Wet phosphoric acid production system and wet phosphoric acid production method

A wet-process phosphoric acid and production system technology, applied in the chemical industry, can solve the problems of fouling and clogging of filters and related pipelines, and achieve the effects of reducing the labor intensity of cleaning, saving maintenance costs, and reducing the number of cleanings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

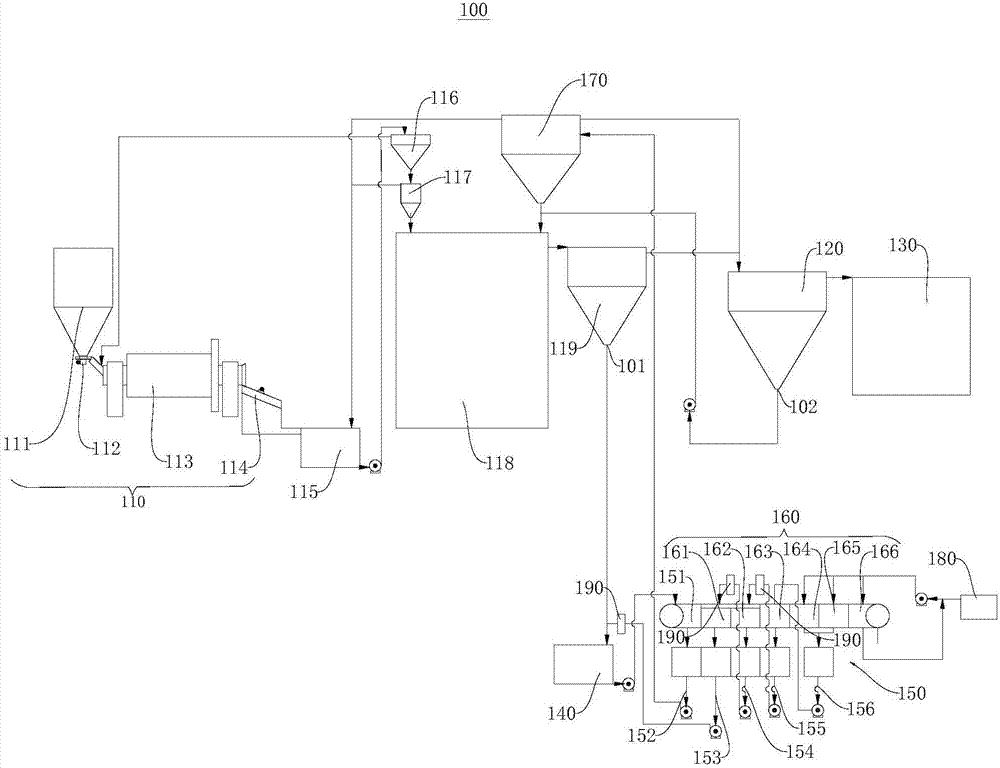

[0031] Please refer to figure 1 , this embodiment provides a wet-process phosphoric acid production system 100 . The wet-process phosphoric acid production system 100 includes mineral material conveying equipment 110, a pulp storage tank 115, a pulp thickening tank 116, a pulp high level tank 117, an extraction tank 118, a slurry thickening tank 119, a phosphoric acid clarification tank 120, a phosphoric acid storage tank 130, a Slurry dilution tank 140, filter cleaning equipment 150 and return acid thickening tank 170.

[0032]Specifically, the discharge port of the mineral material conveying equipment 110 is connected to the feed port of the pulp storage tank 115, the discharge port of the pulp storage tank 115 is connected to the feed port of the pulp thick tank 116, and the discharge port of the pulp thick tank 116 Connected to the feed port of the slurry header tank 117, the discharge port of the slurry header tank 117 is connected to the feed port of the extraction tank...

no. 2 example

[0061] This embodiment provides a method for producing wet-process phosphoric acid. Phosphoric acid is produced using the wet-process phosphoric acid production system 100 in the first embodiment.

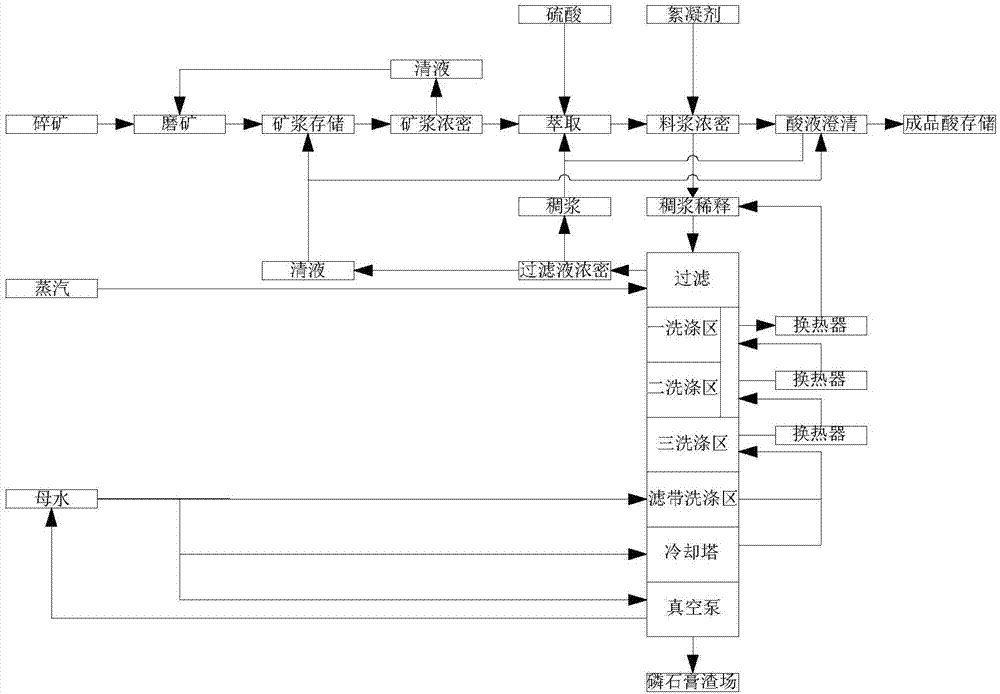

[0062] Please refer to the specific process flow chart figure 2 Firstly, the mineral material enters the slurry storage tank 115 after being crushed and ball milled and screened. Then it is transported to the extraction tank 118 through the pulp thickening tank 116 and the high level tank 117 of the pulp, and then through the slurry thickening tank 119, and a part of the clear liquid is transported to the phosphoric acid storage tank 130 through the phosphoric acid clarification tank 120; the remaining thick pulp is transported through the thick pulp dilution tank 140 After being filtered and cleaned by the filter cleaning equipment 150, it is sent back to the acid thickening tank 170 for recycling again. In the whole production method, the filtration and cleaning equipment 150 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com