Methane oxidation covering material for life refuse landfill

A technology for methane oxidation and covering materials, which is applied in soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., can solve the problem of no methane oxidation effect, etc., and achieve obvious social and economic benefits, extensive promotion, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

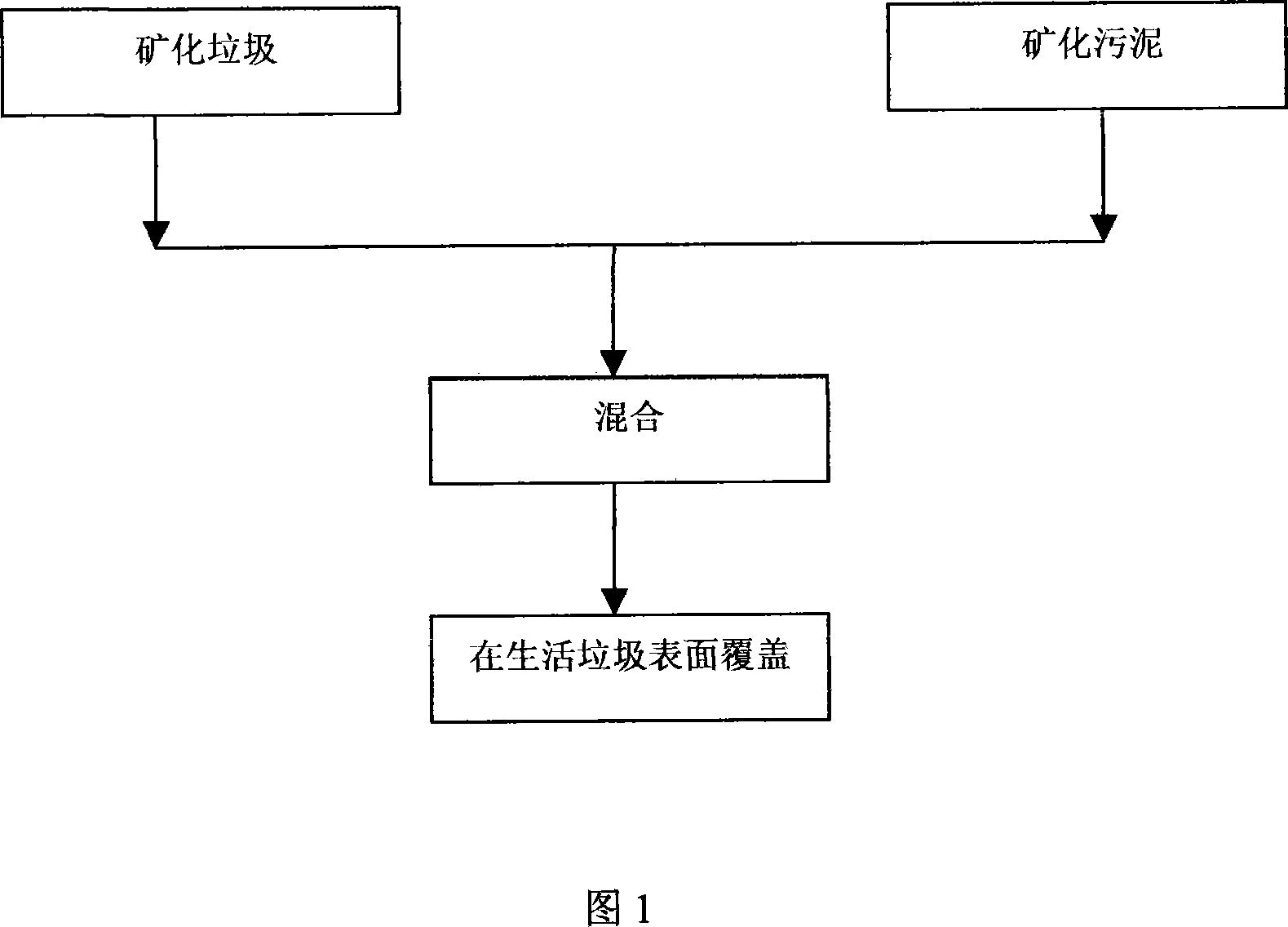

[0029] Please refer to attached picture 1.

[0030] The mass percentage of raw materials used in the present invention is mineralized waste (0.5mm-4cm):mineralized sludge=70%:30% (dry basis).

[0031] Stir and mix the above raw materials evenly and fill them into the domestic waste reaction column as the covering material. At room temperature, the lower ends of the five reaction columns were connected with methane and CO mixed in different proportions. 2 Mixed gas (methane content between 50-60%). Support it with brackets at the bottom of the column. There are three layers of household garbage and covering materials that have been preliminarily screened and processed in sequence on the support. The thickness of domestic garbage is 30cm, the thickness of the first and second covering layers is 18cm, and the thickness of the final covering layer is 30cm. The test point is set at the upper end of each cover layer, and the test point 3 is set after the final cover layer is seale...

Embodiment 2

[0035] Using the same experiment as in Example 1, 4 kinds of mineralized sludge, soil, mineralized garbage, mineralized garbage and mineralized sludge mixture (covering material of the present invention) are used as domestic waste landfill covering materials respectively , the methane oxidation rates in landfill biogas were 10-20, 30-40, 50-70, and 70-80%, respectively. Therefore, the mixture of mineralized waste or mineralized waste and mineralized sludge (dry weight ratio 7:3) has a higher oxidation effect on methane in domestic waste landfill biogas.

[0036] The analysis of methane-oxidizing bacteria in mineralized waste, mineralized sludge, and common cover soil from the molecular level shows that the types and numbers of methane-oxidizing bacteria in mineralized waste are significantly more than those in common cover soil and mineralized sludge. Sequencing results showed that the mxaf gene in mineralized waste had many different mutant forms, further confirming the diver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com