Method for measuring dry-quenching burning loss rate based on exergy balance

A measurement method and coke CDQ technology, which is applied in the thermal development of materials, etc., can solve the problem that the burning loss rate of CDQ coke is difficult to accurately measure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

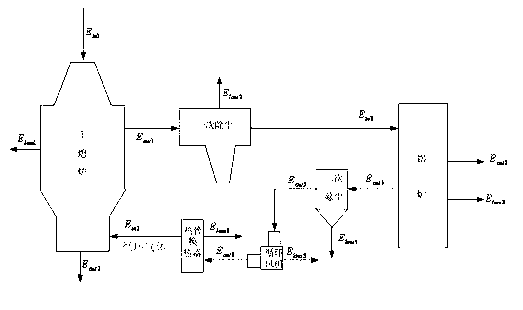

Method used

Image

Examples

Embodiment 1

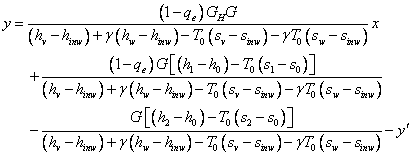

[0054] Suppose the amount of red coke processed per day is ; The amount of medium-pressure steam produced at 450°C and 4.6Mpa is ; Specific enthalpy of medium pressure steam at 450°C and 4.6Mpa and specific entropy ;Enthalpy value of boiler feed water at 105℃ and specific entropy ; Enthalpy of water in boiler at 256°C and specific entropy ;Enthalpy of red coke at 1050℃ and entropy ; Enthalpy of coke at 180°C at CDQ outlet and entropy ; Specific enthalpy of coke combustion ; The proportion of boiler blowdown is ;system fire The coefficient of loss is ; The amount of steam leaked from the boiler . For specific parameter selection, please refer to "Practical Handbook of New Technologies and Standards for Installation and Maintenance of Coking Equipment" edited by Wang Xiaodong (Heilongjiang Cultural Audiovisual Publishing House, 2004 edition). Into the formula:

[0055]

[0056] The burning loss rate obtained by reliable calculation is 2.2%. Und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com