Synchronous calcium-magnesium-silicon removal pretreatment device of coal chemical industry wastewater and application method

A coal chemical wastewater and pretreatment device technology, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problem of lack of synchronous, efficient and mature methods, affecting the recycling of coal gasification wastewater, process equipment and pipeline scaling, to achieve enhanced coagulation and clarification effects, simple structure, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

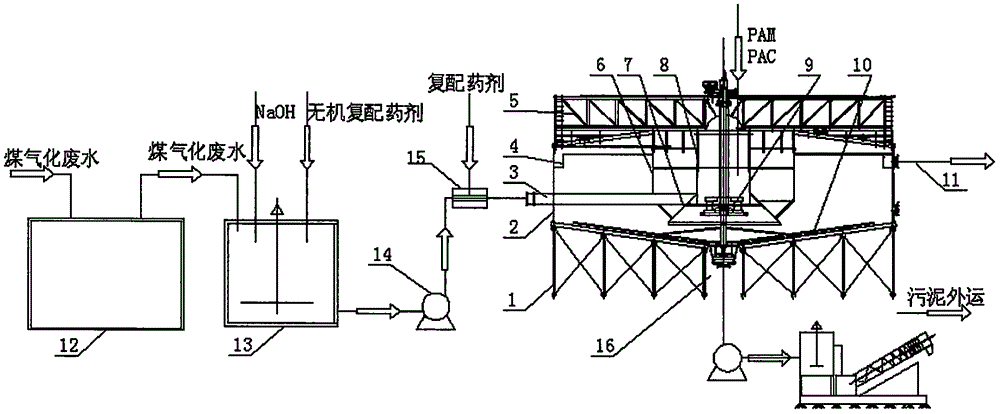

[0027] Such as figure 1 As shown, the synchronous decalcification, magnesium and silicon pretreatment device for coal chemical wastewater includes: a wastewater collection tank 12 , a primary reaction tank 13 and an integrated clarifier 16 .

[0028] The waste water collection pool 12 receives the coal chemical wastewater, and is connected to the primary reaction tank 13 through the pipeline; the coal chemical wastewater passes through the primary reaction tank 13, passes through the pump 14, passes through the liquid medicine mixer 15, and then enters the integrated clarifier 16;

[0029] The integrated clarifier 16 includes: clarifier support 1, clarifier tank body 2, scraper rake support 5, mud scraper 10, guide tube 6, reflection distribution device 7, secondary reaction chamber 8, sludge lifting and stirring device 9. Sewage inlet 3. Sewage outlet 11. Outlet weir 4. Sludge outlet. The clarifier bracket 1 supports the clarifier tank body 2; the sewage inlet 3 and the sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com