Battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and preparation method of filter material

A wet non-woven, membrane filtration technology, applied in the field of textile and electrochemistry, can solve the problems of inability to control the over-temperature closed-cell protection temperature, poor high-temperature corrosion resistance of the membrane, uneven pore size, etc., to improve the over-temperature closure. Pore protection, improved uniformity, uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

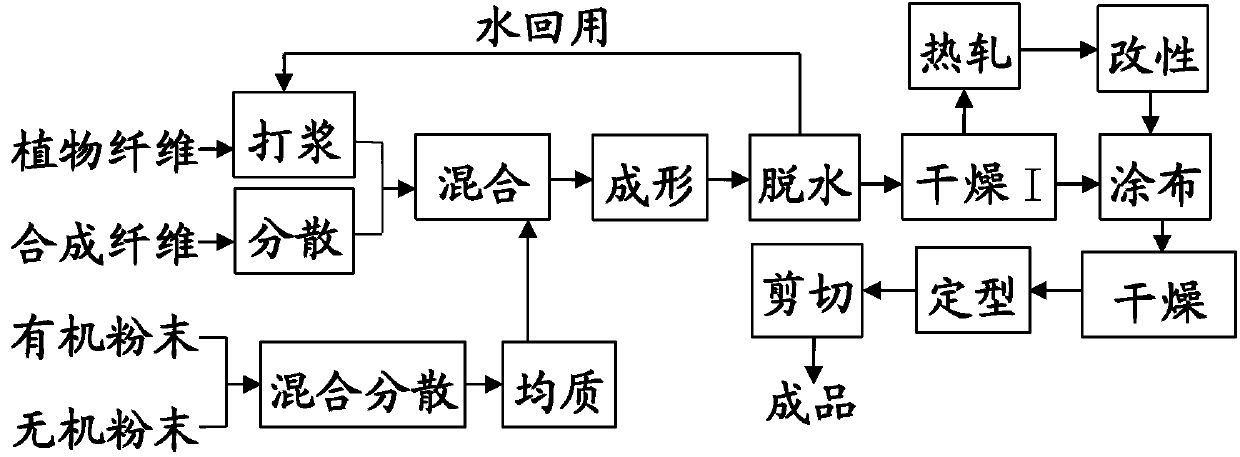

Method used

Image

Examples

Embodiment 1

[0042] (1) 2 kilograms of wood pulp fiber pulp and water are beaten and dispersed by a commercially available beater at a concentration of 0.5%, for subsequent use;

[0043] (2) 98 kilograms of polyvinyl alcohol fibers and water are dispersed into a fiber suspension by a commercially available beater at a concentration of 2%;

[0044] (3) 25 kilograms of activated clay powder, 25 kilograms of silicon oxide powder and 3 kilograms of polyethylene powder are mixed with water into a 5% concentration suspension in proportion, and are mixed and homogenized with a homogeneous pump;

[0045] (4) Add wood pulp fiber slurry, polyvinyl alcohol fiber suspension and activated clay powder, silicon oxide powder and polyethylene powder suspension into a beater or a slurry mixing pump, and mix evenly;

[0046] (5) Use a rotary screen former to form a single layer on the net at a concentration of 0.1%;

[0047] (6) Adopt commercially available vacuum pump to absorb water and commercially avail...

Embodiment 2

[0054] (1) 2.5 kilograms of cotton pulp fiber pulp and water are beaten and dispersed by a commercially available beater at a concentration of 1%, for subsequent use;

[0055] (2) 62 kilograms of polypropylene fibers, 35.5 kilograms of polyvinyl alcohol fibers and water are dispersed into a fiber suspension by a commercially available beater at a concentration of 1%;

[0056] (3) 30 kilograms of potassium titanate powder, 20 kilograms of aluminum oxide powder and 4 kilograms of polypropylene powder are mixed with water in proportion to form a 4% concentration suspension, and homogeneously mixed with a homogenizing pump;

[0057] (4) Add cotton pulp fiber slurry, polypropylene fiber, polyvinyl alcohol fiber suspension, potassium titanate powder, aluminum oxide powder and polypropylene powder suspension into a beater or a pulp mixing pump, and mix evenly;

[0058] (5) Use a rotary screen former to form a single layer on the net at a concentration of 0.05%;

[0059] (6) Adopt co...

Embodiment 3

[0066] (1) 1.5 kilograms of wood pulp fiber pulp and water are beaten and dispersed by a commercially available beater at a concentration of 0.5%, for subsequent use;

[0067] (2) 70 kilograms of polyester fibers, 28.5 kilograms of polyvinyl alcohol fibers and water are dispersed into a fiber suspension by a commercially available beater at a concentration of 1%;

[0068] (3) 20 kilograms of potassium titanate powder, 25 kilograms of activated clay powder and water are mixed in proportion to form a 6% concentration suspension, and the homogeneous pump is used to mix and homogenize;

[0069] (4) Add wood pulp fiber slurry, polyester fiber, polyvinyl alcohol fiber suspension, potassium titanate powder, and activated clay powder suspension into a beater or a pulp mixing pump, and mix evenly;

[0070] (5) Double cylinder formers are used to form double-layer nets at a concentration of 0.06%;

[0071] (6) Adopt commercially available vacuum pump to absorb water and commercially av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com