Flushing system, sewage treatment system and method for flushing screen plate

A flushing system and flushing water technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as clogging of conical filter holes, achieve compact structure, and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

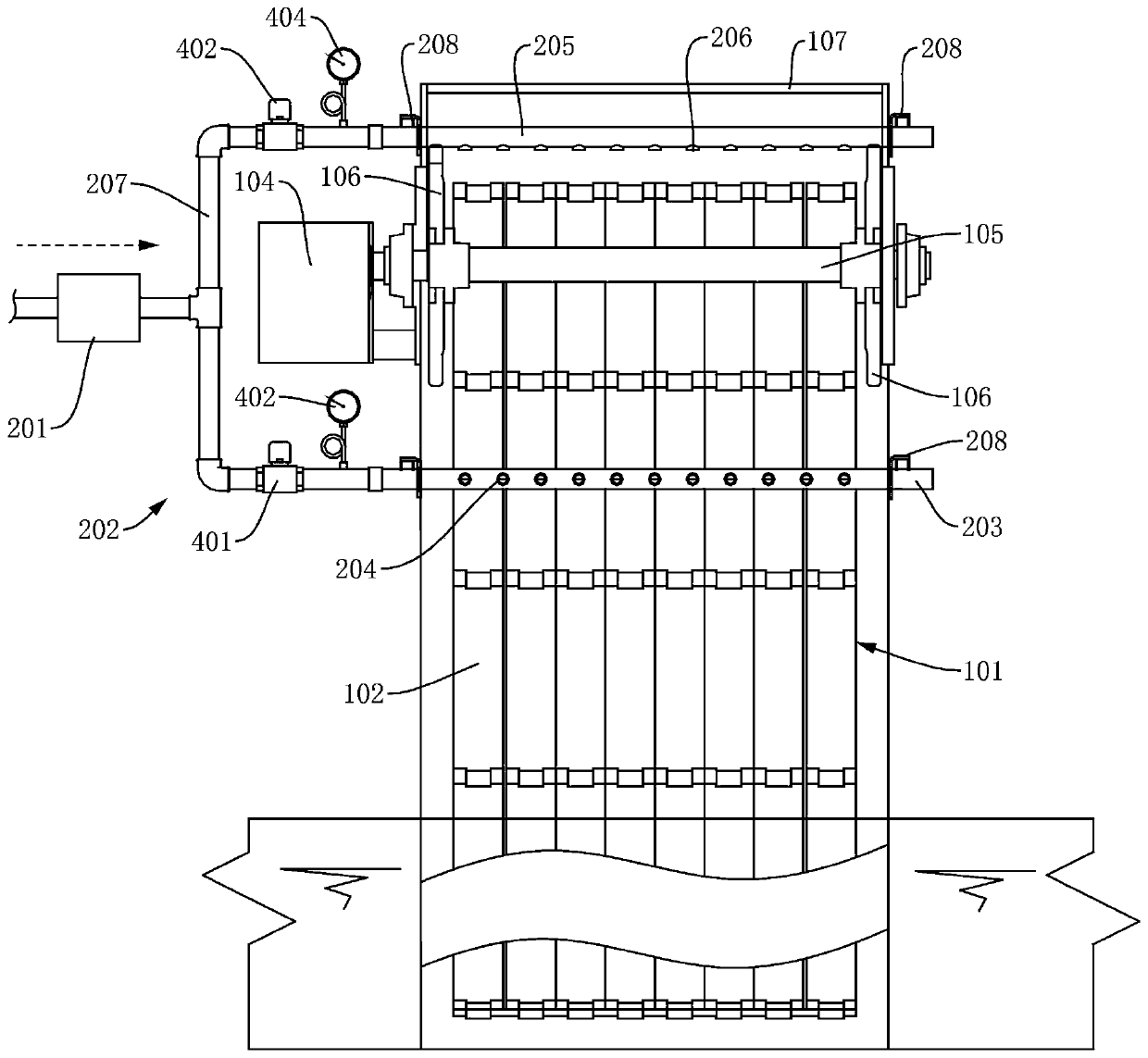

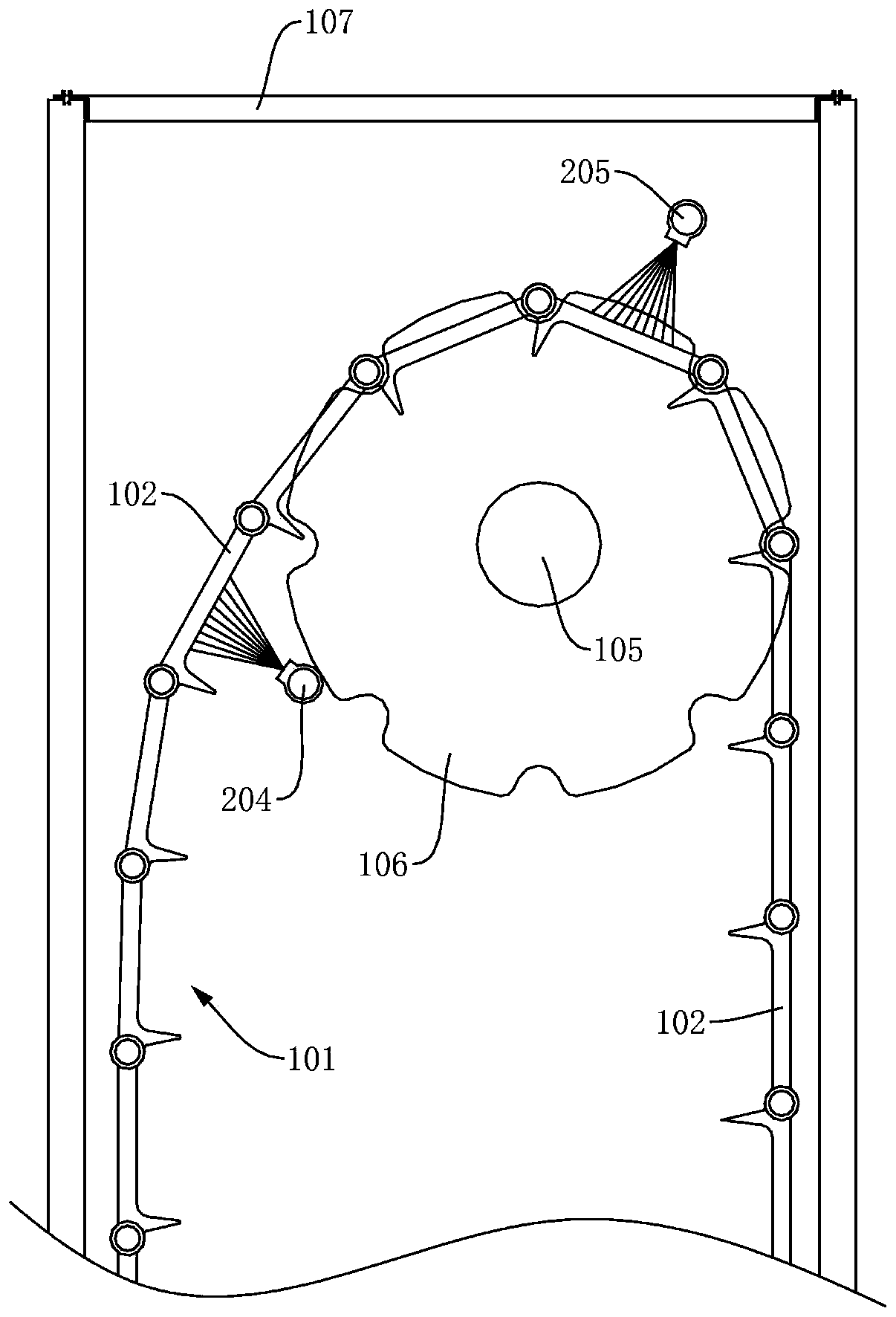

[0051] In the pretreatment stage of sewage treatment, the commonly used pretreatment equipment in the prior art is a grille device, such as an inflow orifice grille device. The existing grille device includes a ring formed by connecting several mesh plates 102 end to end Shaped screen mechanism 101, driving mechanism and frame 107 for supporting endless mesh mechanism 101 and driving mechanism, as an example, as figure 1 As shown, the driving mechanism includes a driving motor 104, a main shaft 105, and a sprocket 106 arranged on the main shaft 105. The main shaft 105 is installed on the upper part of the frame 107 and is connected with the driving motor 104. The upper end of the annular screen mechanism 101 Winding on the sprocket 106, the lower end extends into the sewage to be treated, the driving motor 104 drives the main shaft 105 to rotate, thereby bringing the ring-shaped screen mechanism 101 to rotate, so that the screen 102 in the ring-shaped screen mechanism 101 is co...

Embodiment 2

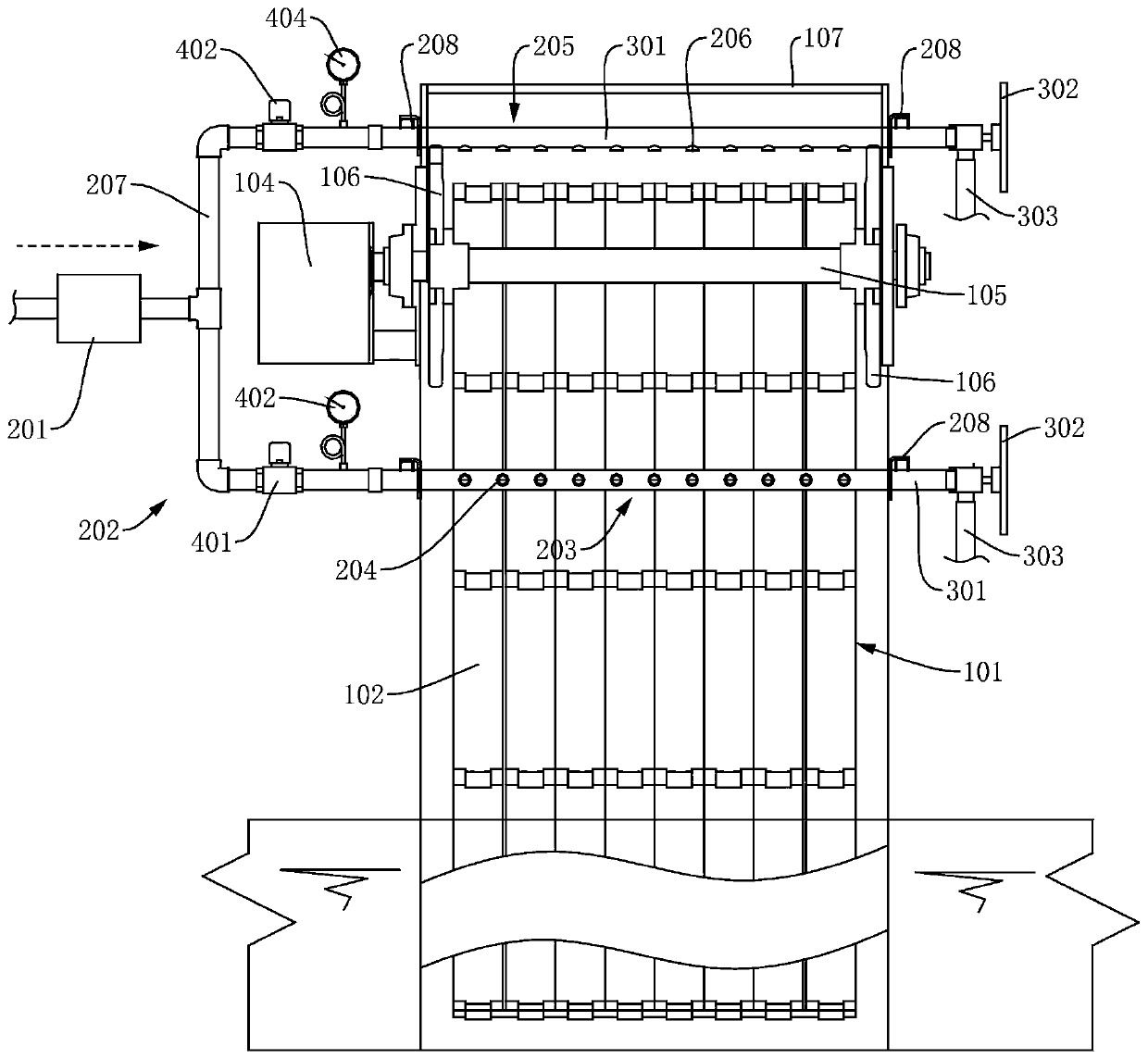

[0058] This embodiment provides a flushing system with another structure, the flushing device includes a first flushing part and a second flushing part, and the first flushing part and the second flushing part are respectively connected to the outlet of the flushing pump 201 By the way, the first nozzle 204 and the second nozzle 206 are respectively arranged in the first flushing part and the second flushing part. In this solution, the inner flushing and the outer flushing are separately connected to the outlet of the flushing pump 201 (i.e. parallel), so that the inner flushing and the outer flushing can be realized at the same time, and the inner flushing and the outer flushing can be performed separately, which is more convenient to use. The scope of application is wider.

[0059] Preferably, the first flushing part includes at least one first flushing pipe 203, the first nozzles 204 are respectively arranged on the first flushing pipes 203, and the second flushing part inclu...

Embodiment 3

[0072] In order to achieve good flushing, especially inner flushing, to avoid clogging of the pores, it is usually necessary to adjust the flushing direction of the inner flushing, that is, to adjust the spray direction of the nozzle on the first flushing pipe 203, so that the staff can Factors, reasonably adjust the injection direction of the nozzle on the first flushing pipe 203, in order to achieve such a purpose, this embodiment 3 provides a flushing system with another structure, and the main difference with embodiment 1 or embodiment 2 is that this In the flushing system provided in the embodiment, the first flushing pipe 203 is movably connected to the connecting pipe, so that the first flushing pipe 203 can rotate relative to its own central axis, such as Figure 9-Figure 13 As shown, it is convenient for the staff to adjust the orientation of the first nozzle 204 on the first flushing pipe 203, so as to achieve the purpose of adjusting the spraying direction of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com