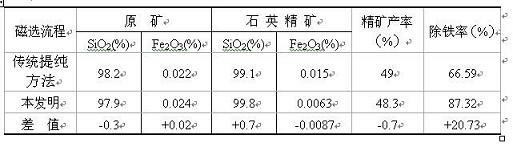

Efficient magnetic separation method for quartz sand

A quartz sand, high-efficiency technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of difficulty in obtaining obvious results in purification, poor production control, heavy workload of workers, etc., and achieve a friendly production environment , low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with embodiment.

[0025] A zero-emission and pollution-free high-efficiency purification method for quartz sand, the specific steps are as follows:

[0026] 1. Crushing - ore washing: The quartz ore is roughly broken by the jaw crusher to a block size of 5cm×5cm or less, and then enters the cone crusher to be finely crushed to a fine ore of about 1cm×1cm, and the fine ore is transported to the vibrating screen by a belt and use high-pressure water to wash the fine ore on the vibrating screen to remove impurities such as clay on the surface of the fine ore. The material under the screen is deslimed and concentrated by the No. 1 desliming hopper to obtain the first glass raw material that can be used as ordinary glass. By-products: quartz sand; the overflow of the No. 1 desilting hopper enters the thickening pool;

[0027] 2. Grinding - initial classification: send the washed fine ore to the rod m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com