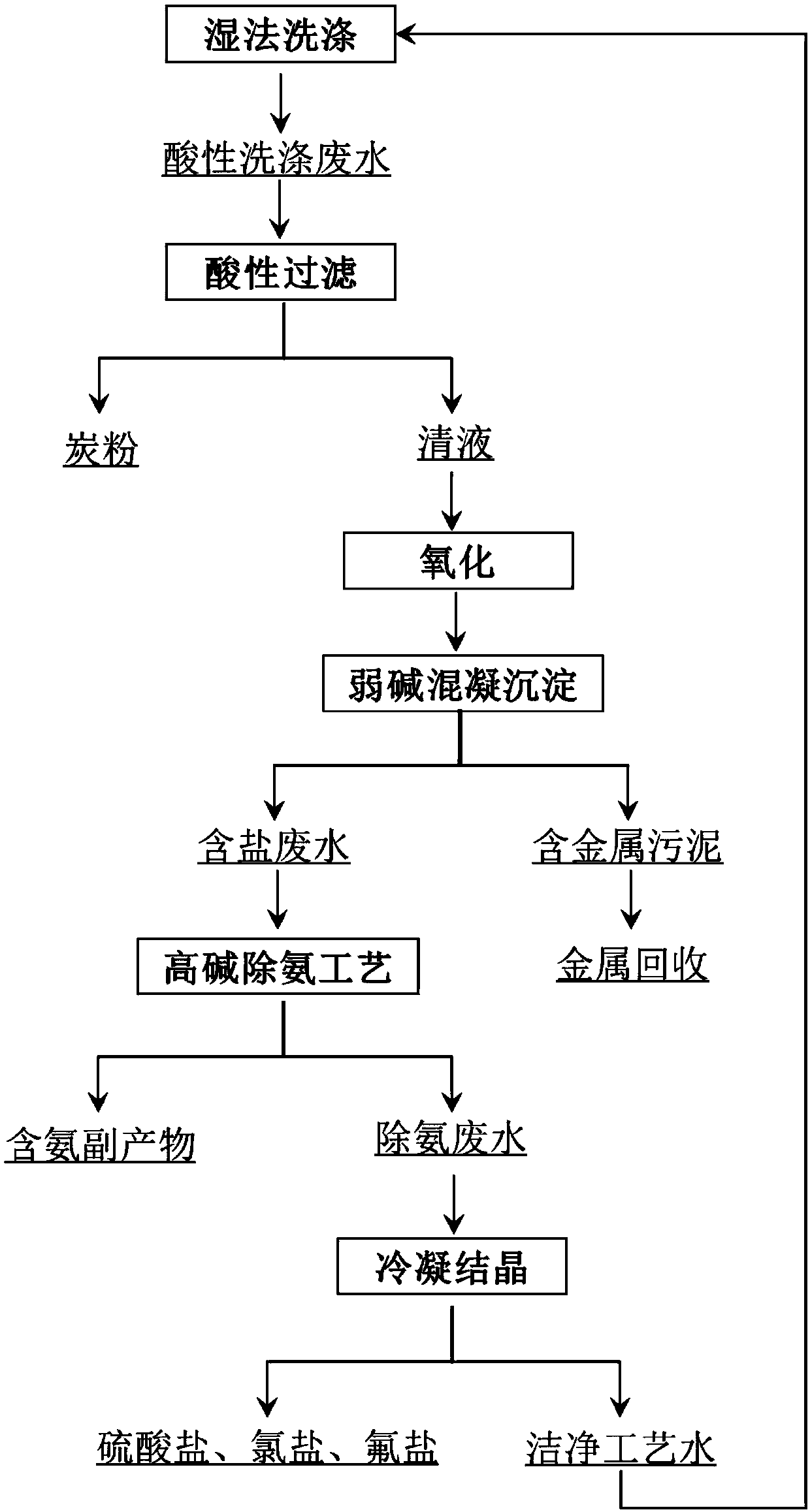

[0151] Such as Figure 5 As shown, a zero-discharge treatment device for acidic flue gas washing wastewater, the device includes a wet scrubbing device 1, an acidic filtration device 2, a flocculation sedimentation device 3, a high alkali ammonia removal device 6 and a condensation crystallization device 7. The acid flue gas is transported to the feed port of the wet scrubbing device 1 . The liquid outlet of the wet scrubbing device 1 is connected to the acid filter device 2 . The liquid outlet of the acid filter device 2 is connected to the flocculation sedimentation device 3 . The liquid outlet of the flocculation sedimentation device 3 is connected to a high alkali ammonia removal device 6 . The liquid outlet of the high alkali ammonia removal device 6 is connected to a condensation crystallization device 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com