Process method for treating precipitated white carbon black wastewater

A technology of precipitated white carbon black and process method, which is applied in the field of treating precipitated white carbon black wastewater, and can solve the problems of expensive treatment cost, high requirements for treatment equipment, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

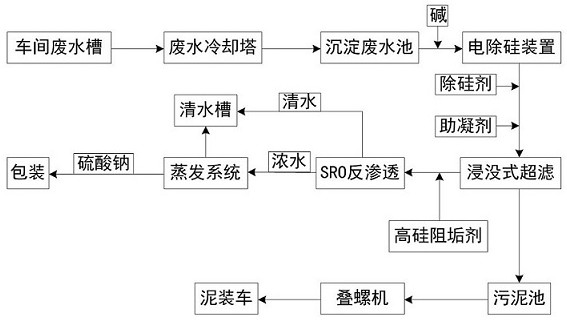

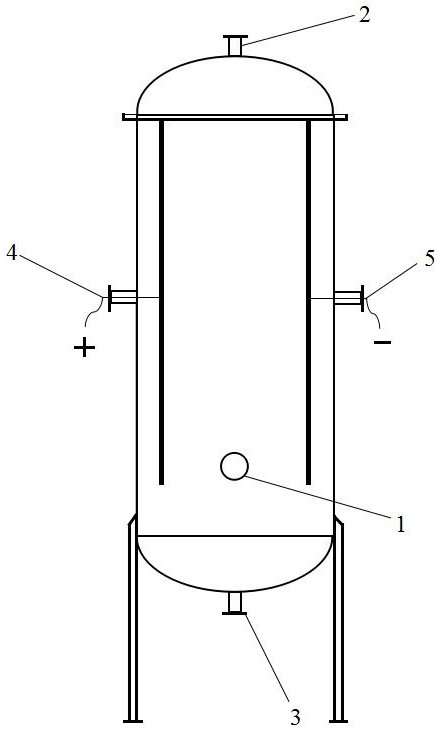

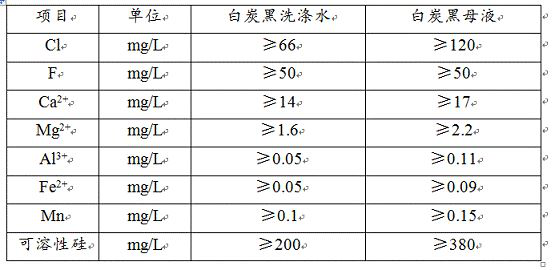

[0057] The precipitated silica wastewater from the workshop wastewater tank is cooled through the wastewater cooling tower, and the cooled wastewater is sent to the sedimentation wastewater tank for natural settlement. The desiliconization device performs electrolytic desiliconization treatment. Add a small amount of desiliconization agent, coagulation aid and reducing agent after electrolytic desiliconization, conduct ultrafiltration treatment through submerged ultrafiltration membrane modules, and perform reverse osmosis through SRO reverse osmosis system after adding high silicon scale inhibitor in ultrafiltration treated water Processing, get "clear water" and "concentrated water". The "concentrated water" is sent to the evaporation system for evaporation treatment to obtain anhydrous sodium sulfate. Send the evaporation condensate of the evaporation system and the above-mentioned "clear water" to the clean water tank for the use of the white carbon black production syste...

Embodiment 2

[0061] The precipitated silica wastewater from the workshop wastewater tank is cooled through the wastewater cooling tower, and the cooled wastewater is sent to the sedimentation wastewater tank for natural settlement, and a large amount of silicon removal agent, coagulation aid and reducing agent are added for chemical removal. Silicon, after chemical desiliconization, conduct ultrafiltration treatment through submerged ultrafiltration membrane modules, add high-silicon scale inhibitors to ultrafiltration treated water, and then conduct reverse osmosis treatment through SRO reverse osmosis system to obtain "clear water" and "concentrated water" . The "concentrated water" is sent to the evaporation system for evaporation treatment to obtain anhydrous sodium sulfate. Send the evaporation condensate of the evaporation system and the above-mentioned "clear water" to the clean water tank for the use of the white carbon black production system. Wherein the amount of each chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com