Formaldehyde scavenging agent with oil solubility and preparation method

A formaldehyde scavenger, oil-soluble technology, applied in the field of oil-soluble formaldehyde scavengers, can solve problems such as poor breathing, long-term existence, poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0607] Now with regard to the preparation method of oil-soluble formaldehyde scavenger of the present invention, take industrialized production mode as example, carry out specific elaboration:

[0608] The oil-soluble formaldehyde scavenger is an oil-soluble compound synthesized from polyols, polybasic acids and / or fatty acids and compounds containing characteristic functional groups by the following preparation method.

[0609] (1) Mixing and stirring compounds containing characteristic functional groups, polyols, polyacids and / or fatty acids;

[0610]The amount of substance (equivalent to mole percentage) of hydroxyl group is 5~75% polyol, the amount of substance of carboxyl group and / or acid anhydride (equivalent to mole percentage content) is 0~49.9% polybasic acid, the substance of carboxyl group The amount (equivalent to mole percentage) of fatty acid is 0-63%, and the amount of ester group substance (equivalent to mole percentage) is 0.1-95% compound containing characte...

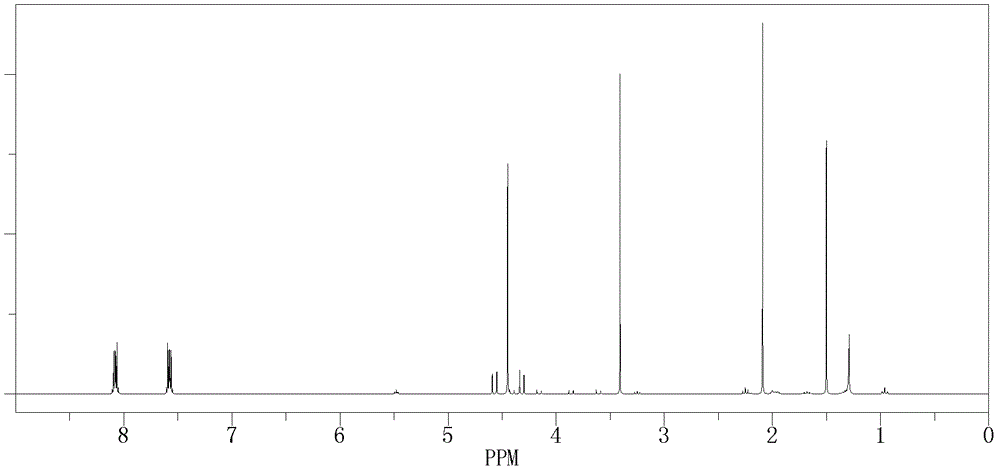

Embodiment 1

[0628] Put 55kg of castor oil, 38.4kg of glycerin, 74kg of phthalic anhydride, and 23.6kg of methyl acetoacetate into the reaction kettle together, stir, and heat up to 150°C within 1 hour, then raise the temperature to 180°C in 1 hour, and then heat up to 180°C in 1 hour. Raise the temperature to 185°C, maintain the temperature for the esterification reaction, and control the temperature not higher than 185°C during the reaction. After reacting for 1 hour, the temperature was raised to 235° C. After reacting for 1 hour, samples were taken to measure the acid value every half hour until the acid value was 6.2 mgKOH / g, and the reaction was stopped to obtain the oil-soluble formaldehyde scavenger A. The oil-soluble formaldehyde scavenger A is a transparent light yellow liquid with a hydroxyl value of 82 mgKOH / g.

[0629] Cool down to 180°C, add 50kg of xylene, dissolve the obtained oil-soluble formaldehyde scavenger A into a solution, filter and purify to obtain the oil-soluble ...

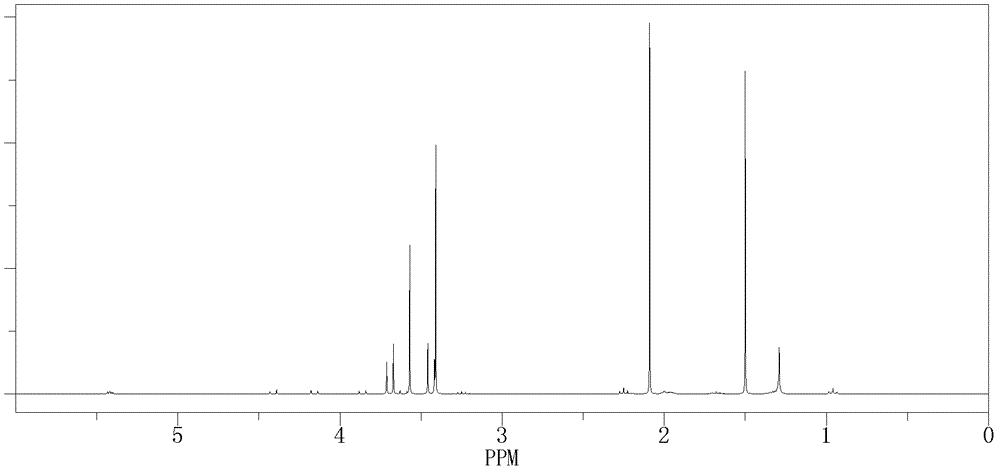

Embodiment 2

[0635] Put 55kg of castor oil, 38.4kg of glycerin, and 127.6kg of ethyl acetoacetate into the reaction kettle together, stir, and raise the temperature to 150°C within 1 hour, then raise the temperature to 180°C in 1 hour, and then raise the temperature to 185°C in 1 hour, keep The esterification reaction is carried out at this temperature, and the temperature is controlled not to be higher than 185° C. during the reaction. After reacting for 1 hour, the temperature was raised to 235°C. After reacting for 1 hour, samples were taken to measure the acid value every half hour until the acid value was 6.0 mgKOH / g, and the reaction was stopped to obtain the oil-soluble formaldehyde scavenger B. The oil-soluble formaldehyde scavenger B is a transparent light yellow liquid with a hydroxyl value of 116.5 mgKOH / g.

[0636] Cool down to 180°C, add 30kg of xylene, dissolve the obtained oil-soluble formaldehyde scavenger B into a solution, filter and purify to obtain the oil-soluble forma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com