Patents

Literature

45 results about "Bioprocessor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

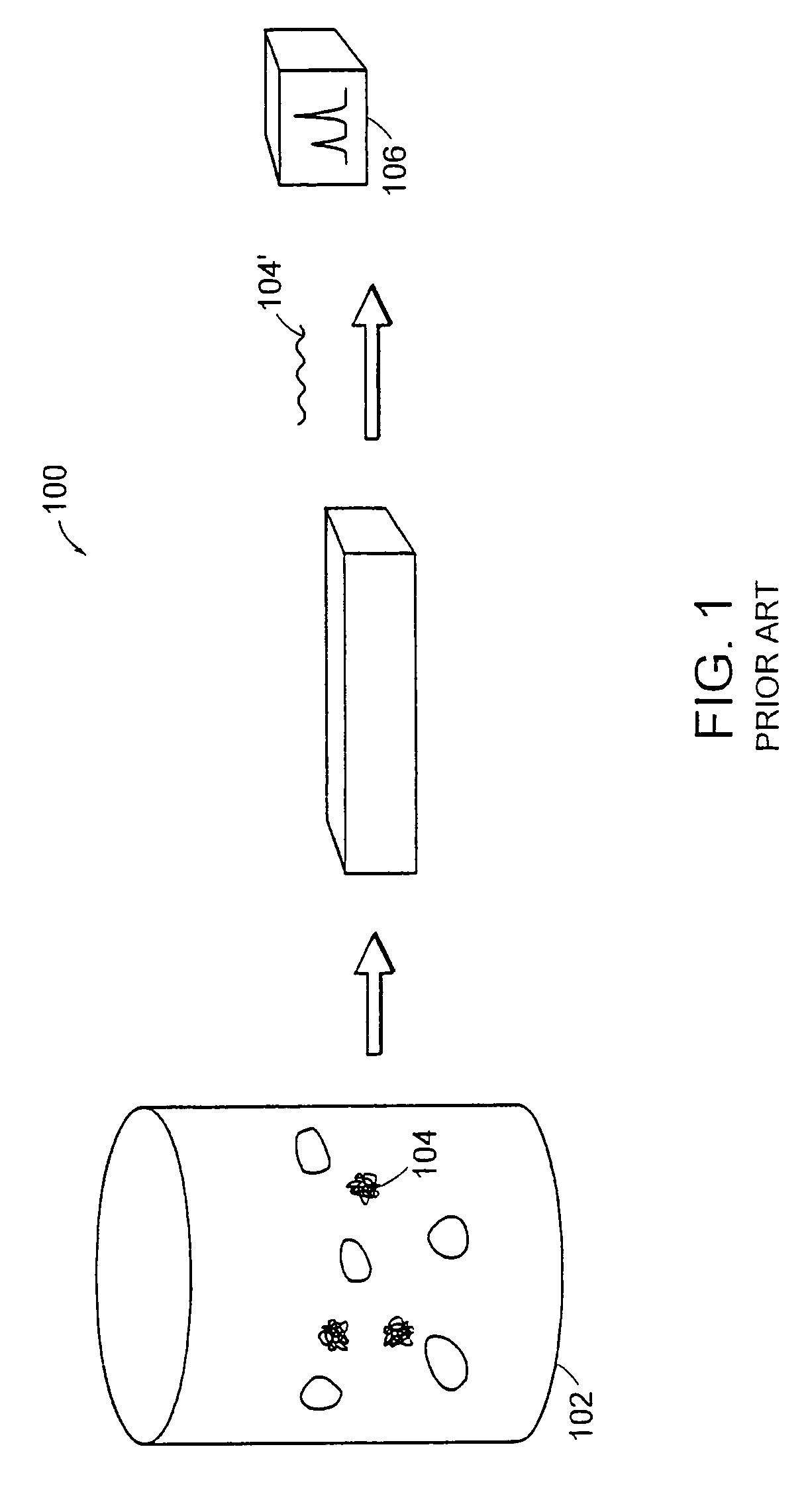

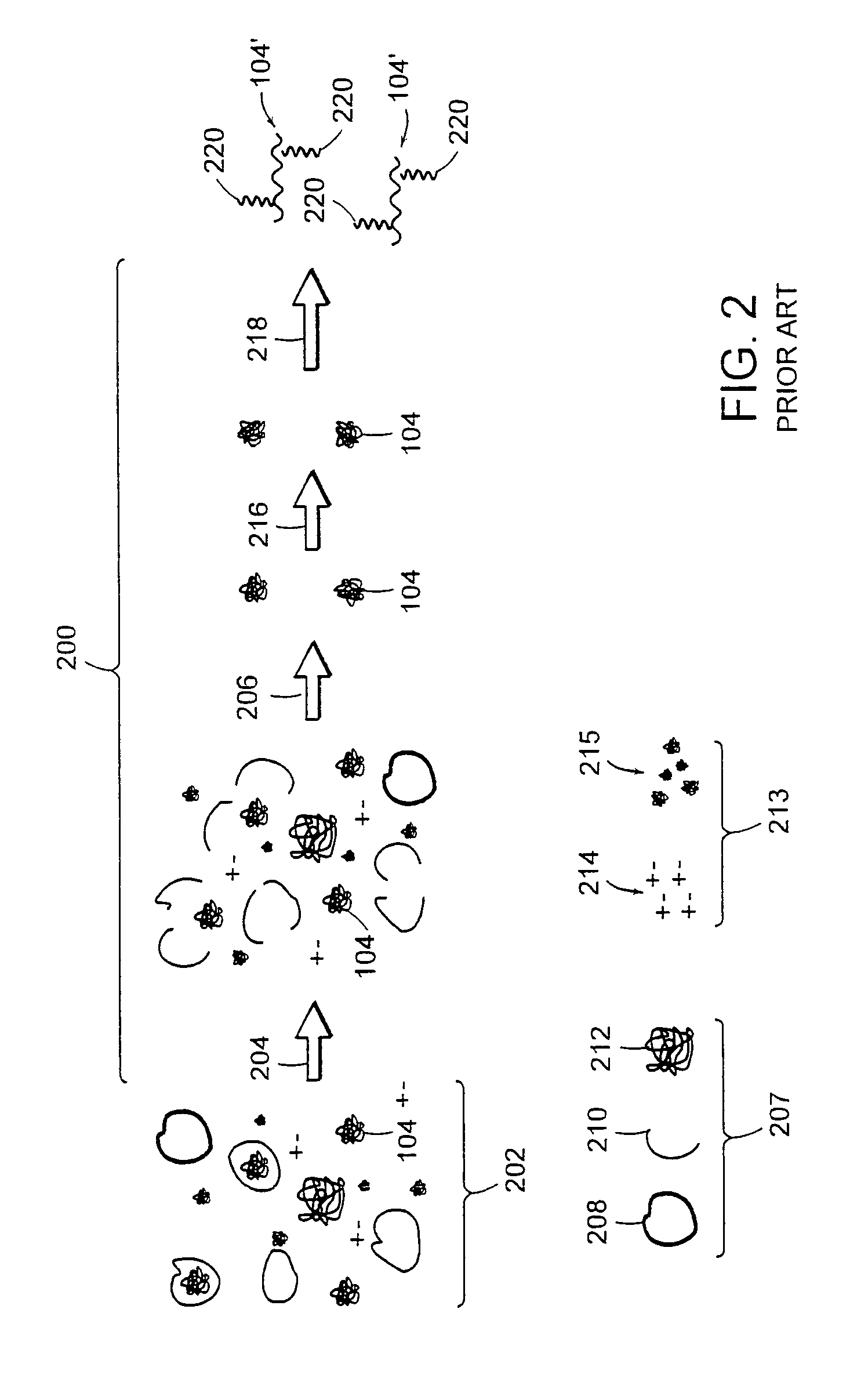

A bioprocessor is a miniaturized bioreactor capable of culturing mammalian, insect and microbial cells. Bioprocessors are capable of mimicking performance of large-scale bioreactors, hence making them ideal for laboratory scale experimentation of cell culture processes. Bioprocessors are also used for concentrating bioparticles (such as cells) in bioanalytical systems. Microfluidic processes such as electrophoresis can be implemented by bioprocessors to aid in DNA isolation and purification.

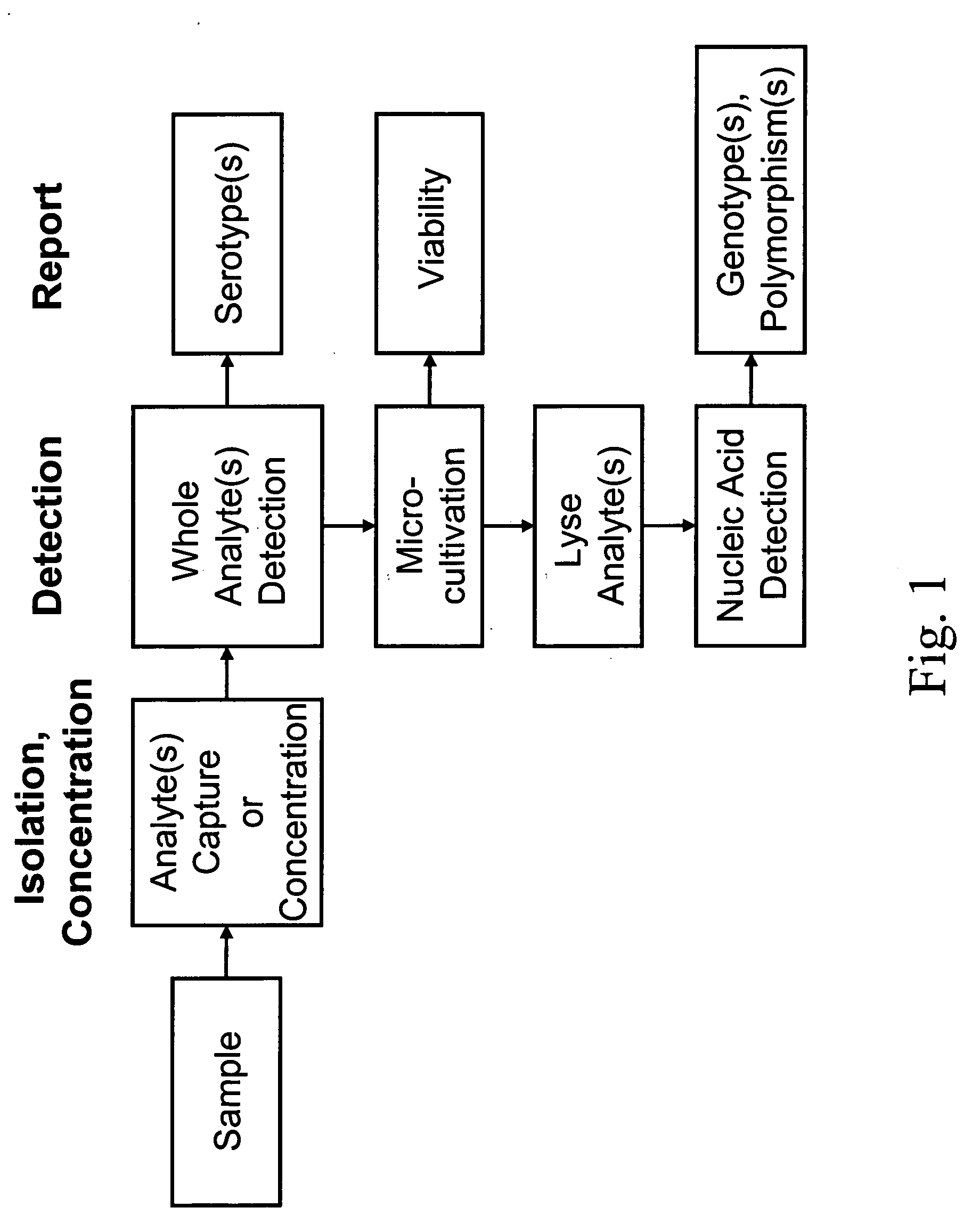

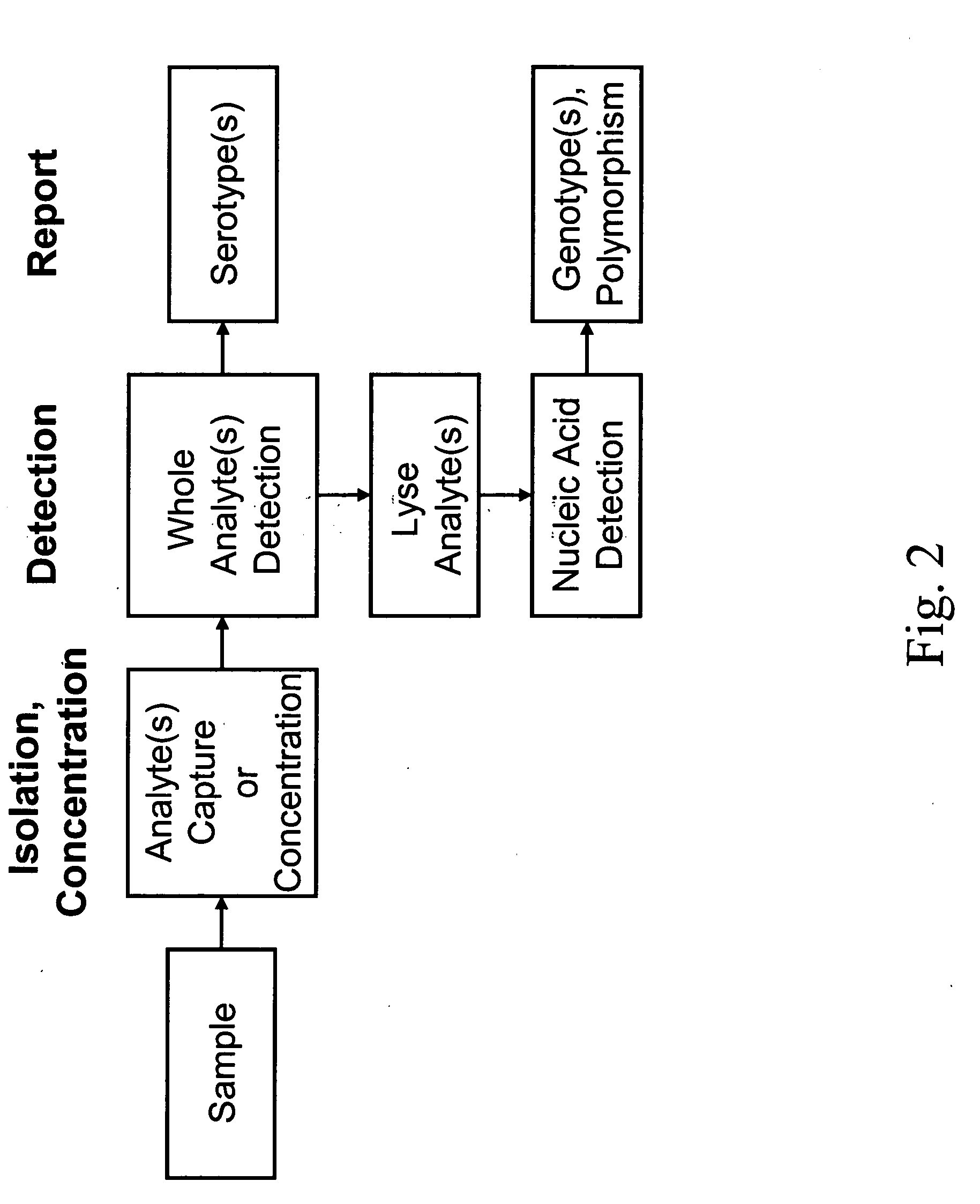

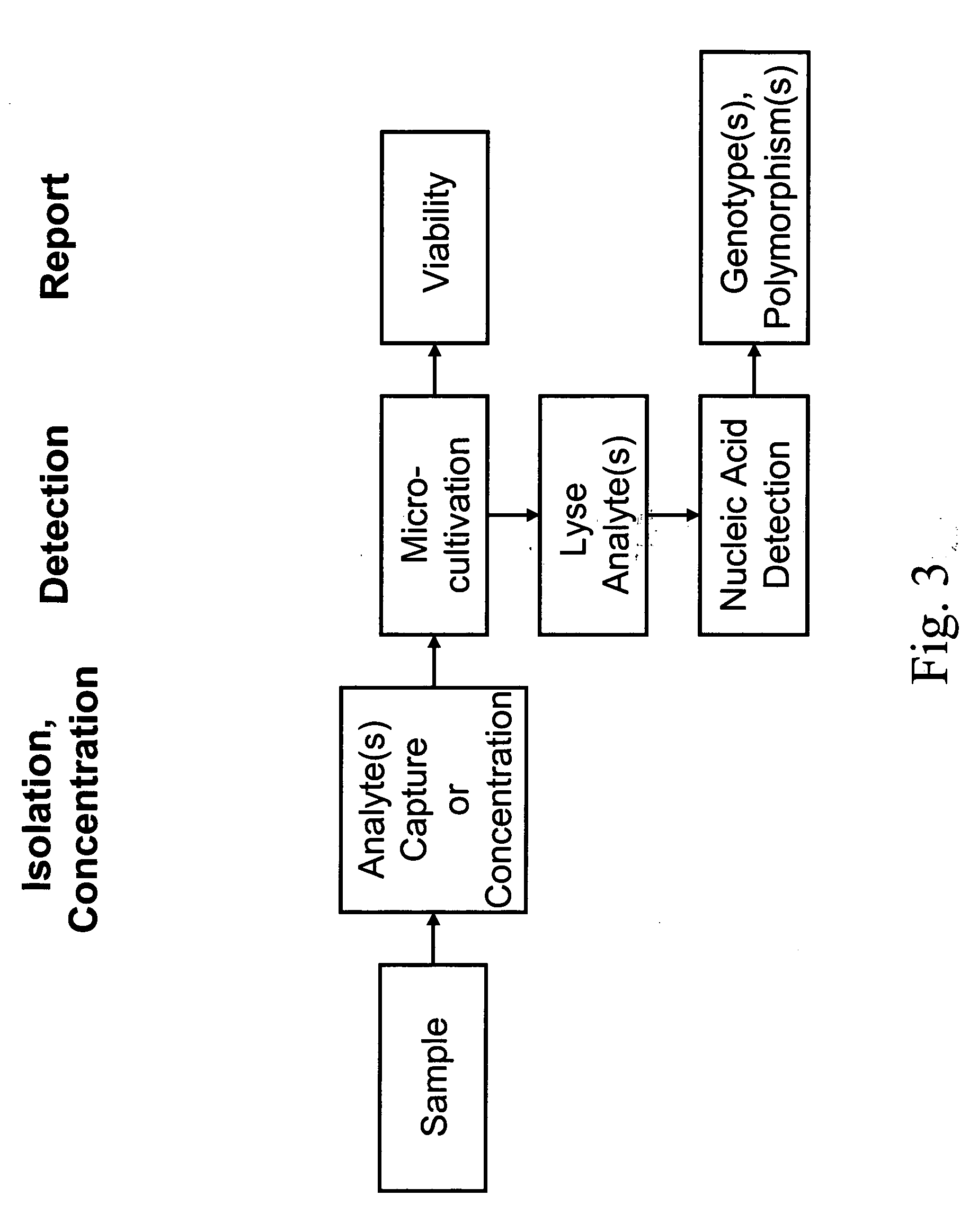

Integrated multistep bioprocessor and sensor

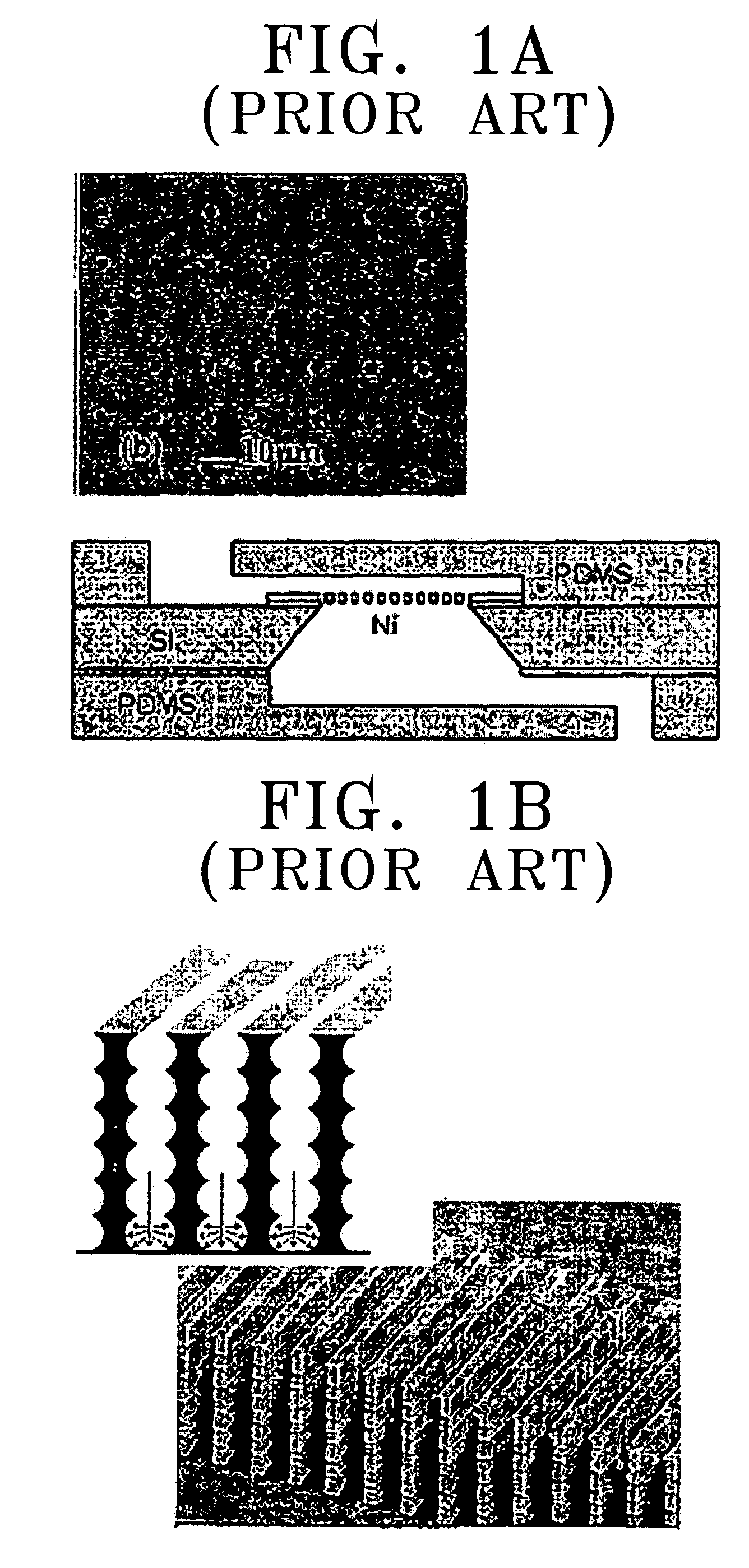

InactiveUS20060068412A1Bioreactor/fermenter combinationsMaterial nanotechnologyBioprocessorNucleic acid detection

The invention provides an integrated biosensor. The integrated bioprocessor consists of an integrated capture chamber having an analyte recognition coating and a structure supporting analyte detection, analyte growth and target nucleic acid detection. The integrated capture chamber can consist of a waveguide, a capillary tube, a mixing flow chamber or an integrated combination thereof. The integrated capture chamber also can contain an antibody or other recognition species as an analyte recognition coating, an illumination source, a radiation detector, a microfluidics handling system, a second chamber for target nucleic acid detection or a combination thereof. Also provided is an integrated biosensor. The integrated biosensor consists of an integrated capture chamber having an analyte recognition coating, an illumination source, a radiation detector and a structure supporting analyte detection, analyte growth and target nucleic acid detection. The integrated capture chamber can consist of a waveguide, a capillary tube, a mixing flow chamber or an integrated combination thereof. The integrated capture chamber also can contain an antibody as an analyte recognition coating, a microfluidics handling system, a second chamber for target nucleic acid detection or a combination thereof.

Owner:CREATV MICROTECH

Process for treating restaurant-kitchen garbage by utilizing Hermitia illucens

ActiveCN102350433AQuickly continue workingContinuous operationSolid waste disposalAnimal feeding stuffBioprocessorMass ratio

The invention discloses a process for treating restaurant-kitchen garbage by utilizing Hermitia illucens, which comprises the following steps of: carrying out solid-liquid separation on restaurant-kitchen garbage, wherein, the water content is 65-85%; crushing the restaurant-kitchen garbage into grains with the grain diameter of 2-50mm; adding auxiliary materials in the restaurant-kitchen garbageto form a treating material, wherein, the mass ratio of the restaurant-kitchen garbage to the auxiliary materials is 1: (0.25-1); adding 5,000,000-12,000,000 Hermitia illucens larvas which are 3-6 days old in per ton of processing material to form a mixture, wherein, the auxiliary materials are vegetable fiber auxiliary materials; adding the mixture into a barrel of a drum-type Hermitia illucens bioprocessor; leading the temperature of the mixture in the barrel to be 32-42 DEG C, and the relative humidity to be 35-75%; unloading after 3-5 days; sieving to separate the Hermitia illucens larvasand the treating remnants; and drying and smashing the treating remnants to be used as a feed. In the process provided by the invention, the treating period is controlled within 72 hours on the ideal condition, thus the restaurant-kitchen garbage can be transformed into a finished product of the feed, thus providing good guarantee for the continuous operations of restaurant-kitchen garbage treatment plants; and the space and resources are saved for the smaller inventory, and the potential pollution risks are avoided.

Owner:深圳市腾浪再生资源发展有限公司

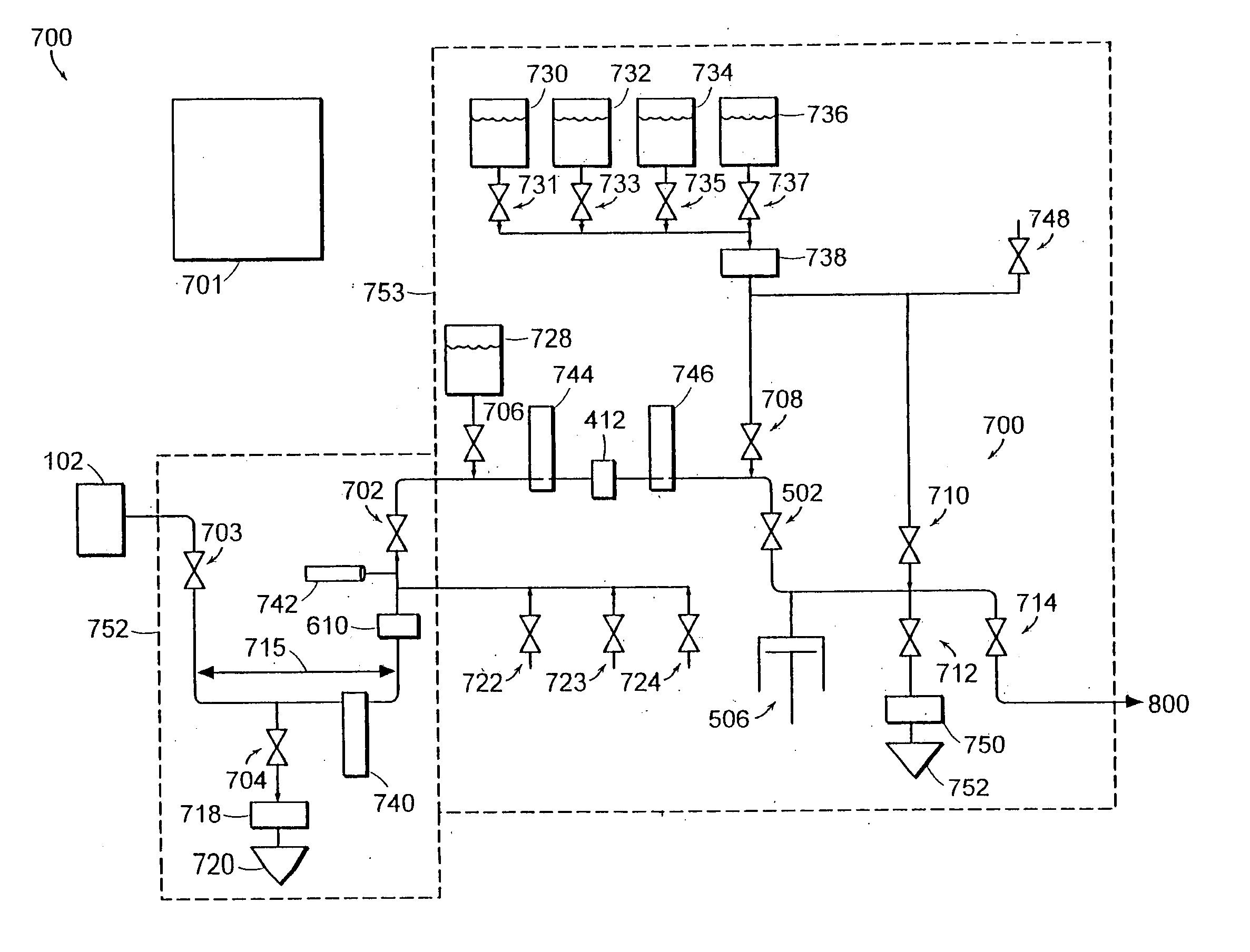

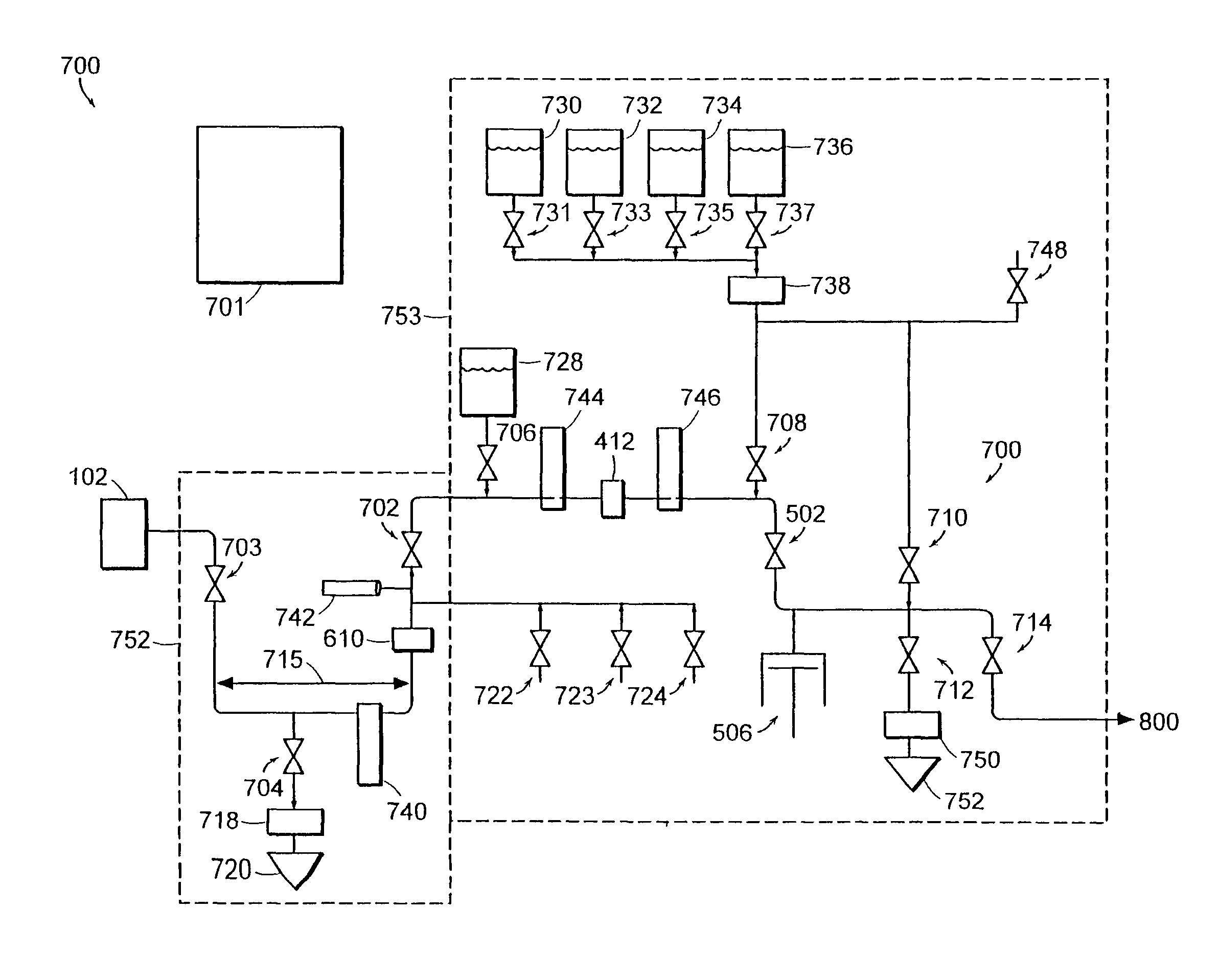

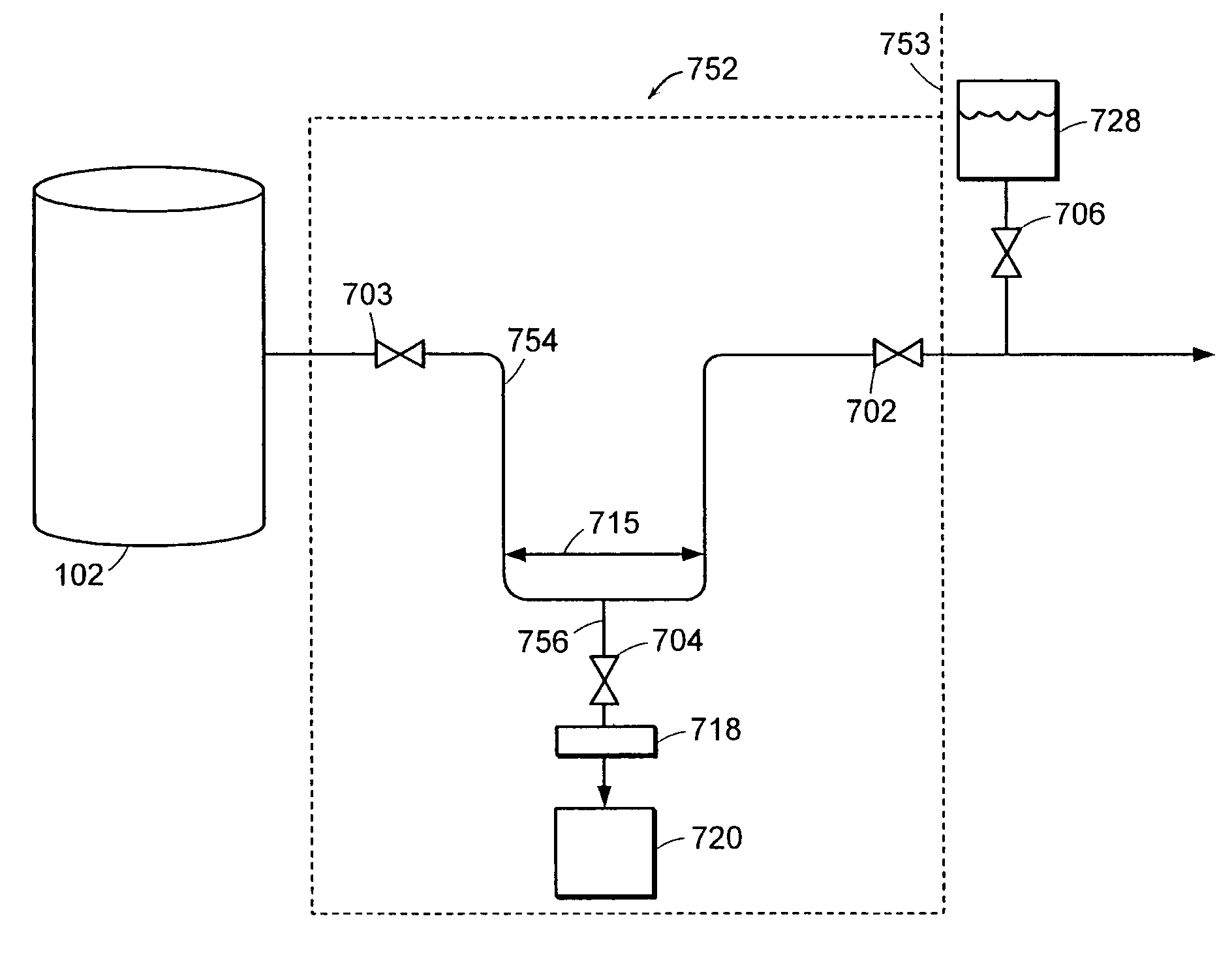

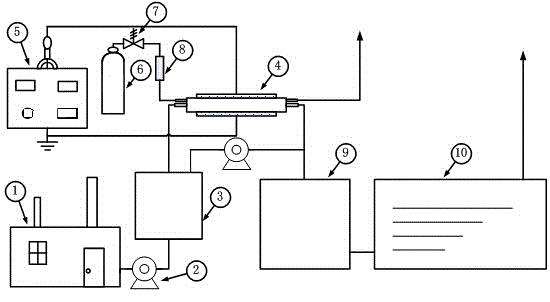

Fluid interface for bioprocessor systems

InactiveUS20070072285A1Low costFacilitates rapid, frequent, automated samplingBioreactor/fermenter combinationsBiological substance pretreatmentsBioprocessorAutomatic control

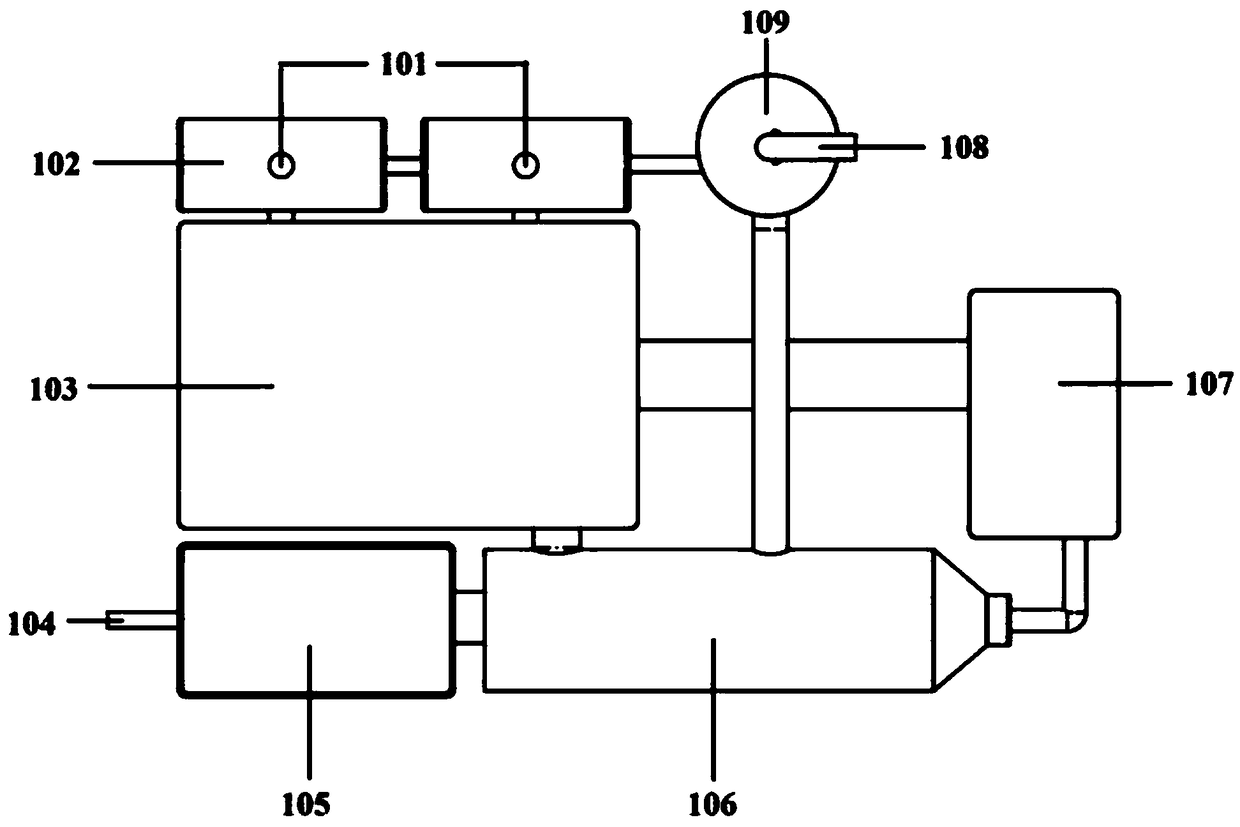

An apparatus and method for an aseptic fluidic interface between bioprocess systems is provided. The apparatus includes an inlet valve, adapted for automatic control, that is coupled to a biofluid source site. A sampling conduit extends from the inlet valve to an outlet valve. The outlet valve is adapted for automatic control and is coupled to a biofluid process site. A trap is at the sampling conduit. A waste valve, adapted for automatic control, is located at a waste conduit extending from the sampling conduit to a waste site. Also included is a wash fluid source that is coupled to at least one of the inlet or outlet valves. In the method, the sample is automatically directed to the biofluid process site by opening the outlet valve, and closing the waste valve Also included is isolating the biofluid sites by closing the inlet and outlet valves, and opening the waste valve to drain biofluid from the trap to the waste site. Another step is cleaning the sampling conduit before sample collection by directing the wash fluid through at least one valve selected from the inlet and outlet valves, and subsequently through the waste valve to the waste site.

Owner:GROTON BIOSYST

Fluid interface for bioprocessor systems

InactiveUS7955843B2Low costFacilitates rapid, frequent, automated samplingBioreactor/fermenter combinationsBiological substance pretreatmentsBioprocessorAutomatic control

An apparatus and method for an aseptic fluidic interface between bioprocess systems is provided. The apparatus includes an inlet valve, adapted for automatic control, that is coupled to a biofluid source site. A sampling conduit extends from the inlet valve to an outlet valve. The outlet valve is adapted for automatic control and is coupled to a biofluid process site. A trap is at the sampling conduit. A waste valve, adapted for automatic control, is located at a waste conduit extending from the sampling conduit to a waste site. Also included is a wash fluid source that is coupled to at least one of the inlet or outlet valves. In the method, the sample is automatically directed to the biofluid process site by opening the outlet valve, and closing the waste valve. Also included is isolating the biofluid sites by closing the inlet and outlet valves, and opening the waste valve to drain biofluid from the trap to the waste site. Another step is cleaning the sampling conduit before sample collection by directing the wash fluid through at least one valve selected from the inlet and outlet valves, and subsequently through the waste valve to the waste site.

Owner:GROTON BIOSYST

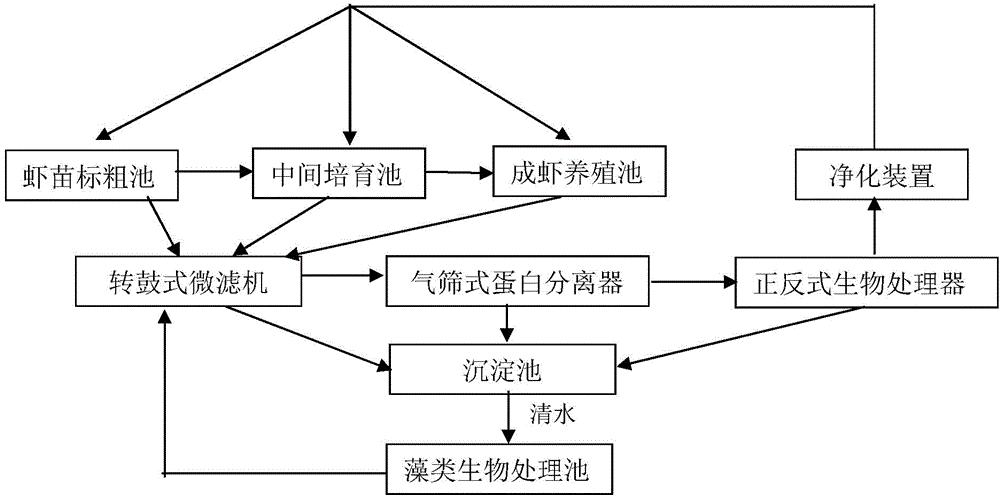

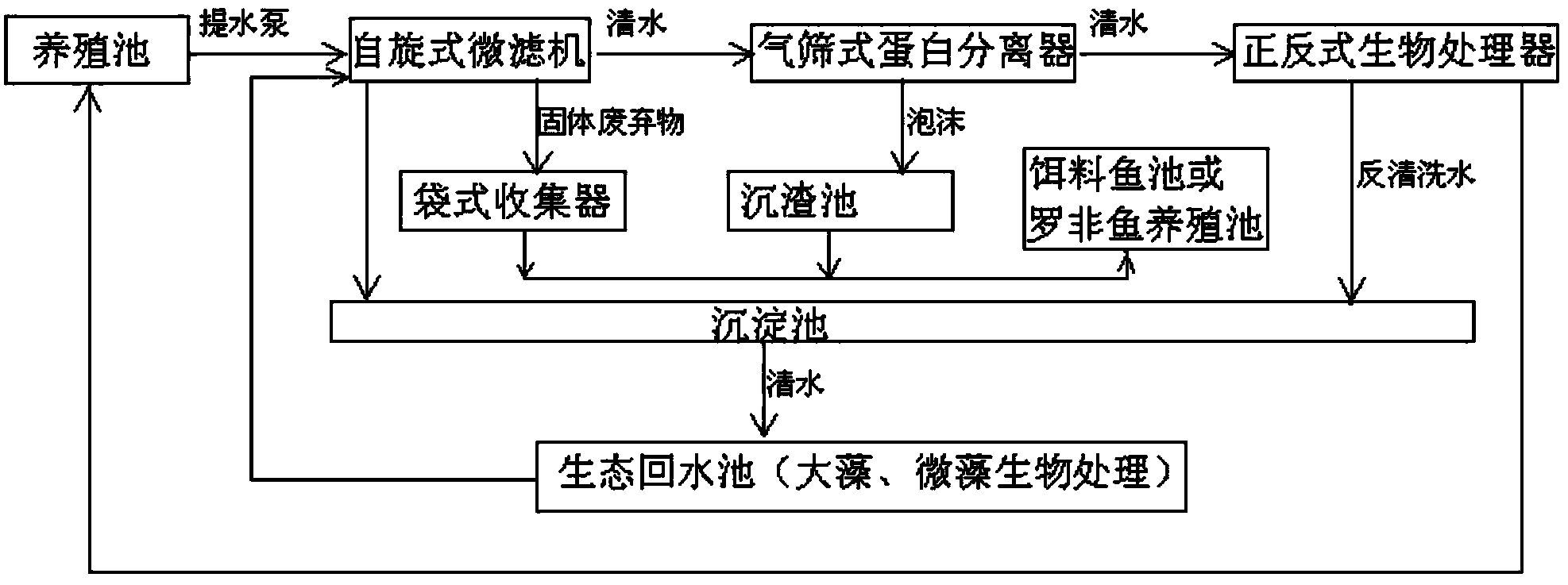

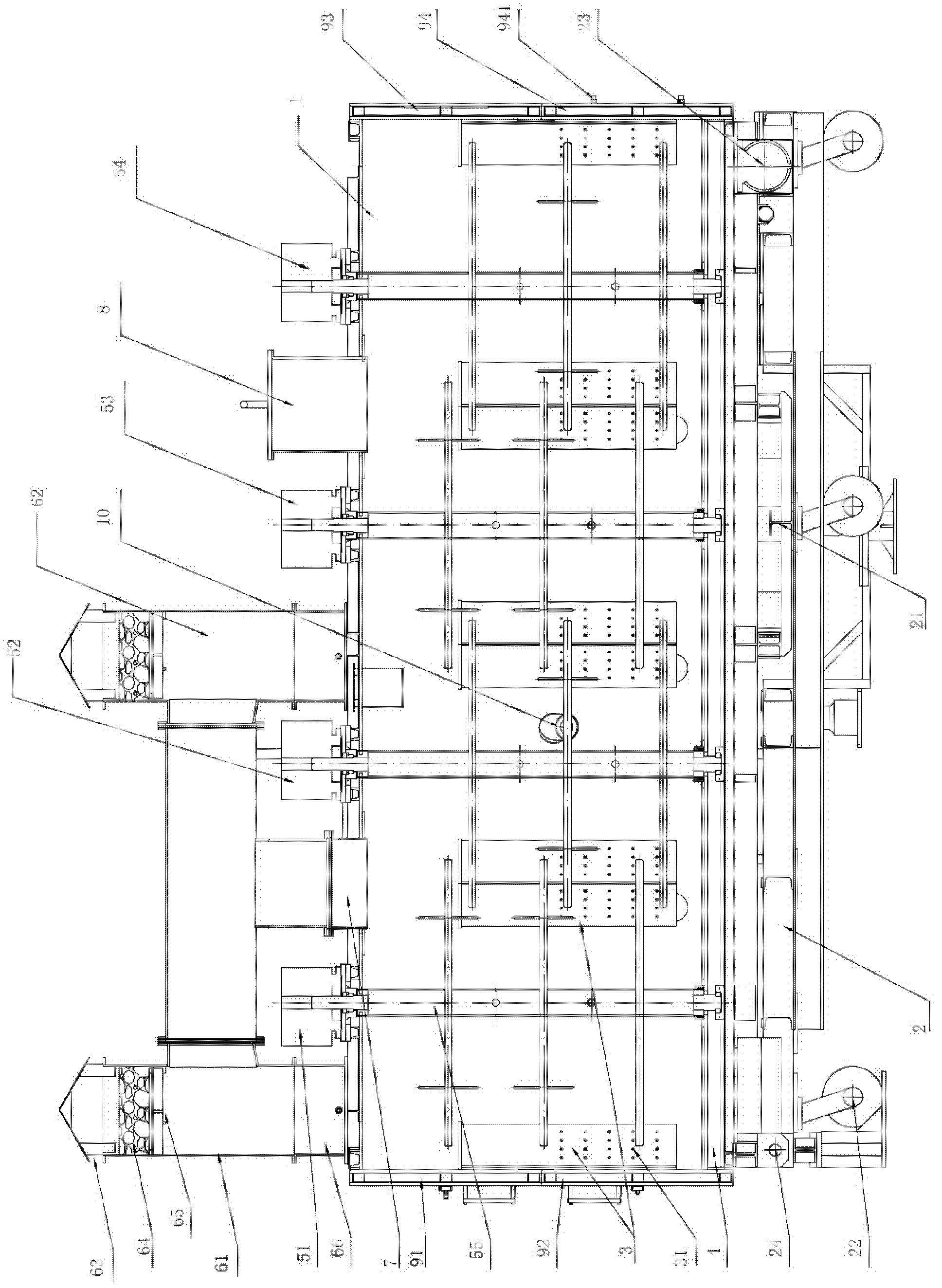

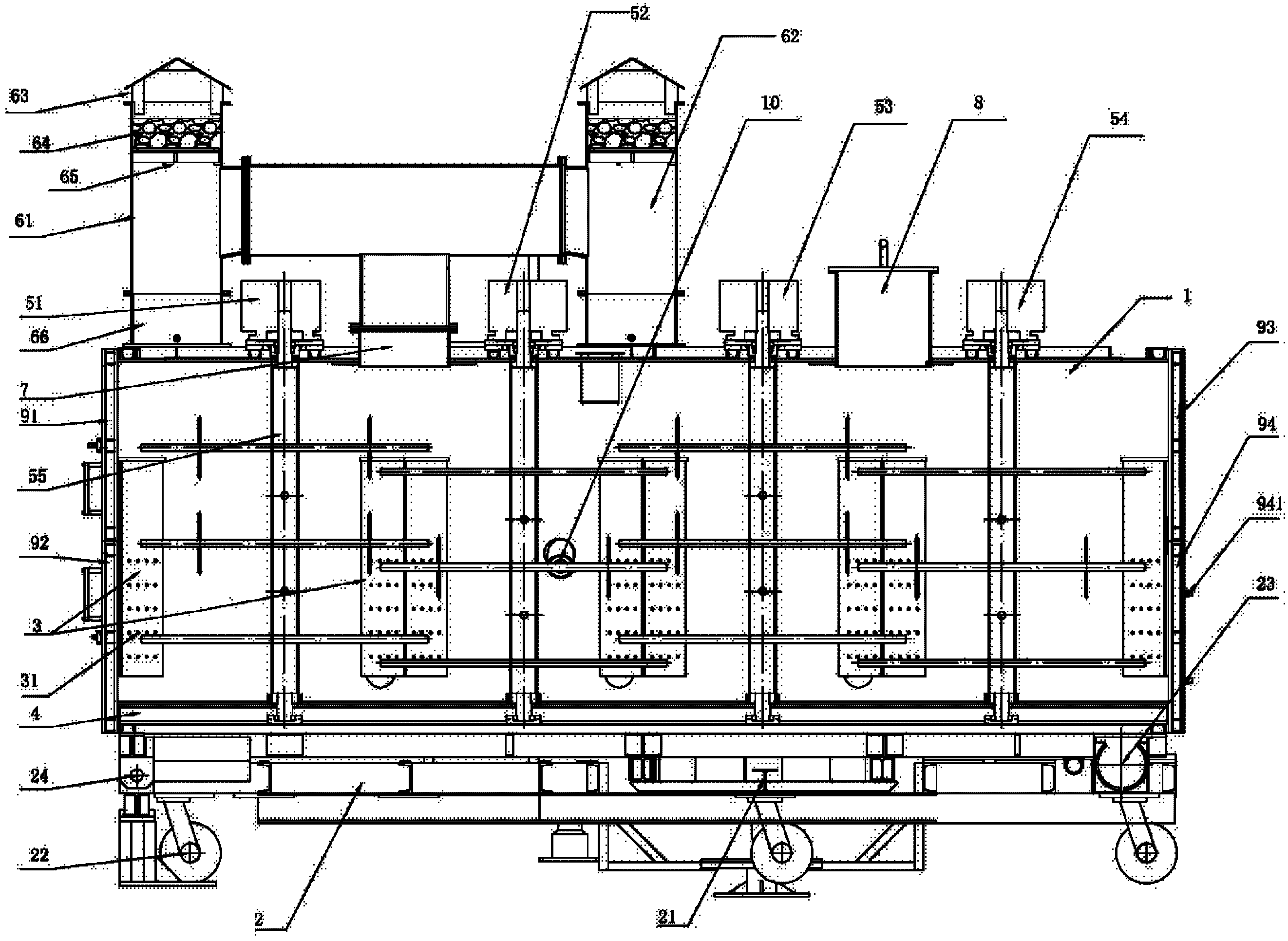

Penaeus monodon industrialized high-density cultivating technology

InactiveCN104542390AIncrease success rateReduce the possibilityClimate change adaptationPisciculture and aquariaWater qualityAquaculture

The invention provides a penaeus monodon industrialized high-density cultivating technology, comprising a young shrimp coarse standard pond, an intermediate cultivating pond, an adult shrimp cultivating pond, a rotary-drum microstrainer, an air-sifter type protein separator, a positive-negative biological processor, a purifying device, a sedimentation tank, an algae biological processor and a controller. According to the penaeus monodon industrialized high-density cultivating technology, the problems that the prawn survival rate is low, the benefit and yield are not prominent, the occupied area is overlarge, and the environmental pollution is severe are fundamentally solved through cultivating penaeus monodon by utilization of industrialized circulating water; by employment of grading multistage cultivation, the aquaculture water space can be sufficiently utilized, the water quality is guaranteed, the possibility of disease occurrence is reduced, the cultivating success rate is improved, drugs are prevented from being used, and the food safety is guaranteed; organic carbon is added in the aquaculture water through a biological floccules device so as to adjust the proportion of carbon to nitrogen, and sufficient oxygenation is combined at the same time, so that the growth of heterotrophic bacteria in the water can be promoted, ammonia nitrogen and nitrite nitrogen are reduced up to 98-100%, the feed quantity required for cultivating creatures is reduced, and the benefit is increased.

Owner:天津西津科捷科技发展有限公司

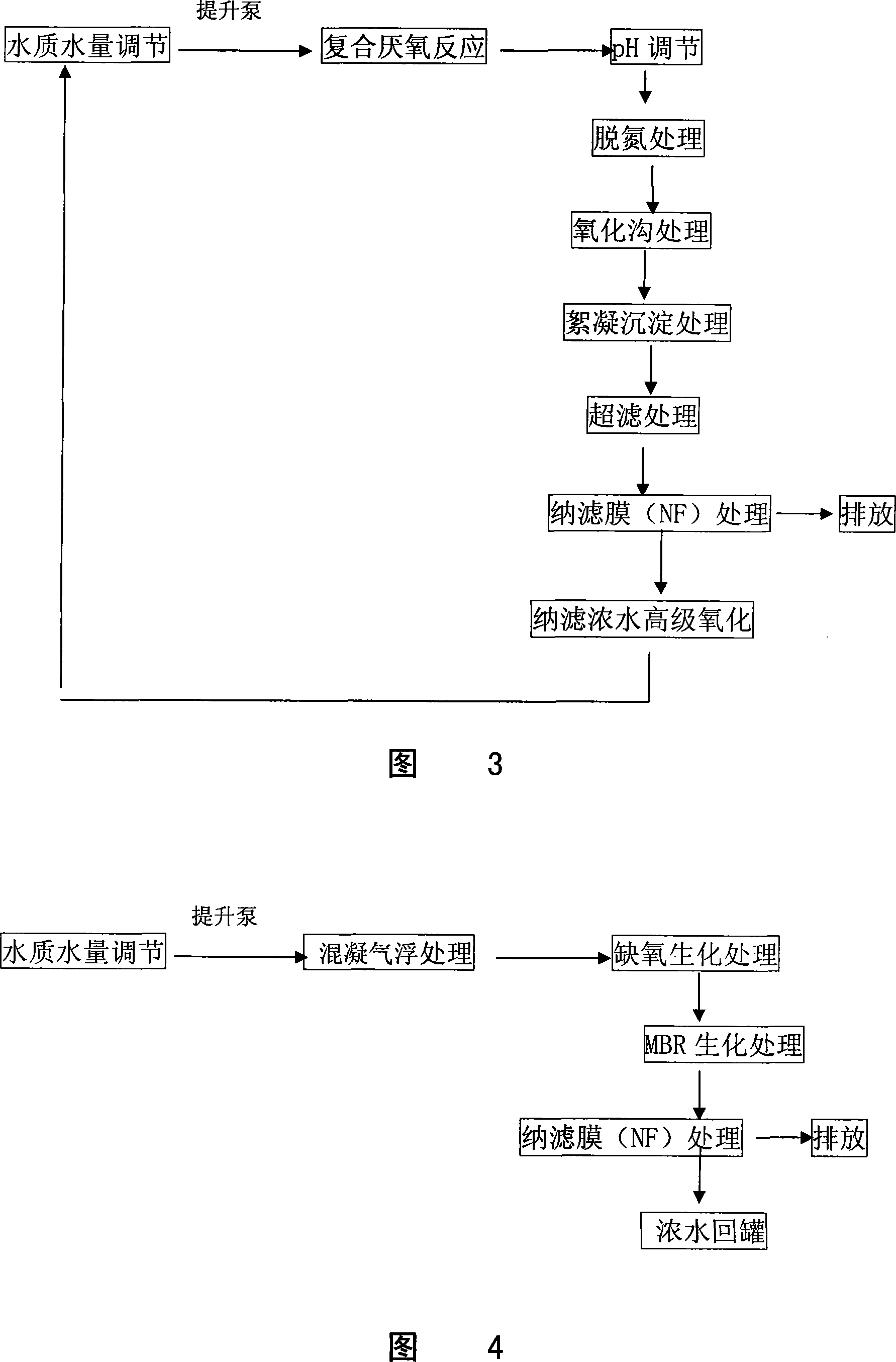

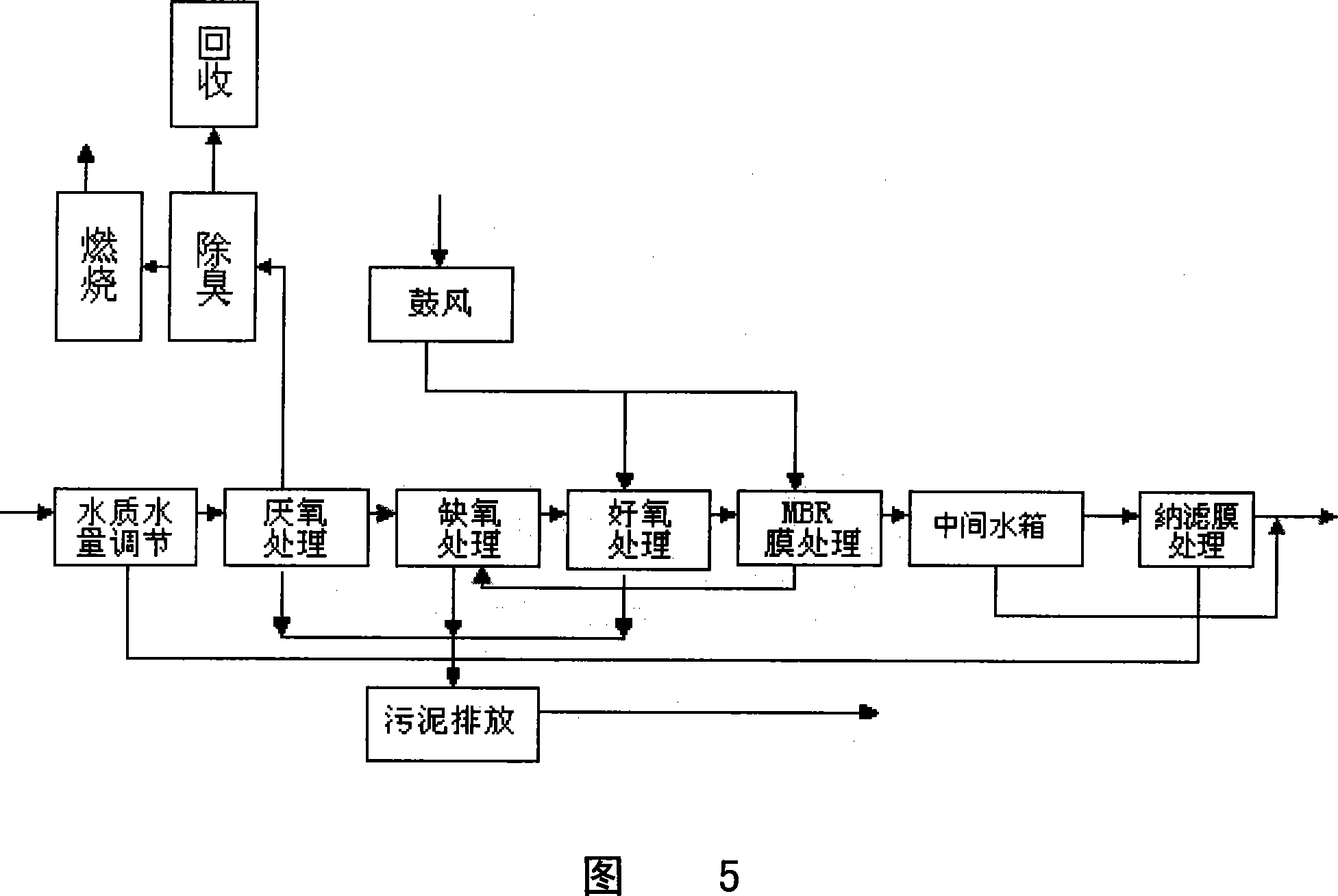

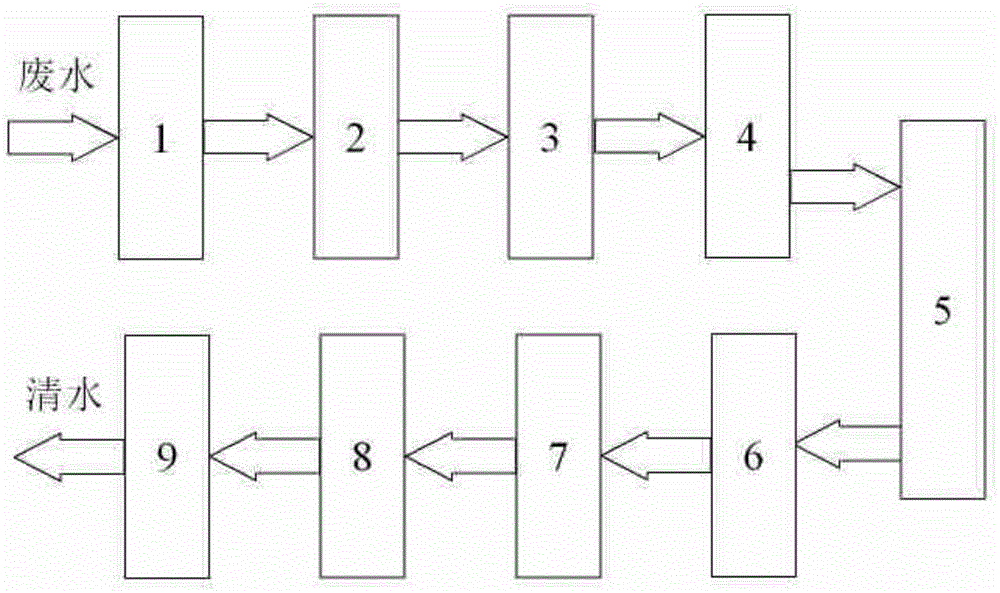

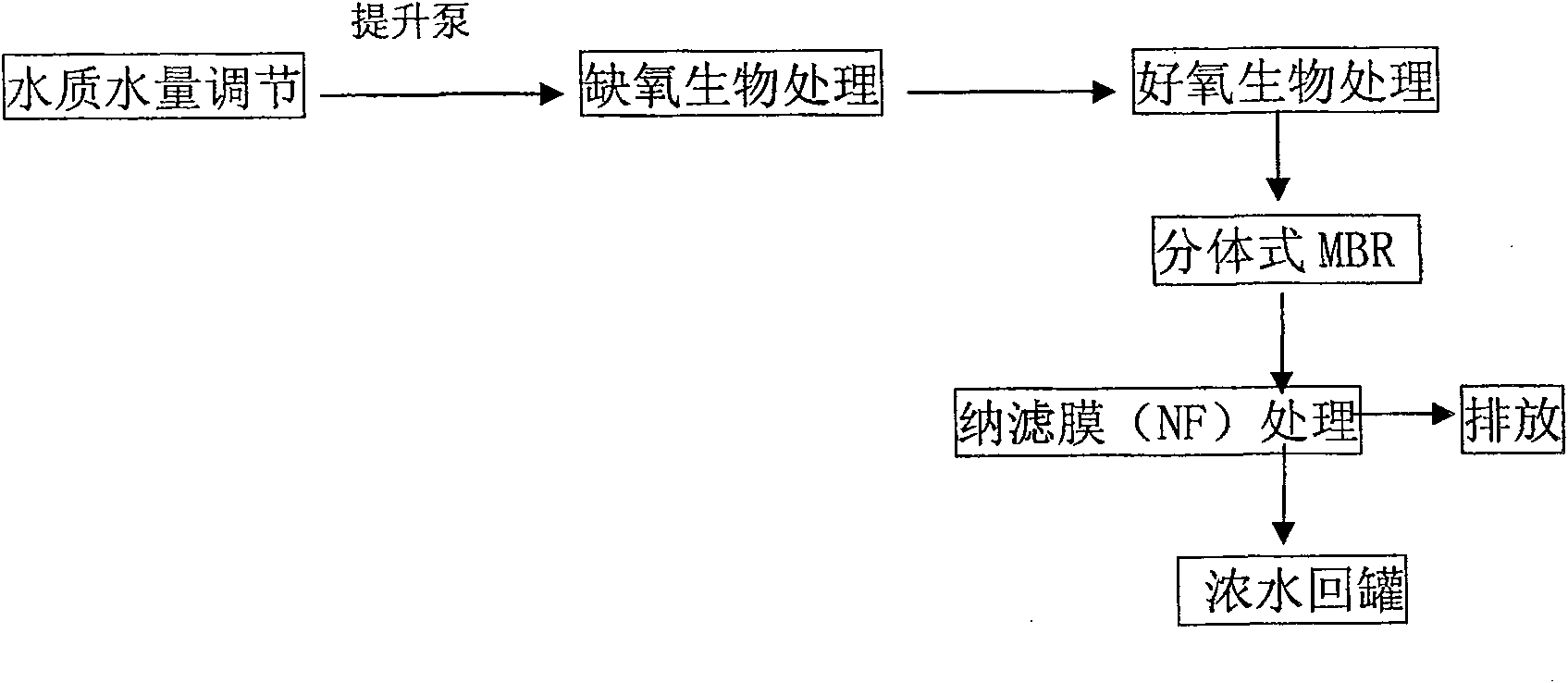

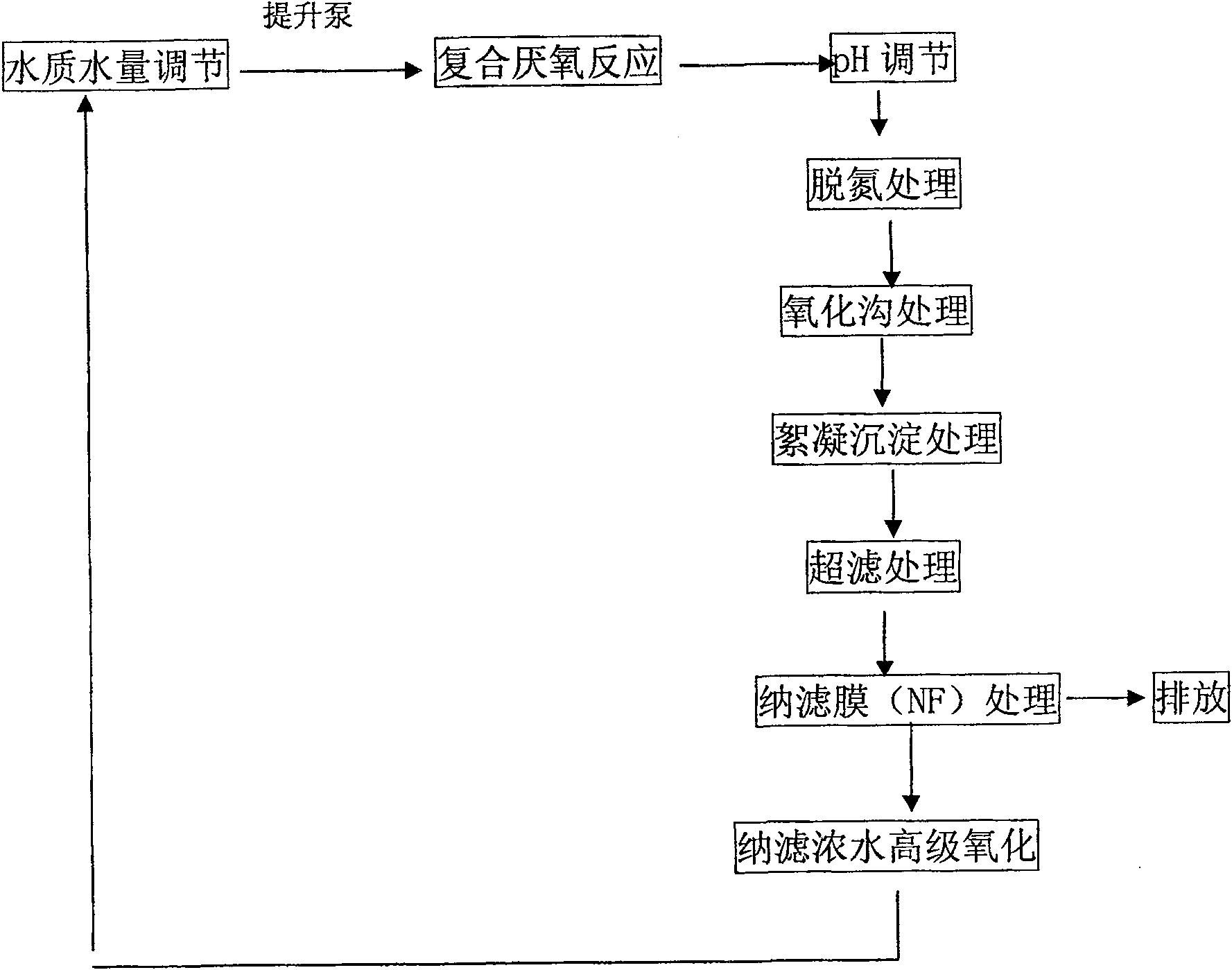

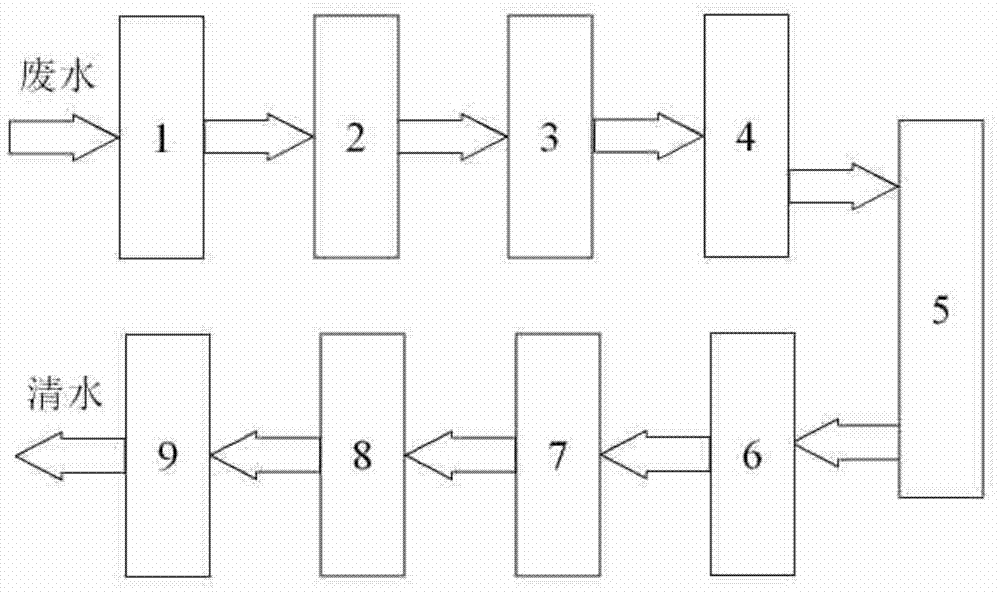

Technique for processing garbage leachate

ActiveCN101219845AShort process flowEasy to controlUltrafiltrationTreatment with aerobic and anaerobic processesRefluxBioprocessor

The invention relates to a process for treating waste leachate, which comprises the steps: (1) water quality and water quantity of the waste leachate is regulated in a regulating tank; (2) the leachate after water quality and quantity regulation is an anaerobic tank and treated by the anaerobic process under 25 DEG C-45DEG C and the anaerobic process time is 50-100 hours; (3) the biogas produced in the anaerobic process is treated and the sludge produced in the anaerobic process is discharged; (4)the leachate after anaerobic process is sent into a hypoxia tank to carry out a hypoxia process and the sludge produced in the hypoxia process is discharged; (5) the leachate after hypoxia process is sent into an aerobic tank to carry out an aerobic process and the sludge produced in the aerobic process is discharged; (6) the leachate after the aerobic process is sent into a membrane biological processor to carry out solid-liquid separation and the reflux is carried out for the sludge produced after the process based on reflux rate 3:1; (7) the leachate after being processed by the membrane biological processor is sent into a middle water tank; (8) the leachate is processed by nanofiltration and the water after being processed is directly metered and discharged or first mixed with the water in the water tank according to certain proportion and then metered and discharged; (9) the concentrated water after nanofiltration is returned back to the regulating tank.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

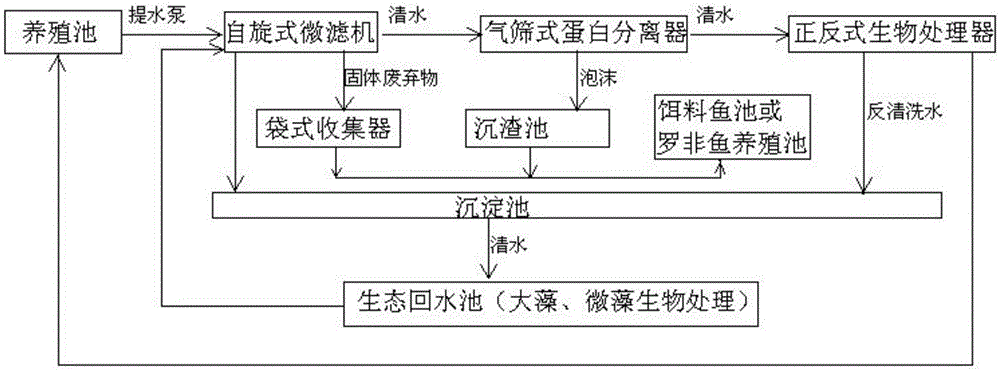

Indoor circulating water prawn high density breeding process

InactiveCN103798164ANo wasteReduce pollutionClimate change adaptationPisciculture and aquariaBioprocessorHigh density

The invention provides an indoor circulating water prawn high density breeding process. A breeding pool, a self-rotating type micro-filter, an air sifter type egg white separator, a forward and backward biological processor, a bag type collector, an ash setting pond, a bait fishpond or a tilapia breeding pond, a setting pond and an ecological water return pond are included. The self-rotating type micro-filter is connected with the breeding pond through a water lifting pump. The bag type collector is used for collecting solid waste of the self-rotating type micro-filter. Clean water obtained through processing of the self-rotating type micro-filter flows to the air sifter type egg white separator and then flows to the forward and backward biological processor. The forward and backward biological processor is connected with the setting pond. The self-rotating type micro-filter is connected with the setting pond. The setting pond is connected with the ecological water return pond. Both the bag type collector and the ash setting pond are connected with the bait fishpond or the tilapia breeding pond. According to the indoor circulating water prawn high density breeding process, no water source waste or residue waste exists so that maximum utilization can be achieved, environment pollution is reduced, and the energy consumption is lowered.

Owner:惠州市德明昌实业发展有限公司 +1

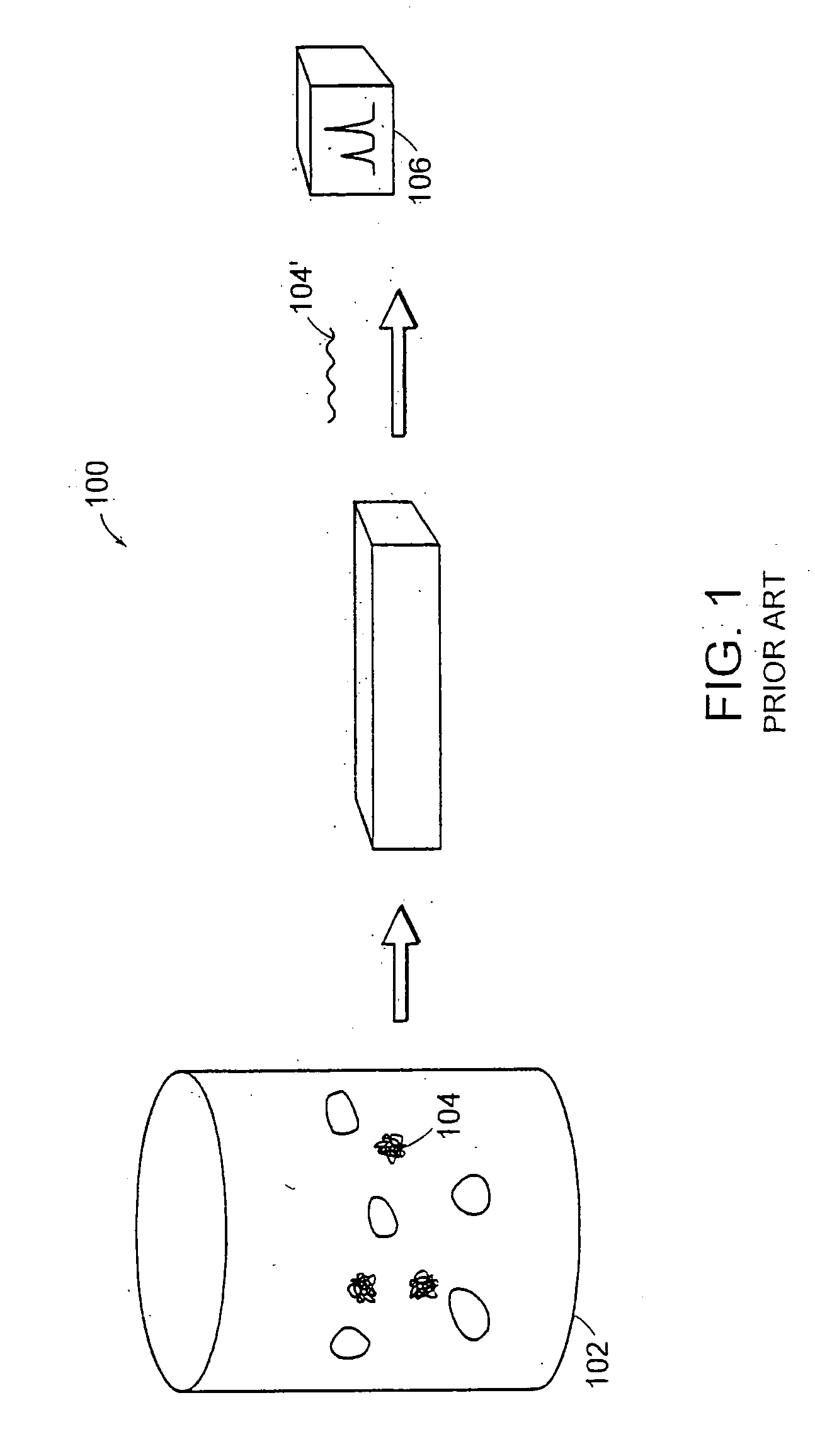

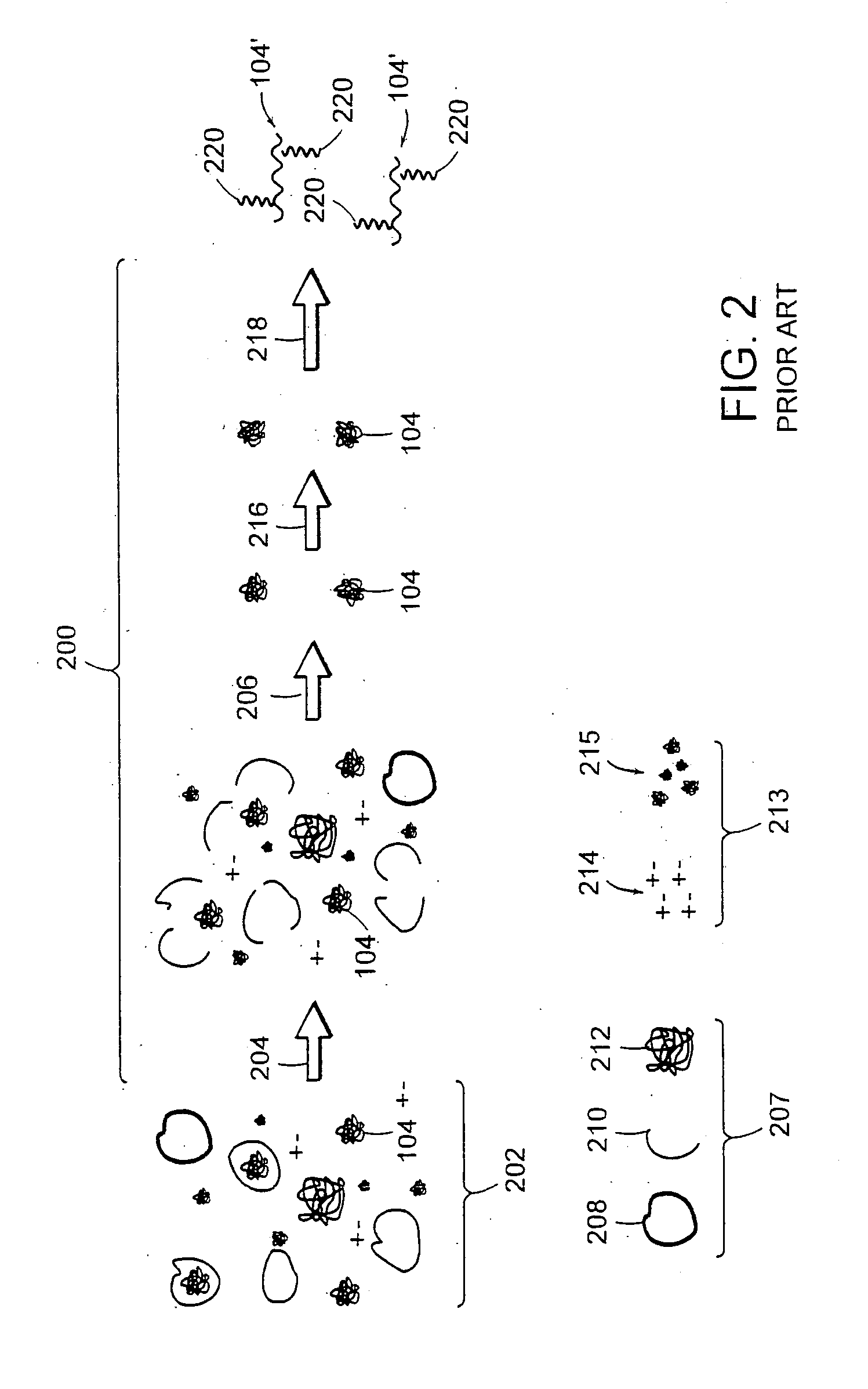

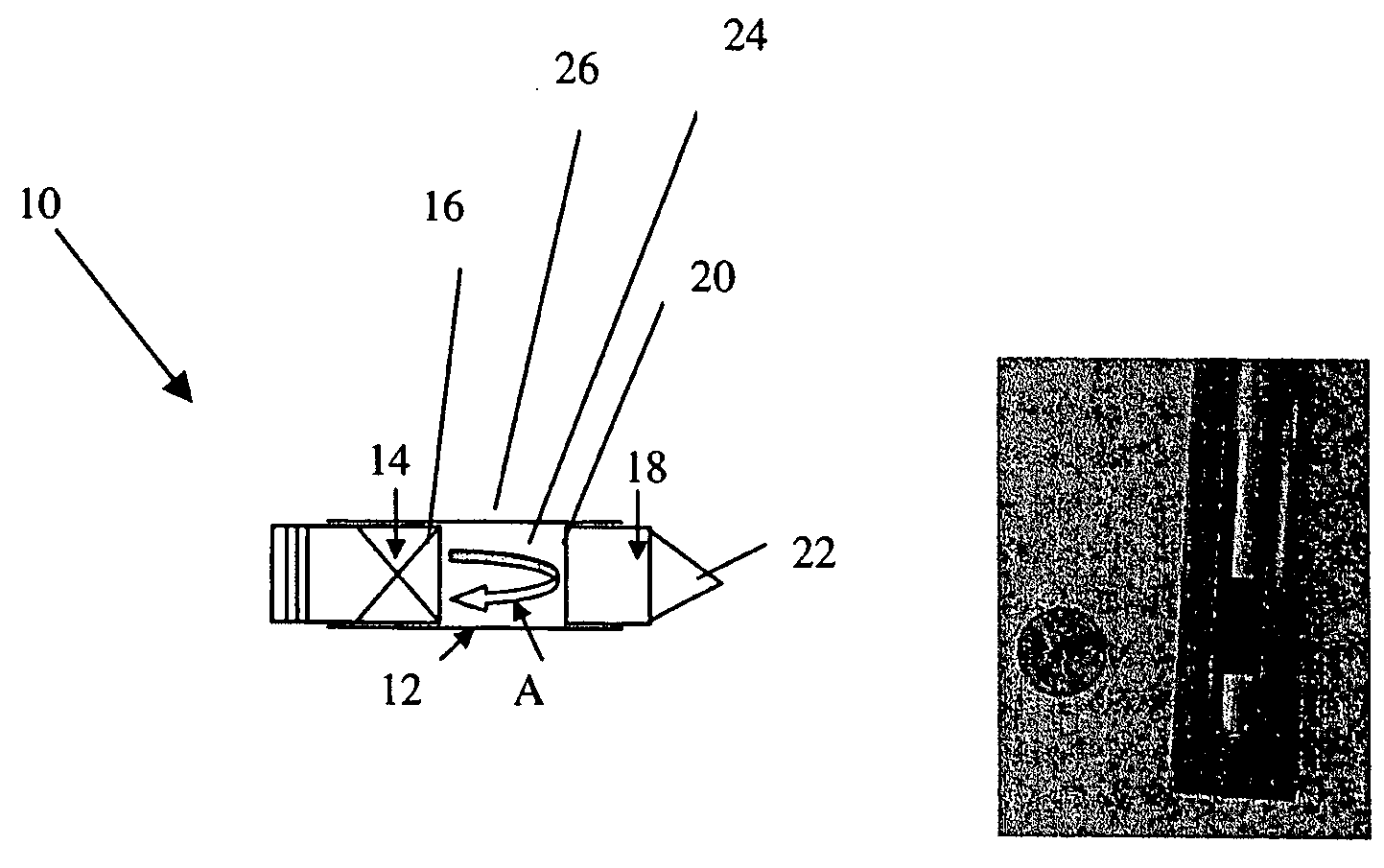

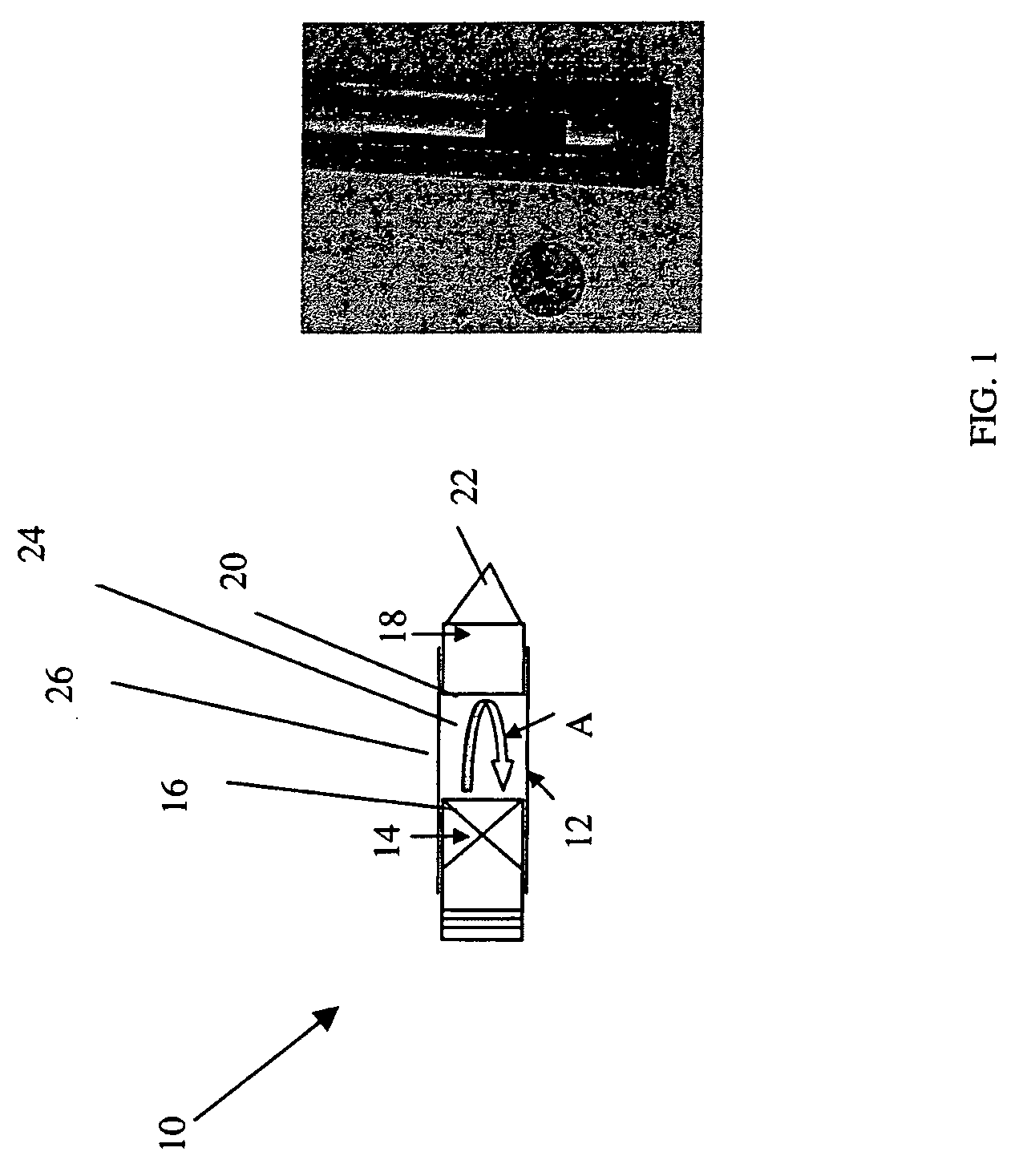

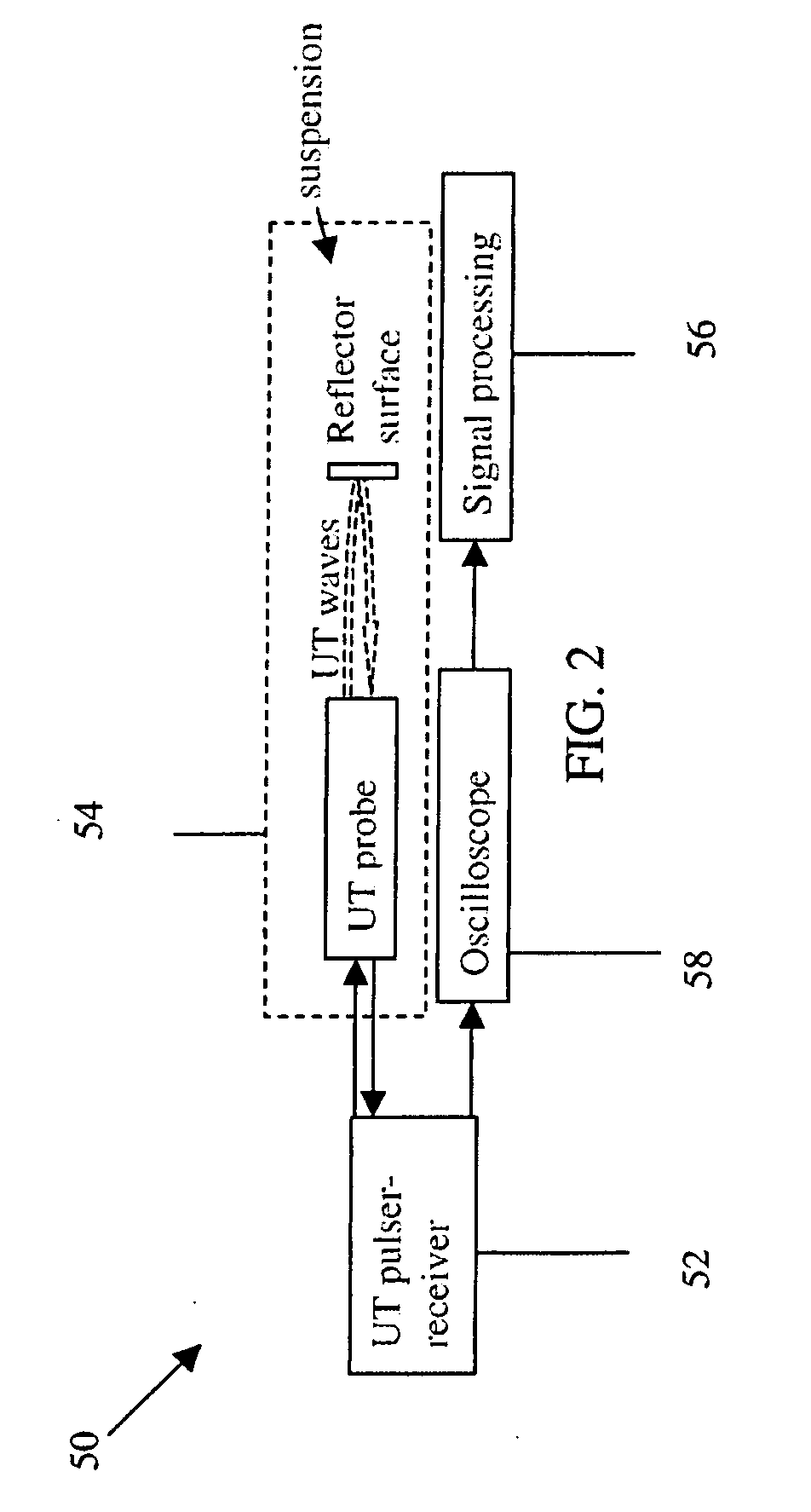

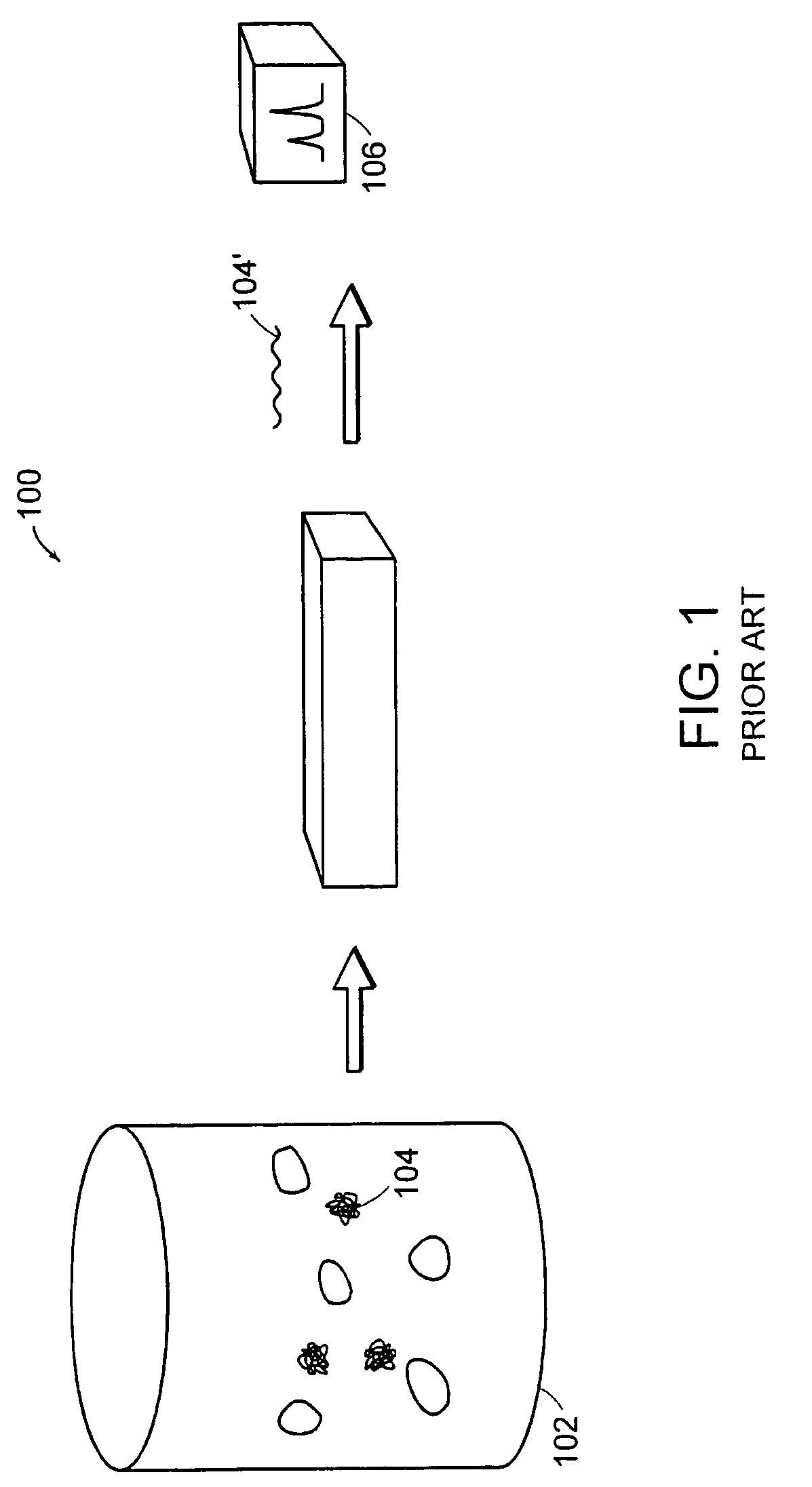

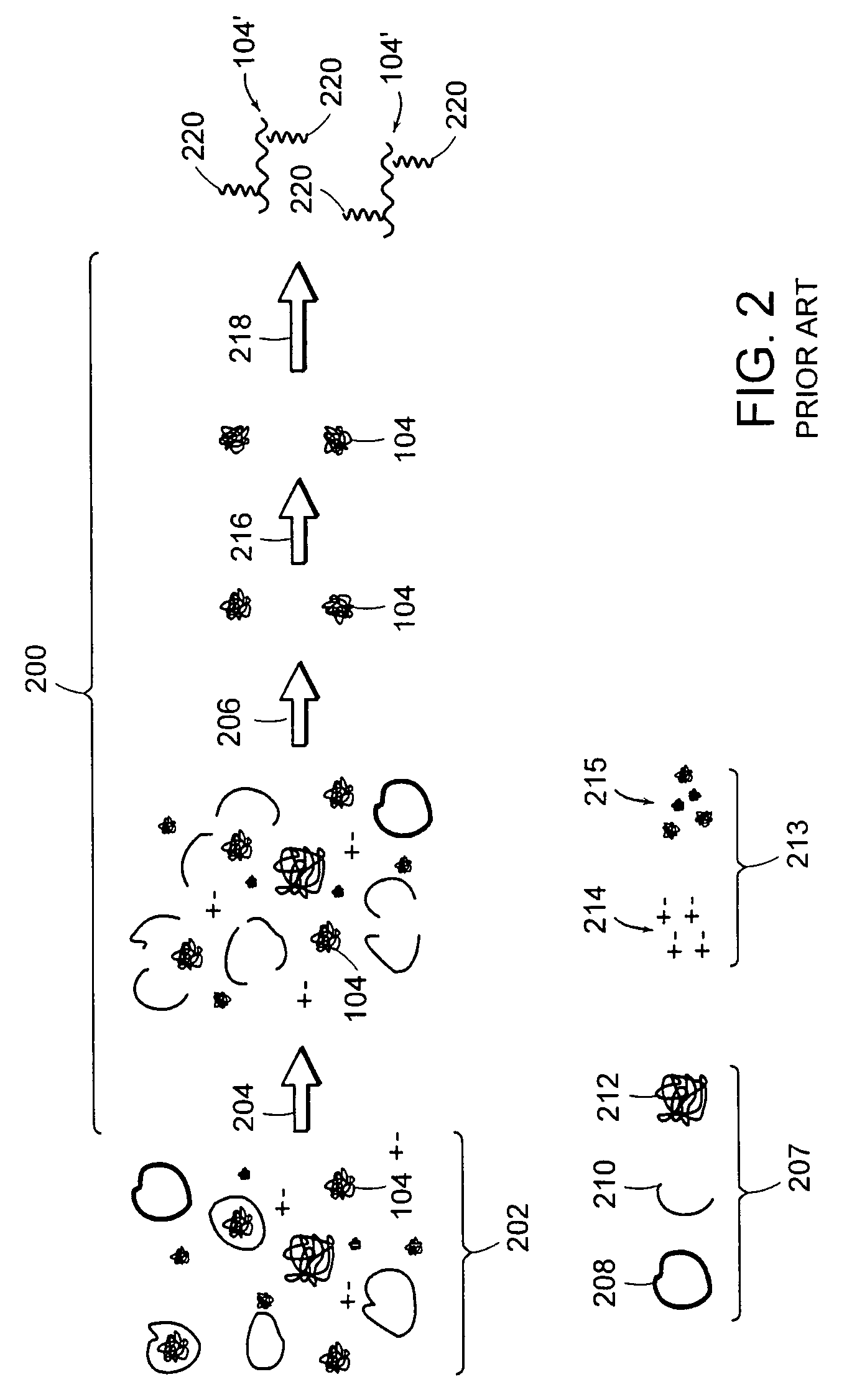

Devices, methods and systems for measuring one or more characteristics of a biomaterial in a suspension

InactiveUS20090158822A1Improve automationReadily portabilityMaterial analysis using sonic/ultrasonic/infrasonic wavesStatic/dynamic balance measurementParticulatesBioprocessor

A system for measuring one or more ultrasound parameters of a suspension comprising particulate biomaterial dispersed in a liquid carrier comprising, a bioprocessor for processing the particulate biomaterial; an immersible device comprising an ultrasound probes and a reflector; a housing, that fixes the probe and the reflector at positions with a space in between the probe surface and the reflective surface, comprising an opening into the housing that is of a size sufficient to allow the suspension to flow into the space between the probe surface and the reflective surface; an ultrasound wave generator / receiver device; and a signal processing device.

Owner:GENERAL ELECTRIC CO

Fluid interface for bioprocessor systems

InactiveUS7169599B2Facilitates rapidFacilitates frequentBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlInlet valve

An apparatus and method for an aseptic fluidic interface between bioprocess systems is provided. The apparatus includes an inlet valve, adapted for automatic control, that is coupled to a biofluid source site. A sampling conduit extends from the inlet valve to an outlet valve. The outlet valve is adapted for automatic control and is coupled to a biofluid process site. A trap is at the sampling conduit. A waste valve, adapted for automatic control, is located at a waste conduit extending from the sampling conduit to a waste site. Also included is a wash fluid source that is coupled to at least one of the inlet or outlet valves. In the method, the sample is automatically directed to the biofluid process site by opening the outlet valve, and closing the waste valve Also included is isolating the biofluid sites by closing the inlet and outlet valves, and opening the waste valve to drain biofluid from the trap to the waste site. Another step is cleaning the sampling conduit before sample collection by directing the wash fluid through at least one valve selected from the inlet and outlet valves, and subsequently through the waste valve to the waste site.

Owner:GROTON BIOSYST

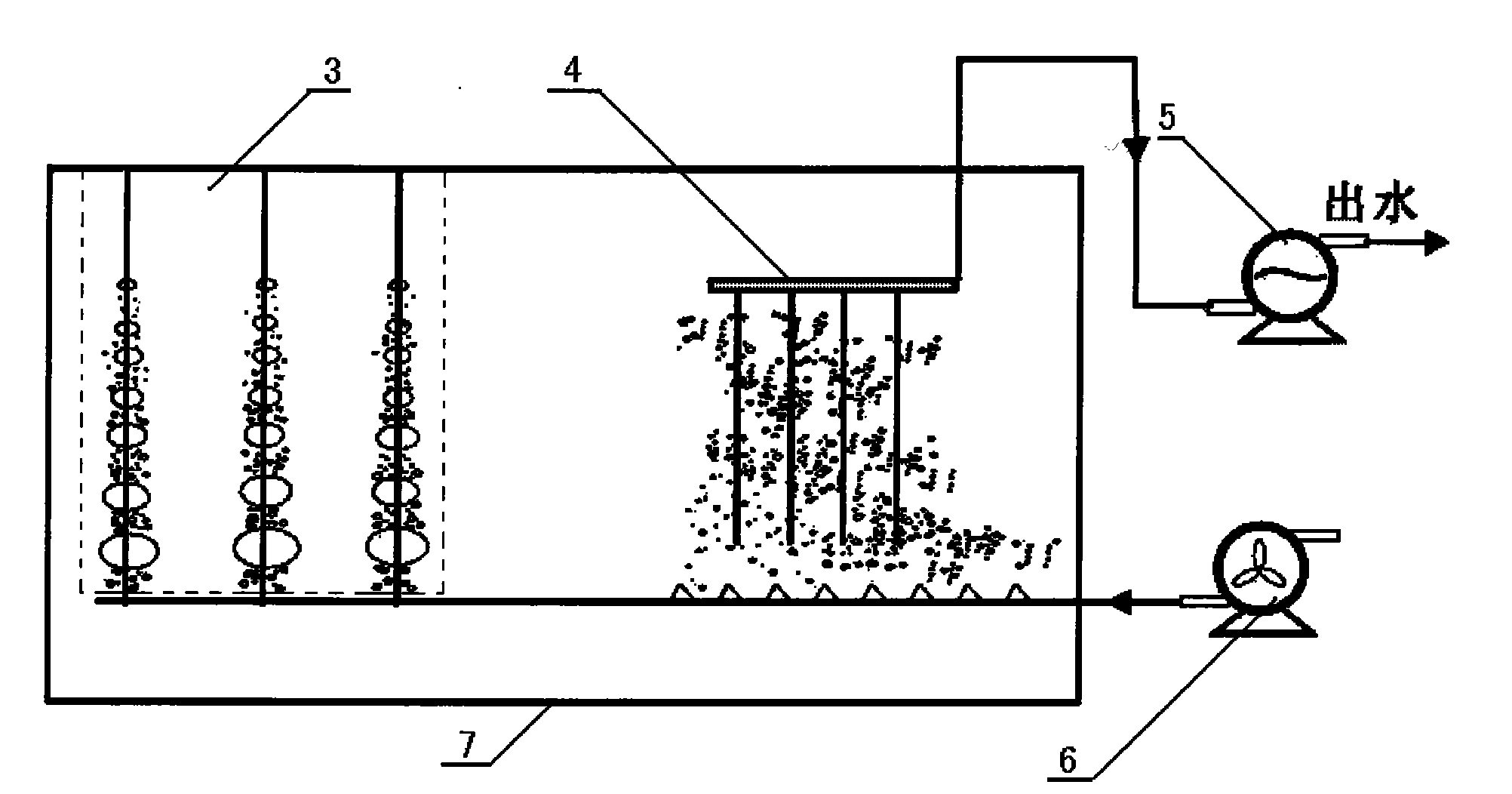

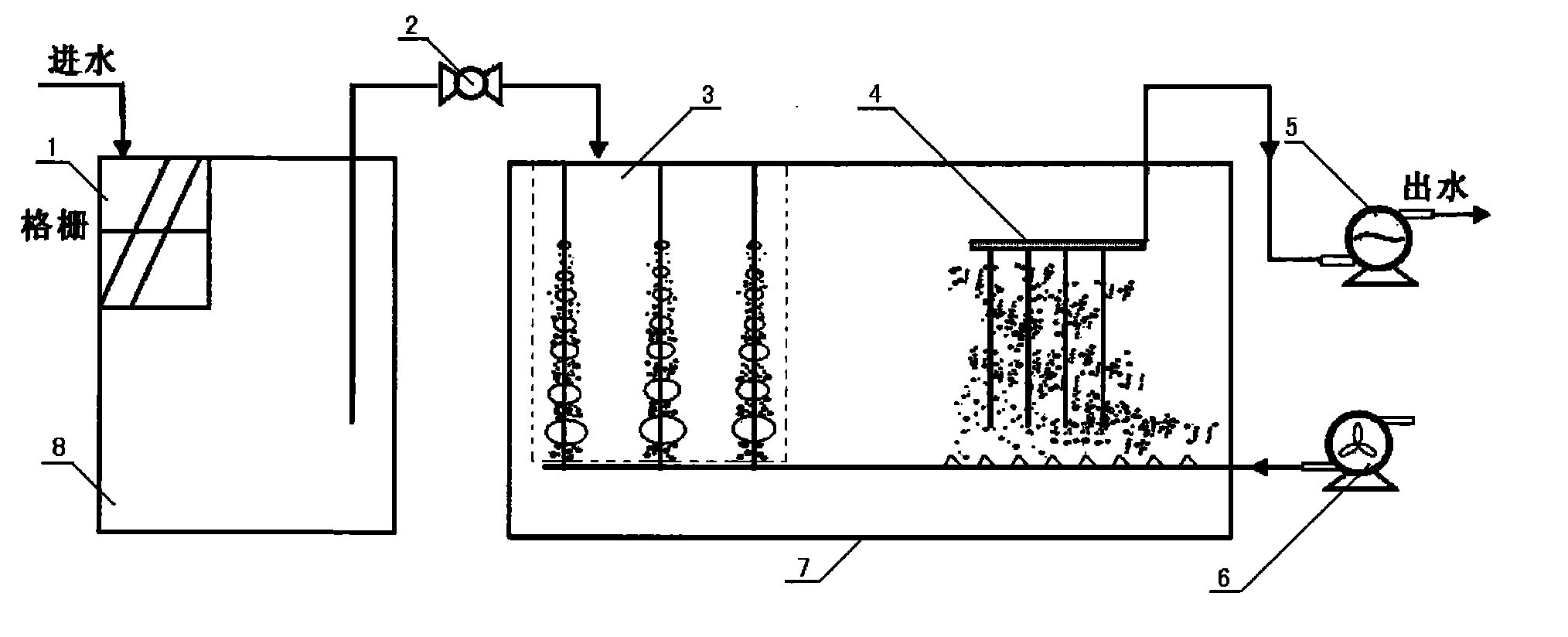

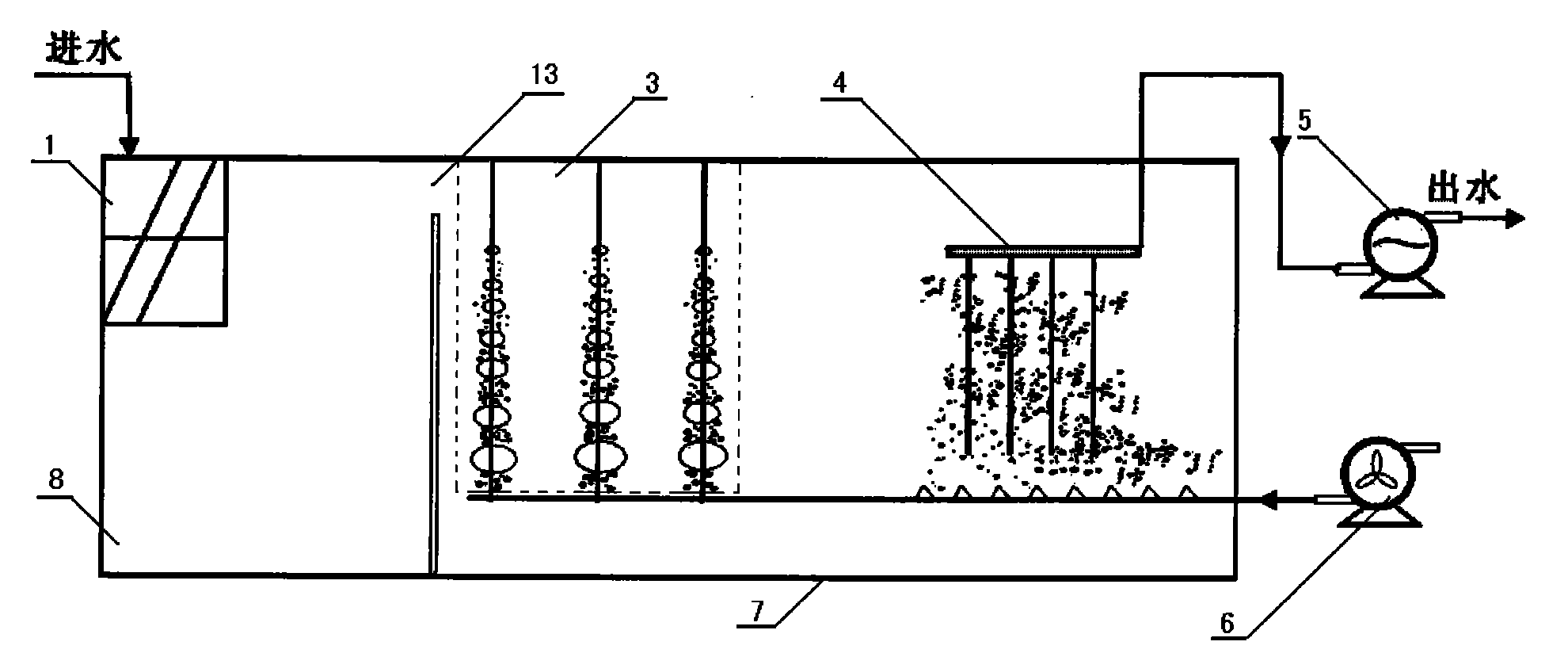

Integral MBR sewage treating and recycling method and treatment device

InactiveCN102101719ASimple structureAct as a membrane filterWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesFiltrationEmission standard

The invention discloses an integral membrane biological reactor (MBR) sewage treating and recycling method, which is characterized in that: pretreated sewage is subjected to anaerobic-aerobic biochemical reaction and biomembrane filtration simultaneously in the same membrane bioreaction purification tank provided with a string hanging type biological treater, a membrane biological reactor and an aeration mechanism to form recycled water. The technology can be widely applied to sewage treatment of catering, chemical engineering, papermaking, printing, landscape ponds, excrement and the like, and the treated water completely meets the emission standard specified by nation and accords with a recycled water recycling index.

Owner:上海川鼎国际贸易有限公司

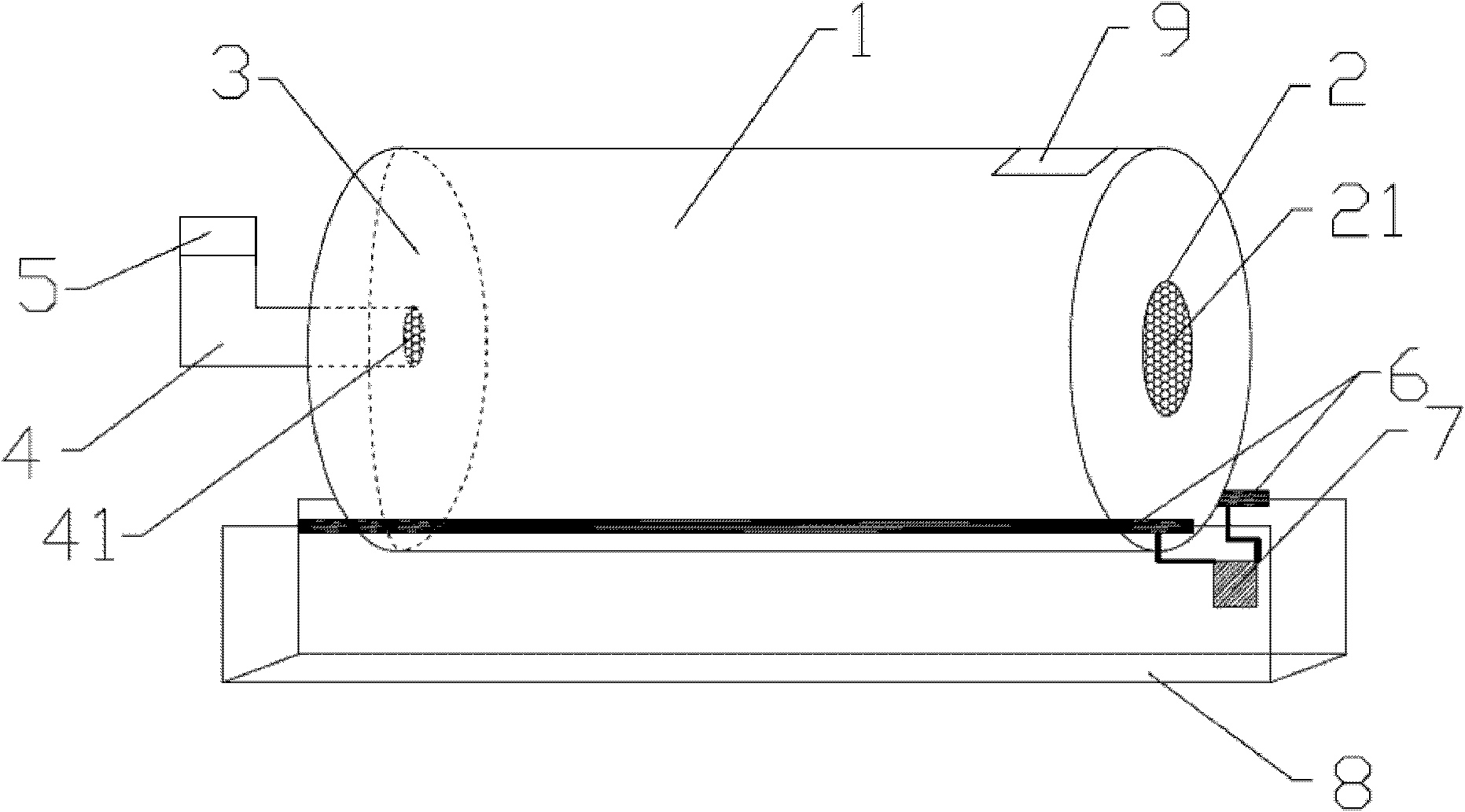

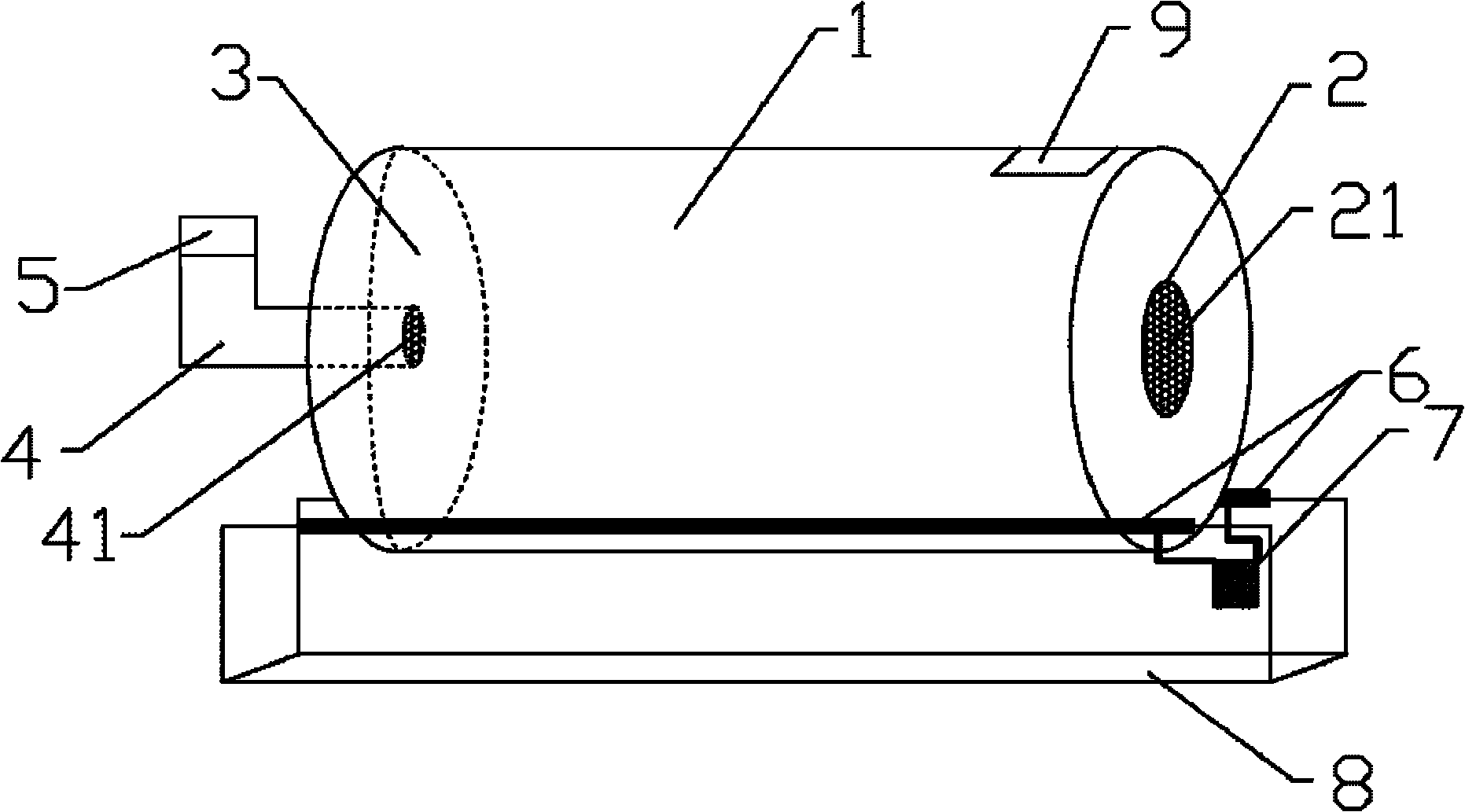

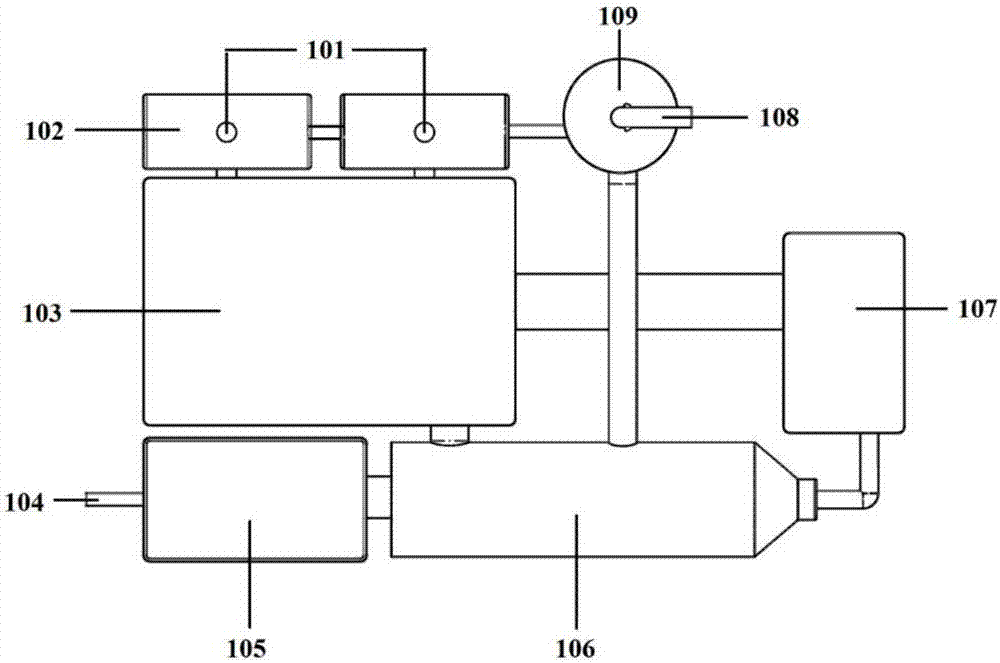

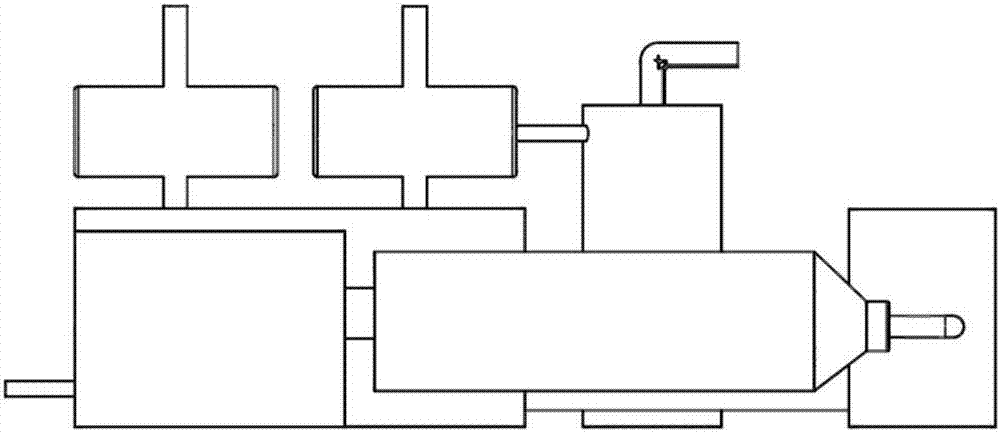

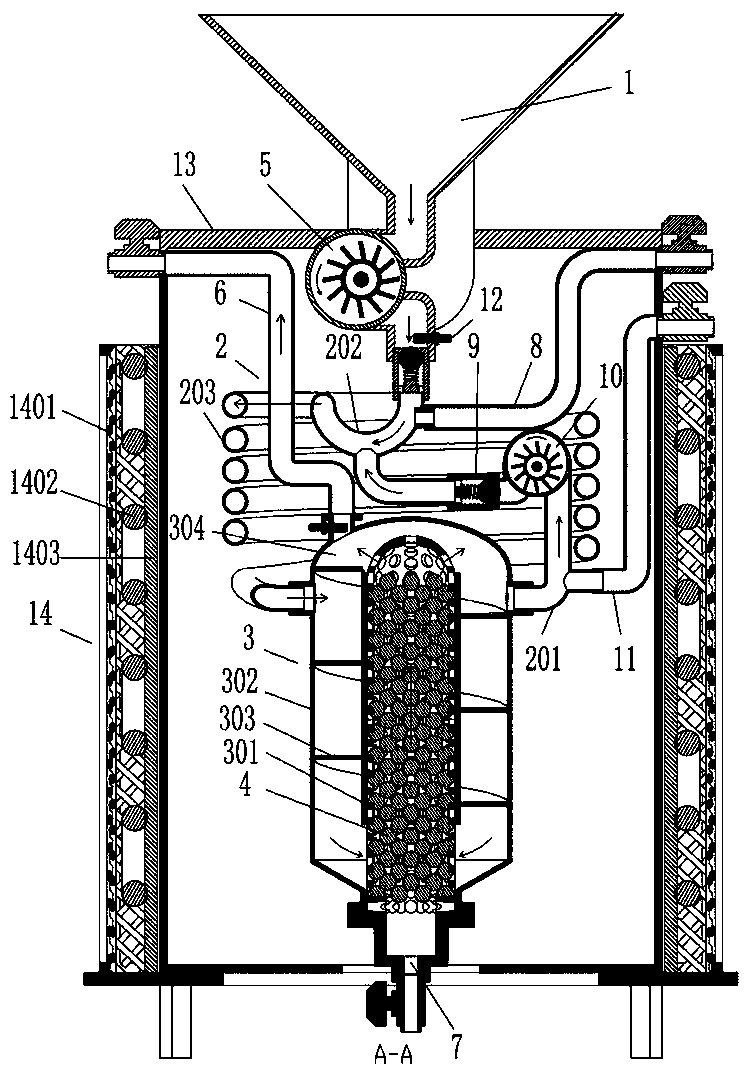

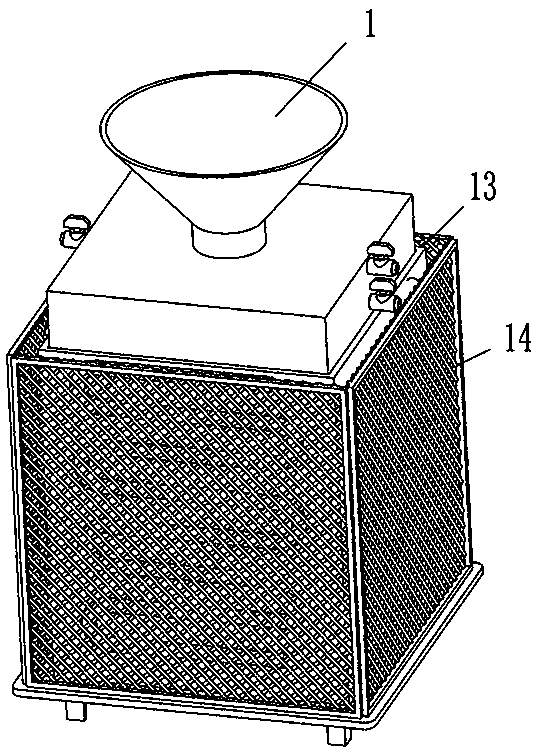

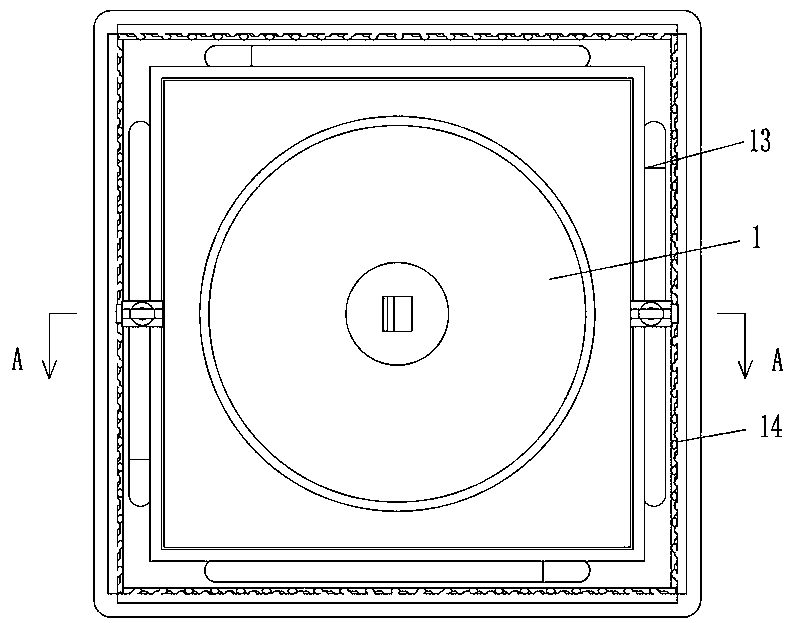

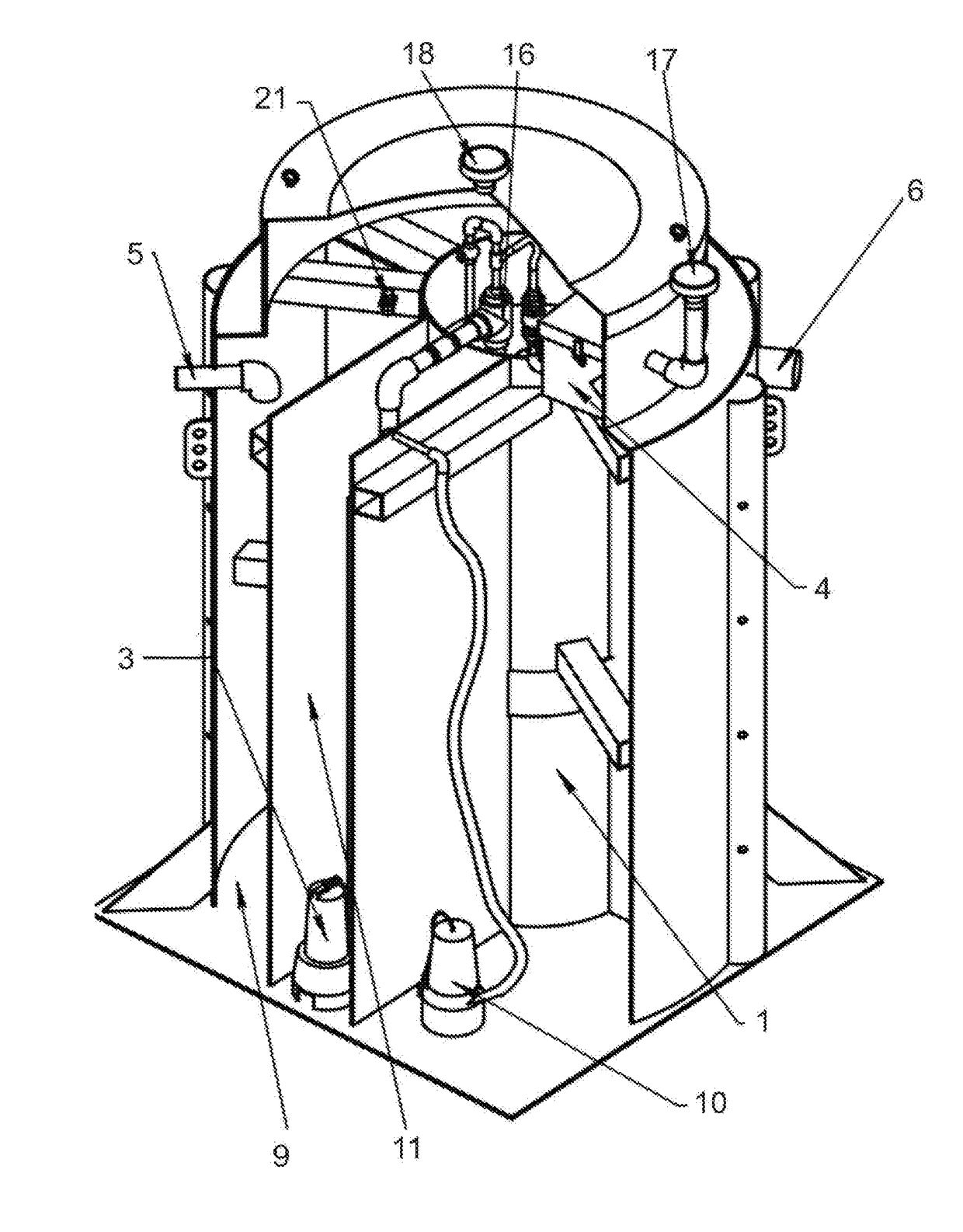

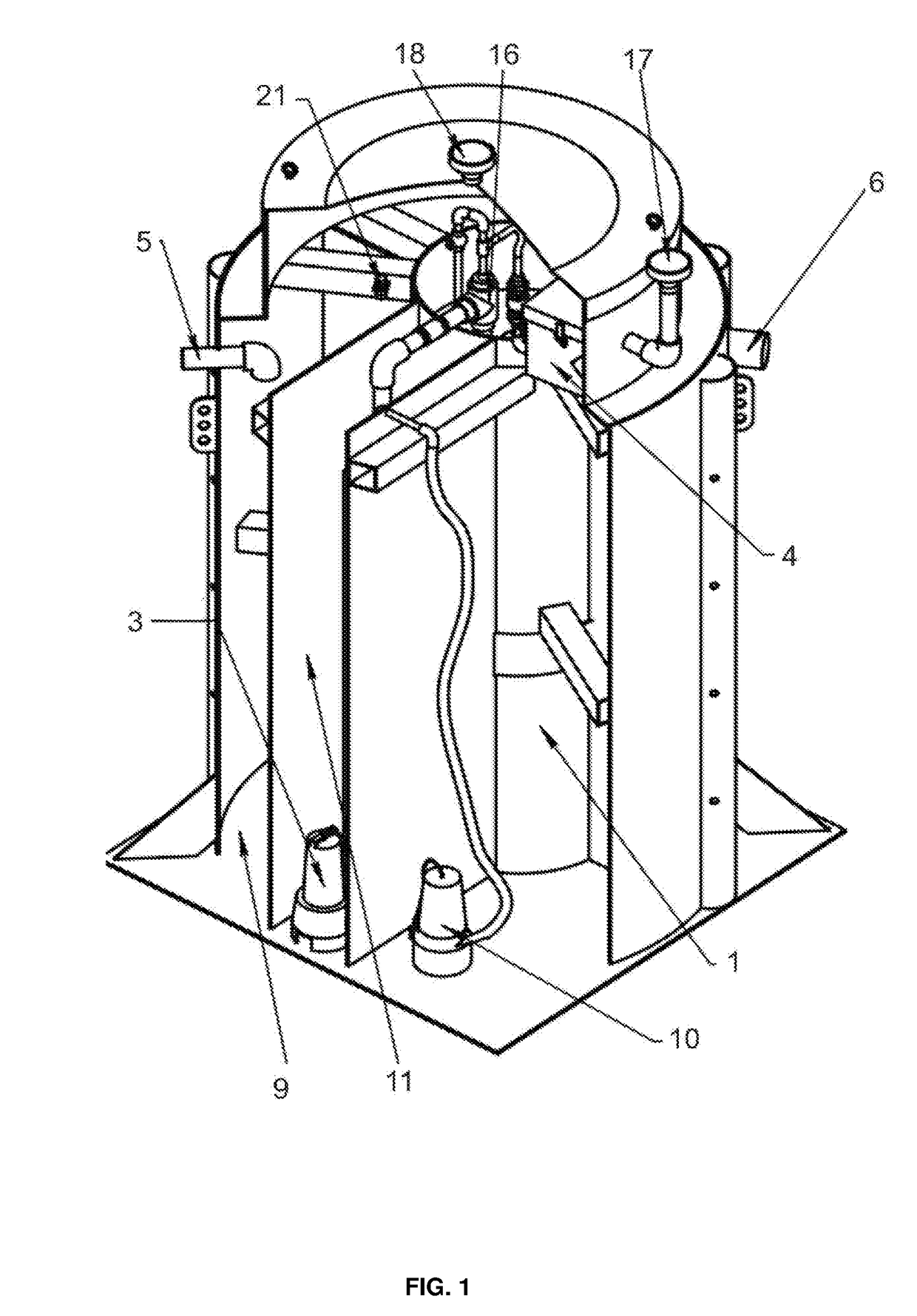

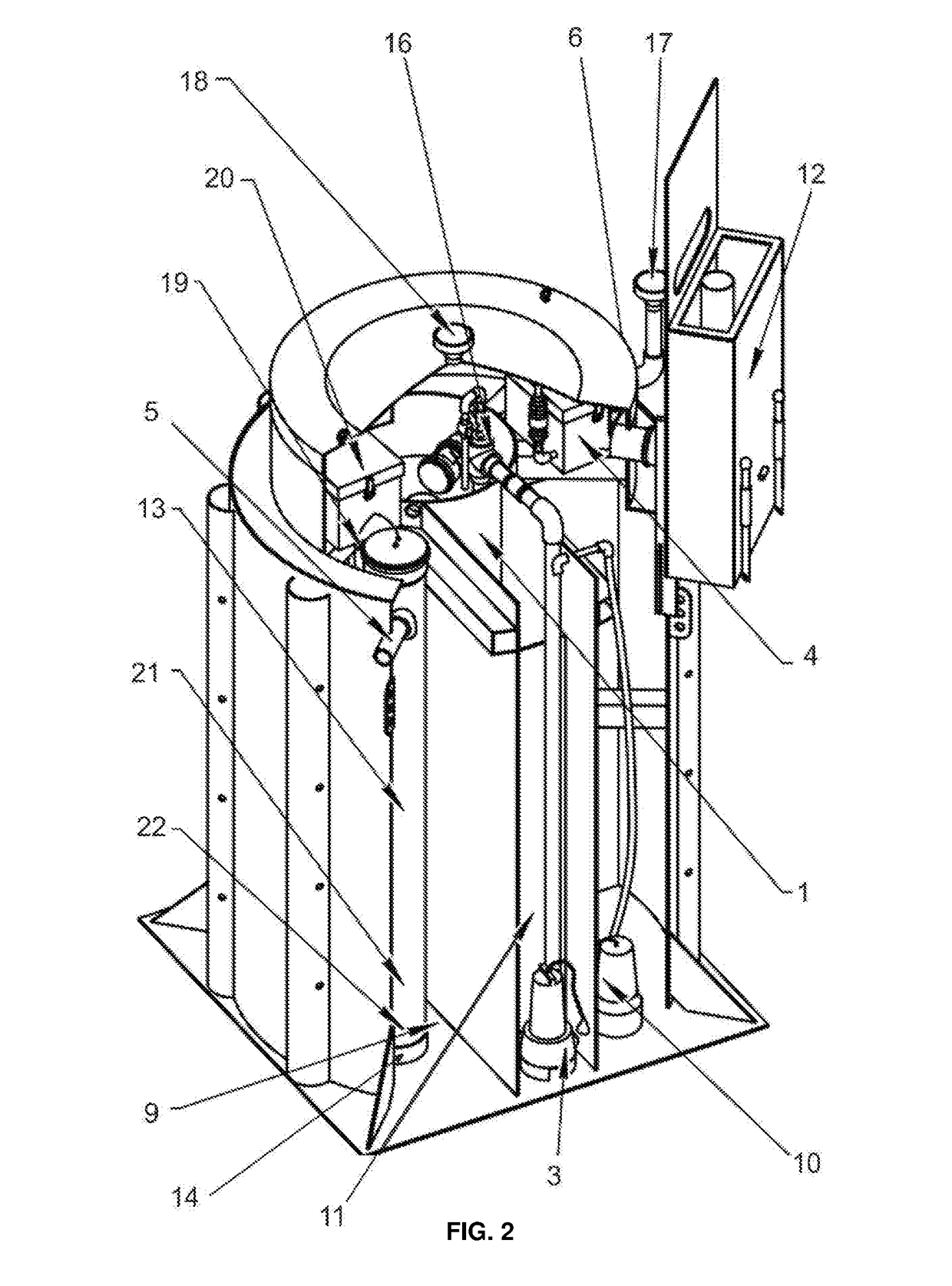

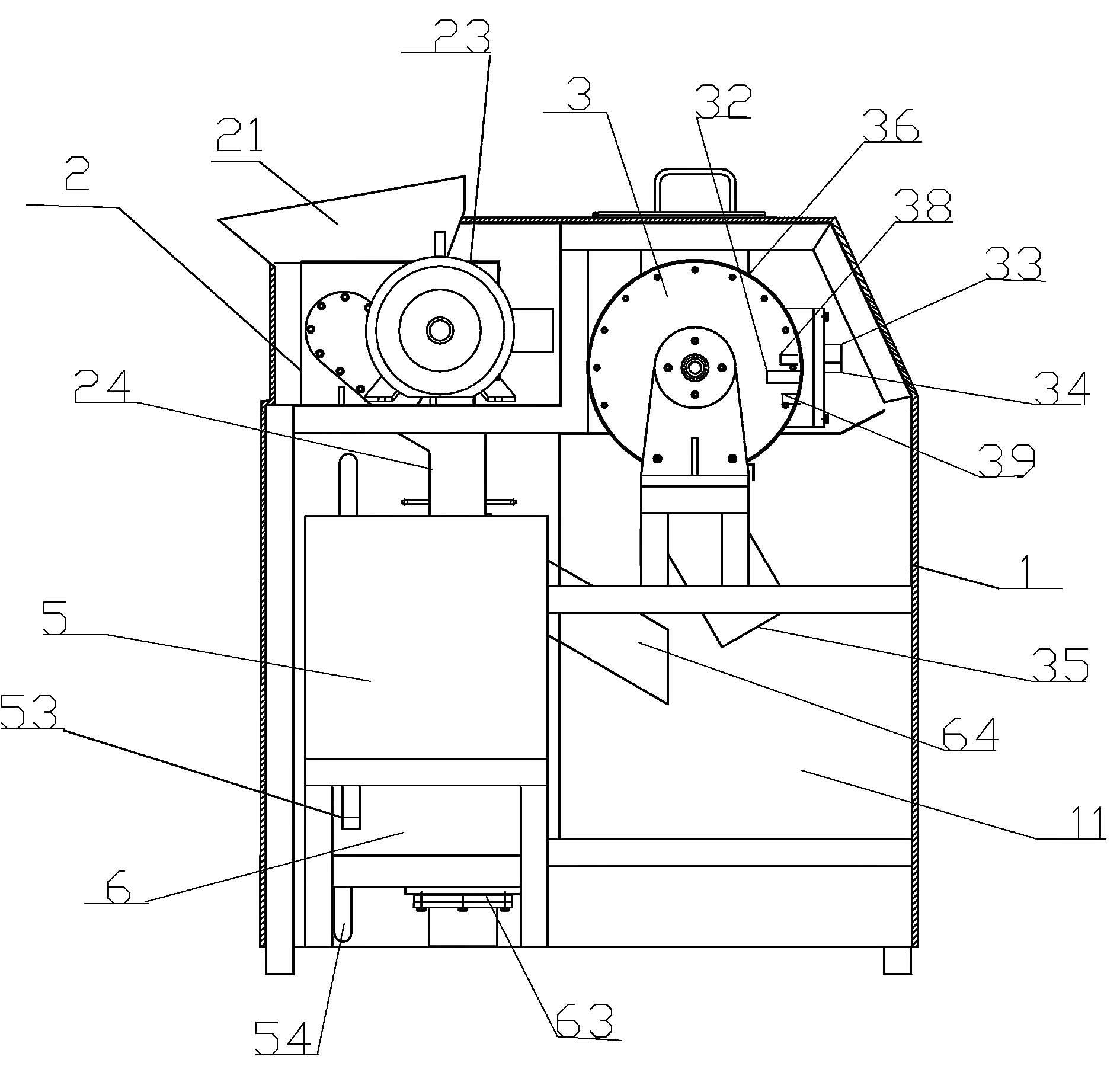

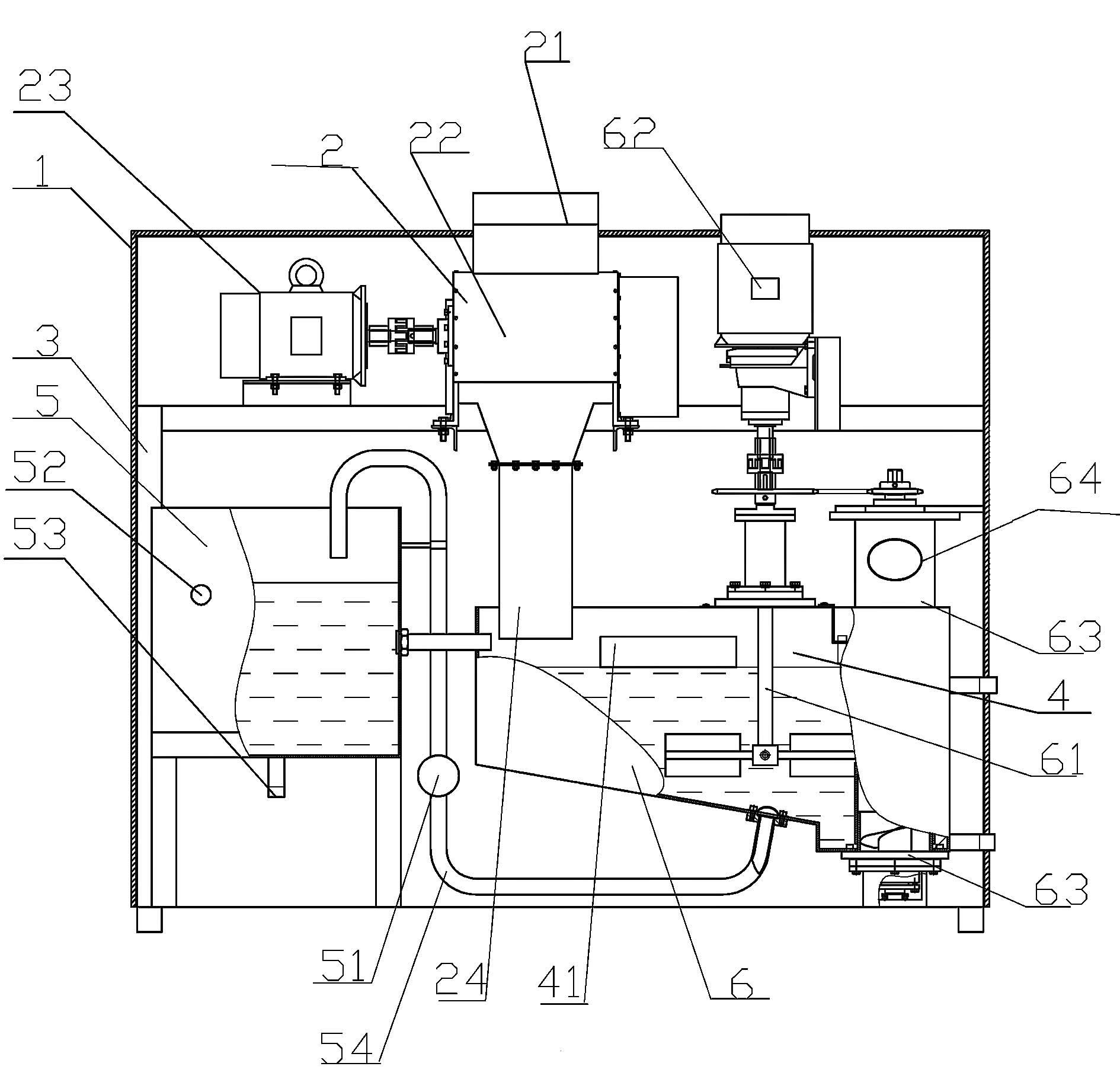

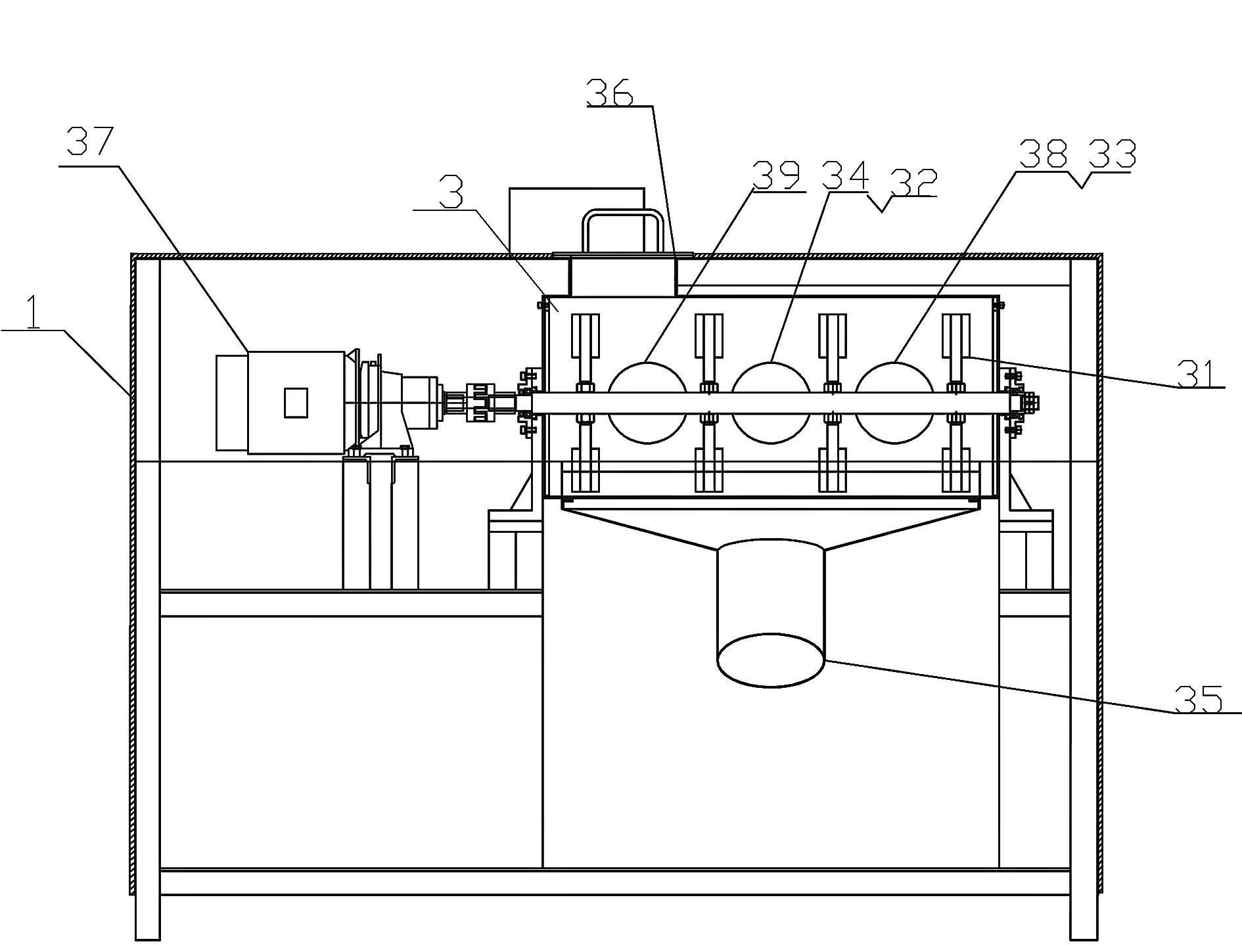

Ventilating and stirring type Hermetia illucens bioprocessor

InactiveCN102499190ASolve the scale processing problemAchieve scaleBio-organic fraction processingProductsBioprocessorWaste processing

The invention discloses a ventilating and stirring type Hermetia illucens bioprocessor, which comprises an incubator and a substrate for supporting the incubator, wherein the surrounding wall and the bottom wall in the incubator are respectively provided with a side wall air chamber and a bottom-layer air chamber which are connected with an air compressor; the walls of the side wall air chamber and the bottom-layer air chamber are provided with air vents communicated with the incubator; a plurality of blenders are fixed on the upper wall of the incubator; the stirring shaft of each blender extends into the incubator to reach the bottom; the upper wall of the incubator is also provided with an air purification device; the air purification device is communicated with the inner space of the incubator via an air duct; the upper wall of the incubator is also provided with a feeding hole; the inner wall of the incubator is also provided with a sensor; one end of the substrate is in rotating connection with the corresponding position of the incubator by a rotating shaft so as to fix the incubator on the substrate; the middle of the substrate is provided with an expansion link capable of supporting the incubator; the substrate is also provided with a vibration motor; and one side of the rotating shaft of the incubator is provided with a discharge door. The ventilating and stirring type Hermetia illucens bioprocessor makes the industrialization of organic matter waste processing possible.

Owner:GUANGDONG ENTOMOLOGICAL INST

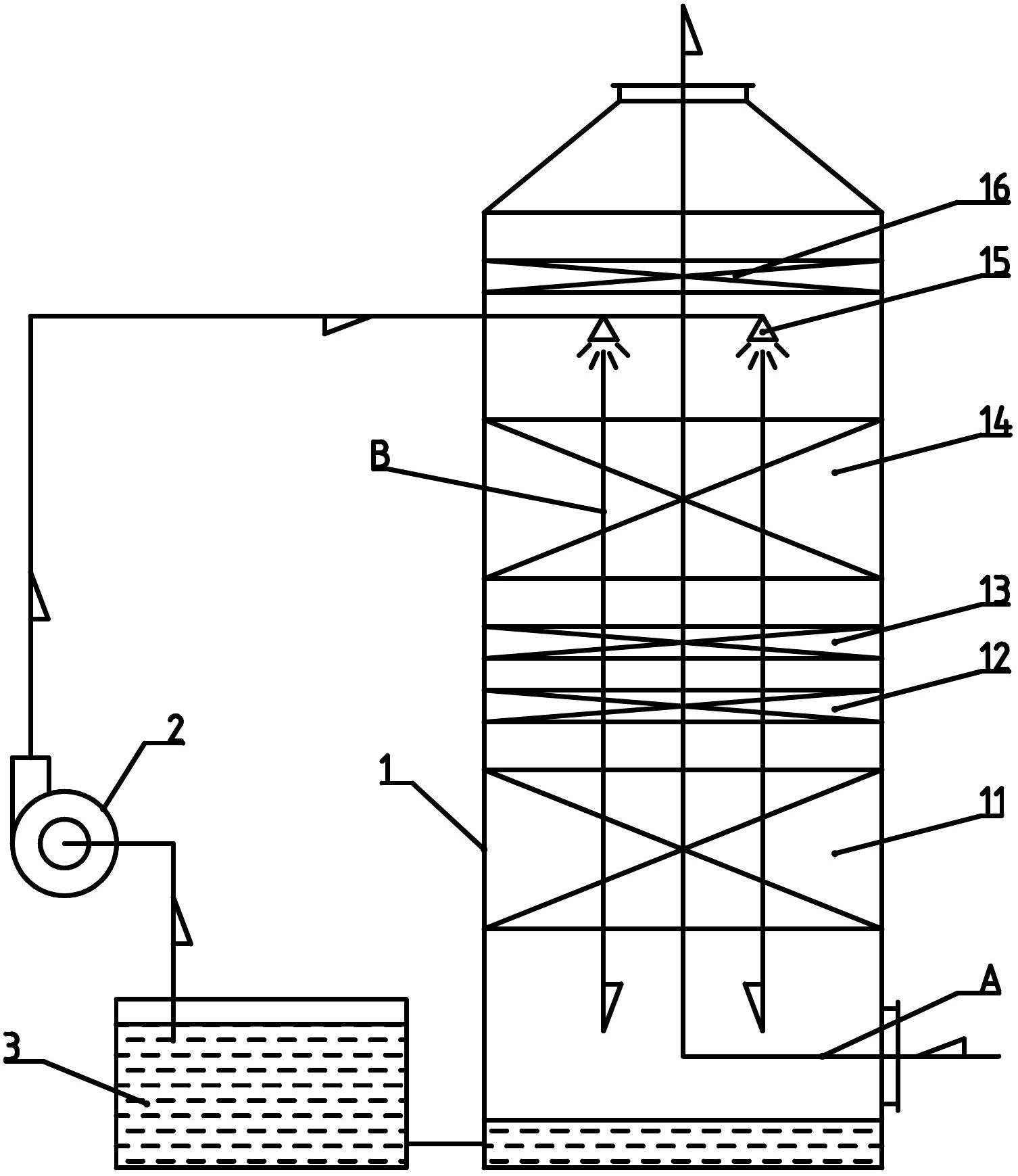

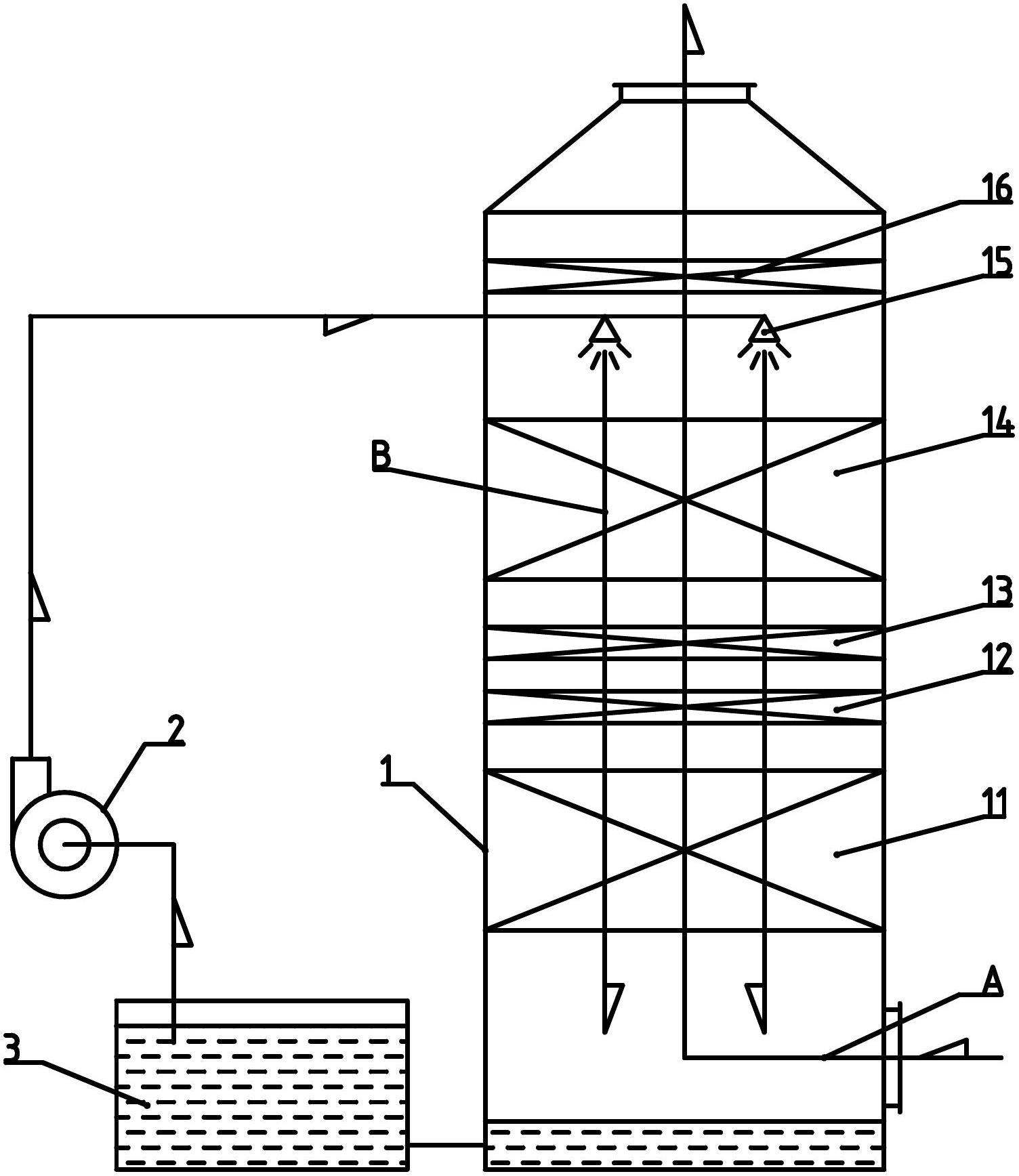

Waste gas purification plant with integration of plasma and biological method

InactiveCN102688669AReduce power consumptionControl formationDispersed particle separationDeodrantsSimple compoundBioprocessor

The invention relates to a waste gas purification plant with integration of plasma and a biological method. The waste gas purification plant comprises a purification tower, a circulating water pump and a regulating tank, waste gas in the purification tower sequentially flows through a plasma generator, a biological treatment device and a spray thrower, the spray thrower is connected with the circulating water pump, a water outlet of the regulating tank is connected with the circulating water pump, a water return port of the regulating tank is connected with the bottom of the purification tower, and culture fluid for culturing microorganisms is filled in the regulating tank. Toxic, harmful and odor pollutant is directly in prophase treatment by large quantities of active particles in the plasma, is converted into simple compounds, then continues to be degraded by the biological method and finally turns into nontoxic, harmless and odorless gas, secondary pollution is prevented, and harmful byproducts are effectively controlled.

Owner:广州广一大气治理工程有限公司

Treatment method and device for waste water containing greasy dirt

ActiveCN105236682AReduced oxygen demandImprove processing efficiencyMultistage water/sewage treatmentMicroorganismFlocculation

The invention relates to the technical field of waste water treatment, in particular to a treatment method and device for waste water containing greasy dirt. The treatment method and device for the waste water containing the greasy dirt are high in treatment efficiency and reasonable in cost. The treatment device is characterized in that a grease interceptor, an air float processor, a high-pressure oxidation device, a first-level acid-base regulating pool, an aerobiotic microorganism processor, a second-level acid-base regulating pool, an anaerobe microorganism processor, a flocculation tank and a filter settling pond are arranged, multi-level grease removing gratings are arranged in the grease interceptor and evenly distributed in the flow direction of the waste water, and oleophylic and lyophobic media used for adsorbing grease are fixed to the grease removing gratings; the high-pressure oxidation device is provided with a shell, and two electrode plates are arranged in the shell and connected with a high-pressure pulse generator outside the shell. Compared with the prior art, macromolecule organic substances in the waste water are treated into a micromolecule structure through the high-pressure oxidation device, the oxygen demand for microorganism treatment in a later stage is lowered, and the treatment device has the remarkable advantages of being reasonable in structure, stable in working, high in treatment efficiency and the like.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

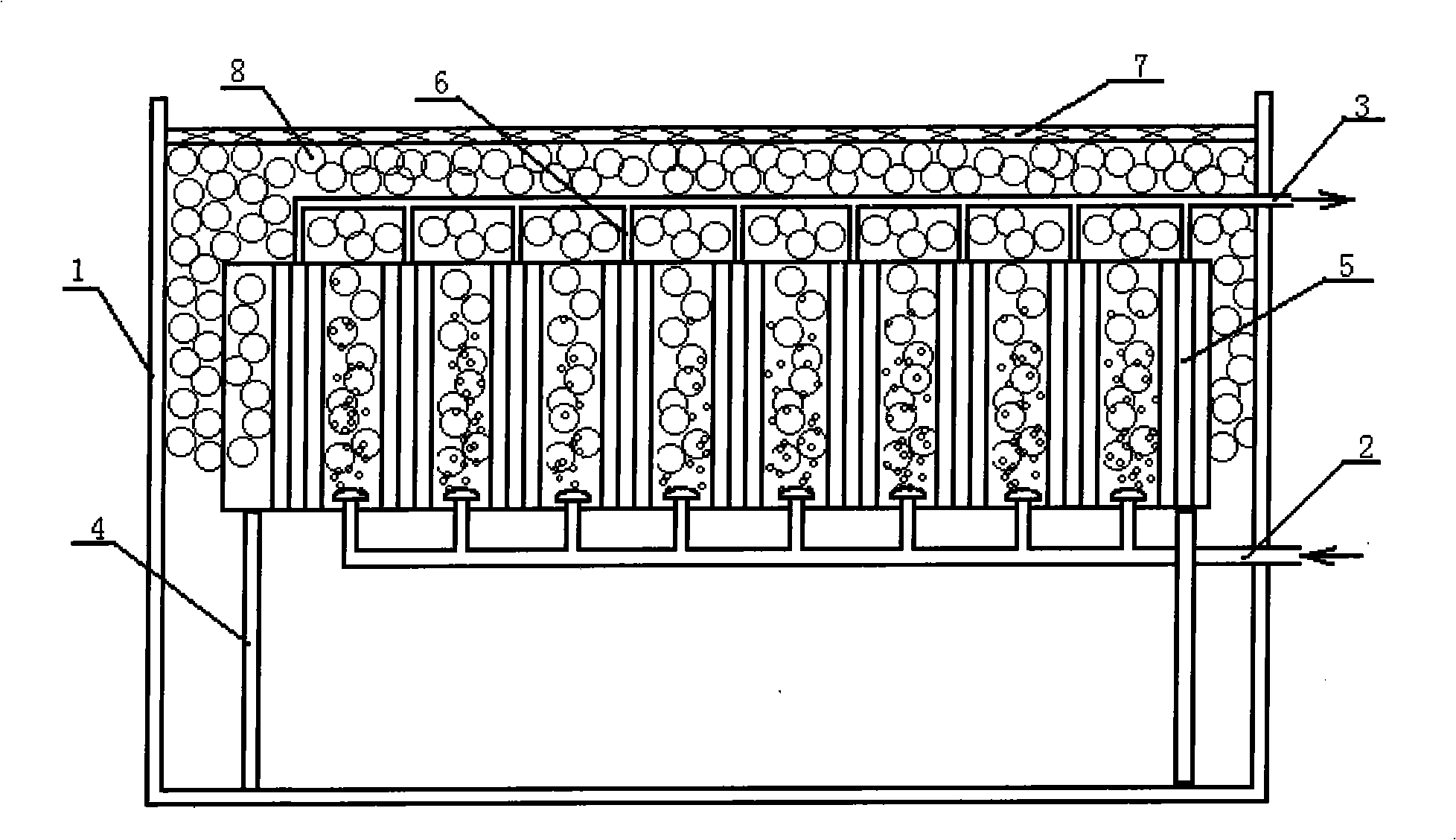

Filled membrane biological processor

InactiveCN101555064APromote degradationGood removal effectTreatment using aerobic processesSustainable biological treatmentVolumetric Mass DensityIon-exchange resin

The invention discloses a filled membrane biological processor which comprises a water treatment vessel, a hollow fiber membrane group, an aeration pipe network, a water collecting main pipe and a bracket, wherein the hollow fiber membrane group consists of a hollow fiber membrane and a water collecting pipe; the water treatment vessel is internally provided with soliquoid with the density of 0.9 to 1.0g / cm, and the soliquoid consists of a multihole shell and filling materials; the material of the multihole shell is polypropylene or polyethylene; and the filling material is at least one out of activated carbon fiber, granular active carbon, mekralon, polyethylene fiber and ion exchange resin. The processor is beneficial for the degradation of organic substances, the elimination of the pollutant of ammonia nitrogen and the cleaning of the hollow fiber membrane; the breakage and enwinding of the hollow fiber membrane are avoided; besides, the processor is beneficial to the distribution of air, avoids the short circuit of air water, and reduces the air water ratio and energy consumption.

Owner:INST OF HYGIENE & ENVIRONMENTAL MEDICINE PLA ACAD OF MILITARY MEDICAL +1

Method and device for treating wastewater containing high-concentration phenol

InactiveCN104609649ANon-toxicToxic effect producedWater contaminantsMultistage water/sewage treatmentBioprocessorUltraviolet lights

The invention discloses a method and device for treating wastewater containing high-concentration phenol. A dielectric barrier discharge plasma treatment method combined with biological treatment is adopted. After the wastewater containing high-concentration phenol is collected, the wastewater is treated with a dielectric barrier discharge plasma reactor, the treated wastewater enters a biological treatment device to be treated, and finally the obtained water is discharged into a river. In the dielectric barrier discharge plasma reactor, .OH, .O, H2O2, O3, high-energy electrons and ultraviolet light, which are generated during high voltage discharge, have strong oxidizing substances, so that the concentration of phenol in wastewater is reduced; meanwhile, phenol is partly oxidized to generate low-carbon aldehyde, alcohol, acid and ester compounds which are easy for biodegradation. Entering the biological treatment device, the aldehyde, alcohol, acid and ester compounds and the phenol which is not treated are further converted into CO2, H2O and other inorganic substances under the microbial action. The method can effectively remove the high-concentration phenol in wastewater, and the removal rate is higher than 99 percent.

Owner:TAIYUAN UNIV OF TECH

Method for advanced treatment of industrial wastewater with biological technique and membrane technique

InactiveCN101492220AThorough governanceNo secondary pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentBioprocessorIndustrial effluent

The invention discloses a method for the advanced treatment of industrial wastewater through biotechnology and membrane technology, which is characterized by comprising the following steps: performing inorganic membrane concentration after the industrial wastewater is filtered by a membrane filter first, and then performing biological treatment; putting the concentrated solution after the concentration through an inorganic membrane into a biological treater which adopts a microorganism flocculating agent to treat the concentrated solution so as to purify the wastewater; and separating the clear solution after the concentration through the inorganic membrane in an organic membrane device, recycling the clear water after the separation, and discharging impurities into the biological treater to be treated. The method can thoroughly control pollutants of the industrial wastewater, has high clear water utilization rate, and is superior to the prior other arts for controlling the industrial wastewater; besides, the facilities used in the method have small occupied area and less investment, and the investment cost for controlling the industrial wastewater is easy to recover.

Owner:范兆科

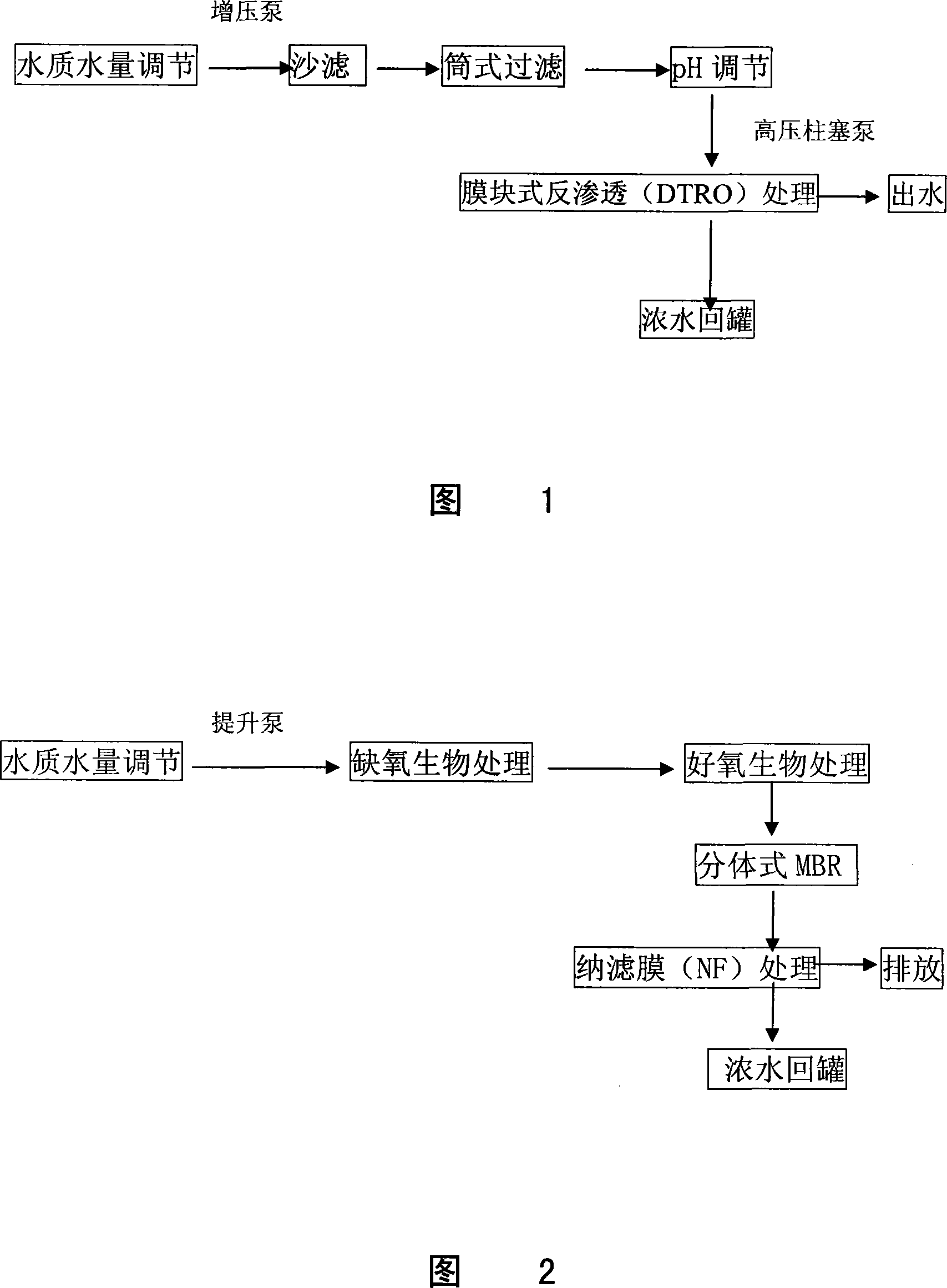

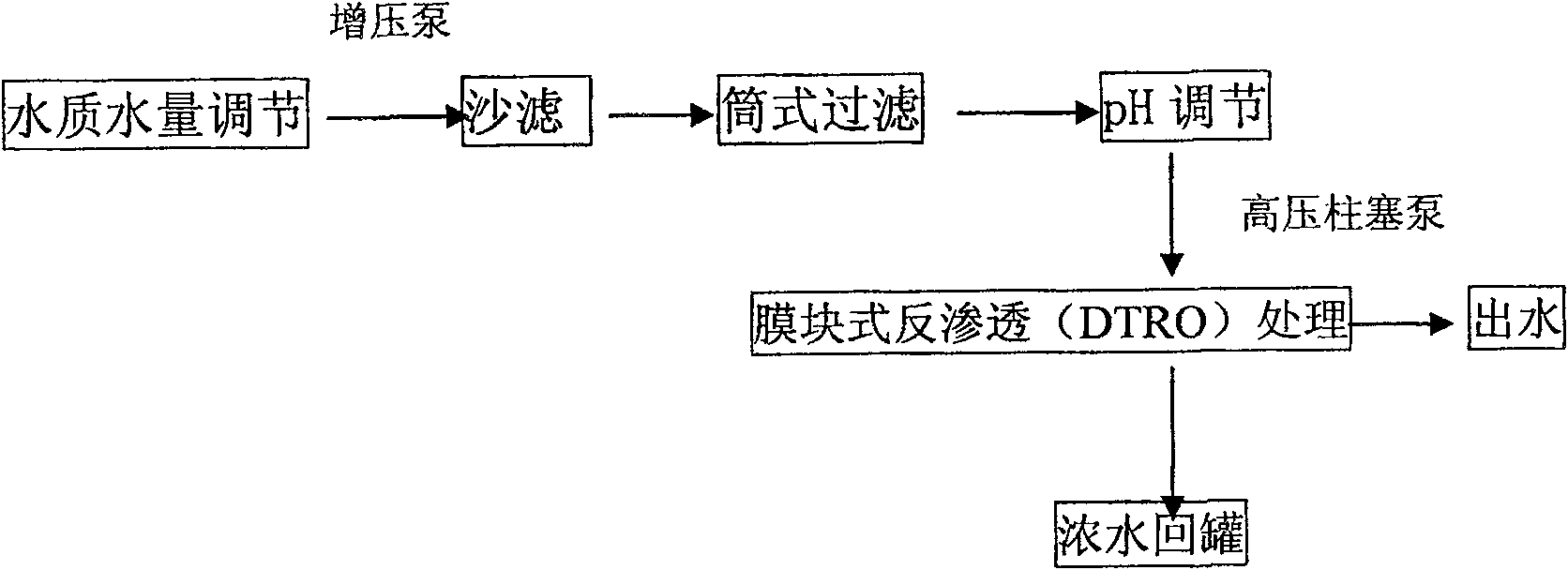

Technique for processing garbage leachate

ActiveCN100567186CShort process flowEasy to controlUltrafiltrationWater/sewage treatment bu osmosis/dialysisWater qualityOxygen

The invention relates to a landfill leachate treatment process, comprising: (1) adjusting the water quality and water quantity of the landfill leachate in a regulating tank; (2) sending the leachate after water quality and water quantity adjustment into an anaerobic tank, Anaerobic treatment is carried out at 25°C to 45°C, and the anaerobic treatment time is 50 to 100 hours; (3) The biogas generated during the anaerobic treatment is treated, and the sludge generated during the anaerobic reaction is discharged; (4) ) Send the leachate after the anaerobic treatment into the anoxic tank for anoxic treatment, and discharge the sludge generated in the anoxic reaction process; (5) send the leachate after the anoxic treatment into the aerobic tank for aerobic treatment (6) Send the leachate after aerobic treatment to the membrane bioprocessor for solid-liquid separation, and the sludge produced after the treatment will be processed according to the reflux ratio of 3:1 to (7) send the leachate treated by the membrane bioprocessor into an intermediate water tank; (8) perform nanofiltration membrane treatment on the leachate, and the treated effluent is directly metered and discharged or mixed with the water in the intermediate water tank (9) concentrated water after nanofiltration membrane treatment is returned to the adjustment tank.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

Amino benzene analog waste water biological treatment method

InactiveCN100341797CHigh mechanical strengthReduce wear rateTreatment using aerobic processesWater contaminantsBenzeneBioprocessor

The invention discloses a method for strengthening amino benzenes production wastewater SBR biological treatment with synthesized macroporous high-molecular polymer as immobilization microbe. For the drawback of the prior microbe carrier, the invention provides a kind of synthesized high-molecular polymer as immobilization microbe, and applies it to strength amino benzenes production wastewater SBR biological treatment. Compared with prior SBR technique, when microbe carrier used is 2-10% of active volume of the reactor, and the technique condition such as aeration volume, reaction time and temperature equals, with the method, the clearance of amino benzenes materials improves by 35-60% and the concentration of ammonia nitrogen in water outlet decreases by 5-15mg / L. The invention can be applied for modifying the prior wastewater treatment device, or building new wastewater treatment device, having good economic profit and environmental benefit.

Owner:NANJING UNIV

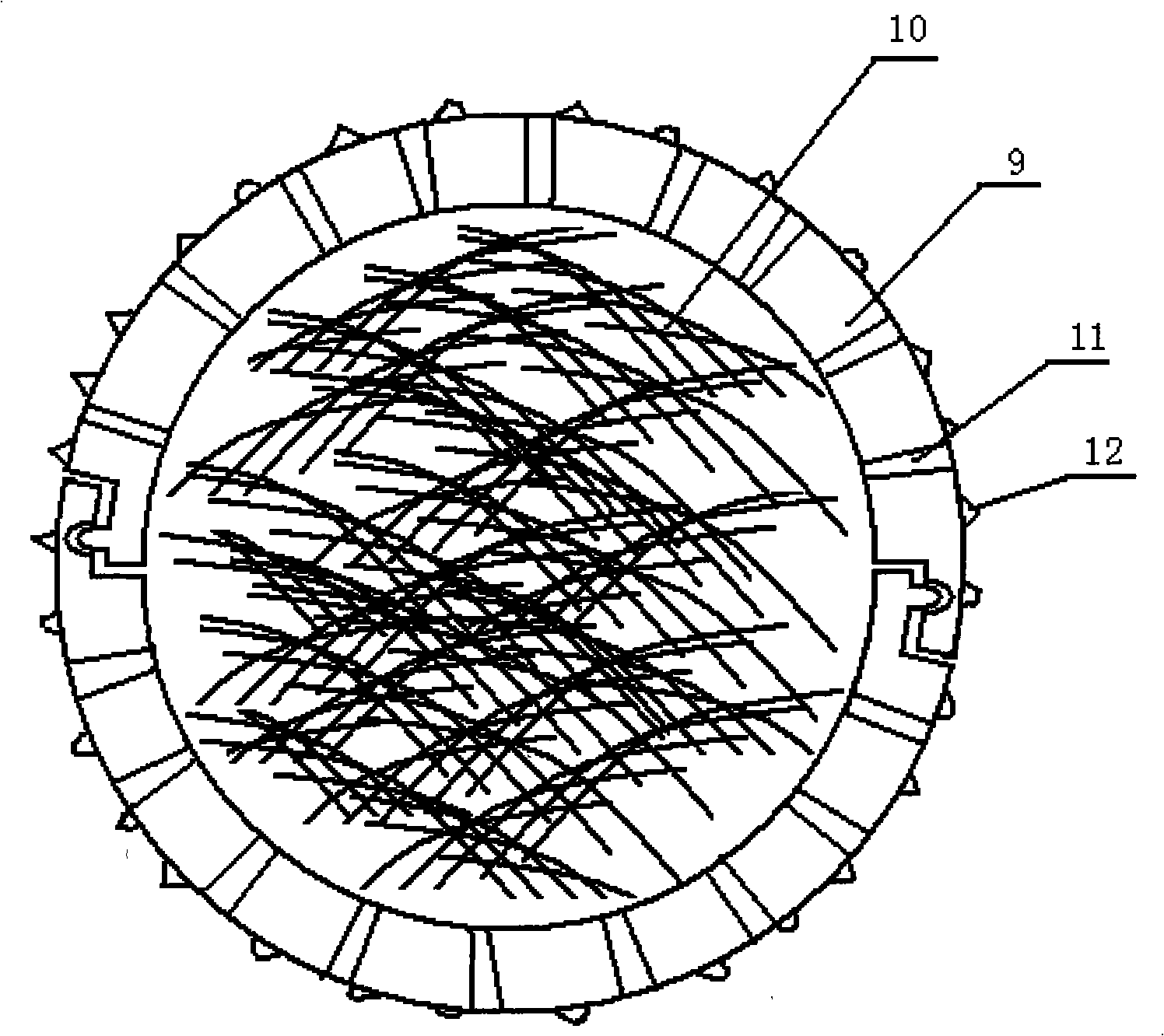

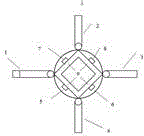

Starfish-shaped biological processor

ActiveCN106115914ATo achieve the purpose of decontaminationStabilize biome structureBiological treatment apparatusTreatment with aerobic and anaerobic processesBioprocessorStarfish

A starfish-shaped biological processor is used for landfill leachate, wastewater treatment plant upgrading, township sewage treatment, smelly water, and governance on polluted rivers and lakes. The main body structure is stainless steel, and the aeration diaphragm is made of a high-molecular corrosion-resistant material. A bionic technology is adopted in the structure, which is similar to starfish in shape; and the processor comprises a central device, eight aeration diaphragms and four supporting claws. The central device comprises a thorough cylindrical venturi drainage tube, a perforated closed square tubes with one short corner and four outlet tubes connected with the square tubes and in symmetrical distribution; the ends of the four outlet tubes are respectively provided with two branch tubes; each branch tube outlet is provided with an aeration diaphragm, and the diameter of the pore on the aeration diaphragm is less than the diameter of the pore on the closed aperture square tubes; and the four supporting claws comprise an air inlet pipe and three supporting legs, which are uniformly distributed in the periphery of the venturi drainage tube.

Owner:北京东方启源环保科技有限公司

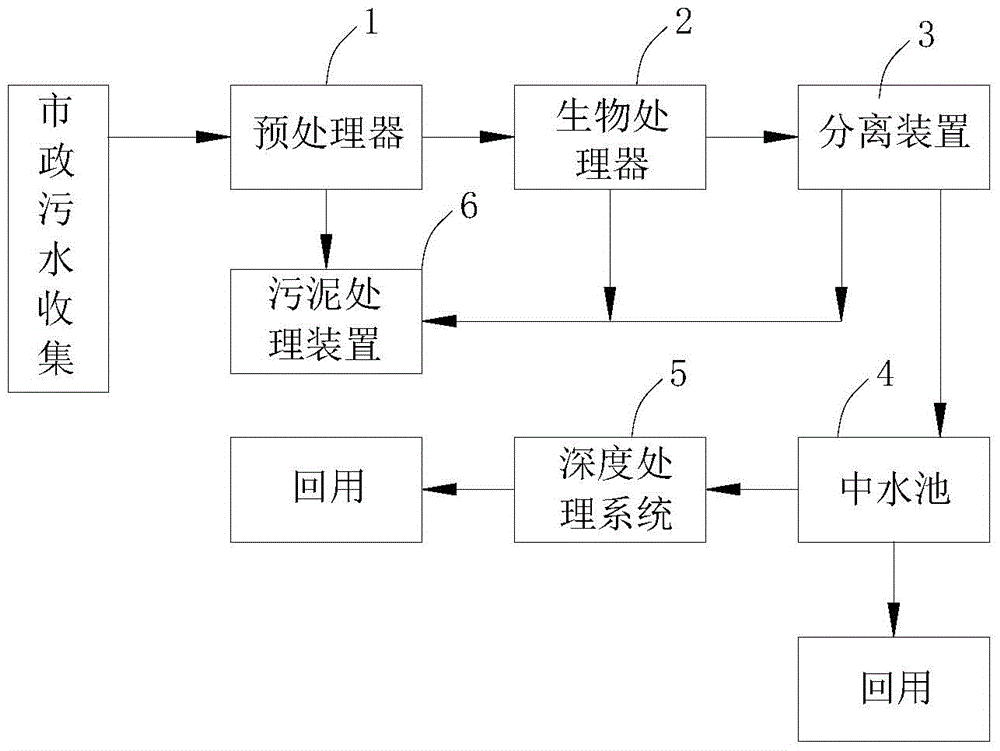

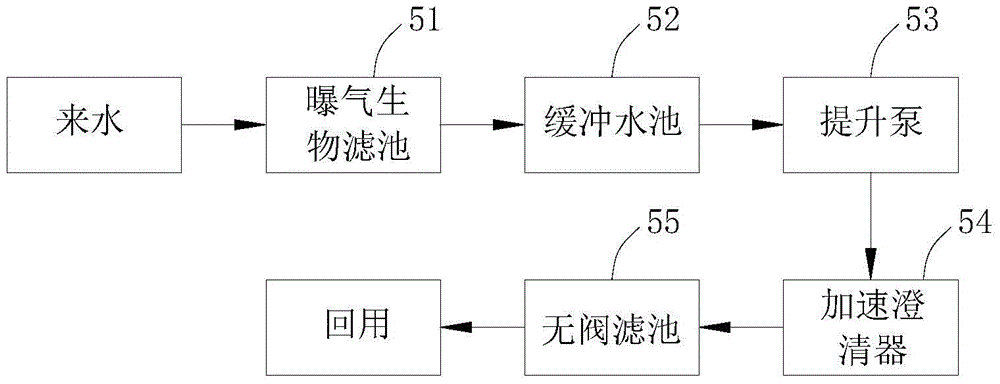

Municipal sewage recycling system

InactiveCN104649505AHigh reuse rateLarge amount of waterMultistage water/sewage treatmentBioprocessorMunicipal sewage

The invention relates to a municipal sewage recycling system. The system comprises a pre-treater, a biological treater, a separation device, a recycled water tank and a depth treatment device, wherein the input end of the pre-treater is connected with the input end of the biological treater; the output end of the biological treater is connected with the input end of the separation device; the output end of the separation device is connected with the input end of the recycled water tank; and the output end of the recycled water tank is connected with the input end of the depth treatment device. The municipal sewage recycling system can be used for treating urban sewage, and has the characteristic of recycling sewage.

Owner:常州市江南环保设备有限公司

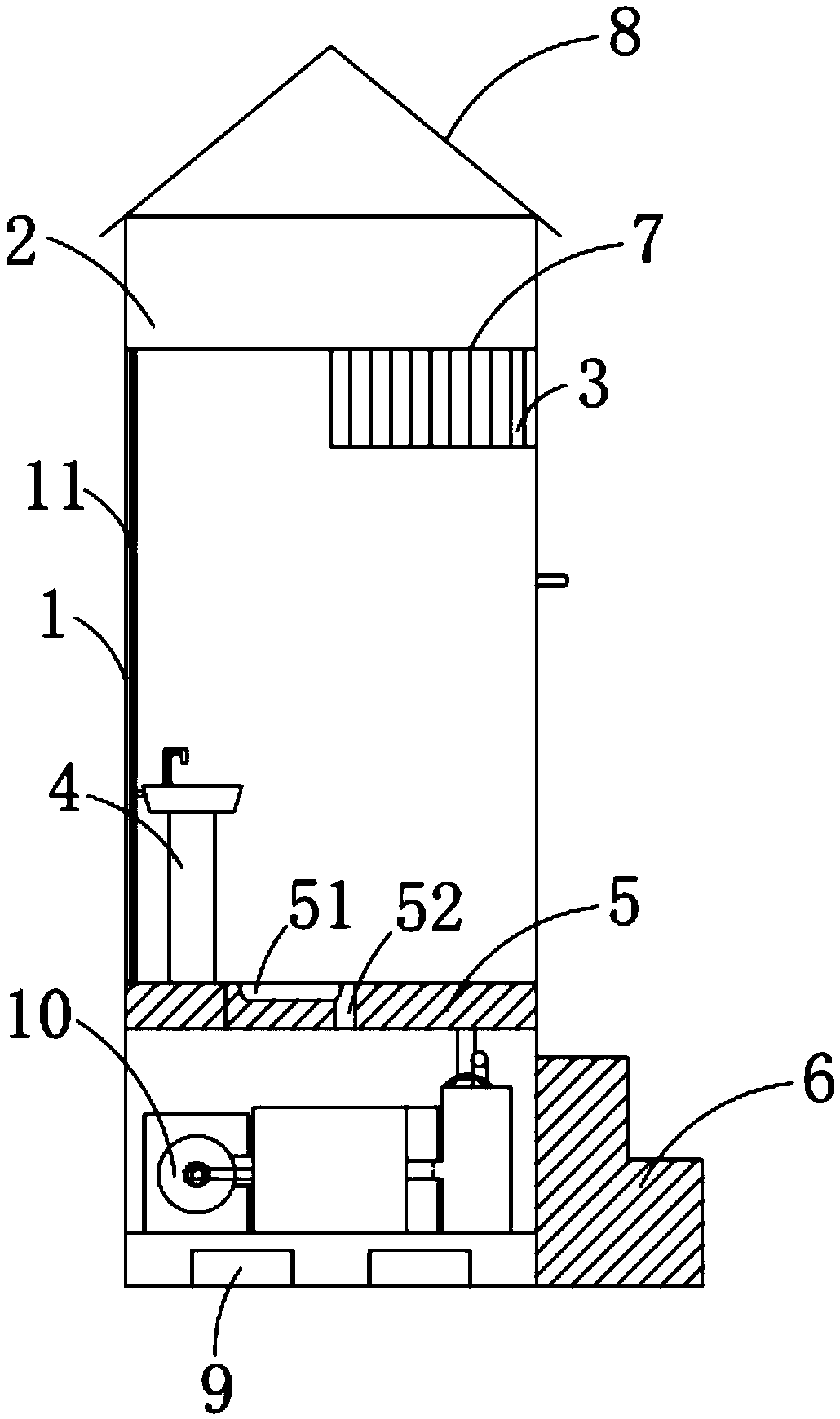

Mobile toilet solid-liquid separation device based on sustainable idea

PendingCN106938871AExtend the life cycleSimple structureSludge treatment by de-watering/drying/thickeningDispersed particle separationBioprocessorDistillation

The invention discloses a mobile toilet solid-liquid separation device based on a sustainable idea. A toilet stool sewage pipe is connected to a vacuum pump. After excreta is subjected to vacuum treatment, gas is pumped into a biological treater and then is treated, the rest of the excreta solid and liquid is fed into a solid-liquid mixing box and is subjected to solid-liquid separation, the separated solid is fed into a solid box and then is subjected to compression treatment, the separated liquid is fed into a distillation kettle and is distilled, volatile gas is pumped into the biological treater and then is treated, distilled water is fed into a water tank and then is condensed, wherein the water tank is connected to a toilet flushing device, and the treated distilled water can be recycled so that sewage treatment is finished. The device has a modular design, has a simple and reasonable structure, occupies a small space, has strong mobility, realizes the microbial green pollution-free treatment, realizes water recycling and conforms to the sustainable idea.

Owner:SOUTHWEST JIAOTONG UNIV

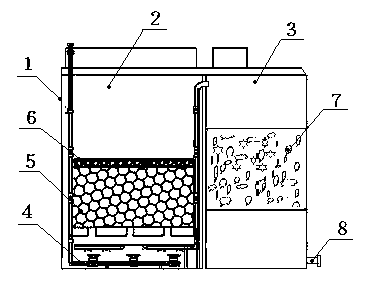

Active formaldehyde absorption and disposal integrated system and working method thereof

PendingCN109569252AEfficient degradationSimple structural designGas treatmentDispersed particle separationBioprocessorEngineering

The invention relates to an active formaldehyde absorption and disposal integrated system which comprises a gas-collecting hood. A gas inlet of the gas-collecting hood is communicated with the lower portion of a bio-processor through a spiral absorption tube component, absorption liquid for dissolving formaldehyde is placed in an inner cavity of the spiral absorption tube component, an inner cavity of the bio-processor is filled with biological stuffing, and a gas outlet is formed in the upper portion of the bio-processor. The invention further relates to a working method of the active formaldehyde absorption and disposal integrated system. The active formaldehyde absorption and disposal integrated system is simple and reasonable in structural design, can efficiently, conveniently and rapidly degrade the formaldehyde and has a wide application prospect.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

Film biological treatment device for reuse of reclaimed water

ActiveCN103708681APromote growthIncrease surface areaMultistage water/sewage treatmentBioprocessorWater quality

The invention discloses a film biological treatment device for reuse of reclaimed water, which comprises a device body, wherein the inside of the device body is provided with a film biological treater and a filtering chamber; the bottom of the film biological treater is provided with an aeration pipe network, and the upper part is provided with a film biological treatment chamber; the aeration pipe network is communicated with the film biological treatment chamber; the film biological treatment chamber is fully filled with suspended matters; a fibrous film is arranged above the film biological treatment chamber; the space above the fibrous film is communicated with the filtering chamber through a water pipe; a fibrous filtering body is arranged in the filtering chamber; a clear water cavity is arranged below the fibrous filtering body; a reuse water outlet pipe is arranged at one side of the clear water cavity; and the suspended matters are composed of porous shells and fillers. The film biological treatment device is simple in structure, provides a favorable growing carrier for microorganisms in the biological treatment chamber and has favorable filtering effect; and the arranged filtering chamber ensures that the effluent water has favorable water quality, the suspended substance content and turbidity of the effluent water approximate zero and the effluent water can be directly reused.

Owner:山东水发环境科技有限公司

Sample processing apparatus and method using vacuum chamber

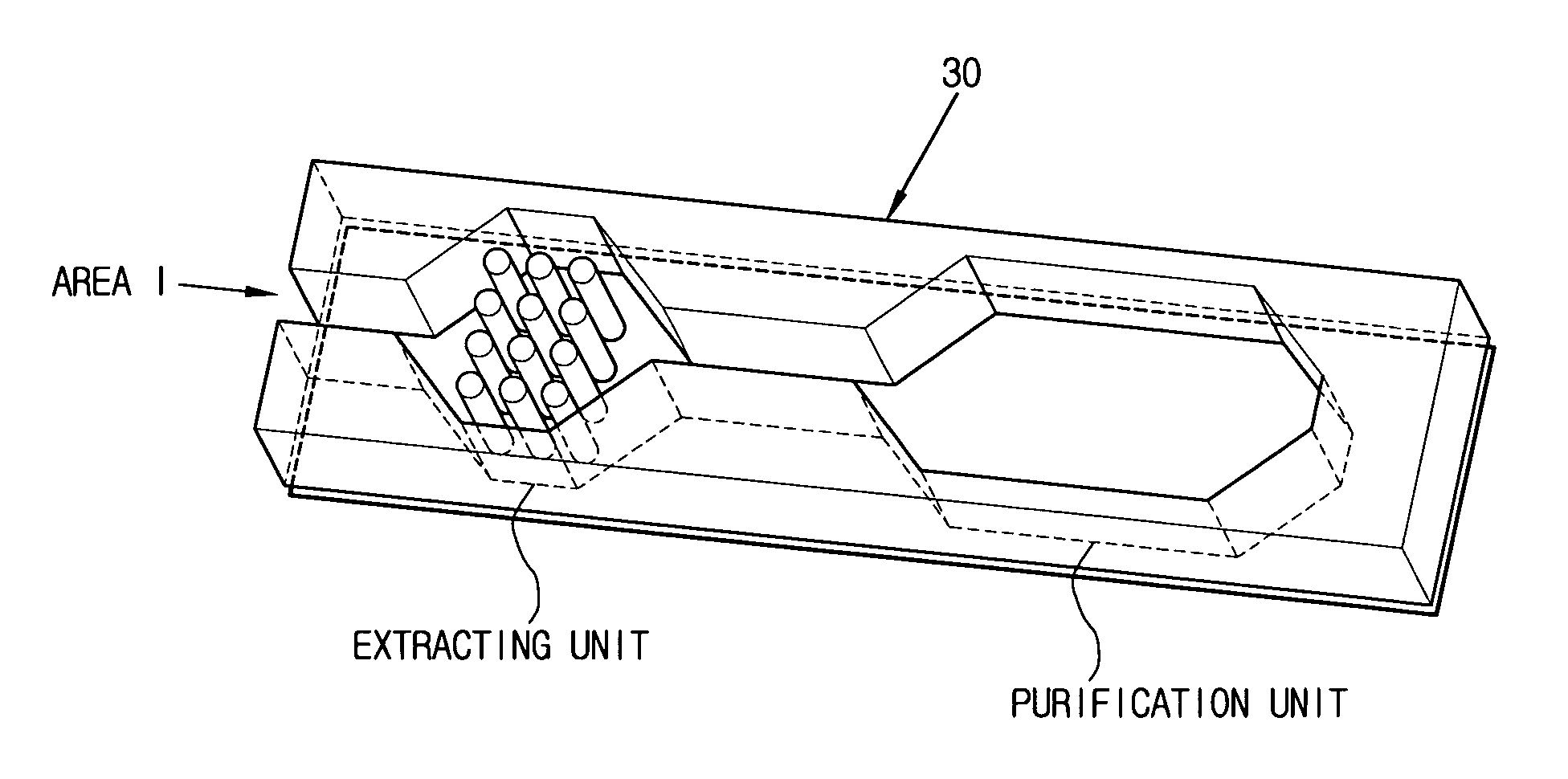

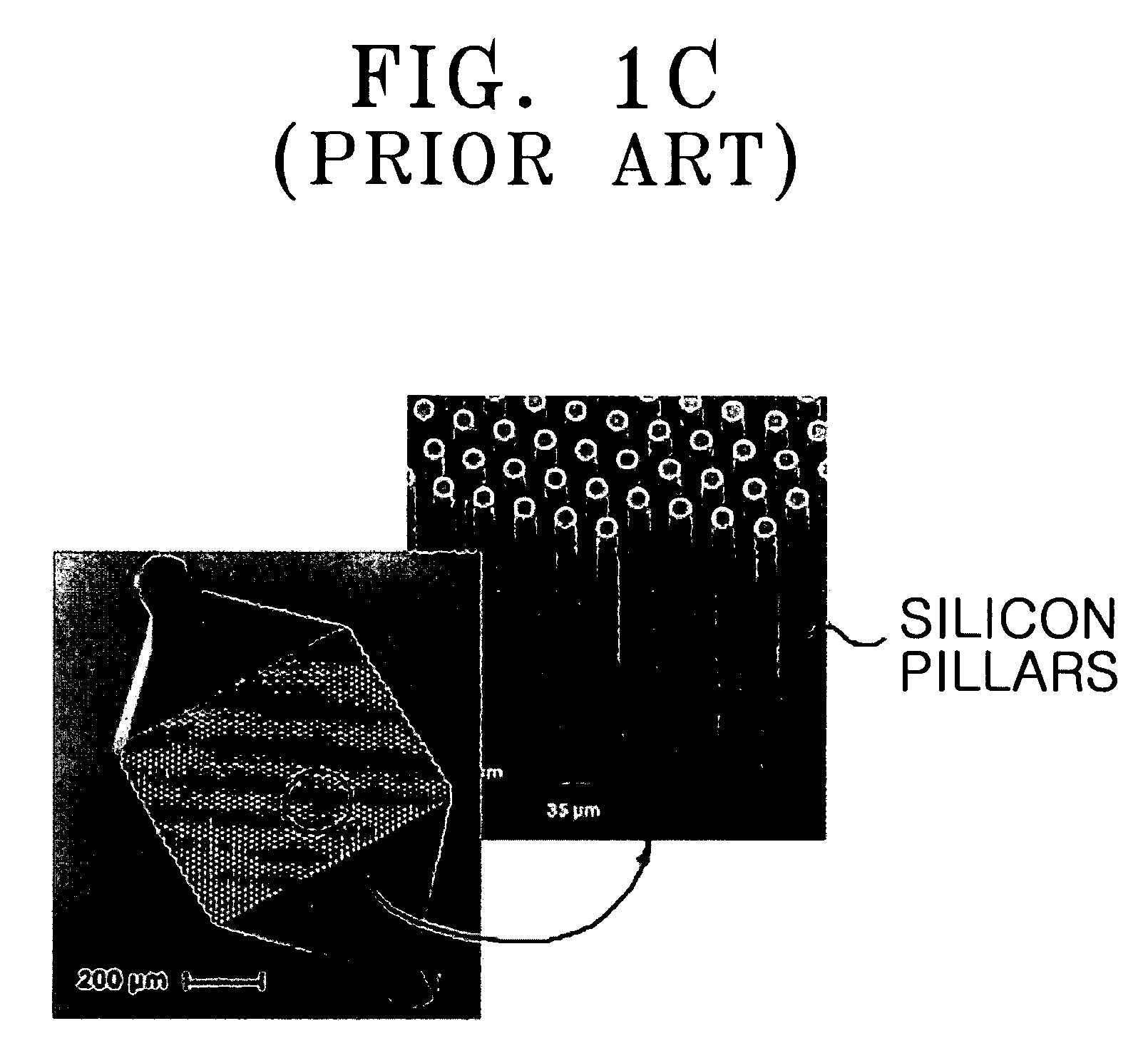

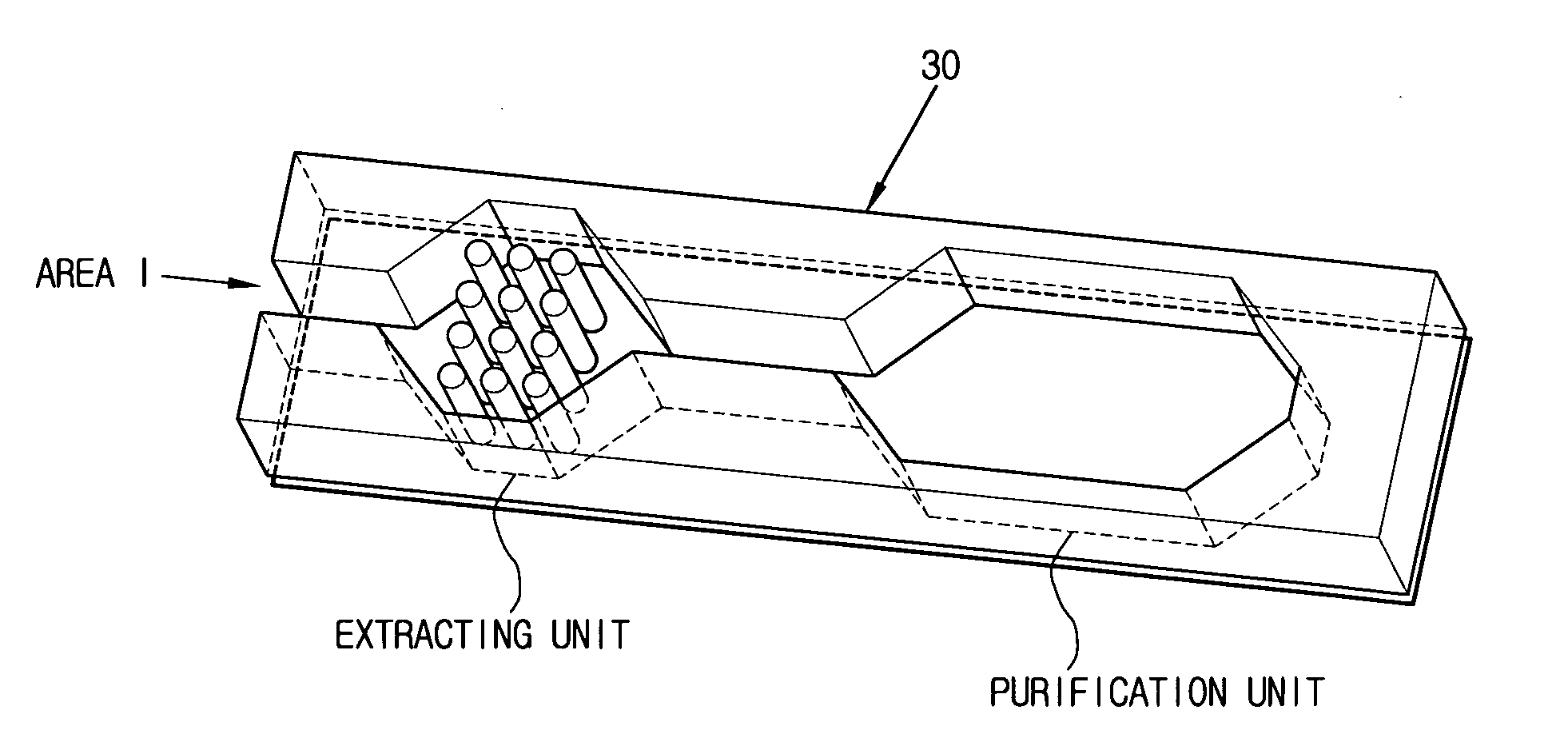

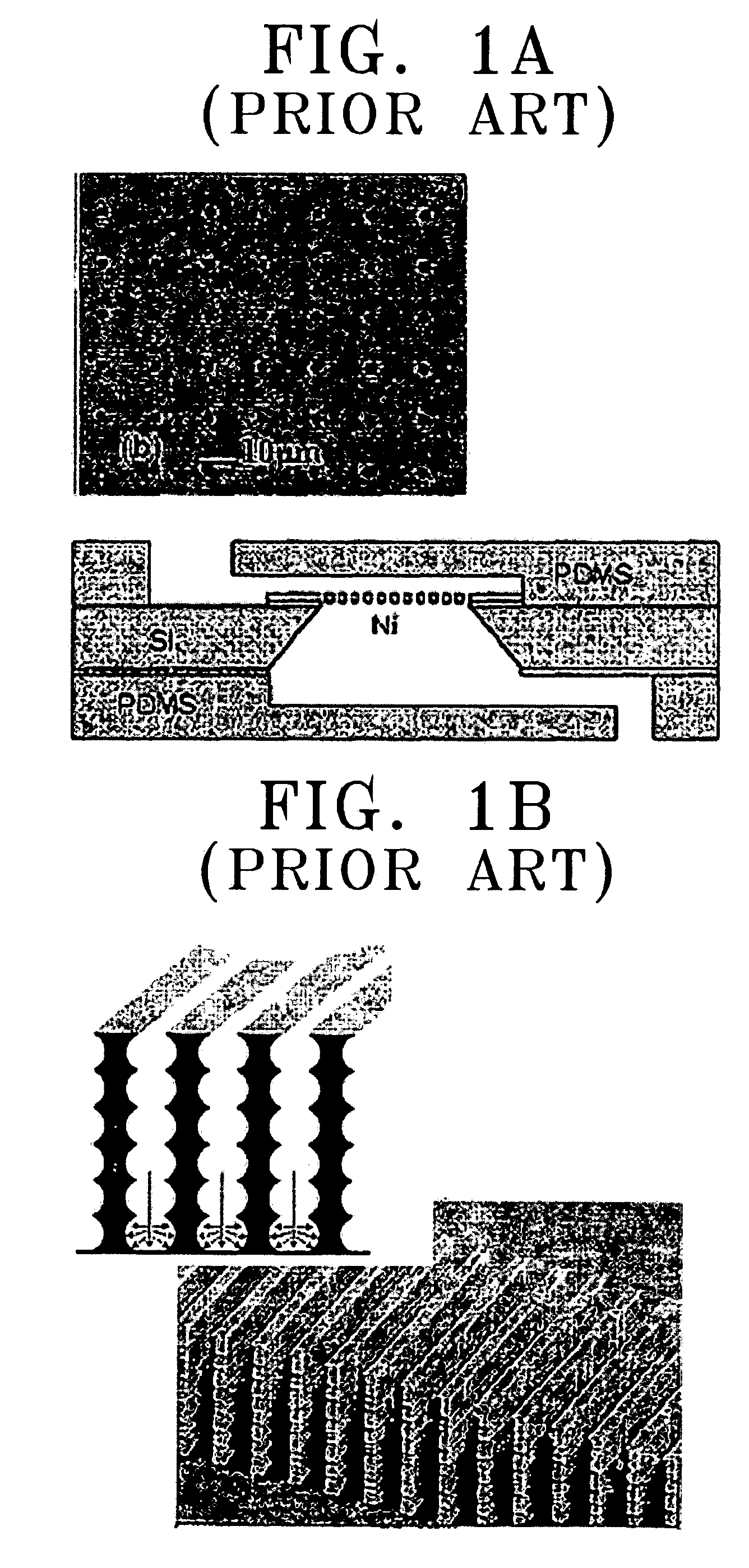

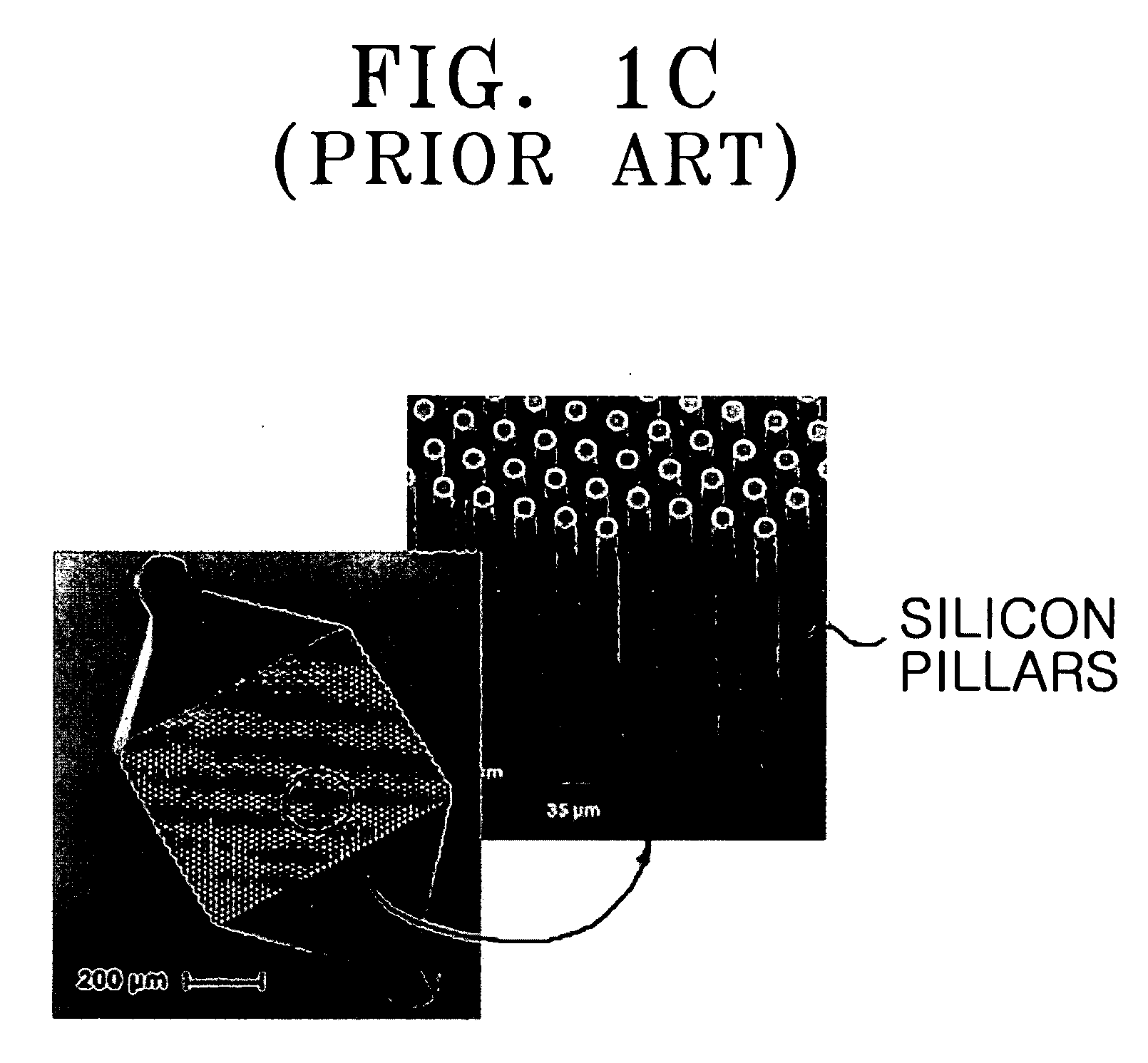

InactiveUS7795011B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBioprocessorEngineering

A bio sample processing apparatus and method using vacuum chambers in which a bio sample is injected into a first vacuum chamber connected with one end of a bio processor and, after processing, is ejected into a second vacuum chamber connected with the other end of the bio processor. The vacuum chambers and bio processor are connected with each other to form an environment with a pressure lower than atmospheric pressure, and the bio sample moves toward the second vacuum chamber due to the pressure difference created by the injection of the bio sample into the first vacuum chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Treatment method and device for oily waste water

ActiveCN105236682BReduced oxygen demandImprove processing efficiencyMultistage water/sewage treatmentFiltrationHigh pressure

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

Biosorption wastewatertreatment system

InactiveUS20180305232A1Avoid enteringImprove stabilityWater treatment parameter controlTreatment using aerobic processesWater dischargeOxygen

The invention relates to wastewater treatment systems, in particular to biosorbers for wastewater treatment, comprising a bioreactor with a fluidized bed of charge and a layer of filtering charge, a system for saturating the water with air oxygen, a sewage treatment pipeline, a purified water discharge line and a recirculated flow line with a circulating Pump. According to the invention, the biosorber includes a receiving and dispensing chamber connected via a metering pump to the chamber with a coal removal trap that is connected to the fluidized bed bioreactor through a circulation pump, the biosorber including an automated biosorber control module, the bioreactor being provided with a convex reflector Active coal, installed in the upper part of the bioreactor, designed to provide laminar upward movement of liquid along the walls of the bioreactor. The technical result achieved is to increase the degree of wastewater treatment while ensuring high reliability of operation.

Owner:PUKEMO MIKHAIL

A high-density cultivation process of prawns in indoor circulating water

InactiveCN103798164BNo wasteReduce pollutionClimate change adaptationPisciculture and aquariaBioprocessorHigh density

Owner:惠州市德明昌实业发展有限公司 +1

Household waste treatment device

ActiveCN102580986AFlexible handlingReduce pollutionSolid waste disposalOrganic synthesisWaste treatment

A household waste treatment device is composed by a box body, a grinding type crusher, a biological processor, a plastic cloth sorter, an oil-water separator and a dry material processor which are arranged in the box body, wherein the rolling type crusher is communicated with the plastic cloth sorter which is connected with the dry material processor, the dry material processor is communicated with the oil-water separator, a timing constant temperature heater, a precision temperature controller, a biological treatment time controller, a waste water controller and a finished product inclined excluder are mounted on a stirrer inside the biological processor respectively, and the precision temperature controller is connected with a single chip microcomputer through a three-way temperature sensor. According to the device, the household waste and biological organic synthesis are converted into biological products without increasing of auxiliary water consumption, so that the wasted usage and regeneration are achieved, environmental pollution is reduced, and the whole treatment process is automatic controlled.

Owner:辽宁六度环保科技有限公司

Solid-liquid separation ecological toilet

InactiveCN109008754AExtend the life cycleFresh airBathroom accessoriesAgainst vector-borne diseasesBioprocessorDistillation

The invention discloses a solid-liquid separation ecological toilet comprising an outer casing, a cover plate is arranged at a top part of the outer casing, a water tank is arranged under the cover plate, a venting window is arranged on one side of a part, positioned below the water tank, of the outer casing; a urinal is fixed on a bottom plate, a solid-liquid separation device connected to the urinal is arranged below the bottom plate, and a plurality of weights are placed on a bottom part of the outer casing. The ecological toilet is characterized in that the solid-liquid separation device comprises a solid-liquid mixing tank, a vacuum pump, a water tank, a solid body box, a distillation still and a biological processor. The ecological toilet disclosed in the invention is simple in structure, small in occupied space, high in economical performance and great in convenience; via the solid-liquid separation device, human excreta can be degraded and compressed to a maximum degree, an aimof lengthening a service cycle of a mobile toilet can be attained, harmless disposal can be realized when gas is subjected to microbial chemical processing, no waste residue is discharged, the venting window is added, air freshness in the toilet can be increased, sewage can be purified after liquid goes through a physical distillation apparatus, and repeated use can be realized.

Owner:CLEAR SUZHOU ENVIRONMENTAL TECH CO LTD

Sample processing apparatus and method using vacuum chamber

InactiveUS20060018801A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBioprocessorEngineering

A bio sample processing apparatus and method using vacuum chambers in which a bio sample is injected into a first vacuum chamber connected with one end of a bio processor and, after processing, is ejected into a second vacuum chamber connected with the other end of the bio processor. The vacuum chambers and bio processor are connected with each other to form an environment with a pressure lower than atmospheric pressure, and the bio sample moves toward the second vacuum chamber due to the pressure difference created by the injection of the bio sample into the first vacuum chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com