Patents

Literature

52 results about "Waste site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

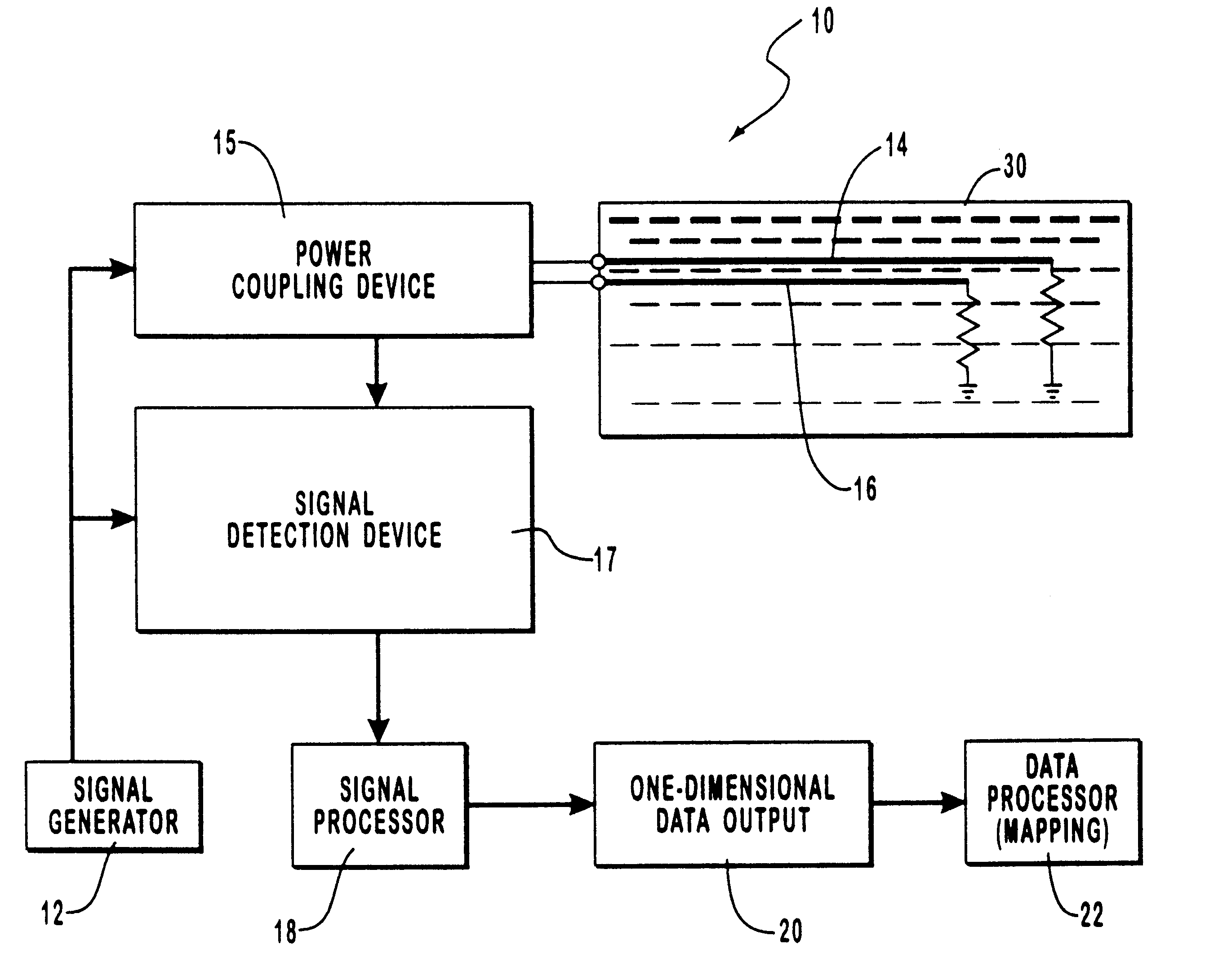

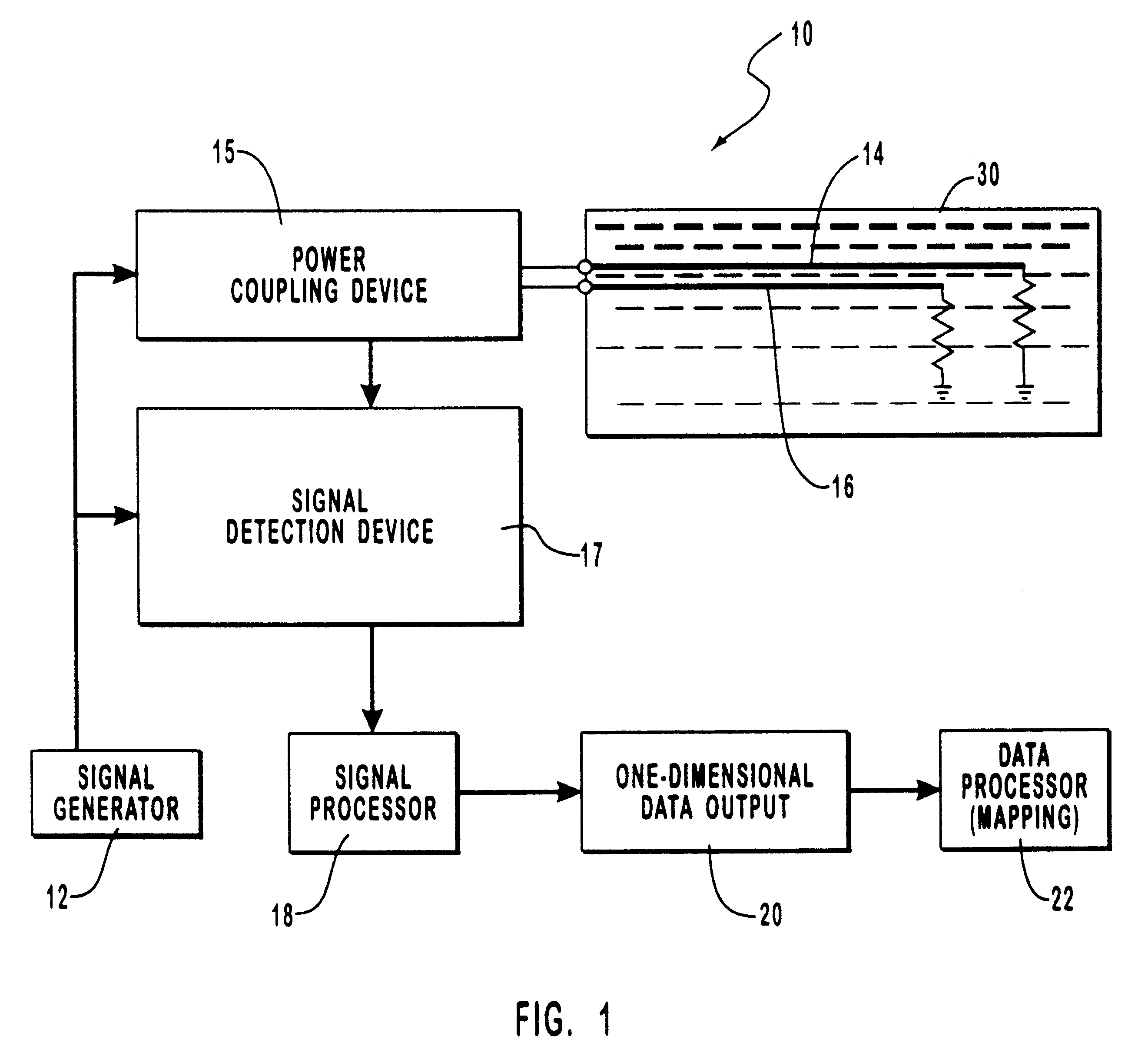

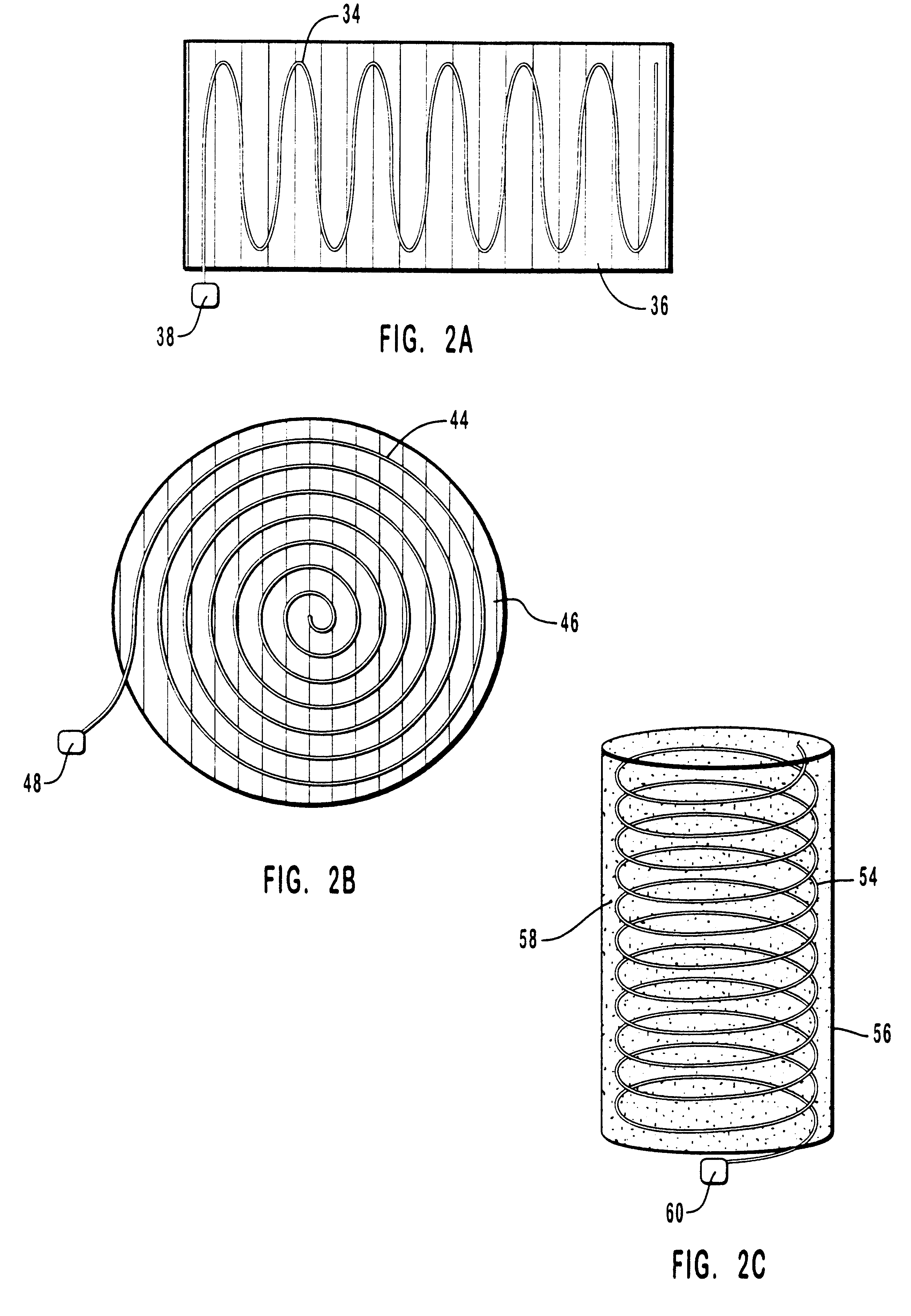

System and method for monitoring water content or other dielectric influences in a medium

Owner:BATTELLE ENERGY ALLIANCE LLC +1

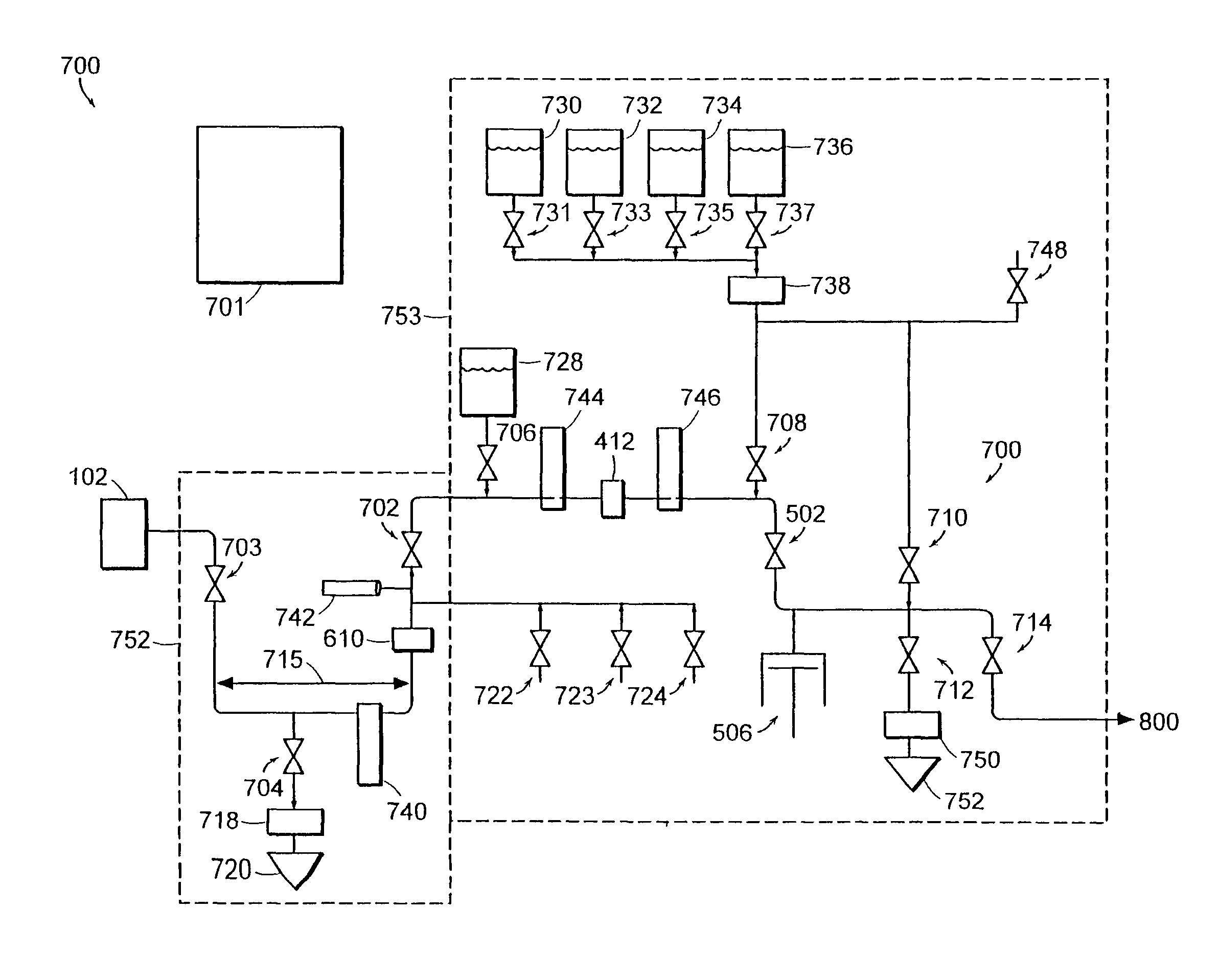

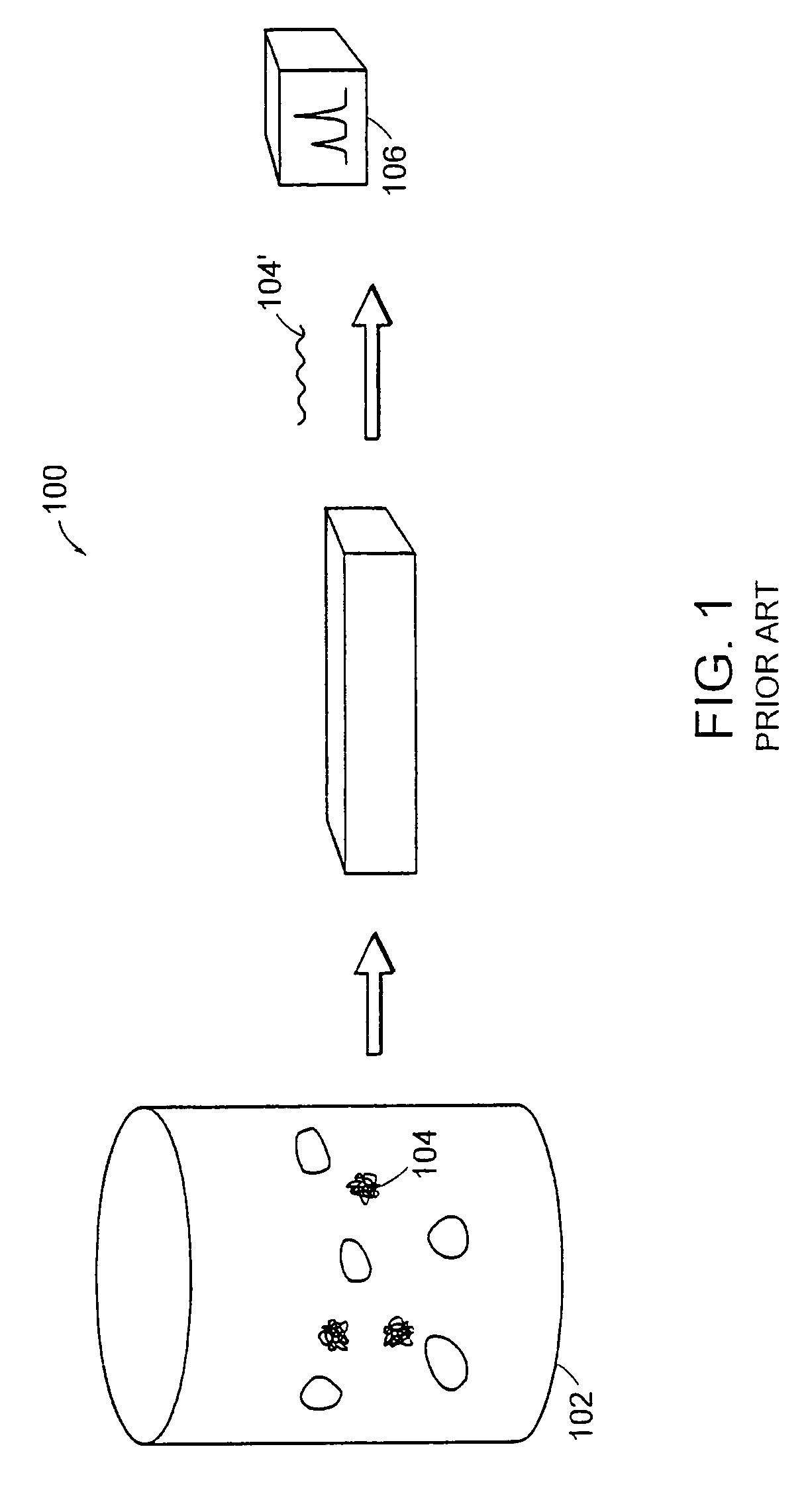

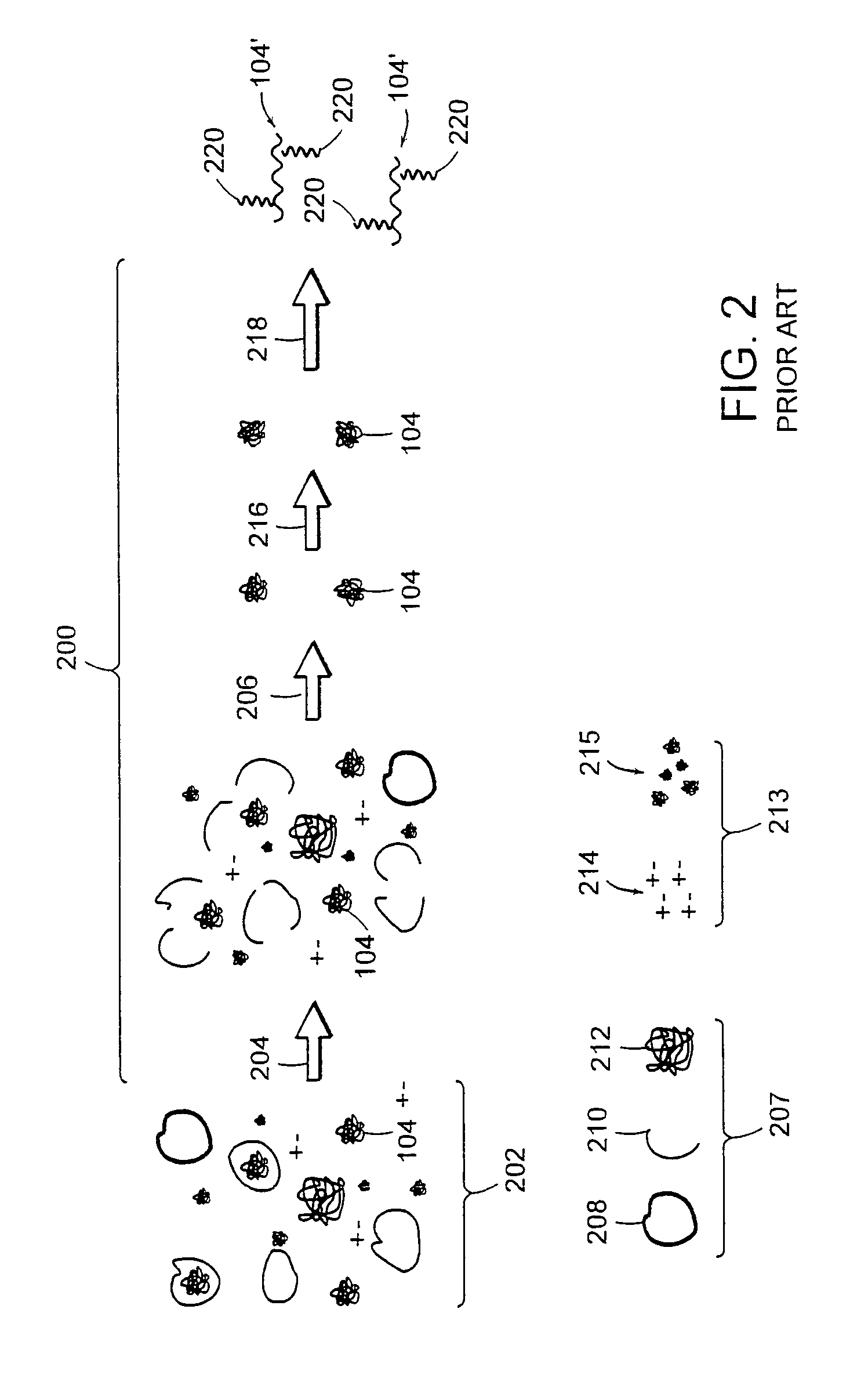

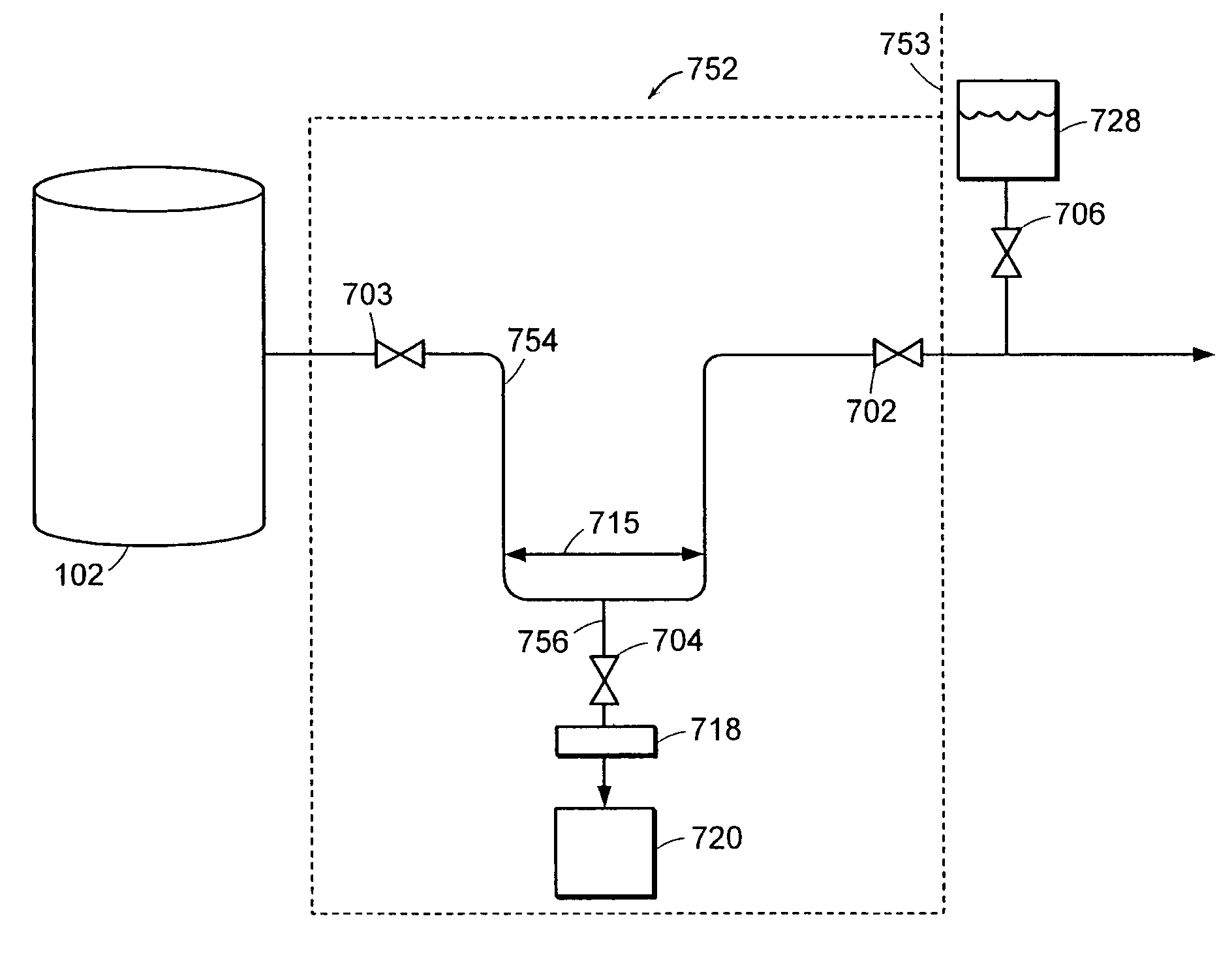

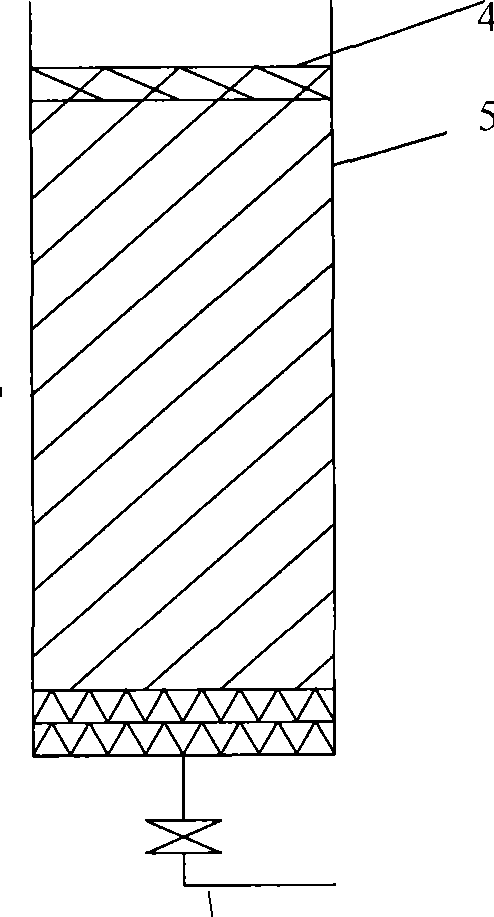

Fluid interface for bioprocessor systems

InactiveUS20070072285A1Low costFacilitates rapid, frequent, automated samplingBioreactor/fermenter combinationsBiological substance pretreatmentsBioprocessorAutomatic control

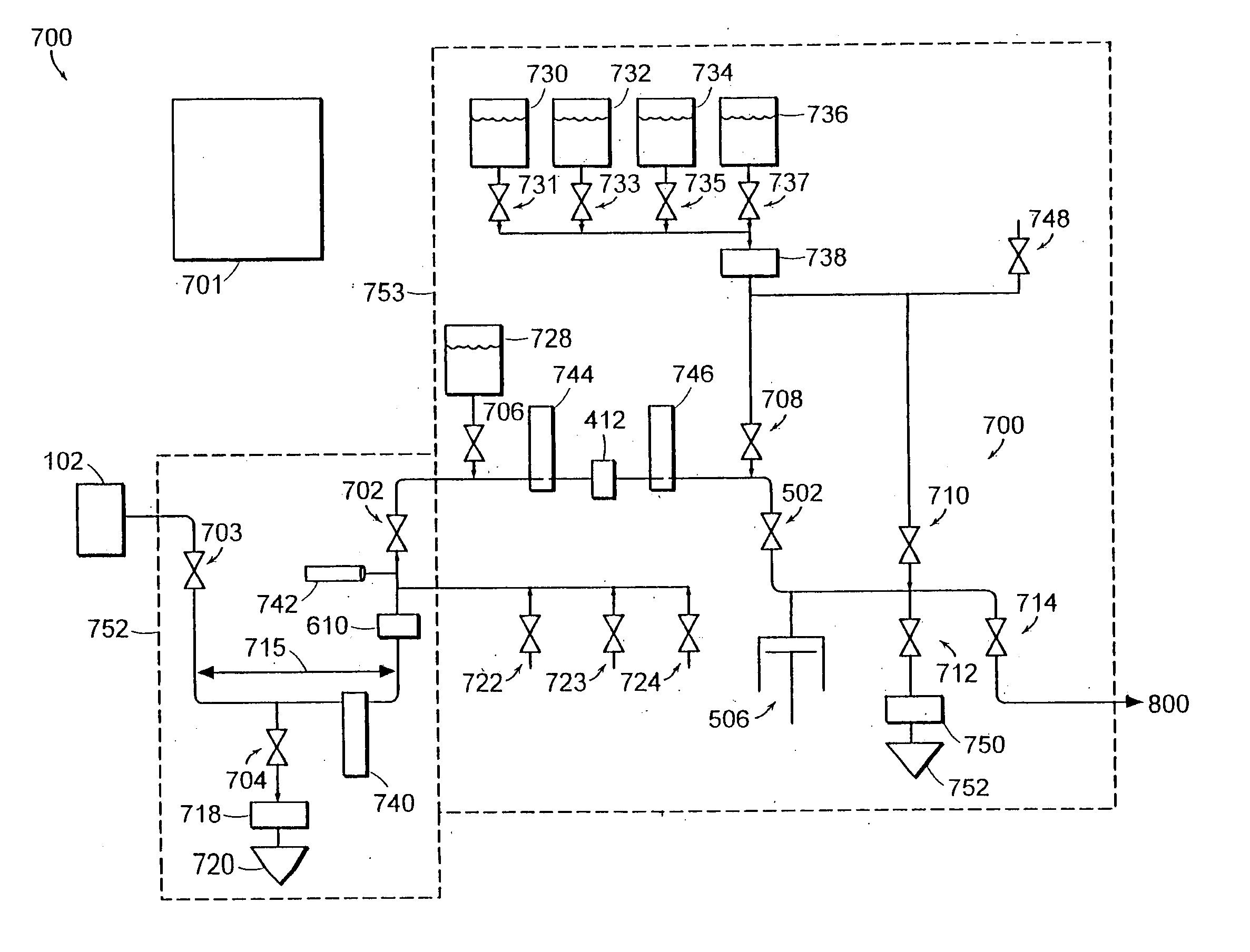

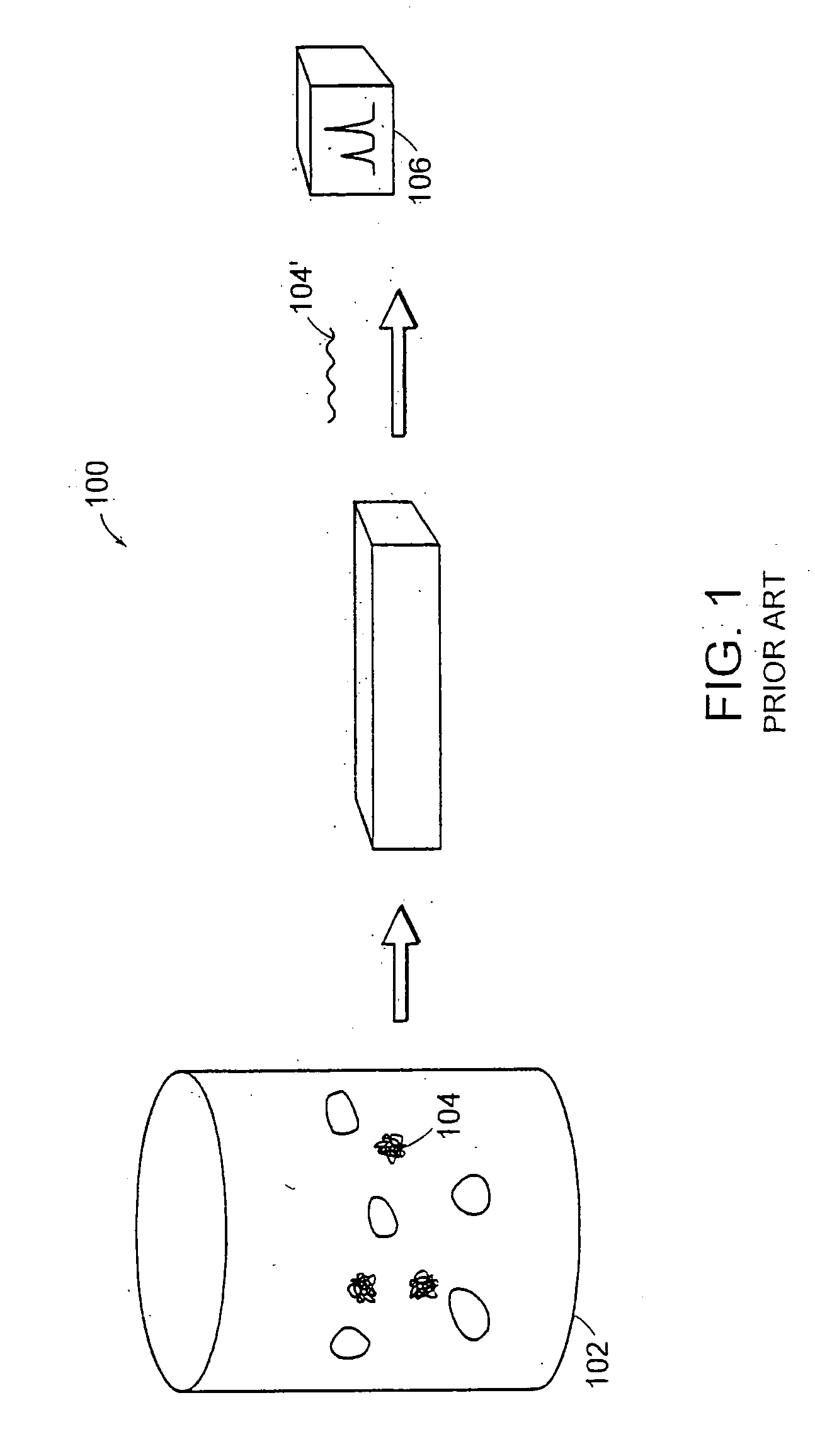

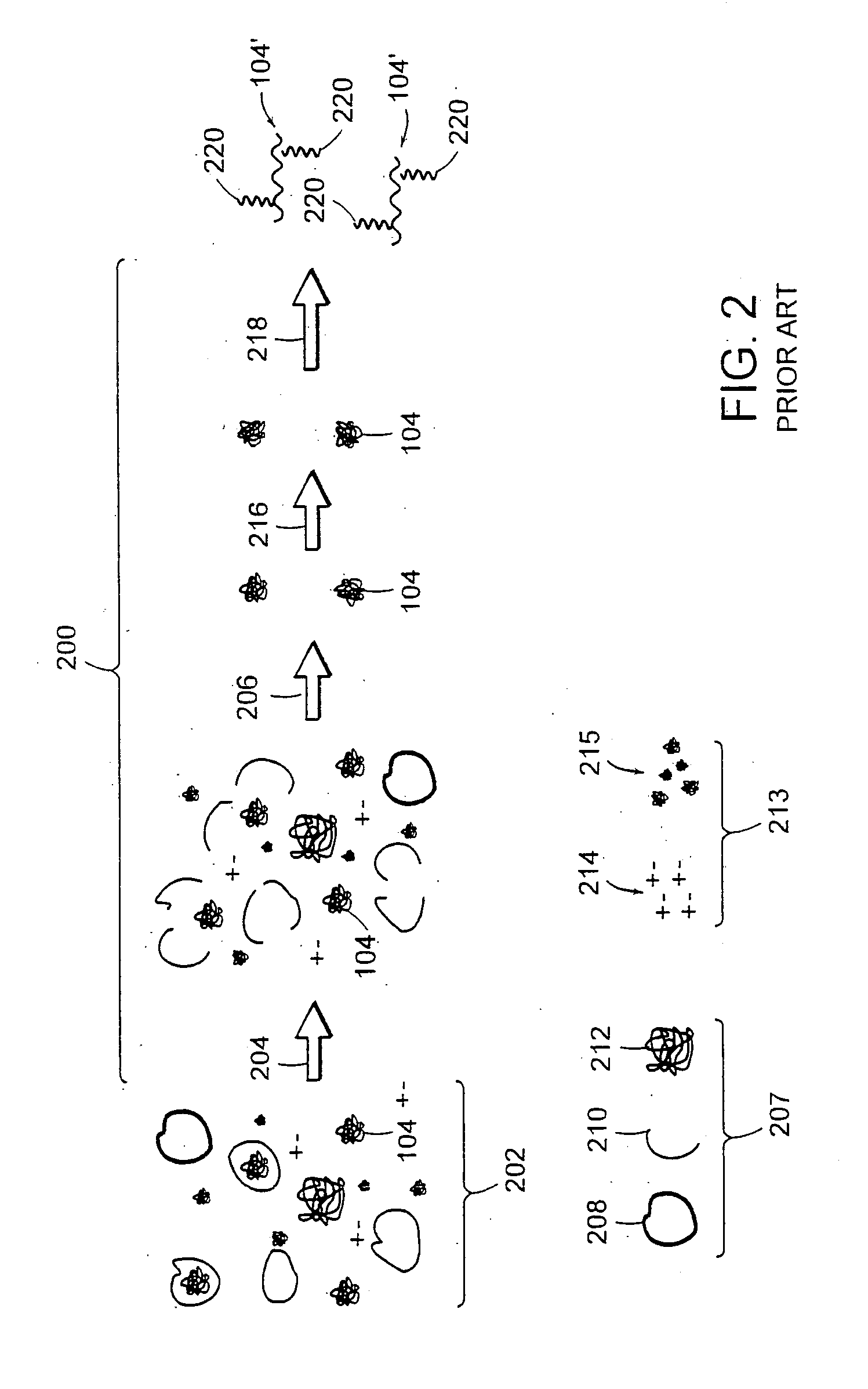

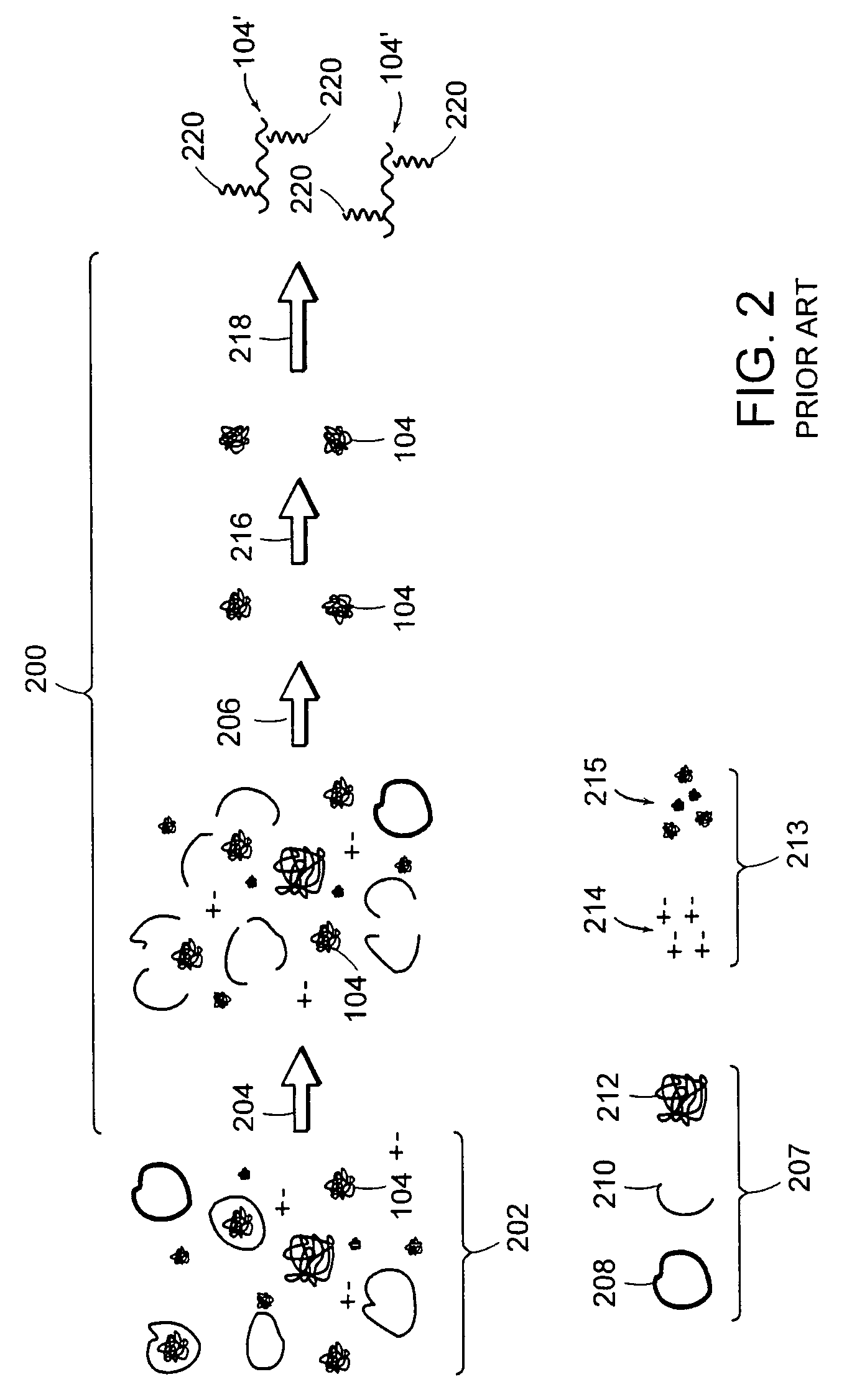

An apparatus and method for an aseptic fluidic interface between bioprocess systems is provided. The apparatus includes an inlet valve, adapted for automatic control, that is coupled to a biofluid source site. A sampling conduit extends from the inlet valve to an outlet valve. The outlet valve is adapted for automatic control and is coupled to a biofluid process site. A trap is at the sampling conduit. A waste valve, adapted for automatic control, is located at a waste conduit extending from the sampling conduit to a waste site. Also included is a wash fluid source that is coupled to at least one of the inlet or outlet valves. In the method, the sample is automatically directed to the biofluid process site by opening the outlet valve, and closing the waste valve Also included is isolating the biofluid sites by closing the inlet and outlet valves, and opening the waste valve to drain biofluid from the trap to the waste site. Another step is cleaning the sampling conduit before sample collection by directing the wash fluid through at least one valve selected from the inlet and outlet valves, and subsequently through the waste valve to the waste site.

Owner:GROTON BIOSYST

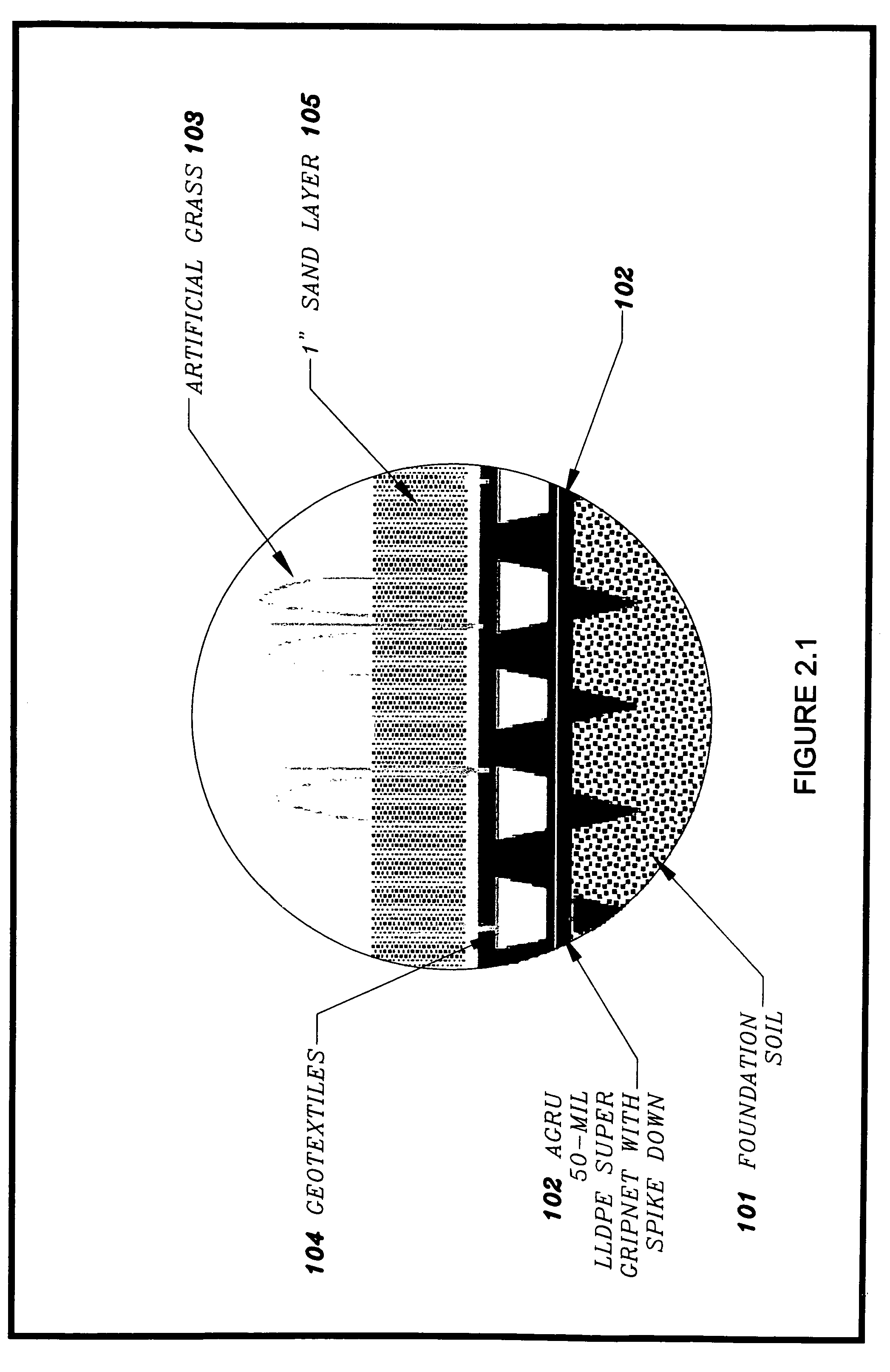

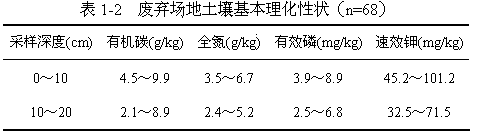

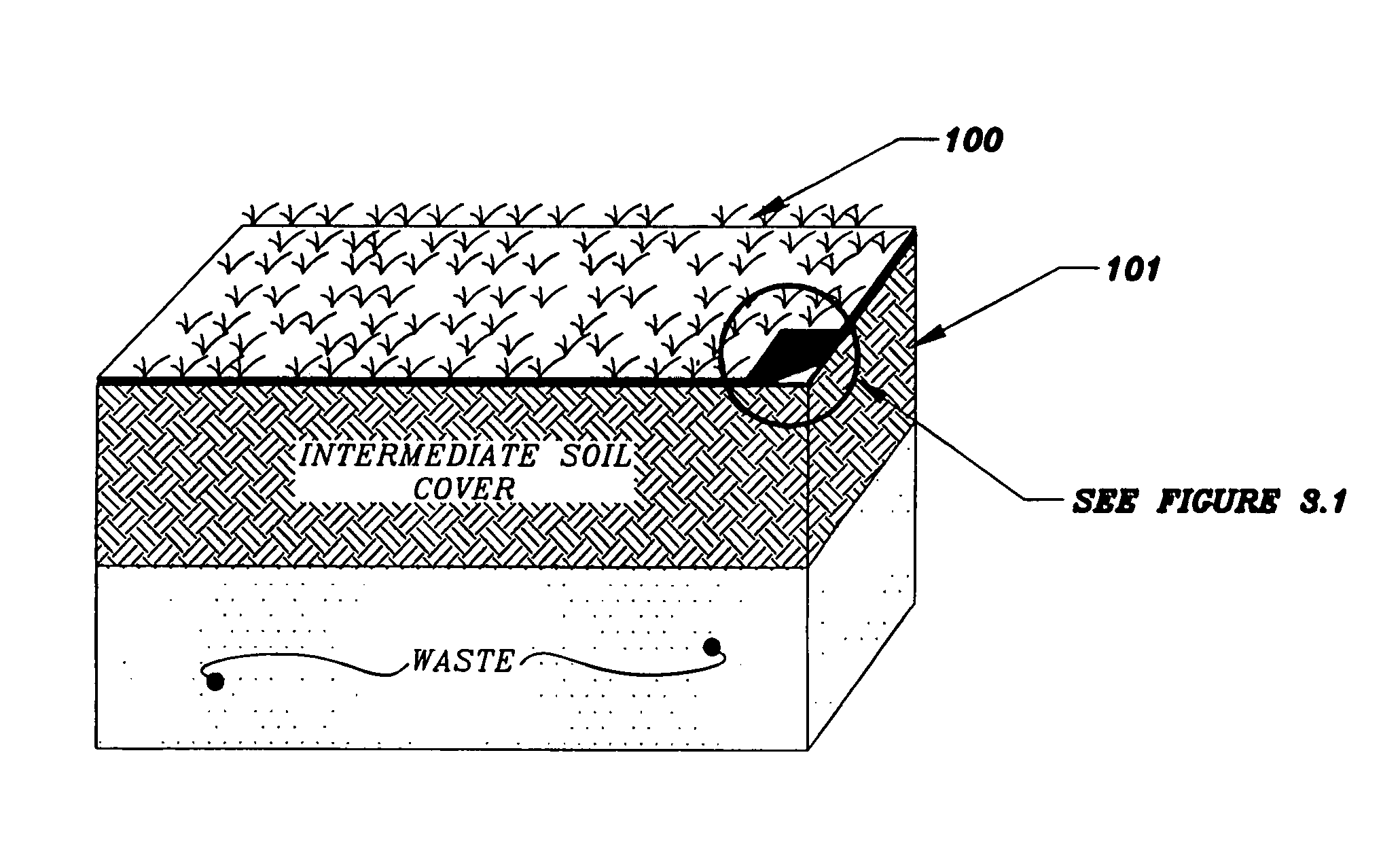

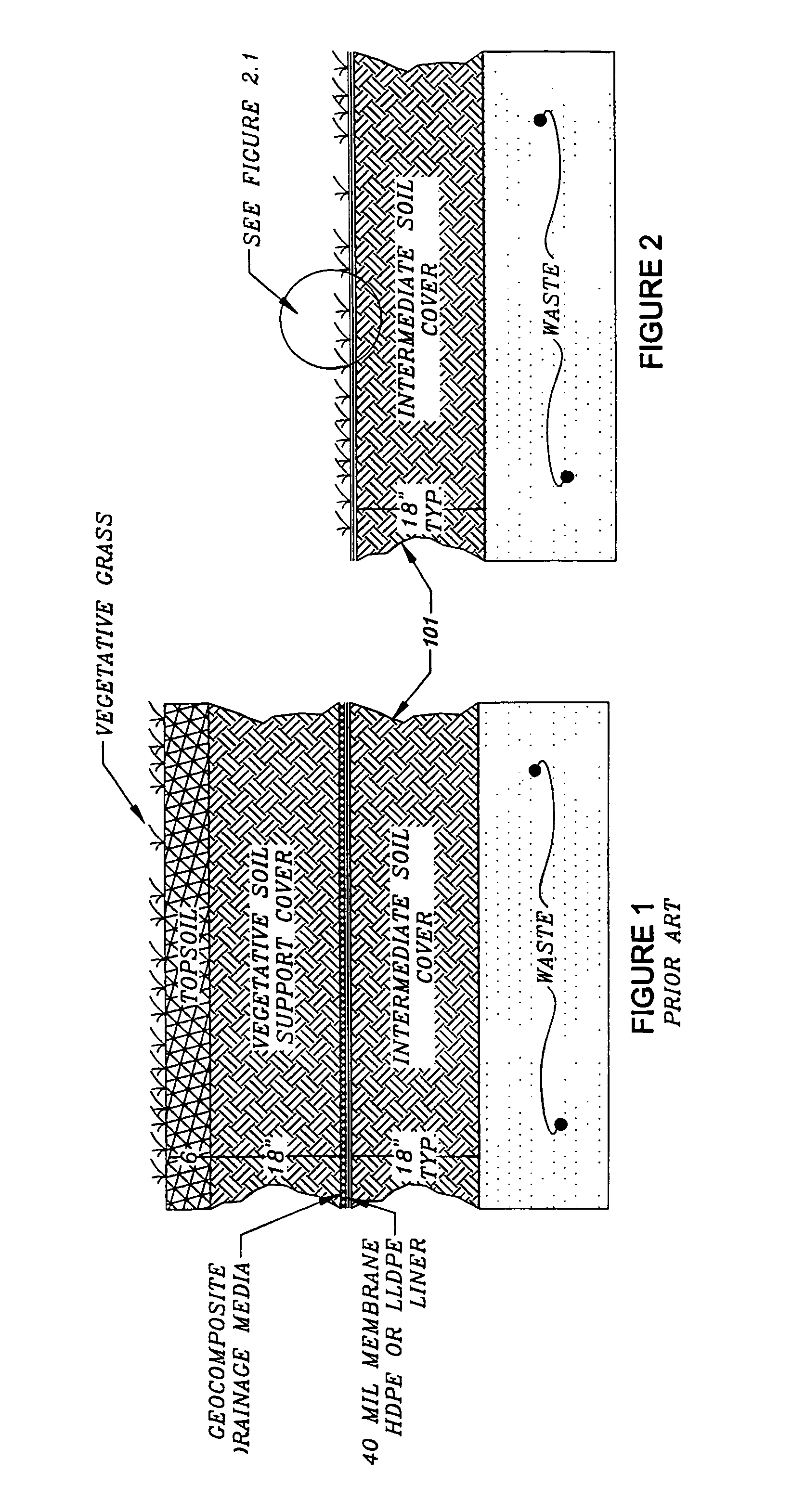

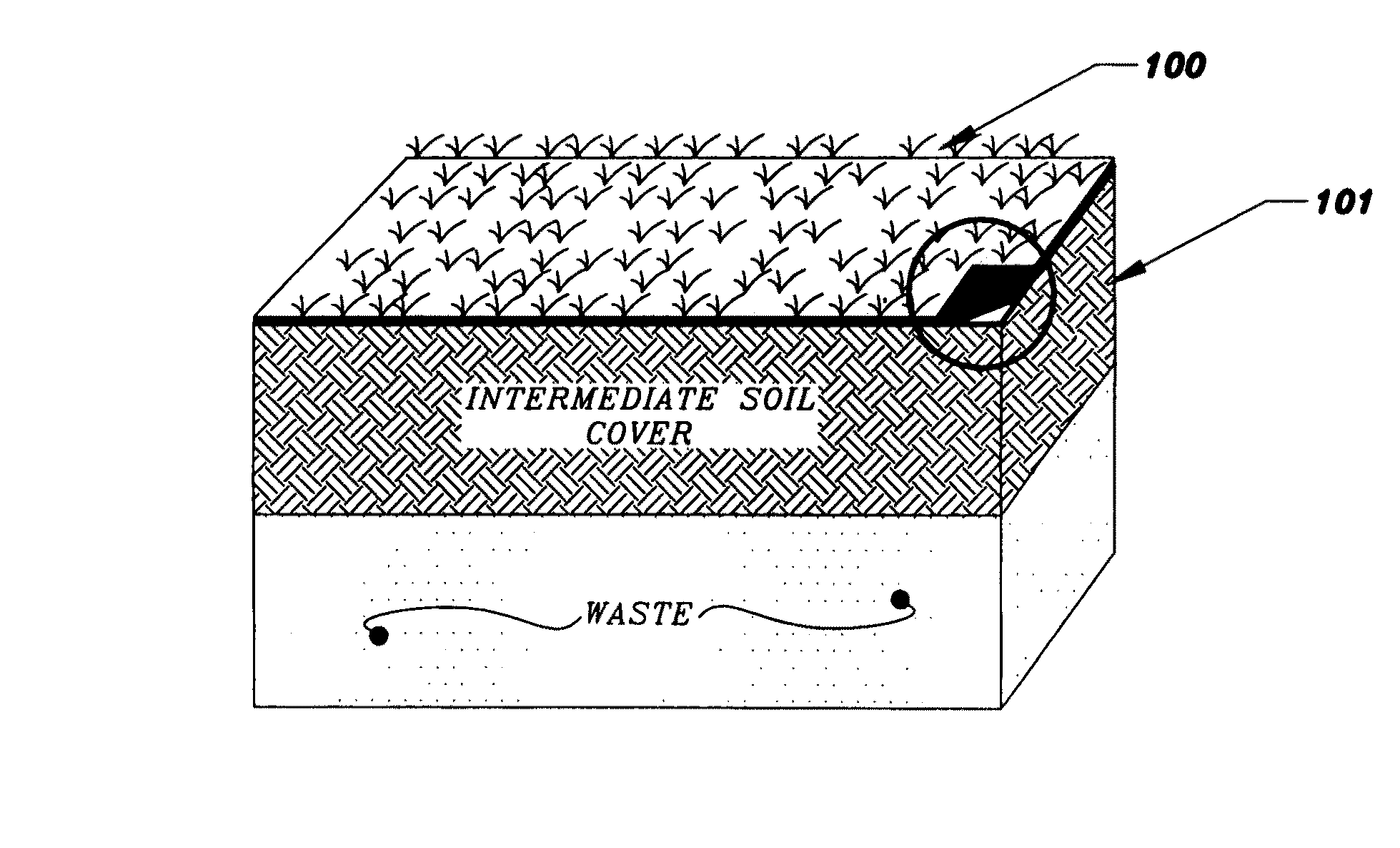

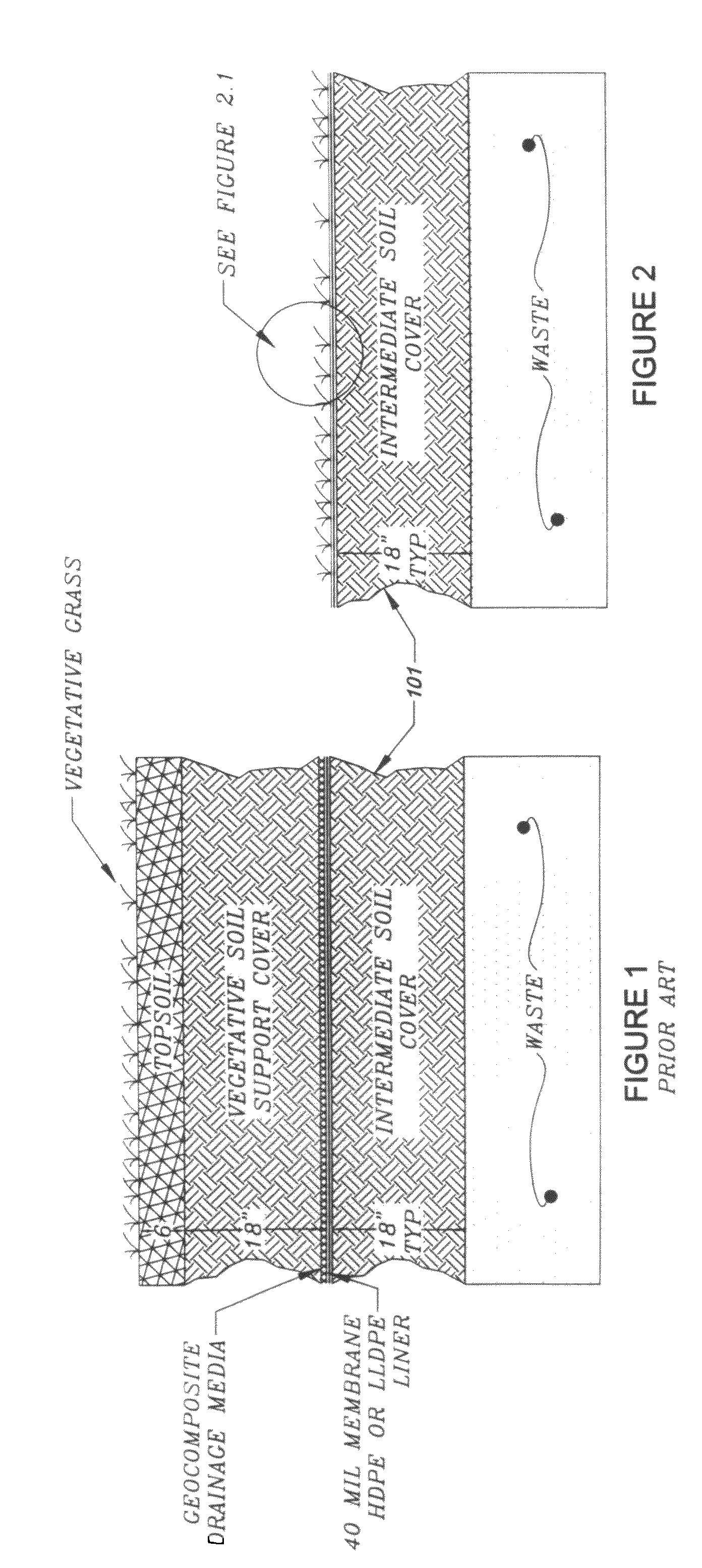

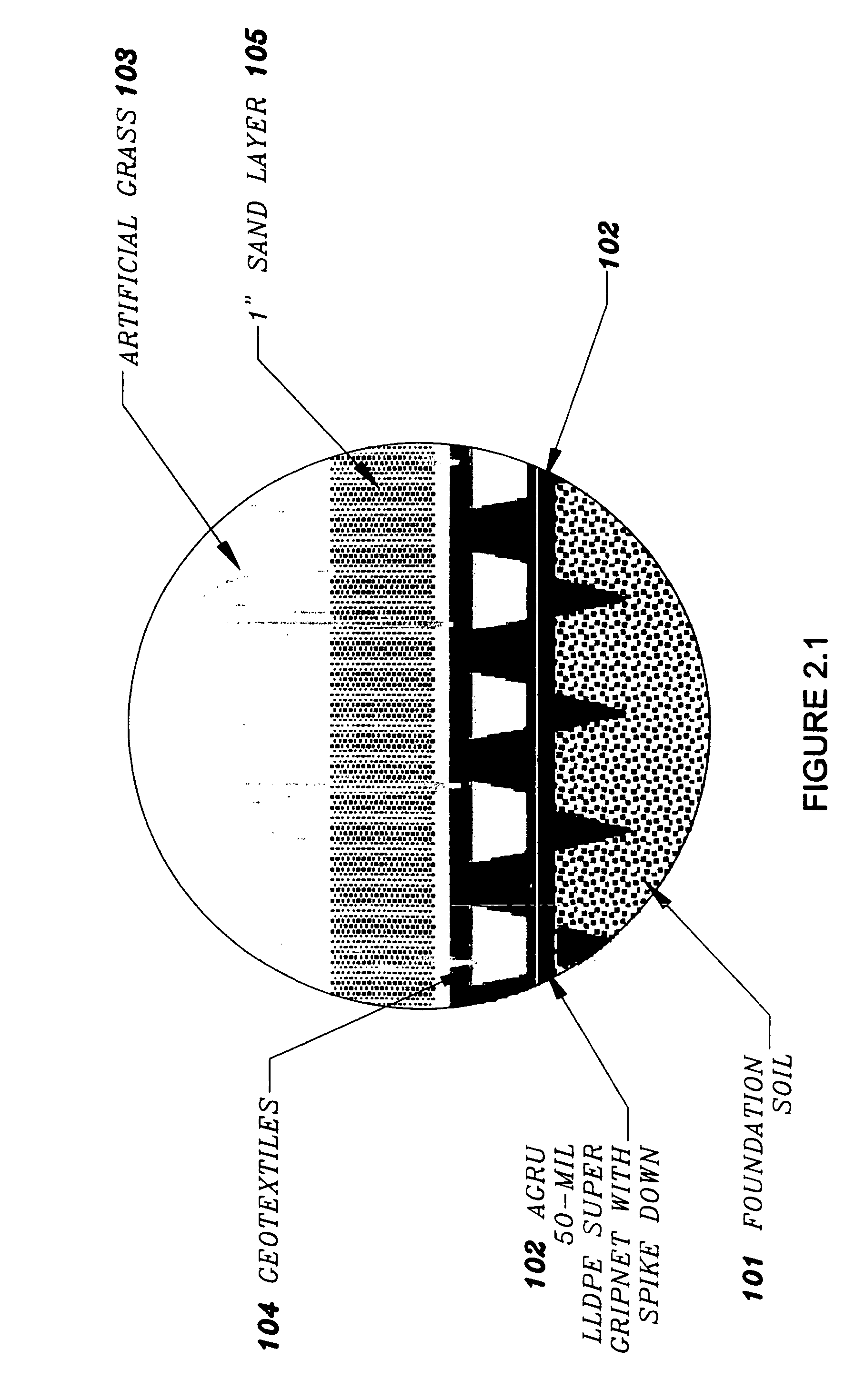

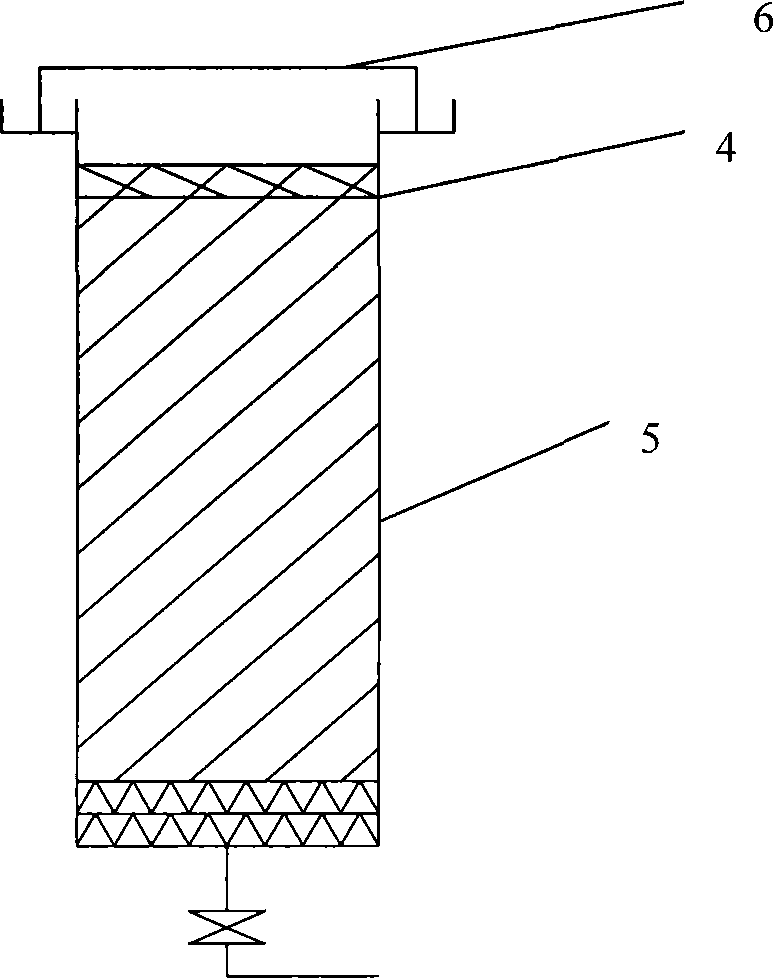

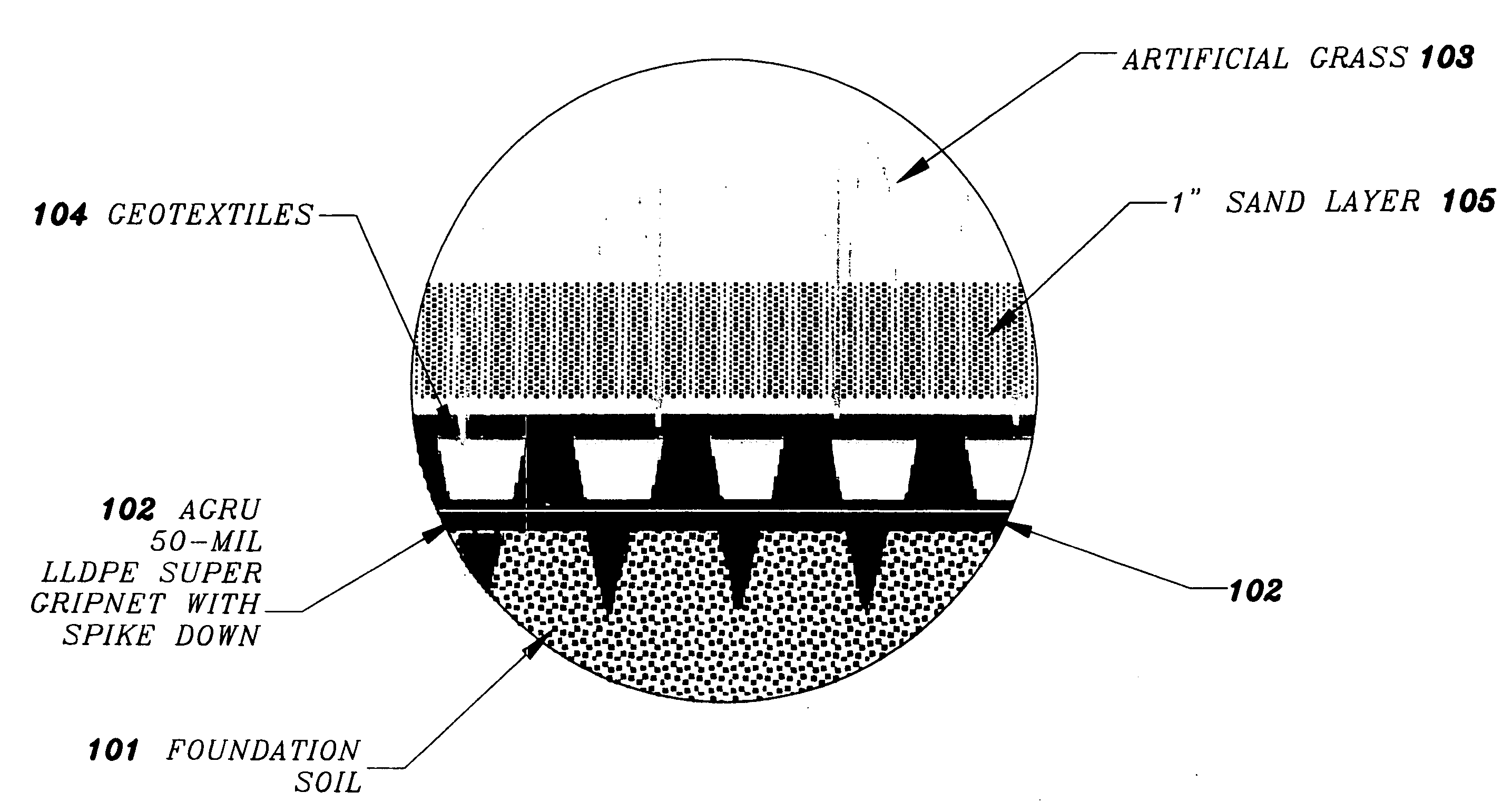

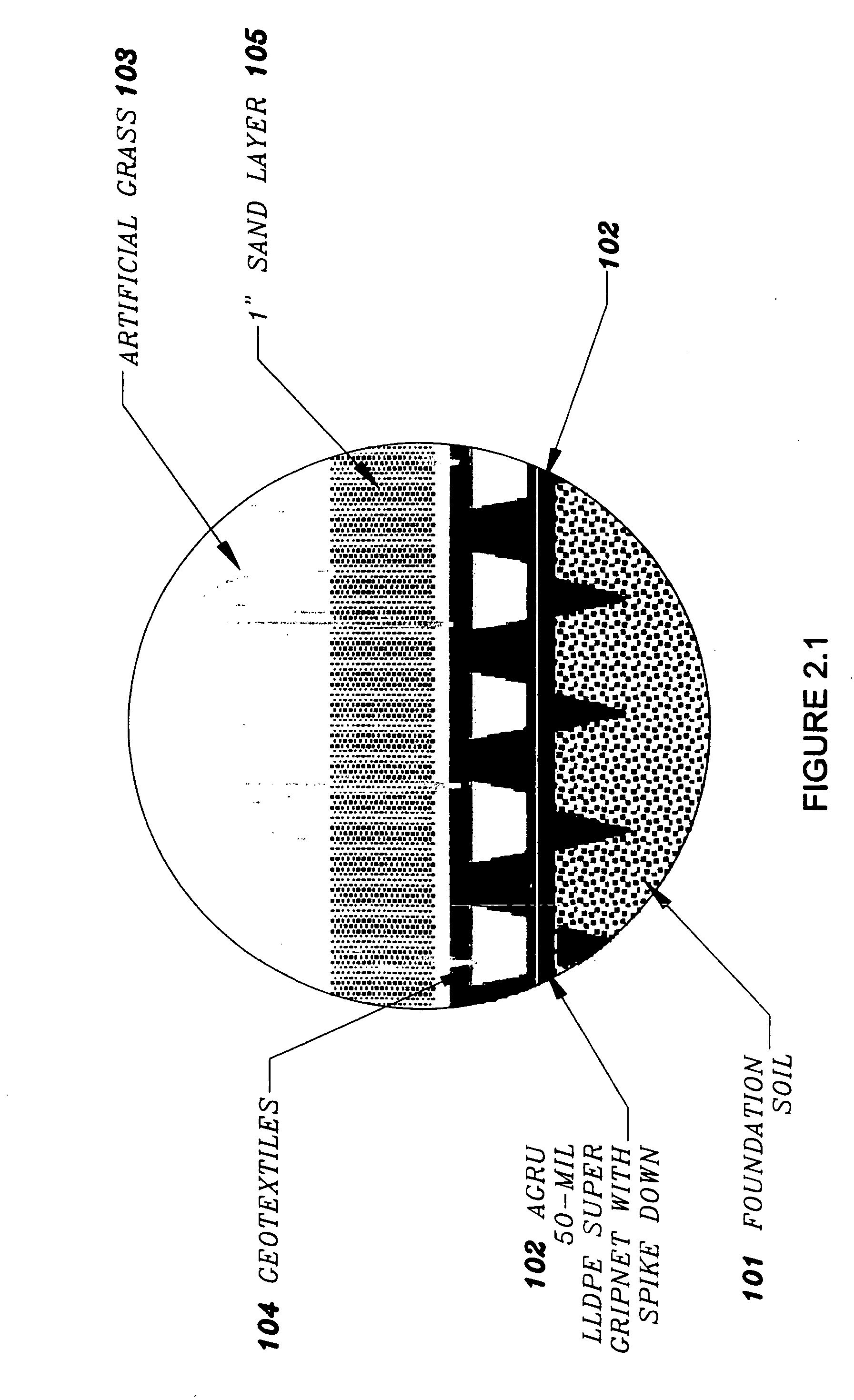

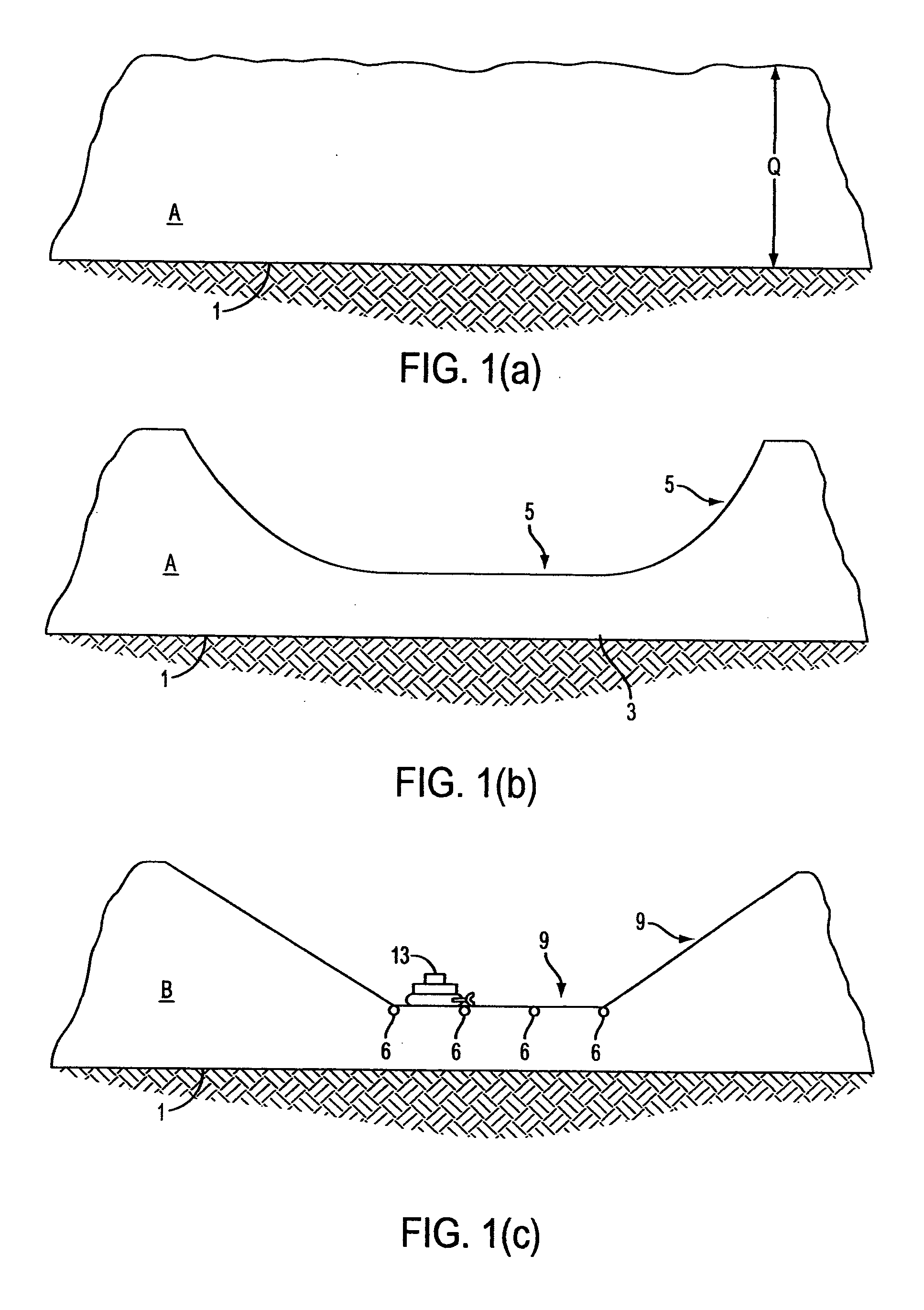

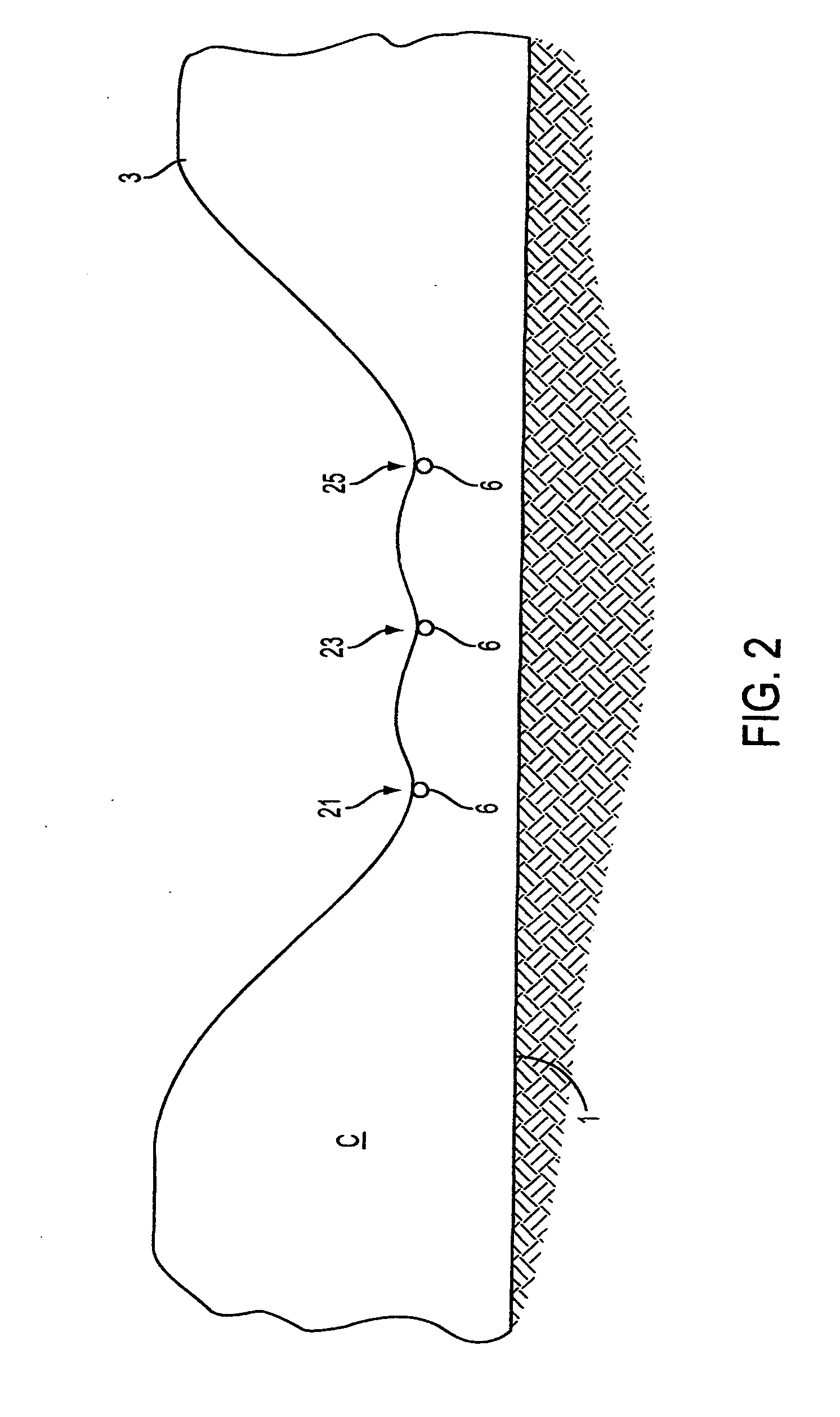

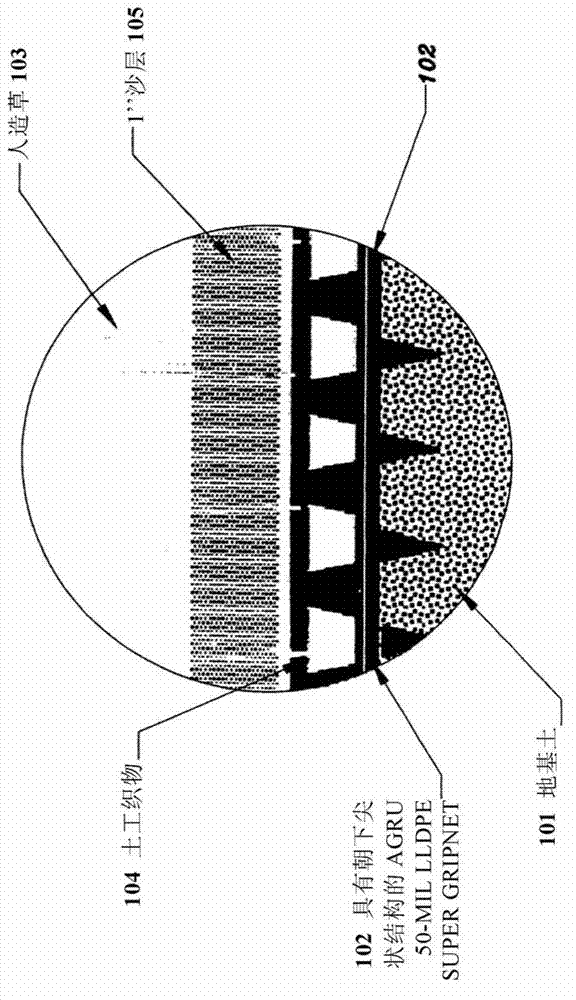

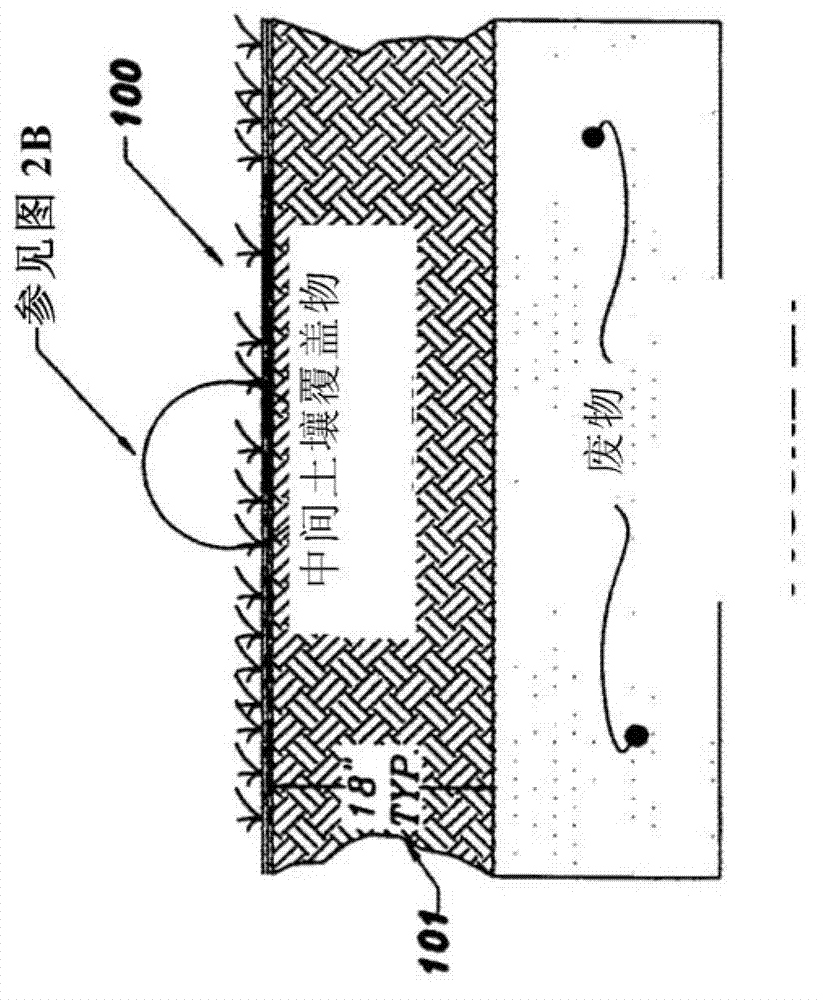

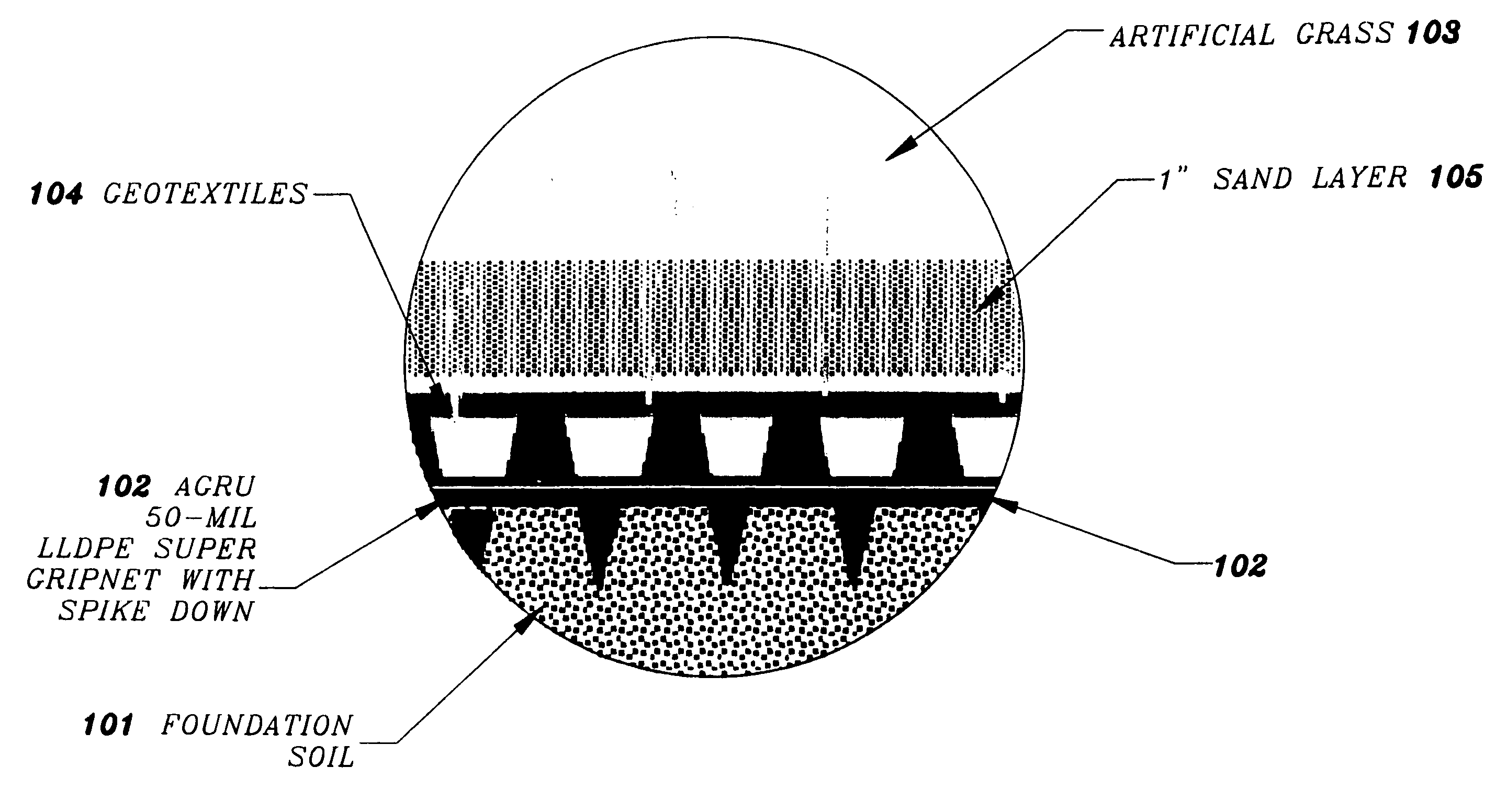

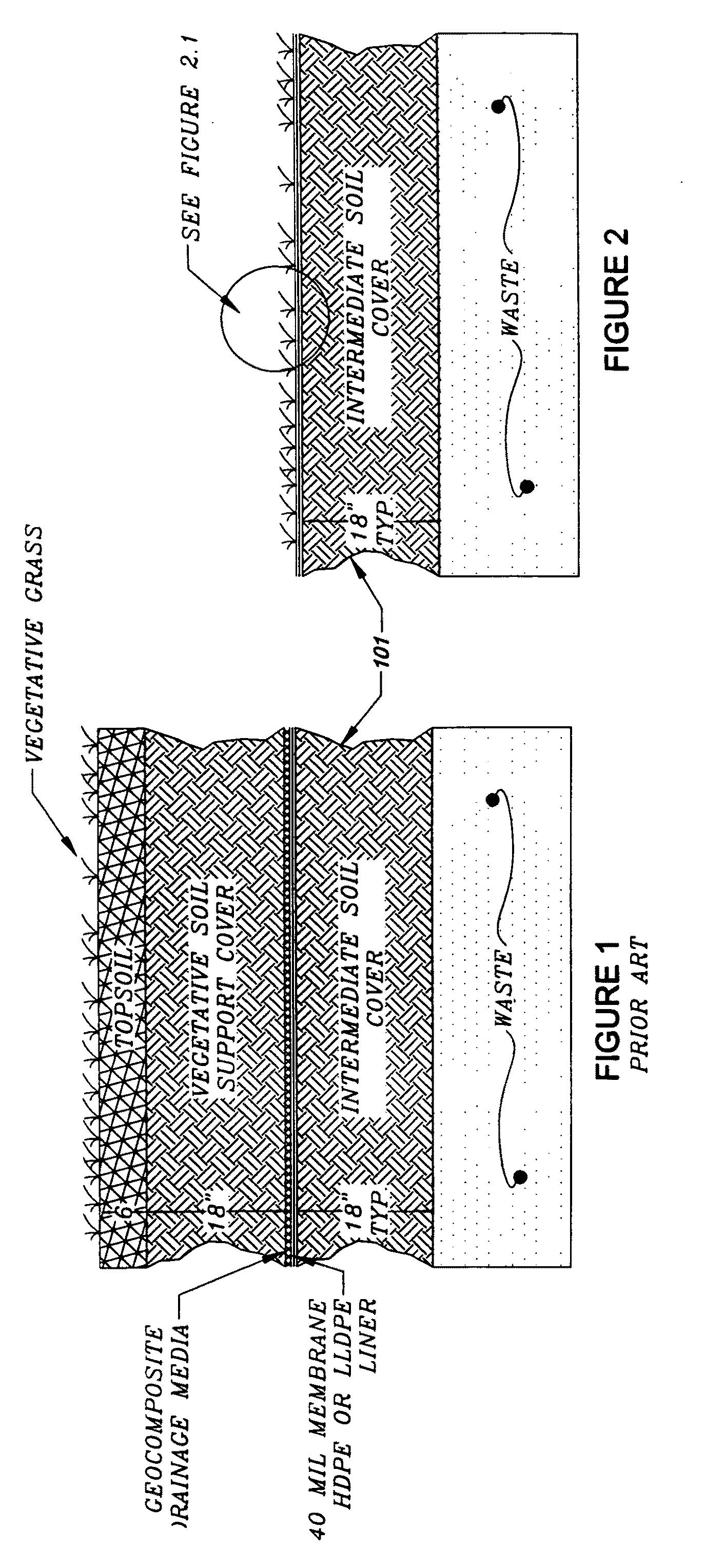

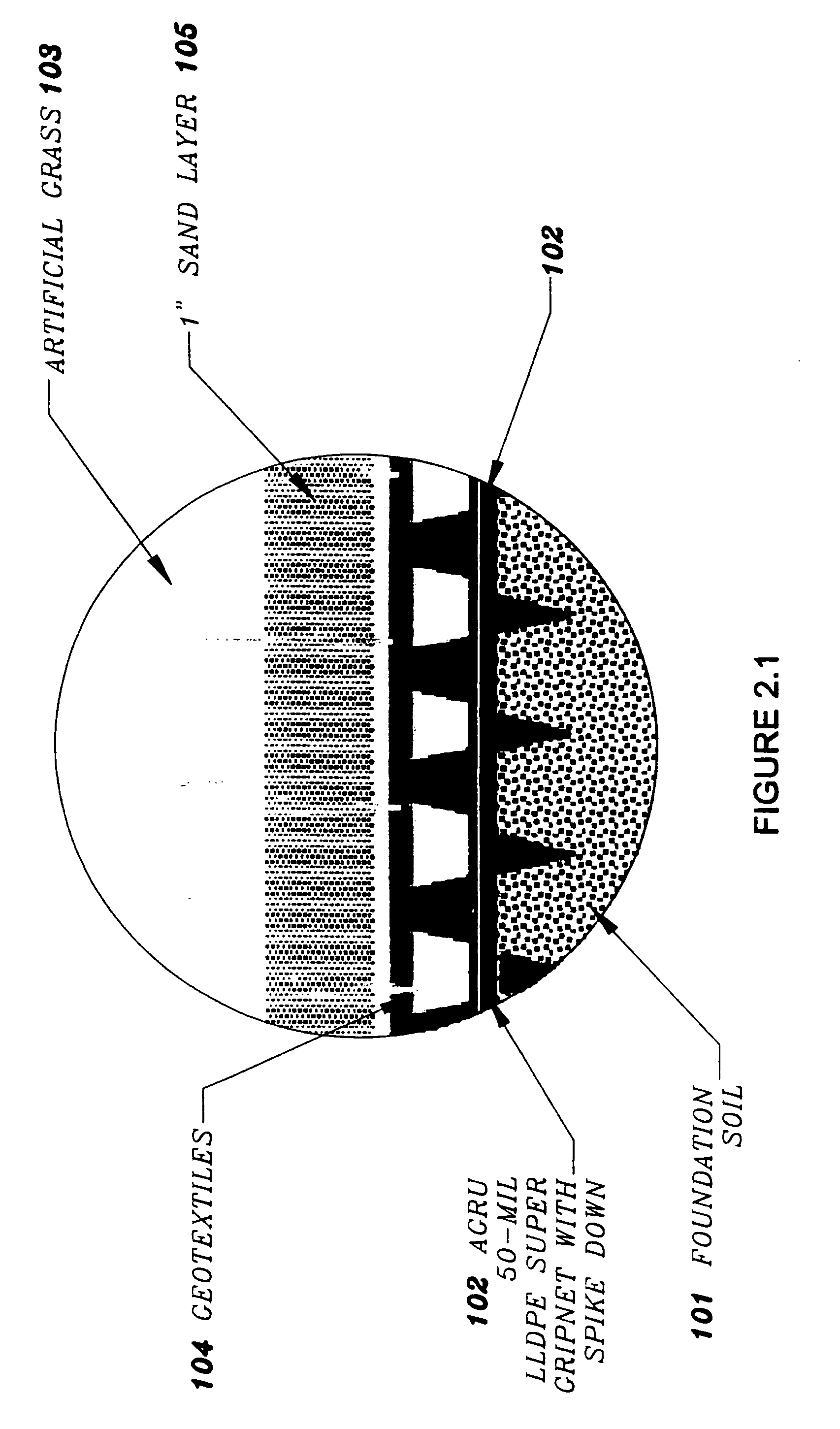

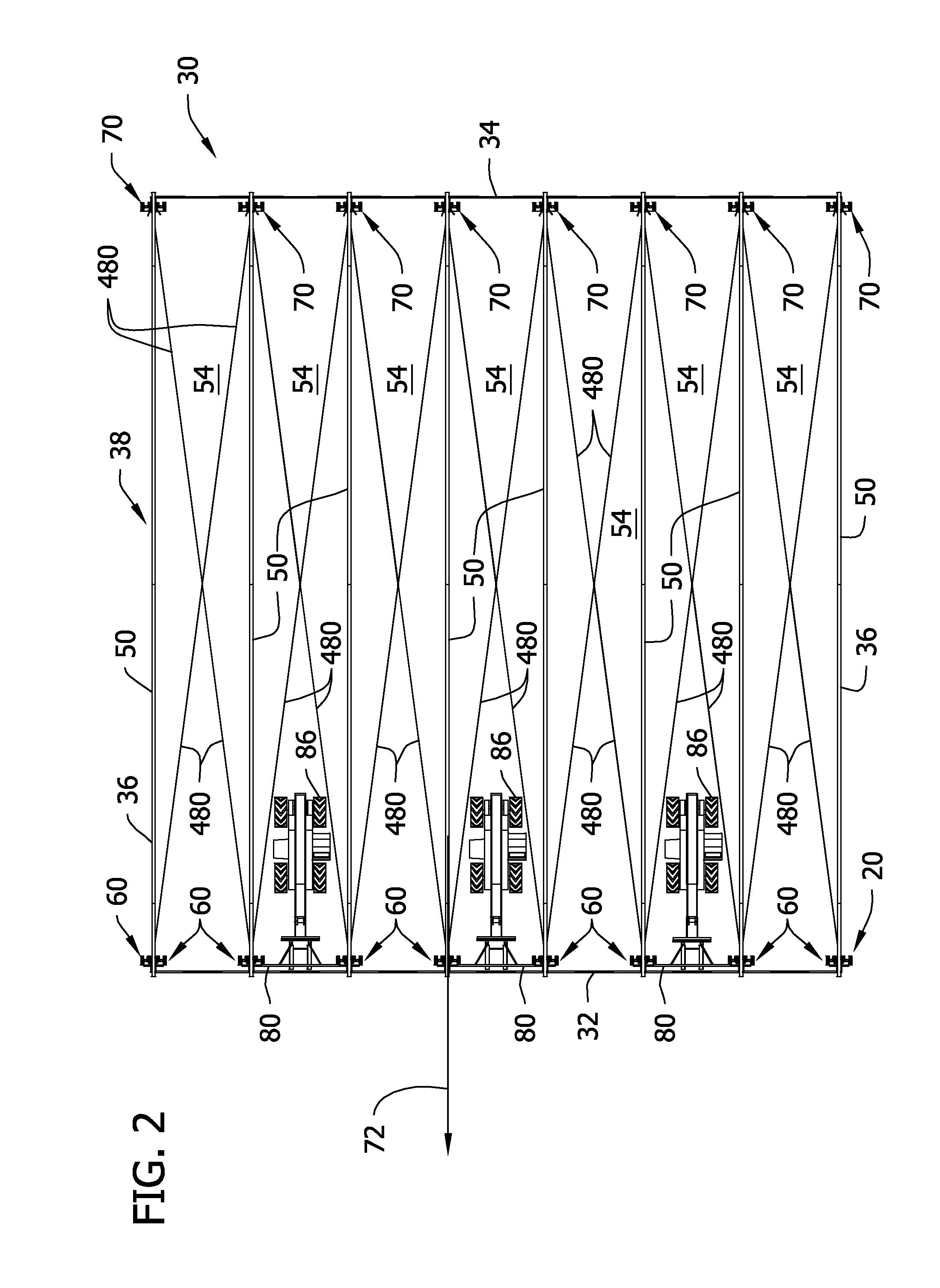

Cover system for waste sites and environmental closures

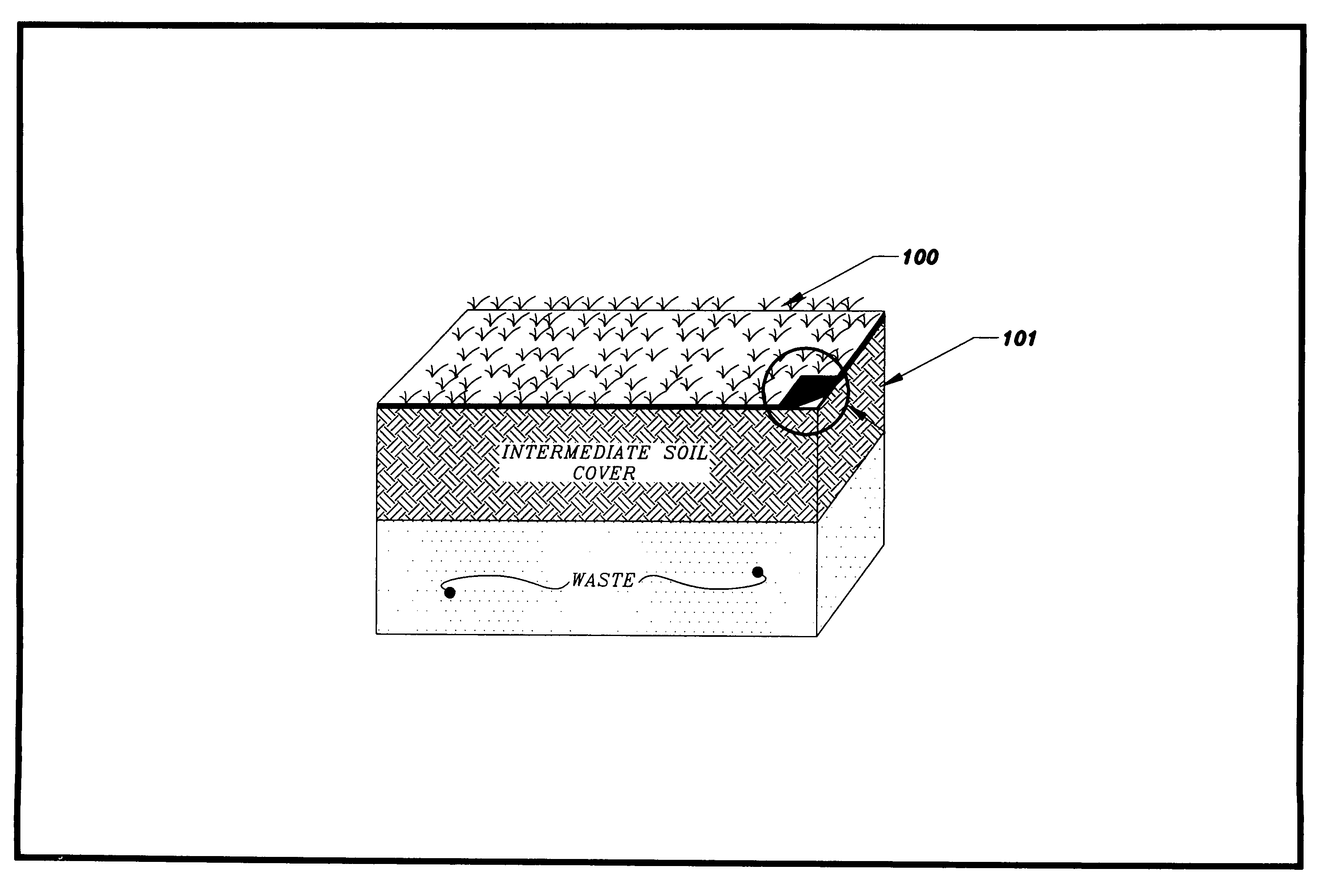

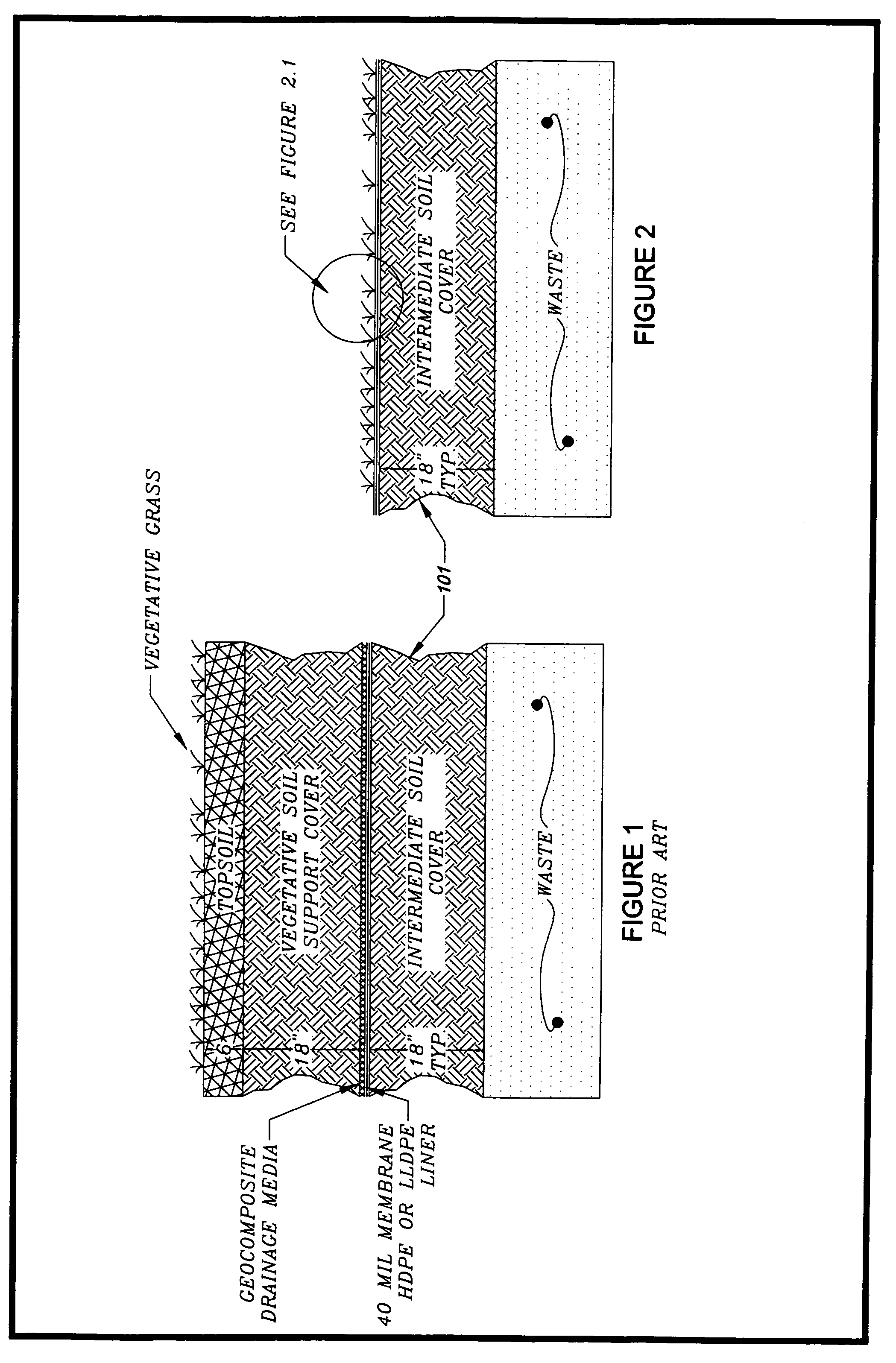

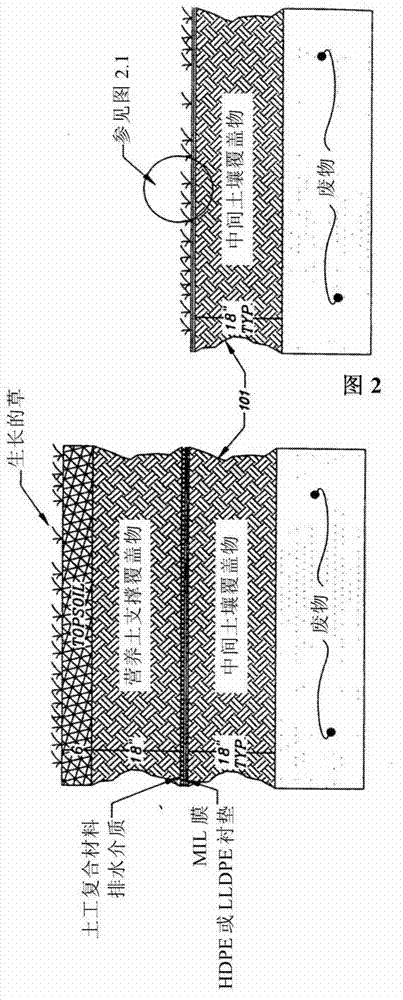

ActiveUS7682105B2Eliminates orReduce wasteLandfill technologiesSolid waste disposalGeomembraneFinal cover

A cover system is provided for waste sites and environmental closures, in which the cover system comprises a synthetic grass and an impermeable geomembrane that can be applied without the use of heavy earthwork equipment as temporary or final cover to control odors, erosion, gas migration and contaminate migration. The invention allows installation on very steep slopes and does not require the use of an extensive anchoring system to resist wind uplift or slope failure.

Owner:WATERSHED GEOSYNTHETICS

Fluid interface for bioprocessor systems

InactiveUS7955843B2Low costFacilitates rapid, frequent, automated samplingBioreactor/fermenter combinationsBiological substance pretreatmentsBioprocessorAutomatic control

An apparatus and method for an aseptic fluidic interface between bioprocess systems is provided. The apparatus includes an inlet valve, adapted for automatic control, that is coupled to a biofluid source site. A sampling conduit extends from the inlet valve to an outlet valve. The outlet valve is adapted for automatic control and is coupled to a biofluid process site. A trap is at the sampling conduit. A waste valve, adapted for automatic control, is located at a waste conduit extending from the sampling conduit to a waste site. Also included is a wash fluid source that is coupled to at least one of the inlet or outlet valves. In the method, the sample is automatically directed to the biofluid process site by opening the outlet valve, and closing the waste valve. Also included is isolating the biofluid sites by closing the inlet and outlet valves, and opening the waste valve to drain biofluid from the trap to the waste site. Another step is cleaning the sampling conduit before sample collection by directing the wash fluid through at least one valve selected from the inlet and outlet valves, and subsequently through the waste valve to the waste site.

Owner:GROTON BIOSYST

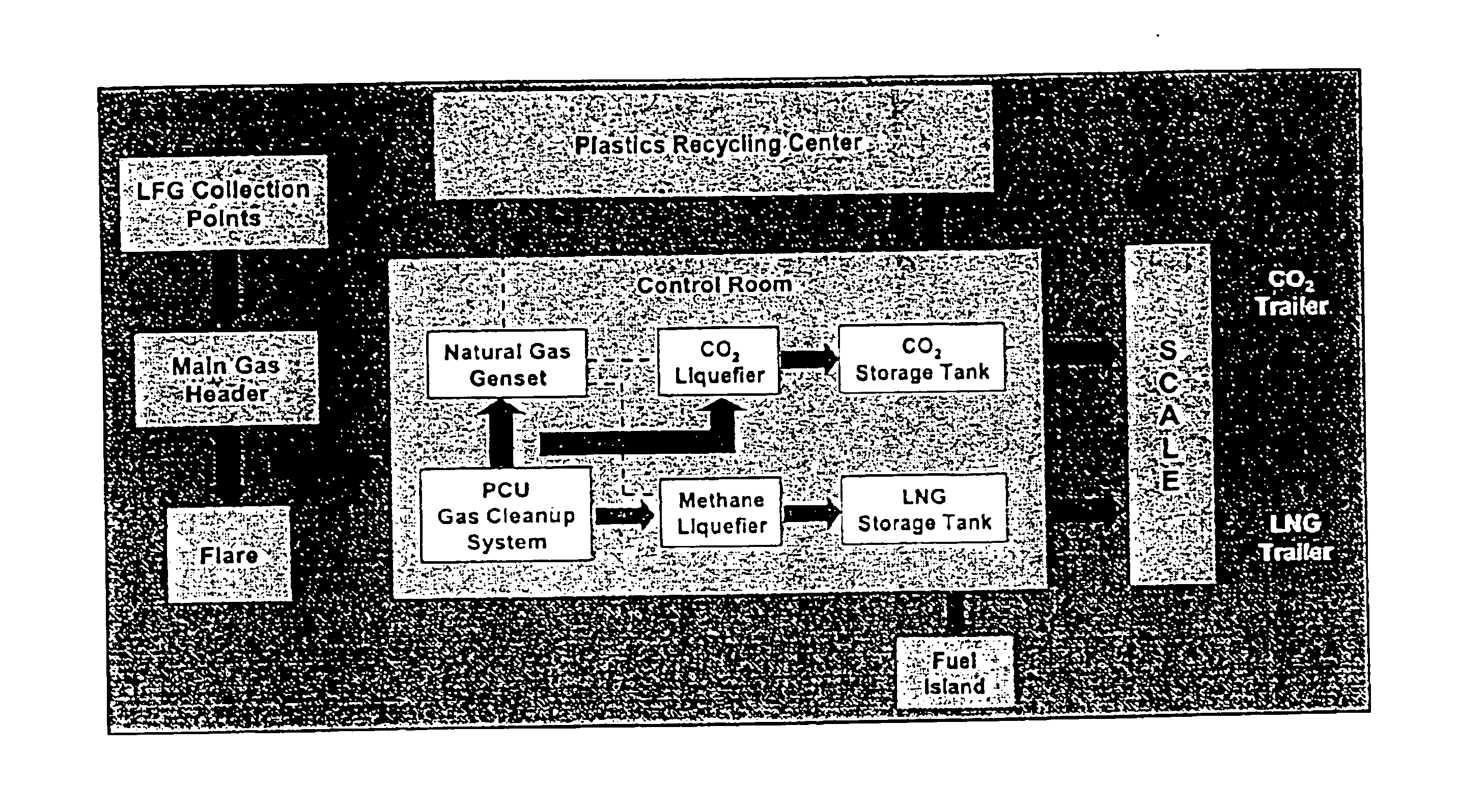

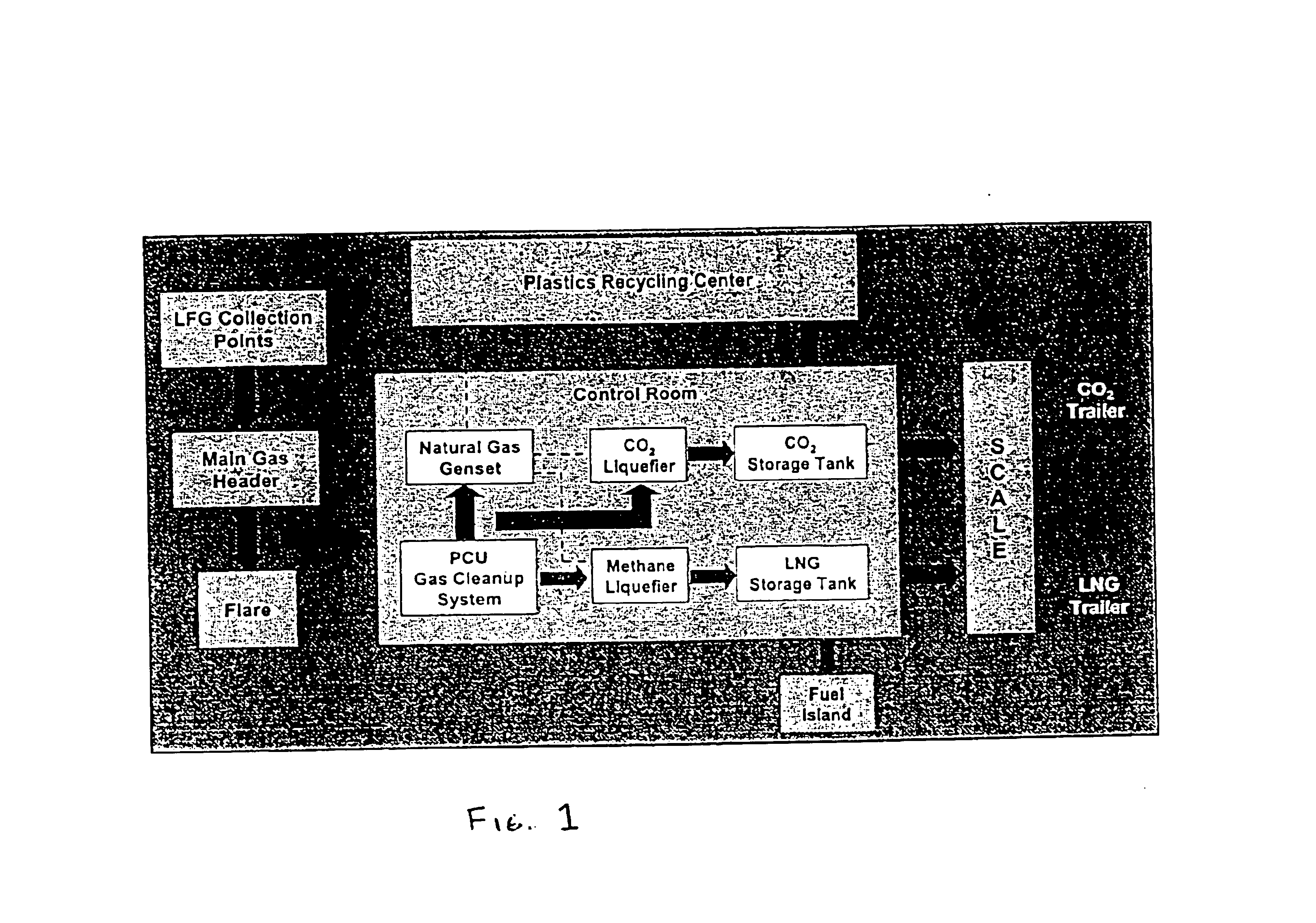

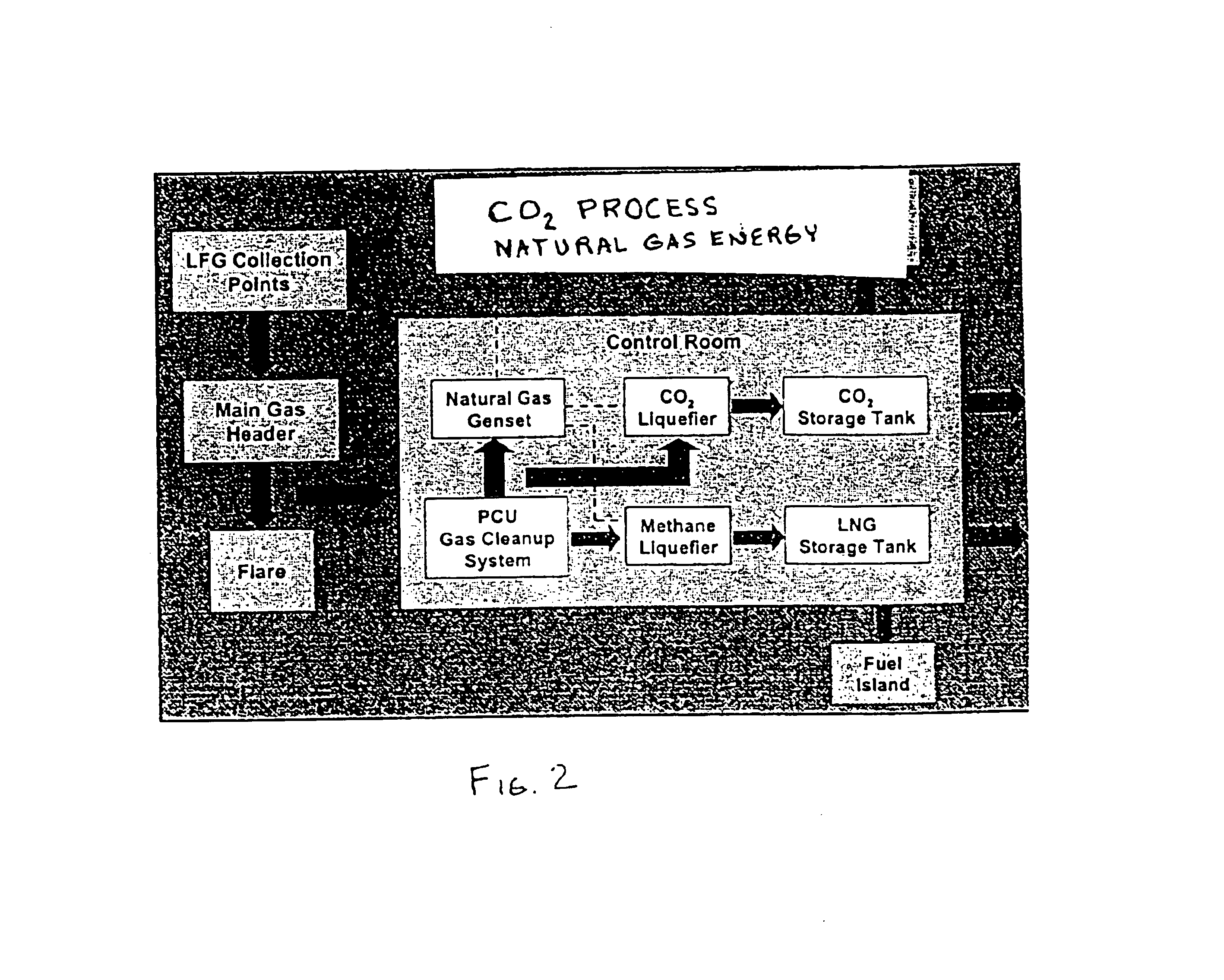

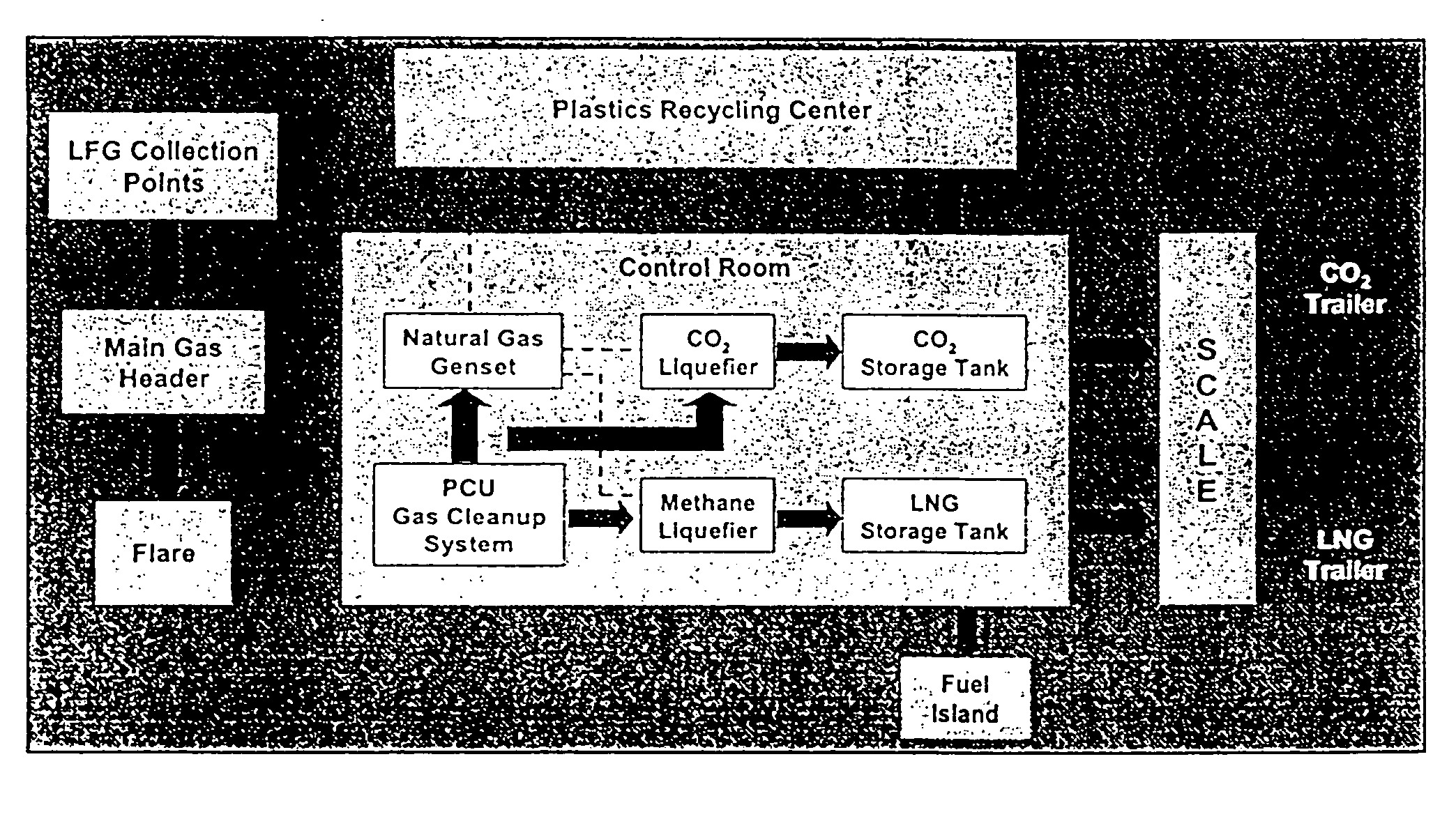

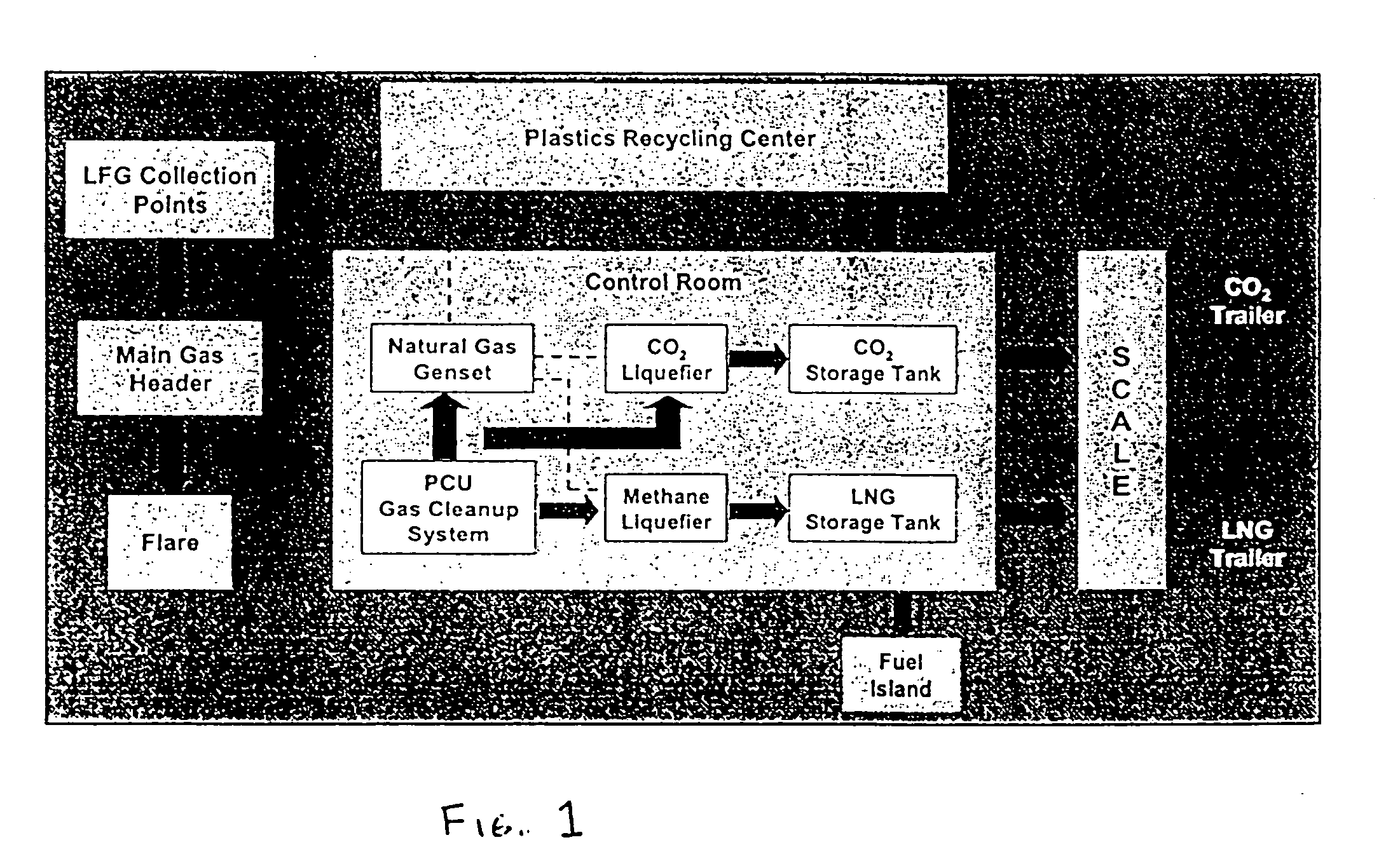

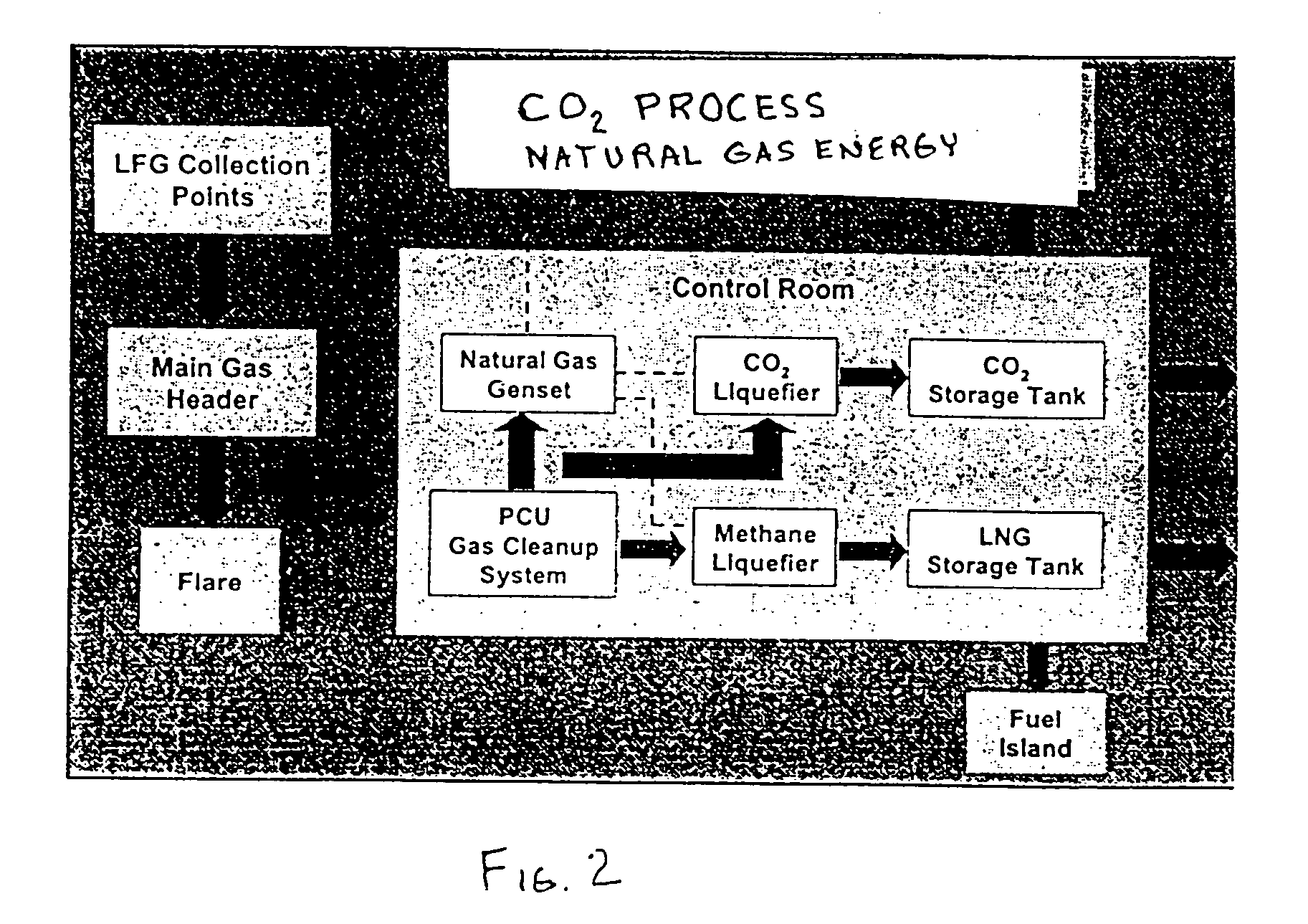

System for use of land fills and recyclable materials

Gases are vented from a waste site such as a landfill, and the gases are separated into at least three streams comprising a hydrocarbon stream, a carbon dioxide stream, and residue stream. At least a portion of the carbon dioxide stream and hydrocarbon stream are liquefied or converted to a supercritical liquid. At least some of the carbon dioxide gas stream (as a liquid or supercritical fluid) is used in a cleaning step, preferably a polymer cleaning step, and more preferably a polymer cleaning step in a polymer recycling process, and most preferably in a polymer cleaning step in a polymer recycling system where the cleaning is performed on-site at the waste site.

Owner:COOL CLEAN TECH

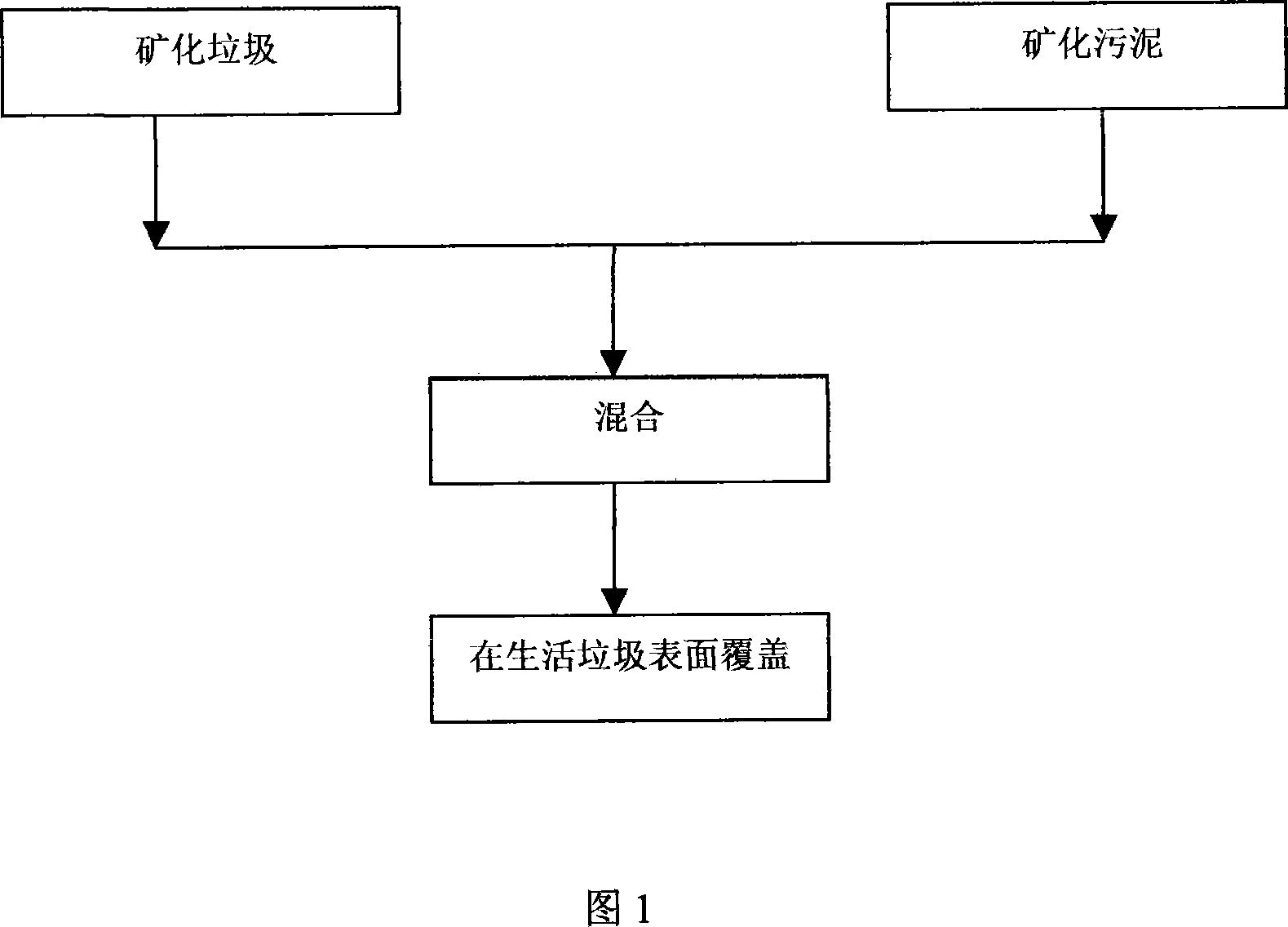

Methane oxidation covering material for life refuse landfill

InactiveCN101062848AAchieve emission reductionReduce manufacturing costSolid waste managementOther chemical processesSocial benefitsSludge

The invention discloses a methane-oxidizing covering material of landfill life waste site, which comprises the following steps: allocating mass percent (dry group) of mineralizing garbage and mineralizing sludge as 20-100% : 0-80%; choosing the mineralizing garbage with grain size at 0. 5mm-4cm and buried above 8 years; choosing the mineralizing sludge with moisture percentage at 50%-70% sludge and buried above 5 years. This invention possesses explicit social benefit and economic benefit and low cost, which can be fit for landfill life waste site widely.

Owner:TONGJI UNIV

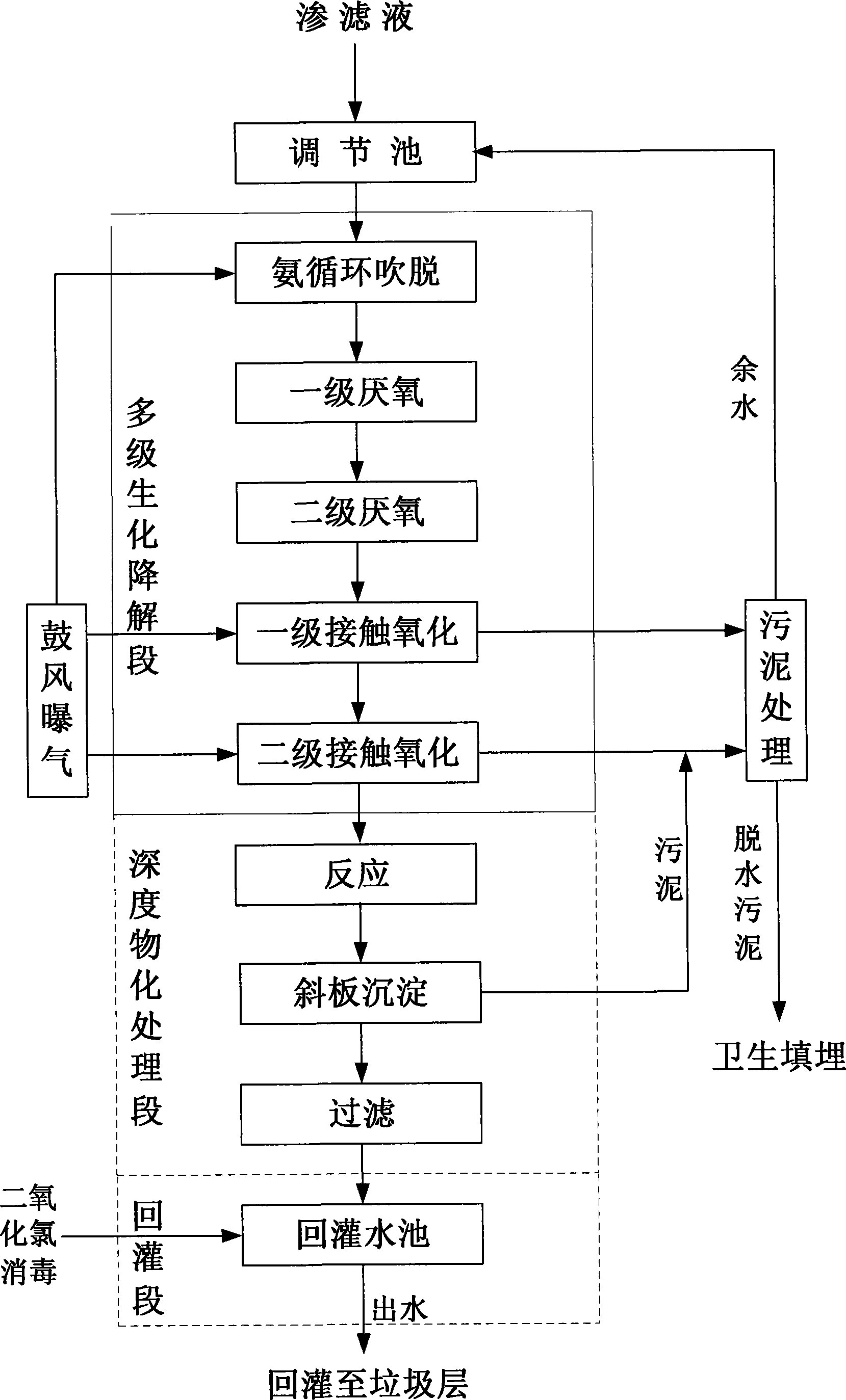

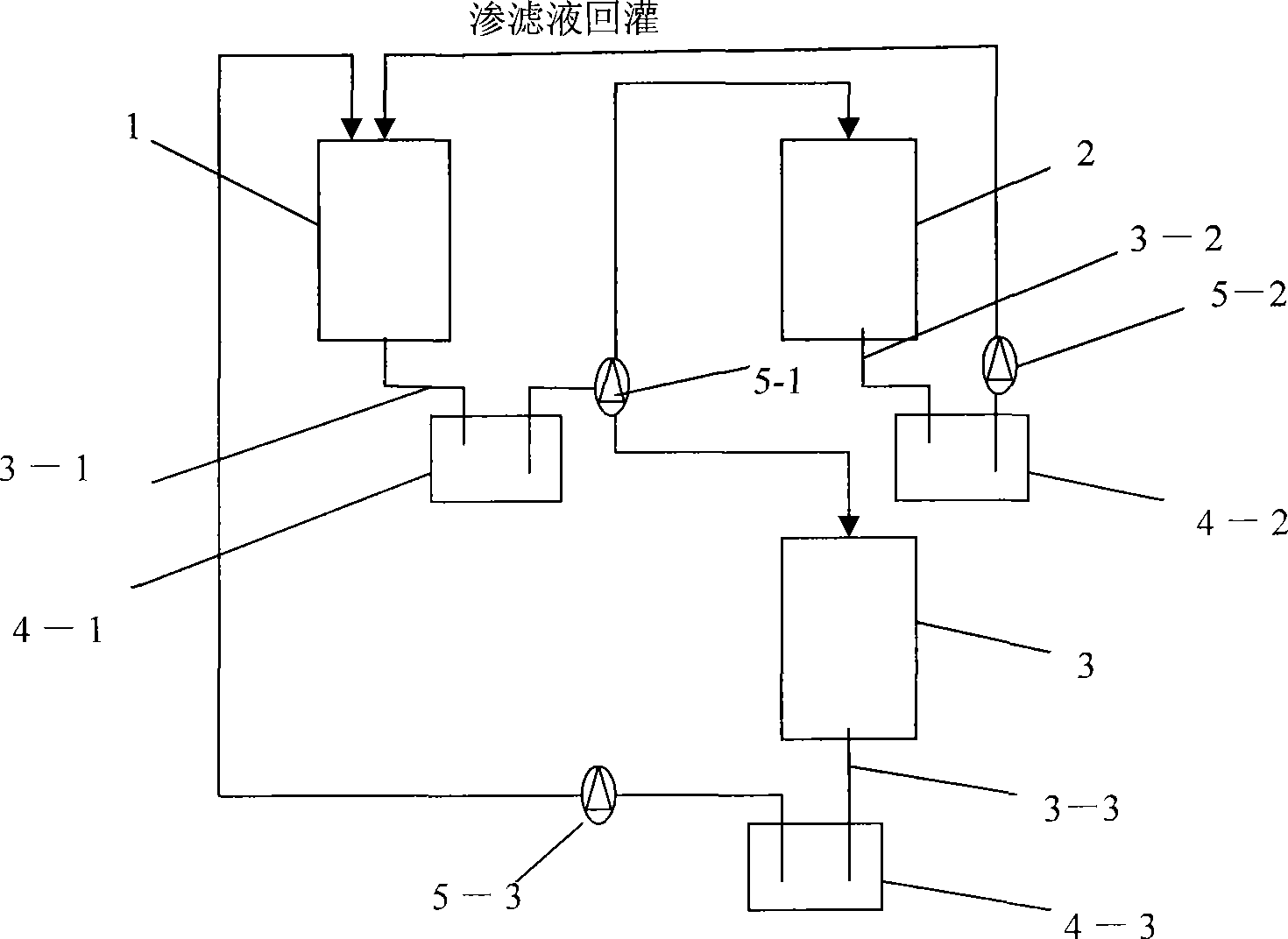

Method for treating percolation liquid of water deficiency area garbage embedding field

InactiveCN101041537AIncrease moisture contentPromote decompositionSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesOperational costsSewage

The invention discloses a disposing method of water deficiency area landfill waste site straining liquid belonging to high concentrate waste water disposing method, which comprises the following steps: installing balancing tank, ammonia blow-off, anaerobic treatment, aerobic treatment, materialized advanced treatment and recharge; possessing stronger placement, higher stability, lower capital expenditure and operating cost; realizing zero discharge of garbage straining liquid; controlling its pollution.

Owner:黄继国 +2

Restoration method for heavy metal and (or) organic hydrocarbon contaminated soil

ActiveCN107457252AEnhanced interactionImprove adsorption capacityOther chemical processesContaminated soil reclamationRestoration methodSlag

The invention provides a restoration method for heavy metal and (or) organic hydrocarbon contaminated soil. The restoration method comprises the following steps of: (1) mixing a molecular sieve, cyclodextrin, activated carbon, diatomite, ferrous sulfate, enzyme slag, plant ash and active iron powder to obtain a mixture, adding clay to knead the mixture, and rolling the mixture into an adsorbing base body with a hierarchical pore structure, and embedding the adsorbing base body into contaminated soil; (2) preparing a restoration agent solution containing cyclodextrin, enzyme and potassium tripolyphosphate to leach the contaminated soil, and adsorbing and preserving; and (3) repeating the step (2) by many times. According to the restoration method provided by the invention, restoration agent solution leaching is combined with adsorbing of the base body with the hierarchical pore structure, so that heavy metal and (or) organic hydrocarbon substance pollutants in the soil are removed in a compounded mode, and therefore, the restoration method is suitable for municipal sludge treatment, and restoration for a contaminated building site, an industrial and mineral waste site, wetland soil obtained by returning farmland to lake (sea) and a wetland park, is simple and easy to operate, is free of secondary pollution, and can be used for industrial production.

Owner:蓝畅

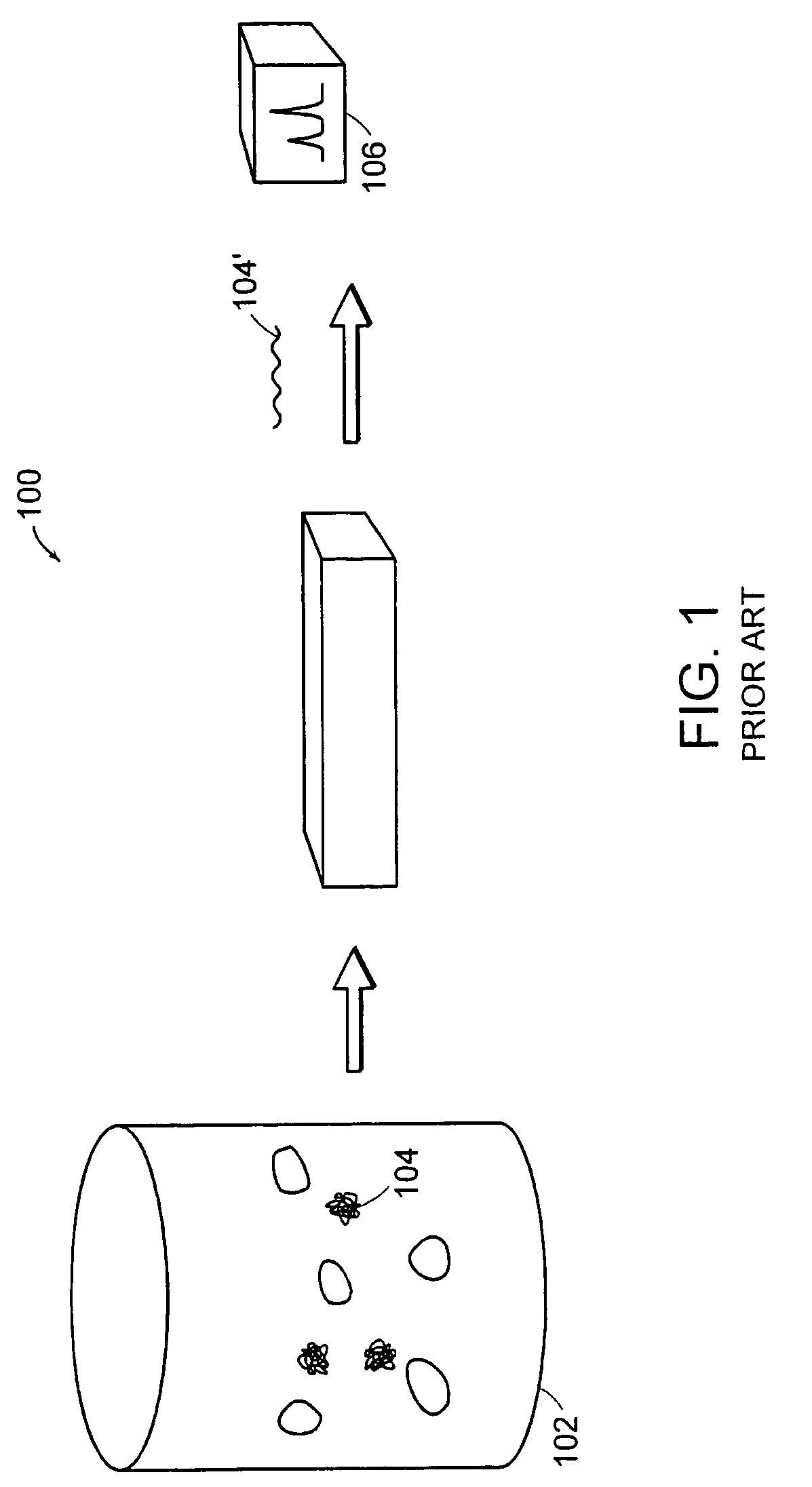

Fluid interface for bioprocessor systems

InactiveUS7169599B2Facilitates rapidFacilitates frequentBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlInlet valve

An apparatus and method for an aseptic fluidic interface between bioprocess systems is provided. The apparatus includes an inlet valve, adapted for automatic control, that is coupled to a biofluid source site. A sampling conduit extends from the inlet valve to an outlet valve. The outlet valve is adapted for automatic control and is coupled to a biofluid process site. A trap is at the sampling conduit. A waste valve, adapted for automatic control, is located at a waste conduit extending from the sampling conduit to a waste site. Also included is a wash fluid source that is coupled to at least one of the inlet or outlet valves. In the method, the sample is automatically directed to the biofluid process site by opening the outlet valve, and closing the waste valve Also included is isolating the biofluid sites by closing the inlet and outlet valves, and opening the waste valve to drain biofluid from the trap to the waste site. Another step is cleaning the sampling conduit before sample collection by directing the wash fluid through at least one valve selected from the inlet and outlet valves, and subsequently through the waste valve to the waste site.

Owner:GROTON BIOSYST

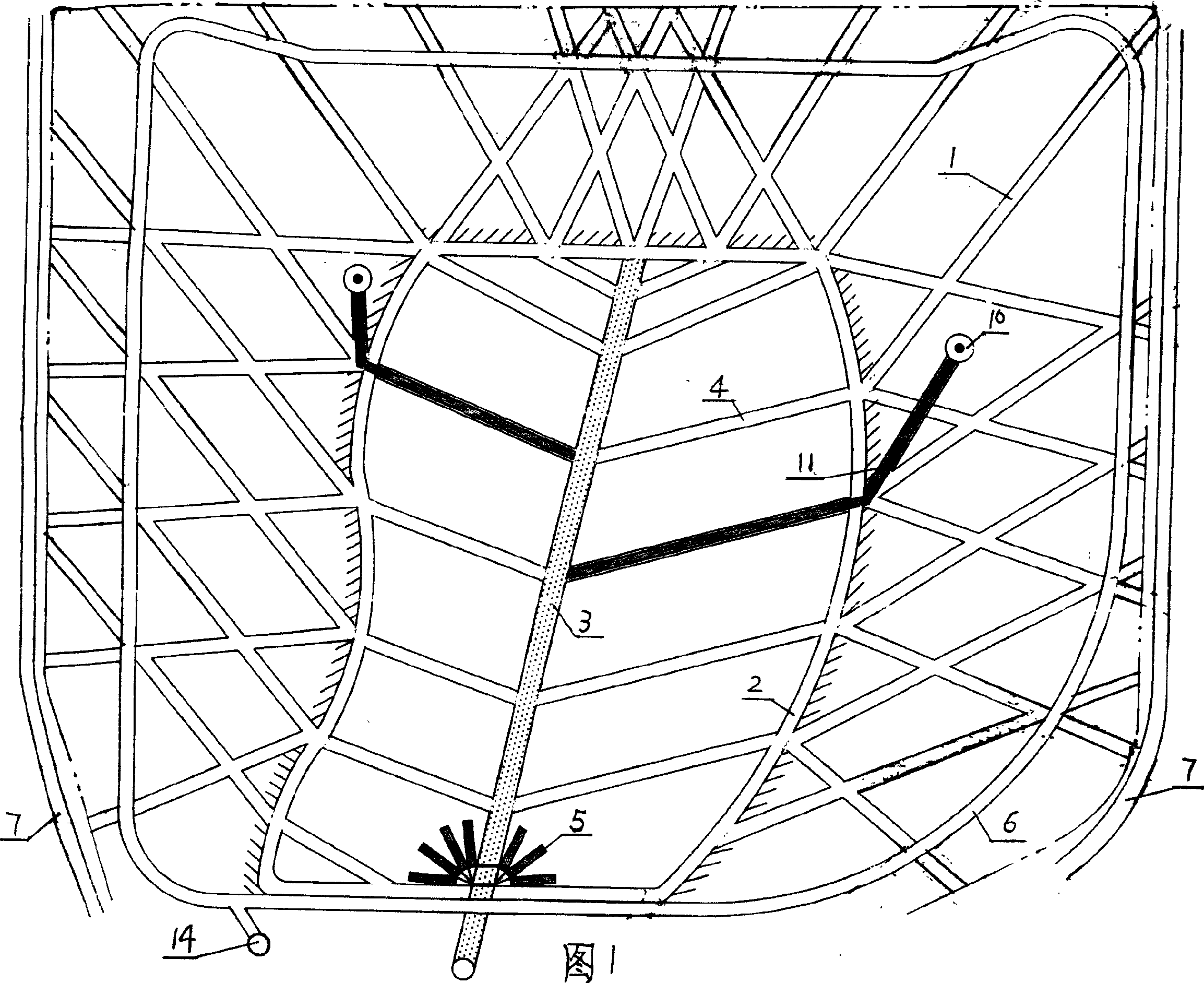

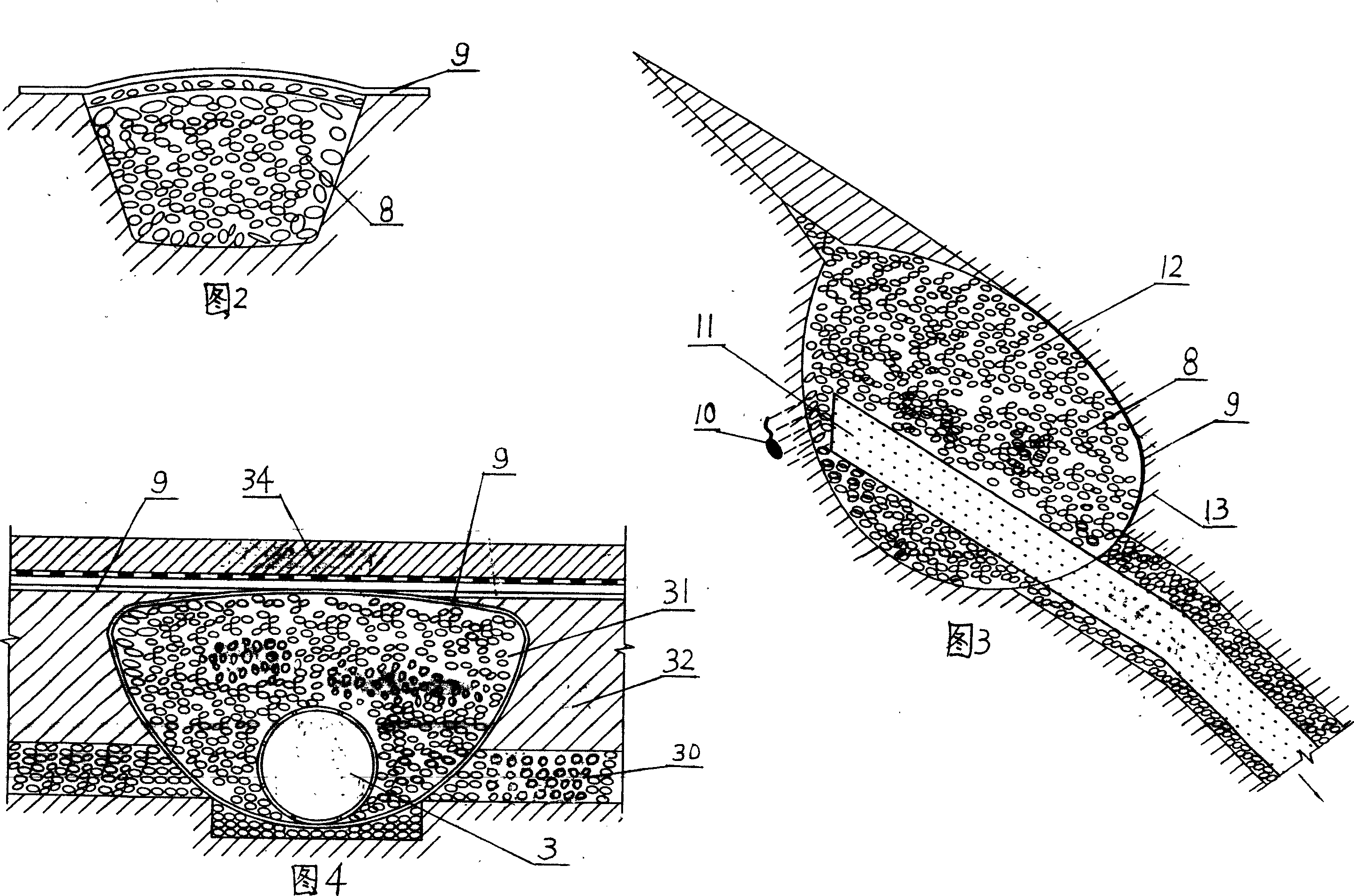

Reticular blind drainage method for groundwater of sanitary landfill for disposing house refuse

InactiveCN101016750AMake sure not to softenPrevent sprawlSewerage structuresSewage drainingLitterWater quality

The invention relates to a meshed blind drain leading and draining water method for groundwater in landfill life waste site, and installs a meshed directing blind drain on an entire warehouse bottom and a side slope which is grade separated with the anchoring groove of every layer opening. An upper opening is up to the planning regional of the landfill site, while a lower opening is connected with an annular directing blind drain. A main groundwater drain is longitudinal installed on the lowest part of the warehouse bottom, and a fishbone-shaped directing blind drain is spread between the main groundwater drain and the annular directing blind drain. The outlet end of the main groundwater drain is positioned at the warehouse dam which is equipped with actinoform fan-shaped draining pipes at the forward. The invention drains out the water timely and ordered via the groundwater influence channel with the meshed directing blind drain, and prevents overflowing, forming water collection and ballooning bag, thereby guaranteeing the soil of the warehouse keeping hard, protecting impervious layers, and eliminating water contamination accidents. The invention guarantees the base and the impervious layer of the warehouse in working order, thereby preventing the water contamination and keeping safety and healthy.

Owner:傅仲萼

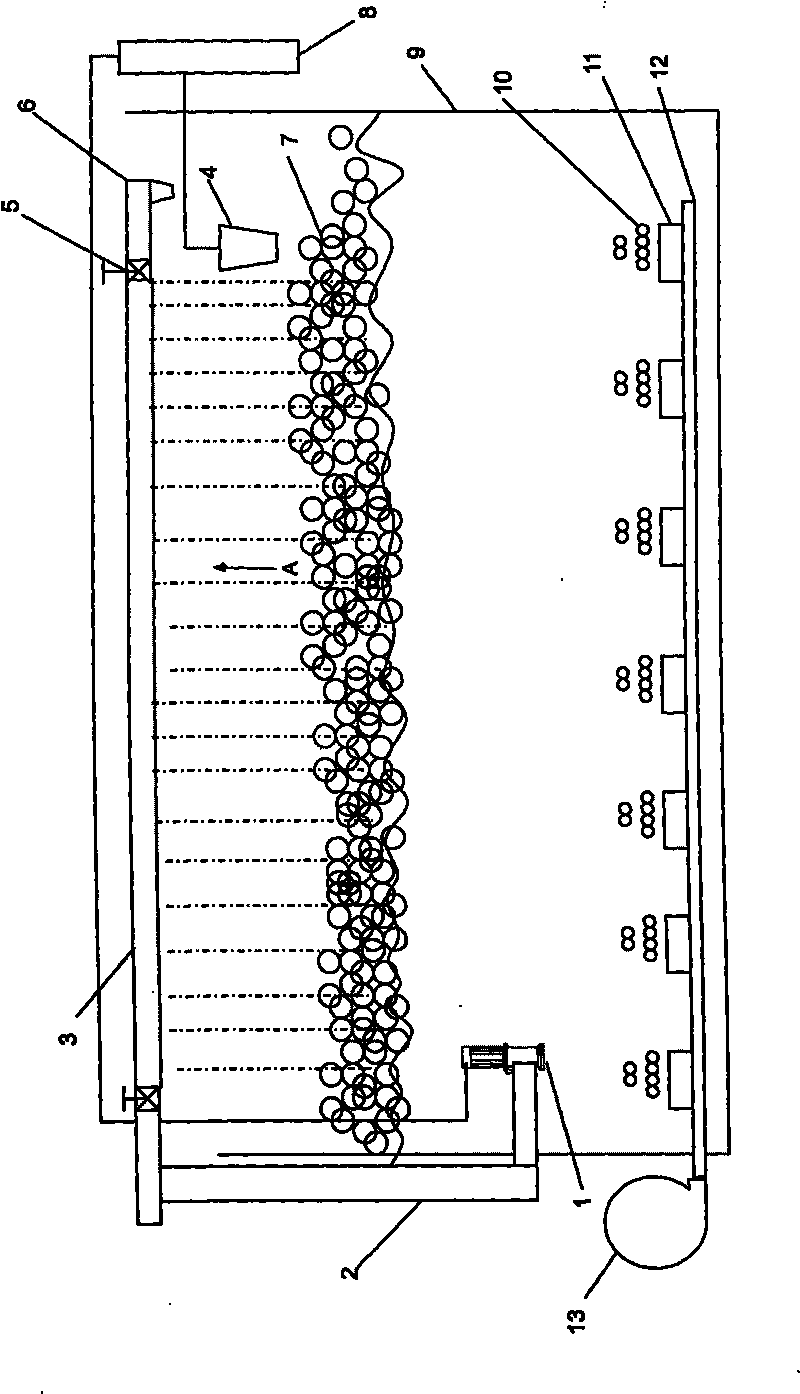

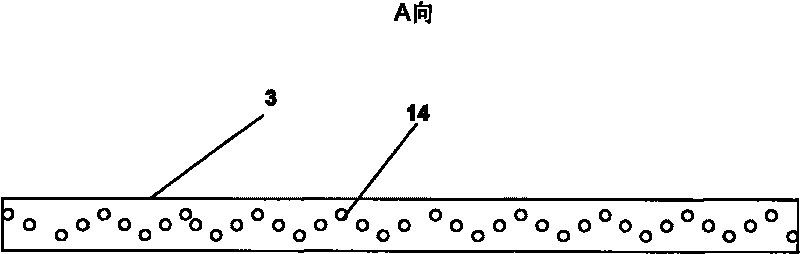

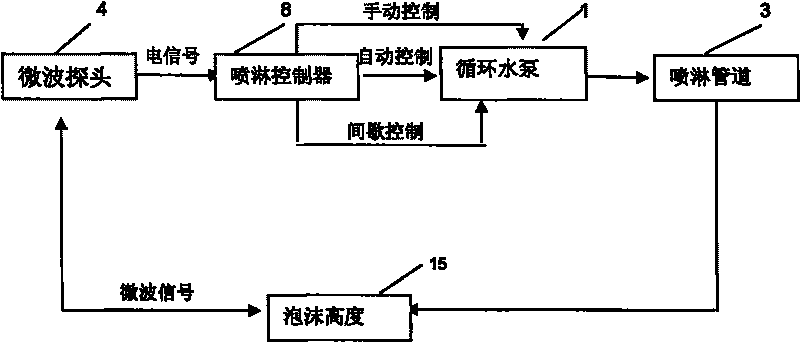

Automatic spraying defoaming device for waste leachate treatment

InactiveCN101700930ASolve fouling and cloggingReduce processing costsTreatment using aerobic processesMultistage water/sewage treatmentWaste treatmentPollution

The invention relates to an automatic spraying defoaming device for waste leachate treatment, which comprises a biochemical reaction basin and an aeration device arranged in the biochemical reaction basin. A microwave probe for detecting foam height and a spraying hole tube are arranged above the water surface of the biochemical reaction basin; the microwave probe is connected with a spraying controller arranged outside the biochemical reaction basin; a control switch of the spraying controller is connected with a circulating water pump arranged under the water surface of the biochemical reaction basin; and the circulating water pump is connected with the spraying hole tube by a connecting tube to form a circulating device for waste water spraying and defoaming. The invention realizes the spraying and defoaming treatment in the aerobic phase of leachate biochemical treatment, solves dirt blockage during waste water spraying, avoids using a defoaming agent, thereby not only preventing secondary pollution, but also saving the cost of waste water treatment, wherein the automatic circulating defoaming treatment saves three fifths of defoaming cost, more than 90% electrical energy, and more than 95% waste water treatment cost, and can be popularized and applied to large-scale waste treatment sites.

Owner:NINGBO CITY YINZHOU DISTRICT LYUZHOU ENERGY UTILIZATION CO LTD +1

Reclamation and improvement method for waste coal gangue stacking area

InactiveCN107743747AAccurate repairRepair goals are clearExcrement fertilisersContaminated soil reclamationEngineeringEarth surface

Provided is a reclamation and improvement method for a waste coal gangue stacking site. The method includes the steps of conducting reconnaissance and measurement on the waste coal gangue stacking site after earth surface arrangement, drawing the topographic map of the site, dividing into grids to conduct grid-type sampling, drawing the pH value distribution map of surface soil according a test result, according to pH value distribution, applying lime in a grading and zoning mode to adjust the pH value of the soil to neutral, after applying a basic fertilizer and spraying composite microbial inoculants, sowing green manure crops, and after turned root returning application, conducting crop rotation on commercial crops and returning application on crop straw. The method provides an effective solution channel for the reclamation, restoration and improvement of Chinese resource-based region coal gangue waste sites, especially, the high-sulfur-bearing waste coal gangue stacking site.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

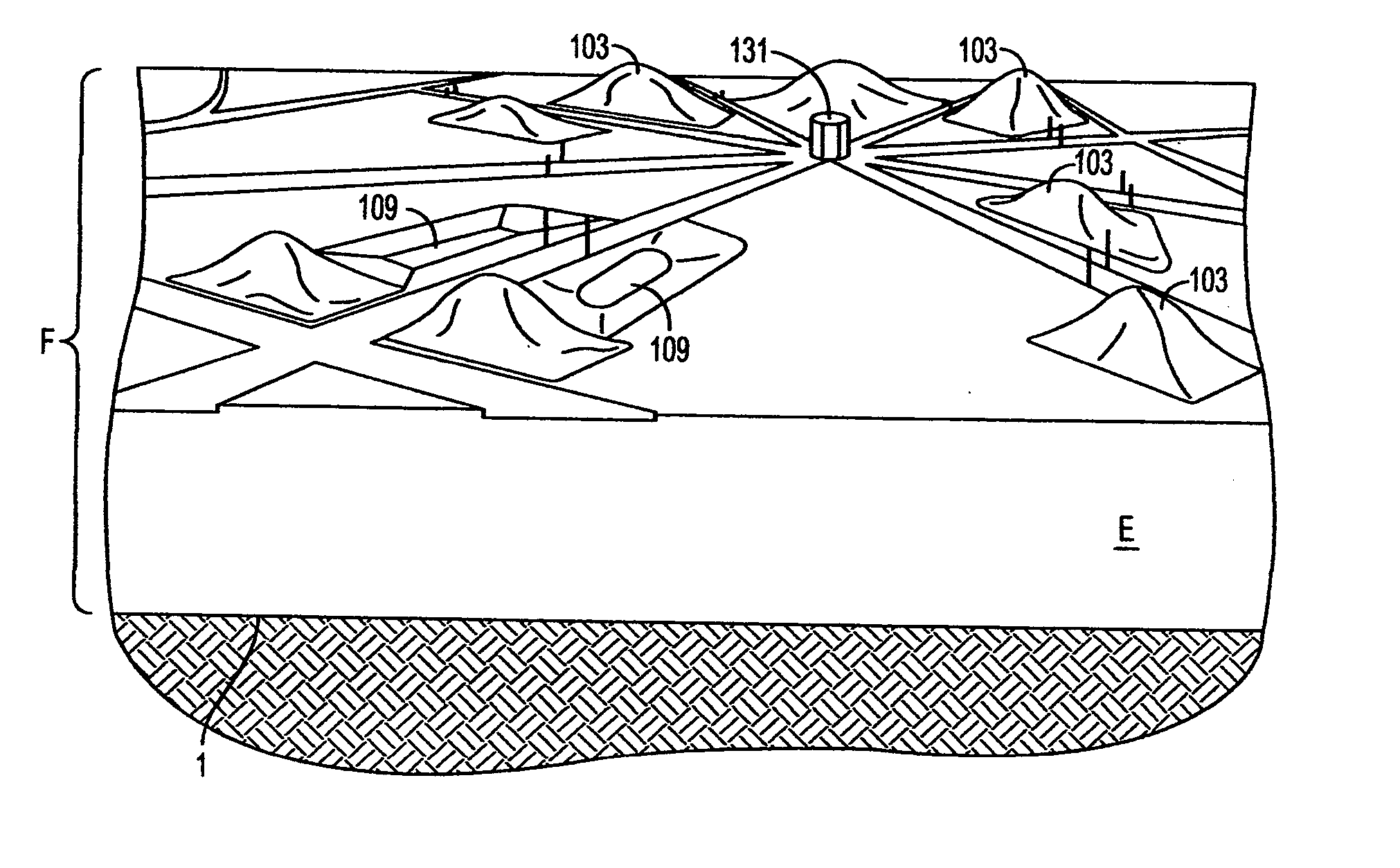

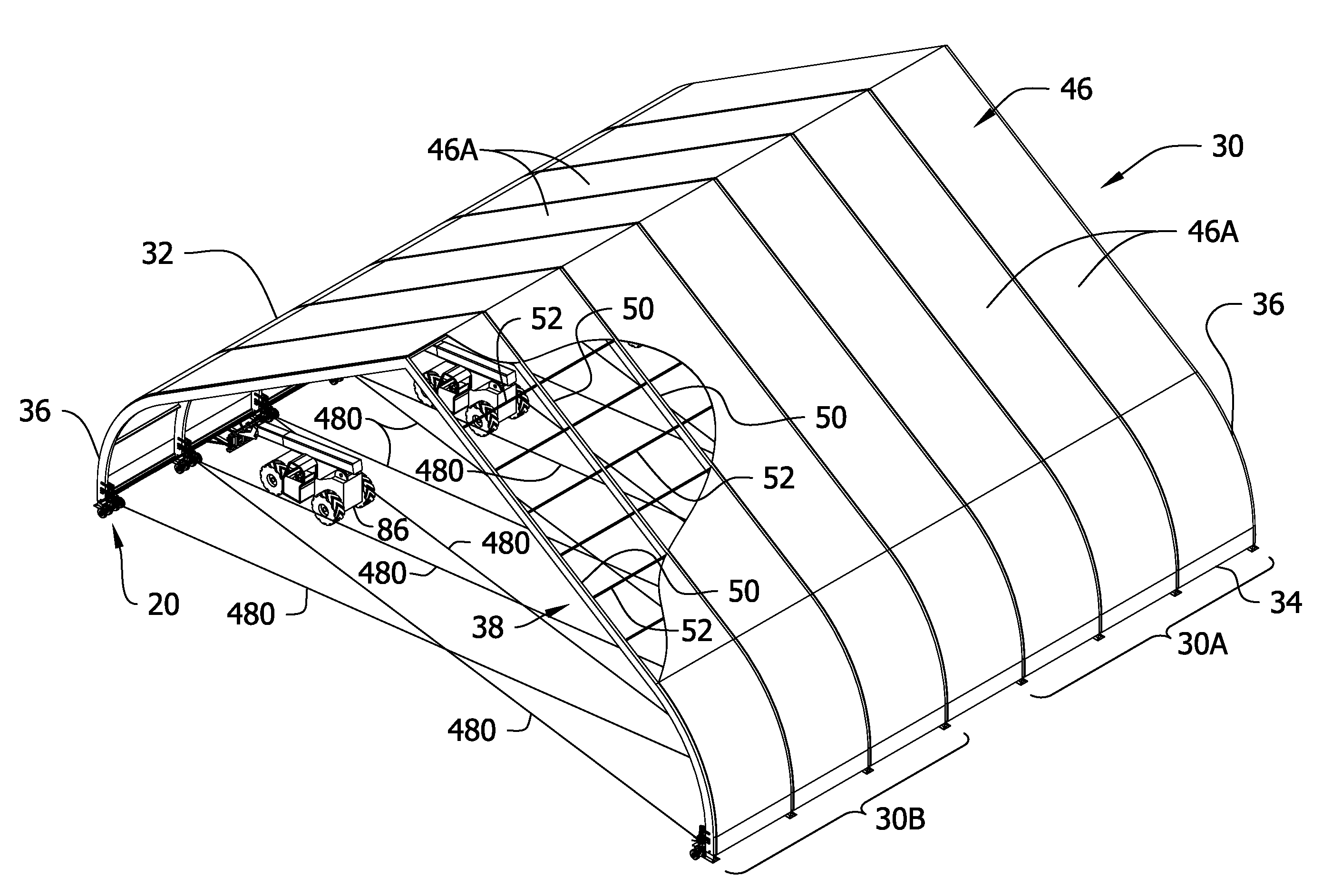

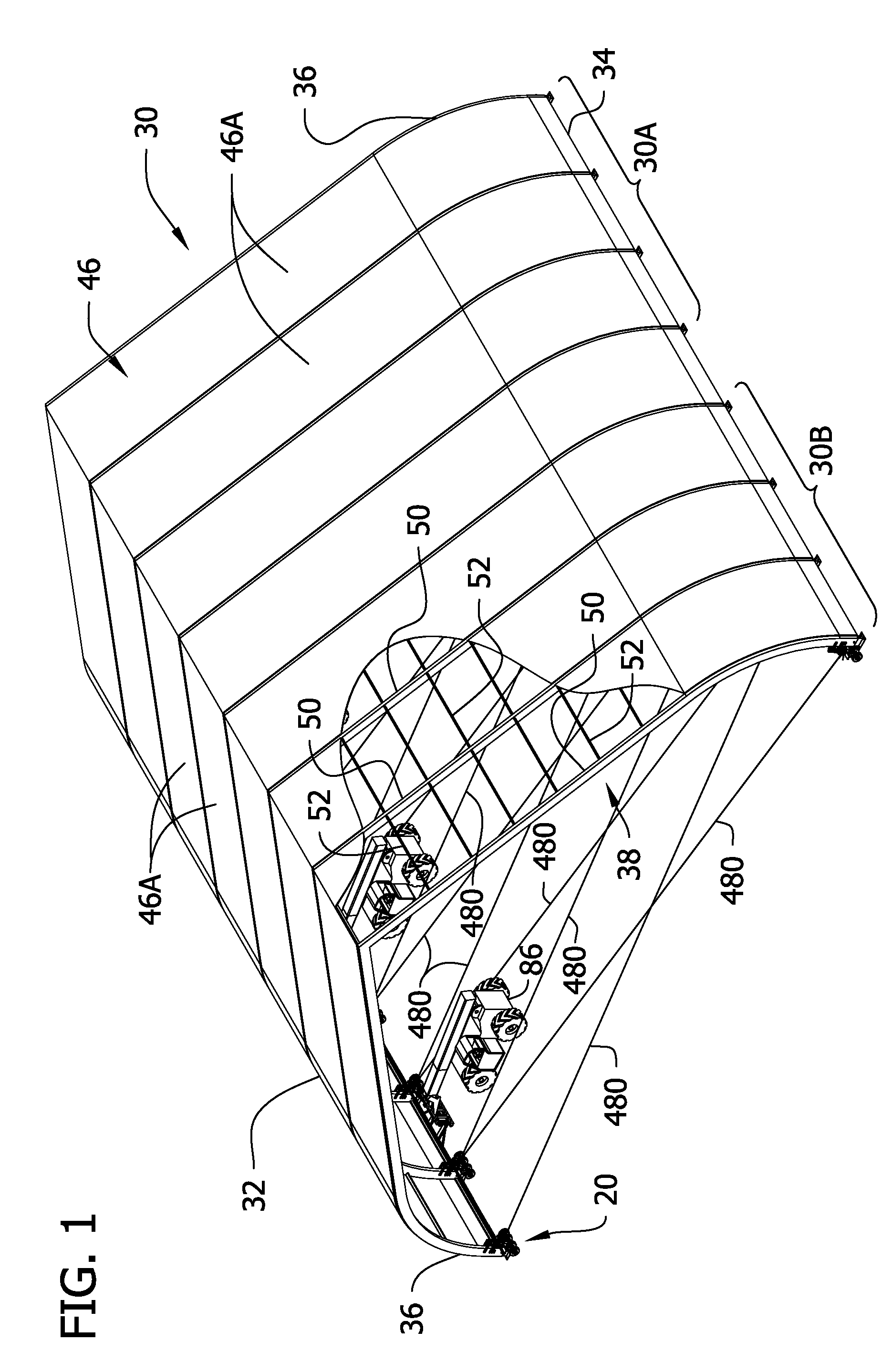

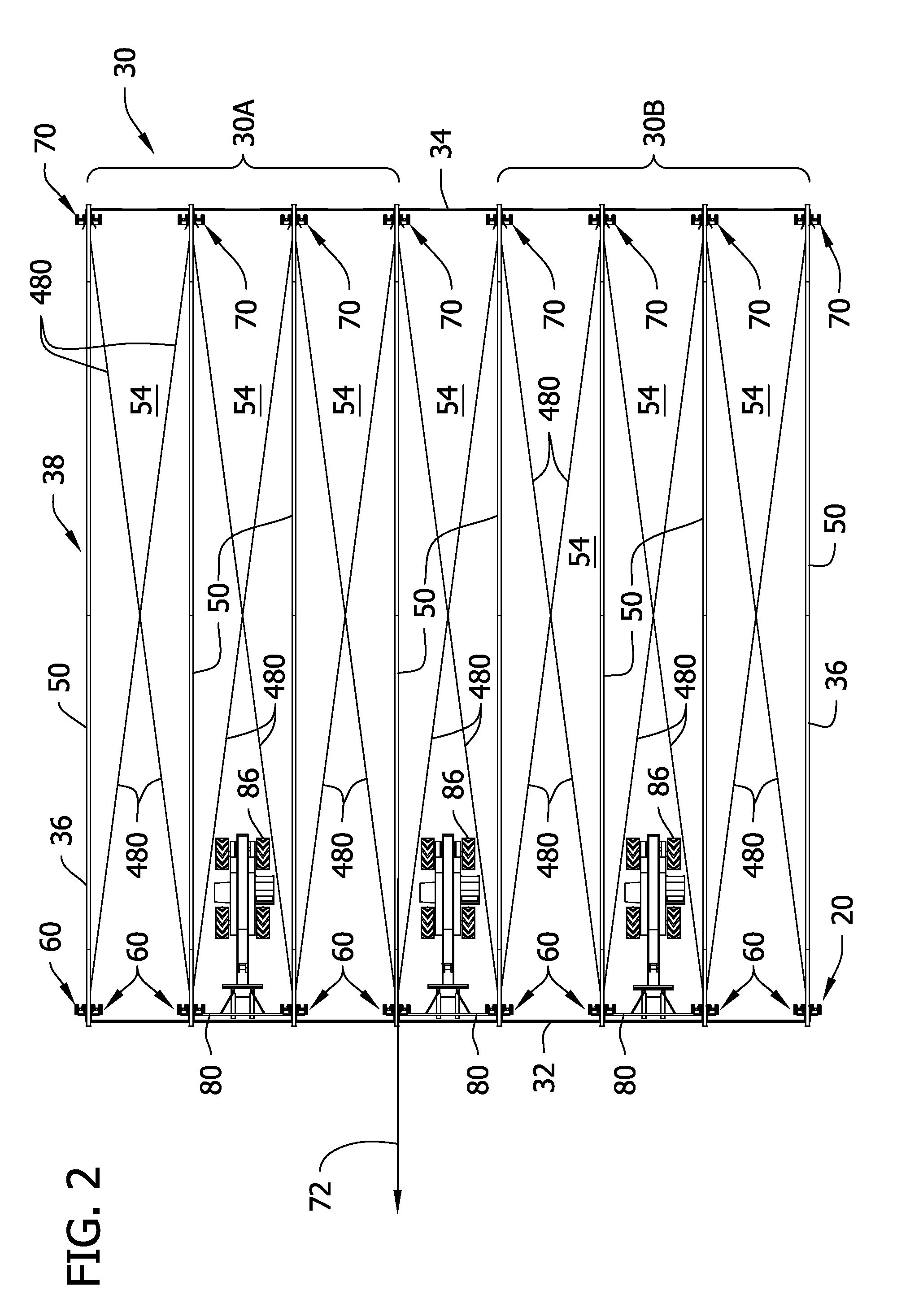

Cover system with gas collection system for waste sites and environmental closures

ActiveUS8585322B2Eliminates orReduce wasteSolid waste disposalLandfill technologiesGeomembraneFinal cover

A cover system is provided for waste sites and environmental closures, in which the cover system comprises a synthetic grass and an impermeable geomembrane that can be applied without the use of heavy earthwork equipment as temporary or final cover to control odors, erosion, gas migration and contaminate migration. The invention allows installation on very steep slopes and does not require the use of an extensive anchoring system to resist wind uplift or slope failure. A gas collection system is located under the cover system for the collection of gas produced by the waste sites.

Owner:WATERSHED GEOSYNTHETICS

Cover system for waste sites

ActiveUS8403597B2Eliminates orReduce wasteSolid waste disposalLandfill technologiesGeomembraneFinal cover

A cover system is provided for waste sites and environmental closures, in which the cover system comprises a synthetic grass and an impermeable geomembrane that can be applied without the use of heavy earthwork equipment as temporary or final cover to control odors, erosion, gas migration and contaminate migration. The invention allows installation on very steep slopes and does not require the use of an extensive anchoring system to resist wind uplift or slope failure.

Owner:WATERSHED GEOSYNTHETICS

Method for processing landfill leachate and special device thereof

InactiveCN101249988AAdvantages of the treatment methodSolve processingWater/sewage treatmentFiltrationWaste site

The invention discloses a method for processing rubbish filtration and the special apparatus. The method for processing rubbish filtration has the advantages that (1) resolving the problem of blocking of the waste reactor, (2) accelerating stabilization of the rubbish for detecting and shortening the landfill waste cycle and filtration processing cycle, (3) achieving zero discharge of the filtration, (4) realizing the sustainable development of the landfill waste site, (5) can flexibly control the recharge rage.

Owner:TSINGHUA UNIV

Cover system for waste sites

ActiveUS20100266342A1Reduce wasteReduces and eliminates infiltration of waterLandfill technologiesSolid waste disposalFinal coverGeomembrane

A cover system is provided for waste sites and environmental closures, in which the cover system comprises a synthetic grass and an impermeable geomembrane that can be applied without the use of heavy earthwork equipment as temporary or final cover to control odors, erosion, gas migration and contaminate migration. The invention allows installation on very steep slopes and does not require the use of an extensive anchoring system to resist wind uplift or slope failure.

Owner:WATERSHED GEOSYNTHETICS

Conversion of gypsum stacks to waste containment facilities and related construction & business methods

InactiveUS20060008325A1Expense is substantially reduced and eliminatedHigh compressive strengthSolid waste disposalLandfill technologiesPhosphateEnvironmental engineering

The invention pertains to the conversion of waste materials derived from gypsum mining and processing, such as existing gypsum stacks, into waste containment or landfill facilities. Advantageously, waste containment facilities and business methods according to the invention enable the creation of a positive revenue stream from previously negative assets such as gypsum stacks. Methods of the invention include the creation of waste containment facilities from existing gypsum stacks, or from the on-site formation of containment facilities from waste gypsum or other waste minerals as they are transported and positioned at a waste site. Waste containment facilities created according to the invention can be used for the short-term, long-term or permanent storage of waste materials such as solid waste, community refuse materials, biomass, industrial waste, phosphate waste, and for composting or otherwise processing materials such as biomass. Containment facilities according to the invention can be lined or unlined, open or capped, depending upon the nature of the material to be resident in the containment facility and relevant governmental regulations. The invention also provides for drainage and recovery systems, monitoring, controlling and communication means, pumps and valving means, and any other means known in the waste containment facility field. The invention comprehends also the storage and processing of materials such as biomass within a containment facility according to the invention and the sale of usable products derived from that processing.

Owner:IANNIELLO PETER J +2

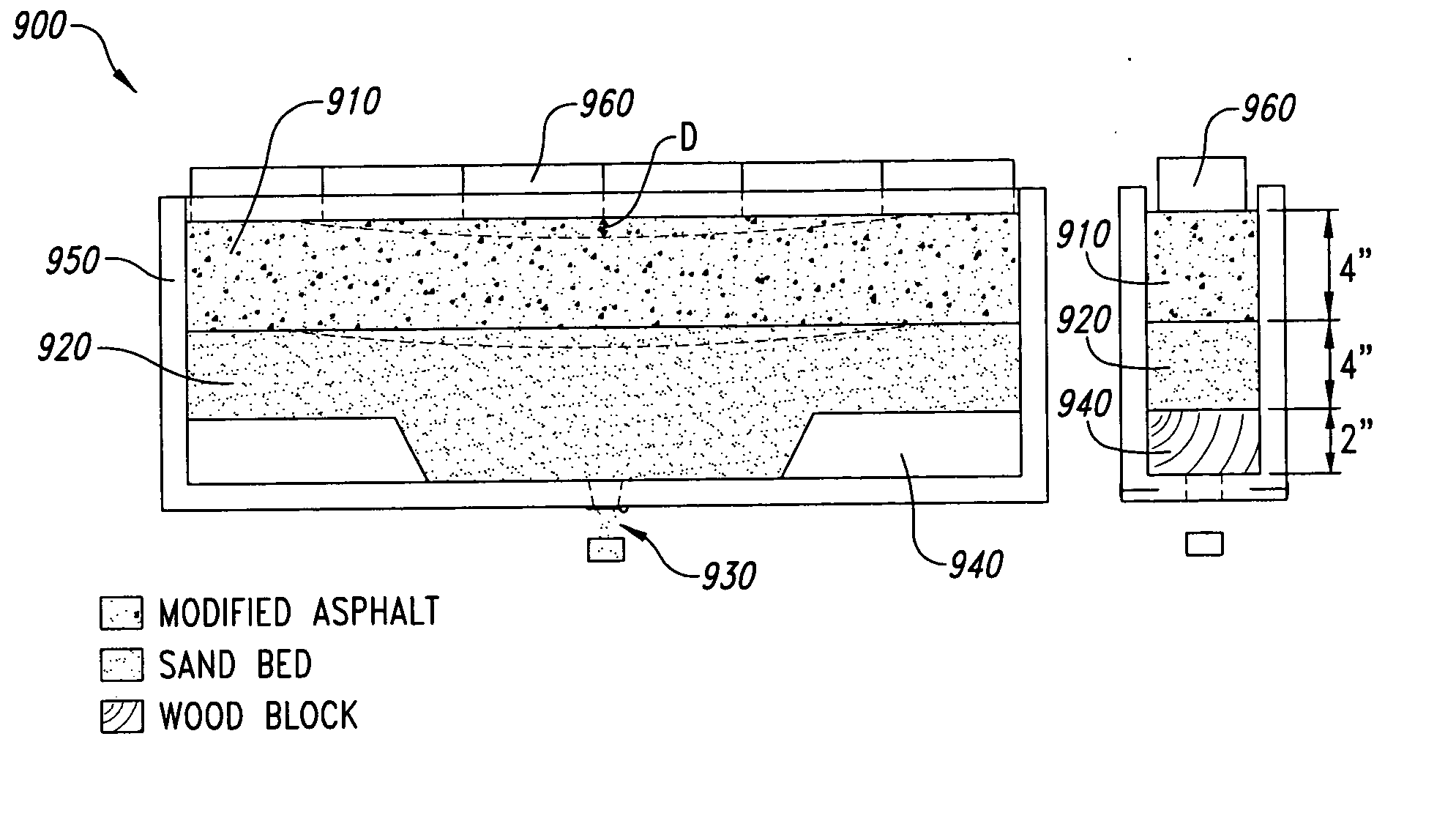

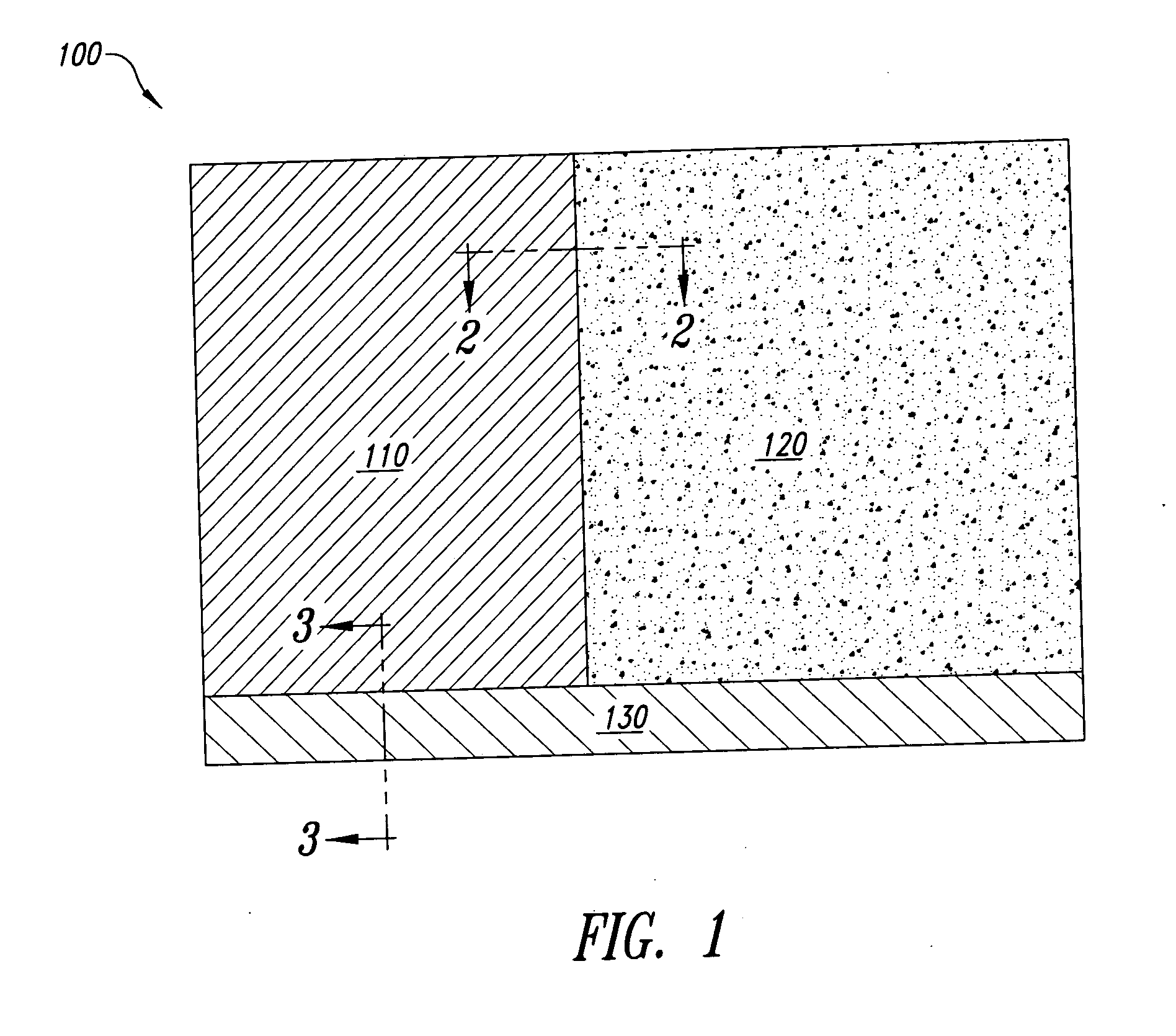

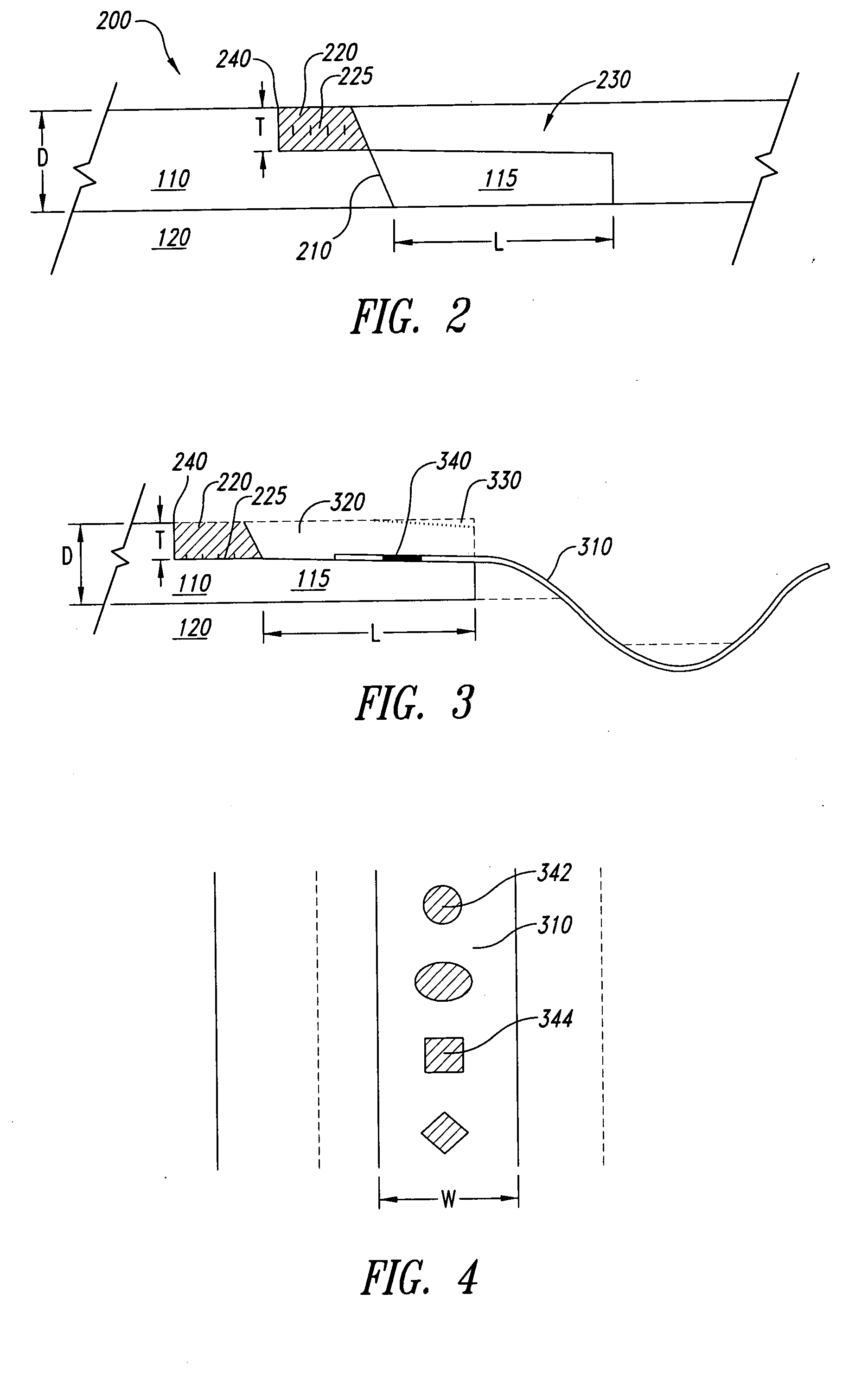

Method and system for containment, such as a containment cap for solid waste constructed of modified asphalt

InactiveUS20050191132A1Longevity easeEasy maintenanceSolid waste disposalLandfill technologiesSuperfund siteSuperfund

The present invention is directed to a waste or environmental containment system that includes modified asphalt specifically designed for containment, and a system of installation that provides a seamless cap over the area to be contained. The modified asphalt of the present invention has a permeability less than 1×10−8 cm / sec and an air void content less than 3 percent. The system of installation includes joint designs that meet the same parameters as the modified asphalt mat to provide a seamless containment cap or liner to contain hazardous wastes at RCRA, Superfund sites, waste sites and environmental containment areas.

Owner:MATCON

Impermeable materials for coating or sealing of garbage hygiene fills

InactiveCN1827728ARich sourcesRich materialOther chemical processesSolid waste disposalCrushed stoneEmission standard

An impervious material used for covering or closing in landfill waste site consists of a main material and an additive of 5-25 % of the total weight, and the additive is characterized in that it is of strong self-hydroscopicity and good glutinosity and can swell when encountered water, in which: (1) the main material is sand, or earth, or crushed gravel-soil; (2) the additive is natural nanomaterial, the water absorption is 3-8 times of self-weight and the acid-swellable is 3-20 times of self-volume. The invention has advantages such as low cost and simple process, can effectively prevent the rain from infiltrating the waste to change to bleeder solution with no more than 1.0X10-7 cm per minute of seepage control coefficient, can evidently reduce the operation cost and strengthen integrated hermeticitycan, can reduce the odour intensity, orderly collect and use the marsh gas, extend the anaerobic process and time of disposing wastes, improve the methane output and bleeder solution biochemistry, then make the bleeder solution continuously and stably discharge according to an emission standard.

Owner:卫永法

Cover system for waste sites

A cover system is provided for waste sites and environmental closures, in which the cover system comprises a synthetic grass and an impermeable geomembrane that can be applied without the use of heavy earthwork equipment as temporary or final cover to control odors, erosion, gas migration and contaminate migration. The invention allows installation on very steep slopes and does not require the use of an extensive anchoring system to resist wind uplift or slope failure.

Owner:WATERSHED GEOSYNTHETICS ELELSI

System for use of land fills and recyclable materials

Gases are vented from a waste site such as a landfill, and the gases are separated into at least three streams comprising a hydrocarbon stream, a carbon dioxide stream, and residue stream. At least a portion of the carbon dioxide stream and hydrocarbon stream are liquefied or converted to a supercritical liquid. At least some of the carbon dioxide gas stream (as a liquid or supercritical fluid) is used in a cleaning step, preferably a polymer cleaning step, and more preferably a polymer cleaning step in a polymer recycling process, and most preferably in a polymer cleaning step in a polymer recycling system where the cleaning is performed on-site at the waste site.

Owner:COOL CLEAN TECH

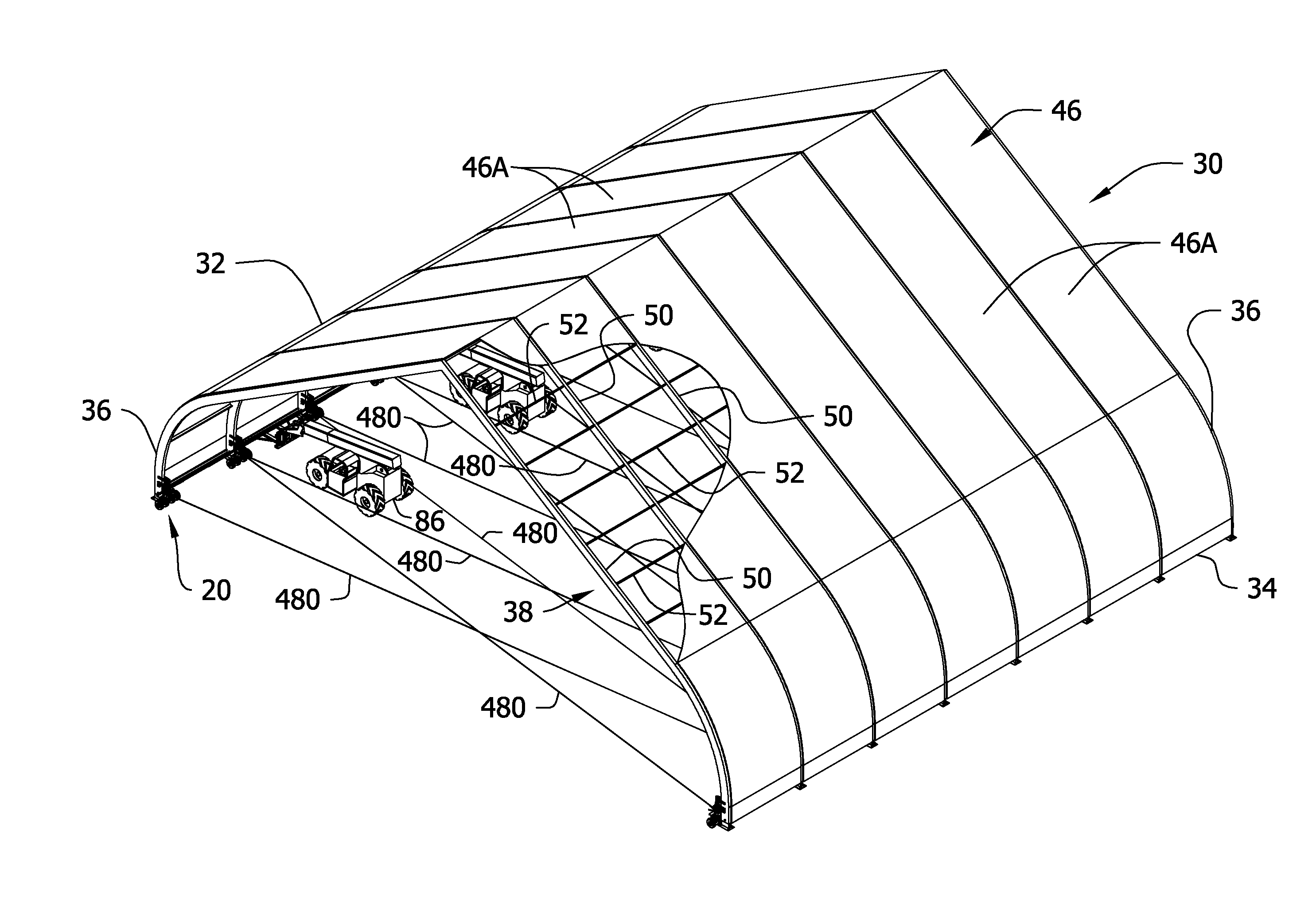

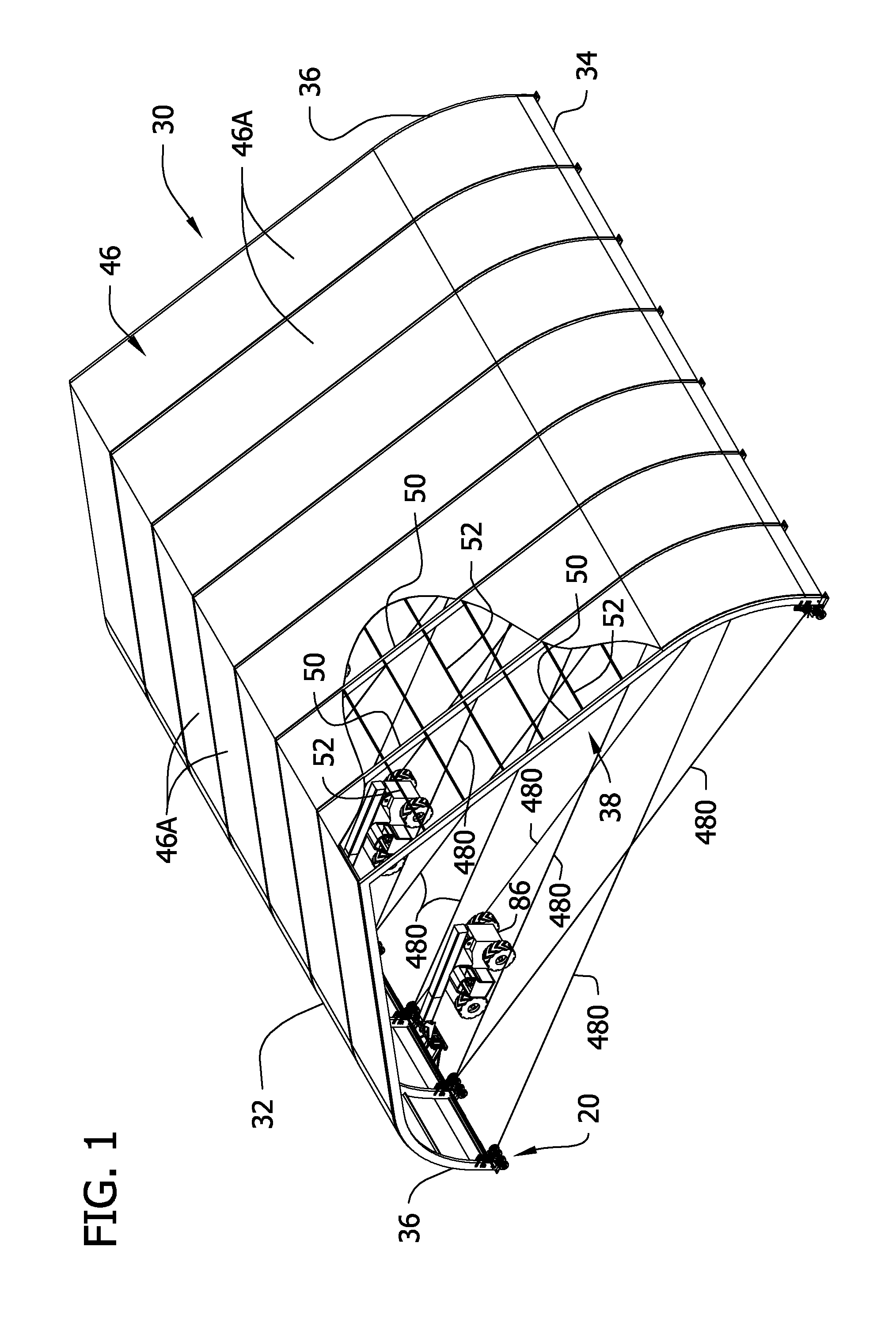

Method of remediating a contaminated waste site

A method and system for moving a large temporary building from a first location to a second location, while the building remains erect, are disclosed. The invention is particularly suited for moving such a building during the remediation of a contaminated waste site.

Owner:AMEREN CORP

Cover system with gas collection system for waste sites and environmental closures

ActiveUS20100272516A1Eliminates orReduce wasteSolid waste disposalLandfill technologiesFinal coverGeomembrane

A cover system is provided for waste sites and environmental closures, in which the cover system comprises a synthetic grass and an impermeable geomembrane that can be applied without the use of heavy earthwork equipment as temporary or final cover to control odors, erosion, gas migration and contaminate migration. The invention allows installation on very steep slopes and does not require the use of an extensive anchoring system to resist wind uplift or slope failure. A gas collection system is located under the cover system for the collection of gas produced by the waste sites.

Owner:WATERSHED GEOSYNTHETICS

Preprocessing method for percolate of domestic garbage landfill

InactiveCN101306893ALess quantitySimple processMultistage water/sewage treatmentAmmonium sulfatesPretreatment methodSludge

The invention belongs to wastewater treatment and relates to a method for pretreating percolate in a landfill waste site. The method selects CaO, Ca(OH)2 or Ca(OH)2 water solution as flocculent sedimentation agent, uses air to blow out ammonia nitrogen in the flocculent sedimentation agent, and then uses sulfuric acid solution to absorb the blown ammonia nitrogen so as to obtain a byproduct-ammonium sulphate. The method not only can perform flocculent deposit but also can separate out ammonia nitrogen and COD, is simple and easy, has low out-of-pocket cost, can obviously reduce the chemical sludge content and the salt content in chemical sludge, and can change separated ammonia nitrogen into resource. The percolate after pretreatment can create a very favorable condition and lay a foundation for further purification treatment and final emission compliance.

Owner:白德贵

Method of using slash pine containerized seedlings to directly renovate metallic mineral waste yard

ActiveCN106718607APromote growthImprove survival rateBioloigcal waste fertilisersGrowth substratesYardPlantlet

A method of using slash pine containerized seedlings to directly renovate a metallic mineral waste yard comprises: (1), germinating slash pine seeds in seedling pots; (2) managing plantlets; (3) transplanting to degradable nonwoven container bags; (4) managing containerized seedlings; (5) preparing a mine mineral waste slope; (6) transplanting. The survival rate of slash pine seedlings grown with slash pine containerized seedling is high, the slash pine seedlings may be transplanted to the mine mineral waste yard to ecologically renovate the waste mine, the need of slash pine seedlings for growth nutrition can be met, the survival rate of slash pine in mineral waste is also increased, and site basis is provided for improving soil matrix of mine mineral waste yard in later stage and field planting of other renovating plants; the method of using slash pine containerized seedlings to directly renovate the metallic mineral waste yard provides a solution to the need of slash pine for growing on mine mineral waste sites.

Owner:INST OF BIOLOGICAL RESOURCES JIANGXI ACAD OF SCI

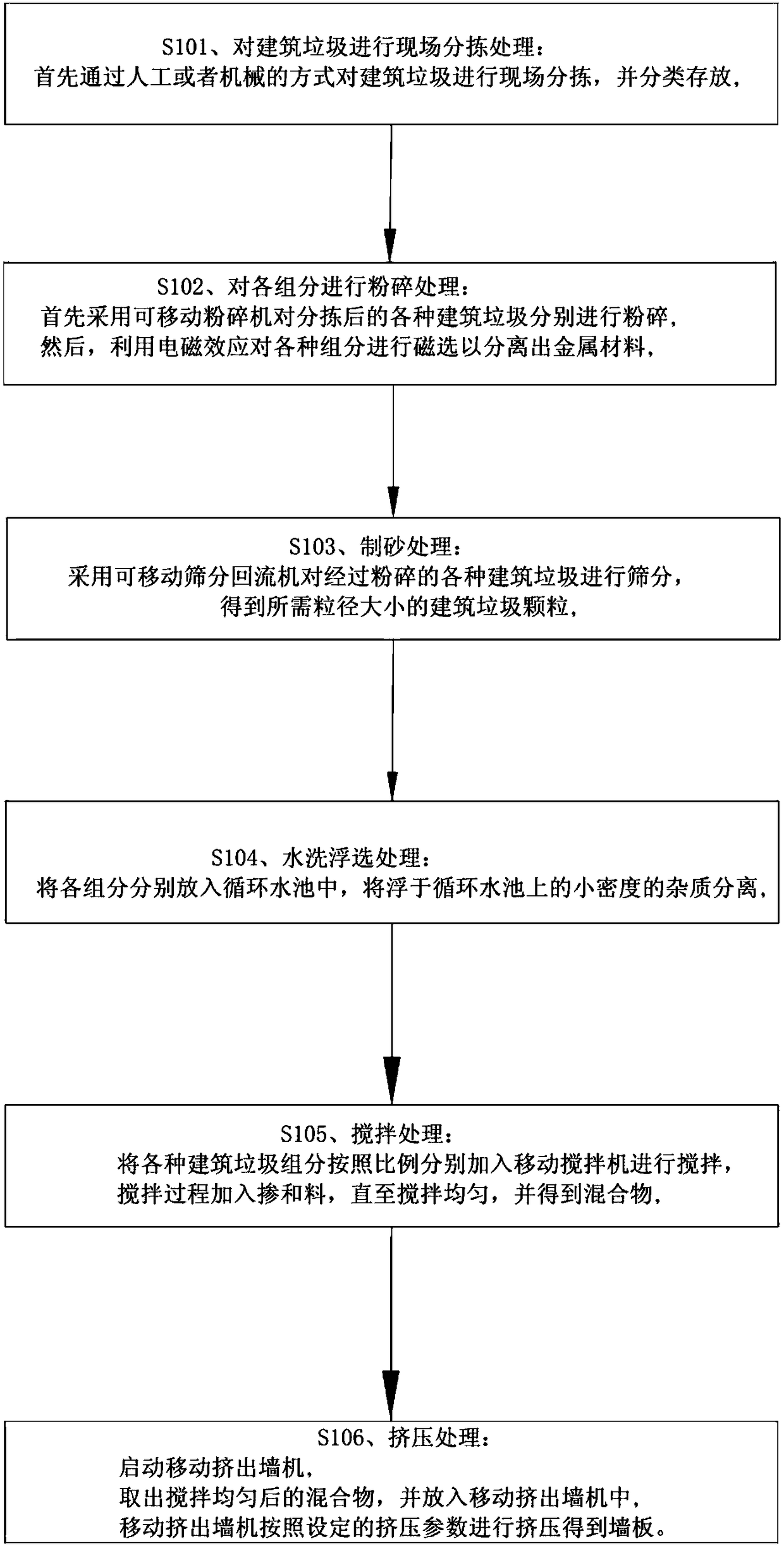

One-stop integrated process for making wallboards on site by using construction waste as raw materials and wallboard

InactiveCN108995018AReduce cleaning and transportation linksImprove utilization conversion rateAuxillary shaping apparatusEngineeringWaste site

The invention discloses an one-stop integrated process for making wallboards on site by using construction waste as raw materials and a wallboard. The process can be used for making the wallboards atconstruction waste sites. Board materials of the wallboard include the construction waste and admixture. The production process includes the following steps: S101, performing on-site sorting treatmenton the construction waste; S102, performing pulverizing treatment on components; S103, performing sand making treatment; S104, performing washing and select flotation treatment; S105, performing stirring treatment; and S106, performing extrusion treatment: namely a step of starting a mobile extrusion wall machine, taking out a uniformly-stirred mixture and placing the mixture in the mobile extrusion wall machine, and performing extrusion by the mobile extrusion wall machine according to a setting extrusion parameter to obtain the wallboard. Through the technical scheme, rapid extrusion molding of board materials of the wallboard based on the construction waste is achieved, automatic production can be ensured, resources are saved, the production efficiency is improved, and the cost is reduced; at the same time, production can be performed on the construction waste site, land is saved, and the transportation cost is reduced.

Owner:深圳市元亨环保产业新技术有限公司

Bacteriostasis composition for garbage burying field and preparation thereof

InactiveCN101268785AReduce usageGrowth inhibitionBiocideSolid waste disposalSocial benefitsMicroorganism

The invention discloses an antimicrobial compound used in a landfill waste site and a preparation method thereof. The antimicrobial compound includes the components and contents that the sum of a microzyme colony is 1 to 3*10<3>cfu / ml; the sum of a lactobacillus colony is 2 to 4*10<5>cfu / ml; the sum of a Bacillus subtilis colony is 1 to 3*10<3>cfu / ml. The antimicrobial compound used in the landfill waste site of the invention is innoxious and uninjurious, can effectively restrain the growing of flies in garbage and the propagation of spoilage organisms, and has obvious social benefit.

Owner:戴志南

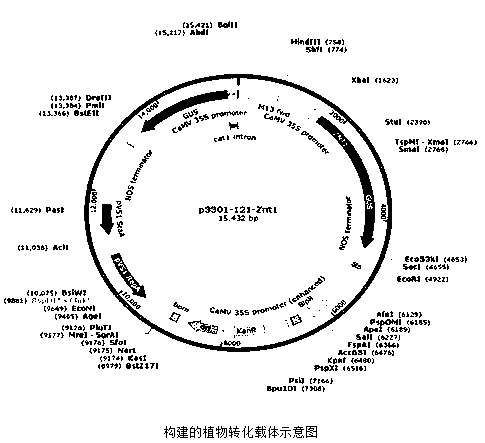

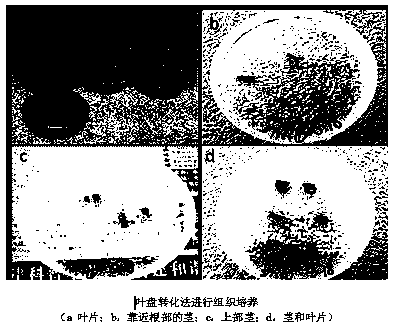

Plant repair method of applying transgenetic plant composite system to polluted soil

ActiveCN110283845AStrong resistanceLarge biomassContaminated soil reclamationGenetic engineeringGenetically engineeredCadmium Cation

The invention discloses a plant repair method of applying a transgenetic plant composite system to polluted soil. A transgenetic plant is obtained by steps of construction of a plant transformation vector, plant genetic transformation and the like. The transgenetic plant can be used for plant repair of heavy metal polluted soil and water bodies. The transgenetic plant shows a hyperaccumulating characteristic and resistance to different heavy metals such as lead and cadmium, can be widely applied to repairing heavy metal polluted soil, and has efficient repair efficiency to the polluted soil. The plant repair method can be used to polluted soil caused by mining, soil pollution of surrounding earth piles, and polluted soil of a waste site of an electroplate factory and the periphery, for example, various composite metal polluted soil such as Cd, Cr, Cu, Pb, Z and Ni. The plant repair method has the multiple advantages of being high in adaptability, environmentally friendly and the like in repair of composite polluted soil, and has a wide application prospect.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Method and system for moving a large temporary building

A method and system for moving a large temporary building from a first location to a second location, while the building remains erect, are disclosed. The invention is particularly suited for moving such a building during the remediation of a contaminated waste site.

Owner:AMEREN CORP

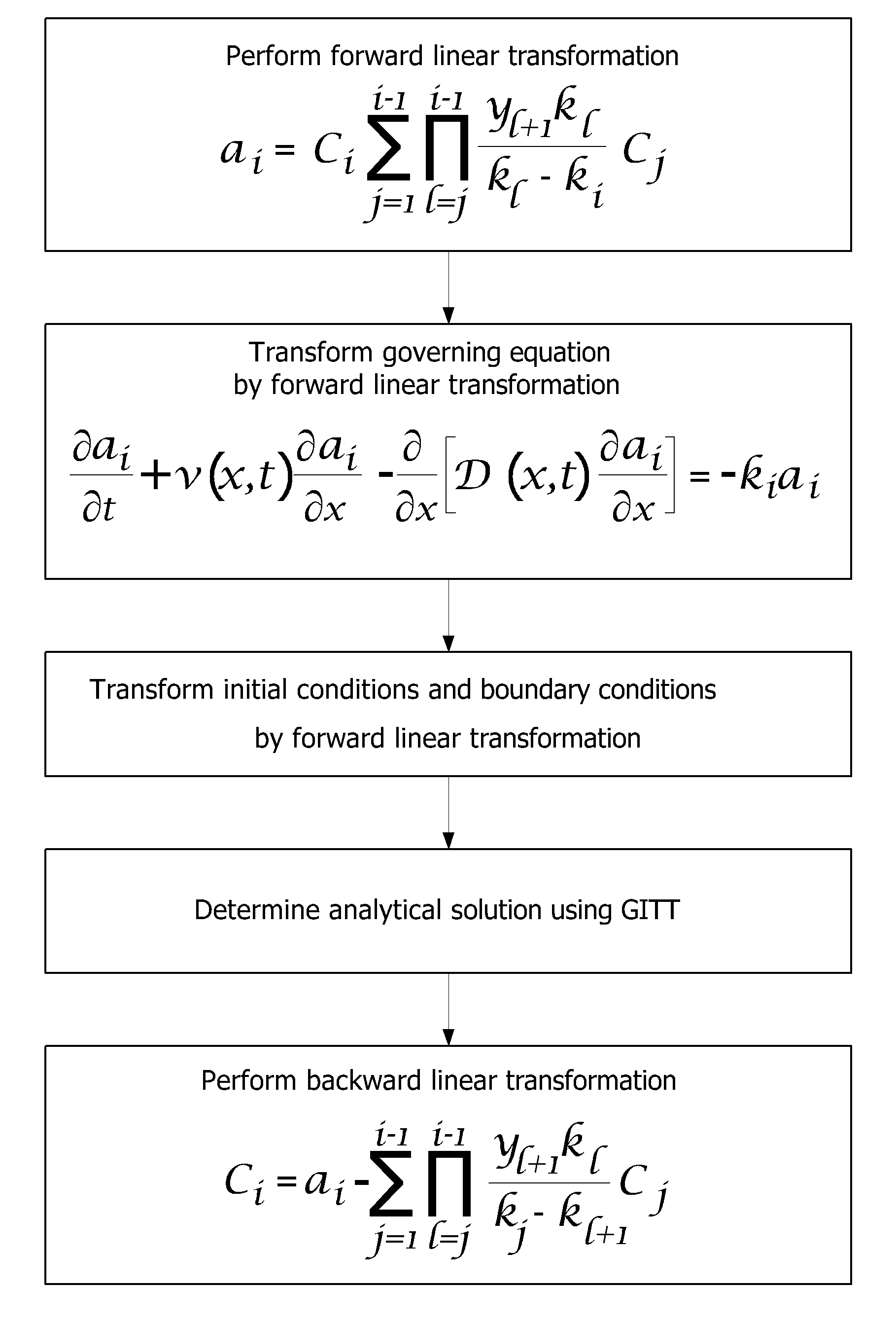

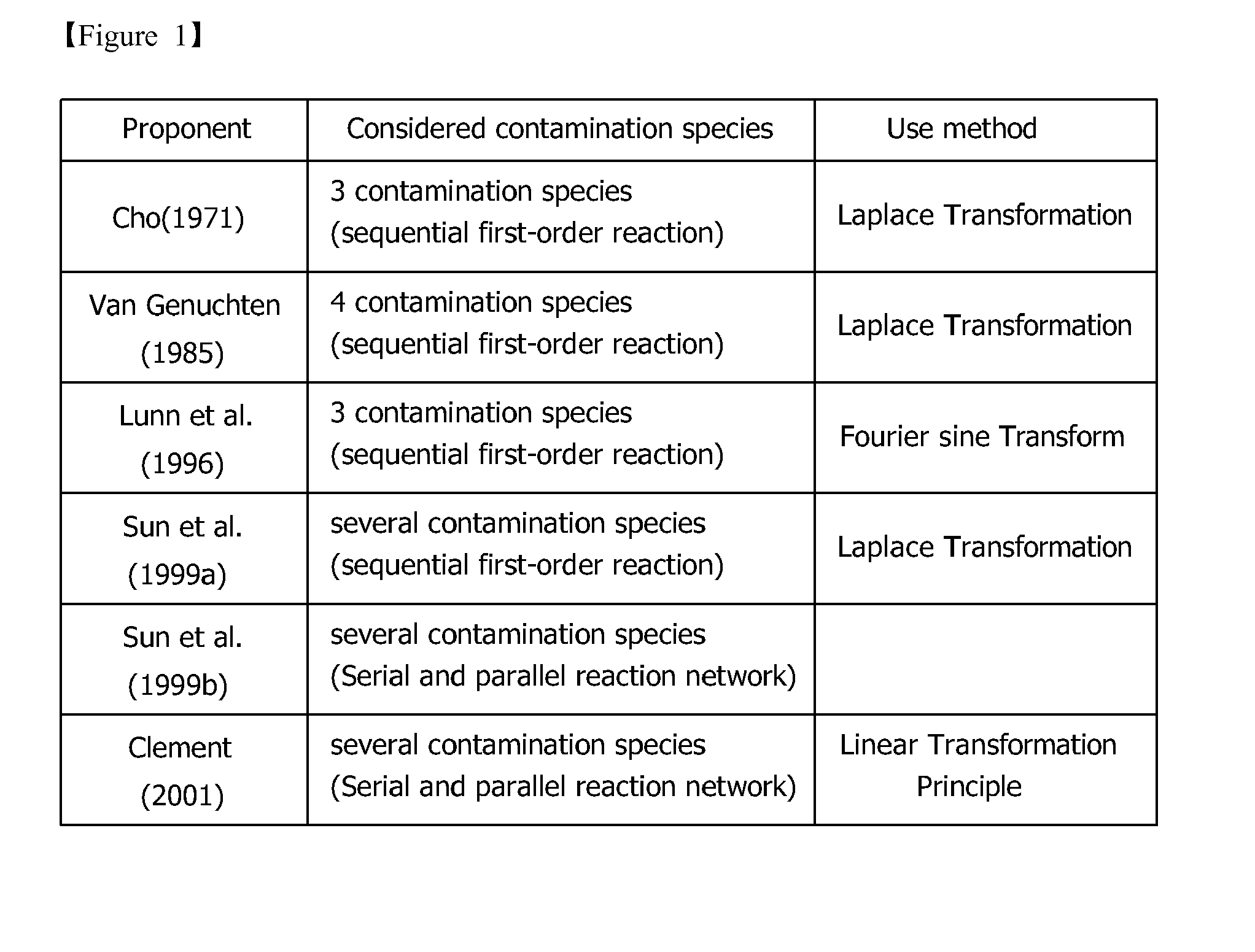

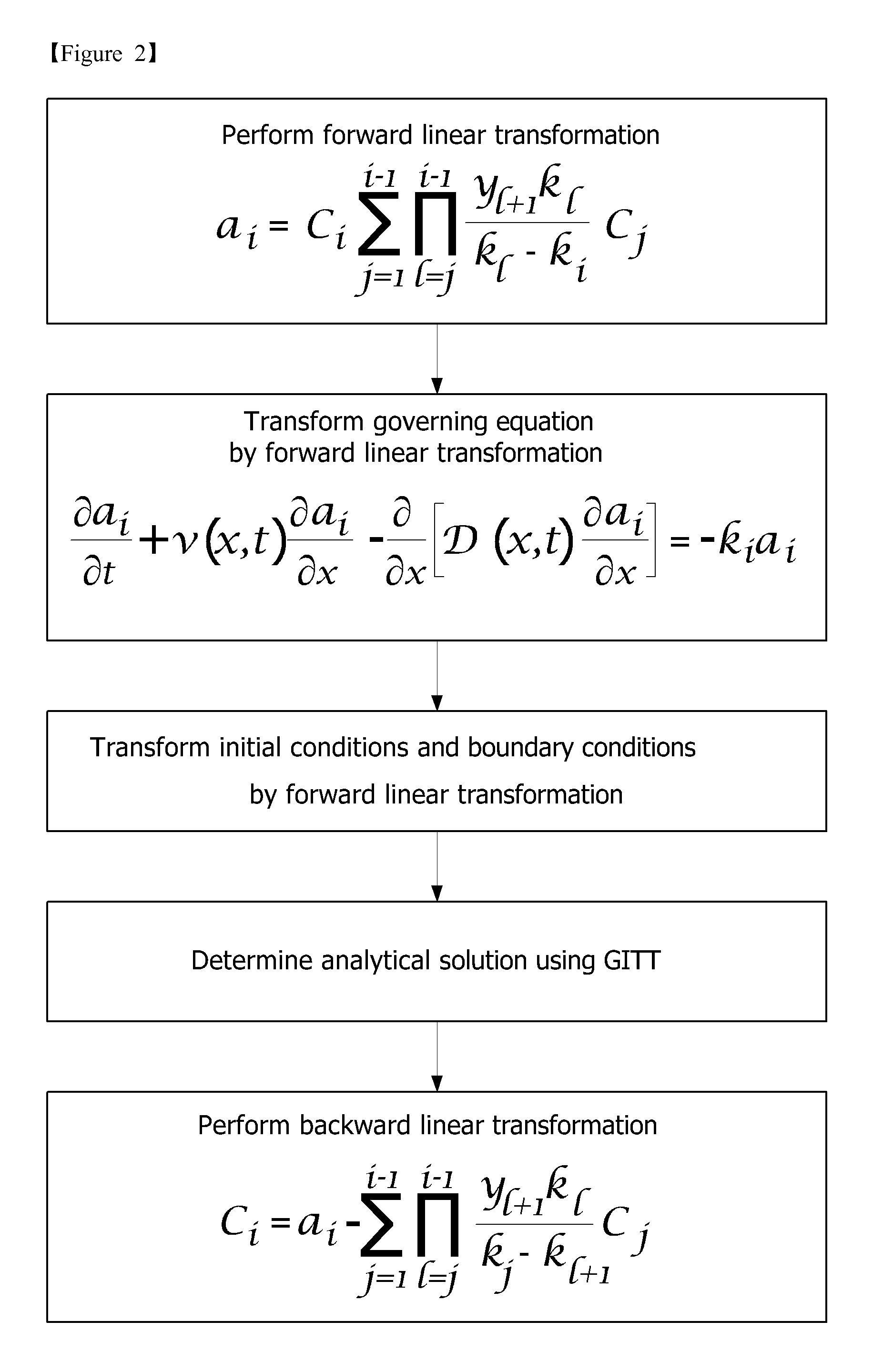

Method of seeking semianalytical solutions to multispecies transport equations coupled with sequential first-order reactions

Disclosed is a method of seeking semianalytical solutions to multispecies transport equations coupled with sequential first-order network reactions under conditions wherein a groundwater flow velocity and a dispersion coefficient vary spatially and temporally and boundary conditions vary temporally. This invention provides a method of seeking semianalytical solutions to dechlorination equations coupled with sequential first-order reactions, wherein analytical solutions to complex problems such as inhomogeneous media and unsteady flow are derived by combining a similarity transformation method of Clement and a generalized integral-transform technique (GITT), and are verified through comparison with 2DFATMIC which is a commercial numerical program, and thereby can be utilized in nuclear waste sites contaminated with radioactive materials and decayed daughter nuclides and industrial complexes contaminated with chlorinated organic solvents such as PCE (tetrachloroethene), TCE (trichloroethene) and biodegradable byproducts thereof, and can also be widely used in verification of developed numerical programs.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com