Automatic spraying defoaming device for waste leachate treatment

A technology of garbage leachate and automatic spraying, which is applied in the direction of aerobic process treatment, sustainable biological treatment, water/sewage multi-stage treatment, etc., to achieve the effect of saving sewage treatment costs, saving electric energy, and solving scaling and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] After the domestic garbage in the large-scale garbage disposal site is piled up and rotted, the rancid leachate must undergo repeated multi-tank oxidation treatment in biochemical reaction tanks. The multi-stage biochemical reaction tanks in this site are gradually changed from sewage to clean water suitable for discharge. The composition of the leachate is complex and needs to be aerated and oxidized repeatedly. Due to the oxygenation by the blast, the organic components and air bubbles in the sewage in the biochemical reaction tank form a turbulent foam flow, which continuously surges to the water surface with the blast time, and it will rise if you are not careful. A few meters above the sewage surface, the overflow of the biochemical reaction tank causes the sewage foam to overflow, and the putrid smell fills the air, especially in the rainy season, which seriously pollutes the ground and air.

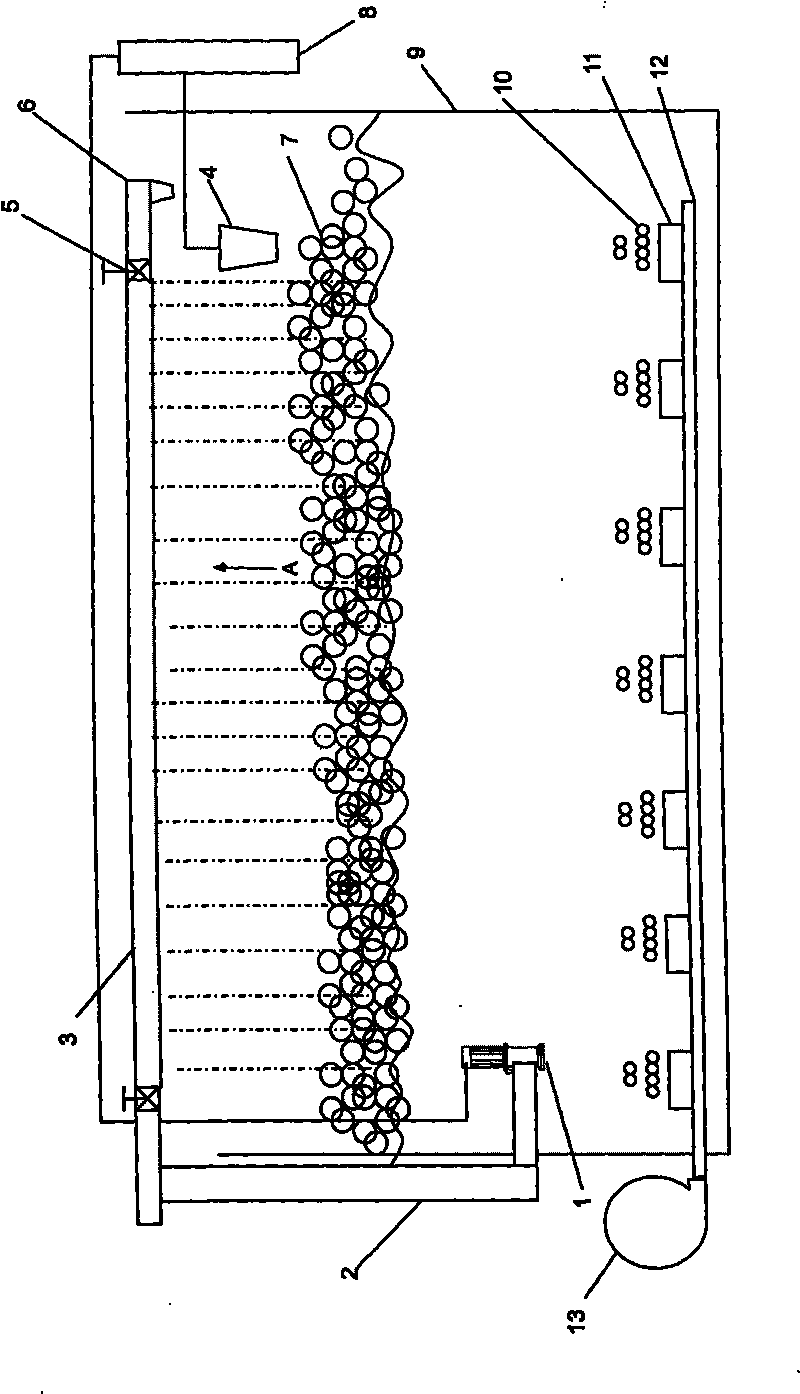

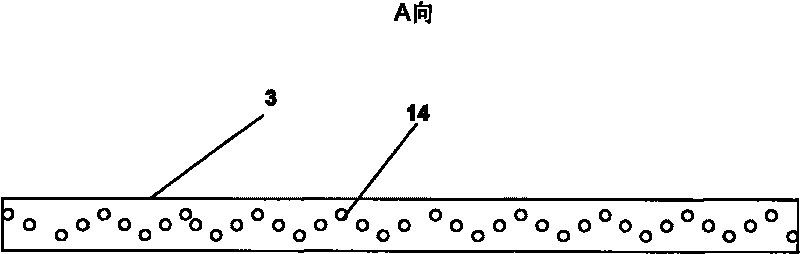

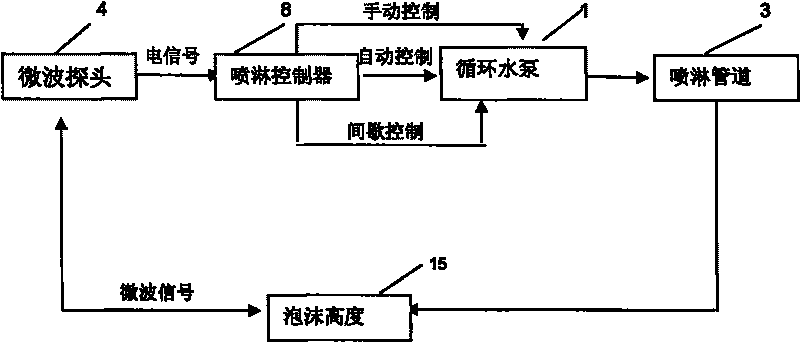

[0014] see figure 1 As shown, the leachate behind the domestic garbage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com