Heat supply system for directly recovering sewage multi-section flashing steam waste heat by using multiple sections of absorption heat pumps

An absorption heat pump and flash steam technology, which is used in the field of waste heat heating system for recycling sewage flash steam, can solve the problems of affecting the temperature rise and temperature loss of hot water for heating, achieve economic benefits and social benefits of emission reduction, and improve The effect of rational utilization of temperature and waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

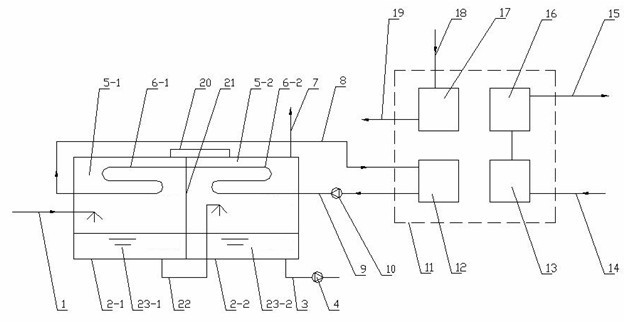

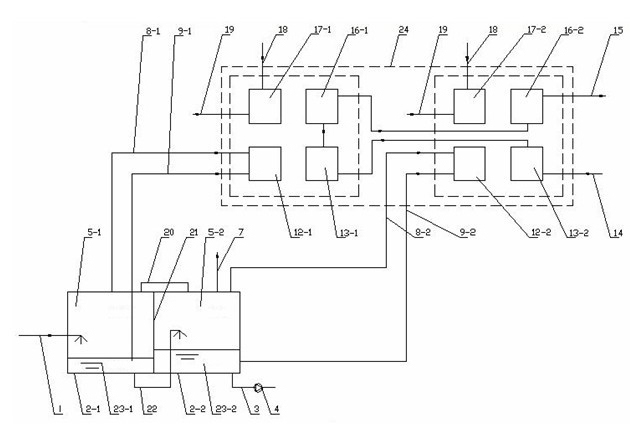

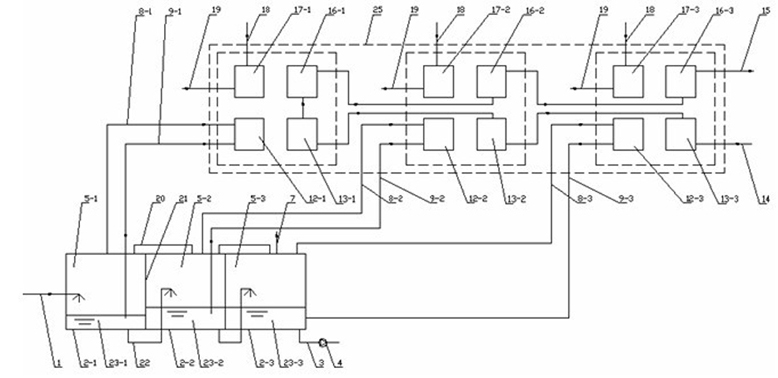

[0014] Such as figure 2 Shown is a schematic diagram of a second-stage flash steam waste heat heating system using a second-stage absorption heat pump to directly recover sewage in the second-stage flash evaporation system of sewage. The sewage inlet pipe 1, the first airtight independent chamber 2-1, the second airtight independent chamber 2-2, the sewage outlet pipe 3, the sewage pump 4, the first gas phase area 5-1, and the second air phase area 5-2 , Non-condensable gas discharge pipe 7, the first flash steam enters the evaporator pipe 8-1, the first flash steam condenses water out of the evaporator pipe 9-1, the second flash steam enters the evaporator pipe 8-2, The second flash steam condensates out of the evaporator tube 9-2, the first evaporator 12-1, the second evaporator 12-2, the first absorber 13-1, the second absorber 13-2, and heat medium water Water return pipe 14, heat medium water outlet pipe 15, first condenser 16-1, second condenser 16-2, first generator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com